Process for separation and purification of glyphosate from glyphosate solution by membrane technology

A technology of glyphosate mother liquor and medium glyphosate, which is applied in the field of separation and concentration of glyphosate mother liquor, can solve the problems of low recovery rate of glyphosate, easy decomposition of glyphosate, and reduction of effective content, and achieve reduction Energy consumption, low operating cost, and the effect of improving product quality and yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

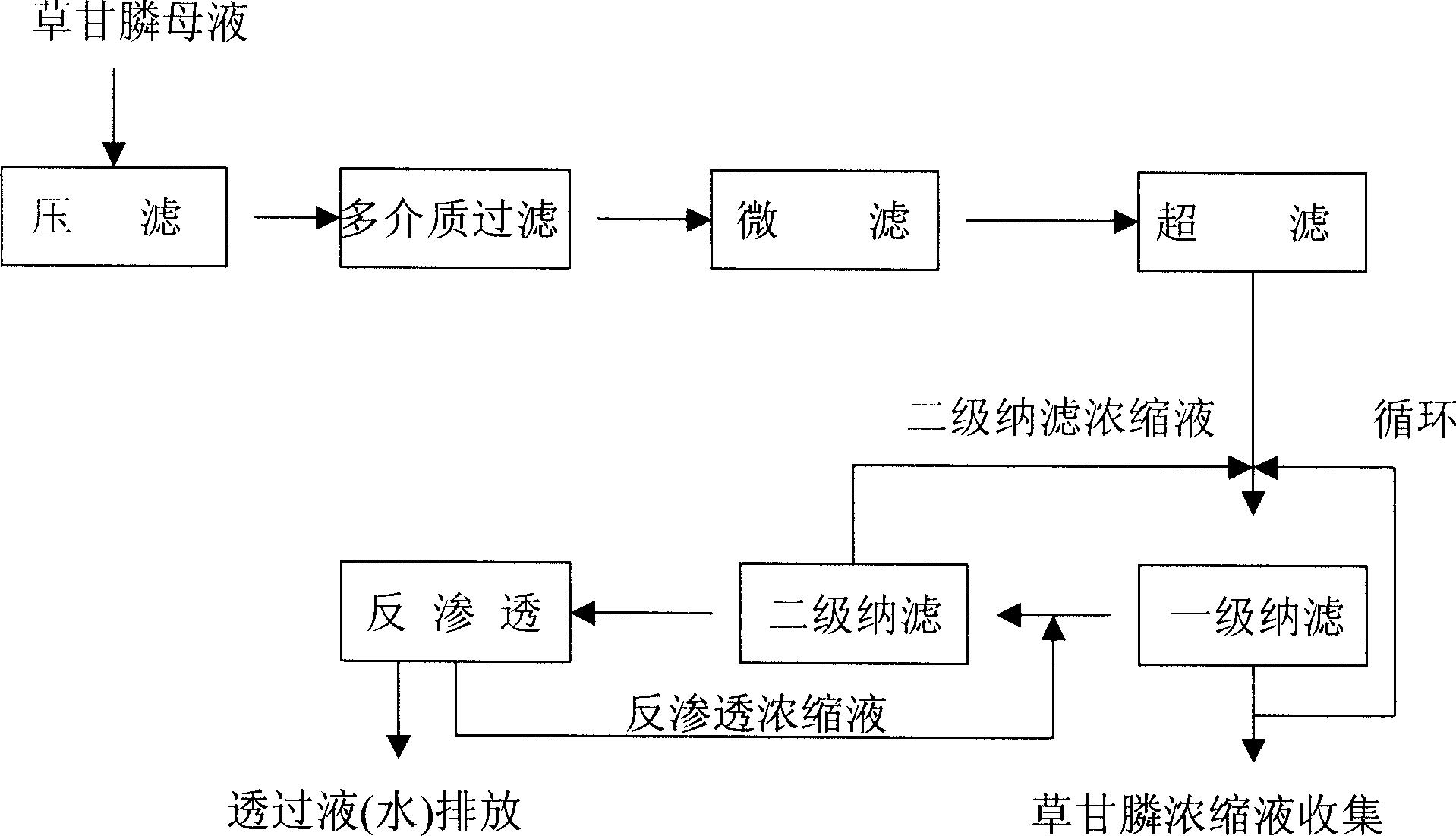

[0017] The mother liquor containing 3.8% glyphosate acid enters the filter press to separate the solid glyphosate raw powder, the mother liquor enters the multimedia filter containing active carbon to remove the viscous liquid in the mother liquor, and then uses a micro filter with a pore size of 1-10 μm The pore filter membrane directly removes submicron, micron particles and flocculent precipitates in the mother liquor, and the ultrafiltration membrane removes soluble macromolecular impurities.

[0018] The mother liquor after the above treatment is pumped into the primary nanofiltration membrane for separation. After the concentrated solution reaches the standard (glyphosate acid mass fraction ≥ 10%), it is collected in the storage tank. If the concentrated solution does not reach the standard, continue to circulate until it reaches the standard. The permeate enters the second-stage nanofiltration membrane for separation, and the second-stage nanofiltration concentrate retur...

Embodiment 2

[0021] The mother liquor containing 3.6% ammonium glyphosate enters the filter press for pressure filtration, then enters the multimedia filter containing activated carbon to remove the viscous liquid in the solution, and then directly removes the viscous liquid in the solution with a microporous filter membrane with a pore size of 1-10 μm. The submicron, micron particles and flocculent precipitates are removed by ultrafiltration membranes to remove soluble macromolecular impurities.

[0022] The mother liquor after the above treatment is pumped into the primary nanofiltration membrane for separation. After the concentrated solution reaches the standard (ammonium glyphosate mass fraction ≥ 10%), it is collected in the storage tank. If the concentrated solution does not reach the standard, continue to circulate until it reaches the standard. The filtrate permeate enters the second-stage nanofiltration membrane for separation, and the second-stage nanofiltration concentrate retur...

Embodiment 3

[0025] The mother liquor containing 1.8% sodium glyphosate enters the filter press for pressure filtration, and then enters the multi-media filter containing activated carbon to remove the viscous liquid in the mother liquor, and then directly removes the viscous liquid in the mother liquor with a microporous filter membrane with a pore size of 1-10 μm. The submicron, micron particles and flocculent precipitates are removed by ultrafiltration membranes to remove soluble macromolecular impurities.

[0026] The mother liquor after the above treatment is pumped into the primary nanofiltration membrane for separation. After the concentrated solution reaches the standard (sodium glyphosate mass fraction ≥ 10%), it is collected in the storage tank. If the concentrated solution does not reach the standard, continue to circulate until it reaches the standard; The filtrate enters the secondary nanofiltration membrane for separation, the secondary nanofiltration concentrate returns to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com