Patents

Literature

429results about How to "Improve preprocessing effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

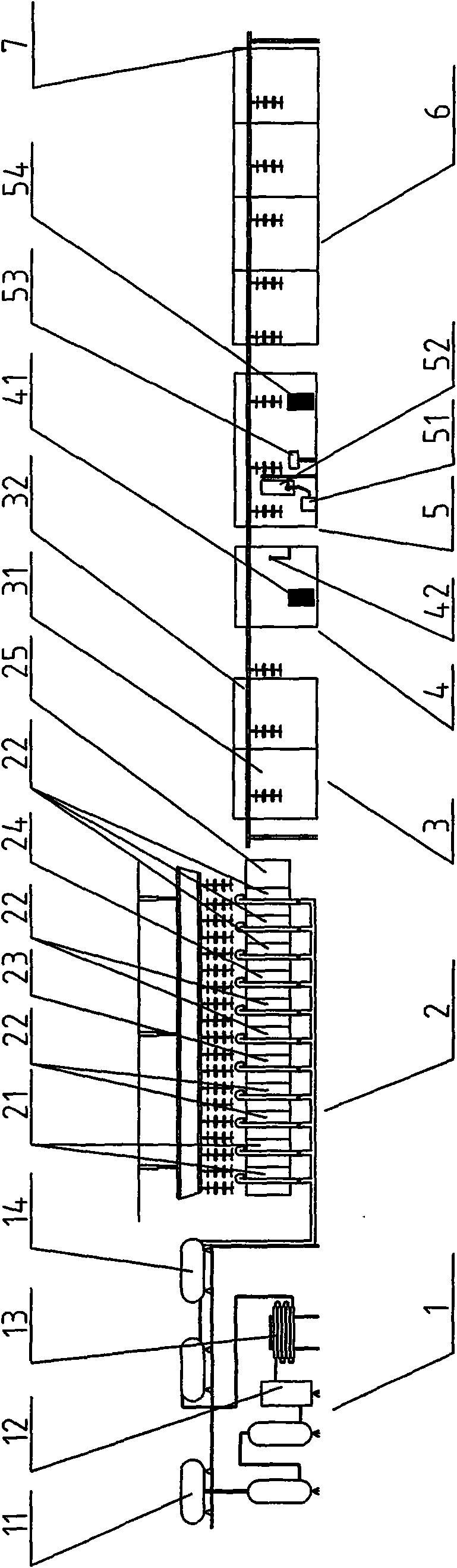

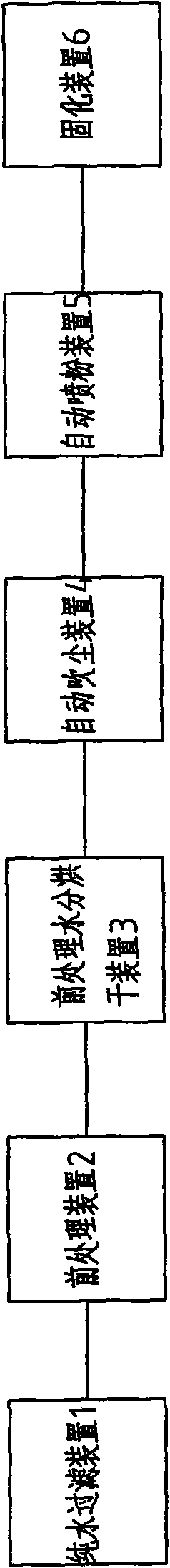

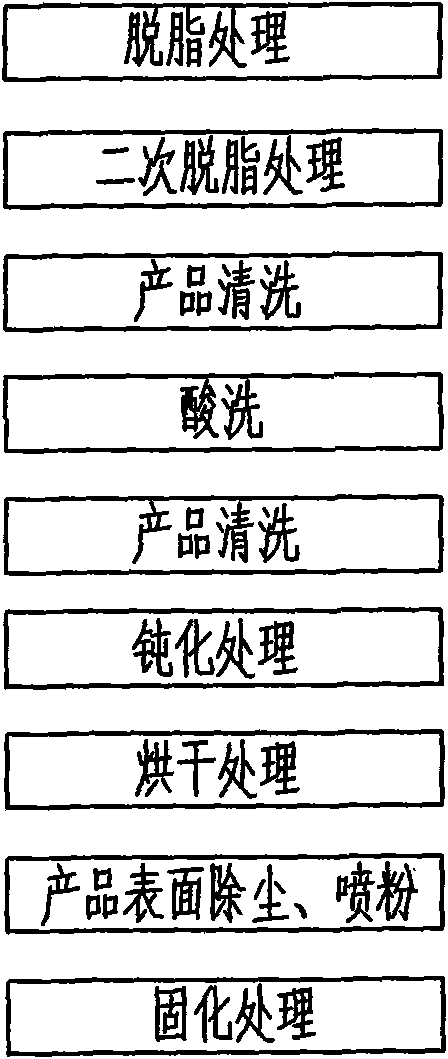

Automatic powder spraying line for automobile wheel hub finishing components and technique thereof

ActiveCN101602042AEvenly distributedSave resourcesLiquid spraying plantsPretreated surfacesSurface cleaningFiltration

The invention relates to an automatic powder spraying line for automobile wheel hub finishing components and a technique thereof; the production line comprises a pure water filtration system for providing pure water for the power spraying line, a pretreatment device, a pretreatment water content drying device, an automatic dust blowing device, an automatic powder spraying device, a solidifying device and a conveying lead rail; wherein, the pretreatment device sequentially comprises a pickling tank, alkaline wash tank and a passivation tank; the automatic powder spraying device comprises a tank body, a powder spraying gun, a powder storage tank, a powder sucking device, a constant temperature and humidity device. The production technique has the following steps: 1) alkali degreasing, 2) product surface cleaning, 3) drying, 4) dust abatement, 5) power spraying, 6) solidification. The production line of the invention features high degree of automation, suitability for mass production, high output benefits and low cost; in addition, the production technique equipped with the production line is more reasonable, components produced by the coating method of powder spraying has more uniform surface color and thickness.

Owner:GUANGZHOU JINZHONG AUTO PARTS MFG

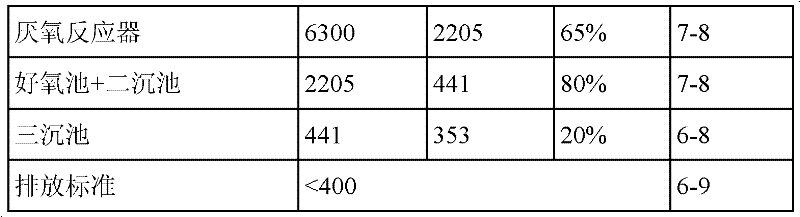

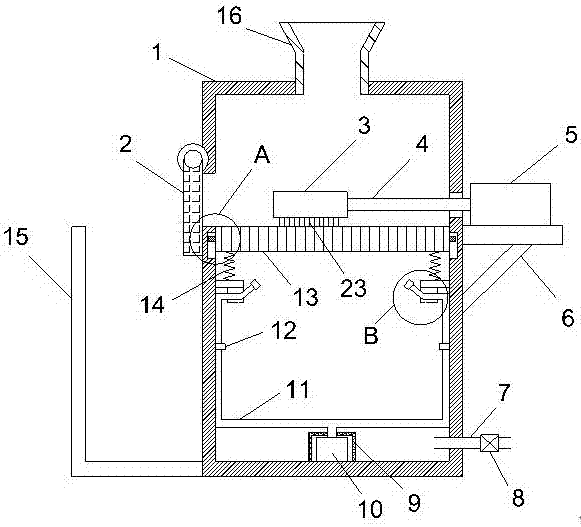

Sewage purifying pretreatment device

InactiveCN107362596AImprove preprocessing effectEffective dredgingStationary filtering element filtersForeign matterHydraulic cylinder

A sewage purification pretreatment device, comprising a box body, a filter screen plate is horizontally arranged in the box body, sliders are fixedly installed at the left and right ends of the filter screen plate, slide grooves are longitudinally arranged on the left and right side walls of the box body, and the slide block Slidingly installed on the chute; fixed plates are symmetrically arranged on the left and right inner walls of the box body, and buffer springs are arranged between the fixed plate and the filter plate; the nozzle pipe is covered with a pipe sleeve, and the pipe sleeve is fixed at the bottom of the fixed plate. A flushing nozzle is installed at the upper end of the spray pipe; a connecting rod is provided at the left end of the telescopic hydraulic cylinder, a brush plate is fixedly installed at the left end of the connecting rod, and a brush is provided at the bottom of the brush plate; Cleaning the sundries attached to the screen plate can effectively dredge the mesh holes of the filter screen plate, and the flushing nozzle sprays water on the filter screen plate obliquely to realize the flushing of the filter mesh holes in the filter screen plate, effectively preventing the mesh The clogging of the sewage greatly improves the effect of sewage pretreatment.

Owner:YANCHENG CIVIL MACHINERY CO LTD

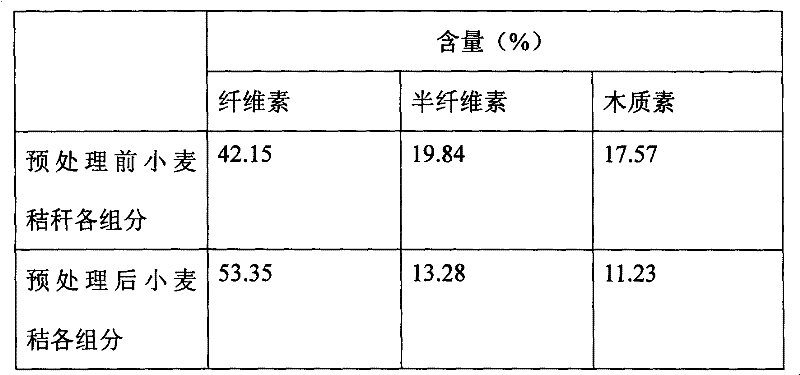

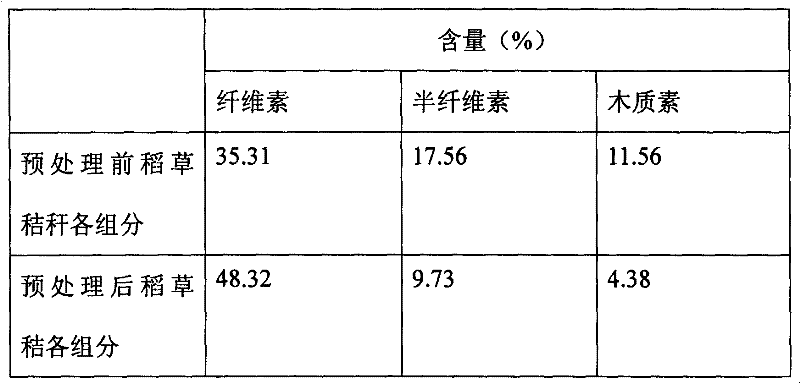

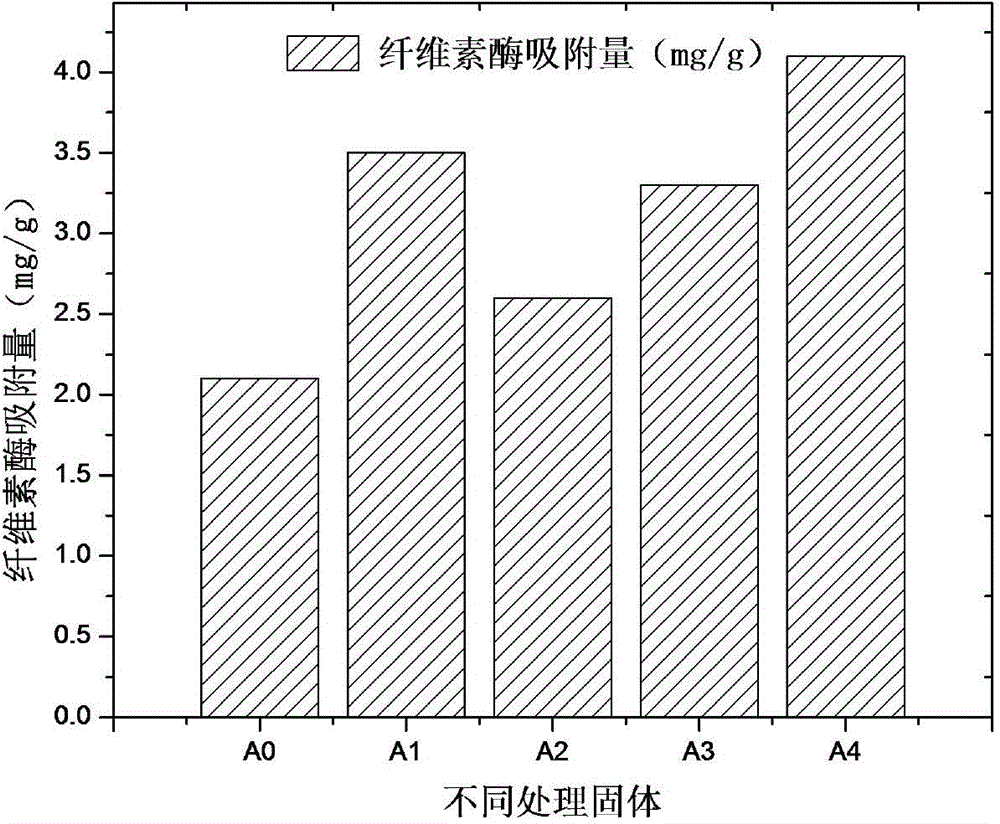

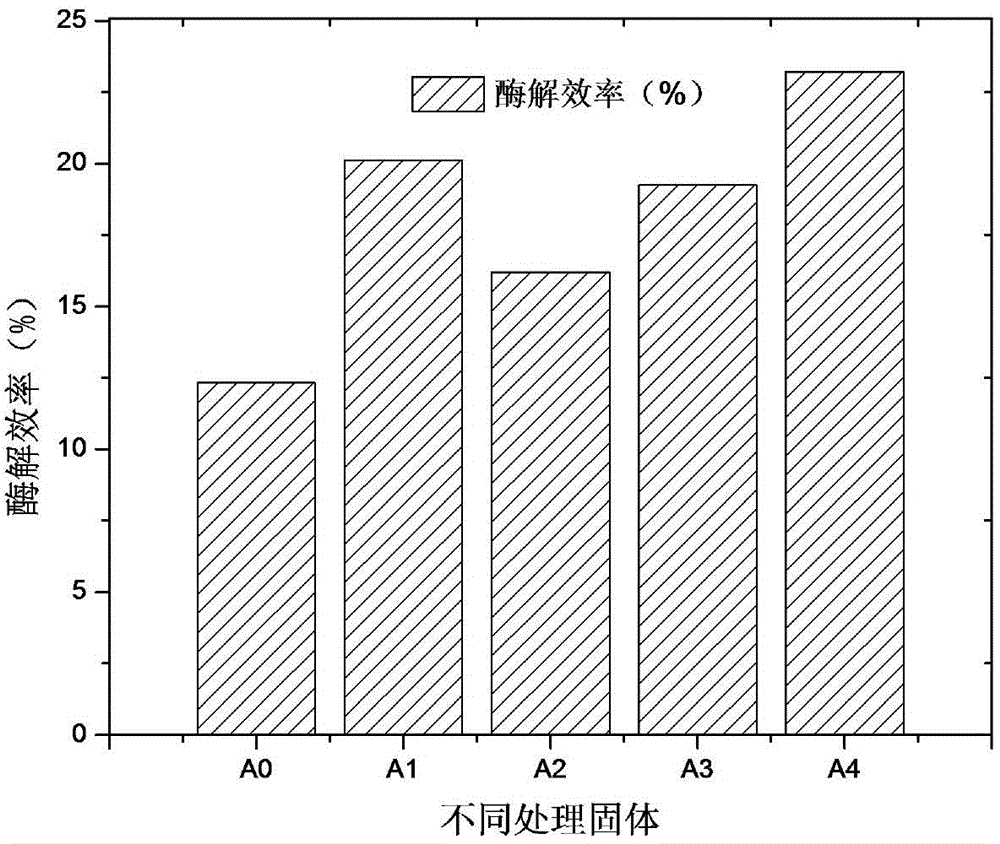

Improved method for preprocessing lignocellulose raw material

InactiveCN101824436AWide variety of sourcesReduce rough cutting strengthBiofuelsMicroorganism based processesCellulosePretreatment method

The invention relates to an improved method for preprocessing lignocellulose raw material, which comprises the following steps of: (1) roughly cutting the lignocellulose raw material to remove sand and stone impurities in coarse grains of straws; (2) preprocessing the coarse grains obtained in the step (1) in a preprocessing reactor; (3) after finishing the preprocessing, further crushing the lignocellulose material after the preprocessing into 0.1 to 10 mm lignocellulose fine grains; and (4) putting the lignocellulose fine grains obtained in the step (3) into an enzyme hydrolysis process and a fermentation process of the next step. The method has the following advantages that: while the preprocessing effect is enhanced, the energy consumption and the cost in the preprocessing process are reduced, the generation of inhibitors is reduced, and simultaneously the enzymatic hydrolysability of the lignocellulose raw material is enhanced.

Owner:EAST CHINA UNIV OF SCI & TECH

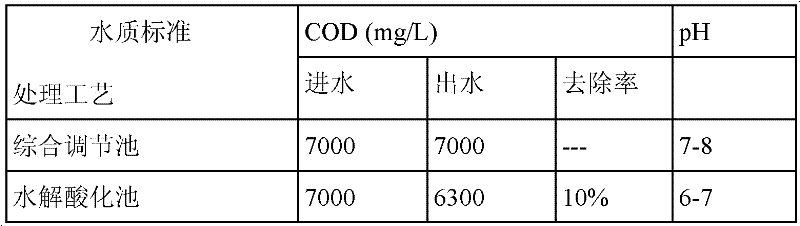

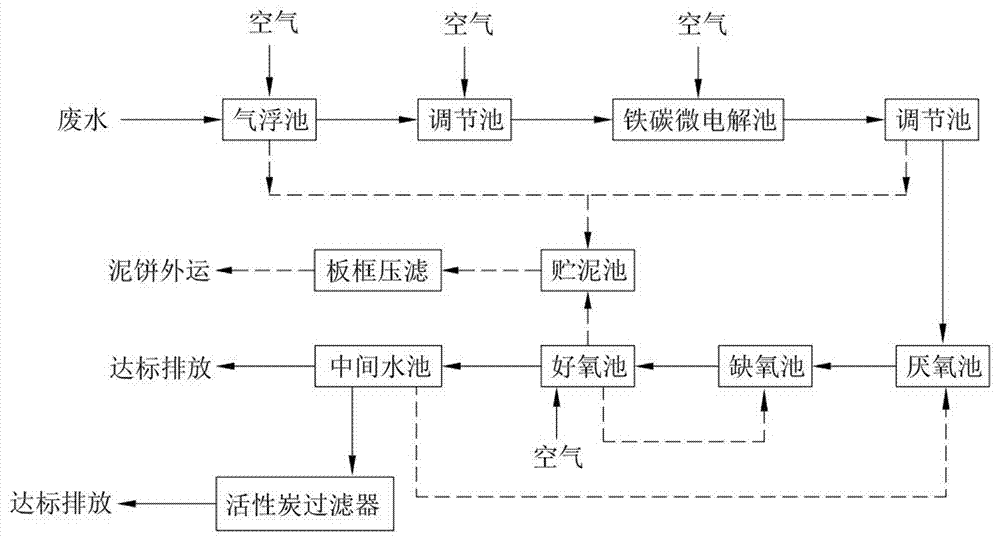

Recycling and processing method for printing and dyeing wastewater

ActiveCN103011524AImprove preprocessing effectSimple processMultistage water/sewage treatmentWaste water treatment from textile industryWater useActivated carbon

The invention relates to a recycling and processing method for printing and dyeing wastewater, which comprises the following steps of: mixing, neutralizing and coagulating the wastewater of acid wax and jacquard workshops and then performing biochemical treatment, so as to discharge the wastewater reaching the required standards; processing the wastewater of blanching and coloring workshop by the processes of adjusting, coagulating, hydrolytic-acidification, contact-oxidization, coagulation and chemical adding processes, so as to discharge the wastewater reaching the required standards; and then producing recycled water by adopting active carbon adsorption and then using ultra-filtration membrane and reverse osmosis membrane. The recycle water recovering rate of the recycled water treatment system is greater than 50%, the water quality index is better than that of tap water, and the influence to the printing and dyeing is avoided.

Owner:HUBEI JUNJI WATER TREATMENT

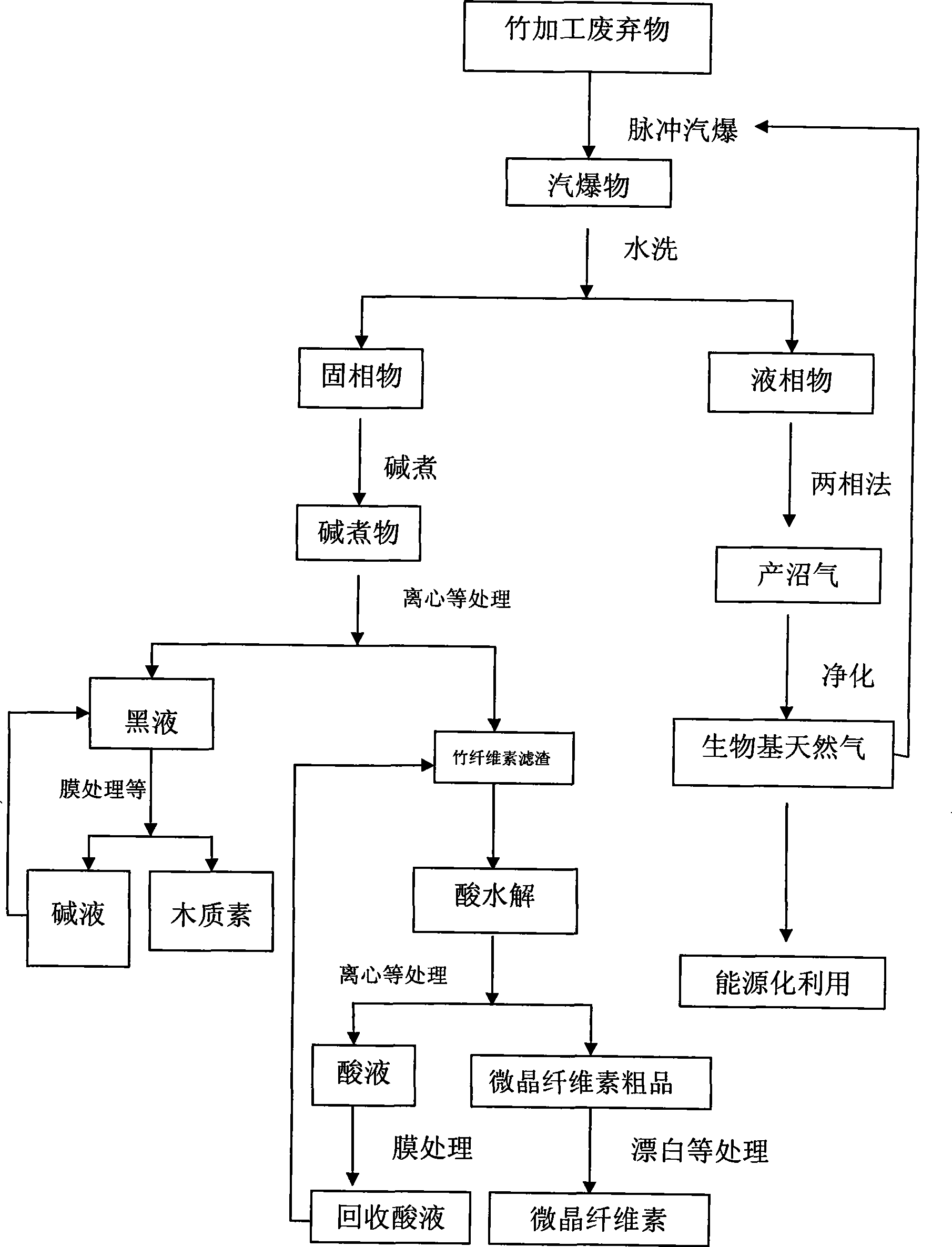

Production process for producing biobase natural gas with coproduction of lignose and microcrystalline cellulose from bamboo processing wastes

ActiveCN101497833ARealize the purpose of anaerobic fermentation to produce biogasGood preprocessing effectGaseous fuelsWaste based fuelFermentationHeat energy

The invention relates to a production process for producing biomass based natural gas, lignose and microcrystalline cellulose by utilizing bamboo-curing waste, which solves the problem that the bamboo-curing waste is utilized economically and effectively. The production process comprises the following steps: performing steam exploded pretreatment to the bamboo-curing waste, lixiviating and separating the steam exploded materials by water, producing marsh by the anaerobic fermentation of liquid phase materials, obtaining bamboo cellulose filter residue and black liquid by the alkali treatment of solid phase materials, separating the black liquid from the lignose, and obtaining the microcrystalline cellulose by the acid hydrolysis of the bamboo cellulose filter residue. The production process has high transition heat energy and can realize energy regeneration of the marsh; the joint lignose and microcrystalline cellulose realizes the energy regeneration utilization of the waste. The production process belongs to a closed circulating system which has high economic benefit and environment-protection without pollution.

Owner:ANHUI GEYI CYCLIC ECONOMY IND PARK

Preparation method of waterworks sludge ceramsites for pretreating micro-polluted water

ActiveCN102515834AIn line with the policy of "circular economy"Effective protectionSustainable biological treatmentCeramicwareWater sourceSludge

The invention provides a preparation method of waterworks sludge ceramsites for pretreating micro-polluted water, belonging to the technical field of pretreatment of micro-polluted water. The method comprises the following steps of: uniformly mixing waterworks sludge serving as a major raw material with fly ash and a pore-forming agent in a certain mass ratio; adding a certain amount of water forpelletizing into balls in a ball forming mill; drying a spherical green stock, and performing continuous variable-temperature and constant-temperature baking; and naturally cooling and sieving to obtain finished ceramsites. In the method, waterworks sludge is fully utilized, and sludge is recycled; and moreover, a preparation process is simple, and cost is low. The ceramsites prepared with the method are provided with a plenty of micropores both on the surfaces and inside, and biofilm formation growth of microorganisms on the surfaces of the ceramsites is facilitated, so that the biological pretreating effect on water of a polluted water source is remarkably enhanced, and good social benefit and environmental protection benefit are achieved.

Owner:丁美华

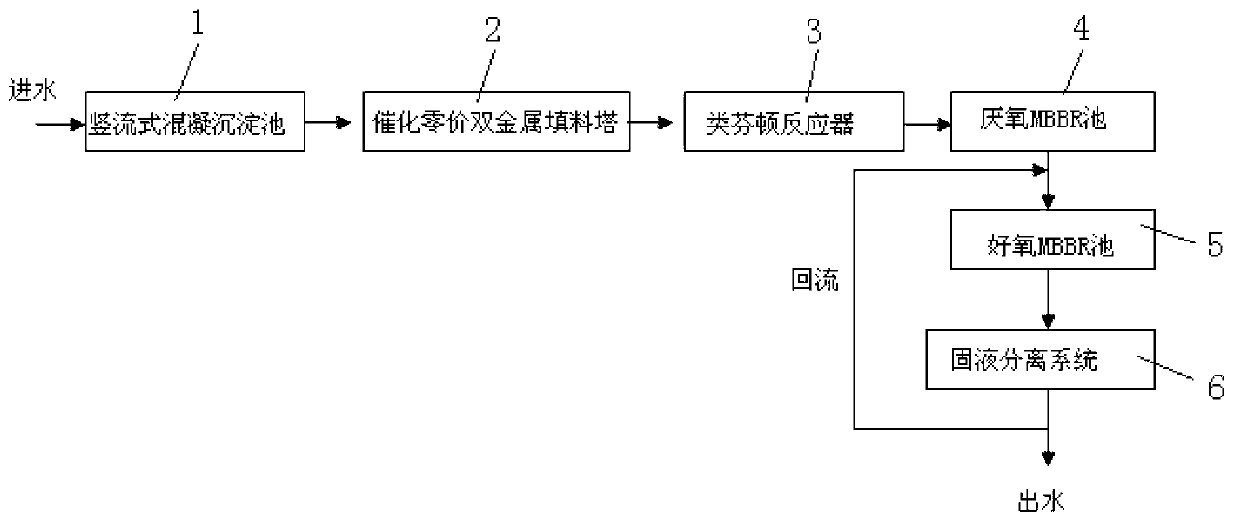

Pharmaceutical chemical wastewater treatment device and treatment method thereof

ActiveCN103011533AReduce consumptionEasy to handleMultistage water/sewage treatmentChemical industryReaction rate

The invention relates to a pharmaceutical chemical wastewater treatment device and a treatment method thereof. The treatment device comprises a vertical flow type coagulative precipitation tank, a catalysis zero valence bimetallic packing tower, a Fenton-like reactor, an anaerobic MBBR (Moving Bed Biofilm Reactor) pool, an aerobiotic MBBR pool and a solid-liquid seperation system which are sequentially connected. The treatment method is a catalysis zero valence bimetallic- Fenton-like-MBBR coupling treatment method. The treatment device has the advantages of being capable of simultaneously treating multiple organic pollutants, occupying a small area and being simple in structure and easy for finalization and industrialization. The catalysis zero valence bimetallic packing tower enables the performance of reducing and treating degradation-resistant organic matters to be stronger, does not harden after running for long-term and is suitable for a wide pH value range and low in operating cost, and the consumption of metallic iron is little. The Fenton-like reactor is faster in oxidation reaction rate and suitable for the wide pH value range. The pharmaceutical chemical wastewater treated by the wastewater treatment method provided by the invention can reach the new emission standard of wastewater in a pharmaceutical chemical industry.

Owner:TAIZHOU UNIV

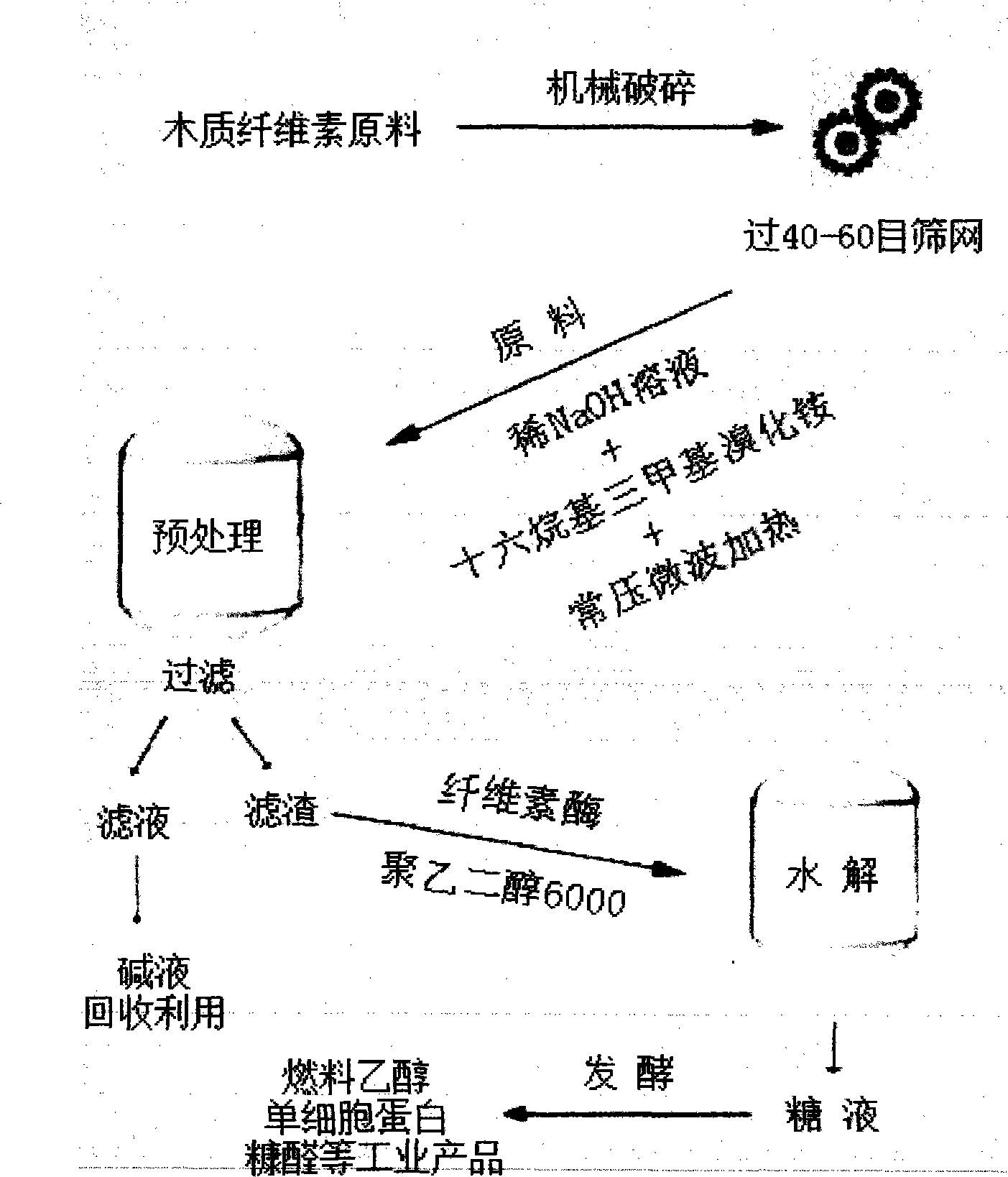

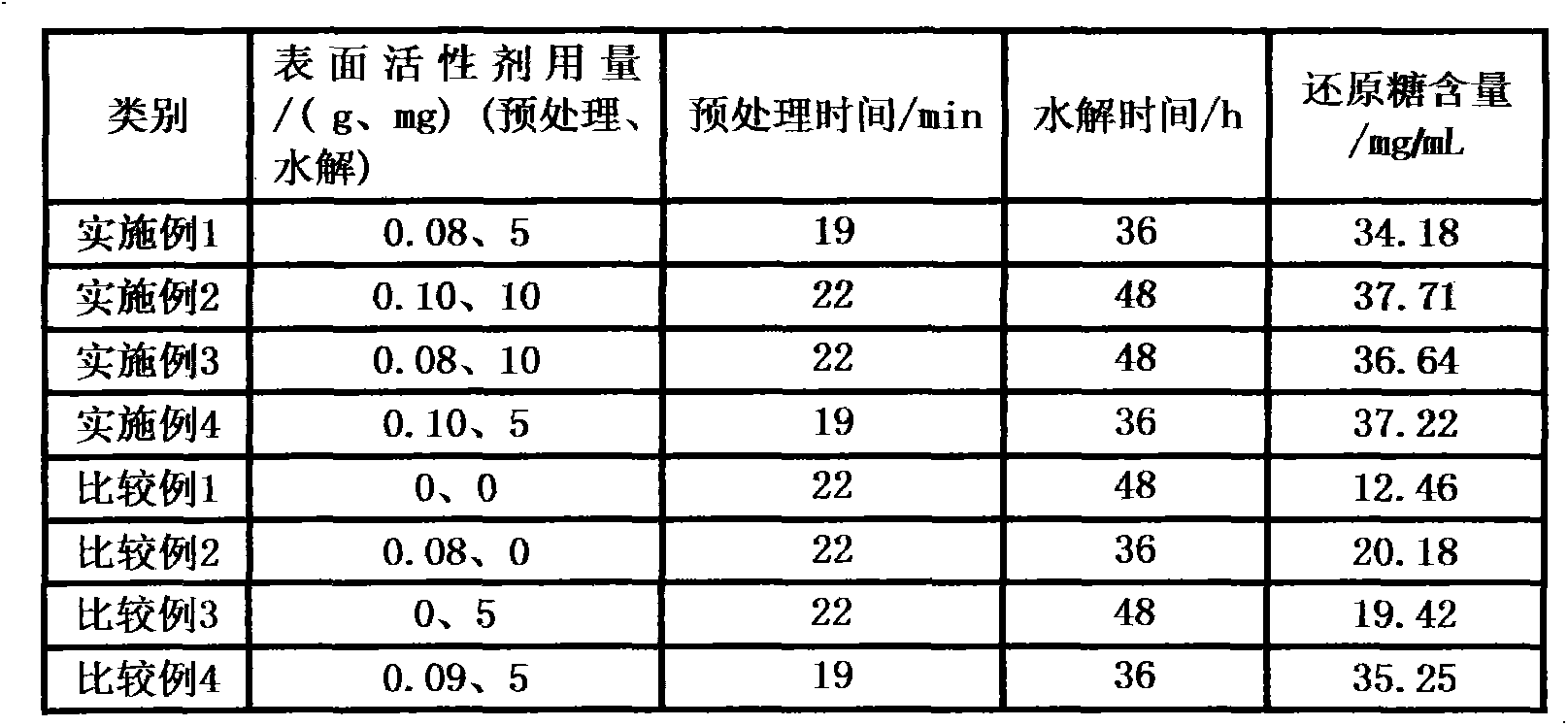

Method for efficiently degrading lignocelluloses raw material

ActiveCN103243139AReduce crystallinityReduce preprocessing timeFermentationCelluloseHigh concentration

The invention discloses a method for efficiently degrading lignocelluloses raw material. The method comprises the following steps of: simple smashing of raw material as well as enzymolysis of normal pressure microwave unite alkali liquor and cationic surface active agent disposal raw material and nonionic surfactant auxiliary cellulose, wherein the roughly smashed lignocelluloses raw material, the cationic surface active agent and the alkali liquor are mixed, after microwave processing at normal temperature, liquid and solid are separated, and furthermore, the nonionic surfactant auxiliary cellulose is added for solid enzymolysis so as to obtain a sugar liquid. According to the method, the advantages of the physical method and the chemical pretreatment method are complementary, so that the degree of crystallinity of the cellulose raw material is effectively lowered, the pretreatment time is shortened, and the pretreatment effect is improved; furthermore, alkali liquor with low concentration is beneficial to effective recycle in industrial production, pretreatment of lignocelluloses raw material at normal temperature can also lower the energy consumption in the pretreatment process obviously, and sugar liquid with higher concentration can be obtained in shorter hydrolysis time as the nonionic surfactant auxiliary cellulose is used for enzymolysis.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

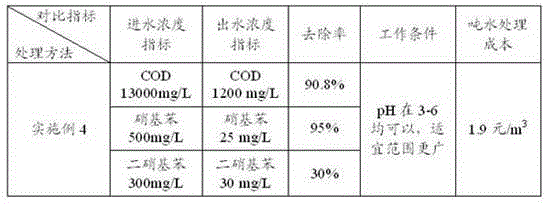

Combination type treatment method for pharmaceutical waste water

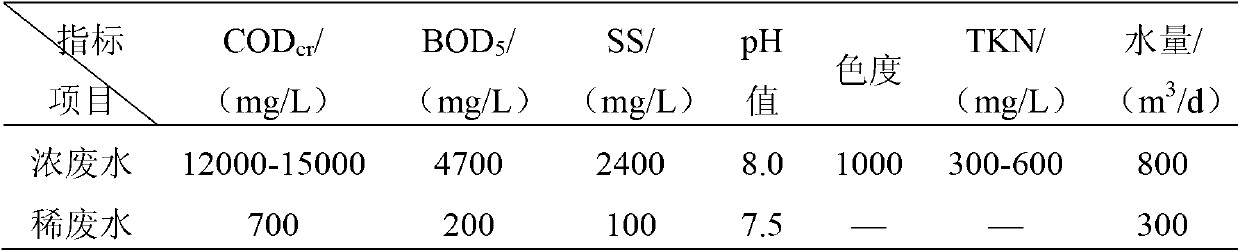

InactiveCN102336502AEfficient removalGuaranteed treatment effectMultistage water/sewage treatmentWater/sewage treatment by neutralisationHigh concentrationWater quality

The invention discloses a combination type treatment method for pharmaceutical waste water, which belongs to the technical field of water treatment. The method comprises the following steps of: first, improving the biodegradability of high concentration of waste water by adopting an efficient pretreatment technology, and finally removing a main pollutant COD (Chemical Oxygen Demand) in the waste water until reaching the standards. The invention has the advantages of stable running, flexible operation, convenience for maintenance, and strong impact resistance capability and strain capability for the variation of water inlet quantity and water quality.

Owner:WUXI TONGYUAN ENVIRONMENTAL PROTECTION TECHNG

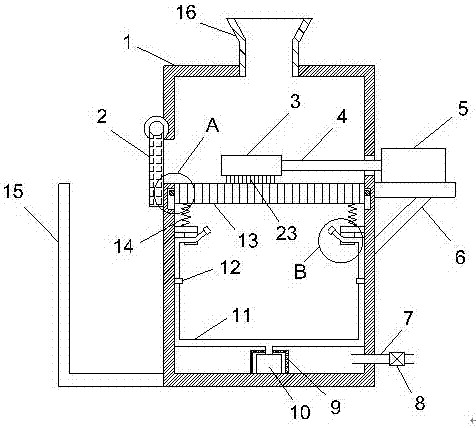

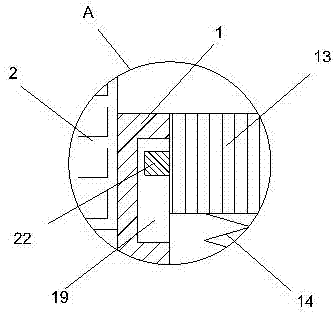

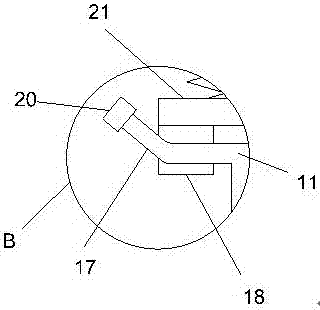

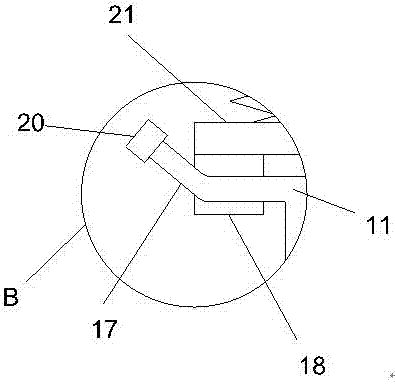

Sewage purifying pretreatment apparatus

InactiveCN107376443AImprove preprocessing effectEffective dredgingStationary filtering element filtersHydraulic cylinderSewage

The invention relates to a sewage purifying pretreatment apparatus. The sewage purifying pretreatment apparatus comprises a casing, a filter screen plate is horizontally arranged in the casing, the slide blocks are fixedly arranged at left and right ends of the filter screen plate, the sliding grooves are vertically arranged on the left and right sidewalls of the casing, the slide blocks are arranged in the sliding grooves in a sliding mode; the fixed plates are symmetrically arranged on the left and right inner walls of the casing, a buffer spring is arranged between the fixed plate and the filter screen plate; a pipe sleeve is sleeved on a jet pipe, the pipe sleeve is fixed at the bottom of the fixed plate, a flushing nozzle is arranged at the upper end of the jet pipe; a connecting rod is arranged at the left end of a telescopic hydraulic cylinder, a brush plate is fixedly arranged at the left end of the connecting rod, and a hairbrush is arranged at the bottom of the brush plate. The filter screen plate performs preliminary filtering on sewage, the foreign materials attached on the filter screen plate can be cleaned by the brush plate, the meshes on the filter screen plate can be effectively dredged, the flushing nozzle is obliquely upward for spraying water to the filter screen plate, so that the meshes in the filter screen plate can be flushed, the mesh obstruction can be effectively prevented, and the sewage pretreatment effect is greatly increased.

Owner:盐城海之诺机械有限公司

Method for preprocessing lignocellulose biomasses by virtue of carbonate and hydrogen peroxide

ActiveCN105154493AHigh retention rateReduce energy consumptionFermentationCelluloseFermentable sugar

The invention belongs to the fields of efficient conversion and utilization of biomasses and particularly relates to a method for preprocessing lignocellulose biomasses by virtue of carbonate and hydrogen peroxide. According to the method, the lignocellulose biomasses are preprocessed at a relatively low temperature by virtue of a combined solution of carbonate and hydrogen peroxide; an adopted alkali reagent is carbonate and is easier to recycle as compared with common hydroxide (such as sodium hydroxide), furthermore, hydrogen peroxide is an environmental-friendly oxidant and is combined with carbonate for use, so that the removal rate of lignin can be increased, the structure of lignin can be changed, more celluloses can be exposed, and the relatively high yield of fermentable sugars is achieved.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

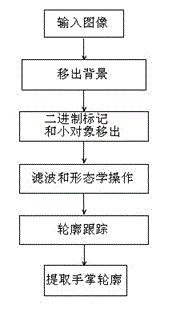

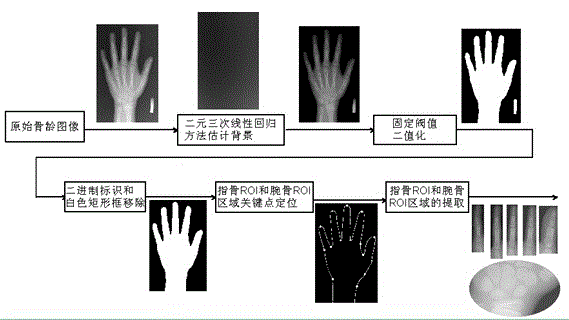

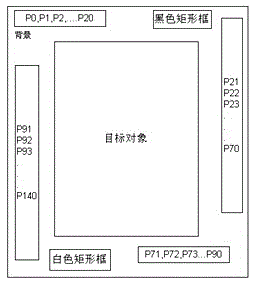

Method for preprocessing robust skeletal age evaluation image and positioning skeletal key point

InactiveCN102945545AImprove preprocessing effectEffective Noise Treatment MethodsImage enhancementImage analysisCrucial pointNoise removal

The invention discloses a method for preprocessing a robust skeletal age evaluation image and positioning a skeletal key point. The method comprises the following steps: step 1, preprocessing a skeletal age X-ray plain film image: selecting a sub-sampling point, fitting a background image by a linear regression method, removing a background of the skeletal age X-ray plain film image, and extracting a target part which is a palm outline image; step 2, performing noise removal processing on the palm outline image obtained in the step 1; and step 3, positioning the skeletal key point in the palm outline image processed in the step 2 by a K cosine method. In the traditional method, the skeletal age is manually decided, the subjective factors of a decider are excessive, and the pressure load is overweight, so that the traditional method is not beneficial for objectively and fairly measuring the skeletal age. According to the method, the preprocessing effect of the skeletal age X-ray plain film image is enabled to be optional and have great robustness, the requirements of operators photographing the skeletal age films on a photographed person is reduced, and the method has great adaptability to skeletal age images.

Owner:CHONGQING MEDICAL UNIVERSITY

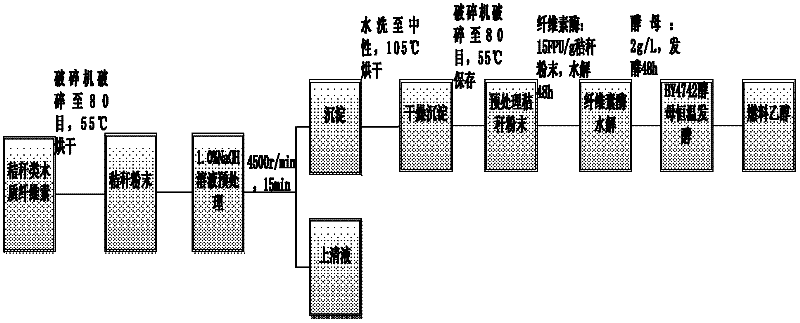

Process for producing fuel alcohol by adopting straw lignocellulose as raw material

InactiveCN102517341AIncrease surface areaWell mixedBiofuelsMicroorganism based processesEthanol fuelCellulose hydrolysis

The invention relates to a process for producing fuel alcohol by adopting straw lignocellulose as a raw material, which comprises the following steps of: (1) crushing of the straw lignocellulose: crushing the straw lignocellulose by using a crushing machine to 80 meshes and drying at the temperature of 55 DEG C to obtain a straw lignocellulose powder; (2) fetching the crushed and dried straw lignocellulose powder, and adding a sodium hydroxide (NaOH) solution of which the mass fraction is 1.0 percent to the straw lignocellulose powder for pretreatment; (3) cellulose hydrolysis saccharification: adding the cellulose to the straw lignocellulose powder prepared in the step (2); and stirring for hydrolysis for 48 hours under the condition that the temperature is 40 DEG C and pH is 4.5 to obtain cellulose hydrolysis saccharification hydrolysate; and (4) alcoholic fermentation: lowering the temperature of the cellulose hydrolysis saccharification hydrolysate to 35 DEG C in a fermentation tank, and adding 2g / L of yeast to perform a constant-temperature fermentation reaction to obtain the fuel alcohol. Compared with the prior art, the process for producing the fuel alcohol by adopting the straw lignocellulose as the raw material has the advantages of rich raw material, low cost, high hydrolysis efficiency, fewer byproducts, high alcohol yield and the like.

Owner:SHANGHAI JIAO TONG UNIV

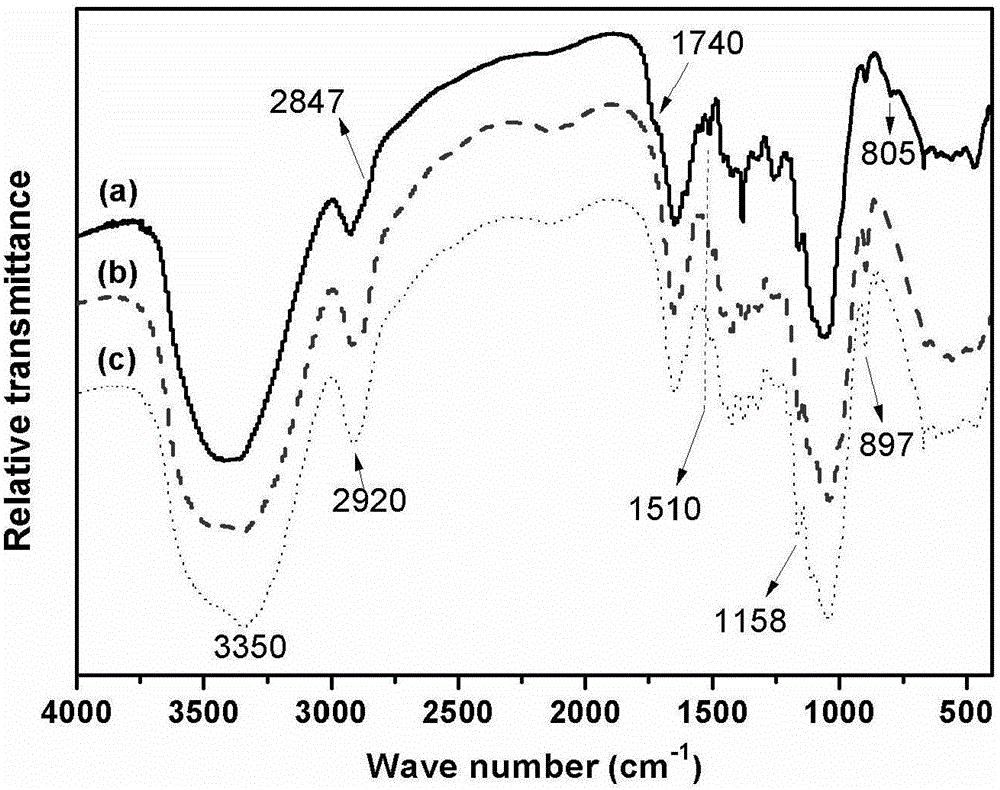

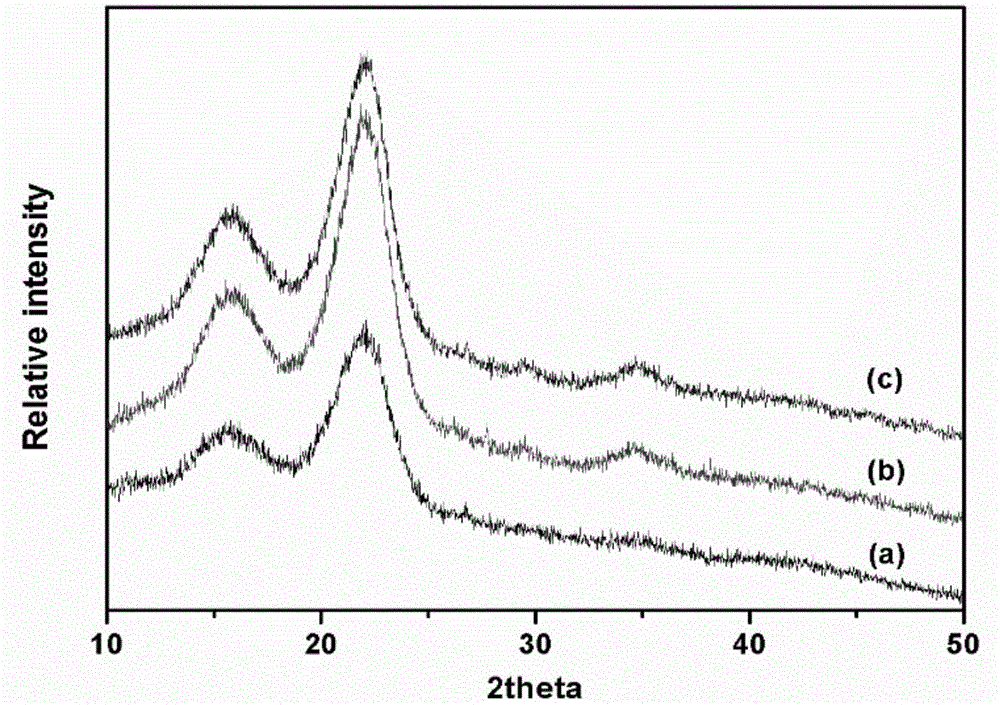

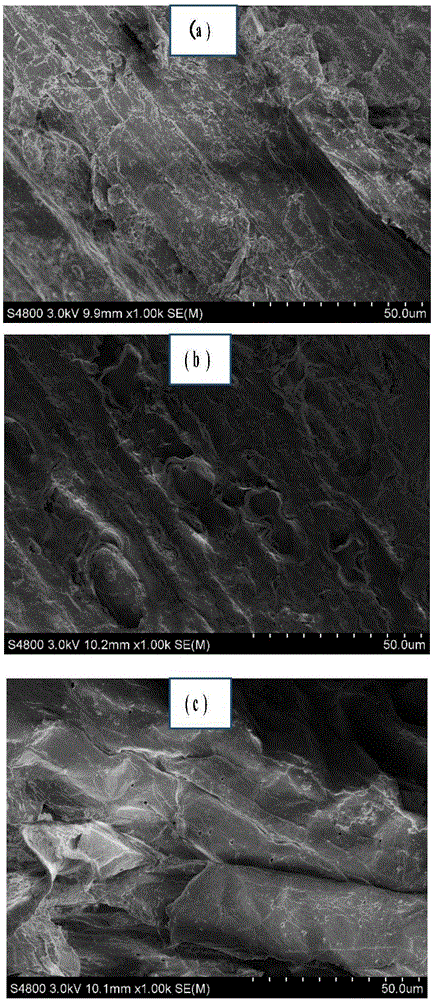

High-purity natural collagenous fiber and preparation method thereof

ActiveCN104189944AGood mechanical propertiesImprove thermal stabilitySurgeryAbsorbent padsFiberCalcanean tendon

The invention discloses a high-purity natural collagenous fiber and a preparation method thereof. The collagenous fiber is characterized in that fresh traceable animal muscle tendon or achilles tendon is used as a raw material, and is subjected to pre-treatment, water soaking, supercritical carbon dioxide fluid degreasing, alkali leaching, first enzyme treatment, acid leaching, secondary enzyme treatment, salting out, centrifugal purification and other processes to obtain the high-purity natural collagenous fiber. The high-purity natural collagenous fiber prepared by the method is aggregation of natural collagen molecules, has the quarternary structure of collagen and the intrinsic bioactivity of collagen, and has more spatial structure features of collagen in natural tissues, so that the natural tissue structure can be further simulated. Compared with a collagen material, the natural collagenous fiber prepared by the method has the advantages of excellent mechanical performance, thermal stability and biodegradation performance, and the structure of the natural collagenous fiber is relatively stable and easy to store; and characteristic group expression of cells can be activated, and normal characteristic expression of cells can be maintained, so that adhesion, growth and proliferation of cells can be benefited. The natural collagenous fiber can be used for preparing hemostatic materials, tissue engineering scaffold materials, medical plastic and cosmetic materials and the like.

Owner:SICHUAN UNIV

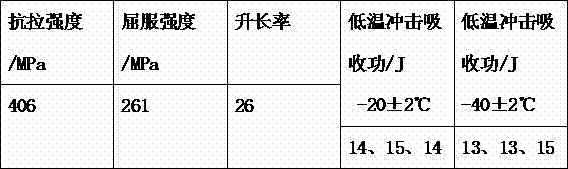

Method for producing two brand numbers of low-temperature ductile irons by adopting molten iron

ActiveCN103882175AGuaranteed nodularityImprove preprocessing effectProcess efficiency improvementChemical compositionSulfur

The invention discloses a method for producing two brand numbers of low-temperature ductile irons by adopting molten iron. The method comprises the following steps: simultaneously adding pig iron, steel scrap, scrap returns, recarburizing agent and scrap iron into a medium-frequency induction furnace, then adding 75 silicon iron; then adjusting Si and Mn to be in a scope required by base iron; melting the molten iron till the temperature reaches 1480-1500 DEG C, pouring the molten iron into a porous plug desulfurization molten iron ladle, simultaneously adding a desulfurization agent, introducing nitrogen into the porous plug so that the desulfurized molten iron rolls over; feeding the desulfurized molten iron to an induction electric furnace, simultaneously adding the recarburizing agent which needs to be supplemented in the furnace, increasing the temperature of the molten iron in the furnace to be 1500-1520 DEG C, preserving heat, standing for 5-10 minutes and adjusting chemical components of the molten iron in the furnace; preprocessing the molten iron and carrying out spheroidizing inoculation, pouring at a temperature of 1330-1350 DEG C and adding 0.15% sulphur oxide stream inoculants during the pouring process; opening a box when the temperature of casting is less than or equal to 300 DEG C. The method is capable of producing products of two different brand numbers (QT350-22AL and QT400-18AL), thus providing convenience for the production.

Owner:江苏力源金河铸造有限公司

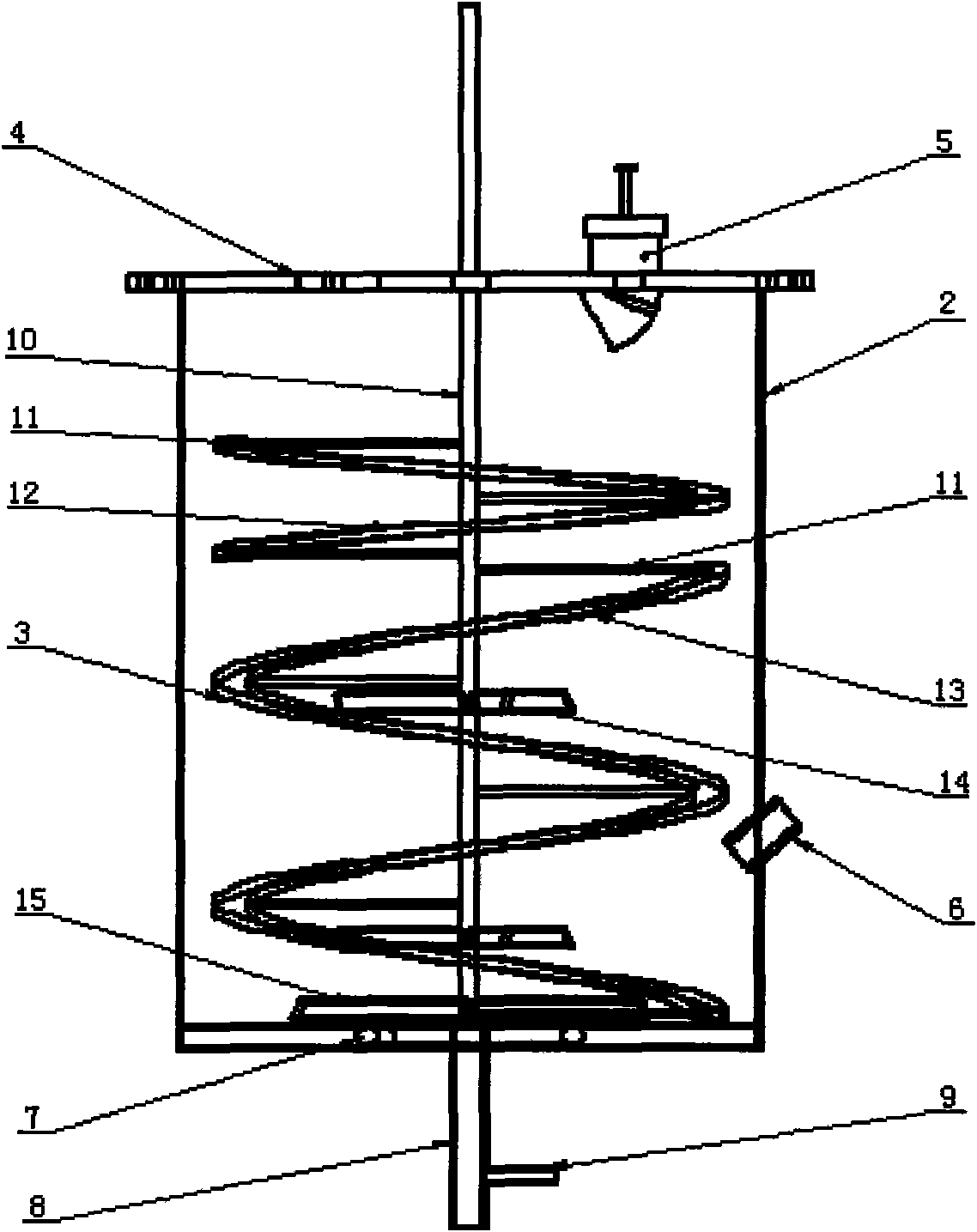

Bioreactor for producing ethanol by using lignocellulose materials with high solid content

InactiveCN101886038AAvoid lostWell mixedBioreactor/fermenter combinationsBiological substance pretreatmentsCelluloseProcess engineering

The invention relates to a bioreactor for producing ethanol by using lignocellulose materials with high solid content, which at least comprises a tank body; a feeder comprises a rubbing unit, the tank body is provided with a charge opening, a discharge opening, a sterile air inlet, a gas disperser and a sensor jack. An anti-spiral screw belt is located at the upper part of the combined agitator blade and the direction of the screw belt is opposite to that of the screw belt of the combined agitator blade. The invention has the advantages that the enzymolysis and fermentation efficiencies of the lignocellulose materials which are rubbed by the feeder are increased, the combined agitator blade ensures that the materials in the tank body are mixed adequately, and transfer mass and heat, the anti-spiral screw belt eliminates the high viscosity bubble or bubble layer generated by the system immediately, parameters are measured accurately under the condition that the positioning way of the sensor does not influence the full mixing and transferring of the system; and the gas disperser disperses the gas introduced to the tank under the condition of not influencing that the system is adequately mixed and transferred.

Owner:EAST CHINA UNIV OF SCI & TECH

Method for blasting plant biomass walls with oxygen

InactiveCN102206928ADecompose thoroughlyBreak down evenlyRaw material divisionProcess engineeringOxygen

The invention discloses a method for blasting plant biomass walls with oxygen, comprising the following steps of: firstly, adding ethanol, hydrogen peroxide with concentration of 30% and water to crushed plant biomass, mixing the materials to oxidize and soak the materials, and conveying the oxidized and soaked materials to an oxygen blasting tank via a feeding port of the oxygen blasting tank; secondly, sealing the feeding port of the oxygen blasting tank, regulating the temperature of the gas in the oxygen blast tank at 80-150 DEG C and the pressure within 1-4 MPa by conveying pressure air to the oxygen blasting tank, preserving heat and keeping pressure for 20-200 seconds to soak the plant biomass into ethanol, hydrogen peroxide with concentration of 30%, steam and water; and finally, completely opening the discharge port of the oxygen blasting tank within 3 seconds to reduce the pressure in the oxygen blasting tank to the normal pressure. The invention aims to provide the method for blasting plant biomass walls with oxygen, which can be used for completely and uniformly decomposing the plant biomass and realizing industrialization production and has high production efficiency.

Owner:BEIJING ZHONGNUO DERUI IND TECH

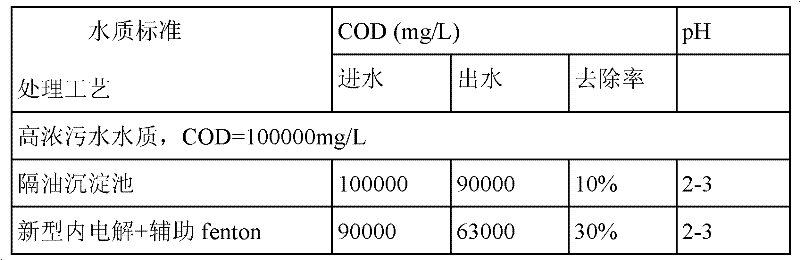

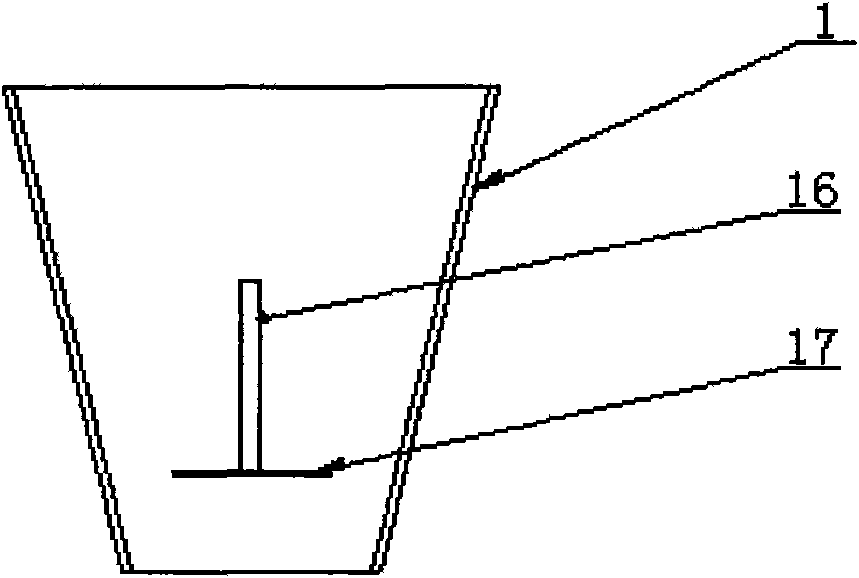

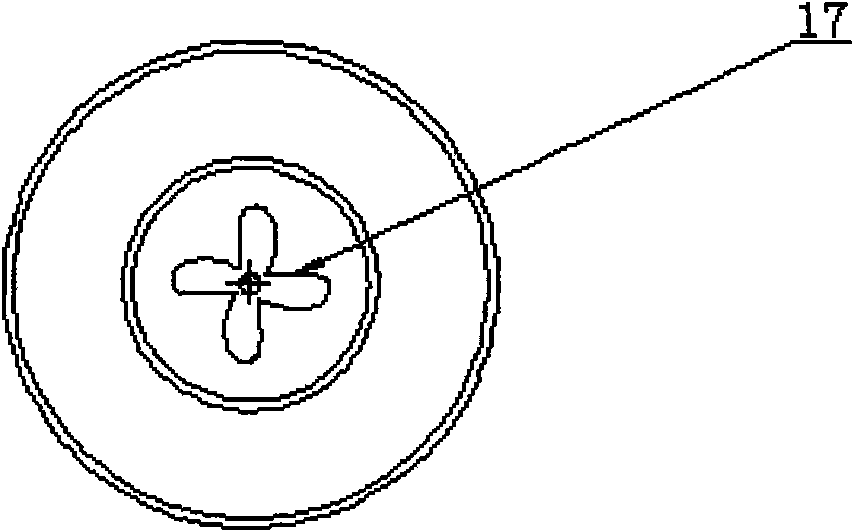

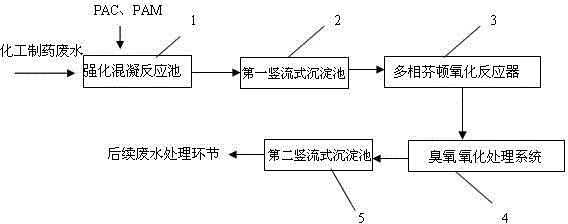

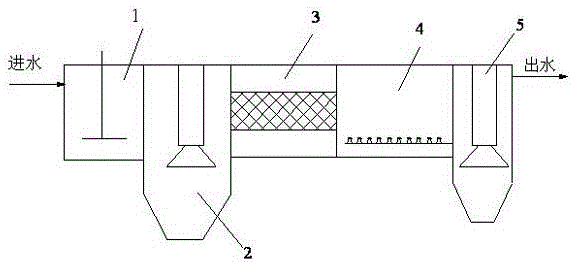

Chemical pharmaceutical wastewater pretreatment enhancement device and enhancement treatment method thereof

ActiveCN104355446AWide pH rangeOxidation reaction rate is fastWater treatment compoundsMultistage water/sewage treatmentPtru catalystEnvironmental engineering

The invention discloses a chemical pharmaceutical wastewater pretreatment enhancement device. The device comprises an enhanced coagulation reaction basin, a first vertical sedimentation basin, a multiphase Fenton oxidation reactor, an ozone oxidation treatment system and a second vertical sedimentation basin which are orderly communicated; and meanwhile, the invention discloses an enhancement treatment method of the device. In comparison with the traditional homogeneous phase Fenton method, the multiphase Fenton oxidation method is wider in suitable pH value, and faster in oxidation rate and better in degradation effect, and can provide catalyst iron ion for the ozone at the same time; the ozone has strong oxidation degradation effect on the organic pollutants in the water, and is capable of converting the complex organic pollutants into simple organics to realize the functions of decoloring, deodorizing, reducing COD and improving biodegradability, and the ozone has the advantages of being fast in speed, good in effect, free from secondary pollution, capable of producing in place and easily obtaining raw materials when reacting with the organic pollutants; and the multiphase Fenton oxidation method and the ozone oxidation form the organic coupling so as to effectively enhance the pretreatment effect of the chemical pharmaceutical wastewater.

Owner:TAIZHOU UNIV

Pretreatment method of lignocellulose by using microwave-assisted alkaline sodium sulfite

The invention discloses a pretreatment method of lignocellulose by using microwave-assisted alkaline sodium sulfite, belonging to the technical fields of biomass resource utilization and agricultural waste comprehensive utilization. The method comprises the following steps: by using lignocellulose as a raw material, pulverizing, screening, and pretreating by using microwave-assisted alkaline sodium sulfite to lower the alkali consumption and enhance the pretreatment effect of the alkaline sodium sulfite; and carrying out solid-liquid separation, flushing the solid residue with an alkaline sodium sulfite solution, and washing with water to obtain the lignocellulose pretreatment product with favorable enzymolysis effect. The method can better remove lignin and reduce the inhibition effect of lignin on cellulose degradation, thereby effectively enhancing the conversion efficiency from lignocellulose to monosaccharide. The method reduces the chemical reagent consumption, is beneficial to environmental protection, and lowers the production cost, thereby generating higher economic value.

Owner:JIANGNAN UNIV

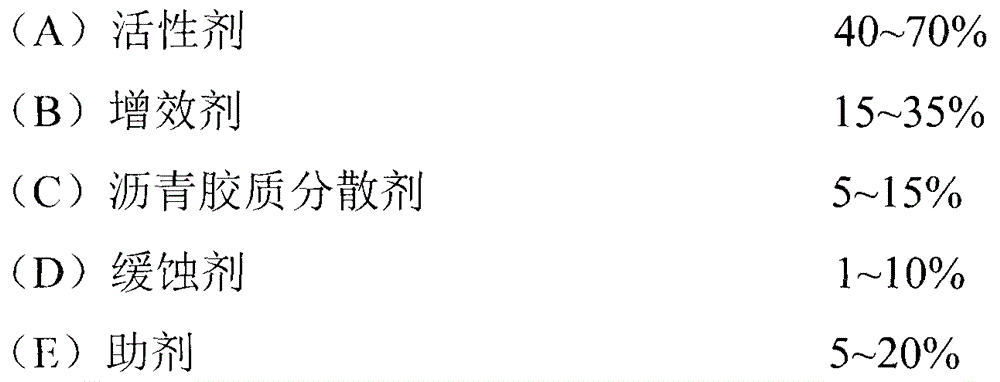

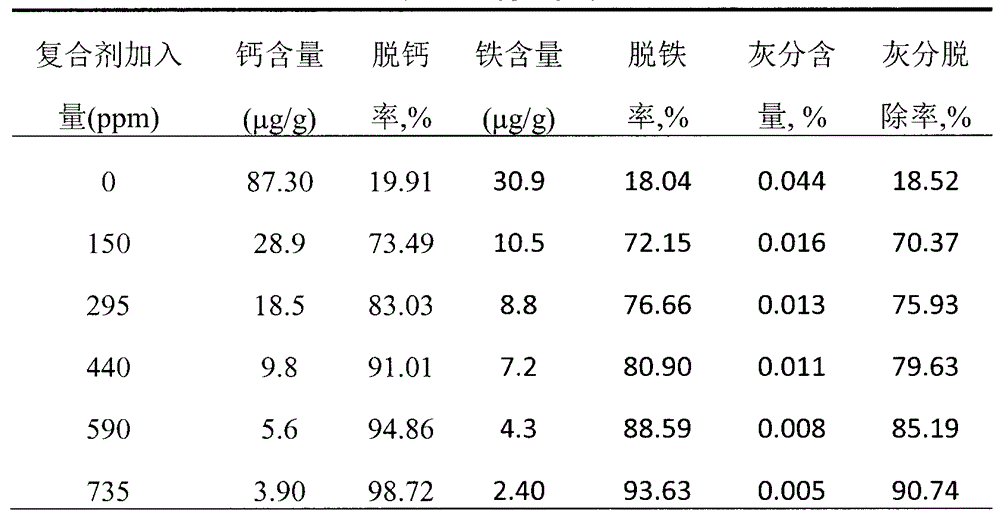

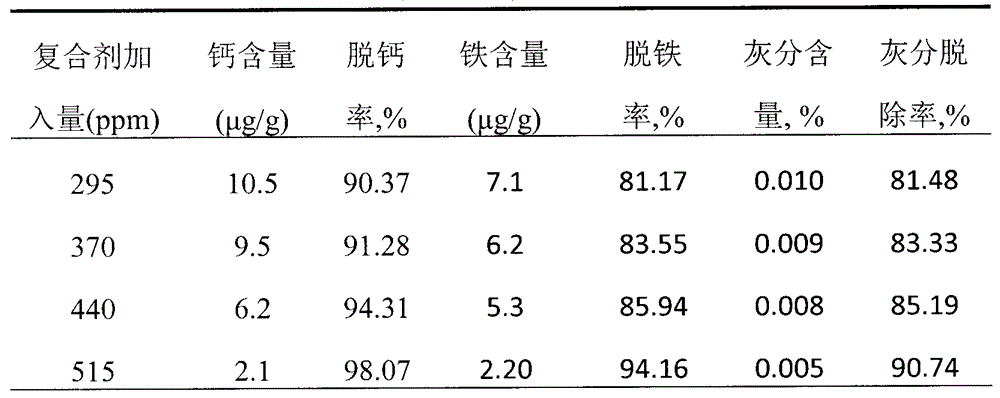

Complexing agent for removing metal and ash in coal tar and use method thereof

InactiveCN105368490AMeet the subsequent hydrogenation process requirementsEasy to operateTreatment with plural serial refining stagesHydrocarbon oils refiningActive agentColloid

The invention discloses a complexing agent for removing metal and ash in coal tar and a use method thereof. The problems that in the prior art, the use amount of a demetallization agent is large, the removal rate is low, and functional groups are limited are solved. The complexing agent is prepared from, by weight, 40%-70% of active agent, 15%-35% of synergist, 5%-15% of pitch colloid dispersant, 1%-10% of corrosion inhibitor and 5%-20% of auxiliary. The complexing agent for removing metal and ash in coal tar is suitable for the fields of coal tar pre-treatment and deep processing. By means of the complexing agent and the method, the use amount of the complexing agent is small, removal efficiency is high, the preparation process is simple, and the use method is convenient.

Owner:LUOYANG PETROCHEMICAL ENG CORP SINOPEC +1

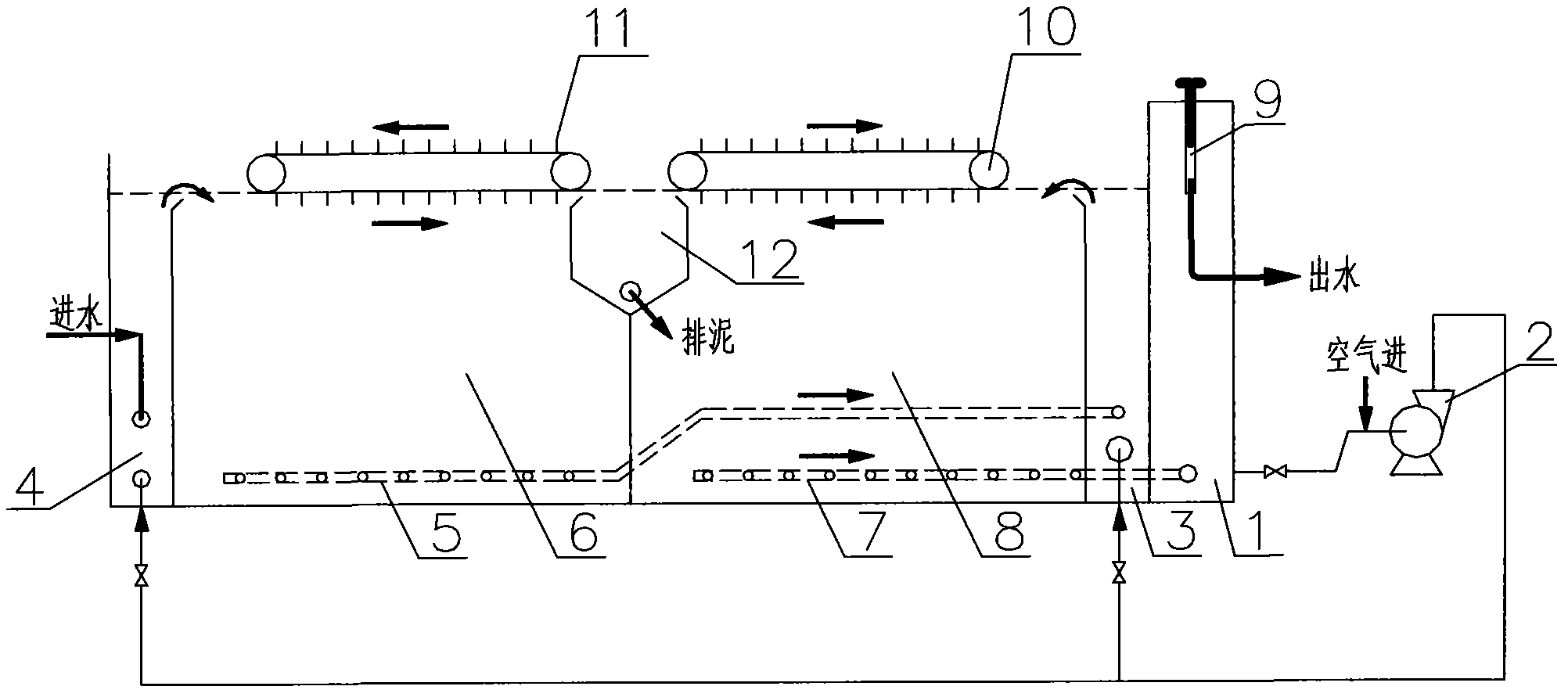

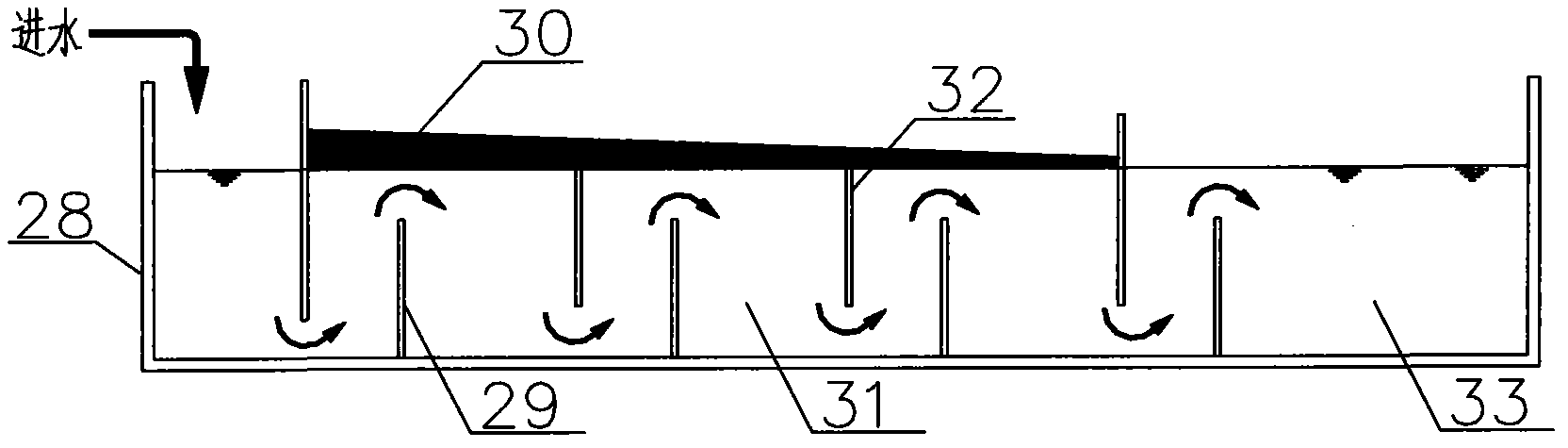

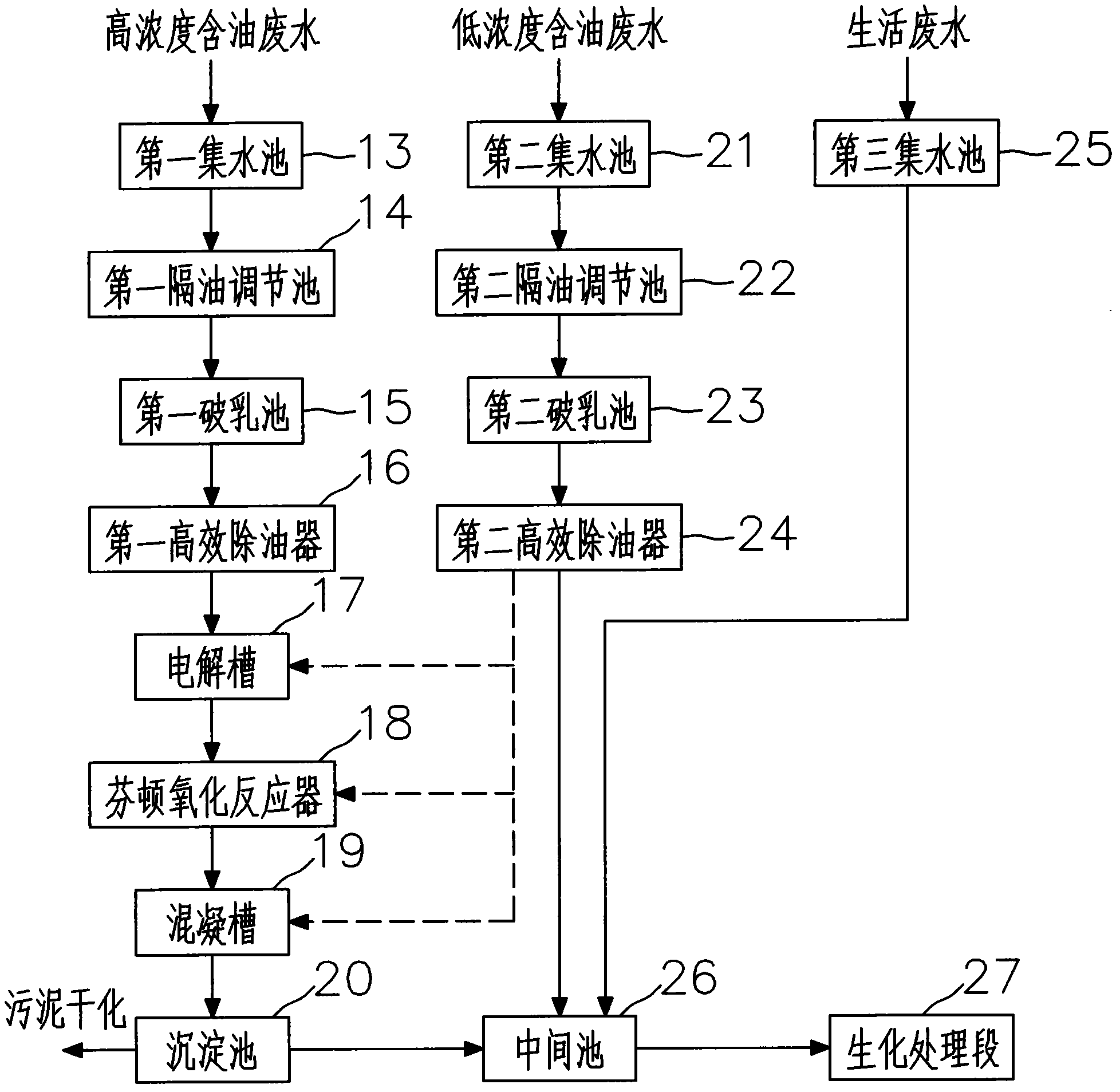

Oily wastewater pretreatment system and high-efficiency oil eliminator arranged in system

ActiveCN102701483APrevent emulsification from reducing the degreasing degree of purificationSimple structureFatty/oily/floating substances removal devicesMultistage water/sewage treatmentHigh concentrationSludge

The invention belongs to the technical field of wastewater treatment and particularly relates to a high-efficiency oil eliminator and an oily wastewater pretreatment system with the high-efficiency oil eliminator. The high-efficiency oil eliminator comprises at least two stages of air floatation treatment devices. An air floatation treatment device at each stage is communicated with an adjacent air floatation treatment device along a water flowing direction. A sludge hopper is arranged on the side of each air floatation treatment device. A sludge scraper which is used for scraping floating sludge in the air flotation treatment device to the sludge hopper is arranged on the upper side of the air flotation treatment device at each stage. The oil eliminator additionally comprises an air dissolving water pump which is used for delivering air dissolving water to the air flotation treatment device through a water delivery pipe. The oily wastewater pretreatment system consists of a high-concentration oily wastewater pretreatment section and a low-concentration oily wastewater pretreatment section. The oily wastewater pretreatment system has the advantages that since a high-concentration and low-concentration oily wastewater quality-based treatment process route is adopted, the operating cost is low and the removal efficiency or degradation efficiency of pollutants is high; and the system is also suitable for pretreatment of all other kinds of high-concentration oily wastewater which is difficult to degrade, or is matched with process units.

Owner:安徽南风环境工程技术有限公司

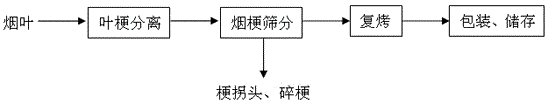

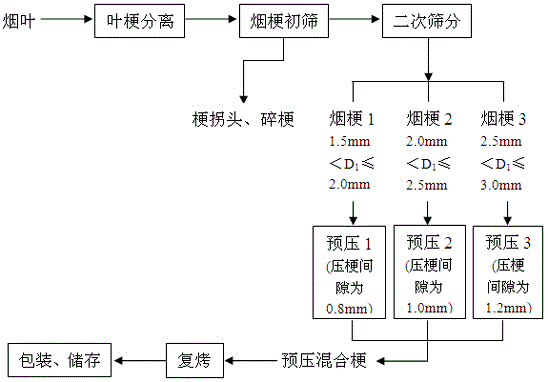

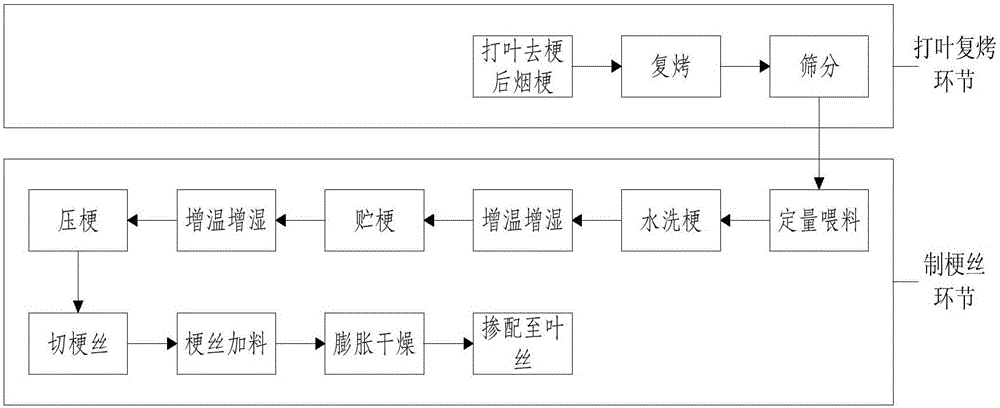

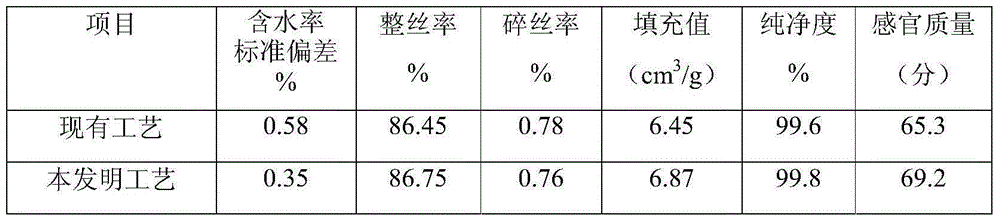

Processing process for threshing, re-drying and classifying tobacco stems

ActiveCN105639715AFacilitate moisture escapeReduce the temperatureTobacco treatmentLoss rateEngineering

The invention discloses a processing process for threshing, re-drying and classifying tobacco stems, which comprises the following steps: firstly performing leaf-stem separation; preliminarily screening stem turning heads and broken stems; then screening the tobacco stems into the three types of tobacco stems with different thicknesses of 1.5-2.0 mm, 2.0-2.5 mm and 2.5-3.0 mm; pre-pressing the three types of tobacco stems, wherein gaps among the pressed stems are 0 .8 mm, 1.0 mm and 1.2 mm respectively; mixing the three types of pre-pressed tobacco stems and re-drying; finally packaging and storing. According to the processing process disclosed by the invention, the tobacco stem re-drying efficiency can be improved, the consistence of the batch water loss rate and the moisture content after re-drying is improved, and the tobacco stem aging progress is accelerated; the tissue destruction difference degree of the tobacco stems with different thicknesses in the cut stem making process is reduced, the stem storage time is shortened, the production efficiency of the cut stem making procedure is improved, the cut stem moisture content fluctuation, the rejection rate and the energy consumption are reduced, and the uniformity of cut stems, the moisture content and the stability of filling values are improved.

Owner:CHINA TOBACCO HENAN IND

Microelectrolytic treatment process of printing and dyeing waste water

PendingCN107352757AImprove biodegradabilityImprove preprocessing effectSludge treatment by de-watering/drying/thickeningWater contaminantsActivated carbonMembrane bioreactor

The invention belongs to the field of treatment of chemical waste water and particularly relates to a microelectrolytic treatment process of printing and dyeing waste water. The microelectrolytic treatment process has the characteristics that an air flotation pool is arranged at the most front end to remove suspended solids in the water, simultaneously carrying out iron-carbon microelectrolytic reaction according to the characteristics of the waste water, carrying out ring opening and chain breaking on nonbiodegradable pollutants in the waste water so as to improve the biodegradability of the waste water, effectively enhance the pretreatment effect and create beneficial conditions for following biochemical treatment; due to addition of a submersible stirring machine in an anaerobic pool, the hydrolytic acidification degree of the waste water is improved; a flat-plate membrane is arranged in an aerobic pool, and by utilization of a membrane bioreactor (MBR) technology, separation of HRT (Hydraulic Retention Time) from SRT (Sludge Retention Time) is realized, sludge load is increased, the biological treatment is stabilized, the SS (Suspended Solid) concentration in the discharged water is effectively reduced and the sewage treatment load is increased, so that the effect of biological treatment of the process is effectively stabilized and the quality of the discharged water is stabilized; and with the purpose of preventing the condition of unstable system operation, active carbon is utilized for adsorption and filtration to guarantee the standard of the discharged water and the deep treatment effect.

Owner:云南今业生态建设集团有限公司

Iron inner electrolysis catalyst and preparation method thereof

InactiveCN101934230ALarger than surfaceImprove oxidation capacityMolecular sieve catalystsWater/sewage treatment by sorptionMolecular sievePre treatment

The invention relates to catalysts for treating industrial waste water, in particular to an iron inner electrolysis catalyst and a preparation method thereof. The iron inner electrolysis catalyst comprises the following components: simple copper supported by molecular sieves, manganese dioxide supported by molecular sieves, and natural manganese ore with the mass ratio thereof being 1:0.5-1.0:0.5-1.0. The preparation method thereof comprises the following steps: respectively immersing roasted molecular sieves in the solutions of soluble copper salt and manganese salt by the supporting capacity of copper and manganese dioxide; dipping, drying and roasting the molecular sieves to respectively obtain the copper oxide and manganese dioxide supported by the molecular sieves; crushing and sieving the natural manganese ore to obtain the natural manganese ore granules; reducing the copper oxide supported by the molecular sieves by using hydrogen to obtain the simple copper supported by the molecular sieves; and mixing the simple copper supported by molecular sieves, manganese dioxide supported by molecular sieves, and natural manganese ore granules by the mass ratio to obtain the product. Accordingly, the invention is suitable for the pre-treatment before the biochemical treatment of high-chromaticity non-biodegradable industrial waste water.

Owner:XIAMEN UNIV

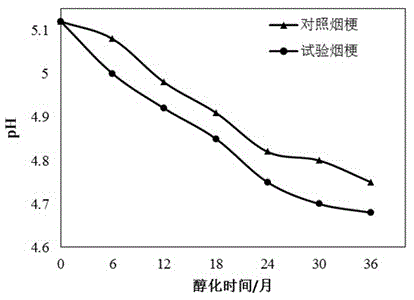

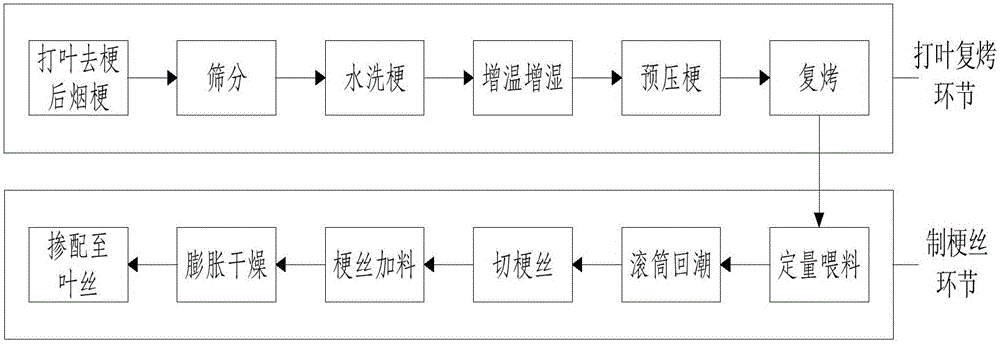

Processing method for pre-pressing threshed and re-dried tobacco stems and producing cut stems

InactiveCN105077563AGood hygroscopicityImprove preprocessing effectTobacco treatmentPulp and paper industryMoisture

The invention discloses a processing method for pre-pressing threshed and re-dried tobacco stems and producing cut stems, and belongs to the technical field of tobacco processing. The processing method comprises the following steps: sieving tobacco stems obtained by threshing tobacco leaves, washing the stems with water, increasing temperature and humidity, pre-pressing the stems, re-drying, quantitatively feeding, regaining moisture by virtue of a roller-type moisture regaining machine, cutting the tobacco stems so as to obtain cut stems, charging the cut stems, and expanding and drying so as to obtain the cut stems. The processing method disclosed by the invention can be used for simplifying a cut stem production technological flow, shortening cut stem production processing time and reducing energy consumption; in the process of producing the cut stems, an effect of preprocessing the tobacco stems is good and the obtained cut stems are uniform in quality; the moisture content stability and the filling performance of the cut stems are increased, and the purity and the sensory quality of the cut stems are slightly improved, so that a purpose of increasing the using proportion of the cut stems in a cigarette formula is improved.

Owner:CHINA TOBACCO ANHUI IND CO LTD

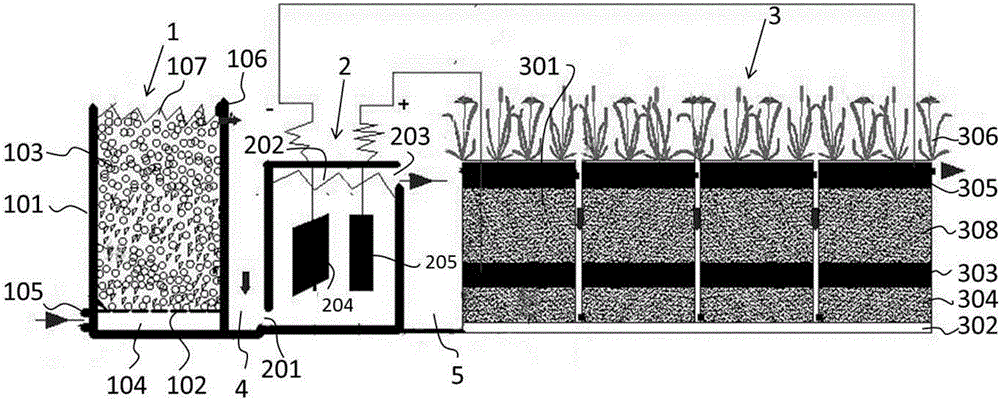

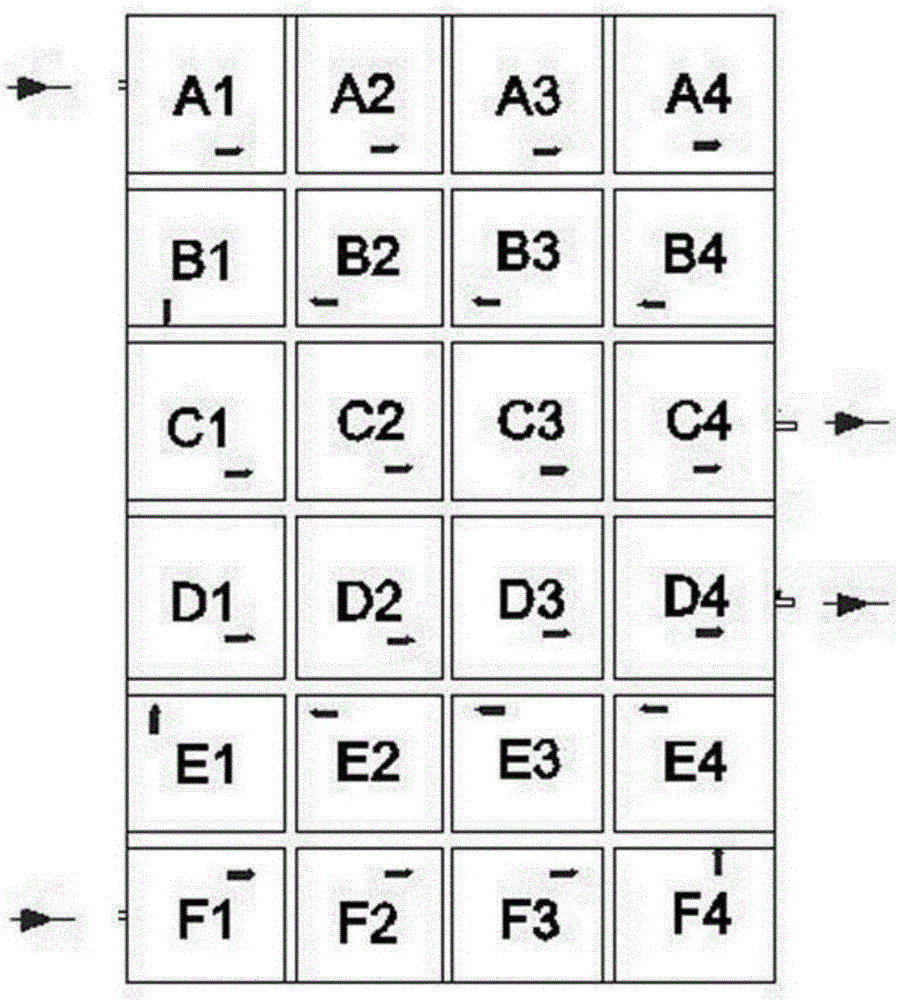

Electro-Fenton wastewater treatment system based on arrayed wetland microbial fuel cell powering and wastewater treatment method

ActiveCN106746230AImprove power generation performanceImprove biodegradabilityTreatment by combined electrochemical biological processesWater contaminantsTreatment systemWater treatment

The invention discloses an Electro-Fenton wastewater treatment system based on arrayed wetland microbial fuel cell powering and a wastewater treatment method. The system comprises: a nano iron-carbon micro-electrolytic reaction region for pretreating wastewater; an Electro-Fenton system reaction region for treating effluent from the nano iron-carbon micro-electrolytic reaction region; arrayed wetland microbial fuel cells for treating effluent from the Electro-Fenton system reaction region and treating the effluent, wherein the arrayed wetland microbial fuel cells refer to a wetland microbial fuel cell bank formed by connecting a plurality of wetland microbial fuel cells; cathode and anode of the wetland microbial fuel cell bank are connected to corresponding anode and cathode of the Electro-Fenton system reaction region through wires respectively. The invention also provides the wastewater treatment method. The joint action of the whole system brings enhanced degrading action with no need for additional energy or fed reagents, and the method is an energy-saving environment-friendly water treatment technique.

Owner:SOUTHEAST UNIV

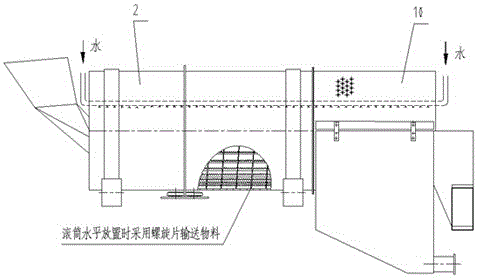

Drum screening machine and application thereof in oil sludge treatment

InactiveCN105688489AEasy to handleEasy to cleanGrain treatmentsMoving filtering element filtersStone particleEngineering

The invention provides a drum screening machine and an application method thereof in oil sludge treatment. The drum screening machine is mainly characterized by comprising a front crushing and tearing device and a rear treatment device, wherein a drum body comprises a screen-mesh-containing drum body and a screen-mesh-free drum body which are connected through subsection welding or through a connecting part, a water spraying device penetrating through the drum body or arranged in a subsection manner is arranged in the drum body, a feeding device is mounted at a feed port in the front end of the drum body, a receiving hopper capable of separating light and heavy impurities is mounted at an impurity discharge port in the rear end of the drum body, and a discharge hopper is mounted at a qualified material discharge port in the lower part of the screen-mesh-containing drum body. The drum screening machine has the advantages that the operation is simple, safe and reliable, oil sludge is sent to the front crushing and tearing device to tear and crush large stone particles, tiles, plastic cloth, woven bags and the like in the material, a to-be-treated material is uniformly sent into the feeding end by a feeding machine, qualified materials discharged from the qualified material discharge end are sent for follow-up treatment, and meanwhile, clean combustible materials with the recovery value are discharged in a classified manner from the impurity discharge end.

Owner:马玉刚

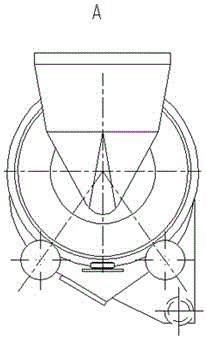

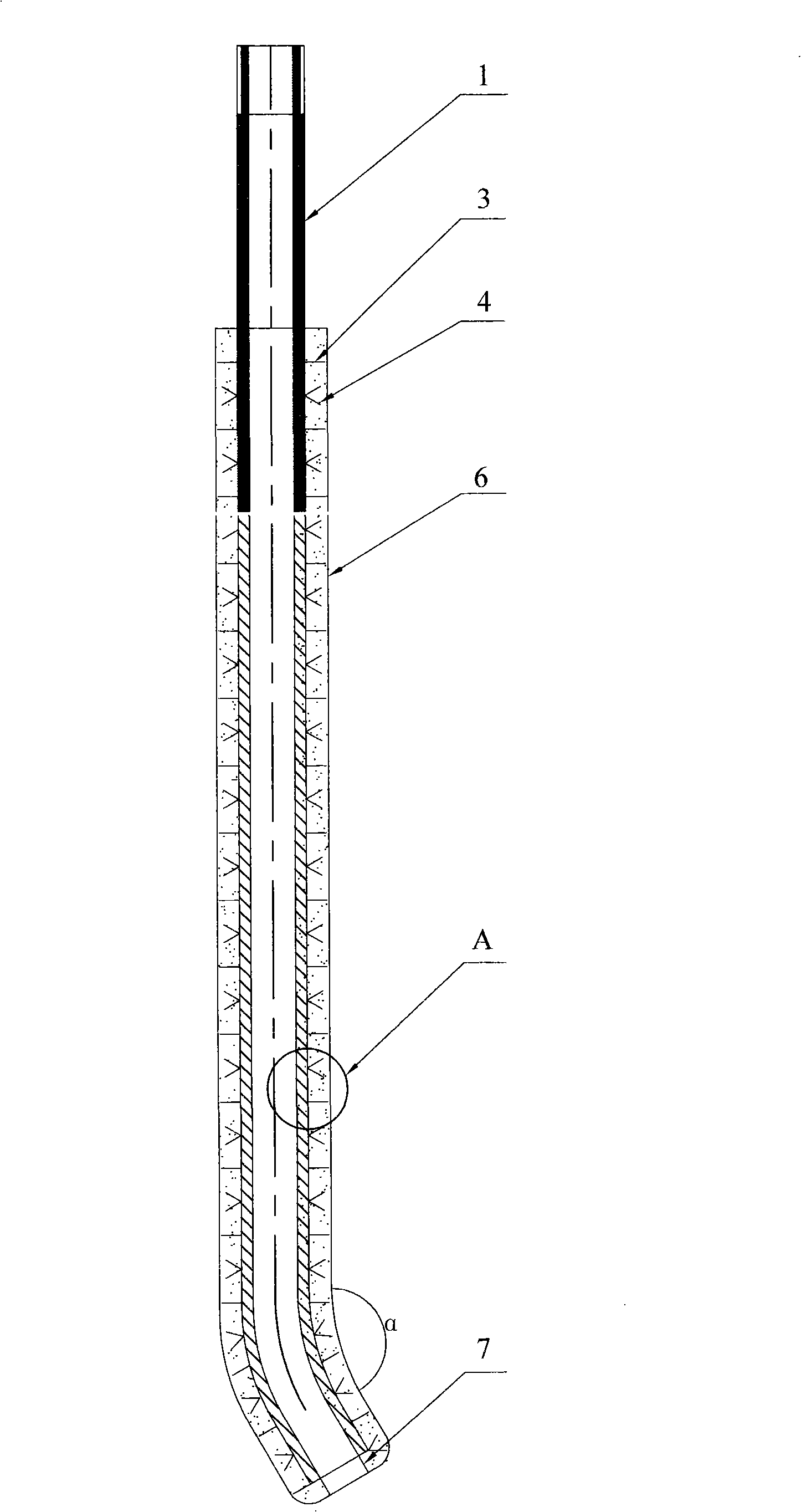

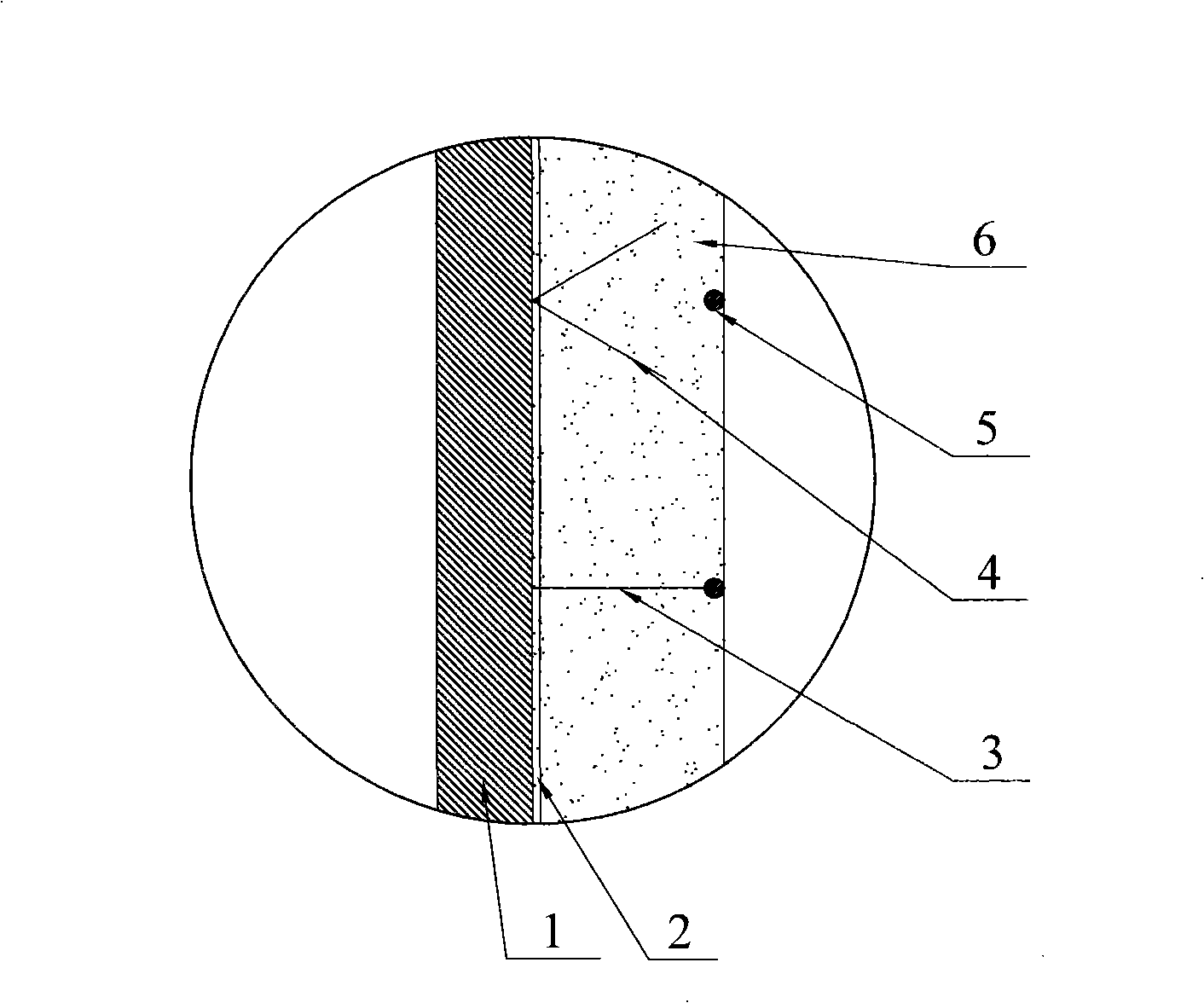

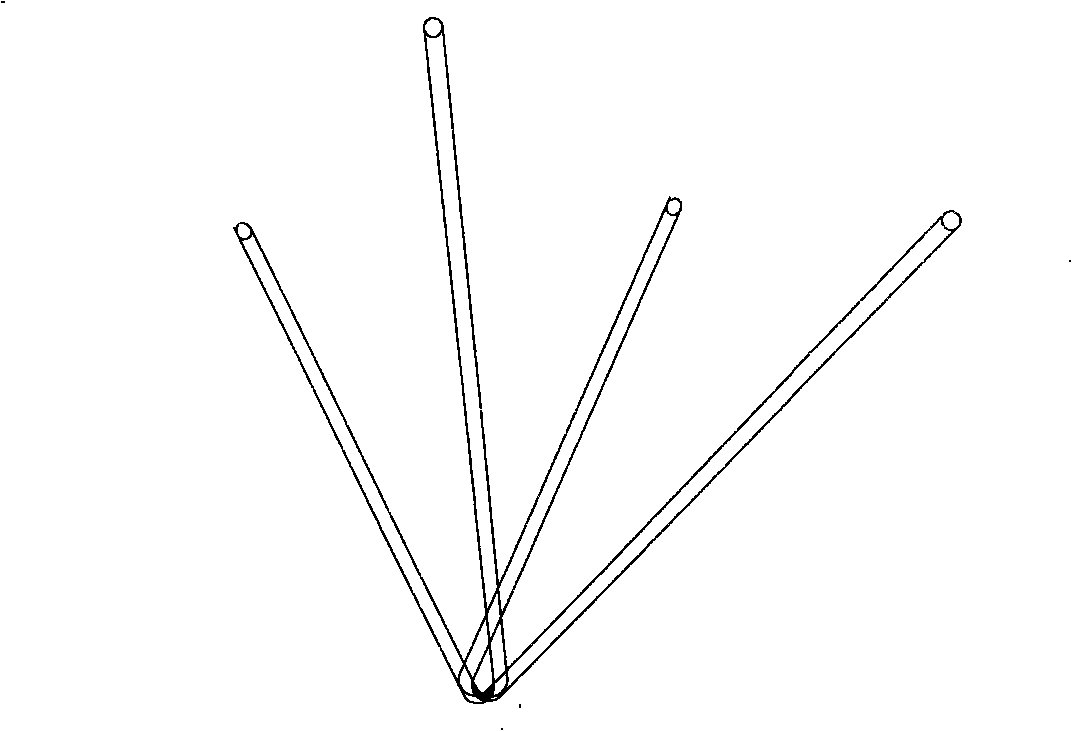

Angle-inserting type hot metal pretreatment spray gun

InactiveCN101337210AExtended service lifeEasy to paintCharge manipulationLiquid spraying apparatusBogieRefractory

The invention discloses an inclined-inserting hot metal pretreatment spraying gun, which is used for jetting treatment for hot metal on a mixing bogie with torpedo retort. The spraying gun comprises a gun core steel pipe, a gun lining made of refractory material, and a plurality of rivet clasping pieces; the lower end of the gun core steel pipe tilts and forms an included angle of 120 to 140 degrees with the longitudinal axial line of the gun core steel pipe; the outer surface of the gun core steel pipe is covered with the gun lining made of the refractory material; each rivet clasping piece is composed of a V-shaped rivet clasping piece, a double-V butterfly-shaped rivet clasping piece and an annular rivet clasping piece, wherein the V-shaped rivet clasping piece and the double-V butterfly-shaped rivet clasping piece are respectively arranged in a working lining made of the refractory material at intervals along the circumferential direction and the axial direction of the gun core steel pipe, and welded with the external circumference surface of the gun core steel pipe; the annular rivet clasping piece is welded at the outer end of the V-shaped rivet clasping piece; the outer surface of the gun core steel pipe is coated with a burning weight-loss coating layer formed by mechanical lubricating oil and polypropylene powder, wherein the weight percentage of the mechanical lubricating oil is 90 to 99 percent, and the weight percentage of the polypropylene powder is 1 to 10 percent. Finally, the purposes of prolonging the service life of the spray gun and improving the service performance of the spray gun are achieved.

Owner:WUHAN IRON & STEEL (GROUP) CORP +1

Pan grinder bleaching process of italian poplar APMP pulp and process optimizing method

InactiveCN1350091AImprove the extrusion effectImprove prepreg effectChemical/chemomechanical pulpColor printingBleach

The present invention discloses an optimized disc-grinding and bleaching process of Italian poplar pulp, and is mainly characterized by that in first stage of disc grinding adding bleaching agent to make disc grinding and bleaching to make pulp, and optimizing the processes of wood chips washing, presteaming, extruding, soaking, second-stage grinding, screening and bleaching so as to reduce the consumption of chemicals for making Italia poplar APMP pulp and raise its quality. Said invention uses 20-50% matched quantity of APMP pulp, and can make high-grade colored printing news-paper, offset printing book-magazine paper, double gummed paper and LWC (light weight coating) paper, etc.

Owner:YUEYANG FOREST & PAPER CO LTD

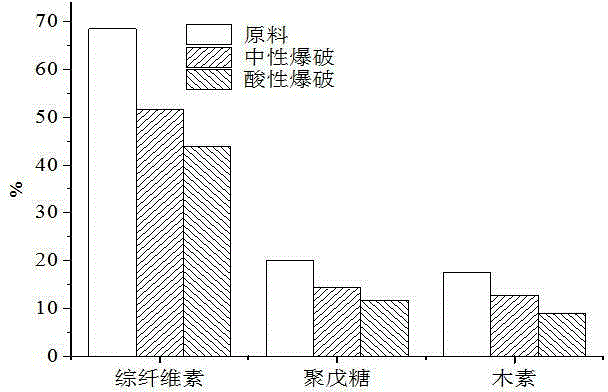

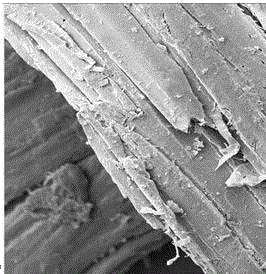

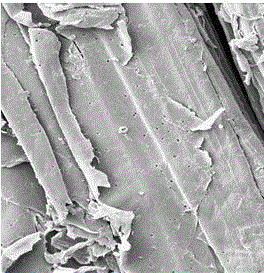

Method for pretreating ethyl alcohol produced from corn straws

InactiveCN104878055AReduce the amount of sulfuric acidImprove preprocessing effectBiofuelsFermentationChemistryMoisture

The invention discloses a method for pretreating ethyl alcohol produced from corn straws. The method comprises the following steps: taking corn straws as a raw material, pulverizing the corn straws, and conducting air drying to obtain corn straw powder; balancing moisture in the corn straw powder, adding water and acid liquor, conducting slightly acidic medium pressure steam explosion pretreatment, after hydrolysis reaction is finished, conducting centrifugal separation on the exploded sample and hydrolysate, and separately collecting a sample a and a hydrolysate I; balancing moisture in the corn straw powder, conducting neutral steam explosion pretreatment, after hydrolysis reaction is finished, conducting centrifugal separation on the exploded sample and hydrolysate, and separately collecting a sample b and a hydrolysate II; washing the sample a and the sample b subjected to prehydrolysis to be clean, and mixing so as to obtain a cellulose substrate used for follow-up enzymolysis fermentation. According to the method, a scientific overall process is provided, the pretreated sample obtains excellent application effects on the aspect of ethyl alcohol preparation through enzyme hydrolysis, and certain technical guidance is provided for the engineering application of converting the corn straws into the biological ethyl alcohol.

Owner:SOUTH CHINA UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com