Preparation method for high-efficiency catalyst of fixed bed vinyl acetate synthetic reaction

A vinyl acetate synthesis reaction technology, applied in the direction of catalyst activation/preparation, carboxylate preparation, chemical instruments and methods, etc., can solve the problems of low VAC yield, low catalyst loss activity, many by-products, etc., to achieve improvement Quality, sufficient activation, and the effect of broadening the activation conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

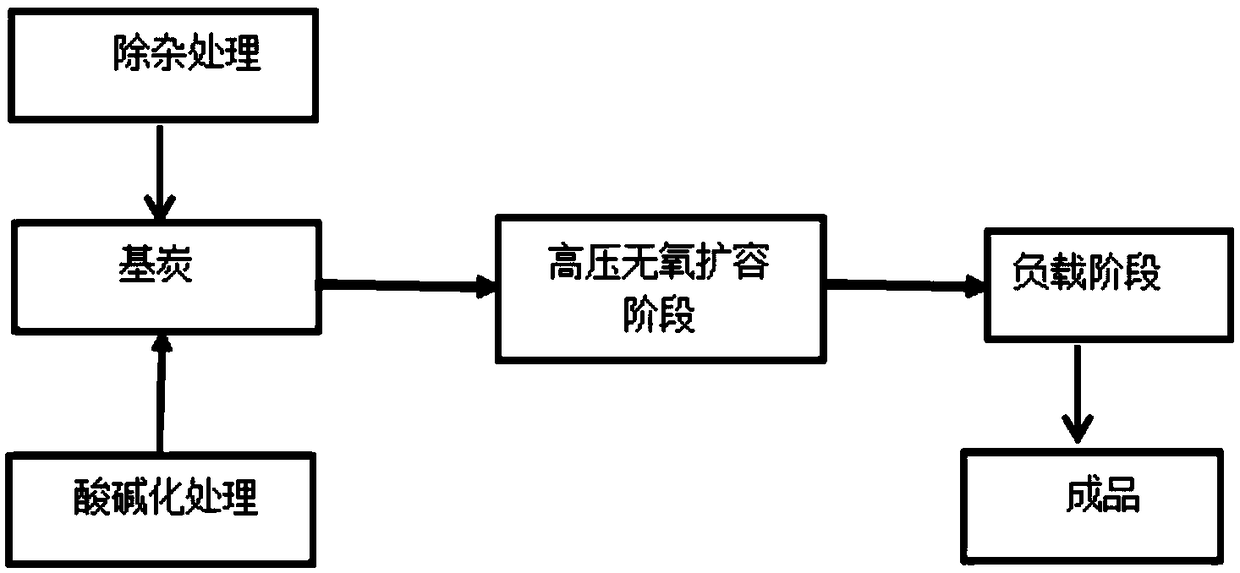

Method used

Image

Examples

Embodiment 1

[0031] Choose 5000g of anthracite as raw material, crush the anthracite to 6 mesh, add auxiliary agent acetic acid liquid according to 1% mass fraction to fully impregnate, let it stand for 2 hours, then add 2% mass fraction of sodium hydroxide mixed solution and stir well, anticorrosion at 0.5Mpa Air-isolated disposal in a pressure vessel for 2 hours. After the above samples are processed, they are transferred to the high-pressure anaerobic activation pilot equipment for activation.

[0032] Stay at 500°C for 1h, then raise the temperature to 800°C and stay for 2h, use a corrosion-resistant tube to feed the activator, which is a mixture of high-temperature water vapor and carbon dioxide in equal proportions, and the flow rate is 0.5m 3 / min, the internal pressure is maintained at 0.3MPa, and the activation equipment is kept airtight.

[0033] The material is expanded through the pressure relief aperture, and then enters the dilute hydrochloric acid liquid with a mass fractio...

Embodiment 2

[0036] The raw material is 4000g of coconut shell carbonized material, crush the coconut shell carbonized material to 10 mesh, add additives such as acetic acid, dilute hydrochloric acid, nitric acid and other proportions according to the mass fraction of 3%, and mix the liquid for full impregnation, let it stand for 1 hour, and then add 4% mass fraction The sodium hydroxide ratio mixed solution was stirred well, and it was treated in a 0.8Mpa anti-corrosion pressure vessel with air isolation for 1 hour. After the above samples are processed, they are transferred to the high-pressure anaerobic activation pilot equipment for activation.

[0037] Stay at 800°C for 1h, then raise the temperature to 1000°C and stay for 2h, use a corrosion-resistant tube to feed the activator, which is a mixture of high-temperature water vapor and carbon dioxide in equal proportions, and the flow rate is 2m 3 / min, the internal pressure is maintained at 0.8MPa, and the activation equipment is kept ...

Embodiment 3

[0041] The raw material is 3000g of coconut shell carbonized material, and the coconut shell is carbonized and crushed to 10 meshes, and the auxiliary agent acetic acid, dilute hydrochloric acid, nitric acid and other proportions are added according to the mass fraction of 4%. Stir the sodium hydroxide ratio mixture fully, and treat it in a 0.7Mpa anti-corrosion pressure vessel with air isolation for 3 hours. After the above samples are processed, they are transferred to the high-pressure anaerobic activation pilot plant for activation.

[0042] Stay at 900°C for 1h, then raise the temperature to 1050°C and stay for 2h, use a corrosion-resistant tube to feed the activator, which is a mixture of high-temperature water vapor and carbon dioxide in equal proportions, and the flow rate is 1m 3 / min, the internal pressure is maintained at 0.7MPa, and the activation equipment is kept airtight.

[0043] After the material is expanded through the pressure relief aperture and cooled, i...

PUM

| Property | Measurement | Unit |

|---|---|---|

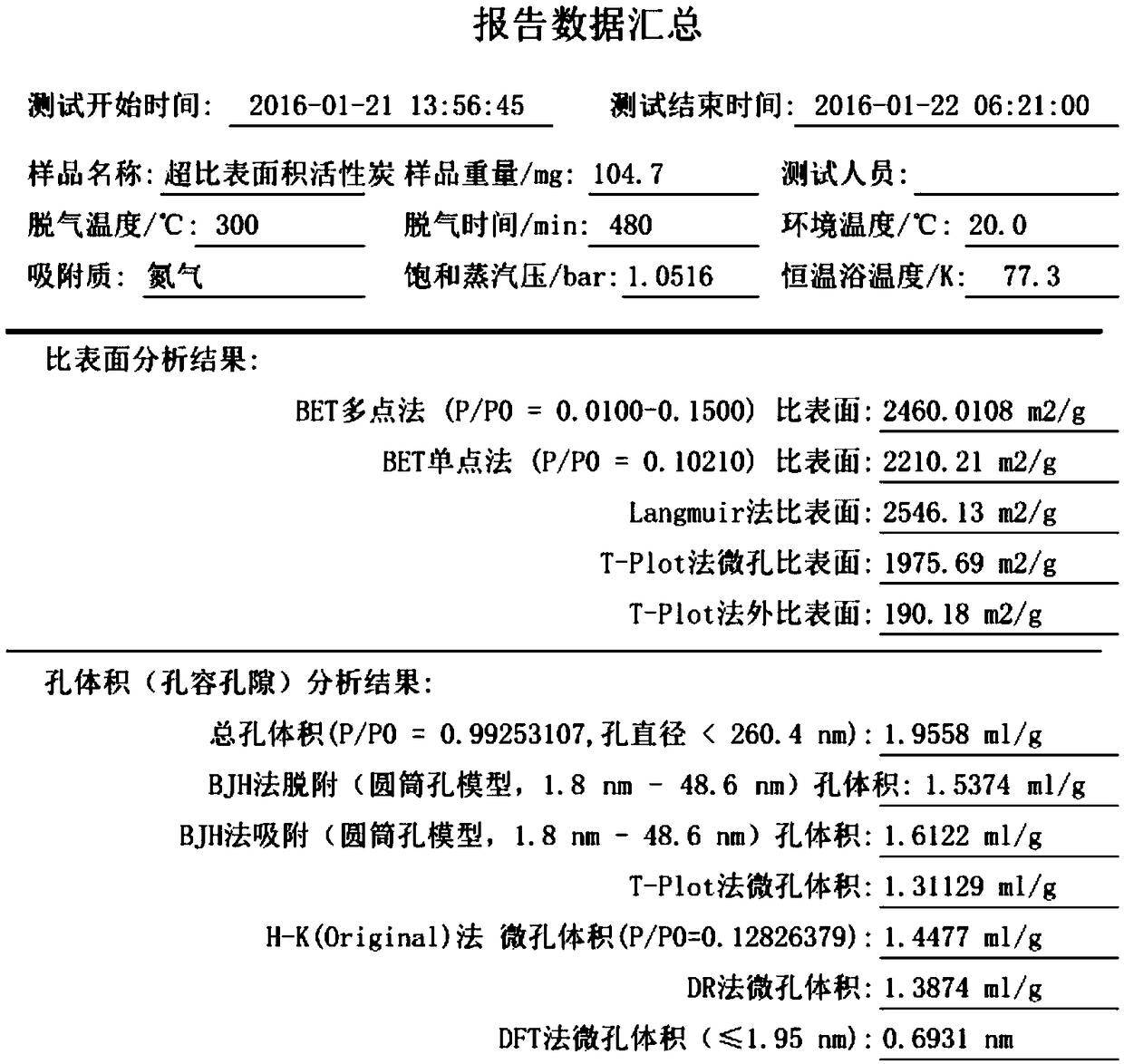

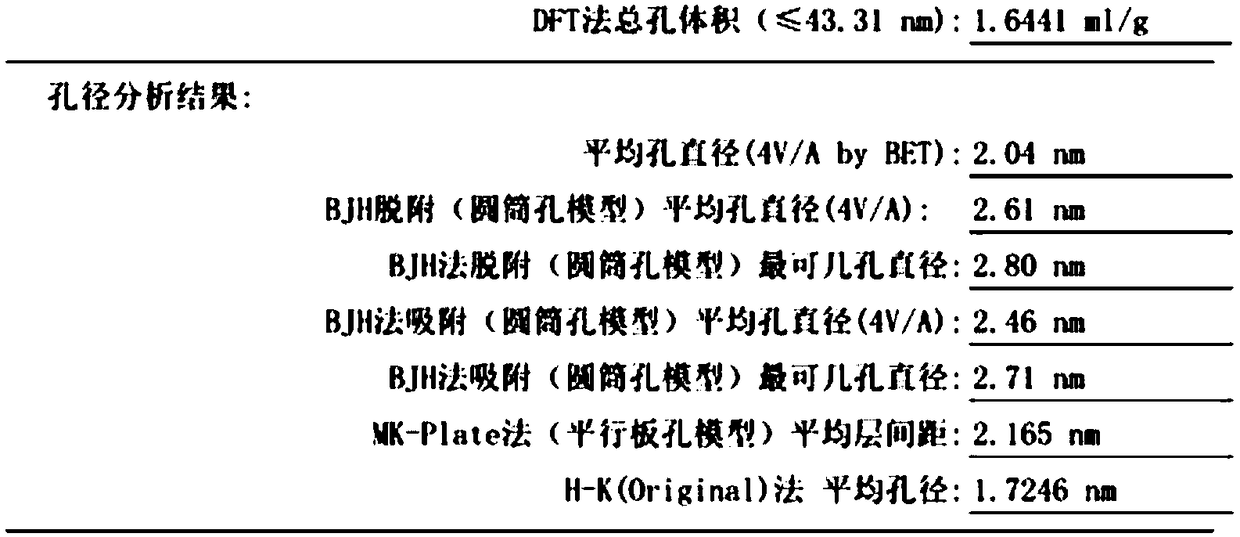

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com