High-heat-resistant high-toughness low-dielectric-constant fluorenyl benzoxazine resin composition as well as preparation method and application thereof

A technology of benzoxazine resin and oxazine resin, applied in chemical instruments and methods, lamination, layered products, etc., can solve problems such as low bending strength, low product yield, and large steric hindrance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0095] Preparation of the prepreg: select a flat and smooth E-glass fiber cloth with a thickness of 0.2mm, soak it in the above composition (solution), take it out, and then bake it in an oven at 130-170°C for 4-7 minutes. The resin weight percentage content of the prepreg is 32%-68%.

[0096] Preparation of laminated boards: stack the prepreg pieces, cover the top and bottom with a release film, and then place them in a hot press, keeping the heating rate at 1-3°C / min. After reaching the temperature, press 0.2-3MPa and 150- It is formed by pressing at 250°C for 1 to 4 hours.

[0097] Preparation of copper-clad laminate: stack the above prepreg cut pieces, cover both sides or one side of the prepreg with copper foil, and press at 0.2-3MPa pressure and 130-250°C for 1-4 hours.

[0098] The comparison of some technical performances between the high heat-resistant, high-toughness and low-dielectric fluorenyl benzoxazine resin composition copper-clad laminate (halogen-free) prepa...

Embodiment 21

[0126] A high heat-resistant, high-toughness, low-dielectric fluorenyl-benzoxazine resin composition, the high-heat-resistant, high-toughness, low-dielectric fluorenyl-benzoxazine resin composition has a weight ratio of resin: inorganic filler: accelerator : Solvent=100:30:0.01:57 mixture of resin, inorganic filler, accelerator and solvent;

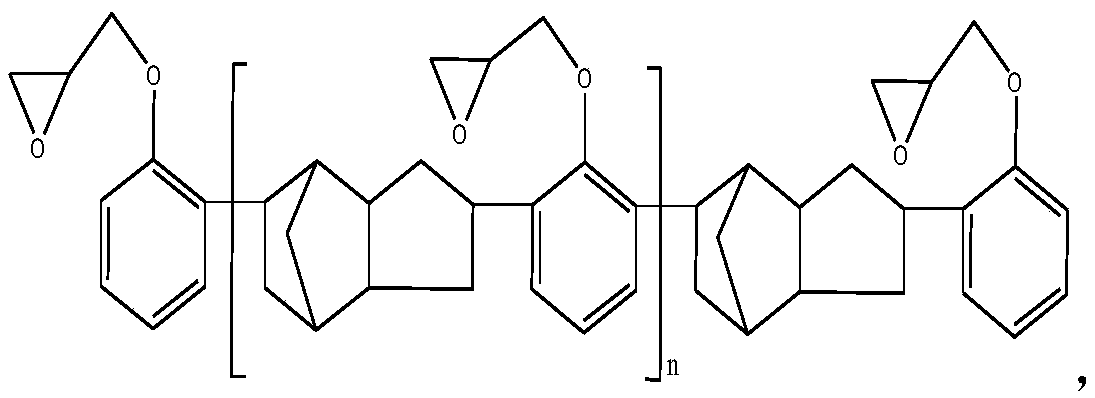

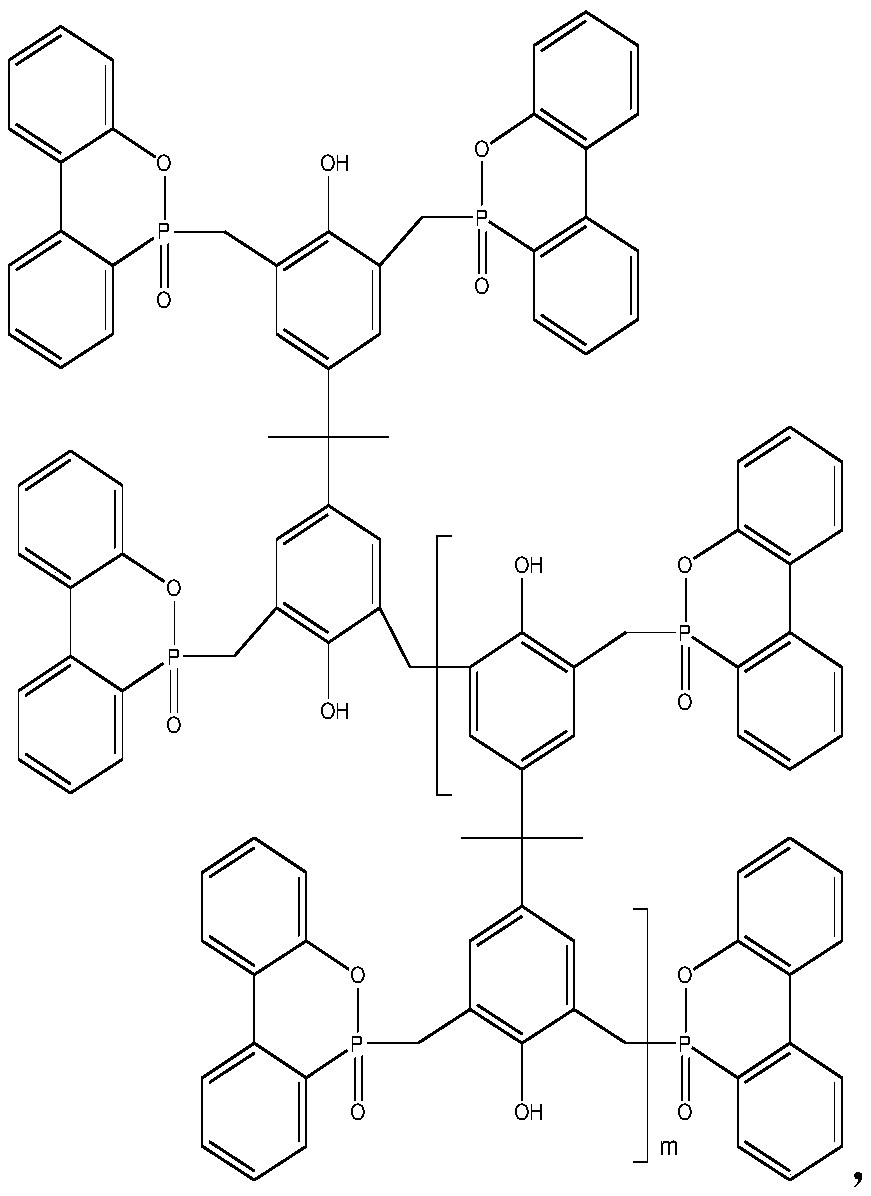

[0127] The resin is a mixture with a weight ratio of benzoxazine resin: DCPD epoxy resin: phosphorus-containing phenolic resin=100:40:10;

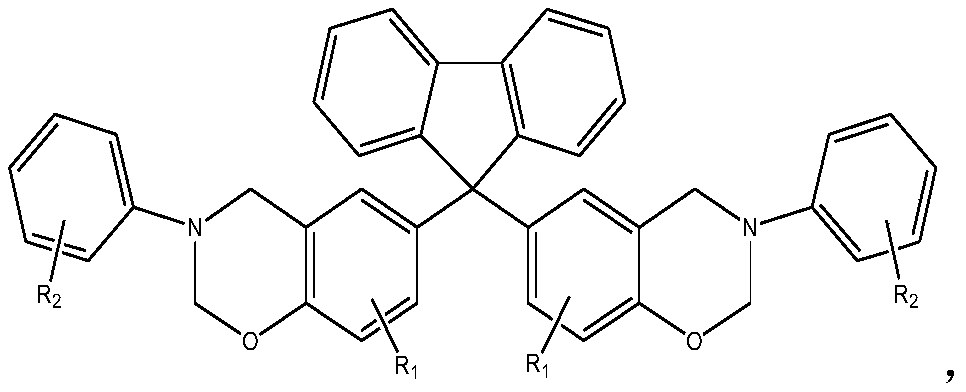

[0128] The benzoxazine resin is a fluorenyl benzoxazine resin with high heat resistance, high toughness and low dielectric.

Embodiment 22

[0130] A high heat-resistant, high-toughness, low-dielectric fluorenyl-benzoxazine resin composition, the high-heat-resistant, high-toughness, low-dielectric fluorenyl-benzoxazine resin composition has a weight ratio of resin: inorganic filler: accelerator : Solvent=100:70:1:80 mixture of resin, inorganic filler, accelerator and solvent;

[0131] The resin is a mixture with a weight ratio of benzoxazine resin: DCPD epoxy resin: phosphorus-containing phenolic resin=100:80:40;

[0132] The benzoxazine resin is a fluorenyl benzoxazine resin with high heat resistance, high toughness and low dielectric.

PUM

| Property | Measurement | Unit |

|---|---|---|

| bending strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com