Complexing agent for removing metal and ash in coal tar and use method thereof

A technology of coal tar and compounding agent, which is applied in the petroleum industry, refining hydrocarbon oil, and only multi-stage serial refining process treatment, etc., can solve the problems of large amount of demetallization agent, limited functional groups, and low removal rate, and achieve the expected Good treatment effect, simple operation, and the effect of improving the removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

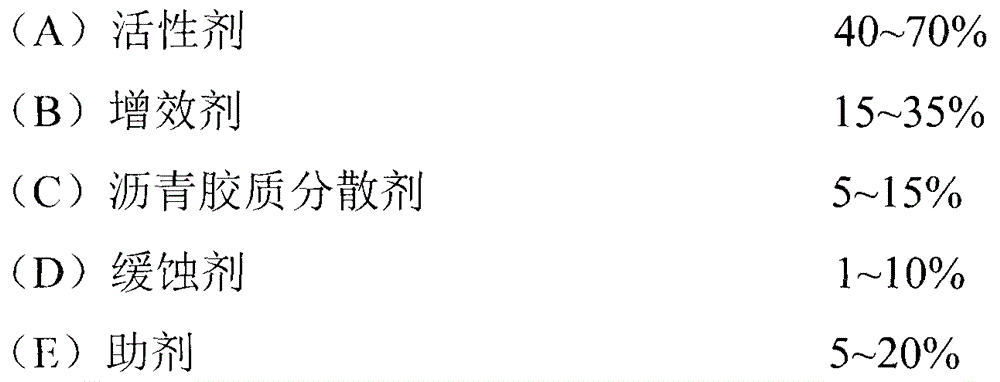

[0033] Compound agent DM1, its composition is A: disodium edetate 50%; B: oxalic acid 20%; C: dodecylbenzenesulfonic acid 10%; D: hydroxyethylidene diphosphonic acid 5%; E: water 15%

[0034] The above active agent A, synergist B, asphalt colloidal dispersant C, corrosion inhibitor D, and auxiliary agent E were prepared according to weight percentage, and stirred and reacted at 60°C for 30 minutes to obtain the metal and ash removal product in coal tar. Complex agent DM1.

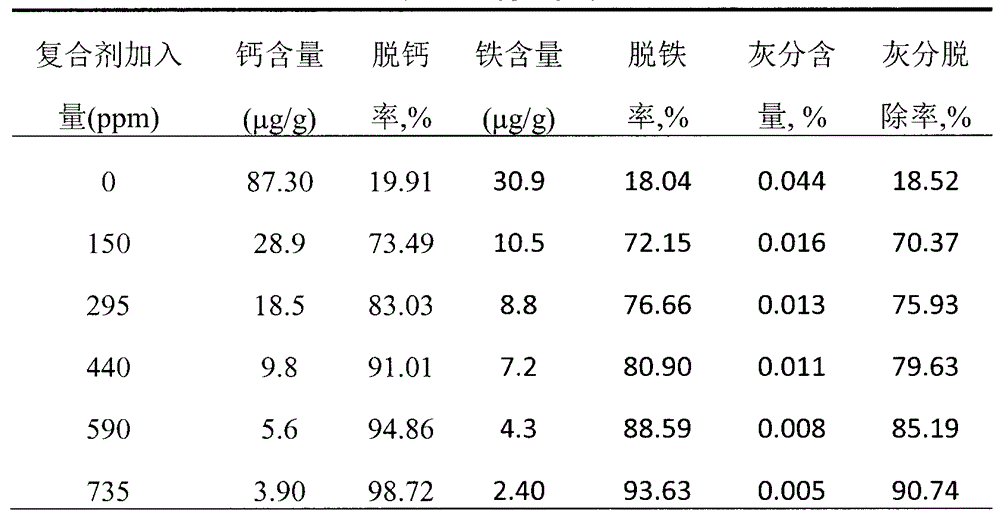

[0035] The coal tar in this embodiment is Shaanxi low-temperature coal tar. The coal tar is a black waxy substance, opaque, and has a pungent and unpleasant taste. Inferior oil products with high content of , asphaltenes and aromatics, and coal tar contains a large number of impurity elements that are not conducive to subsequent hydroprocessing. The coal tar has a water content of about 2%, a salt content of 10mg / L, a relatively high calcium and iron content in the metal content of 109μg / g and 37.7μg / g, a...

Embodiment 2

[0041] Compound agent DM2, its composition is A: disodium edetate 60%; B: maleic anhydride 25%; C: dodecylbenzenesulfonic acid 5%; D: hydroxyethylidene diphosphonic acid 5%; E: Water 5%.

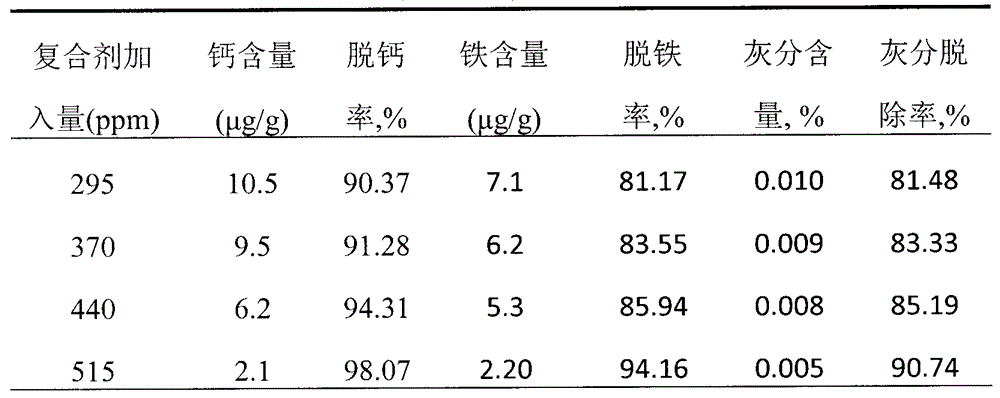

[0042] The preparation method of composite agent DM2 is the same as DM1 in Example 1, and in addition, the test oil is also the same as Example 1. Inject the demulsifier GT940 20ppm into the coal tar, add fresh water 10%wt, mix evenly, preheat to 80°C and enter the three-phase centrifuge for high-speed centrifugation, the centrifugation speed is 3000r / min, and the centrifugation time is 6min; centrifugation The final coal tar raw material is mixed with complex agent DM2, demulsifier GT940 and water, further heated to 120°C, and reacted for 30 minutes; then desalted and dehydrated by electricity to obtain treated raw material oil. The electric desalination conditions are: electric desalination temperature 120°C, residence time 30min, electric field strength 700V / cm, demulsifier GT940 dosage ...

Embodiment 3

[0046] The composite agent DM3 is composed of A: 65% sodium hexametaphosphate; B: 20% oxalic acid; C: 5% dodecylbenzenesulfonic acid; D: 5% aminotrimethylene phosphonic acid; E: 5% water.

[0047] The preparation of composite agent DM3 is the same as DM1 in Example 1, and the test oil is also the same as Example 1. Inject fresh water 10%wt, demulsifier ERI116020ppm into this coal tar, after mixing evenly, preheat to 80 ℃ and enter three-phase centrifuge to carry out high-speed centrifugation, centrifugation speed is 3000r / min, centrifugation time is 6min; After centrifugation The coal tar raw material is mixed with complex agent DM3, demulsifier ERI1160 and water, further heated to 120°C, and reacted for 30 minutes; then desalted and dehydrated by electricity to obtain treated raw material oil. The electric desalination conditions are: electric desalination temperature 120°C, residence time 30min, electric field strength 700V / cm, demulsifier ER11160 dosage 20ppm, electric desa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com