Oily wastewater pretreatment system and high-efficiency oil eliminator arranged in system

A degreaser and pretreatment technology, applied in flotation water/sewage treatment, oxidized water/sewage treatment, water/sewage multi-stage treatment, etc., can solve complex molecular structure, high pollutant concentration, large oil content, etc. problems, to achieve the effect of low operating cost, compact equipment layout, and increased effective volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

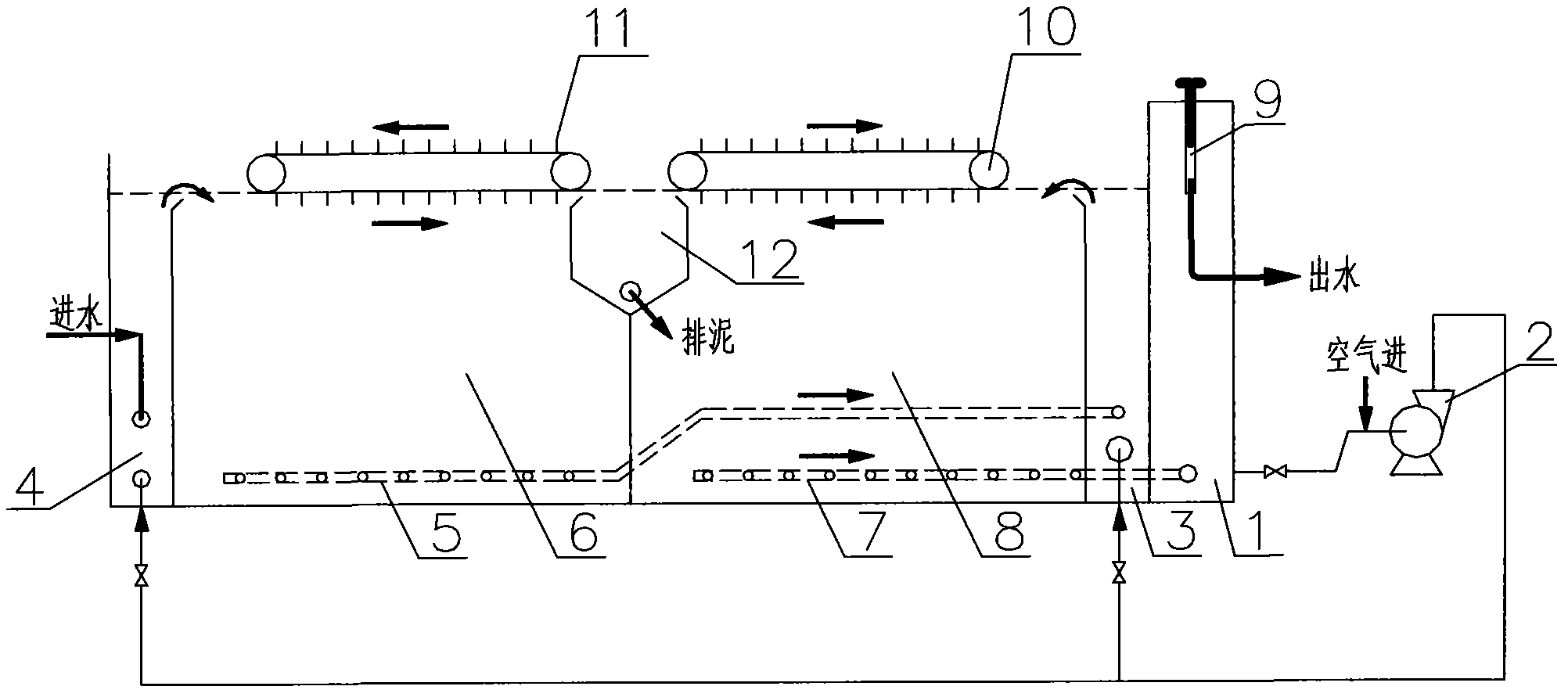

[0048] Such as figure 1 As shown, the degreaser is composed of a first-stage air flotation treatment device and a second-stage air flotation treatment device. The first-stage air flotation treatment device is composed of a first water inlet chamber 4 and a first air flotation chamber 6. The first stage air flotation treatment device is composed of the second water inlet chamber 3 and the second air flotation chamber 8; the first air flotation chamber 6 and the second air flotation chamber 8 are adjacent to each other, and the mud bucket 12 is sandwiched between the first Between the air flotation chamber 6 and the second air flotation chamber 8; the first water inlet chamber 4 is arranged on the side of the first air flotation chamber 6 away from the second air flotation chamber 8, and the second water inlet chamber 3 is arranged on The side of the second air flotation chamber 8 far away from the first air flotation chamber 6; It is connected with the water outlet chamber 1 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com