Polylactic resin composition with high heat resistance and high flexibility and preparation method of composition

A technology of polylactic acid resin and composition, which is applied in the field of high heat-resistant and high-toughness polylactic acid resin composition and its preparation, can solve the problem that polylactic acid resin cannot have both high heat resistance and high toughness, and achieve high heat resistance The effect of high stability, high processing efficiency and good processing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

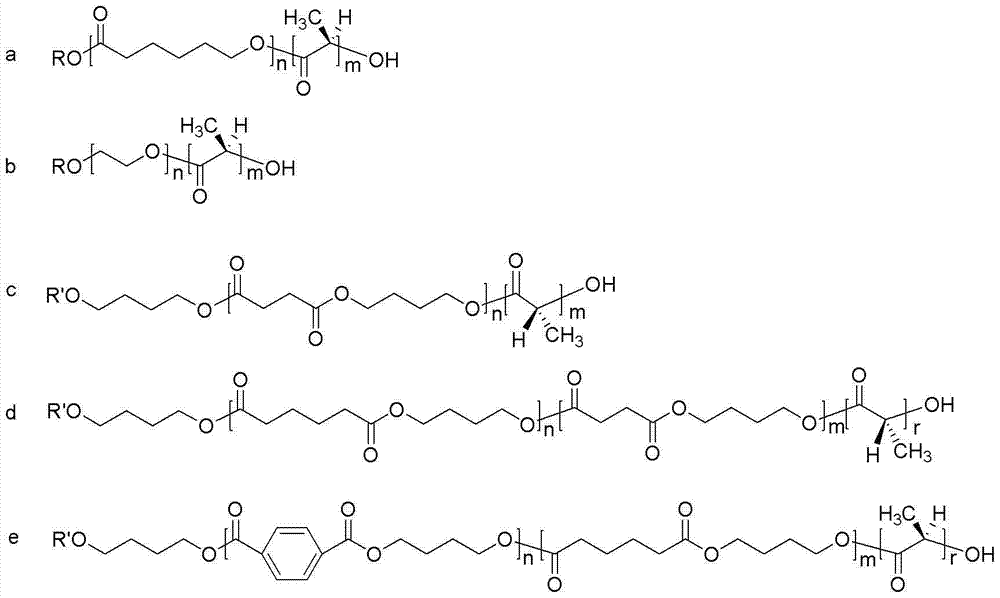

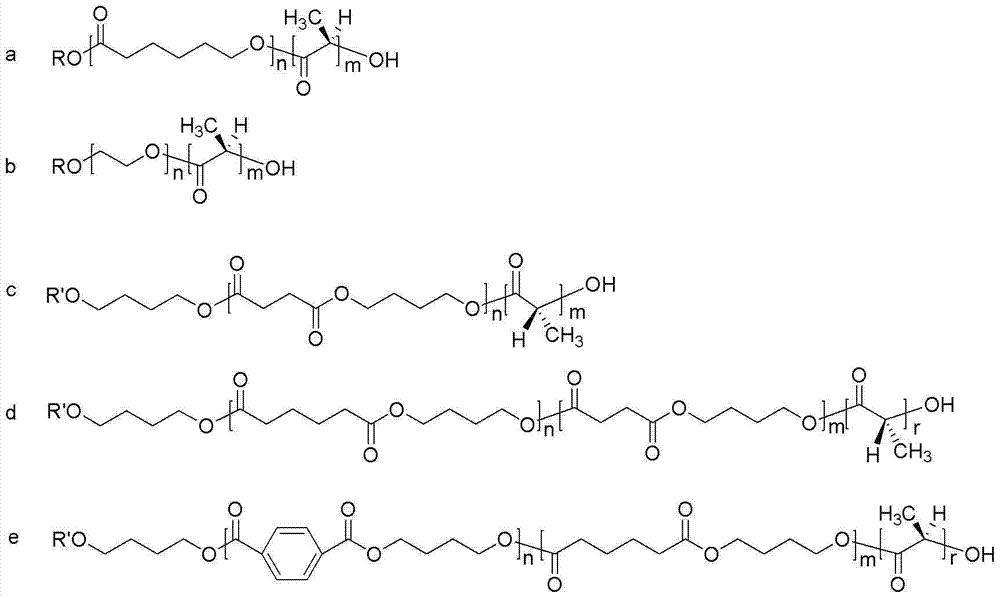

[0040] The poly-D-lactic acid copolymer is prepared from poly-D-lactic acid and the second component, and its preparation process is a well-known technology in the art. The present invention provides a preparation method of the poly-D-lactic acid copolymer, and the second component is added in the reaction device , initiator and catalyst, stir to disperse the components evenly, raise the temperature to 120-140°C and continue to stir for 1-3 hours, add poly-D lactic acid and replenish the catalyst under stirring, raise the temperature to 140-160°C for reaction 1 -3 hours, rise to 160-180°C and continue to react for 1-3 hours until the reaction is completed, the product is vacuumized, granulated, and dried to obtain poly-D lactic acid copolymer;

[0041]Wherein, initiator is the alcohol containing 1-18 carbon atoms, preferably dodecyl alcohol, and according to the difference of target molecular weight, its consumption is 0.1-1% of poly-D lactic acid quality;

[0042] The catalys...

Embodiment 1

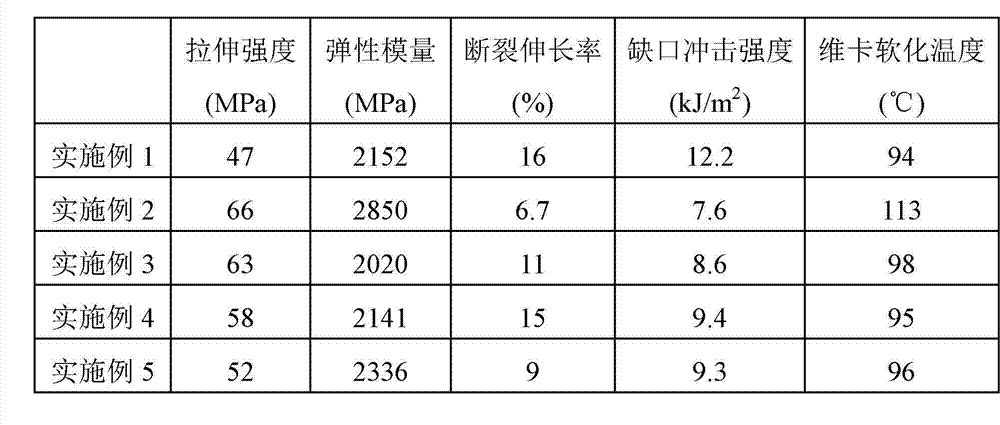

[0063] Poly-D lactic acid, 50 parts by weight of a diblock poly-D-lactic acid copolymer sample with a polycaprolactone molar ratio of 1:1, and 50 parts by weight of a poly-L-lactic acid homopolymer were blended and granulated in a twin-screw extruder. The temperature settings of each section are: 190°C, 200°C, 210°C, 220°C, 210°C, the speed is: 50rpm, after granulation, it is injected into the injection molding machine, and the injection temperature is: 210°C , the injection pressure is 100MPa, the cooling time of the melt in the mold is 40 seconds, and the mold temperature is set at 85°C to obtain a polylactic acid resin composition. The polylactic acid resin composition was tested for mechanical and heat resistance properties, and the results are shown in Table 1.

Embodiment 2

[0065] Poly-D-lactic acid, polybutylene terephthalate-co-butylene adipate molar ratio of 5:1 diblock poly-D-lactic acid copolymer sample 30 parts, poly-L-lactic acid homopolymer 70 parts Blending and granulation in a twin-screw extruder, the temperature settings of each section of the screw are: 190°C, 200°C, 220°C, 230°C, 220°C, and the speed is 50rpm. After granulation, it is injected Injection molding in the machine, the injection temperature is: 210°C, the injection pressure is 100MPa, the cooling time of the melt in the mold is 60 seconds, and the mold temperature is set at 95°C to obtain a polylactic acid resin composition. The polylactic acid resin composition was tested for mechanical and heat resistance properties, and the results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com