Method for producing two brand numbers of low-temperature ductile irons by adopting molten iron

A technology of molten iron and low temperature, which is applied in the field of producing two grades of low-temperature ductile iron in molten iron, which can solve problems such as production inconvenience, achieve convenient production, improve the effect, and improve the effect of low-temperature impact absorption energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

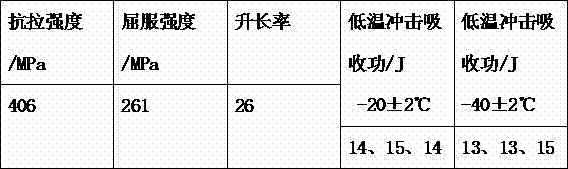

[0031] The technical solutions of the present invention will be described in detail below in conjunction with specific embodiments.

[0032] 1. Raw materials

[0033] 1.1 Ingredients

[0034] The mass percentage of each component in the raw material is: pig iron 60±2%, scrap steel 10±2%, and returned material 30±2%; the amount of auxiliary materials: recarburizer is 0.2% of the raw material mass, 75 ferrosilicon is 0.5% of the raw material mass , the nodulizer is 0.9-1.0% of the tapped iron mass, the inoculant is 0.35-0.45% of the tapped iron mass, and the flow inoculant is 0.1-0.15% of the tapped iron mass.

[0035] 1.2 Selection of raw materials

[0036] 1.2.1 Pig iron

[0037] Pig iron with high purity is used, and the harmful elements Mn, P, S and trace elements Cr, Ti, V are all low, so that the final mechanical properties of the casting can be improved. The chemical composition is as follows:

[0038] C 4.25% Si 0.15% Mn 0.016% P 0.023% S 0.006%

[0039] Cr 0.03...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com