Honing oilstone and preparation method and application thereof

A technology for honing oil stones and diamonds, which is applied in the field of honing oil stones and its preparation. It can solve the problems of affecting grinding efficiency, precision, poor processing and grinding effects, and poor processing surface integrity. It achieves high processing efficiency, small grains, and The effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

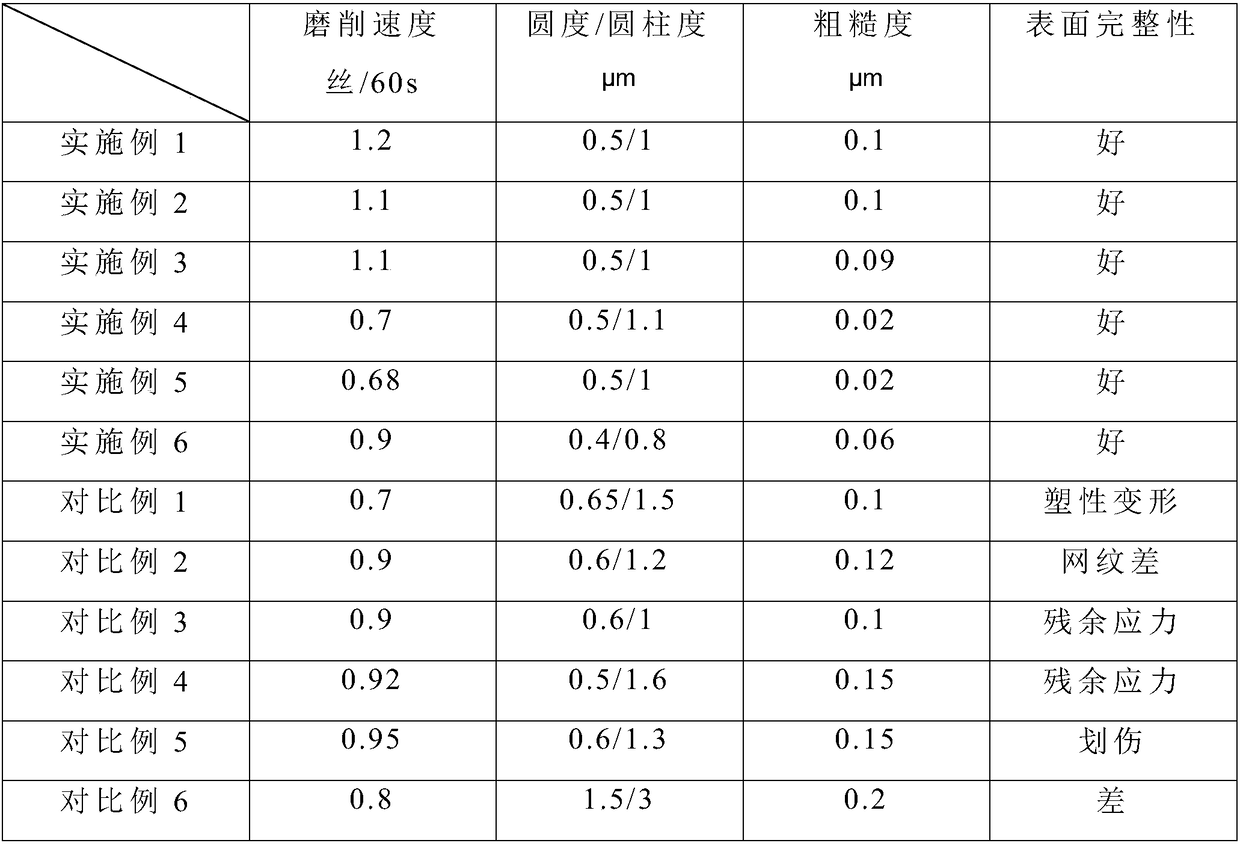

Examples

Embodiment 1

[0029] The present embodiment provides a kind of honing oil stone (volume V is 10 cubic centimeters, is used for fine grinding, k is 10%), and its raw material comprises:

[0030] 60 parts of copper, 20 parts of tin, 5 parts of zinc, 3 parts of silver, 1 part of antimony, 2 parts of iron-phosphorus alloy, 5 parts of sodium hexafluoroaluminate, 2 parts of bronze 663, 2 parts of graphite, 0.3 parts of paraffin, 0.88 parts of diamond powder share.

[0031] Its preparation method includes:

[0032] The raw materials weighed above are mixed, and then sintered at 660° C. and a pressure of 80 KN to obtain the honing stone.

Embodiment 2

[0034] The present embodiment provides a kind of honing oilstone (volume V is 20 cubic centimeters, is used for fine grinding, k is 20%), and its raw material comprises:

[0035] 65 parts of copper, 15 parts of tin, 4 parts of zinc, 4 parts of silver, 1 part of antimony, 3 parts of iron-phosphorus alloy, 4 parts of sodium hexafluoroaluminate, 2 parts of bronze 663, 2 parts of graphite, 0.4 parts of paraffin, 3.52 parts of diamond powder share.

[0036] Its preparation method includes:

[0037] The raw materials weighed above are mixed, and then sintered at 680° C. and a pressure of 85 KN to obtain the honing stone.

Embodiment 3

[0039] The present embodiment provides a kind of honing oilstone (volume V is 30 cubic centimeters, is used for fine grinding, k is 30%), and its raw material comprises:

[0040] 58 parts of copper, 22 parts of tin, 4 parts of zinc, 4 parts of silver, 1 part of antimony, 2 parts of iron-phosphorus alloy, 6 parts of sodium hexafluoroaluminate, 1 part of bronze 663, 2 parts of graphite, 0.5 parts of paraffin, cubic nitriding 7.92 parts of boron powder.

[0041] Its preparation method includes:

[0042] The raw materials weighed above are mixed, and then sintered at 700° C. and a pressure of 85 KN to obtain the honing stone.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com