Patents

Literature

329results about How to "Suitable for industrial continuous production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Extrusion foaming thermoplastic polyurethane elastomer bead and preparation method thereof

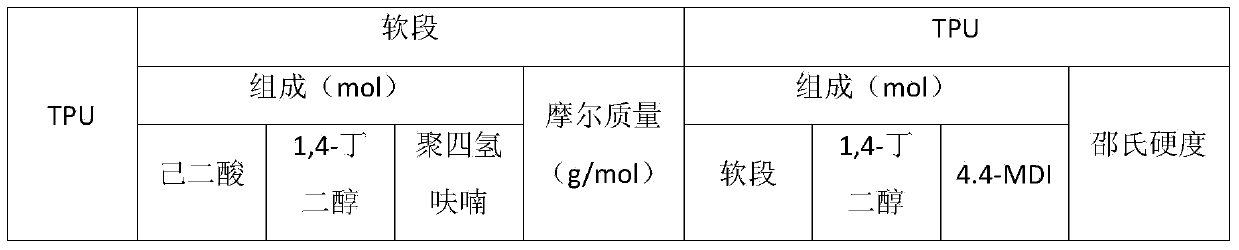

The invention discloses an extrusion foaming thermoplastic polyurethane elastomer bead. The extrusion foaming thermoplastic polyurethane elastomer bead comprises the following components in parts by weight: 100 parts of thermoplastic polyurethane elastomer, 0.01-0.5 parts of a foaming nucleating agent, and 0.01-0.2 parts of an antioxidant, wherein a foaming process adopts supercritical fluid with the addition amount of 1-40 parts. The invention also discloses a preparation method of the extrusion foaming thermoplastic polyurethane elastomer bead. The extrusion foaming thermoplastic polyurethane elastomer bead and the preparation method have the advantages that the foaming process does not cause environmental pollution; the obtained foaming material is stable in quality and high in foaming ratio; and the operation method in production is easy and suitable for continuous industrial production.

Owner:MIRACLL CHEM

Extruded foaming thermoplastic polyurethane elastomer particles and preparation method thereof

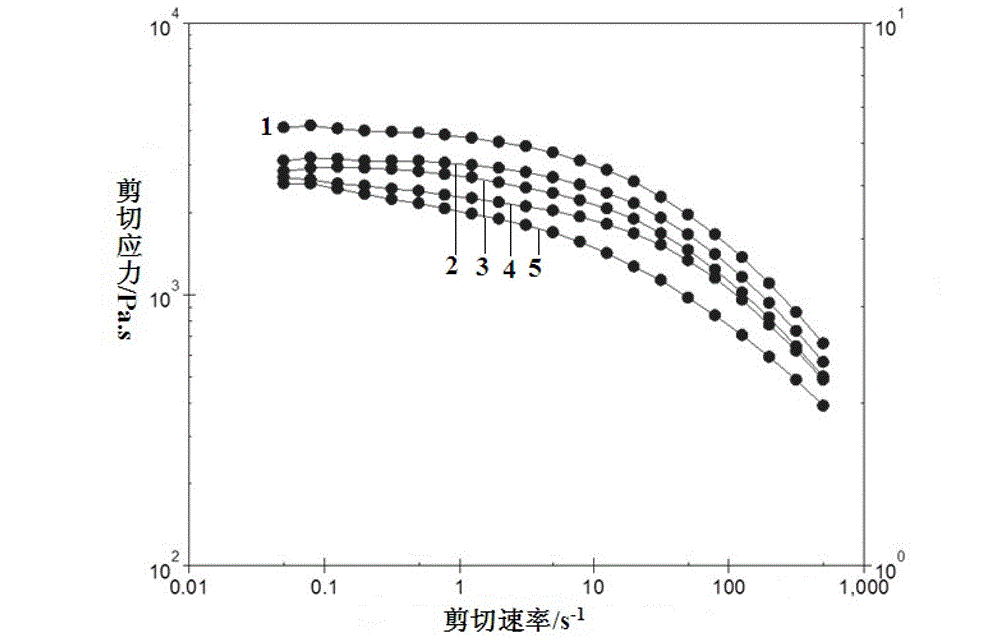

The invention relates to extruded foaming thermoplastic polyurethane elastomer particles and a preparation method thereof. The particles comprise the following components in parts by weight: 100 parts of thermoplastic polyurethane elastomer, 0.01-0.5 part of foaming nucleating agent, and 0.01-0.2 part of antioxidant. The preparation method comprises steps of firstly, mixing the materials, then throwing the mixture into an extruder to prill to obtain a bead raw material suitable for foaming, finally, throwing the beads into a special extruder for foaming, and after foaming by an opening die, pelletizing underwater so as to prepare the particles. The thermoplastic polyurethane foaming particles are prepared through an extrusion method; by controlling the foaming technology conditions, the foaming particles are controllable in density and have uniform cell density; the whole production method is simple to operate, has no special limitation and requirement on the equipment, and is applicable to industrial continuous production.

Owner:MIRACLL CHEM

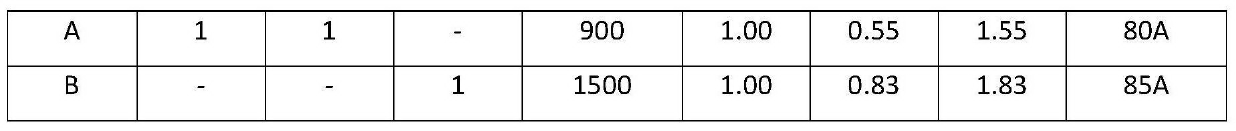

Super active carbon preparation method

The invention relates to a preparation method for super active carbon. Wherein, carbonizing and breaking up the raw material of coco shell or walnut shell to predetermined particle size and mix evenly with solid potassium hydroxide; activating the mixture in microwave oven with nitrogen protection during the process to obtain activation material; clearing the material with muriatic acid and then distilled water for many times to neutrality and obtain the said product. The product with this method has strong adsorption property, high specific surface area and high adsorption value to iodine and methylene blue. The method is simple and convenient to control.

Owner:KUNMING UNIV OF SCI & TECH

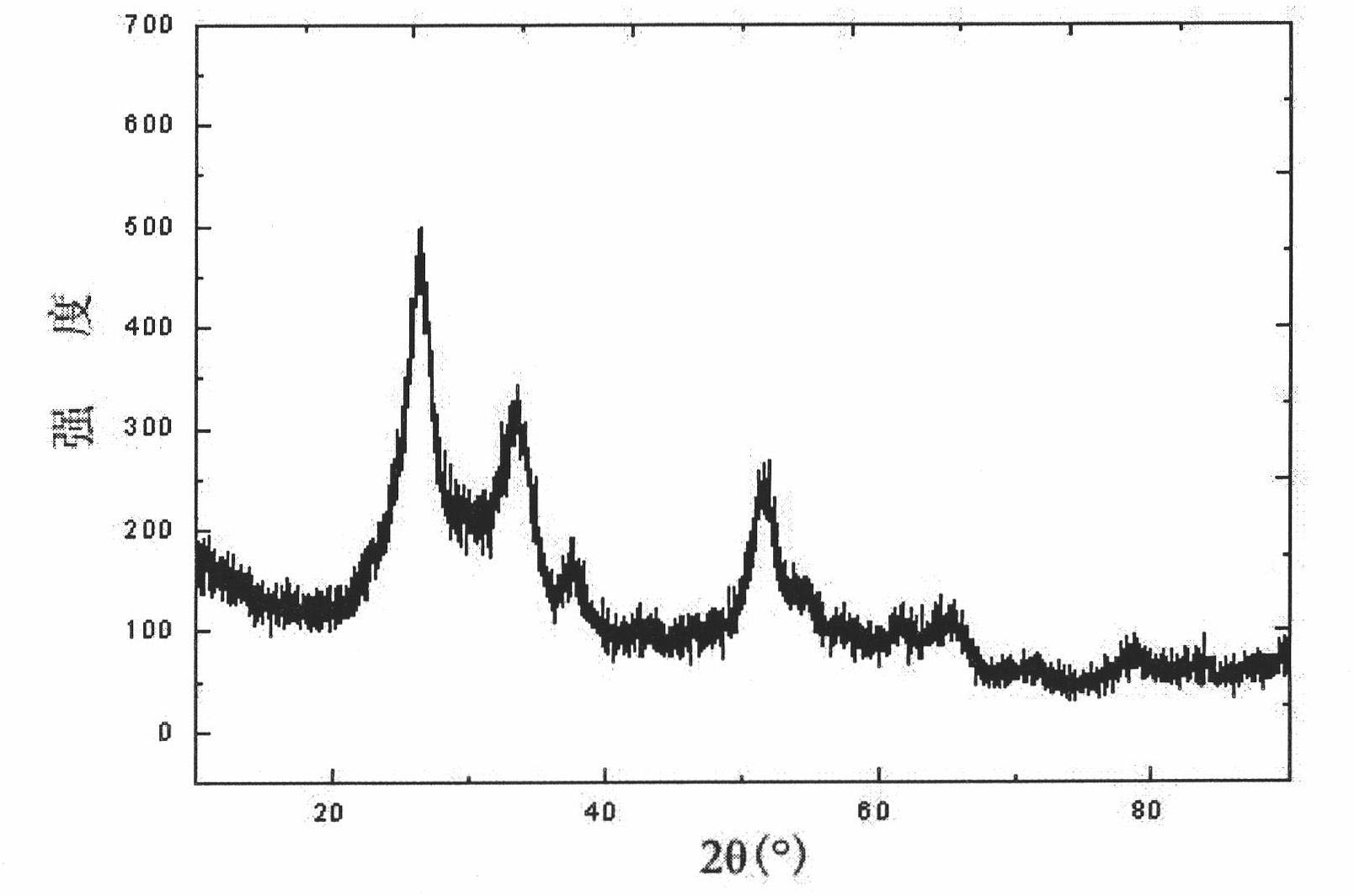

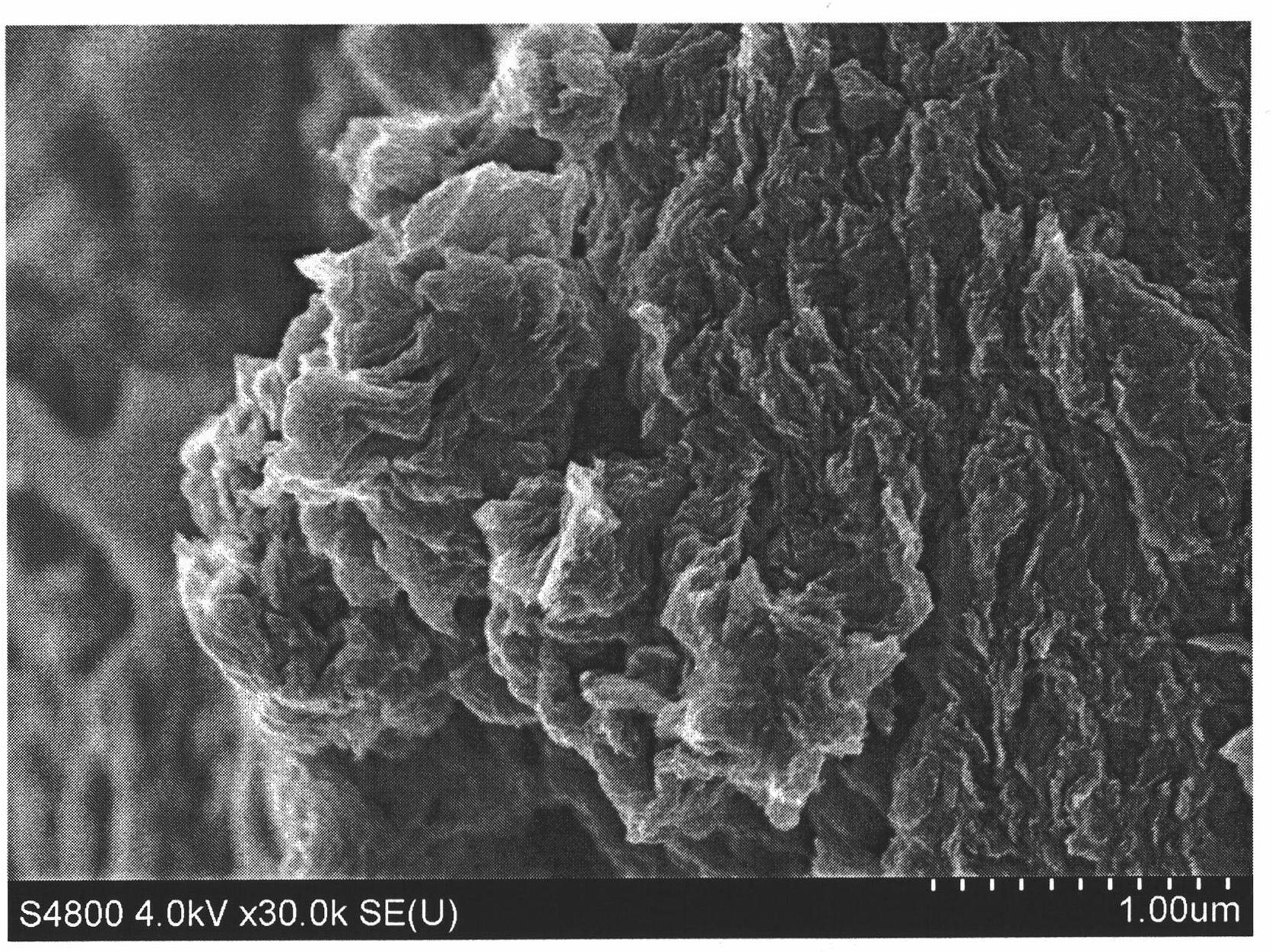

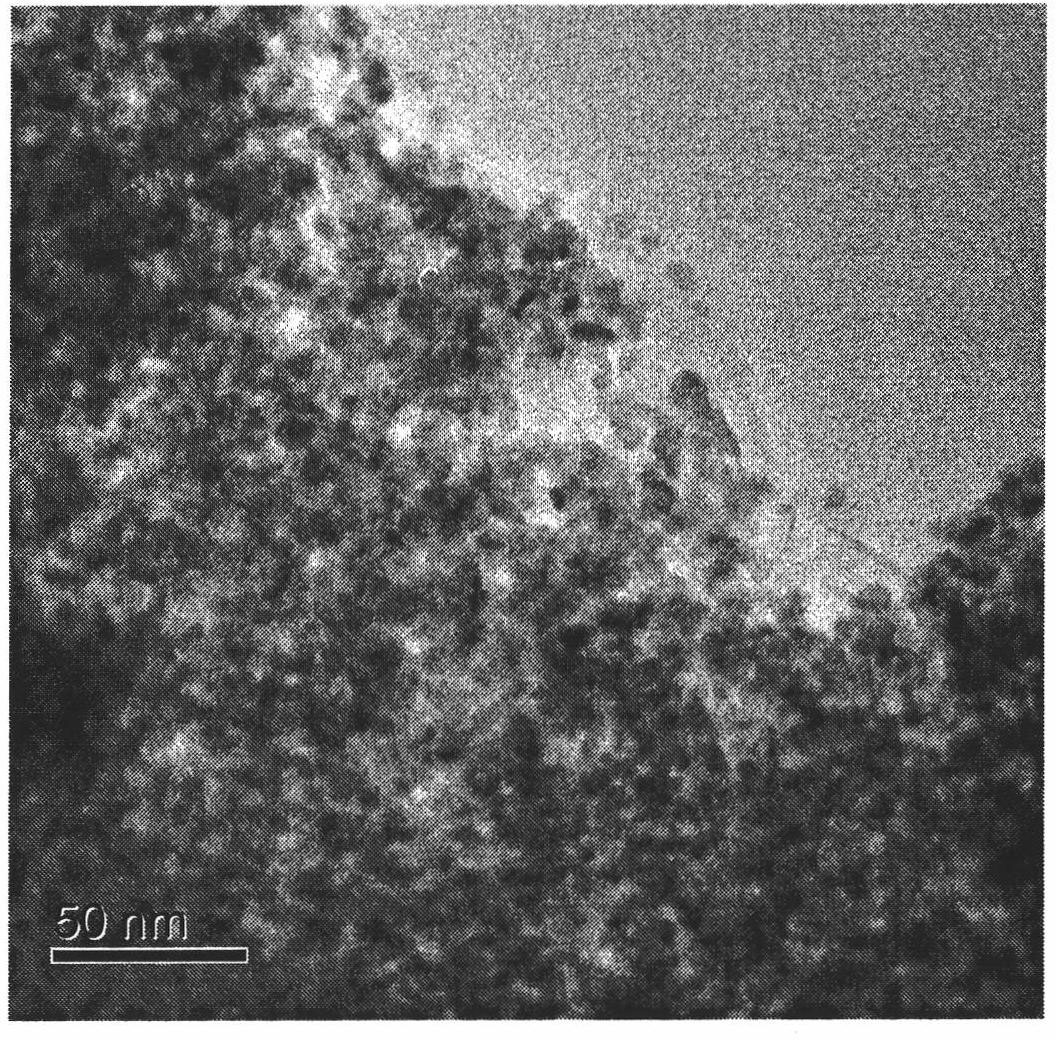

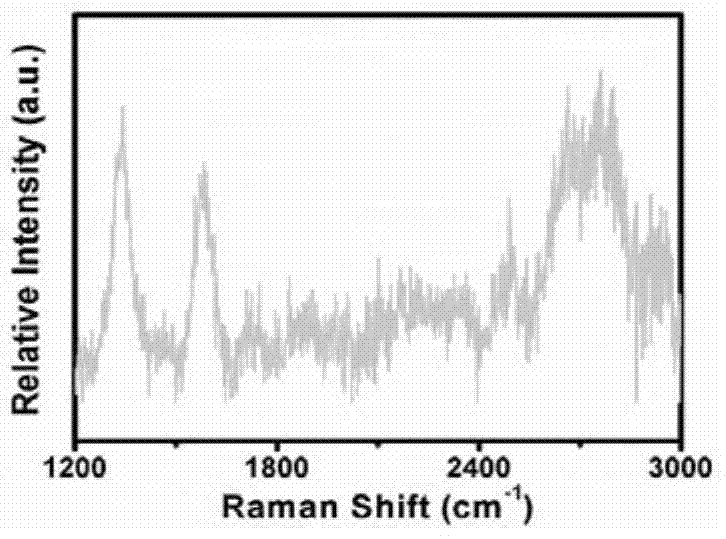

Preparation method of stannic oxide or metallic tin and grapheme lamella composite material

ActiveCN102255072AImprove structural stabilityImprove electrochemical performanceCell electrodesTin dioxideHYDROSOL

The invention provides a preparation method of a stannic oxide and grapheme lamella composite material. The preparation method comprises the following steps of mixing at least one organic solvents, graphene oxide lamella hydrosol and at least one tin salt, heating the mixture at a temperature of 60 to 200 DEG C for 0.5 to 12 hours to obtain a solid substance, and heating the solid substance in the inert gas atmosphere at a temperature of 400 to 700 DEG C for 0.5 to 10 hours. The invention also provides a preparation method of a metallic tin and grapheme lamella composite material. The preparation method comprises the following step of preparing a stannic oxide and grapheme lamella composite material through the preparation method of a stannic oxide and grapheme lamella composite material, and heating the prepared stannic oxide and grapheme lamella composite material in the reducing gas atmosphere at a temperature of 400 to 1000 DEG C for 0.5 to 4 hours. The preparation methods of the invention can improve a structural stability and an electrochemical performance of a material and is beneficial to improve a high-speed charging and discharging performance and a conductivity of a composite material. The preparation methods have the characteristics of cheap and easily available raw materials, simple process, and good applicability for industrial continuous production.

Owner:陕西埃普诺新能源科技有限公司

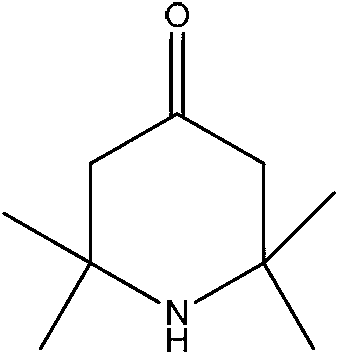

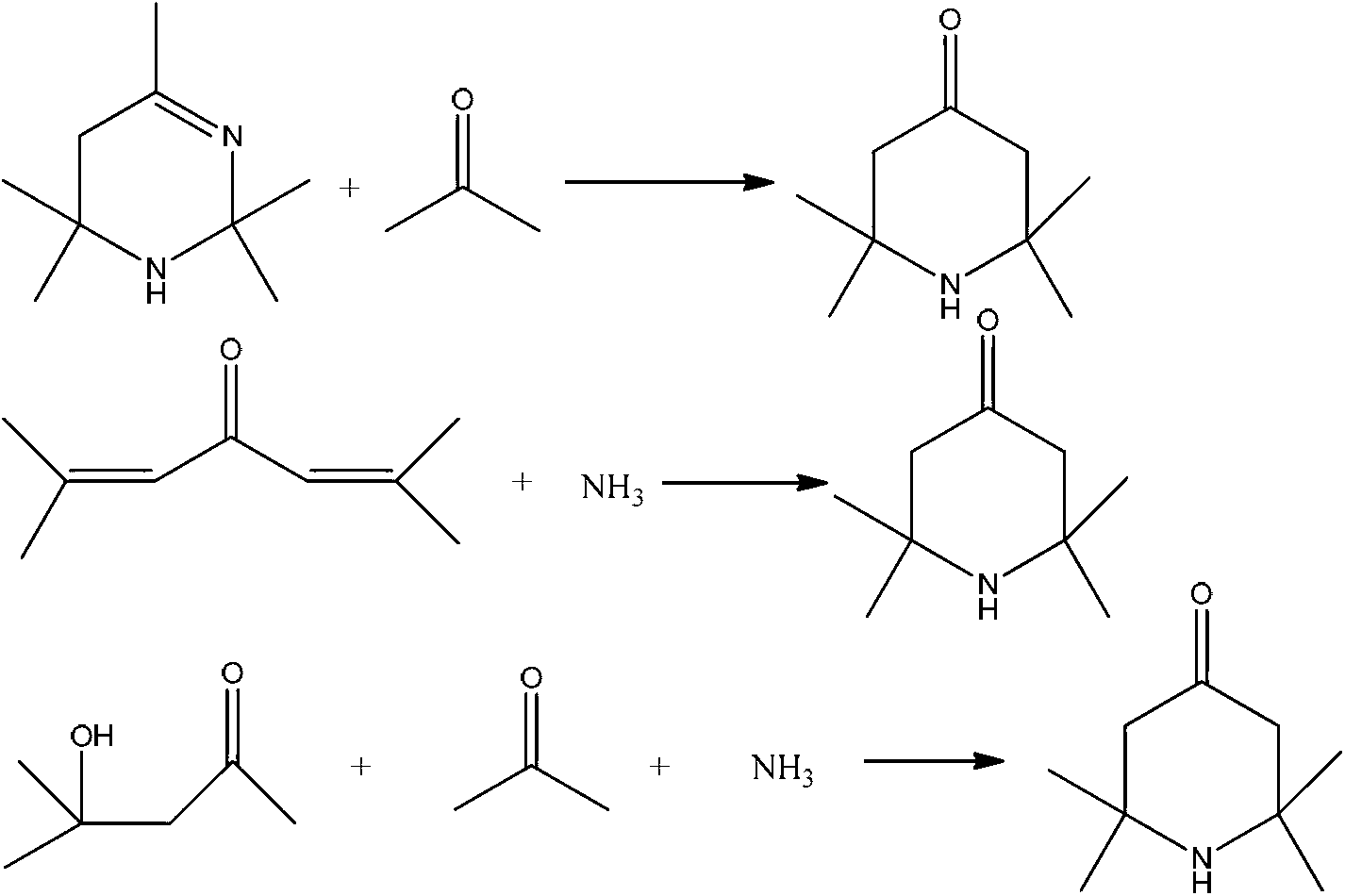

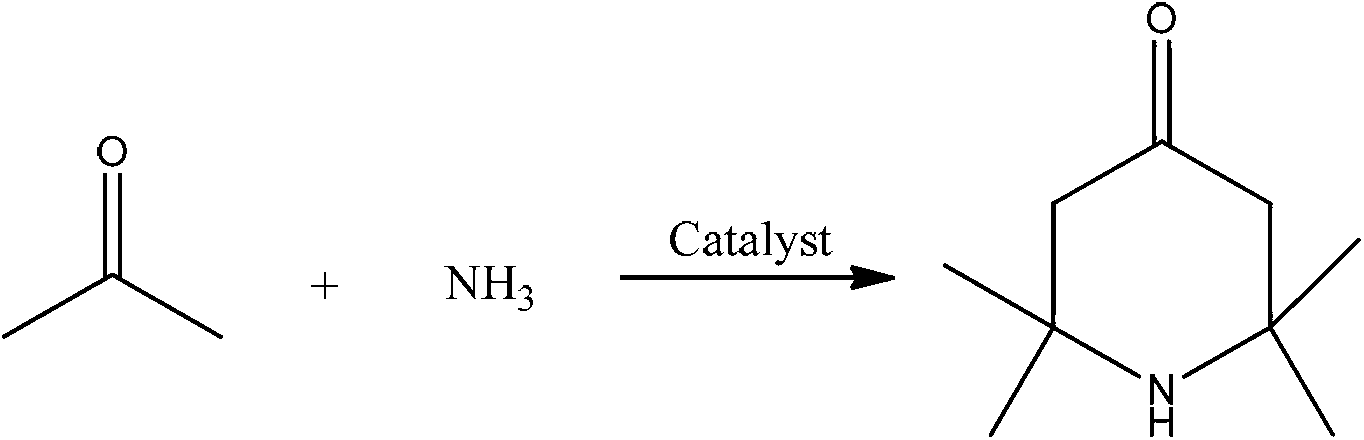

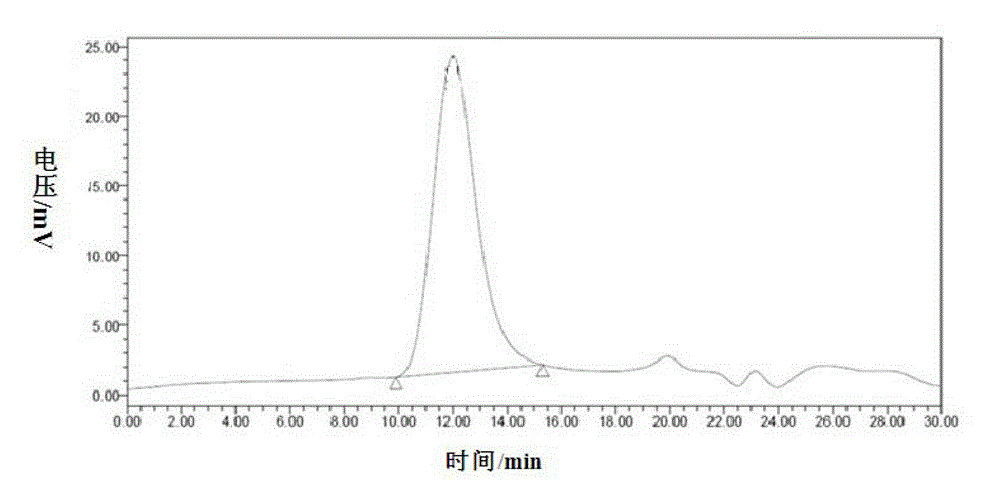

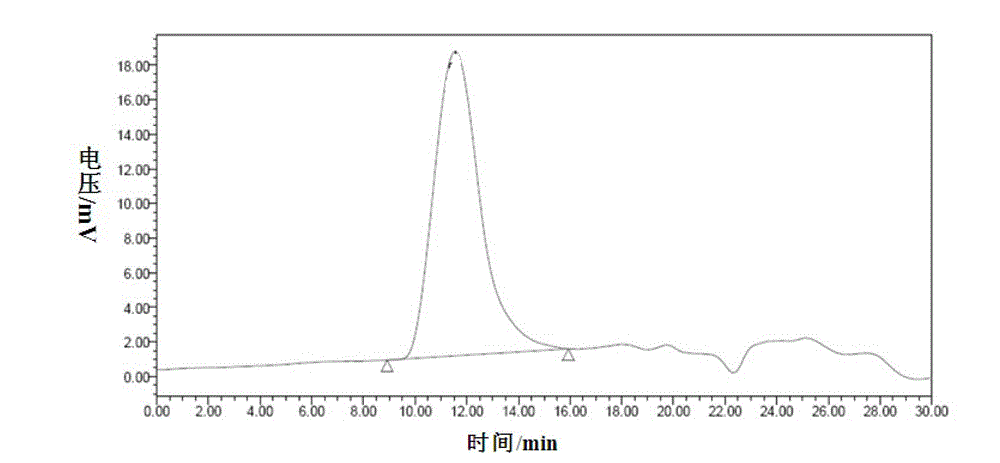

2,2,6,6,-tetramethyl-4-piperidone continuous synthesis method

ActiveCN103224465ASubsequent separation is simpleAvoid pollutionOrganic chemistrySynthesis methodsFixed bed

The invention discloses a 2,2,6,6,-tetramethyl-4-piperidone continuous synthesis method. The 2,2,6,6,-tetramethyl-4-piperidone continuous synthesis method comprises the following steps of 1, filling an acidic resin into a fixed bed reactor, and carrying out heating so that a temperature of the fixed bed reactor is in a range of 40 to 70 DEG C, and 2, feeding acetone and ammonia gas into the fixed bed reactor according to a mole ratio of 3-9: 1 under the conditions of acetone hourly space velocity of 0.15 to 1.17h<-1> and ammonia gas hourly space velocity of 5.25 to 124.20h<-1>, and cooling the product to obtain a 2,2,6,6,-tetramethyl-4-piperidone crude product. The 2,2,6,6,-tetramethyl-4-piperidone continuous synthesis method has simple processes and a low cost, is suitable for industrial continuous production, does not adopt an organic solvent or water as a solvent, avoids the pollution produced by the organic solvent on the environment, has mild reaction conditions, can be carried out at a temperature of 40 to 70 DEG C, has low energy consumption, and avoids the influence caused by impurities produced at a high temperature on the product.

Owner:安徽兴欣新材料有限公司

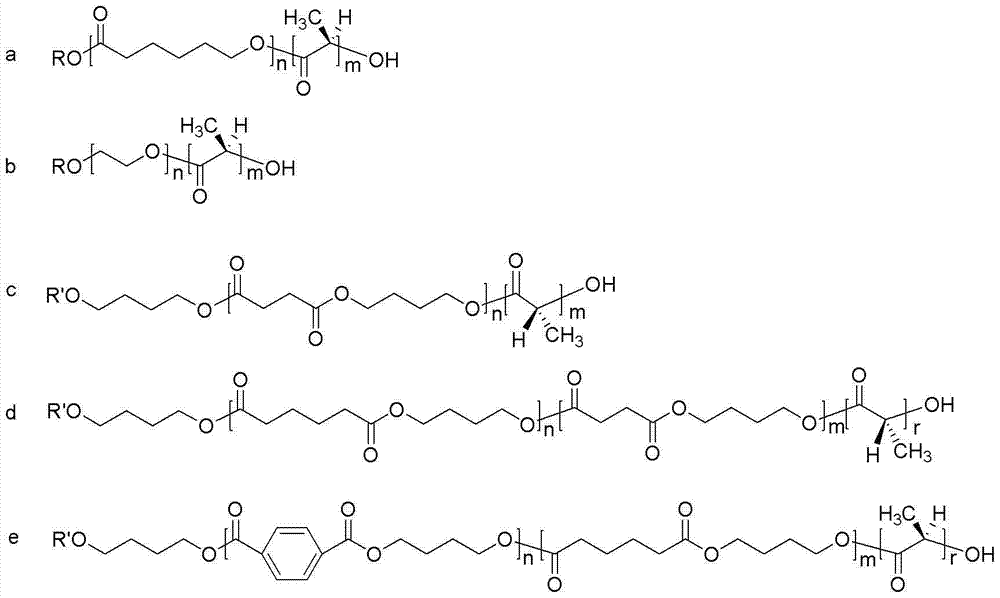

Degradable polylactic acid diblock copolymer, preparation method and application to modified polylactic acid

The invention discloses a degradable polylactic acid diblock copolymer, a preparation method and application to modified polylactic acid, solving the problems of instable performance, high preparation cost and unsuitability for industrialized continuous production of modified polylactic resin in the prior art. The preparation method of the degradable polylactic acid diblock copolymer comprises the following steps of: adding dried and dewatered polylactic acid A with an end group being hydroxy into a reaction device under the protection of an inert atmosphere, adding diisocyanate B, heating to 185-190 DEG C, reacting with stirring for 5-8h, adding degradable high polymer C containing hydroxy, reacting with stirring for 1-2h at the temperature of 185-190 DEG C, adding the diisocyanate B, and reacting at the temperature of 185-190 DEG C until the stirring is difficult to obtain the degradable polylactic acid diblock copolymer. The degradable polylactic acid diblock copolymer disclosed by the invention is good in compatibility with the polylactic resin, is used for modifying the polylactic resin, is capable of remarkably improving processing property and mechanical property of the polylactic resin, and has the elongation at break reaching 60 percent.

Owner:CHANGZHOU INST OF ENERGY STORAGE MATERIALS &DEVICES

Graphene composite electrode material and preparation method and application thereof

InactiveCN107026259AImprove controllabilityControl coating amountMaterial nanotechnologyCell electrodesComposite electrodeGraphene

The invention discloses a graphene composite electrode material and a preparation method and application thereof. The graphene composite electrode material comprises a lithium ion battery electrode material and graphene, wherein the graphene is coated on a surface of the lithium ion battery electrode material, and the thickness of the graphene is 0.3-5 nanometers. The preparation method of the graphene composite electrode material comprises the following steps of 1) calcining a lithium ion battery electrode raw material, and reducing a temperature after calcination is completed; and 2) rising the temperature of the lithium ion battery electrode material processed in the step 1), and introducing a carbon source for chemical vapor deposition reaction, thereby obtaining the graphene composite electrode material. The preparation method is simple, is high in controllability and is suitable for industrial continuous production.

Owner:PEKING UNIV

Carbon fiber reinforced nylon 6 resin composite material and preparation method thereof

The invention relates to a carbon fiber reinforced nylon 6 resin composite material with excellent heat conducting performance and a preparation method thereof. The composite material consists of the following materials in parts by weight: 100 parts of nylon 6 resin, 20-80 parts of carbon fiber, 10-20 parts of inorganic filling material, 0.5-5 parts of coupling agent, 0.2-1 part of antioxidant and 0-3 parts of lubricating agent. The preparation method comprises the following steps: weighing each component raw material in proportion; mixing each component raw material except for the carbon fiber at a high speed; adding an obtained mixed material into a double-screw extruder hopper, adding the carbon fiber from a fiber charging opening of the extruder, and then extruding and pelletizing. Compared with the prior art, the composite material provided by the invention is high in rigidity and good in heat conducting performance, is suitable for production and processing of thin-walled and light-weight automobile parts and electronic / electrical products; meanwhile, the composite material is low in raw material cost and simple in manufacturing process, and is suitable for industrial continuous production.

Owner:SHANGHAI JIAO TONG UNIV

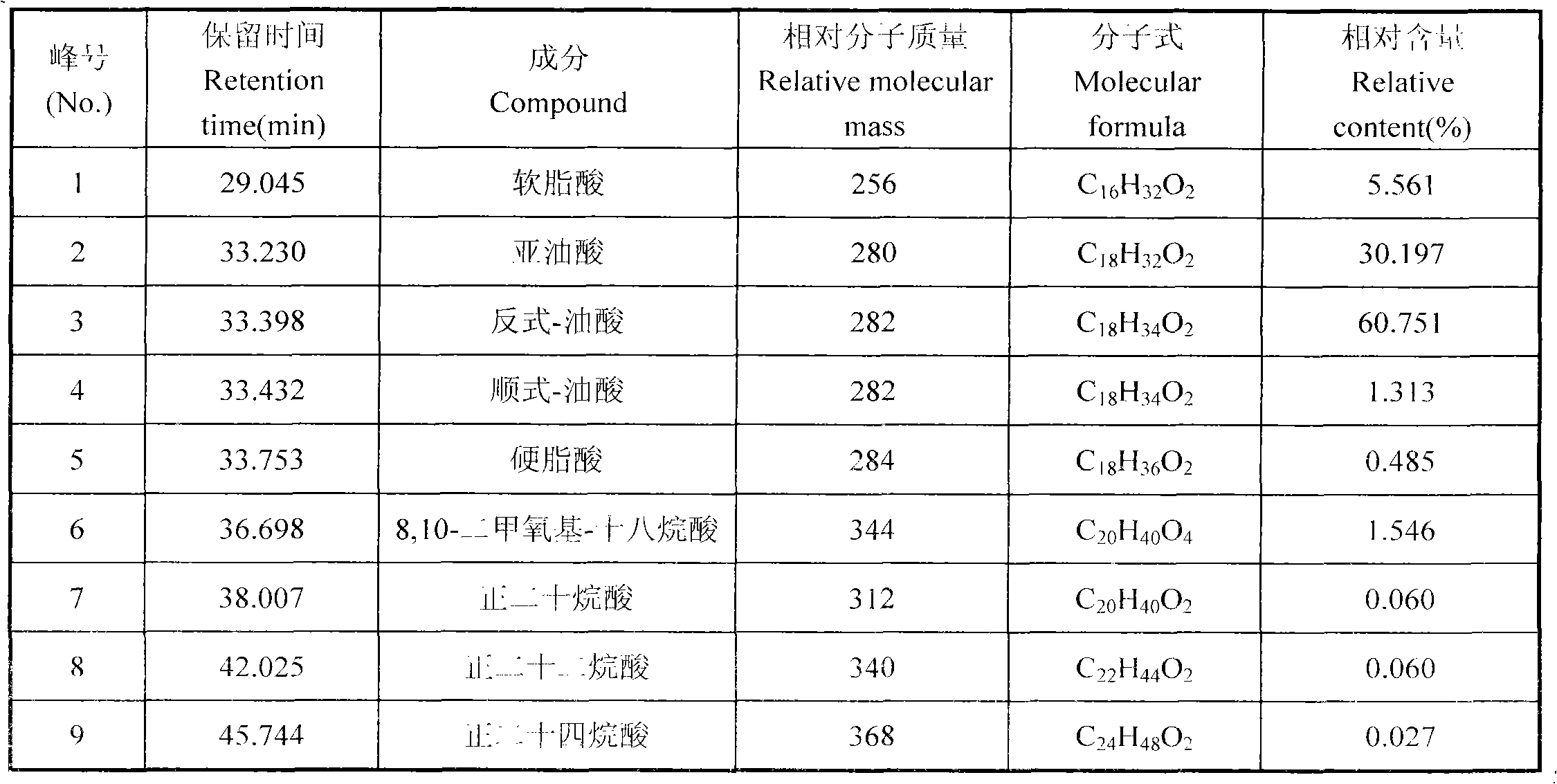

Pressing-low-temperature continuous phase-change castor oil extraction method

InactiveCN103173275AAbundant resourcesReduce manufacturing costFatty-oils/fats productionCastor SeedSulfur hexafluoride

Owner:曹庸

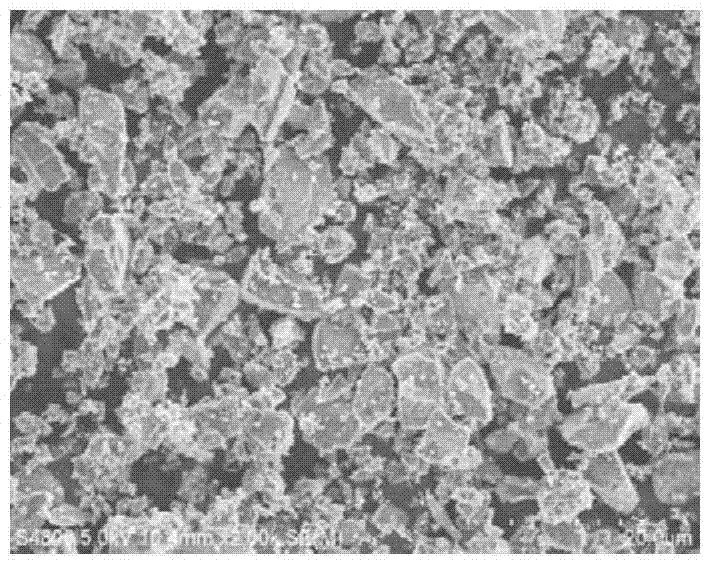

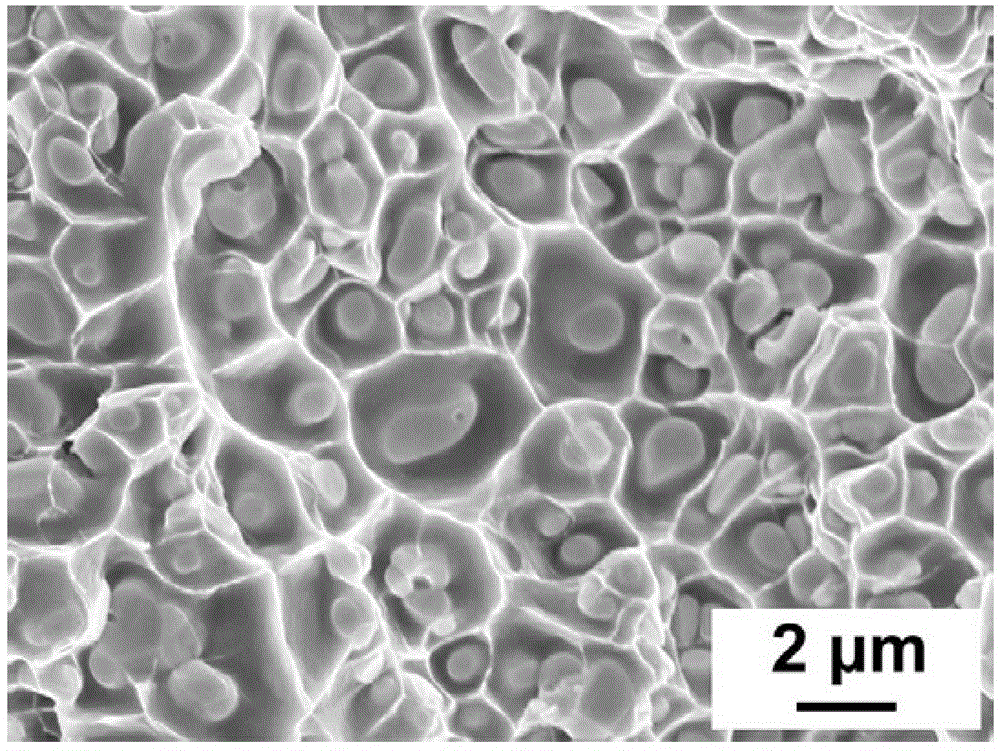

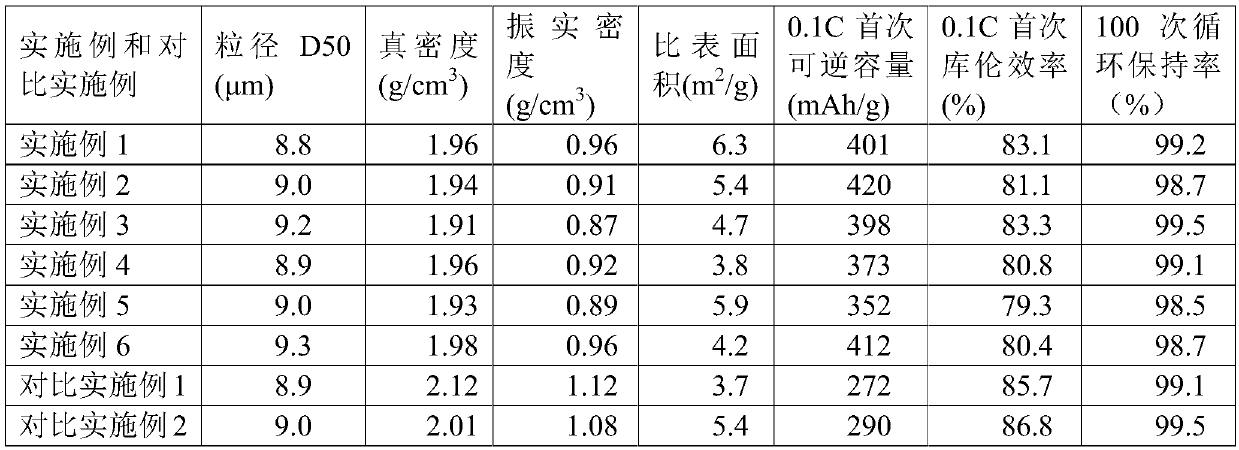

Preparation method of spherical hard carbon negative electrode material of high-capacity lithium ion battery

PendingCN106995210AOvercoming complexityOvercome costsCell electrodesSecondary cellsHigh rateCarbonization

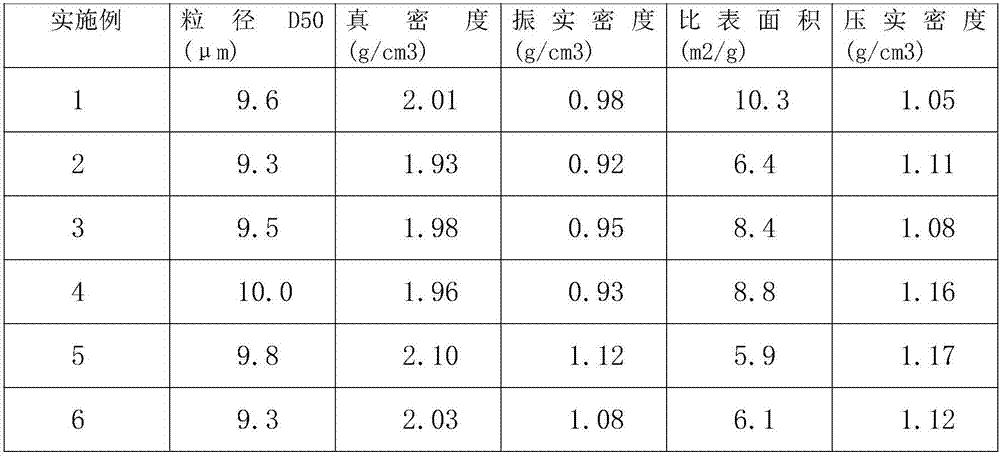

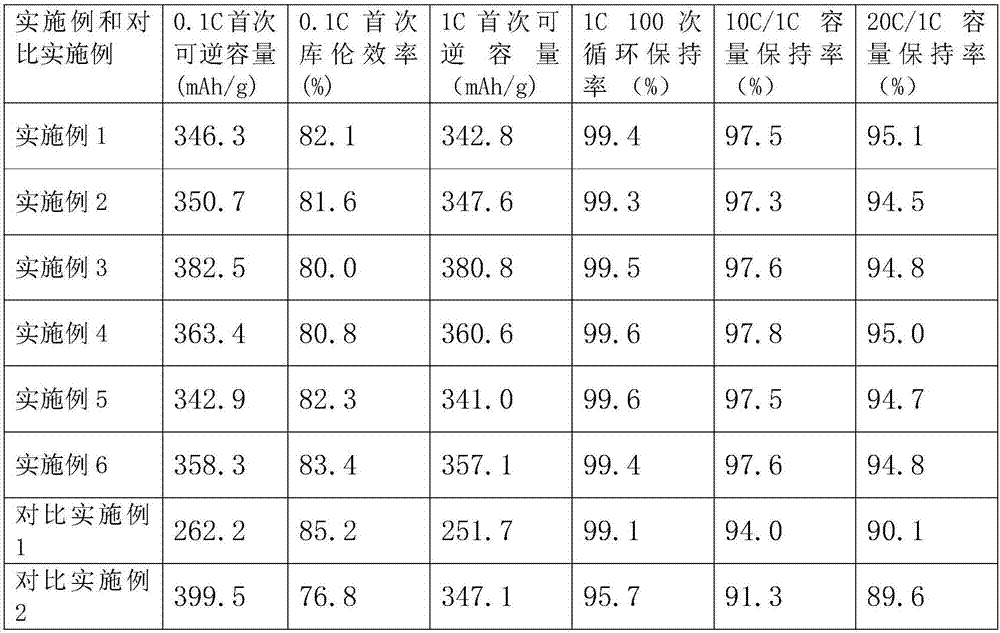

The invention relates to the technical field of a lithium ion battery, in particular to a preparation method of a spherical hard carbon negative electrode material of a high-capacity lithium ion battery. The preparation method is characterized by comprising the following steps of (1) material mixing; (2) precrosslinked polymerization reaction; (3) crushing and grading; (4) polymer powder pelletizing treatment; (5) oxidation stability treatment; (6) pre-carbonization treatment; (7) carbonization treatment. Compared with the prior art, the preparation method has the advantages that the raw material sources are wide; the preparation process is simple; the structure and the processing performance of a precursor organic carbon source can be effectively improved through the precrosslinked polymerization reaction; the prepared spherical hard carbon has unique appearance and good pore diameter distribution, and also has the advantages of particle granularity distribution uniformity, high stacking density and the like; high capacity, high first coulombic efficiency, excellent high-rate performance and excellent circulation performance are also realized.

Owner:SHANGHAI SHANSHAN TECH CO LTD

Continuous phase-changed extraction method for orange peel oil

ActiveCN103146486AAbundant resourcesImprove qualityEssential-oils/perfumesFatty-oils/fats productionProduct gasPhase change

The invention provides a continuous phase-changed extraction method for orange peel oil. The method comprises the following steps of: placing dry crushed orange peel raw materials into an extraction kettle; compressing an extraction agent into a liquid under the condition that the pressure and the temperature are always lower than the critical pressure and the critical temperature of the extraction agent; enabling the extraction agent to flow through the extraction kettle at the flow speed of 100-150L / h under the conditions that the extraction temperature ranges from 35 DEG C to 55 DEG C, and the extraction pressure ranges from 0.5Mpa to 2Mpa, and continuously extracting for 50-120min; after the orange peel oil is extracted, enabling the extraction agent to flow into a liberation kettle for liberating at the temperature of 65-75 DEG C and the pressure of 0.1-0.4Mpa; heating and carrying out pressure-reduced phase change on the extraction agent to enable the extraction agent to become a gas, then, immediately condensing the gas to enable the gas to become a liquid, and enabling the liquid to flow through the extraction kettle for extracting the materials again; and circulating many times in such a way. The continuous phase-changed extraction method has the advantages of high supercritical extraction efficiency, no solvent residues in products and high aroma component retention rate; in addition, the extraction pressure and the liberation pressure are lower than the supercritical pressure and temperature; and meanwhile, the continuous phase-changed extraction method has the characteristics of large extraction volume, high mass handling capacity and low production cost of a conventional solvent.

Owner:GREENCREAM BIOTECH +2

Method for extracting sea buckthorn seed oil through subcritical fluid method

InactiveCN102504939AReduce manufacturing costReduce consumptionFatty-oils/fats productionRoom temperatureSolvent

The invention relates to a method for extracting sea buckthorn seed oil through a subcritical fluid method. The method for extracting the sea buckthorn seed oil comprises the following steps: (1), juicing fresh clean sea buckthorn fruit to obtain seeds, drying the seeds in shade under a room temperature, selecting the seeds, smashing the selected seeds, and screening the smashed seeds to obtain a raw sea buckthorn seed material; (2), grinding and drying the raw sea buckthorn seed material; (3), putting the ground dry sea buckthorn seeds and an extracting agent into a subcritical fluid extraction device, so as to obtain an extract; and (4), separating the extract through a pressure reducing and temperature increasing method to obtain an extraction liquid, and standing the extraction liquid under the room temperature to obtain the sea buckthorn seed oil. The method has the advantages that the production cost is effectively reduced; the separation time is shortened; the solvent consumption and the energy consumption in the technological process are reduced; the technological process is simple; the operability is high; the extraction efficiency is high; environmental protection and zero contamination are realized; the security and the repeatability are good; and large-scale industrialized continuous production can be realized.

Owner:CHINA ACAD OF SCI NORTHWEST HIGHLAND BIOLOGY INST

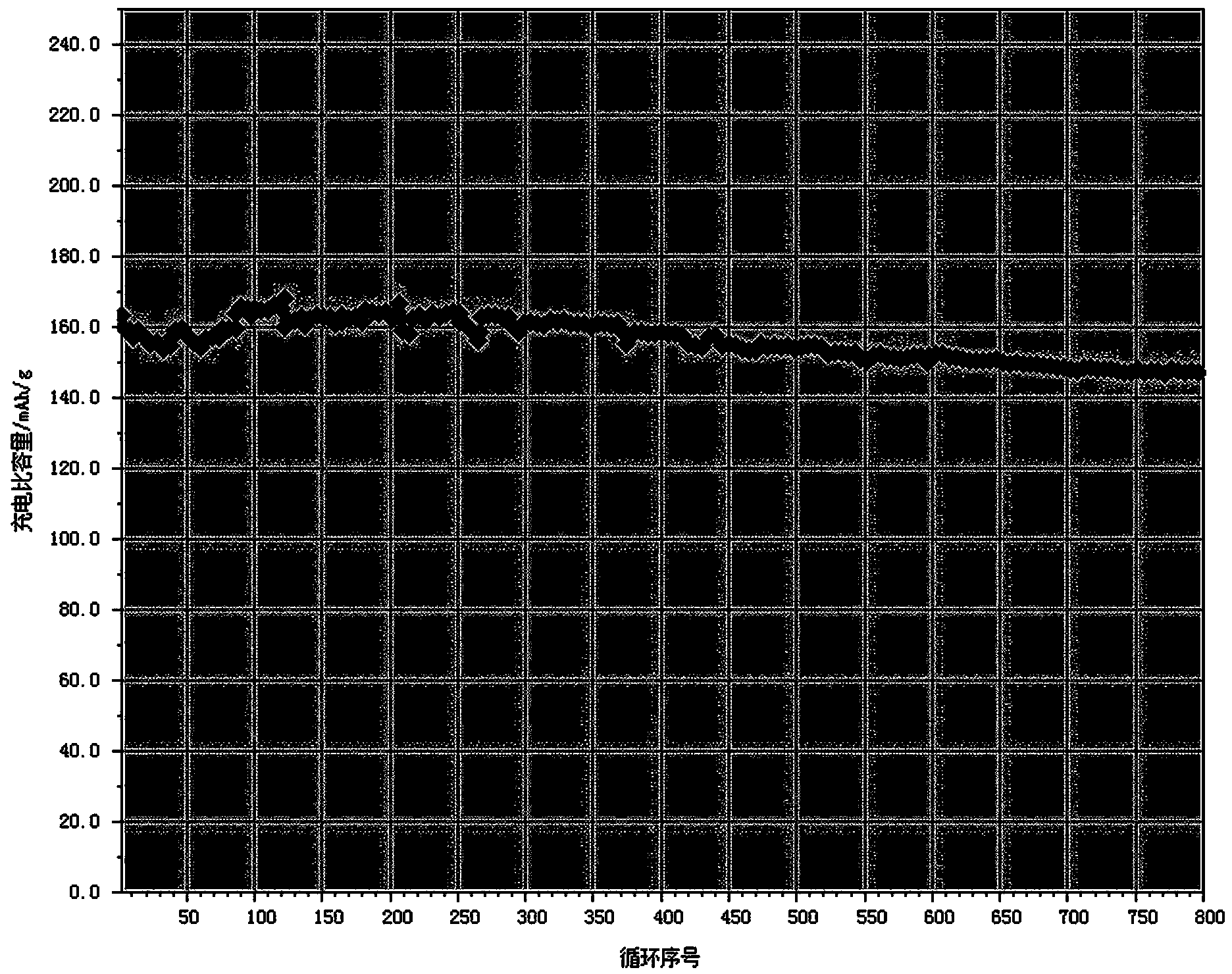

Method for preparing carbon-coated lithium titanate negative electrode material for lithium battery

ActiveCN103730649AMolecular weight controllableSmall molecular weight distributionCell electrodesCarbon layerPolymer science

The invention discloses a method for preparing a carbon-coated lithium titanate negative electrode material for a lithium battery. The method comprises the following steps: preparing a polymer with controllable molecular weight by adopting living polymerization, performing ball milling and mixing with raw materials of lithium titanate, and sintering to obtain a lithium titanate material coated with a conductive carbon layer. The adopted polymerization method has the advantages that range of optional monomers is wide, polymers of different carbon chain lengths can be obtained by adjusting the raw material ratio, the carbon chain length distribution is uniform, and the finally obtained carbon-coated lithium titanate material is uniform and stable in performance. Moreover, the initial charge specific capacity of the obtained lithium titanate material reaches over 160mAh / g under the rate of 1C (1C=175mA / g), and the capacity is kept over 90 percent due to cycle of 800 times.

Owner:中国东方电气集团有限公司

Industrial production method of lycopene microemulsion

ActiveCN106344510AIncrease dosageAvoid lostHydrocarbon active ingredientsAntinoxious agentsVegetable oilOrganic solvent

The invention discloses an industrial production method of a lycopene microemulsion. The method comprises the following steps: uniformly mixing a lycopene crystal, a co-emulsifier, an oil-soluble emulsifier and an antioxidant to obtain a suspension; carrying out nano grinding on the suspension to obtain an oil phase; uniformly mixing water with a water-soluble emulsifier to obtain a water phase; and finally, uniformly mixing the water phase and oil phase, thereby obtaining the lycopene microemulsion. According to the method, the co-emulsifier and oil-soluble emulsifier are added into the raw material lycopene crystal and subjected to nano grinding to obtain the nano oil suspension, and the nano oil suspension is mixed with the water and water-soluble emulsifier to obtain the lycopene microemulsion. The material treatment capacity is increased, and the industrial production efficiency is enhanced only by grinding the oil phase without using vegetable oil or organic solvent to dissolve the lycopene. The method has the advantages of simple technique and high product safety, can prepare the high-content lycopene microemulsion, is suitable for industrialized continuous production, and has obvious economic benefits.

Owner:CHENGUANG BIOTECH GRP CO LTD

Carbon fiber reinforced ABS (Acrylonitrile Butadiene Styrene) resin composite material with superior heat conductivity and preparation method

InactiveCN104151768ALow costOvercome the shortcomings of previous technologies that cannot be balancedFiberCarbon fibers

The invention discloses a carbon fiber reinforced ABS (Acrylonitrile Butadiene Styrene) resin composite material with superior heat conductivity and a preparation method. The composite material consists of the following materials in parts by weight: 90 parts of ABS resin, 10 parts of maleic anhydride grafted ABS, 10-80 parts of carbon fibers, 10-20 parts of an inorganic filler, 0.5-5 parts of a coupling agent, 0.2-1 part of an antioxidant and 0-3 parts of a lubricating agent. The preparation method comprises the following steps: mixing the raw materials in a certain mixture ratio; mixing the raw materials except the carbon fibers at a high speed; and adding an obtained mixture into a hopper of a double-screw extruder, adding the carbon fibers through the fiber inlet of the extruder, extruding the mixture, and granulating the extruded mixture. Compared with the prior art, the composite material provided by the invention has high rigidity and high heat dissipation performance and is suitable for the production and machining of thin-wall light electronic / electric products; and moreover, the raw material cost is low, a preparation process is simple, and the method is suitable for industrial continuous production.

Owner:SHANGHAI JIAO TONG UNIV

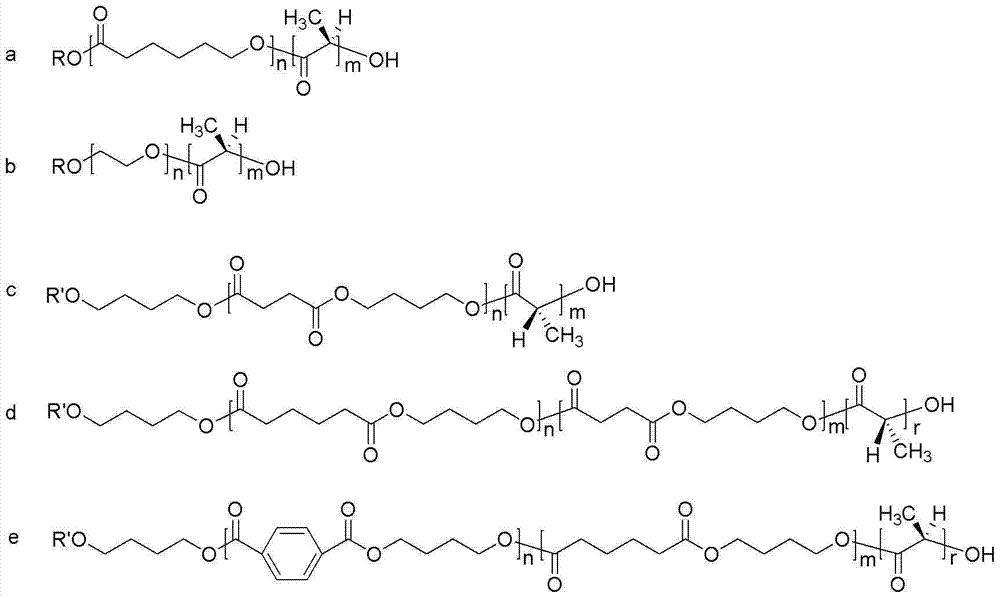

Polylactic resin composition with high heat resistance and high flexibility and preparation method of composition

InactiveCN102924892AHigh heat resistance and high toughnessImprove toughnessPolymer scienceHeat resistance

The invention discloses a polylactic resin composition with high heat resistance and high flexibility and a preparation method of the composition, solving the problem that polylactic resin with high heat resistance and high flexibility does not exist in the prior art. The polylactic resin composition consists of the following components in parts by weight: 50 to 99.5 weight parts of poly-L-lactic acid homopolymer and 0.5 to 50 weight parts of poly-D-lactic acid copolymer, wherein the poly-D-lactic acid copolymer is prepared from poly-D-lactic acid and a polymer with a flexible chain structure. The invention also provides the preparation method of the polylactic resin composition with high heat resistance and high flexibility. The preparation method is simple and suitable for industrialized production; and the prepared polylactic resin composition has high flexibility and heat resistance, the elongation at break reaches 16 percent, the notch impact strength reaches 12.2kJ / m<2>, and the vicat softening temperature reaches 113 DEG C.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

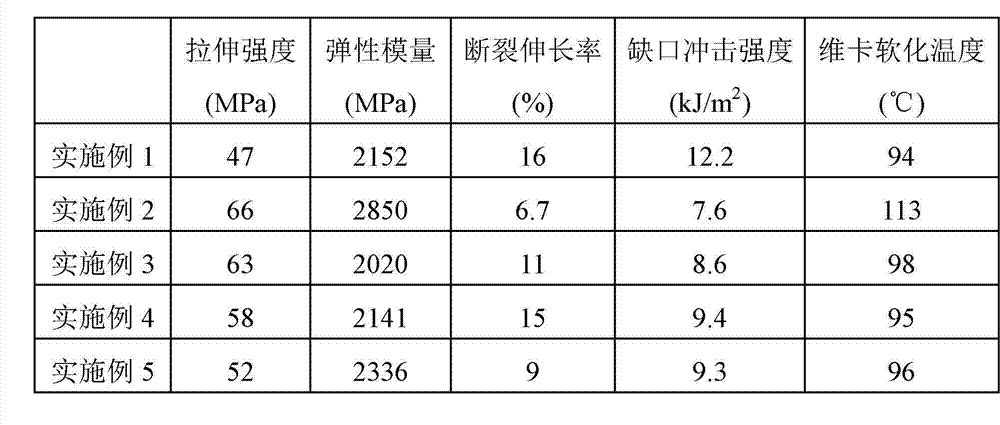

Fiber-rich wet extrusion plant meat and preparation method thereof

InactiveCN112841397AGood water dispersibilityHigh in fiberProteins working-up by texturisingVegetable proteins working-upWater bindingSoybean Proteins

The invention discloses a fiber-rich wet extrusion plant meat and a preparation method thereof. According to the preparation method, soybean protein and vital gluten are used as main raw materials, a certain content of citrus fibers is added, and the plant meat is prepared in a twin-screw extrusion mode. When the vegetable protein artificial meat is prepared, the vegetable protein artificial meat is prepared by mixing the following raw materials in parts by weight: 40-80 parts of soybean protein, 40-80 parts of vital gluten and 1-40 parts of citrus fibers. The method has the advantages that the citrus fiber is a raw material with a label cleaning function, and is high in water binding capacity, easy to obtain, low in energy consumption and low in processing amount; the soybean protein has good gelling property, so that the protein is relatively high in plasticity; the vital gluten has a certain promotion effect on the improvement of texture and the rigidity and chewiness of the finished product; and the preparation process adopts a twin-screw extruder, and is simple, easy to operate and suitable for industrial continuous production.

Owner:SOUTH CHINA UNIV OF TECH

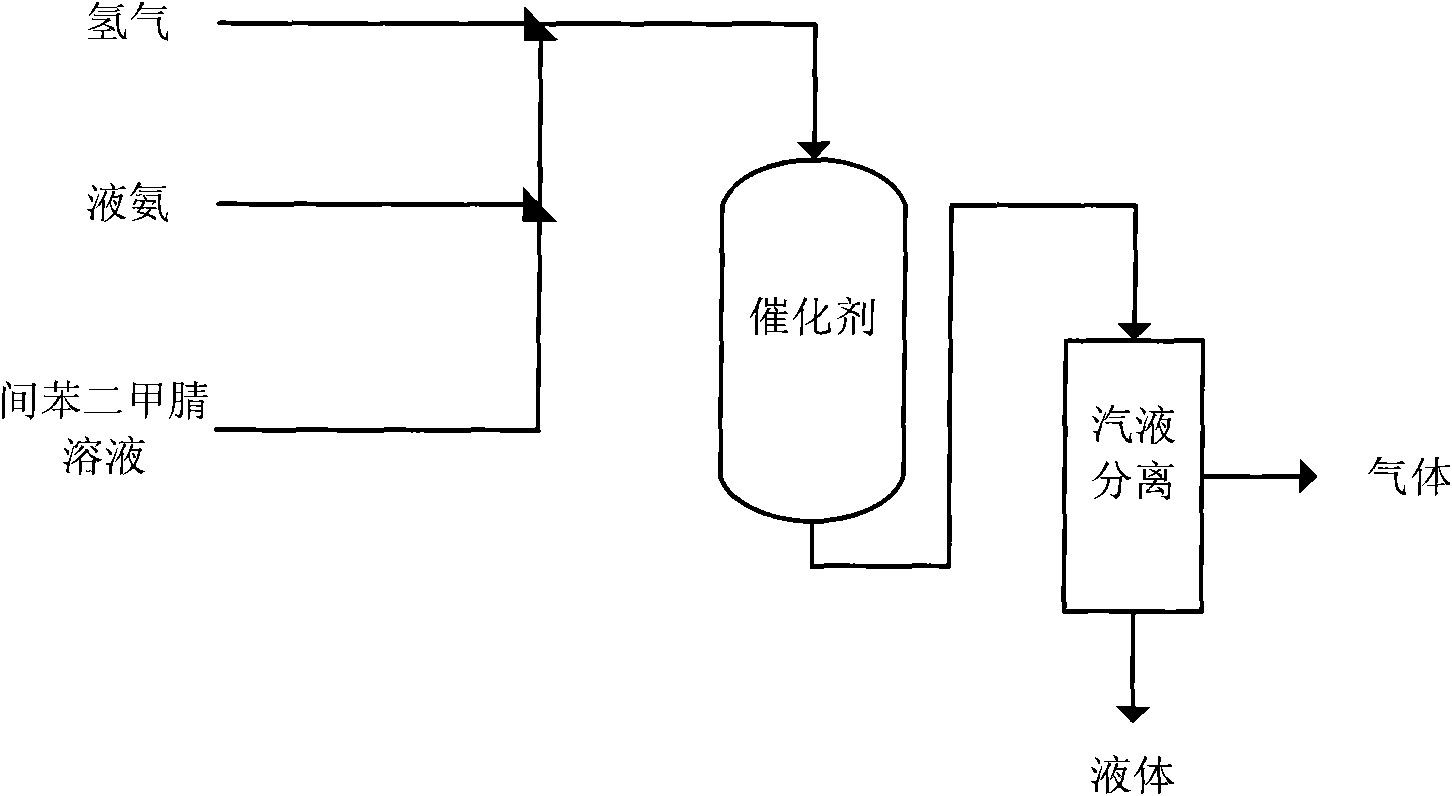

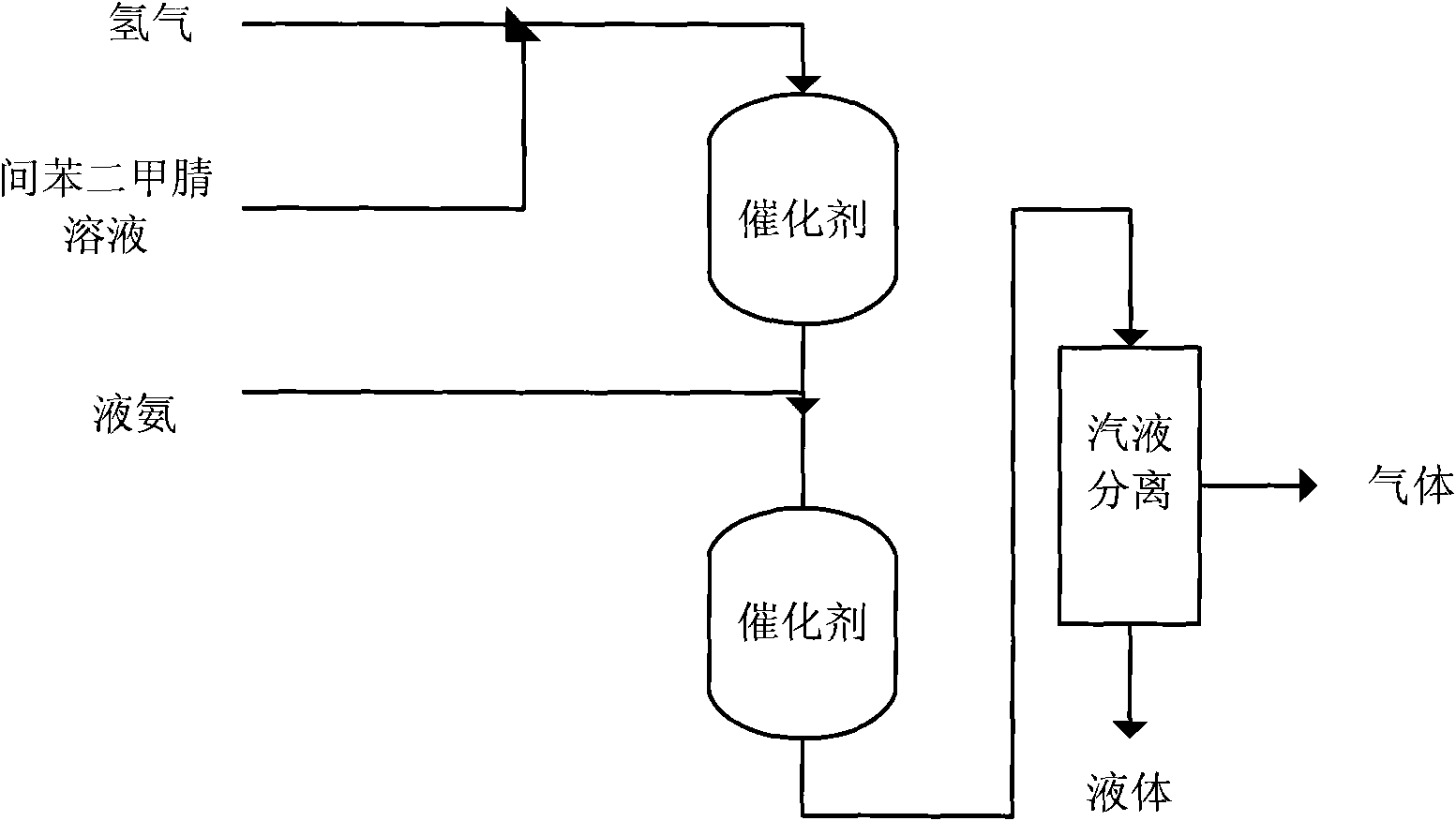

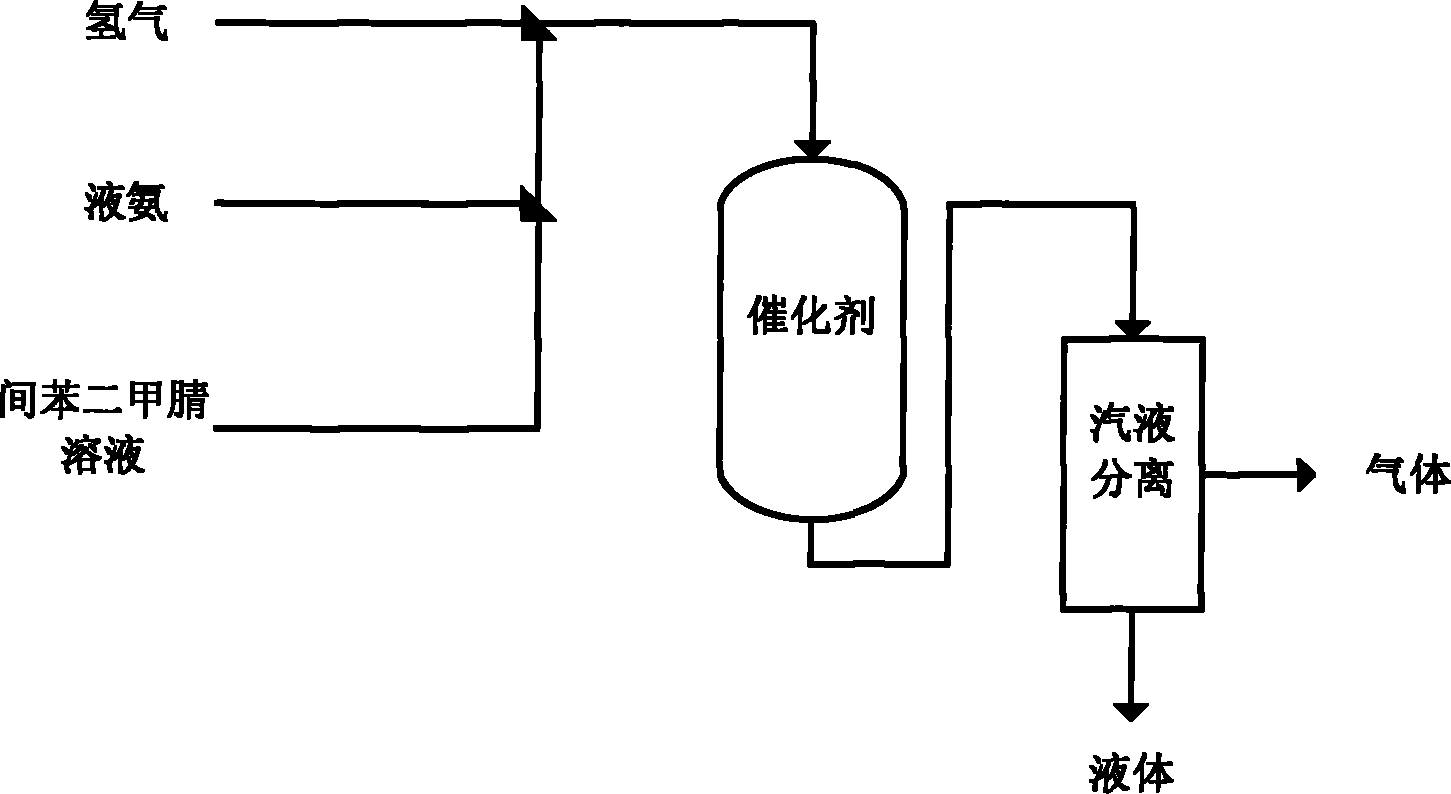

Method for preparing m-xylylenediamine

ActiveCN101774928AHigh utilization rate of raw materialsGood catalytic activityIsocyanic acid derivatives preparationOrganic compound preparationSolventOrganic acid

The invention discloses a method for preparing m-xylylenediamine. The method includes the following steps that: a fixed-bed hydrogenation reactor is adopted, and isophthalonitrile is dissolved in organic acid amide solvent, and then enters a bed containing catalyst in the form of solution to react with hydrogen under the conditions of the reaction temperature of 50 DEG C to 100 DEG C, preferably 70 DEG C to 90 DEG C, and the reaction pressure of 5MPa to 10 MPa, preferably 7MPa to 8MPa, so that the m-xylylenediamine is prepared. Xylyl diisocyanate (XDI) can be directly prepared by the liquid phase salifying phosgenation method without refining and separating the prepared m-xylylenediamine reaction liquid; the method improves the prior XDA production technique, energy is saved, emission is reduced, the reaction conditions are mild, selectivity is high, the prepared m-xylylenediamine can be directly used for phosgenation reaction without being refined and purified.

Owner:WANHUA CHEM GRP +1

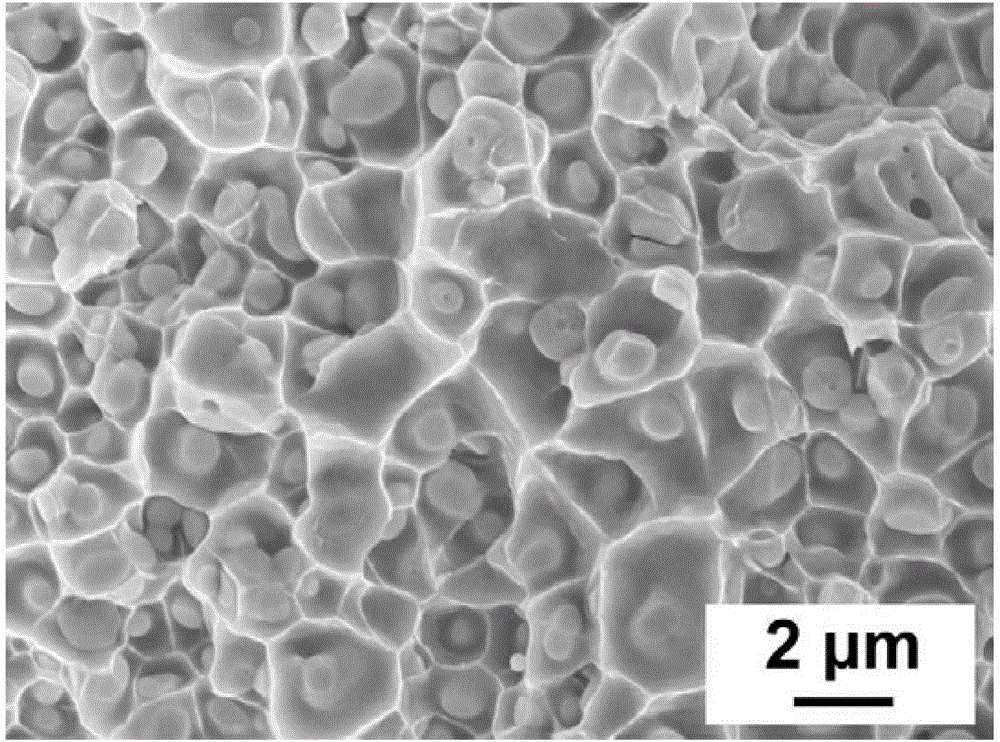

Method for preparing tungsten-copper alloy by low-temperature sintering of tungsten skeleton

ActiveCN103981389ALow impurity contentAchieve low temperature sinteringHydrogen atmosphereTube furnace

The invention discloses a method for preparing tungsten-copper alloy by low-temperature sintering of a tungsten skeleton. The method comprises the steps of carrying out wet grinding on tungsten powder of which the purity is 99.9% and the particle size is 1-7 mum and WOx powder which accounts for 5%-20% of the total mass of the powder and of which the particle size is 1-15 mum, uniformly mixing, drying and sieving, carrying out isostatic pressing on the mixed powder to obtain a green compact, sintering the green compact to obtain the tungsten skeleton, calculating the copper infiltration amount, cutting a copper plate of which the purity is greater than 99.5% into copper sheets with the same surface size as that of the tungsten skeleton, placing the copper sheets on the tungsten skeleton, feeding into a tubular furnace, heating to 1200-1400 DEG C under hydrogen atmosphere and carrying out copper infiltration. The content of copper in the tungsten-copper alloy is 15wt%-40wt%, and the balance is tungsten; the tungsten-copper alloy has more than 98% of density and the tungsten-copper alloy is suitable for being used as an electrical contact and electrode material, an electronic packaging material, a high-temperature sweating materials and the like.

Owner:XIAMEN UNIV OF TECH

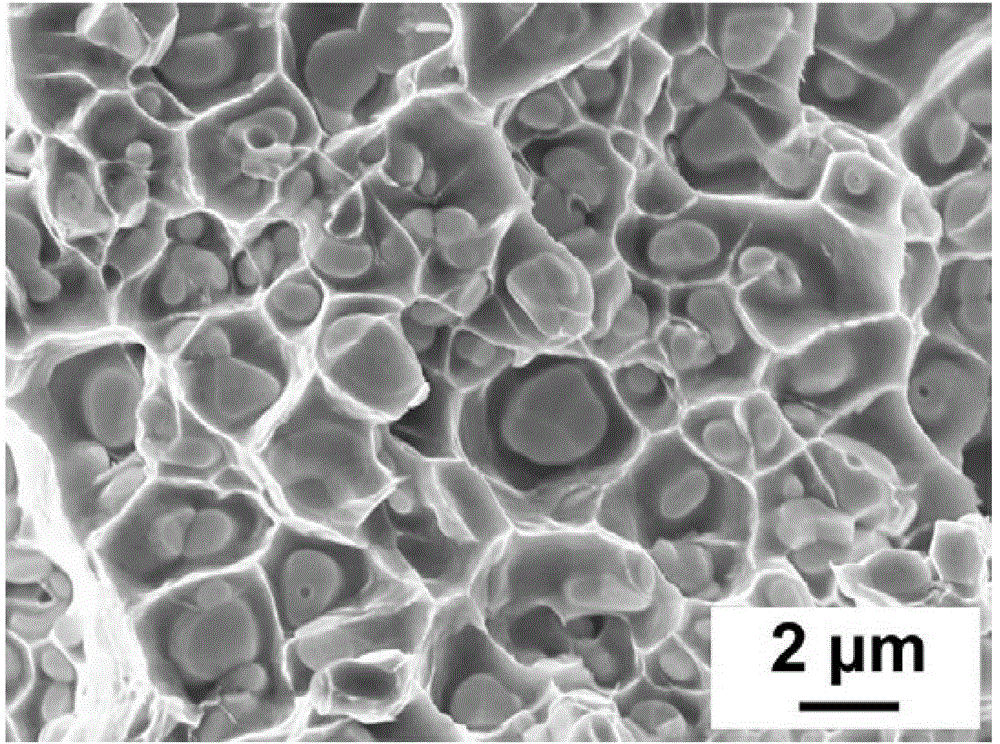

Method for preparing high-capacity hard carbon negative electrode material of lithium ion battery

InactiveCN109921020AExtensive sources of raw materialsReduce manufacturing costCell electrodesSecondary cellsCarbon sourceLithium electrode

The invention relates to the technical field of lithium ion batteries, and in particular to a method for preparing a high-capacity hard carbon negative electrode material of a lithium ion battery. Themethod comprises the following steps: preparing carbon source precursor powder; mixing the carbon source precursor powder with an oxidant; performing a low temperature oxidation reaction and a high temperature oxidation reaction on the mixture in sequence; and performing a pre-carbonization treatment and a carbonization treatment. Compared with the prior art, the method provided by the inventionhas the advantages that organic carbon sources such as resin and asphalt or the like can be widely used as a base material for hard carbon synthesis, so that the raw material source is wide,and it isconducive to reducing the production cost to a certain extent; furthermore, the preparation process is simple, the conditions are mild and controllable, which is conductive to improving the product batch stability and is suitable for industrial continuous production; and the prepared high-capacity hard carbon negative electrode material has high discharge capacity and first charge and discharge efficiency, and a button battery made of the high-capacity hard carbon negative electrode material has excellent comprehensive performance.

Owner:NINGBO SHANSHAN NEW MATERIAL TECH

A kind of preparation method of ion membrane electrode for pure water electrolysis

InactiveCN102260877ASimple preparation processEasy to useCellsElectrodesPtru catalystElectrolysed water

The invention relates to a preparation method of an ion membrane electrode for pure water electrolysis, belonging to the technical field of hydrogen production by water electrolysis. The preparation method comprises the following steps: separately preparing a cathode catalyst solution and an anode catalyst solution from a cathode catalyst, an anode catalyst, a Nafion solution, isopropyl alcohol, glycerol and distilled water; separately applying the cathode catalyst solution and the anode catalyst solution on two transfer-printing templates, and drying the templates at the temperature of 80-130 DEG C in vacuum; and fixing the two dried transfer-printing templates on both sides of an ion membrane, treating at the temperature of 130-190 DEG C and the pressure of 6 MPa for 2-5 minutes, cooling to room temperature while maintaining the pressure at 6 MPa, peeling off the transfer-printing templates, placing the templates in an oven and treating in vacuum at the temperature of 70-110 DEG C for 1 hour. By using the transfer-printing templates in the preparation method, under the premise of ensuring the combination firmness degree of the ion membrane and the catalyst layer, the direct damage to the ion membrane is reduced, thereby the service life of the membrane electrode is prolonged, the energy consumption is lowered, the electrolysis efficiency is improved, the preparation time is shortened and the production cost is reduced.

Owner:SHANDONG SAIKESAISI HYDROGEN ENERGY

Carbon fiber reinforced thermoplastic resin composite material and preparation method of carbon fiber reinforced thermoplastic resin composite material

ActiveCN104194286AOvercome mechanical propertiesOvercoming thermal conductivityPolytetramethylene terephthalateCarbon fibers

The invention relates to a carbon fiber reinforced thermoplastic resin composite material and a preparation method of the carbon fiber reinforced thermoplastic resin composite material. The carbon fiber reinforced thermoplastic resin composite material comprises the following raw materials in parts by weight: 100 parts of PBT resin, 20-80 parts of asphalt-based chopped carbon fiber, 10-20 parts of inorganic filler, 0.5-5 parts of a coupling agent, 0.2-1 part of an antioxidant and 0-3 parts of a lubricating agent. Compared with the prior art, the composite material provided by the invention has the advantages of high rigidity, good heat-conducting property, low raw material cost, simple preparation process, is suitable for production and manufacturing of thin-wall and lightweight car parts and electronic / electric products and is suitable for industrial continuous production.

Owner:SHANGHAI JIAO TONG UNIV

Continuous-phase-change tea oil extraction method

InactiveCN103173279AReduce consumptionReduce energy consumptionFatty-oils/fats productionGas phaseProduct gas

The invention provides a continuous-phase-change tea oil extraction method. According to the invention, a dried and crushed tea seed raw material is placed into an extraction kettle of a continuous-phase-change extraction device; under a condition with a pressure constantly lower than an extracting agent critical pressure and a temperature constantly lower than an extracting agent critical temperature, the extracting agent is compressed into a liquid by using a high-pressure pump; the extracting agent flows through the extraction kettle with a certain flow rate, such that tea oil is extracted; the material is delivered into a resolution kettle; heating and pressure reducing are carried out, such that the extracting agent is changed into a gas phase; instant compression is carried out, the extracting agent is changed into liquid, and flows through the extraction kettle, such that the material is extracted again. The steps are repeated several times. The method provided by the invention has the advantaged of high efficiency, no solvent residue in product, and high aroma component retention rate of supercritical extraction and subcritical extraction methods. Extraction pressure and resolution pressure of the method are lower than those of supercritical extraction. The method also has the advantages of large extraction volume, large-amount batch production, low production cost, and the like of conventional solvent extraction methods. Also, the continuous-phase-change extraction method has the advantages that the extraction time is short, instant continuous extraction process can be realized, solvent demand is low, and the solvent can be recovered.

Owner:曹庸

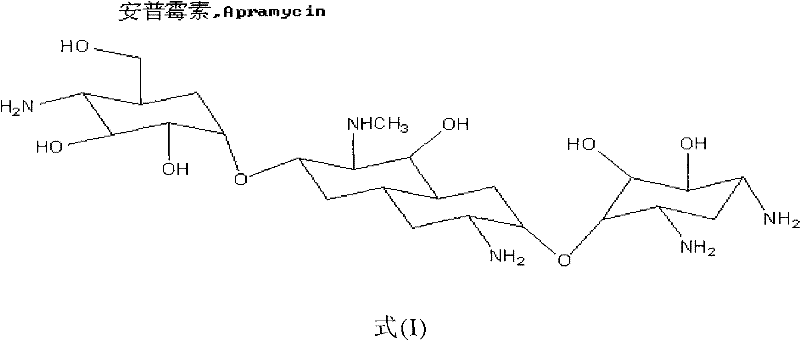

Method for extracting apramycin

InactiveCN102477052AIncrease profitReduce manufacturing costSugar derivativesSolid sorbent liquid separationHydrolysisStreptomyces tenebrarius

The invention provides a method for extracting apramycin, comprising the following steps: purifying a Streptomyces tenebrarius broth for producing carbamoyltobramycin through a cation resin to obtain a rough solution of carbamoyltobramycin containing apramycin; carrying out hydrolysis to obtain a rough solution of tobramycin containing apramycin; and then purifying through the apramycin to obtain an apramycin solution. According to the method, a by-product apramycin can be extracted while apramycin is produced from the Streptomyces tenebrarius broth, thus utilization rate of the by-product in the production process of tobramycin is raised, and simultaneously the production cost of the product is reduced, and the environmental protection risk is reduced.

Owner:PEKING UNIV FOUNDER GRP CO LTD +2

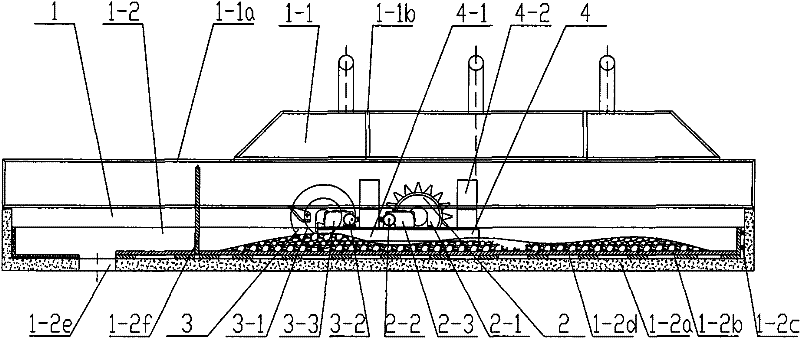

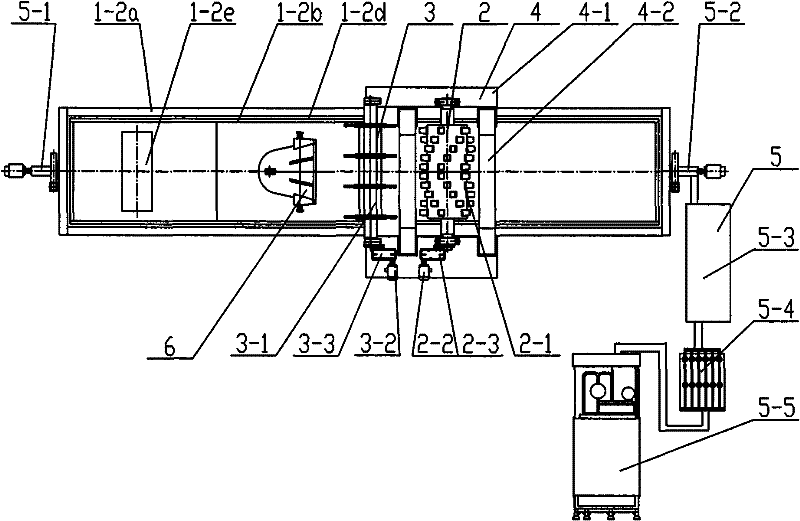

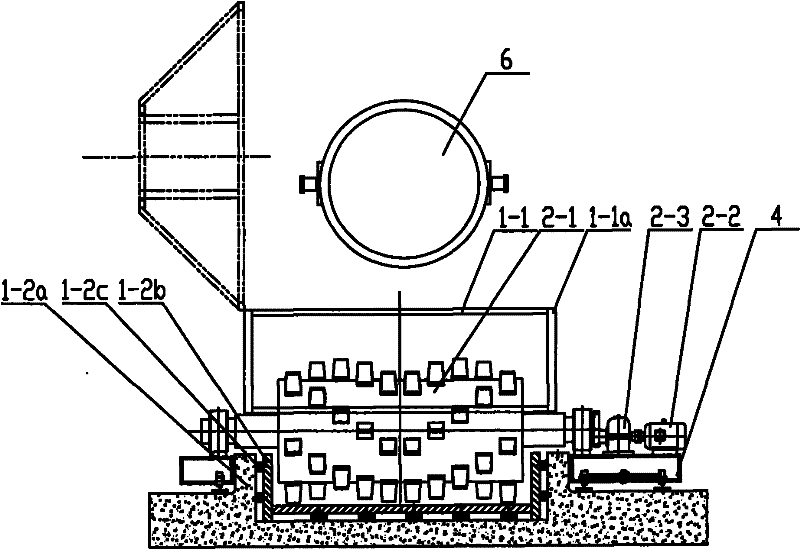

Aircooled crushing device and method of molten steel slag

ActiveCN102191343AImprove crushing efficiencyAvoid pollutionRecycling and recovery technologiesProcess efficiency improvementSlagMolten steel

The invention discloses an aircooled crushing device of molten steel slag. The device comprises a rolling crushing chamber (1), a rolling crushing device (2), a slag pushing device (3), a traveling trolley (4) and an afterheat recycling device (5), wherein the rolling crushing device (2) and the slag pushing device (3) are positioned on the traveling trolley (4); and the traveling trolley (4) moves in the rolling crushing chamber (1) along rails on the two sides of the rolling crushing chamber (1). An aircooled crushing method comprises the following steps of: pouring the molten steel slag into the rolling crushing chamber (1); blowing normal-temperature air with an air supply device (5-1) to cool the molten steel slag; crushing big steel slag of which the surface is crusted into small steel slag with the rolling crushing device (2), and turning the molten steel slag under the hard crusts to the surfaces at the same time so as to improve the heat exchange efficiency; repeatedly performing air cooling and crushing on the steel slag until the temperature of the steel slag is cooled to certain temperature, wherein the normal-temperature air is heated at the same time and enters the afterheat recycling device (5) for power generation, heat supply and the like; and pushing cooled blocky steel slag to a slag groove through a chute by using the slag pushing device (3), and stabilizing the blocked steel slag.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP +2

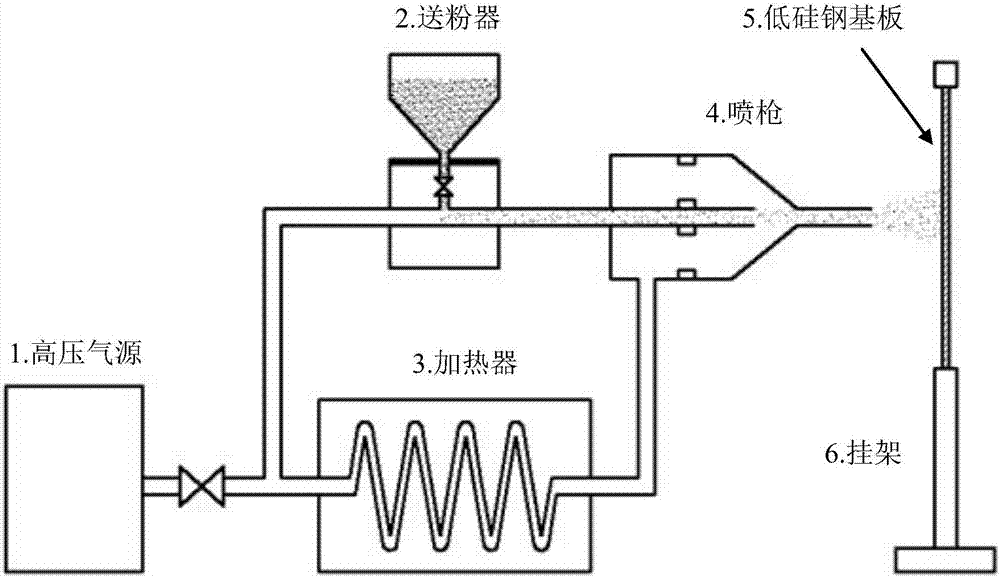

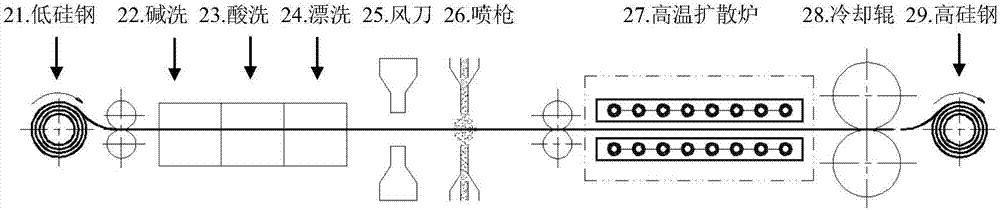

Method for preparing high silicon steel thin plate through gas power spraying

InactiveCN107338432AIncrease productivityFast film formationPressure inorganic powder coatingHydrogenProduct gas

The invention relates to a method for preparing a Fe-Si alloy thin plate, in particular to a method for preparing Fe-5.5wt.%-6.5wt.%Si high silicon steel thin plate with excellent soft magnetic properties through the gas power spraying (cold spraying) technology. According to the method for preparing the high silicon steel thin plate through gas power spraying, gas power spraying is adopted for spraying micron-order Fe-23wt.%-40wt.%Si alloy micro powder on one face or double faces of a low-silicon steel thin plate, then high temperature diffusion treatment is carried out in a hydrogen gas reduction atmosphere, Si atoms in an Si coating are inwards diffused to permeate into a low-silicon steel base until the Si content in the base reaches 5.5wt.%-6.5wt.%, the high silicon steel thin plate with the excellent soft magnetic properties is obtained, and the using requirement of high-performance iron core materials is met. According to the method, the coating preparation rate is high, the working efficiency is high, the quality in the preparing process is controllable, and therefore the method is particularly suitable for industrial application.

Owner:LANZHOU JIAOTONG UNIV

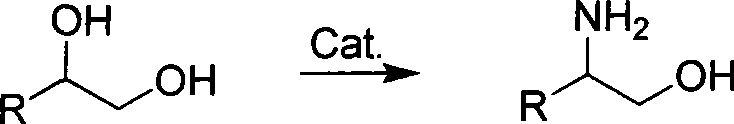

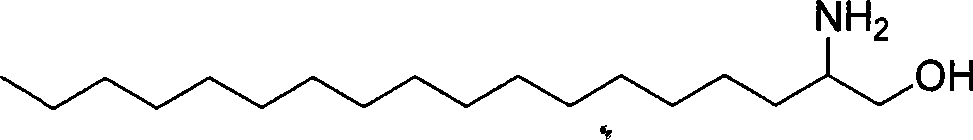

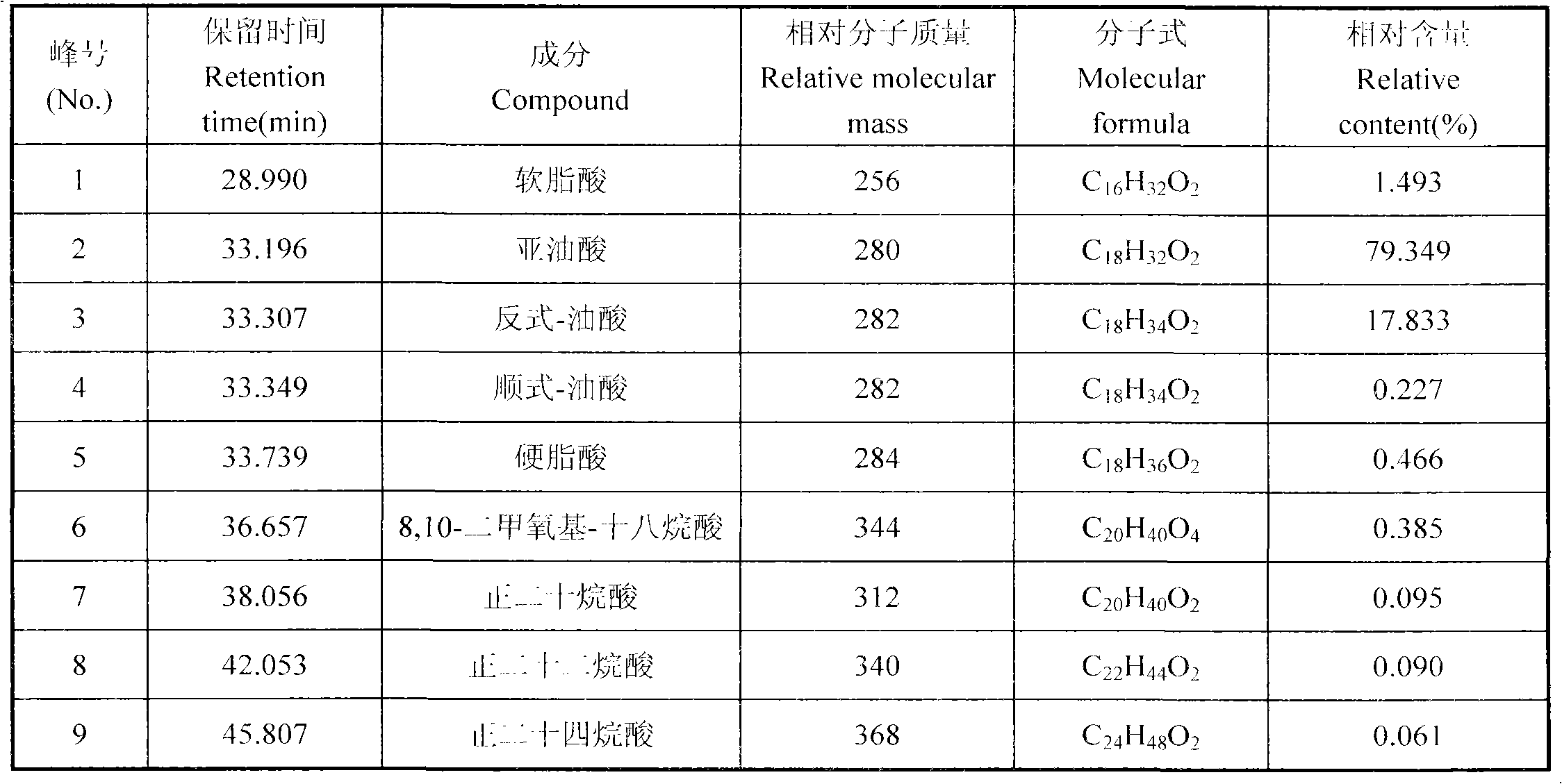

Method for preparing 2-amido-1-alkyl alcohol and catalyst preparation method

InactiveCN101391964ASolution to short lifeSimple processOrganic compound preparationMetal/metal-oxides/metal-hydroxide catalystsDouble tubeHydrogen pressure

The invention relates to methods for preparing 2-amino-1-alkyl alcohol and catalyst. The solid catalyst is filled in a single-tube type or double-tube type fixed bed reactor, the temperature in a preheater and the reactor is kept between 130 to 250 DEG C, the hydrogen pressure is kept between 1.0 to 10.0MPa; 1, 2-diol solution with the volume ratio of 10 to 30 percent and ammonia gas are led into the fixed bed reactor from the upper end, the mol ratio between 1, 2-diol and ammonia gas is 1:3 to 1:15, the volume airspeed of the 1, 2-o-diol solution is 30 to 300h<-1>, the obtained liquid is added with methanol for being regulated to homogeneous phase, and transferred into a still after being filtered, and then rectified to obtain the product after the solvent is removed by evaporation. The preparation method of the catalyst adopts the immersion method or the extruding method. The quality of the products of the invention meets the standards of the first class of the industrial products, the content of 2-amino-1-butyl is equal to or more than 99.0 percent; the prepared catalyst for catalysis and amination has long service life; the technology is simple and suitable for continuous industrial production; the cost is low, and the economic benefit is high.

Owner:TIANJIN UNIV

Method for extracting nitraria seed oil from subcritical fluid

InactiveCN102504940AReduce manufacturing costReduce consumptionFatty-oils/fats productionEnvironmental resistanceOperability

The invention relates to a method for extracting nitraria seed oil from subcritical fluid. The method comprises the following steps of: (1) squeezing juice of fresh and clean nitraria fruit, drying the obtained seed at room temperature in the shade and sequentially carrying out sorting, crushing and sieving to obtain nitraria seed raw materials; (2) milling and baking the nitraria seed raw materials to obtain treated nitraria seed; (3) carrying out continuous extraction through putting the treated nitraria seed and extracting agents into an extraction kettle of a subcritical fluid extraction device to obtain extracts; and (4) using a pressure reduction temperature rise method for separating the extracts to obtain extraction liquid and carrying out still standing on the extraction liquid at room temperature to obtain the nitraria seed oil. After the method is adopted, the production cost is effectively reduced, the extraction and separation time is shortened, the solvent consumption and the energy consumption in the technical process are reduced, in addition, the technical flow process is simple, the operability is high, the extraction efficiency is high, the environment is protected, the pollution is avoided, the safety and the repeatability are good, and the large-scale industrial continuous production can be realized.

Owner:CHINA ACAD OF SCI NORTHWEST HIGHLAND BIOLOGY INST

Gas phase process of preparing nanometer alumina particle

The gas phase process of preparing nanometer alumina particle includes the following steps: burning gasified and air carried aluminum isopropoxide with hydrogen in a combustion chamber, hydrolysis to produce nanometer alumina particle, cooling and collecting nanometer alumina particle product. The process has no pollutant exhaustion, and is simple, low in cost and suitable for industrial production.

Owner:EAST CHINA UNIV OF SCI & TECH

Carbon fiber reinforced thermoplastic resin composite material with superior heat dissipation performance and preparation method

The invention relates to a carbon fiber reinforced thermoplastic resin composite material with superior heat dissipation performance and a preparation method. The composite material consists of the following materials in parts by weight: 100 parts of polycarbonate, 10-80 parts of carbon fibers, 0-40 parts of inorganic filler, 0.5-5 parts of a coupling agent, 0.2-1 part of an antioxidant and 0-3 parts of a lubricating agent. The preparation method comprises the following steps: fully drying the carbon fibers serving a raw material and the polycarbonate serving as a thermoplastic resin substrate; weighing the raw materials according to a mixture ratio; mixing the raw materials except the carbon fibers at high a speed; and adding the mixture into a hopper of a dual-screw extruder, adding the carbon fibers through the fiber inlet of the extruder, and extruding and granulating the mixture and the carbon fibers. Compared with the prior art, the composite material provided by the invention has high rigidity and high heat dissipation performance, and is suitable for the production and machining of thin-wall light electronic / electrical products. Moreover, the preparation method is simple in the preparation process, is continuous and stable in the extruding process, and is suitable for industrial continuous production.

Owner:SHANGHAI JIAO TONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com