Method for preparing sulfur-oxygen co-doped porous carbon based on paper

A technology of co-doping and porous carbon, applied in chemical instruments and methods, carbon compounds, hybrid/electric double-layer capacitor manufacturing, etc., can solve the problems of high operational risk, low S doping amount, unstable structure, etc. Achieve high operability, low reaction temperature, and reduce the loss of sulfur element

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention is specifically described below by the examples. It is necessary to point out that the following examples are only used to further illustrate the present invention, and cannot be interpreted as limiting the protection scope of the present invention. Without departing from the spirit and essence of the present invention All modifications or replacements made to the methods, steps or conditions of the present invention fall within the scope of the present invention.

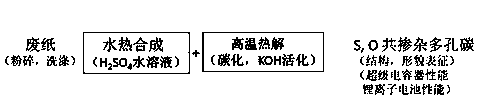

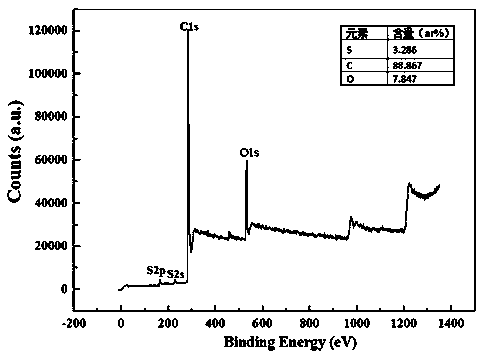

[0024] The specific process for preparing S, O co-doped porous carbon materials is as follows: figure 1 As shown, the experimental part is mainly divided into two parts: hydrothermal synthesis and high temperature pyrolysis. The morphology and composition of the prepared materials were characterized by SEM, XPS and BET analysis. The capacitive performance of the material and the performance of the lithium-ion battery were tested. The following is the specific implementation process o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com