Method for extracting nitraria seed oil from subcritical fluid

A subcritical fluid and Nitraria seed technology, which is applied in the direction of fat oil/fat production and fat generation, can solve the problems of long extraction time, long pressing time of mechanical pressing method, and large solvent consumption, so as to reduce solvent consumption and Energy consumption, shortened extraction and separation time, good safety and repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

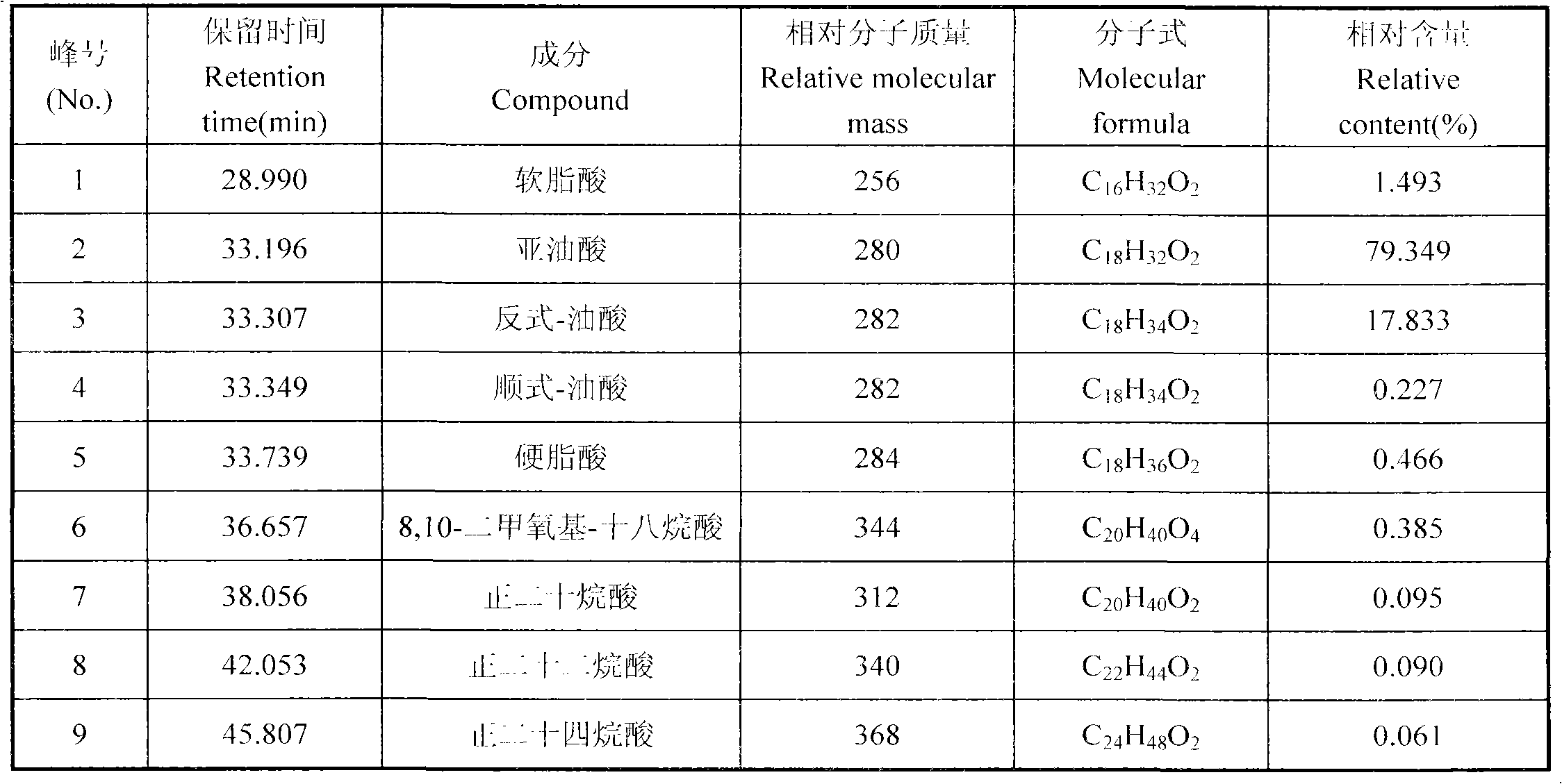

Image

Examples

Embodiment 1

[0022] Embodiment 1 A method of subcritical fluid extraction of Nitraria japonica seed oil, comprising the following steps:

[0023] (1) The seeds obtained after squeezing fresh and clean Nitraria fruit are dried in the shade at room temperature, sorted, crushed, and passed through a 20-mesh sieve to obtain Nitraria seed raw material.

[0024] (2) The Nitraria seed raw material was rolled at 30° C. for 60 minutes and then dried for 8 hours to obtain treated Nitraria seeds.

[0025] (3) The processed Nitraria thorn seeds and extractant—propane are put into the extraction kettle of the subcritical fluid extraction device according to the mass-volume ratio (g / mL) of 1:1, and the extraction temperature is 5° C. Under the condition that the pressure is 0.15MPa and the flow rate of the extractant is 10L / h, the extract is continuously extracted once, each time for 10min, to obtain the extract.

[0026] (4) Using the method of decompression and heating, the extract is separated under...

Embodiment 2

[0028] Embodiment 2 A kind of subcritical fluid extracts the method for Nitraria japonica seed oil, comprises the following steps:

[0029] (1) The seeds obtained after squeezing fresh and clean Nitraria fruit are dried in the shade at room temperature, sorted, crushed, and passed through a 60-mesh sieve to obtain Nitraria seed raw material.

[0030] (2) The Nitraria seed raw material was rolled at 70° C. for 10 minutes and then dried for 3 hours to obtain treated Nitraria seeds.

[0031] (3) The Nitraria thorn seeds after treatment and the extractant——dimethyl ether are put into the extraction kettle of the subcritical fluid extraction device at a material-solution mass-volume ratio (g / mL) of 1:8, and the extraction temperature is 55° C. , extraction pressure is 0.35MPa, extraction agent flow rate is 40L / h under the conditions of continuous extraction 10 times, each 90min, to obtain the extract.

[0032] (4) Using the decompression and heating method to separate the extract ...

Embodiment 3

[0034] Embodiment 3 A kind of subcritical fluid extracts the method for Nitraria japonica seed oil, comprises the following steps:

[0035] (1) The seeds obtained after squeezing fresh and clean Nitraria fruit are dried in the shade at room temperature, sorted, crushed, and passed through a 40-mesh sieve to obtain Nitraria seed raw material.

[0036] (2) The Nitraria seed raw material was rolled at 62° C. for 30 minutes and then dried for 5 hours to obtain treated Nitraria seeds.

[0037] (3) The treated Nitraria thorn seeds and extractant—butane are put into the extraction kettle of the subcritical fluid extraction device at a material-solution mass-volume ratio (g / mL) of 1:5, and the extraction temperature is 45° C. Under the conditions of extraction pressure of 0.52MPa and extractant flow rate of 70L / h, continuous extraction was carried out for 6 times, 40min each time, to obtain the extract.

[0038] (4) Using the method of decompression and heating, the extract is separa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com