Patents

Literature

51results about How to "Promote pore formation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

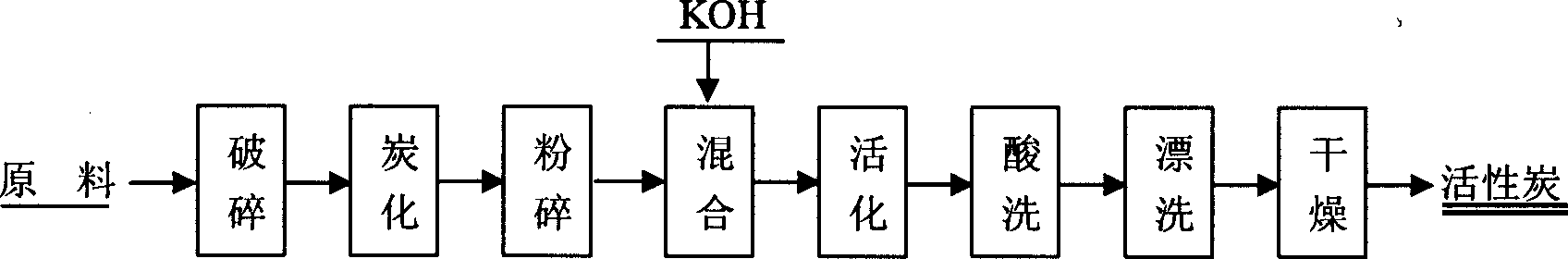

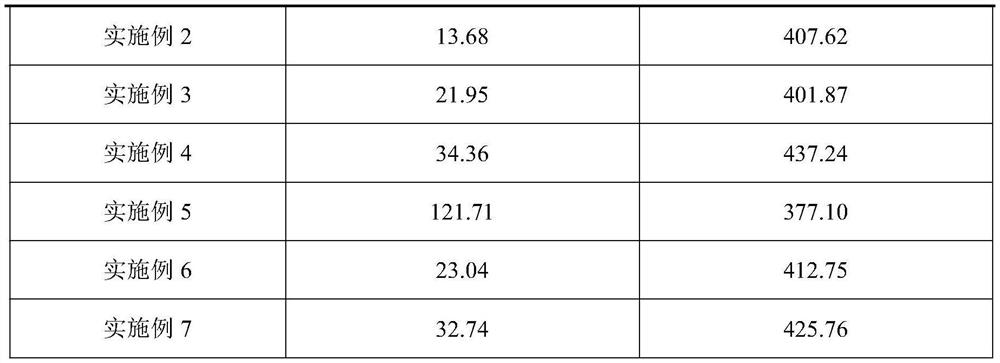

Super active carbon preparation method

The invention relates to a preparation method for super active carbon. Wherein, carbonizing and breaking up the raw material of coco shell or walnut shell to predetermined particle size and mix evenly with solid potassium hydroxide; activating the mixture in microwave oven with nitrogen protection during the process to obtain activation material; clearing the material with muriatic acid and then distilled water for many times to neutrality and obtain the said product. The product with this method has strong adsorption property, high specific surface area and high adsorption value to iodine and methylene blue. The method is simple and convenient to control.

Owner:KUNMING UNIV OF SCI & TECH

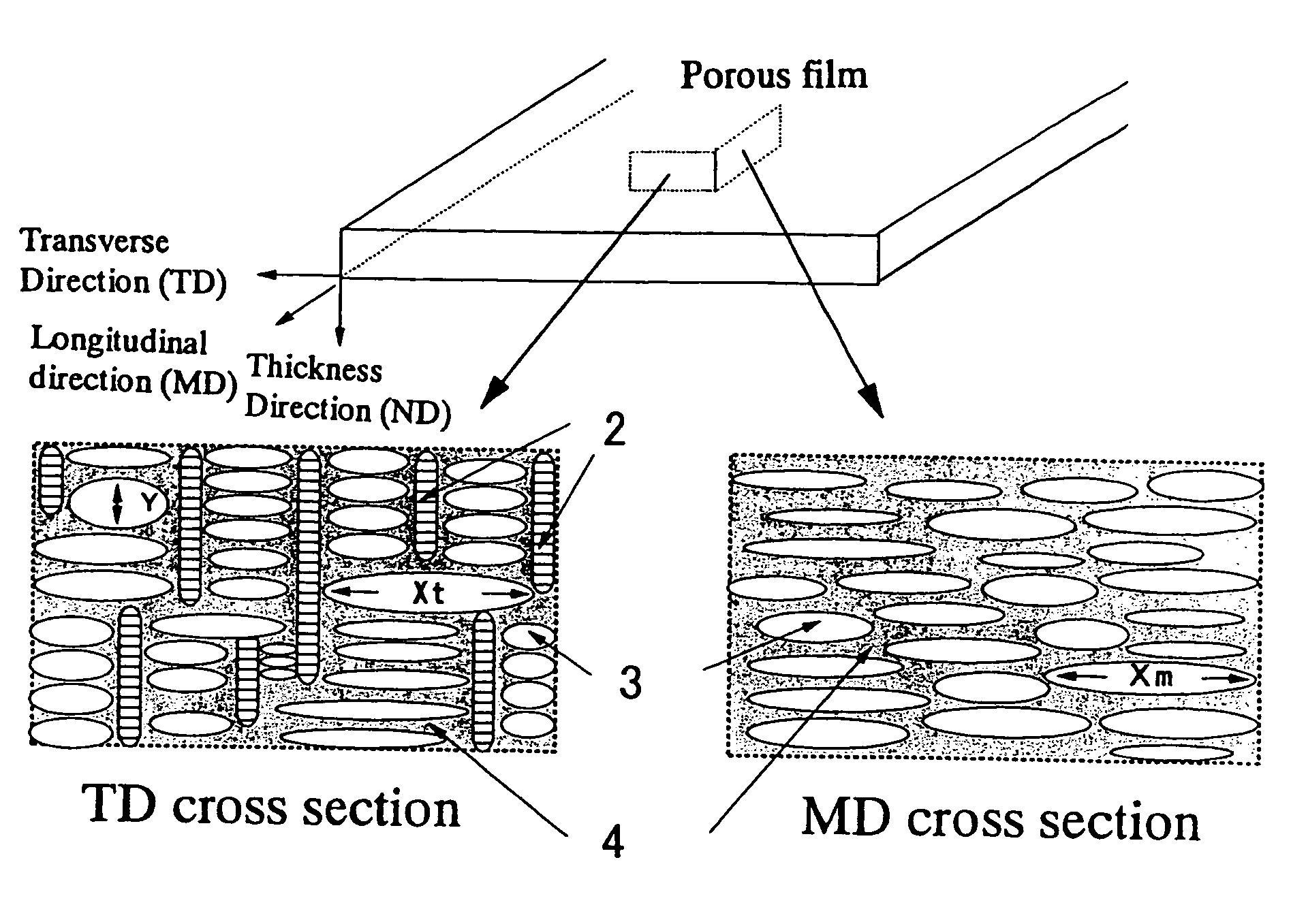

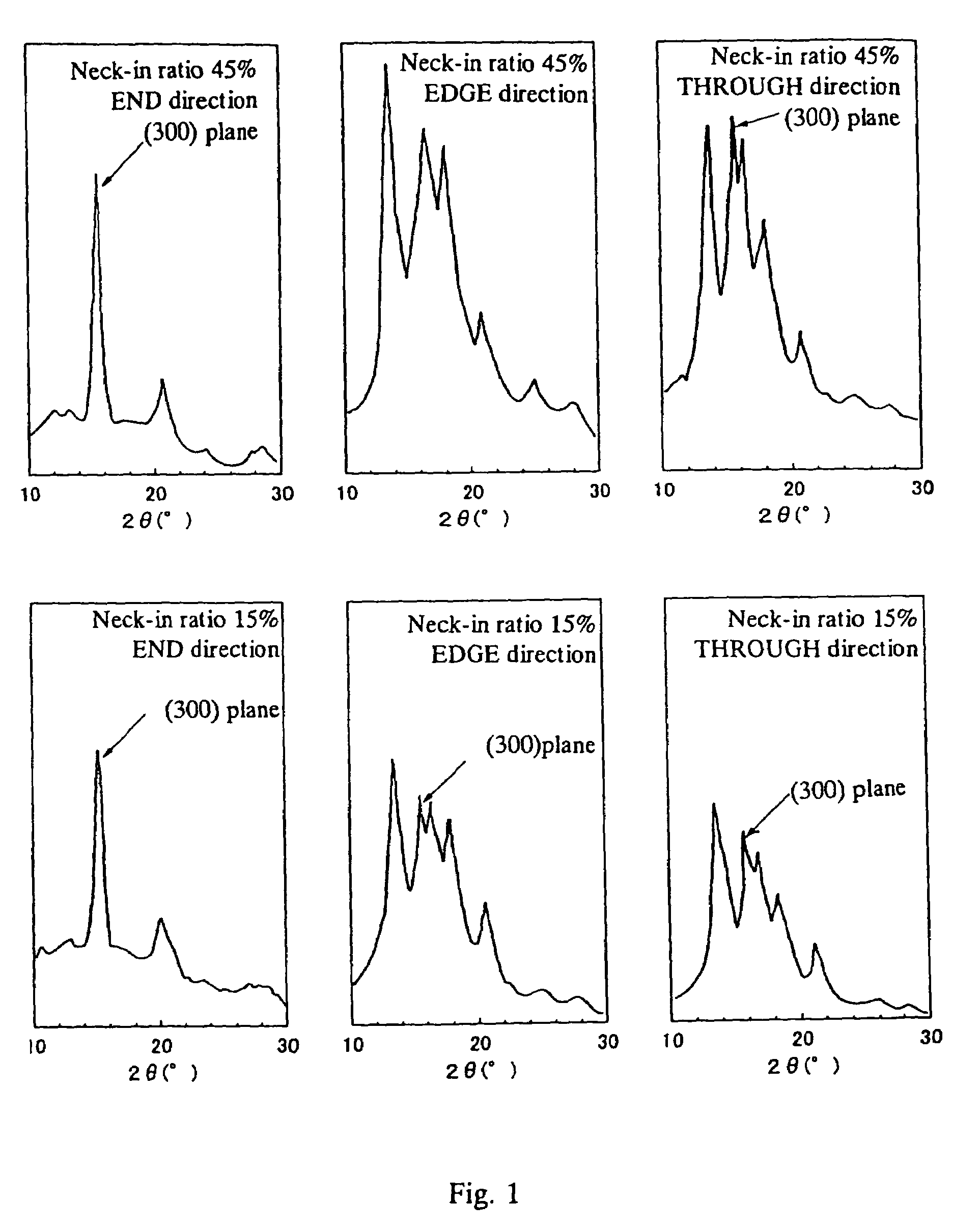

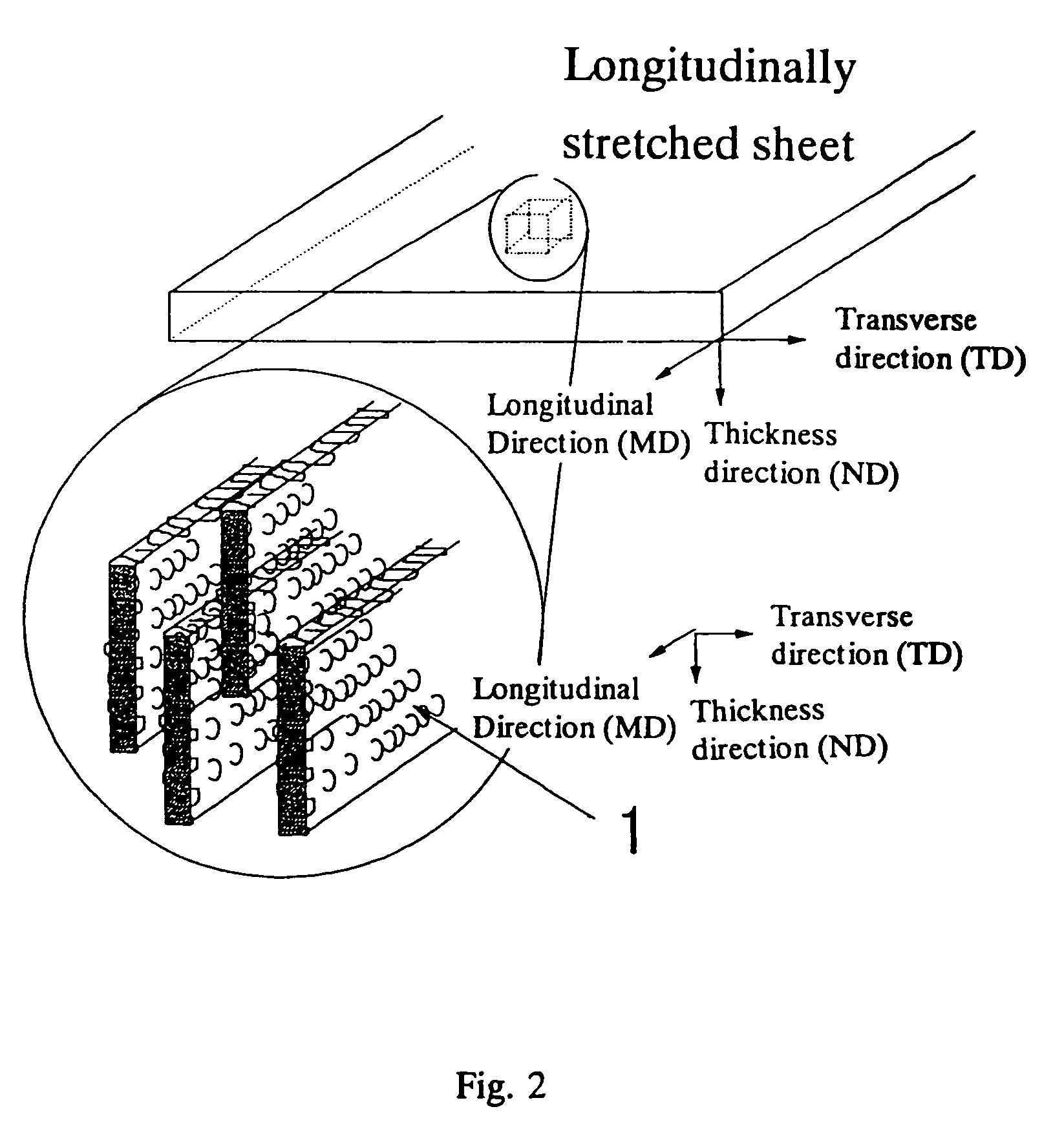

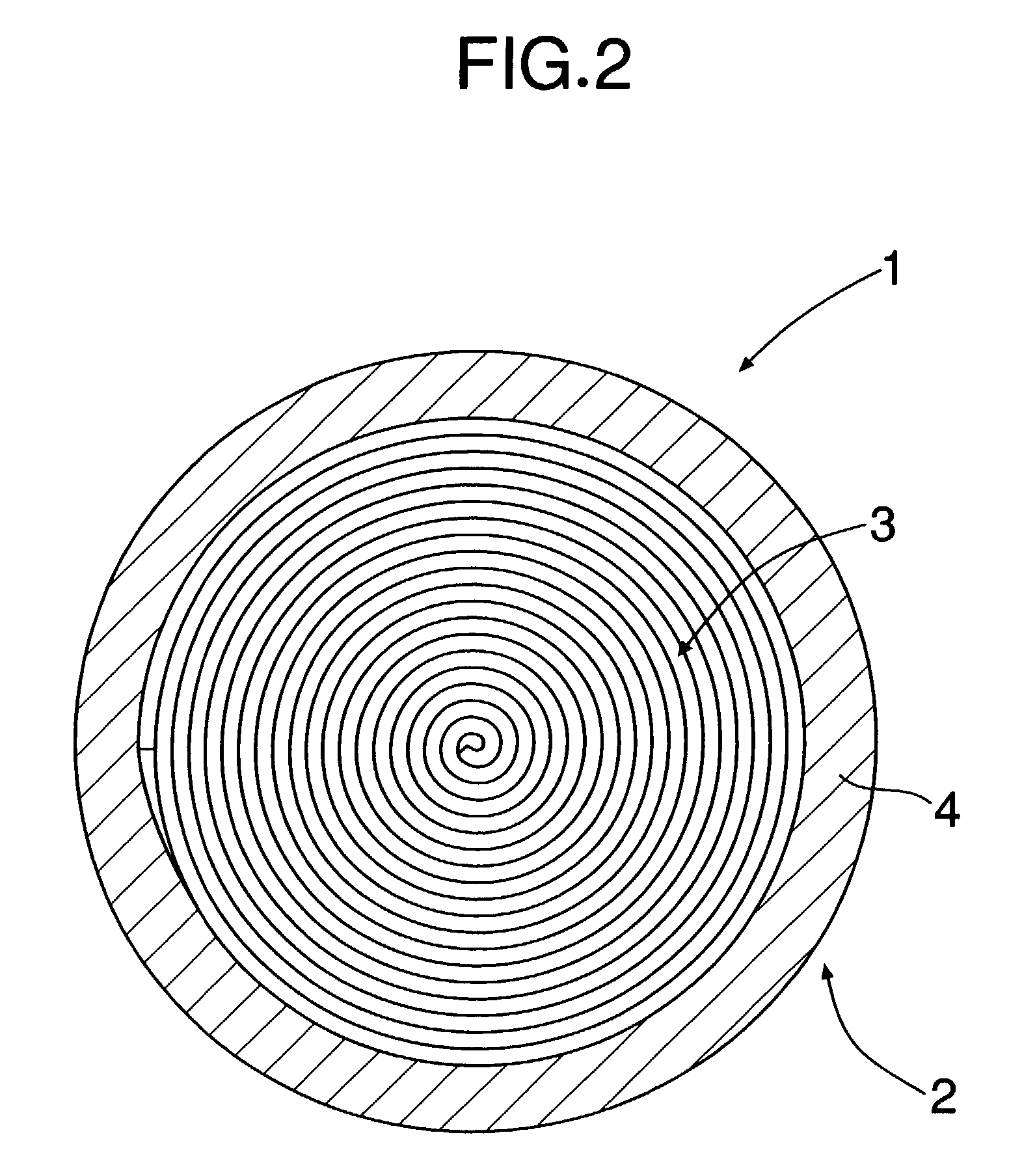

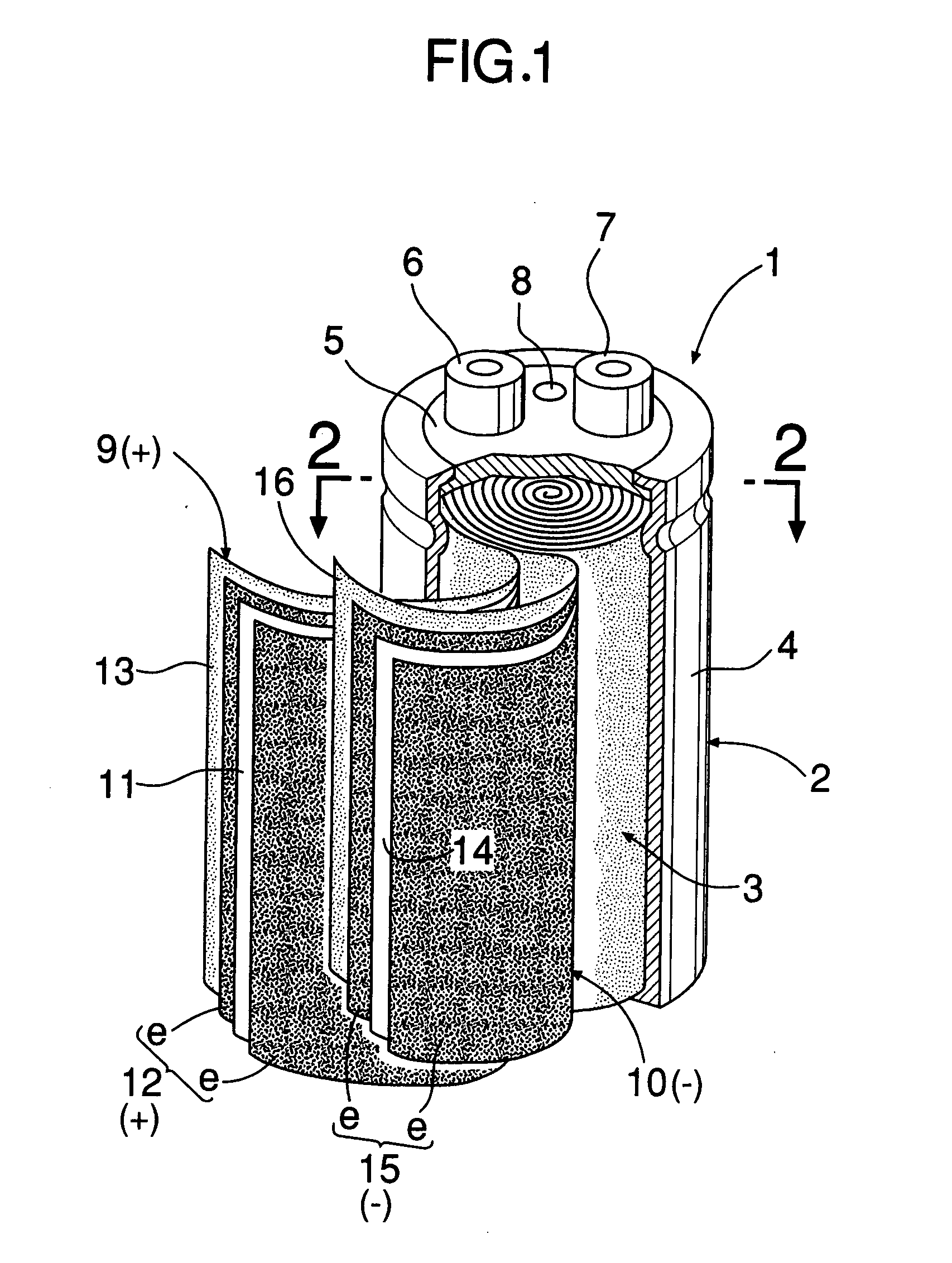

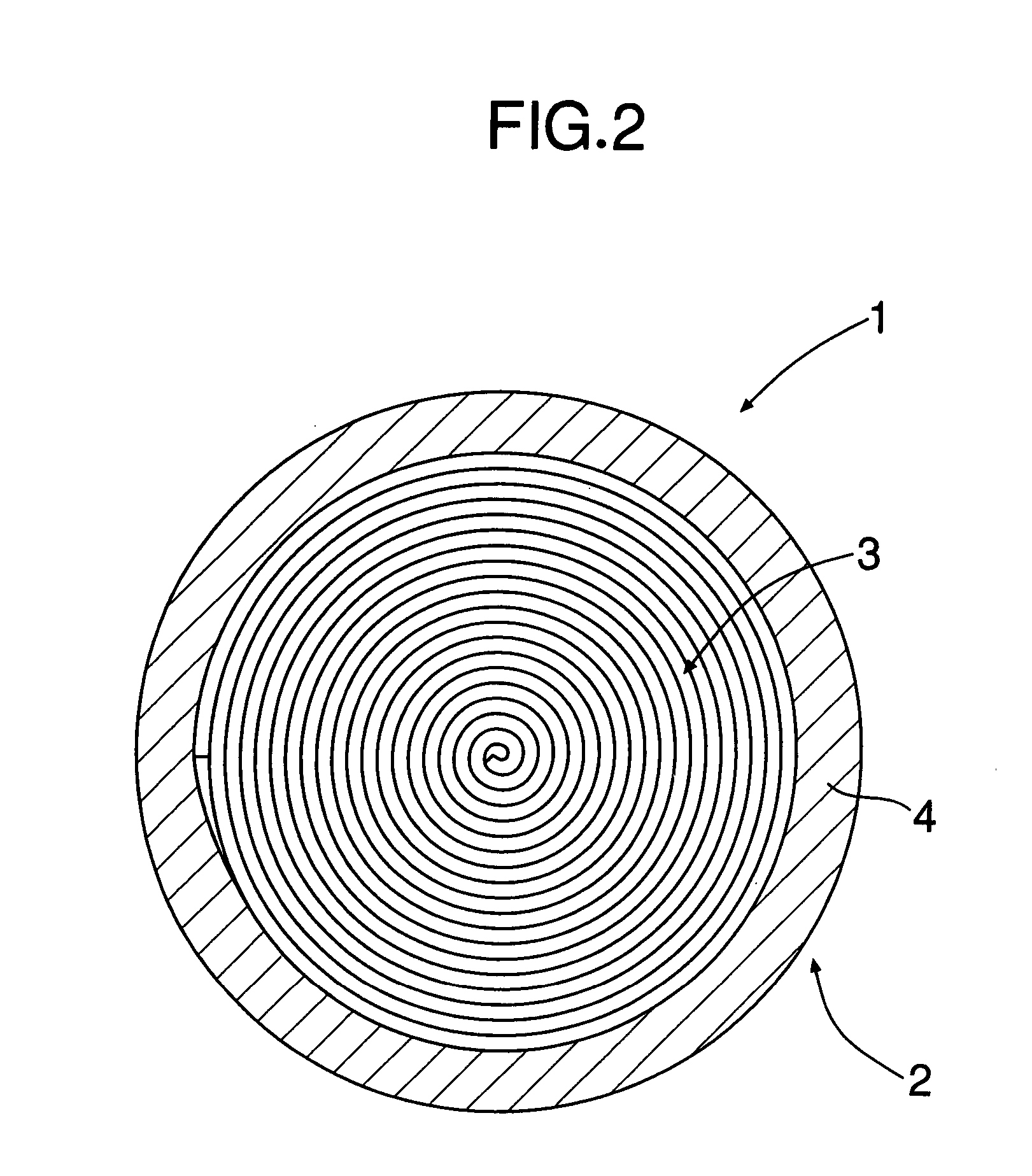

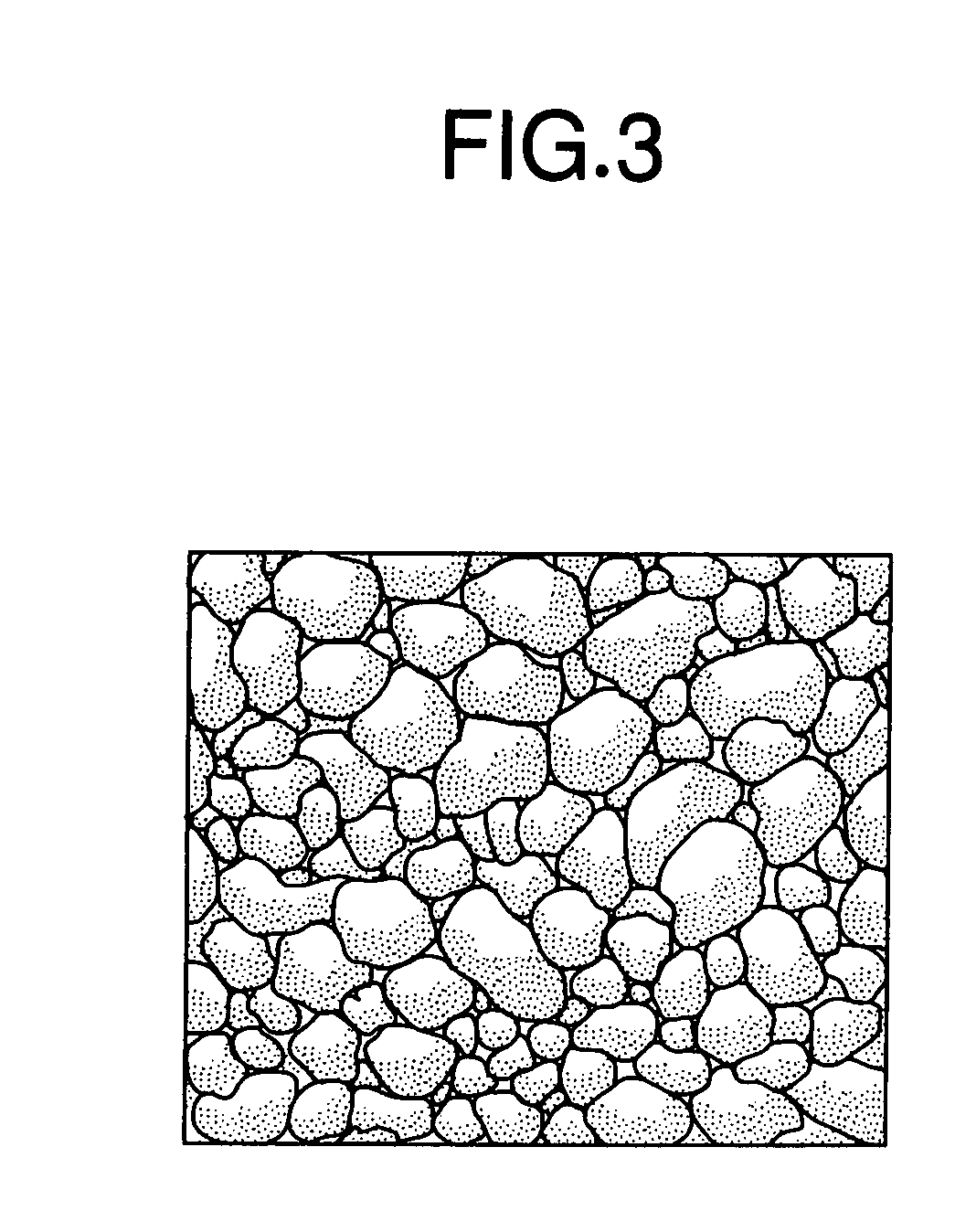

Successively biaxial-oriented porous polypropylene film and process for production thereof

InactiveUS7235203B2Feel goodGood electrical resistanceCell component detailsThin material handlingPorosityCrystal orientation

Disclosed is a successively biaxially stretched film obtained by successive biaxial stretching method comprising extruding a melt of a β-crystal nucleating agent-containing polypropylene-based resin composition from a T-die, cooling the extruded resin on a chill roll, and stretching the resulting web sheet longitudinally and then transversely, wherein the longitudinally stretched sheet is made to have a degree of β-crystal orientation of less than 0.3 by the following method (I) and / or (II), optionally subjected to annealing treatment, and transversely stretched:method (I): melting the polypropylene-based resin composition containing needle crystals of a specific β-crystal nucleating agent at a temperature not lower than m.p. of the polypropylene-based resin and lower than dissolution temperature of the β-crystal nucleating agent in the polypropylene-based resin melt, and extruding the melt from the T-die at the same temperature,method (II): adjusting neck-in ratio during longitudinal stretching to 25 to 55%.The porous polypropylene film has good breakage resistance during manufacture, excellent thickness uniformity, high porosity and air-permeability, and is useful for battery separators.

Owner:NEW JAPAN CHEM CO

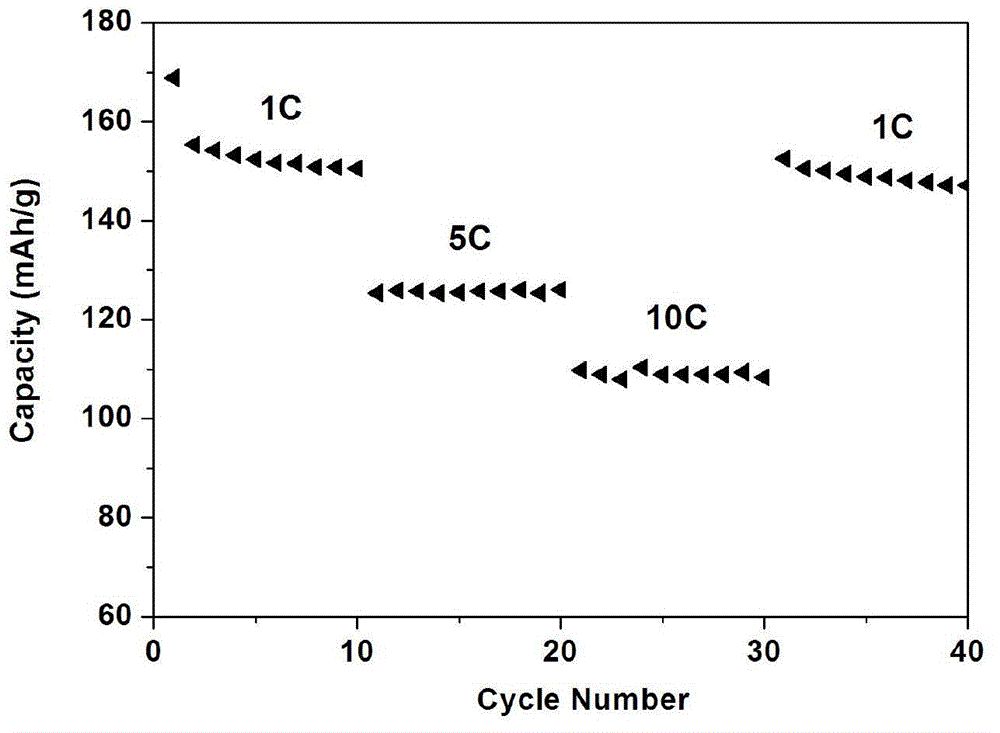

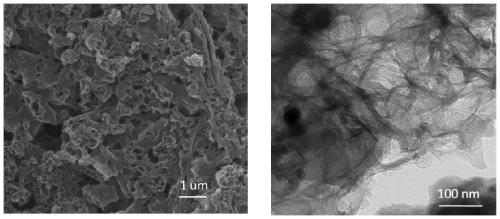

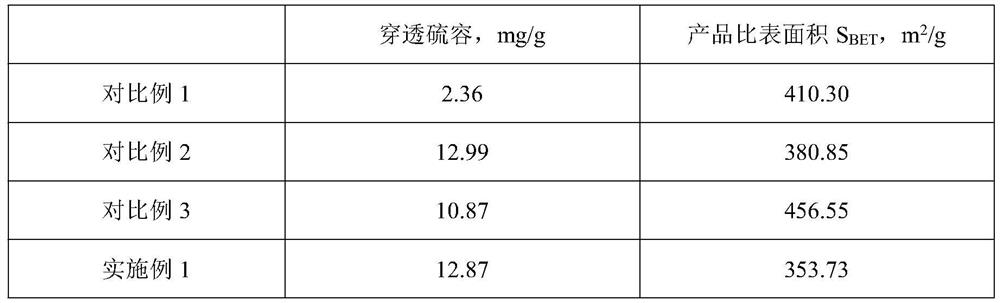

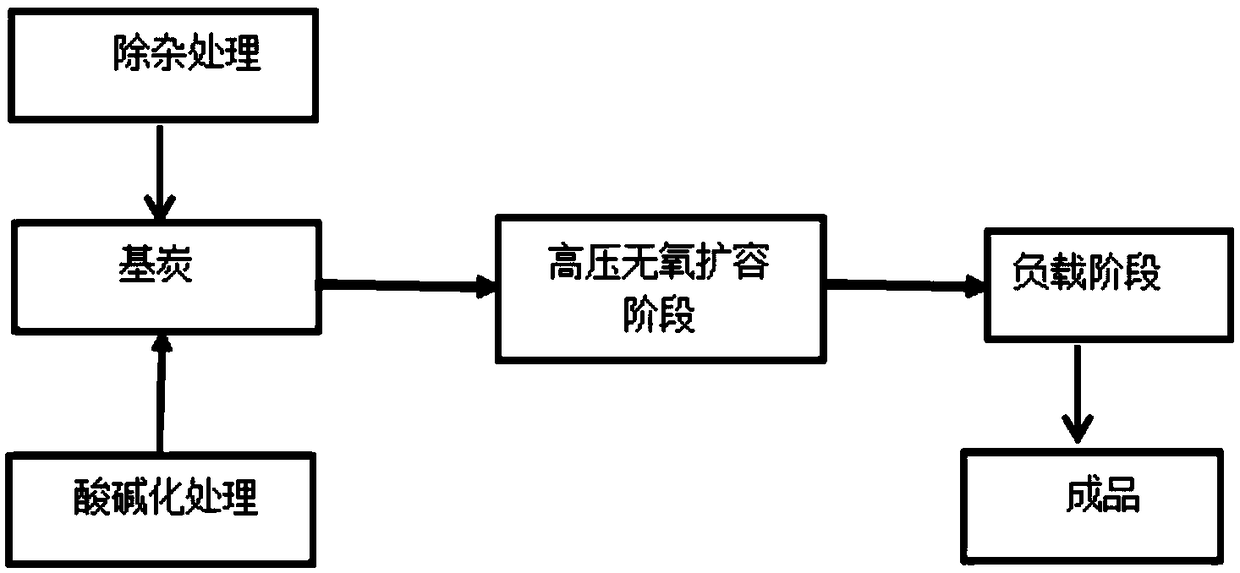

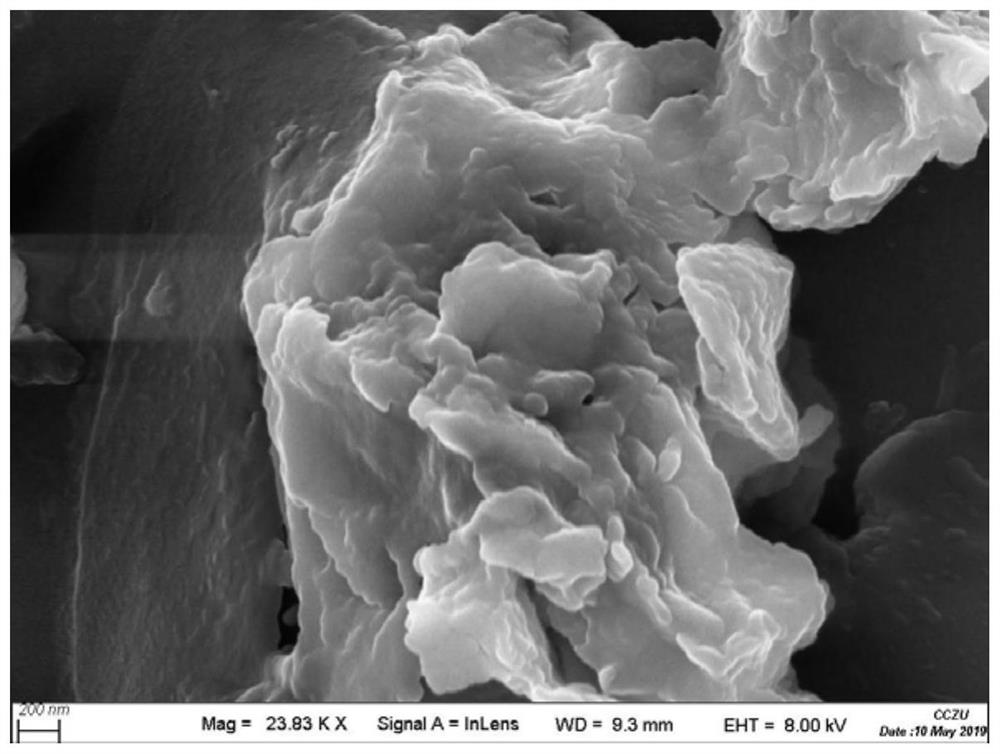

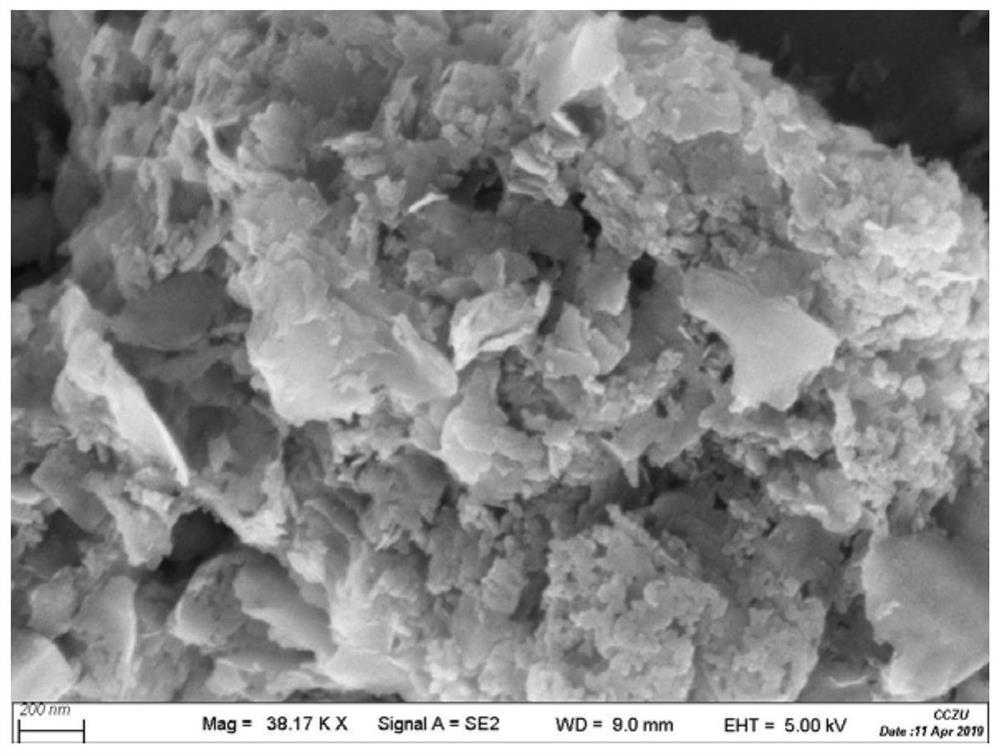

Composite petroleum coke-based activated carbon and preparation method thereof and supercapacitor

ActiveCN106082213ALower internal resistanceReduce problems such as large internal resistanceCarbon compoundsHybrid capacitor electrodesInternal resistanceOxygen

The invention provides composite petroleum coke-based activated carbon and a preparation method thereof. Activated active sites can be formed on the surface of petroleum coke through the dipping, coking and pre-activating processes of an oxidizing medium, chemical activation part pore-forming is promoted, the use amount of alkali is reduced, the mesopore rate is increased, and the problem that due to the fact that the surface of the petroleum coke is compact, pore forming is difficult is solved. Graphene oxide is reduced into graphene, a conductive network is formed, the conductivity of the activated carbon is improved, and the internal resistance of the activated carbon is reduced. High-temperature heat treatment is carried out jointly, surface functional groups are reduced, and the stability of super-capacitor carbon is improved. The prepared composite petroleum coke-based activated carbon has the advantages of being reasonable in pore size distribution, large in specific surface area, low in internal resistance, high in capacity, low in impurity and low in oxygen-containing functional group and can serve as the super-capacitor carbon, and the super-capacitor with better performance is obtained.

Owner:SHANDONG OBO NEW MATERIAL CO LTD

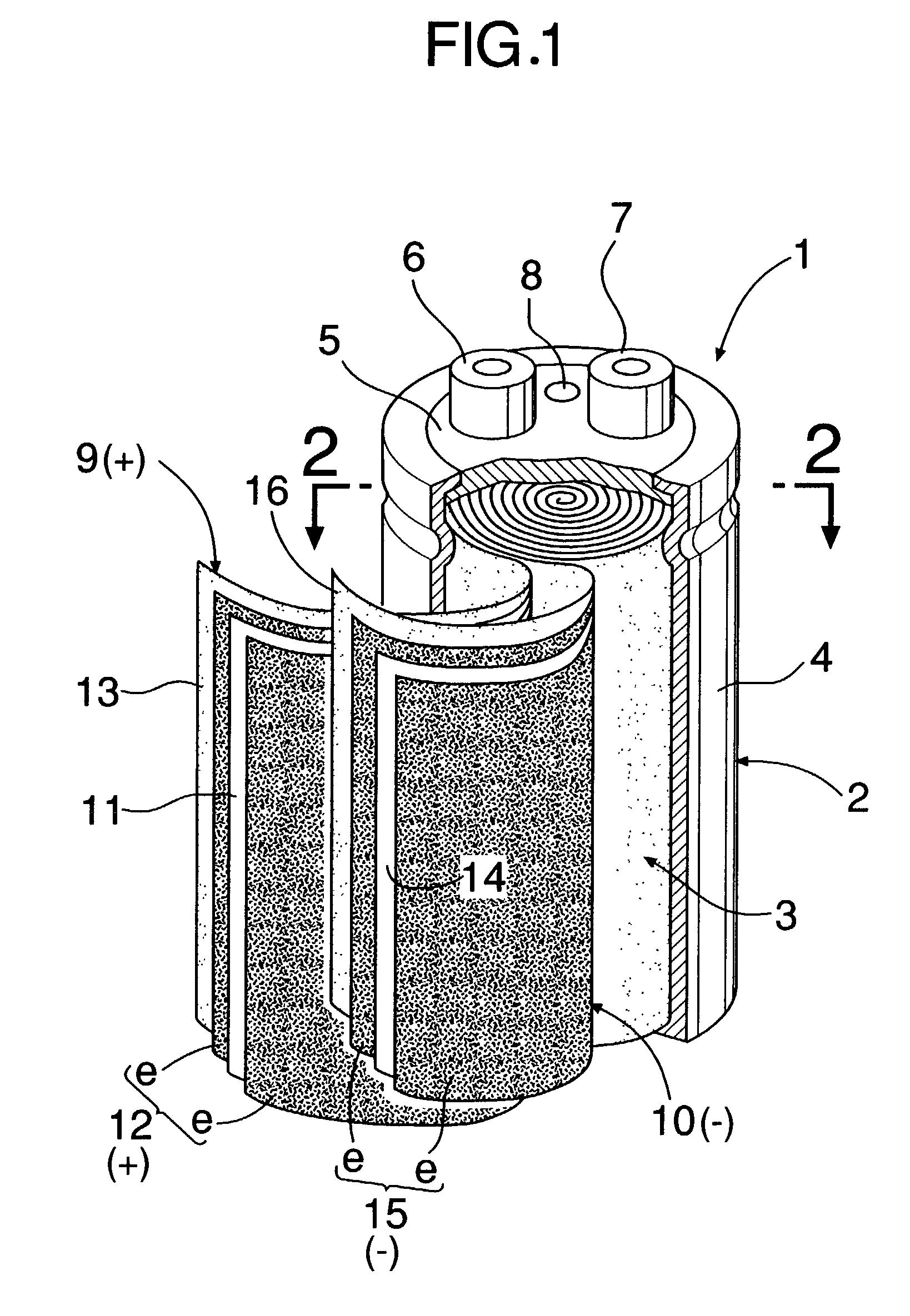

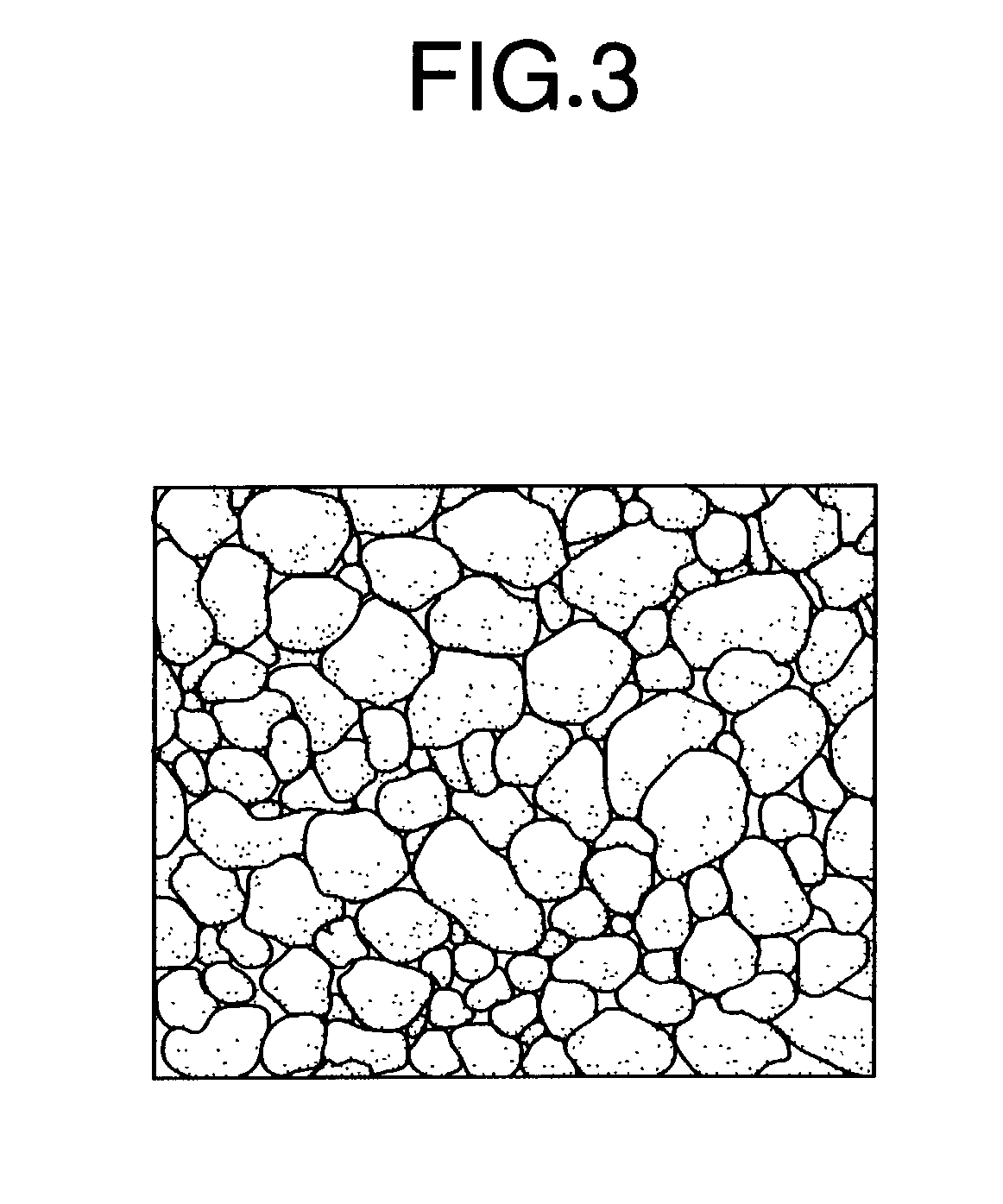

Method for producing activated carbon for electrode of electric double-layer capacitor

InactiveUS7214646B1Solve the small densityFacilitated DiffusionHybrid capacitor electrolytesHybrid capacitor electrodesActivated carbonAtmospheric air

To produce activated carbon for an electrode of an electric double-layer capacitor, the following steps are carried out sequentially: a step of subjecting a massive mesophase pitch to a pulverizing treatment to provide a pulverized powder; a step of subjecting the pulverized powder to an infusibilizing treatment under conditions of a temperature in a range of 300° C. (inclusive) to 450° C. (inclusive) in the atmospheric air current, a step of subjecting the pulverized powder to a carbonizing treatment under conditions of a temperature in a range of 600° C. (inclusive) to 900° C. (inclusive) in an inert gas current to provide a carbonized powder, a step of subjecting the carbonized powder to an alkali activating treatment under conditions of a temperature in a range of 500° C. (inclusive) to 1,000° C. (inclusive) in an inert gas atmosphere, followed by the post treatments, thereby producing alkali-activated carbon, and a step of subjecting the alkali-activated carbon to a pulverizing treatment. If an electrode is produced using the activated carbon, the electrode density can be increased.

Owner:HONDA MOTOR CO LTD +1

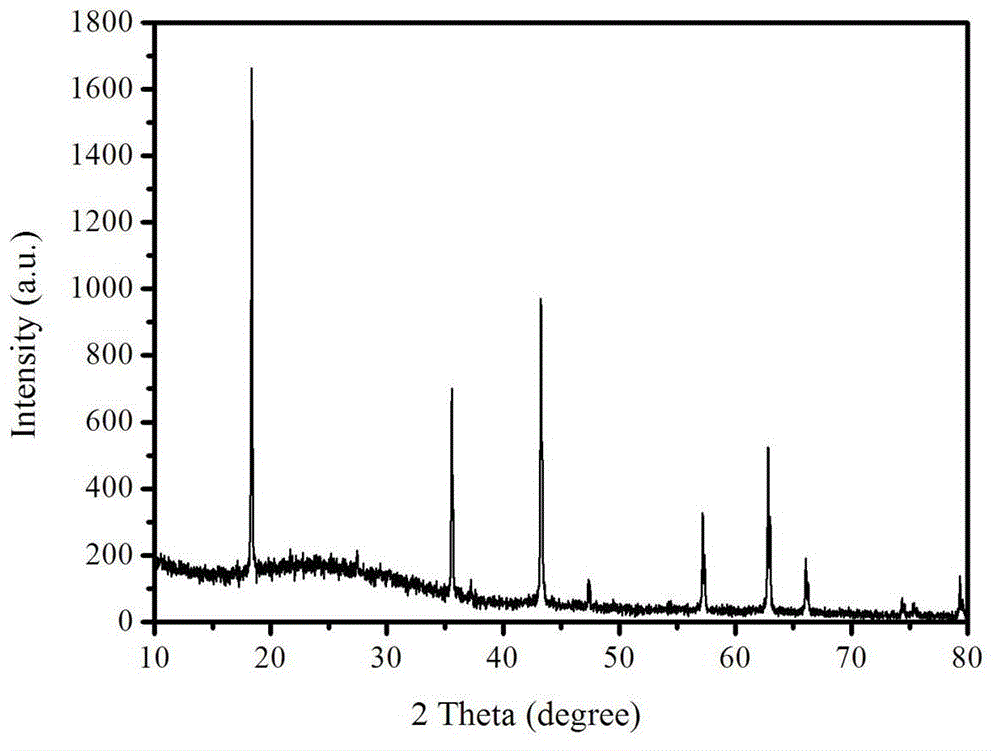

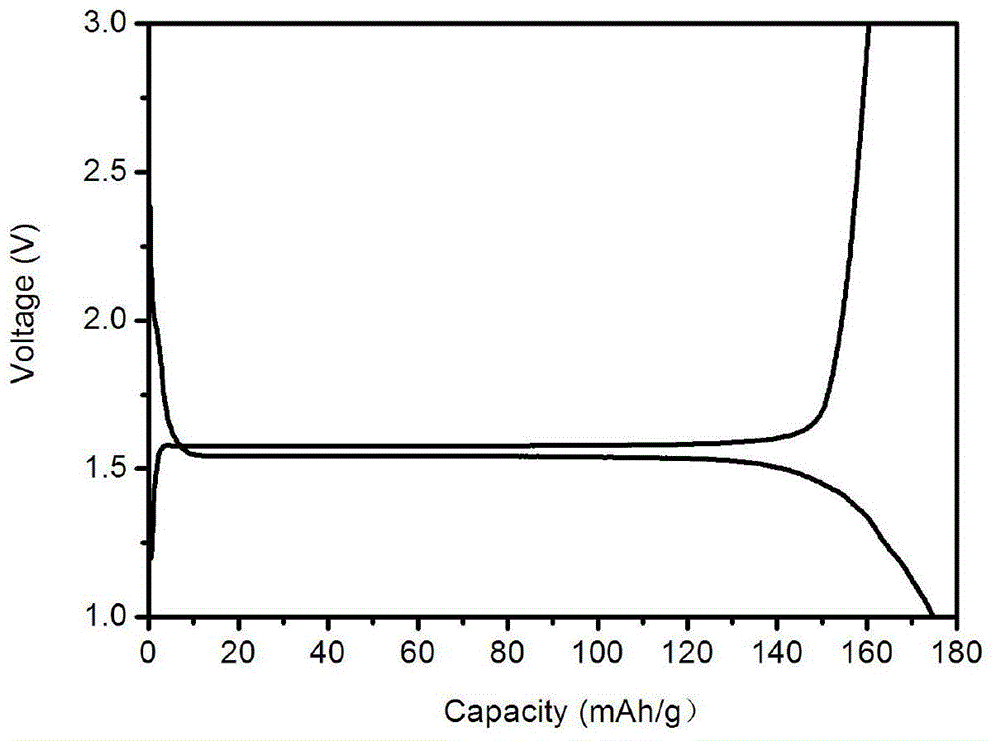

Method for preparing anode material carbon coated lithium titanate for lithium ion power batteries

InactiveCN102945952AOvercome the disadvantage of large particle sizeImprove conductivityCell electrodesCarbon layerCarbon coated

The invention provides a method for preparing anode material carbon coated lithium titanate for lithium ion power batteries, and belongs to the technical field of electrochemical energy materials. According to the invention, titanium dioxides are coated with carbon firstly, and then technological processes of lithiation and calcining are performed, so that a carbon layer coated on the surface of the titanium dioxides both can effectively suppress the size increasing of particles in the process of sintering, and improves the electrical conductivity of lithium titanate materials; and in the process of lithiation, a small amount of lithium oxalate is added in lithium salts, thereby reducing the alkalinity of a solution, and facilitating the melting of TiO2 / C. The invention aims to overcome the defects of poor battery rate performance difference and the like caused by the fact that lithium titanate materials prepared by using the traditional solid phase method is large in particle size and poor in electronic conductivity, and provides a method for preparing carbon coated lithium titanate materials which can improve the battery rate performance. The method is simple in process operation, and suitable for large-scale production.

Owner:JILIN UNIV

Preparation method of graded porous carbon

PendingCN111285346AReduce productionUniformity is moreCarbon preparation/purificationSolid carbonFoaming agent

The invention discloses a preparation method of graded porous carbon. According to the technical scheme, the preparation method comprises the steps: firstly, adding a foaming agent into a low-melting-point solid carbon-containing substance, and mixing for later use; then under a certain pressure and atmosphere, heating to a temperature T1, and homogenizing for t1; and under a certain pressure andatmosphere, heating to a temperature T2, carrying out a reaction for t2, heating to a temperature T3, carrying out a reaction for t3, cooling to room temperature, cleaning and drying to obtain the graded porous carbon. The basic concept of the invention comprises that a macroporous structure is formed by a foaming technology, the porosity of the carbon material is further increased by utilizing generated reducing gas, and then more micropores and small mesopores are generated by utilizing cracking and intercalation of anode ions under heat treatment to form porous carbon with a micropore-mesopore-macroporous hierarchical pore structure. The method has the advantages of being high in operability, large in aperture adjusting range, accurate in regulation and control and the like.

Owner:ZHENGZHOU UNIV

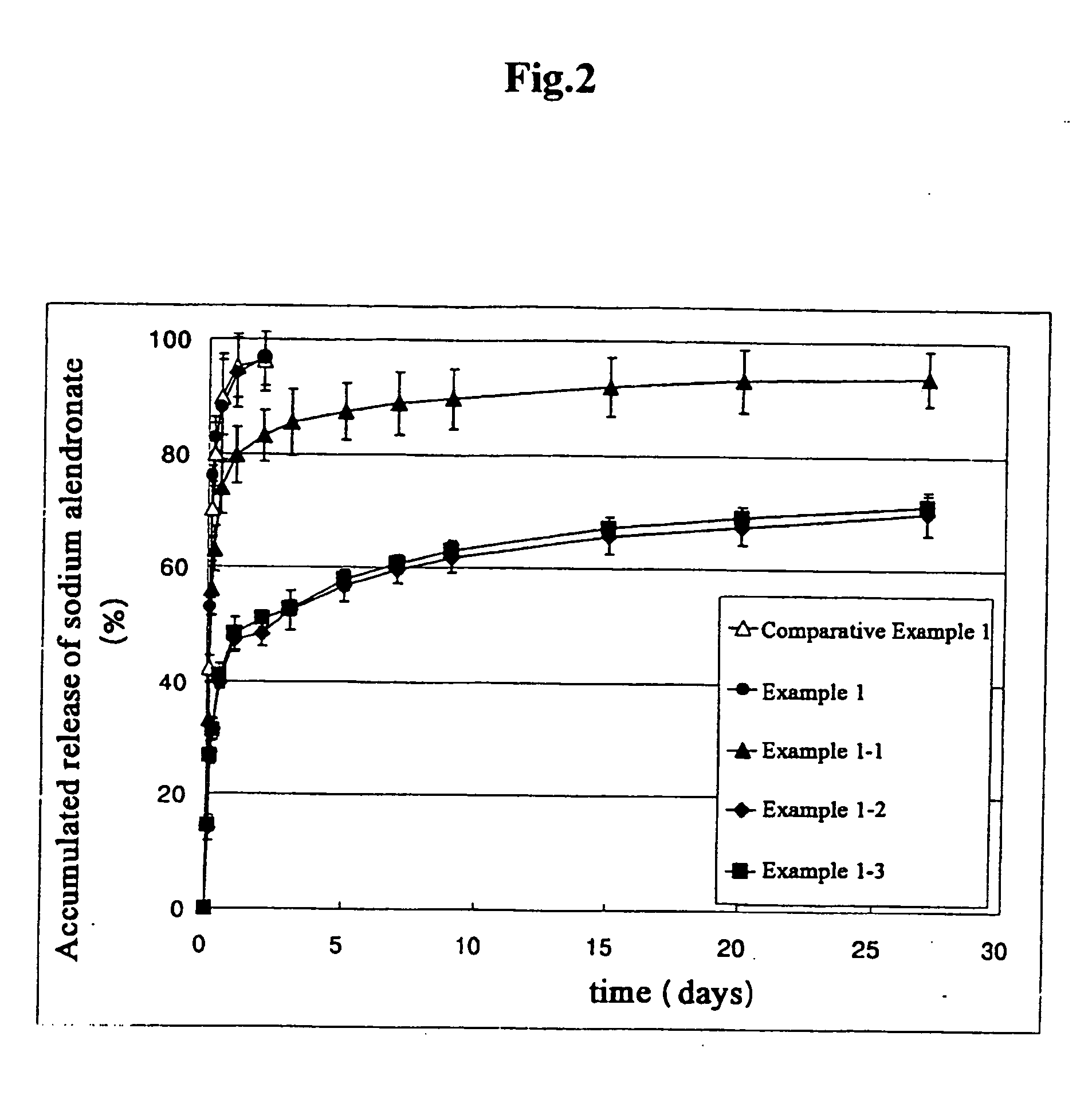

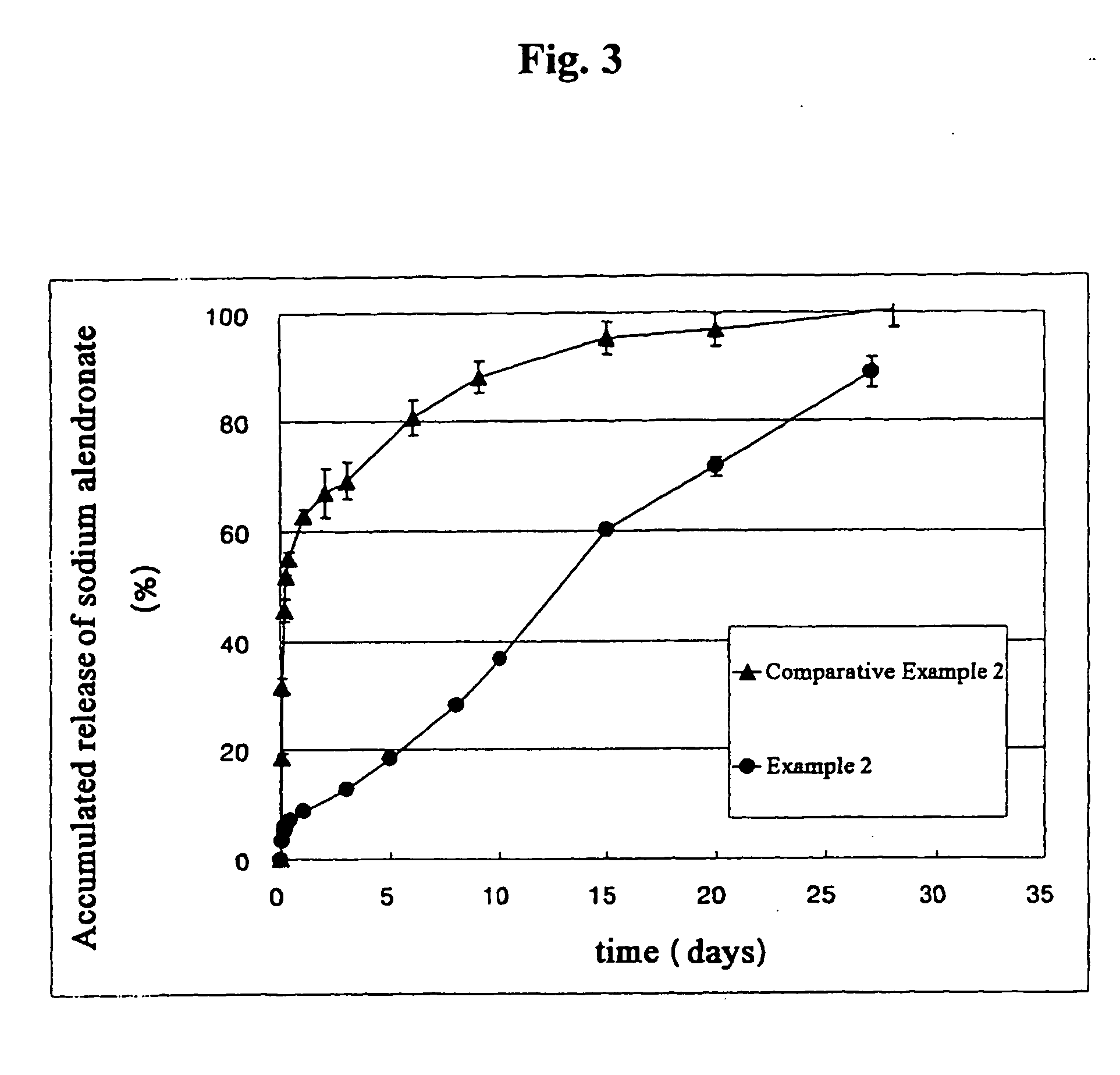

Polymeric microparticulates for sustained release of drug and their preparation methods

InactiveUS20060057221A1Increase surface areaControl releaseGranular deliveryLiposomal deliverySustained release drugMedicine

The present invention relates to polymeric microparticulates for sustained release of drug and to the process for the preparation thereof. The process of the present invention for preparing polymeric microparticulates based on microcoagulation phenomenon of water-soluble polymer not only improves loading amount of drug but also minimizes initial burst of drug, thereby providing polymeric microparticulates enabling sustained and prolonged release of drug

Owner:AMOREPACIFIC CORP

Method for preparing ceramsite through microwave sintering and curing of heavy metal chromium

InactiveCN107353034AAvoid the phenomenon of different sintering progressImprove curing efficiencyCeramicwareClaywaresPotassiumReducer

The invention relates to a method for preparing ceramsite through microwave sintering and curing of heavy metal chromium. The method comprises specific steps as follows: graphite powder, ferric oxide, aluminum powder and potash feldspar are added to chromium-polluted soil, spheres are prepared and then heated with a microwave sintering method, and the ceramsite is prepared. The ceramsite is prepared from chromium-polluted soil as a main raw material, land pollution can be effectively treated, and effective utilization of waste resources is realized. Besides, the graphite powder is added to the raw materials, can serve as a pore-forming agent and also can serve as a reducer, toxic hexavalent chromium can be converted into trivalent chromium, and non-toxic treatment of chromium is realized. With the adoption of the microwave sintering technology, heating is more uniform, the sintering atmosphere is controllable, the sintering speed is high, the sintering quality is good, and hexavalent chromium can be converted into trivalent chromium through a sufficient reaction.

Owner:WUHAN UNIV OF TECH

Process for producing activated carbon for electrode of electric double-layer capacitor

InactiveUS20070183958A1Solve the small densityFacilitated DiffusionPigmenting treatmentHybrid capacitor electrolytesActivated carbonAtmospheric air

Owner:HONDA MOTOR CO LTD +1

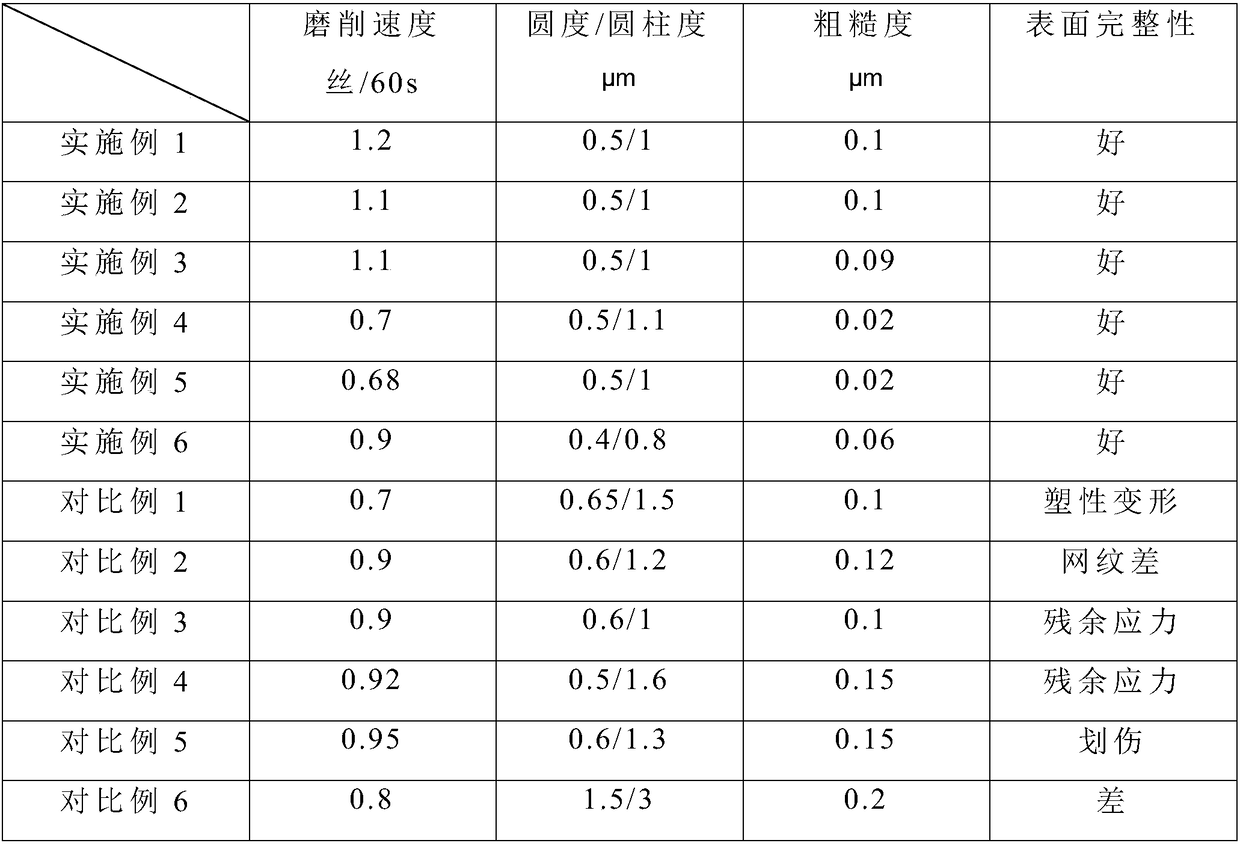

Honing oilstone and preparation method and application thereof

ActiveCN108115546APromote pore formationHigh hardnessAbrasion apparatusGrinding devicesSuperhard materialAlloy

The invention discloses a honing oilstone and a preparation method and application thereof. The honing oilstone comprises copper, tin, zinc, silver and superhard materials, and further comprises antimony, ferrophosphorus alloy, sodium hexafluoroaluminate, bronze, lubricant and wetting agent, wherein the feeding mass ratio of the copper, tin, zinc, silver, antimony, ferrophosphorus alloy, sodium hexafluoroaluminate, bronze, lubricant and wetting agent is 40-80:10-30:1-10:1-5:1:1-3:1-10:1-3:1-3:0.1-1, and the honing oilstoneis formed by mixing and sintering the raw materials. The preparation includes the steps of weighing raw material except the superhard materials according to the formula, mixing each weighed raw material with the superhard materials, sintering the mixture, and obtaining the honing oilstone. The application is the application of the honing oilstone in processing stainless steel materials. When the prepared honing oilstone is used to process materials difficult to process, such as stainless steel, no cutter adhesion, high precision and good processing surface integrity can be achieved, the preparation of the honing oilstone is simple, the cost is low, and the processing efficiency is high.

Owner:SUZHOU XINNENG PRECISE MACHINERY

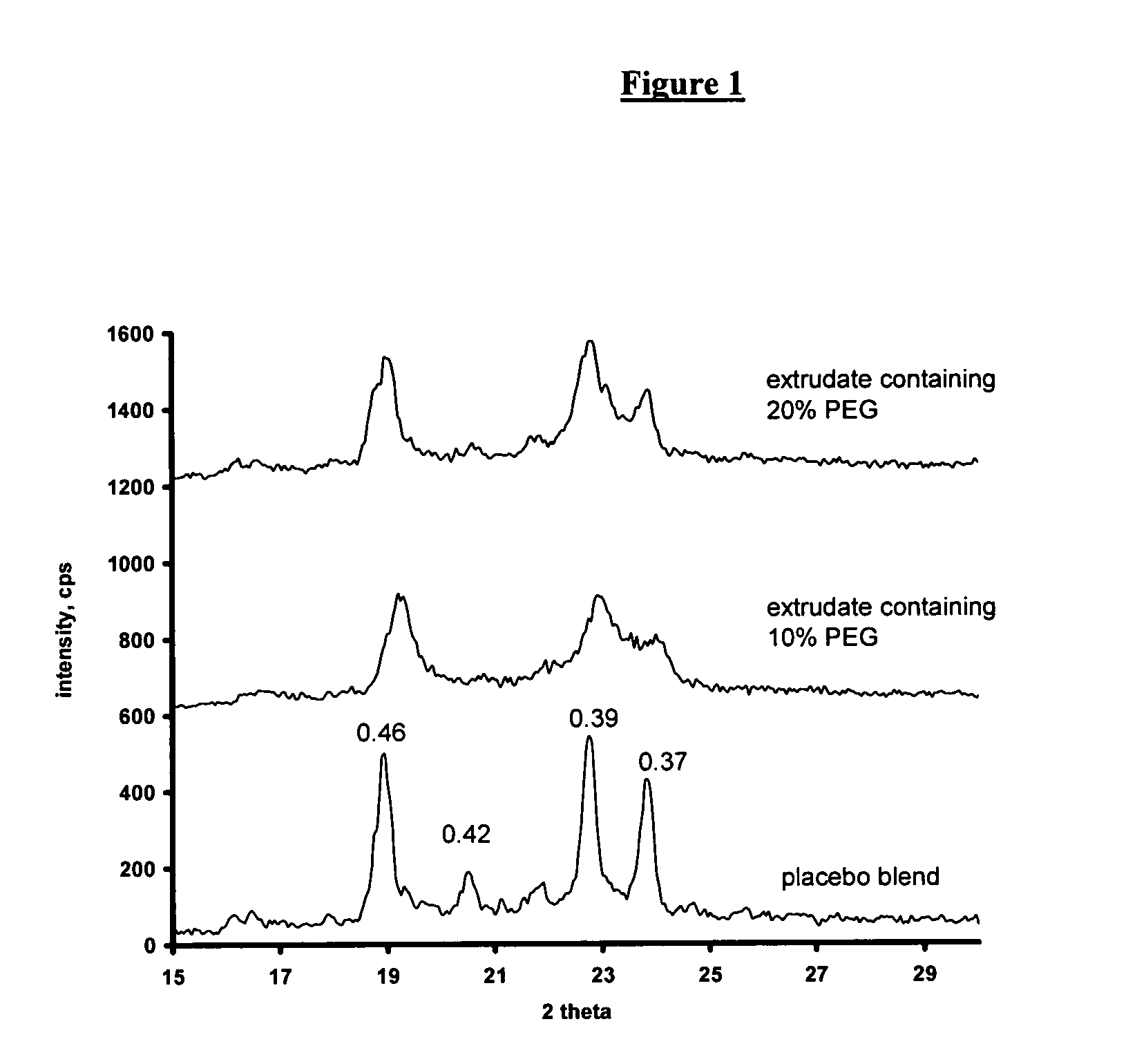

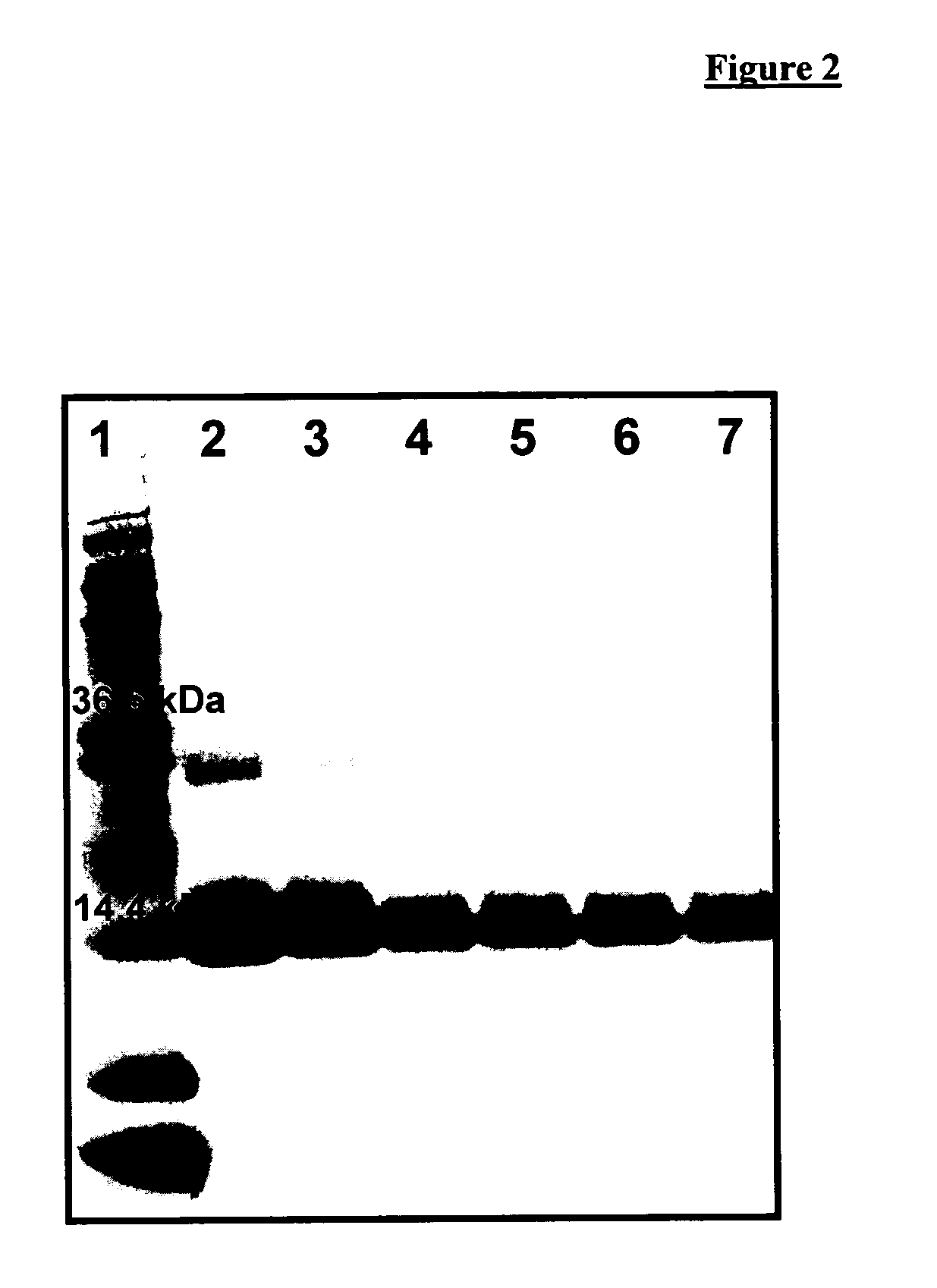

Extruded rod-shaped devices for controlled release of biological substances to humans and animals

InactiveUS20110059140A1Easy to operatePromote formationPowder deliveryOrganic active ingredientsControlled releaseLipid formation

The present invention relates to an extruded rod-shaped device which comprises at least one biological substance and a lipoid composition that comprises a high melting lipid or lipoid component and a low melting lipid or lipoid component. The extruded rod-shaped device according to the present invention is obtainable by extrusion of a preparation comprising the lipoid composition and the at least one biological substance, the preparation being extruded at a temperature which is at or above the melting point of the low melting lipid or lipoid component but below the melting point of the high melting lipid or lipoid component. Such an extruded rod-shaped device is capable of continuously and homogenously releasing the biological substance into the body of an animal or a human while maintaining the biological activity the biological substance and may for example be used as an implant.

Owner:LUDWIG MAXIMILIANS UNIV MUNCHEN

Tungsten-added type nanometre titanium dioxide catalyst for flue gas denitrification and preparation method for catalyst

InactiveCN103657688AImprove denitrification activityLarge specific surface areaPhysical/chemical process catalystsDispersed particle separationTungstateSlurry

The invention discloses a tungsten-added type nanometre titanium dioxide catalyst for flue gas denitrification and a preparation method for the catalyst. The tungsten-added type nanometre titanium dioxide catalyst for the flue gas denitrification comprises the components by weight percent: 3-10% of WO3, 1-4% of SO4<2-> and the balance being TiO2. The tungsten-added type nanometre titanium dioxide catalyst for flue gas denitrification is large in specific surface area, simple in process, easy to operate, low in energy consumption, environmentally friendly, and beneficial to improving the acidity of a carrier and improving the final denitrification performance of the catalyst. The preparation method comprises the following steps: hydrolyzing a titaniferous solution prepared by adopting a sulphuric acid method as a raw material to obtain metatitanic acid, sequentially sieving and washing to prepare metatitanic acid slurry, uniformly stirring the obtained metatitanic acid slurry, then adding ammonium sulphate and tungstate, then performing press-filtering, and conveying a filter cake to a rotary kiln to obtain a product, namely, the tungsten-added type nanometre titanium dioxide catalyst for the flue gas denitrification.

Owner:安徽迪诺环保新材料科技有限公司

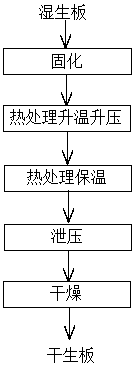

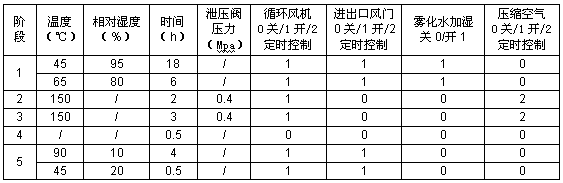

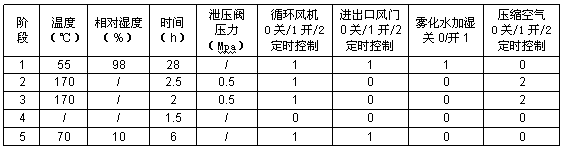

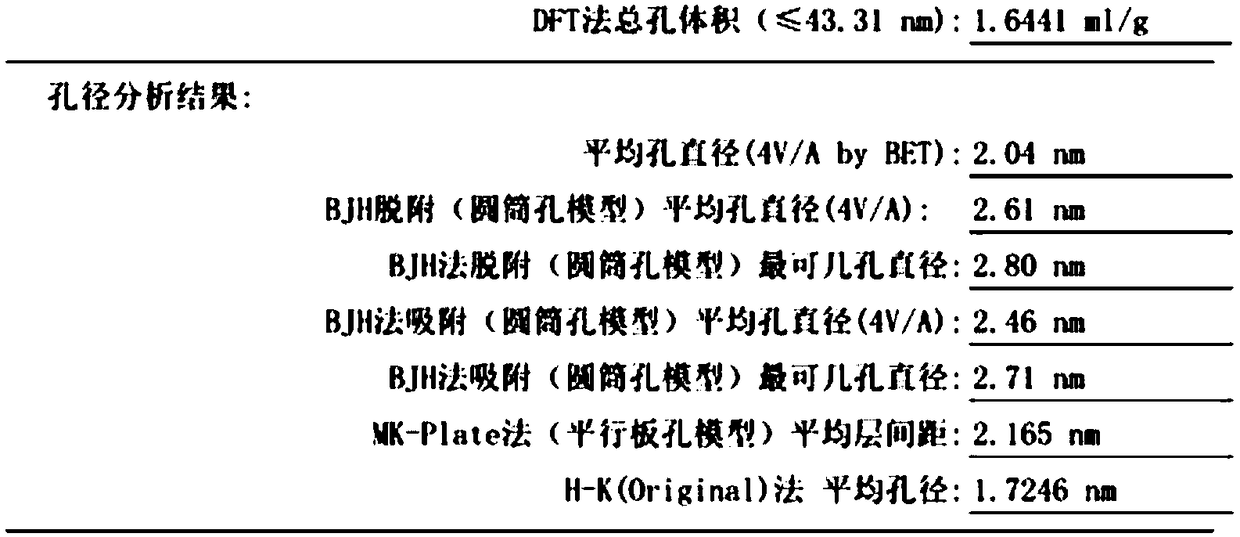

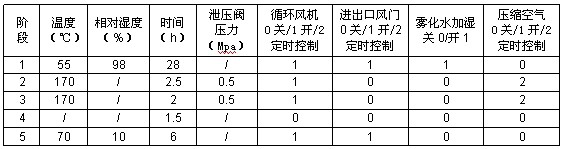

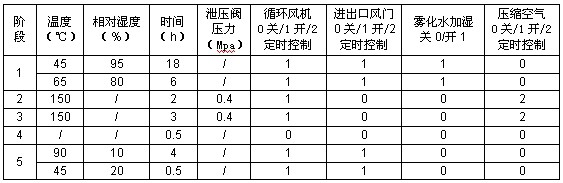

Method for curing and thermal-treatment drying of cathode wet raw plate

ActiveCN109301172AImprove corrosion resistanceHigh bonding strengthLead-acid accumulator electrodesMetallurgyThermal treatment

A method for curing and thermal-treatment drying of a cathode wet raw plate, belonging to the technical field of lead-acid storage batteries, includes: curing the cathode wet raw plate at 40-70 DEG Cfor 18-40 h, relative humidity being 80-100%; setting temperature at 150-180 DEG C and opening pressure of a relief valve under 0.4-0.8 MPa and increasing the temperature for 1-3 h; when a preset temperature is reached, maintaining the temperature for 1.5-5 h; after the temperature maintenance is finished, reducing the pressure of the relief valve to normal pressure; finally, performing normal pressure drying for 3-8 h. In the curing and drying process of the wet raw plate, thermal treatment on a cathode grid is achieved, thus improving the anti-corrosion performance of the cathode grid, and meanwhile effectively shortening the total time of the curing and thermal-treatment drying. The method avoids the adverse effect such as addition of production steps and transfer working load and increase of production period, which are caused by independent thermal-treatment on a cathode lead tape or the cathode grid.

Owner:CAMEL GRP XIANGYANG BATTERY

Nitrogen-doped formed biochar as well as preparation method and application thereof

PendingCN113120898AUniform and stable dispersionImprove pore structurePhysical/chemical process catalystsCarbon compoundsCatalytic oxidationCarbonization

The invention belongs to the field of biochar preparation, and particularly relates to a method for preparing biochar from waste biomass pyrolysis residues and the obtained formed biochar. To overcome a technical problem, the invention provides the method for preparing the nitrogen-doped formed biochar from the waste biomass pyrolysis residues. The method comprises the following steps: uniformly mixing the biomass pyrolysis residues and a nitrogen source, then adding a binder, conducting uniform mixing, carrying out extrusion molding, performing drying, and then carrying out oxidation, carbonization and activation to obtain the nitrogen-doped formed biochar. The method is simple in process and low in cost, and the obtained biochar has a good catalytic oxidation or / and adsorption effect on acid gas.

Owner:SICHUAN UNIV

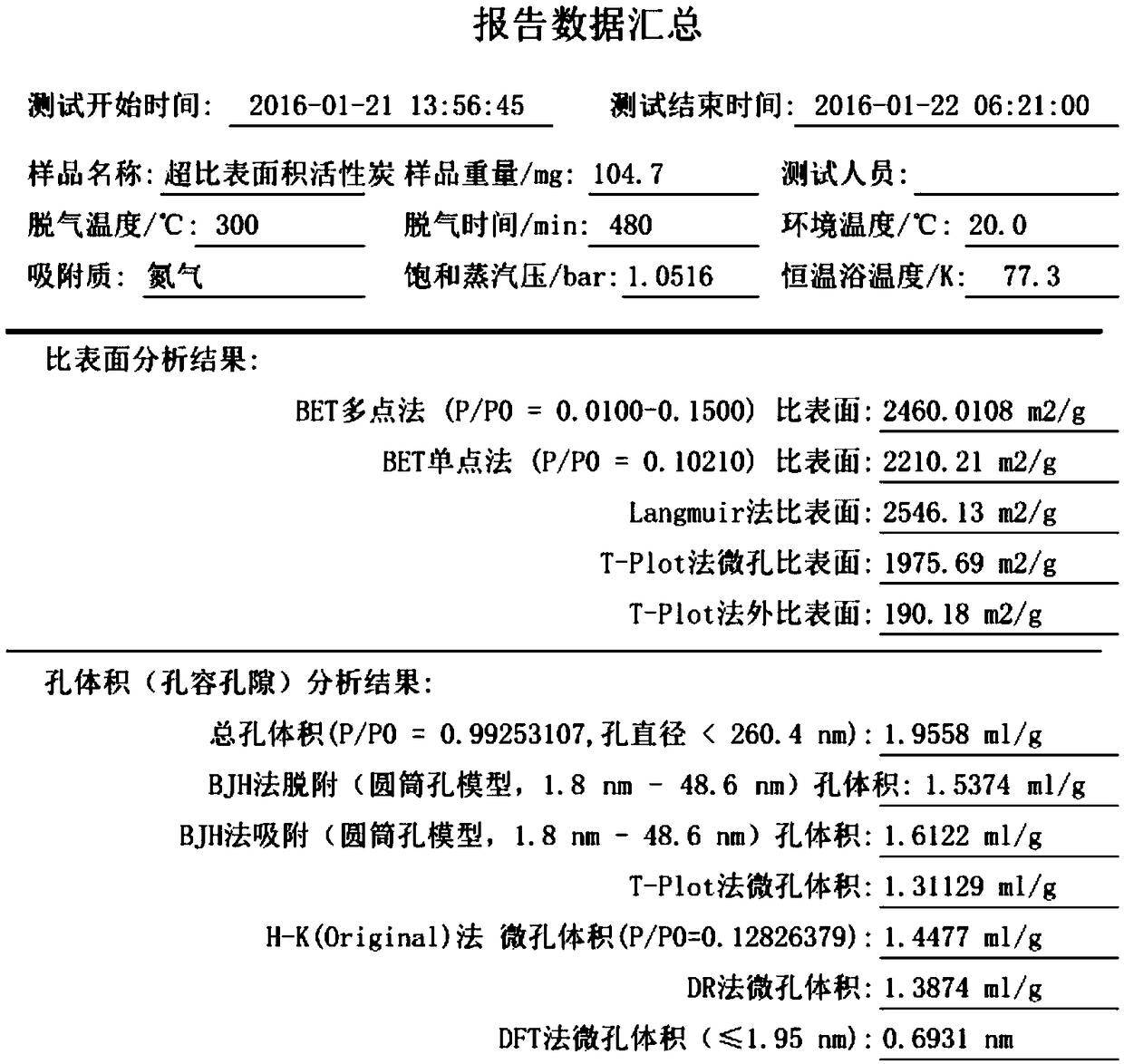

Super active carbon preparation method

The invention relates to a preparation method for super active carbon. Wherein, carbonizing and breaking up the raw material of coco shell or walnut shell to predetermined particle size and mix evenly with solid potassium hydroxide; activating the mixture in microwave oven with nitrogen protection during the process to obtain activation material; clearing the material with muriatic acid and then distilled water for many times to neutrality and obtain the said product. The product with this method has strong adsorption property, high specific surface area and high adsorption value to iodine and methylene blue. The method is simple and convenient to control.

Owner:KUNMING UNIV OF SCI & TECH

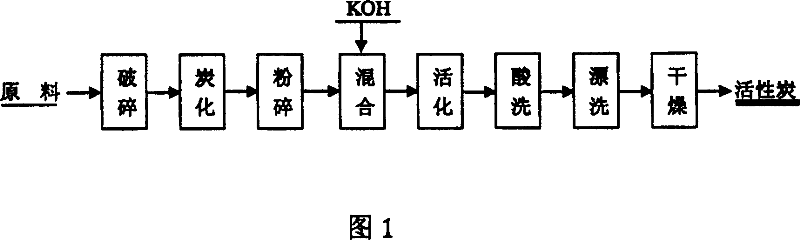

Solar-power-based sludge low-shrinkage energy-saving drying method

ActiveCN105645729APromote pore formationGood shrink resistanceSludge treatment by de-watering/drying/thickeningSpecific water treatment objectivesPhotocatalytic reactionSludge

The invention relates to a solar-power-based sludge low-shrinkage energy-saving drying method. The method is characterized in that a bulking conditioner is added into sludge subjected to centrifugal dehydration, uniformly mixed and distributed, and the mixture enters a solar-power interlayer drying system; and the conditioning effect of the bulking conditioner is combined with the solar-power interlayer drying process to complete the framework establishment, bulking conditioner implantation and photocatalytic reaction, thereby implementing the low-shrinkage drying on the sludge on the premise of increasing the sludge drying rate. The bulking conditioner is formed by sufficiently and uniformly stirring the following components in percentage by mass: 40-60% of ammonium carbonate / ammonium bicarbonate, 10-20% of magnesium oxide / magnesium chloride / calcium oxide, 10-30% of Laminaria digitata powder / seaweed powder / blue algae powder and 5-10% of UEA calcium sulphoaluminate bulking agent. The addition amount of the bulking conditioner is 5-20% of the sludge on dry basis. The solar-power heating drying effect and the combined action of the bulking conditioner for conditioning the sludge are utilized, thereby establishing the sludge drying basic structure and being beneficial to the pore forming and shrinkage resistance in the subsequent sludge heat treatment.

Owner:SHANGHAI JIAO TONG UNIV

Preparation method of porous nano polymer composite material

InactiveCN103588988AEasy to prepareLow costOther chemical processesAlkali metal oxides/hydroxidesPolymer scienceAniline

A preparation method of a porous nano polymer composite material comprises the following steps: (1) adding pure attapulgite into a 0.1-0.5 mol / L acid solution, and dispersing by stirring for 0.5 h; (2) adding aniline and gamma-methylacryloyloxypropyl trimethoxysilane, and stirring for 0.5 h; (3) adding ammonium persulfate as an initiator, standing for 0.5 h after stirring; (4) adding acetanilide, and dispersing by stirring for 0.5h; (5) leaching till the mixture is neutral, drying at 60 DEG C, and grinding; (6) washing with ethanol solution, leaching, drying at 60 DEG C, and grinding to obtain the dark green composite material.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

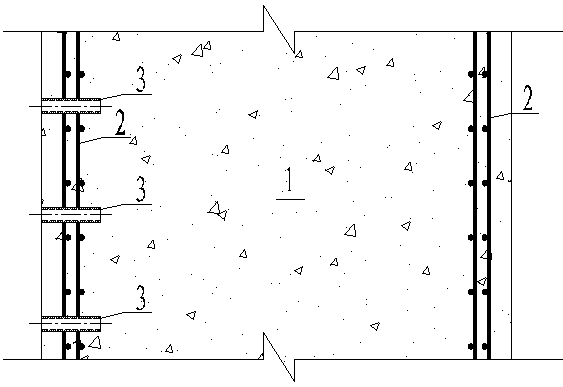

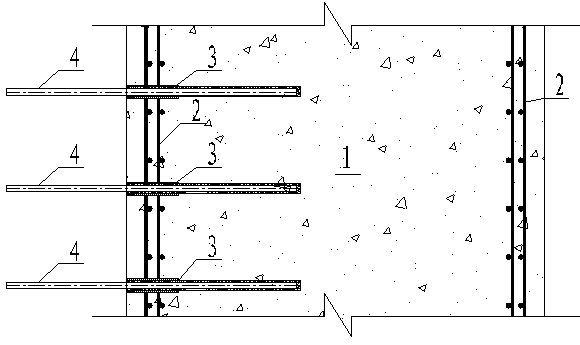

Concrete rear-planting anchoring rib construction method

InactiveCN109184221AGuarantee the construction qualityPromote pore formationBuilding repairsBuilding material handlingSocial benefitsReinforced concrete

The invention relates to a concrete rear-planting anchoring rib construction method and belongs to the building engineering technology field. In the invention, a rear-planting anchoring rib guide pipeis pre-embedded in a precast concrete structure so as to guarantee that later-period anchoring rib hole making can avoid the influence of a reinforcing steel bar; anchoring rib hole making becomes convenient; a hole making formation rate and construction efficiency are increased; the influence on the precast concrete structure is reduced; and anchoring rib construction quality is guaranteed. Compared with a direct pre-embedded insertion rib, the influence on precast concrete template manufacturing, installation and dismounting can be reduced, which is good for the rapid construction of the precast concrete structure. Compared with a conventional rear-planting anchoring rib construction method, by using the construction method of the invention, a rear-planting anchoring rib hole making process can be ensured to effectively avoid the reinforcing steel bars in the precast concrete structure, construction efficiency is increased, unnecessary damages to the precast concrete structure are avoided, construction quality is easy to control and construction is convenient. And simultaneously, the method can be extended into other hole drilling construction projects in reinforced concrete, ausage range is enlarged, an application prospect is good, and good economic and social benefits are achieved.

Owner:SINOHYDRO BUREAU 14 CO LTD

Porous carbon material for filtering and preparation method thereof

The invention discloses a porous carbon material for filtering and a preparation method thereof. The preparation method specifically comprises the following steps that a raw material, an adhesive anda pore-forming agent are prepared, wherein the raw material is one of green petroleum coke and raw asphalt coke, the adhesive is petroleum asphalt, and the pore-forming agent is a mixed powder of butadiene styrene rubber powder and tire rubber powder; the preparation method comprises the following steps: crushing and balling the raw materials into powder, then screening the obtained powder by using a vibrating screen to obtain two-stage raw materials of -60 to +80 meshes and -80 to +120 meshes, and finally proportioning the two-stage raw materials of-60 to + 80 meshes and-80 to + 120 meshes according to a mass ratio of (30-40): (60-70); heating and mixing the prepared raw material and the pore-forming agent, then adding the adhesive which is heated and melted in advance, and mixing for 2 hours at the temperature of 150 DEG C to obtain a mixture; wherein the mass part ratio of the raw material to the adhesive to the pore-forming agent is (60-76): (20-30): (4-10); carrying out compression molding on the mixture to form a blank; and introducing the blank in a roasting furnace for segmented heating roasting to obtain the porous carbon material. The porous carbon material prepared by the method is narrow in pore size distribution and high in strength.

Owner:ZIGONG YUXING CARBON PRODS

Processing technology of polyurethane foam for fireproof insulation board

The invention discloses a processing technology of polyurethane foam for a fireproof insulation board, and belongs to the technical field of chemical engineering. The processing technology comprises following steps: stirring and mixing a biomass liquefied product, water, triethylene diamine, silicone oil and catalyst, then adding the modified mixed biomass crushed materials and enzymatic chitosanliquid; performing a stirring reaction, then adding castor oil, isoamyl acetate and modified graphene oxide are added, and performing a heating reaction; sequentially carrying out injection molding, foaming, curing and demolding to prepare the polyurethane foam based on the biomass raw material. In the preparation process, calcium oxide deposited in the modified mixed biomass crushed aggregates reacts with water, so that calcium ions are fused into the system, and the calcium ions can promote cross-linking of the enzymed chitosan to form a three-dimensional network, so that deposited aluminumoxide and iron oxide of the system are fixed, and the mechanical property of the system is improved. The polyurethane foam based on the biomass raw material provided by the invention has excellent mechanical properties and thermal insulation properties.

Owner:朱晶晶

Preparation method of biomass porous carbon

InactiveCN109052362AImprove liquidityReduce liquidityCarbon preparation/purificationPorous carbonNitrogen atmosphere

The invention discloses a preparation method of biomass porous carbon, which belongs to the technical field of a functional material. The preparation method comprises the following steps: mixing and ball milling vinasse, starch and glycerin, and obtaining ball milled uniform slurry; mixing and fermenting the ball milled uniform slurry, cryolite, modified additives, Carbomer, gum Arabic solution, adding aluminum chloride solution which is 0.2 to 0.3 times of the mass of the ball milled homogenous slurry, stirring and mixing, dropwise adding a sodium hydroxide solution, adjusting pH to 10.3 to 10.6, drying, pulverizing, screening, and obtaining a blank; gradually heating the blank in a nitrogen atmosphere, electrifying, reacting at the high temperature, cooling, and obtaining a carbonized blank; and mixing the carbonized blank and water according to a mass ratio of (1:10) to (1:20), soaking the carbonized blank, filtering, and drying, thus obtaining the biomass porous carbon. The biomassporous carbon provided by the invention has excellent specific surface area and porosity.

Owner:FOSHAN SENANG BIO TECH CO LTD

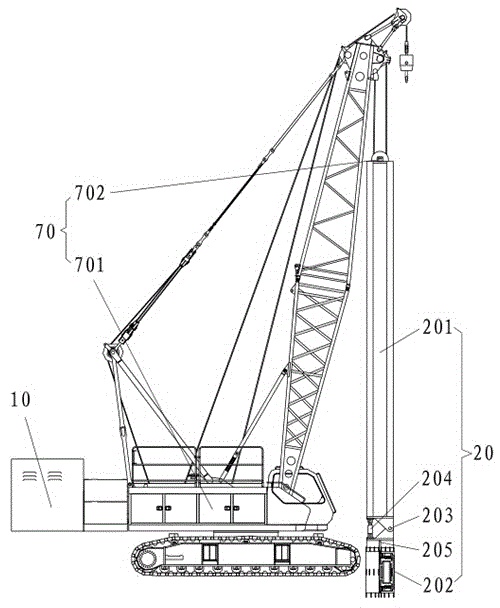

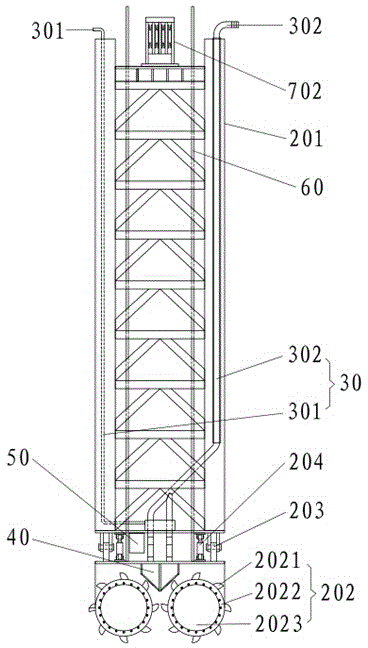

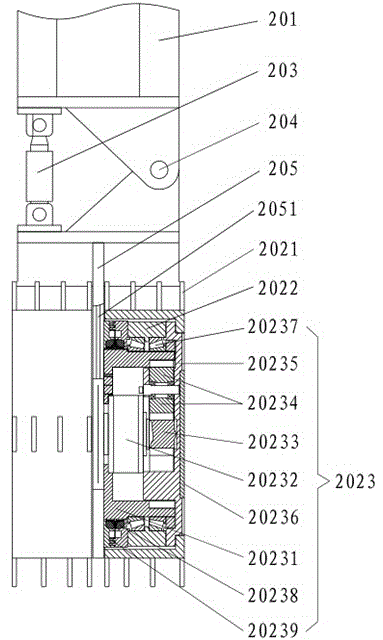

Pore forming machine with symmetrical rotating wheels for geotechnical engineering

ActiveCN104314121ASimple structureHigh torqueMechanical machines/dredgersHydraulic motorControl system

The invention discloses a pore forming machine with symmetrical rotating wheels for geotechnical engineering. The pore forming machine comprises a main control system and an excavating device, wherein the excavating device comprises a guide frame and a rotating cutter head mechanism; the rotating cutter head mechanism comprises a cutter, a cutter head ring and the rotating wheels; each rotating wheel comprises a fixed machine shaft with a bowl-shaped structure, a hydraulic motor, a sun gear, a plurality of planetary gears, a planetary gear carrier and a cover plate; each hydraulic motor is fixed in the corresponding fixed machine shaft; a center shaft of each hydraulic motor is connected with that of each sun gear; an inner gear ring is arranged on the inner wall of each fixed machine shaft; each planetary gear is meshed with the corresponding sun gear and is meshed with the corresponding inner gear ring; each planetary gear carrier is an end cover arranged on the corresponding fixed machine shaft in a covering way; the center shaft of each planetary gear is axially jogged with the end face of the corresponding end cover; each cutter head ring is fixedly arranged at the periphery of the corresponding end cover; a plurality of cutters are uniformly distributed on each cutter head ring. The pore forming machine disclosed by the invention has the advantages of compact and reasonable integral structure, high power, good insulating property, good stability, good flexibility and durability.

Owner:钟景尧

Biomass raw material-based polyurethane foam for fireproof thermal insulation boards, and processing technology thereof

The invention discloses a biomass raw material-based polyurethane foam for fireproof thermal insulation boards, and a processing technology thereof, and belongs to the technical field of chemical engineering. The processing technology comprises the following steps: stirring and mixing a biomass liquefaction product, water, triethylenediamine, silicone oil and a catalyst, then adding crushed modified mixed biomass and an enzymatic chitosan liquid, stirring and reacting the above obtained mixture, adding castor oil, isoamyl acetate and modified graphene oxide, heating and reacting the obtained mixture, and sequentially carrying out injection molding, foaming, aging and demolding to obtain the biomass raw material-based polyurethane foam. Calcium oxide deposited in the crushed modified mixedbiomass reacts with water in the preparation process to make calcium ions merged in the system, and the calcium ions can promote the cross-linking of enzymatic chitosan to form a three-dimensional network, so alumina and iron oxide deposited in the system are immobilized, and the mechanical properties of the system are improved. The biomass raw material-based polyurethane foam provided by the invention has excellent mechanical properties and an excellent thermal insulation property.

Owner:乐清市钜派企业管理咨询有限公司

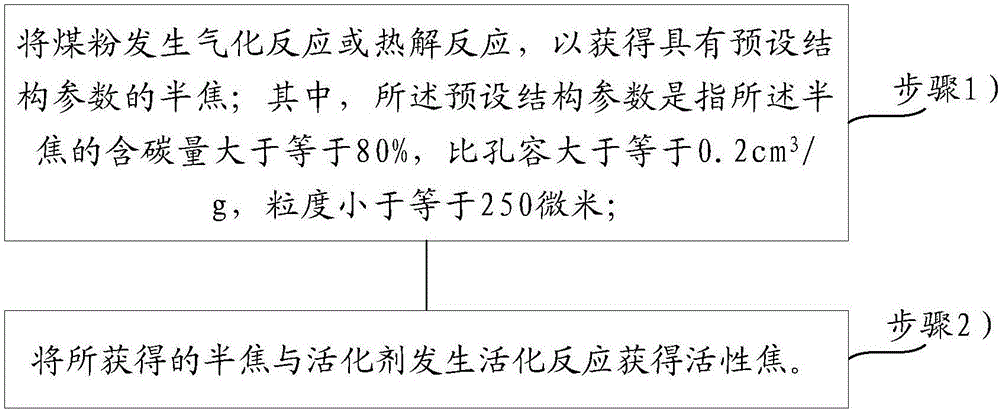

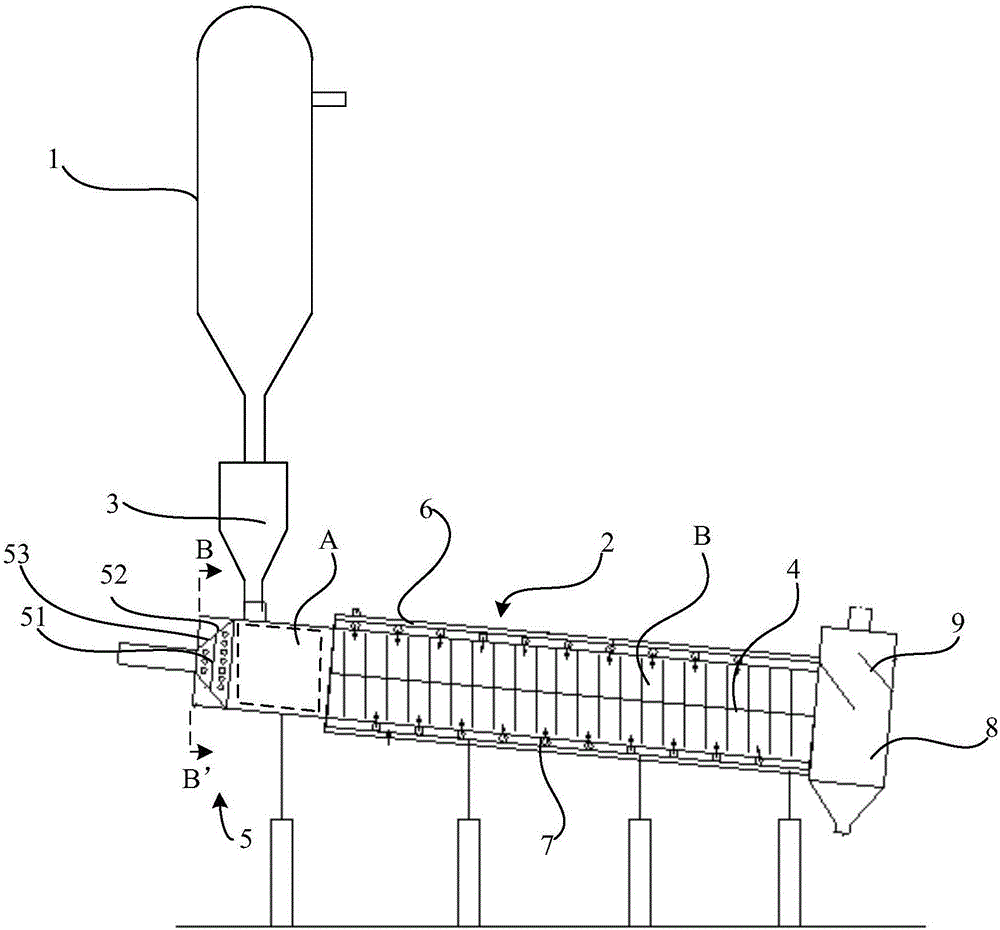

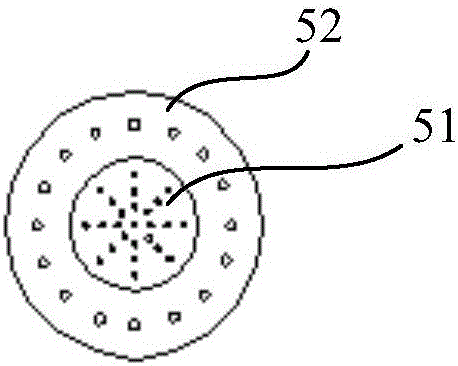

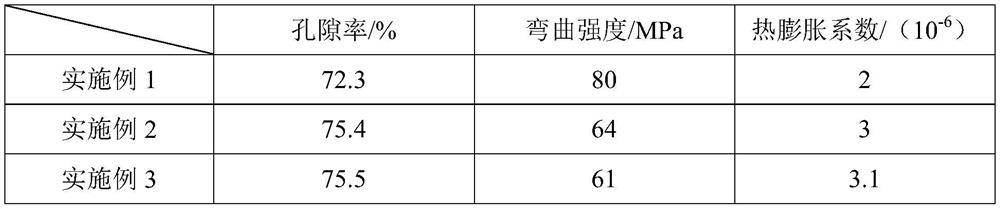

Active coke preparation method and preparation device

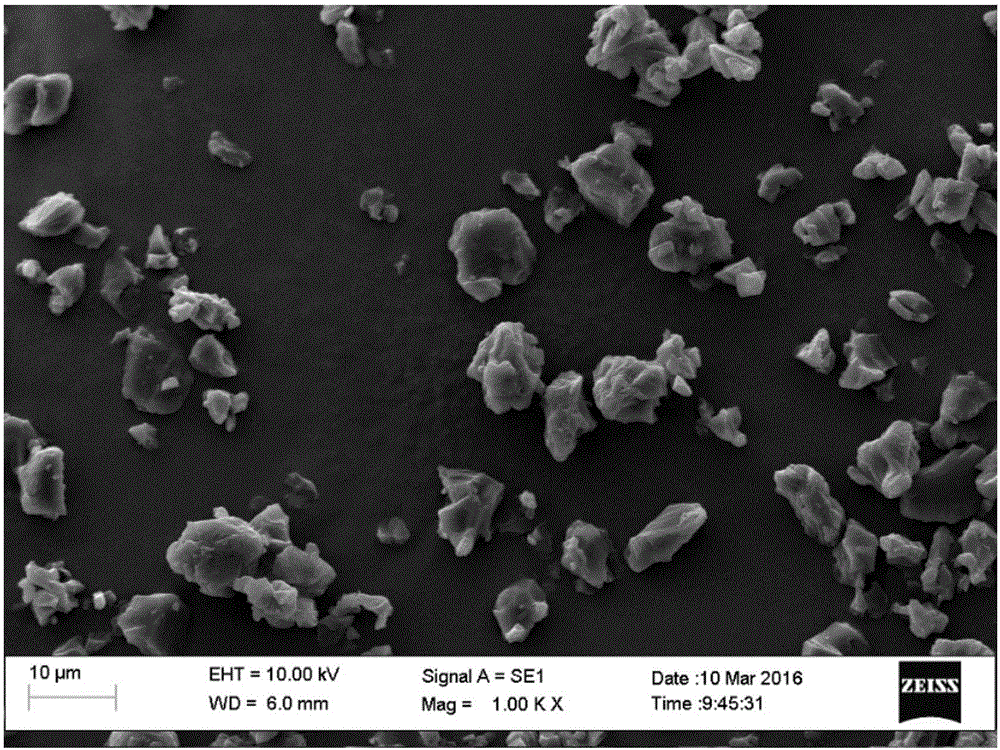

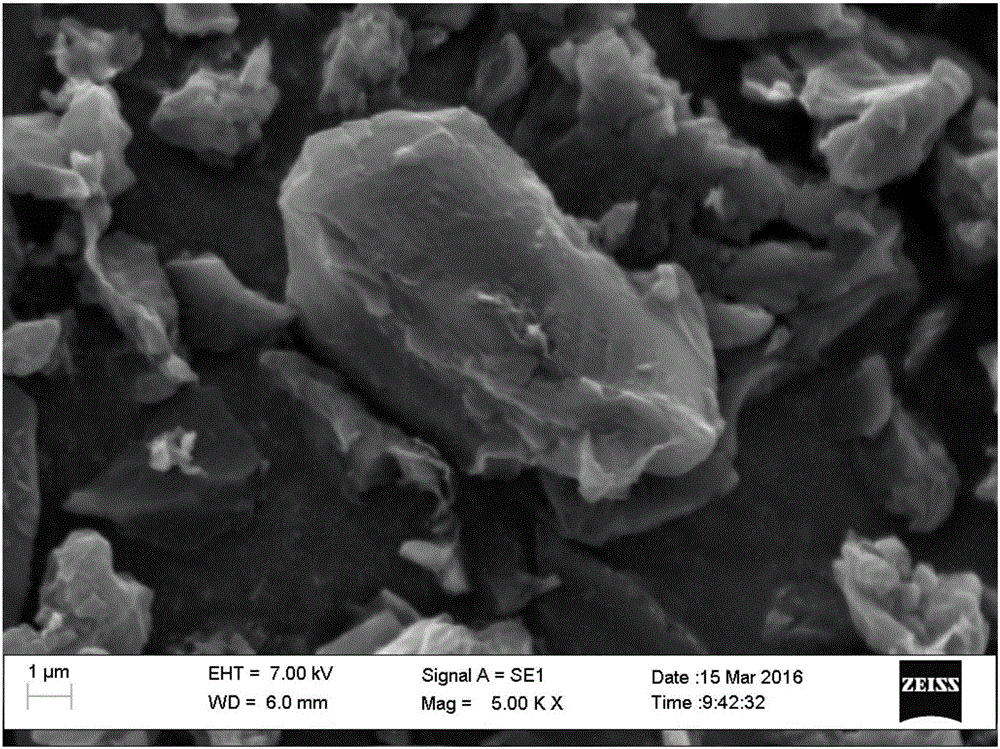

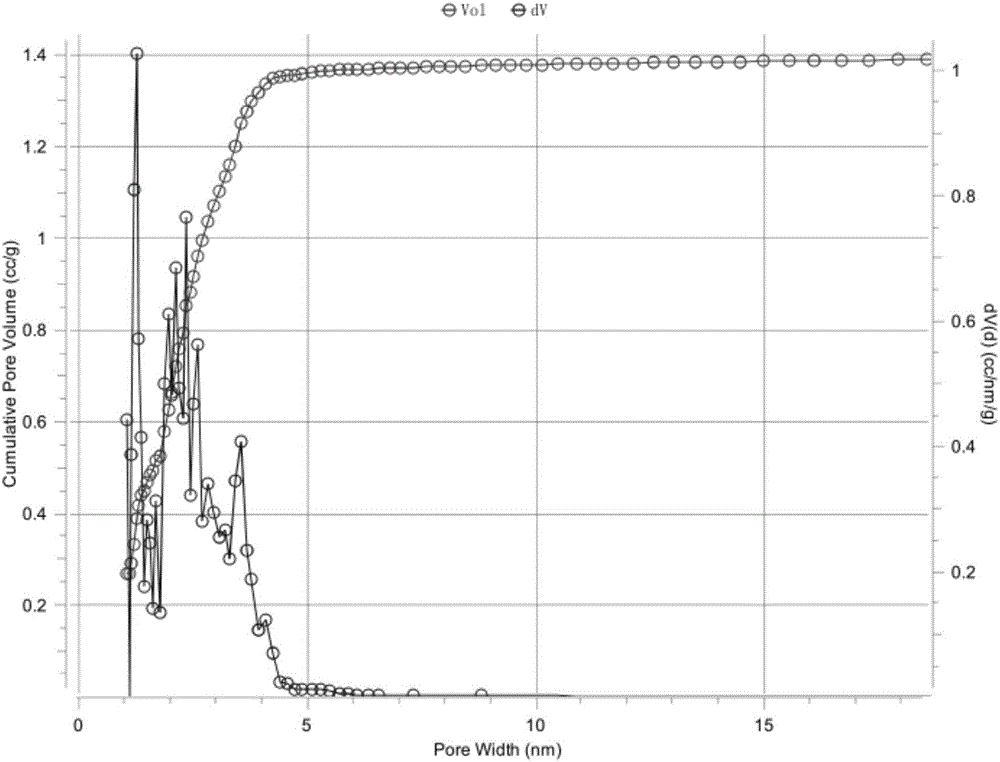

ActiveCN106744942AHigh specific pore volumeSpecific pore volumeCarbon compoundsGranularityMicrometer

The invention relates to the technical field of active coke, in particular to an active coke preparation method and preparation device. The active coke with large specific pore volume, high specific surface area and good adsorption performance can be obtained. The active coke preparation method includes the steps: 1) performing gasification reaction or pyrolysis reaction on pulverized coal to obtain semi-coke with preset structural parameters; 2) performing activating reaction of the semi-coke and activators to obtain the active coke. The preset structural parameters indicate that the carbon content of the semi-coke is larger than or equal to 80%, the specific pore volume is larger than or equal to 0.2cm<3> / g, and granularity is smaller than or equal to 250 micrometers. The active coke preparation method is used for preparing the active coke.

Owner:ENN SCI & TECH DEV

Porous silicon carbide ceramic and preparation method thereof

The invention relates to the field of silicon carbide ceramics, and particularly discloses a porous silicon carbide ceramic and a preparation method thereof. The porous silicon carbide ceramic comprises the following components in parts by weight: 80-100 parts of silicon carbide micro powder, 2-10 parts of a sintering aid, 1-5 parts of a pore-forming agent, 1-5 parts of a cross-linking agent, 3-6 parts of a dispersing agent and 45-55 parts of deionized water, wherein the pore-forming agent is straw micro powder with the particle size of 1-30 [mu]m. The preparation method comprises the steps: mixing and stirring the silicon carbide micro powder, the sintering aid, the cross-linking agent, the dispersing agent and the deionized water, then adding the pore-forming agent and a permeation accelerating agent, and stirring under a vacuum condition to obtain silicon carbide ceramic slurry; and performing vacuum suction filtration on the silicon carbide ceramic slurry, putting the silicon carbide ceramic slurry into a mold, baking to obtain a porous silicon carbide ceramic biscuit, and sintering the porous silicon carbide ceramic biscuit in an argon atmosphere to obtain the porous silicon carbide ceramic. The porous silicon carbide ceramic prepared by the preparation method is good in environmental protection property, low in cost, large in porosity and excellent in performance.

Owner:深圳市德澳美科技有限公司

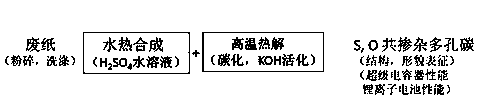

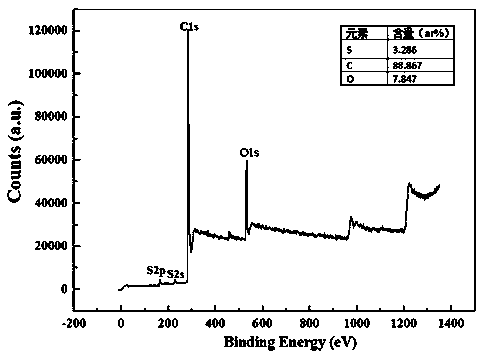

Method for preparing sulfur-oxygen co-doped porous carbon based on paper

PendingCN110902678AReduce lossesReduce collapseCarbon compoundsHybrid capacitor electrodesCapacitancePorous carbon

The invention belongs to a method for preparing sulfur-oxygen co-doped porous carbon from paper, particularly waste paper. The sulfur doping content of a porous carbon material is regulated and controlled through hydrothermal synthesis of a sulfuric acid solution by utilizing hydrothermal synthesis and high-temperature pyrolysis technologies on the basis of inherent structural characteristics of the paper; and the S and O co-doped porous carbon material is prepared through KOH assisted pyrolysis. The sulfur element doping amount of the prepared porous carbon material can be regulated to 0.3 at%-4at%, and the material presents a reticular hierarchical pore structure. A symmetrical capacitor assembled by taking the material as an electrode has the specific capacitance retention rate of 96% after 10000 times of circulation, has good electric circulation stability, and is worthy of market popularization and application.

Owner:NINGXIA UNIVERSITY

Preparation method for high-efficiency catalyst of fixed bed vinyl acetate synthetic reaction

InactiveCN108636392ABroaden the activation conditionsFully activatedOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsActivated carbonVinyl acetate

Owner:MULINSEN ACTIVATED CARBON JIANGSU

A method for curing and heat-treating drying of positive electrode wet raw board

ActiveCN109301172BImprove corrosion resistanceHigh bonding strengthLead-acid accumulator electrodesHeat conservationHeat treated

The invention discloses a method for solidifying and heat-treating a positive electrode wet raw board, which belongs to the technical field of lead-acid batteries. The method for curing and heat-treating the positive wet raw board is characterized in that: the positive wet green board is cured for 18-40h at a temperature of 40-70°C and a relative humidity of 80%-100%; then the temperature is set to 150-180°C , the opening pressure of the pressure relief valve is set to 0.4‑0.8Mpa, and the temperature rises for 1‑3h; after reaching the set temperature, keep warm for 1.5‑5h; . The invention can realize the heat treatment of the positive grid of the wet raw board during the curing and drying process of the wet raw board, improve the corrosion resistance of the positive grid, and at the same time effectively shorten the total time of curing and heat treatment and drying, and avoid separate treatment of the positive lead belt or The heat treatment of the grid will cause adverse effects such as new production processes, increased transshipment workload, and prolonged production cycle.

Owner:CAMEL GRP XIANGYANG BATTERY

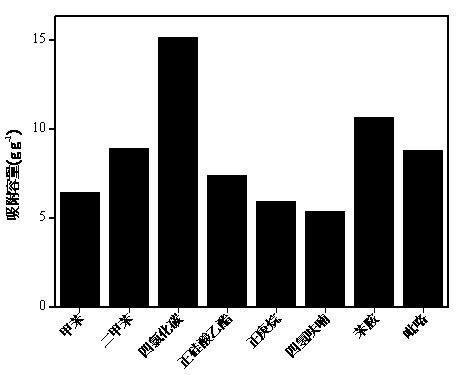

A method of preparing high-efficiency adsorption material from paraffin oil decolorization waste soil and its application

ActiveCN110368917BTurn waste into treasureSolve pollutionOther chemical processesWater contaminantsCarbon compositesSorbent

The invention discloses a method for preparing high-efficiency adsorption materials from paraffin oil decolorization waste soil and an application thereof, belonging to the field of adsorbent materials. In the present invention, paraffin oil decolorization waste soil is placed in a tube furnace, and the temperature is raised to 450°C to 650°C at a heating rate of 10°C / min to 20°C / min in a nitrogen atmosphere, and the temperature is kept for 1 to 4 hours to obtain Clay / carbon composite material: quickly add the obtained clay / carbon composite material into the ammonium phosphate solution to extract and cool, after impregnation, filter, put the obtained filter cake in a nitrogen atmosphere, and keep it warm at 400°C-500°C for 1-2 Hours, the clay / carbon porous adsorption material is prepared. The invention uses the residual coke and asphaltene impurities in paraffin oil decolorization waste clay as carbon source to prepare clay / carbon composite adsorption material, which not only solves the pollution problem of solid waste decolorization waste soil, but also prepares the adsorption material that is beneficial to the waste water containing Physical and chemical adsorption of nitrogen and phosphorus compounds.

Owner:CHANGZHOU UNIV

Reed flower biochar-based electrode material and preparation method thereof

ActiveCN112886026AEnhanced specific surface pore volumeEasy accessCell electrodesFinal product manufactureChemical reactionPotassium hydroxide

The invention relates to a reed flower biochar-based electrode material and a preparation method thereof. The preparation method comprises the steps of carbonizing reed flowers in a nitrogen atmosphere, and performing high-temperature activation and nitrogen doping by taking potassium hydroxide as an activating agent and a nitrogen-containing compound as a nitrogen doping agent to obtain reed flower biochar; and mixing the reed flower biochar with acetylene black and polytetrafluoroethylene emulsion, tabletting and drying to obtain the reed flower biochar-based electrode material. The reed flowers are selected to prepare the electrode material, carbonization, activated pore-forming and nitrogen doping are completed in one step, and the preparation process is simple and easy to operate; the selected nitrogen-containing compound such as diethanol amine has hydroxyl and can chemically react with carboxyl on the surface of reed flowers, so that the nitrogen-containing compound can be better combined with biomass carbon, and the nitrogen doping amount is high; and meanwhile, diethanol amine has alkalinity and water solubility, can easily enter the plant fibers, is easier for pore forming in the high-temperature carbonization process, and serves as a nitrogen doping agent and an auxiliary pore forming agent in the biochar-based material preparation process.

Owner:深圳市瑞斯伟新能源有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com