Method for preparing commercial vehicle steering gear housing

A technology for steering gears and commercial vehicles, which is applied in the direction of manufacturing tools, casting molding equipment, metal processing equipment, etc., and can solve problems such as easy cracking of products, unqualified pearlite content, shrinkage cavities and shrinkage porosity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Example 1 product model, 1139395

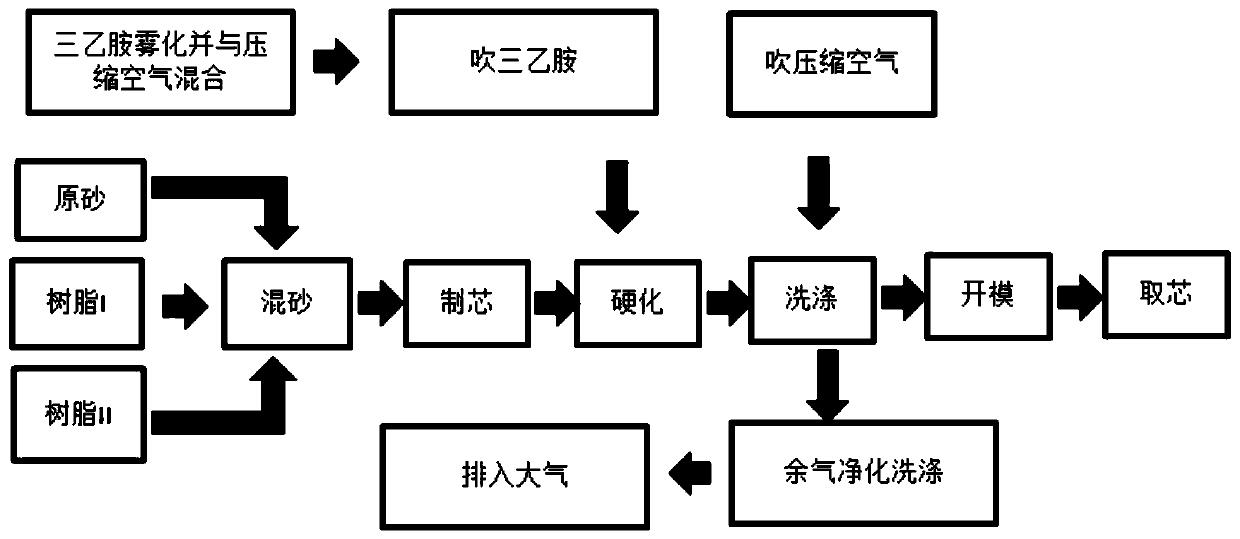

[0052] A method for preparing a commercial vehicle steering gear housing, including the production of cold sand cores, the design steps of the composition of the original molten iron, the casting process steps, the use of the cover core, and the design steps of the low-tension pressure riser; the casting process steps include the top injection process Steps and iron mold covered with sand chilled iron.

[0053] The production of the cold sand core, the specific steps are as follows: the ratio of raw materials is as follows: the amount of furan resin added accounts for 0.8% of the weight of the original sand, the proportion of type I resin in furan resin accounts for 50%, the proportion of type II resin accounts for 50%, and the amount of catalyst added It accounts for 0.2% of the weight of the original sand; add the raw materials for sand mixing, and then perform core making, hardening, washing, mold opening, and core removal in sequen...

Embodiment 2

[0071] Embodiment 2 product model, 1138395.

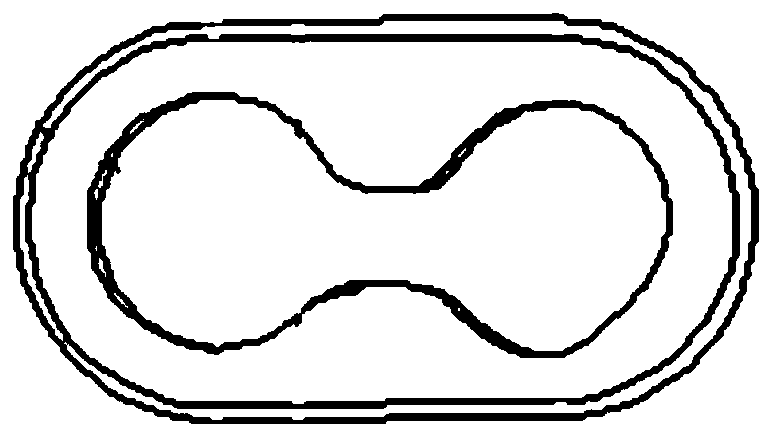

[0072] Please fill in the parameters that have changed. The following iron mold is made of sand-coated cold iron with a length of 110mm, a width of 50mm and a thickness of 15mm, and the sand-coated process in the middle; refer to Figure 9 .

Embodiment 3

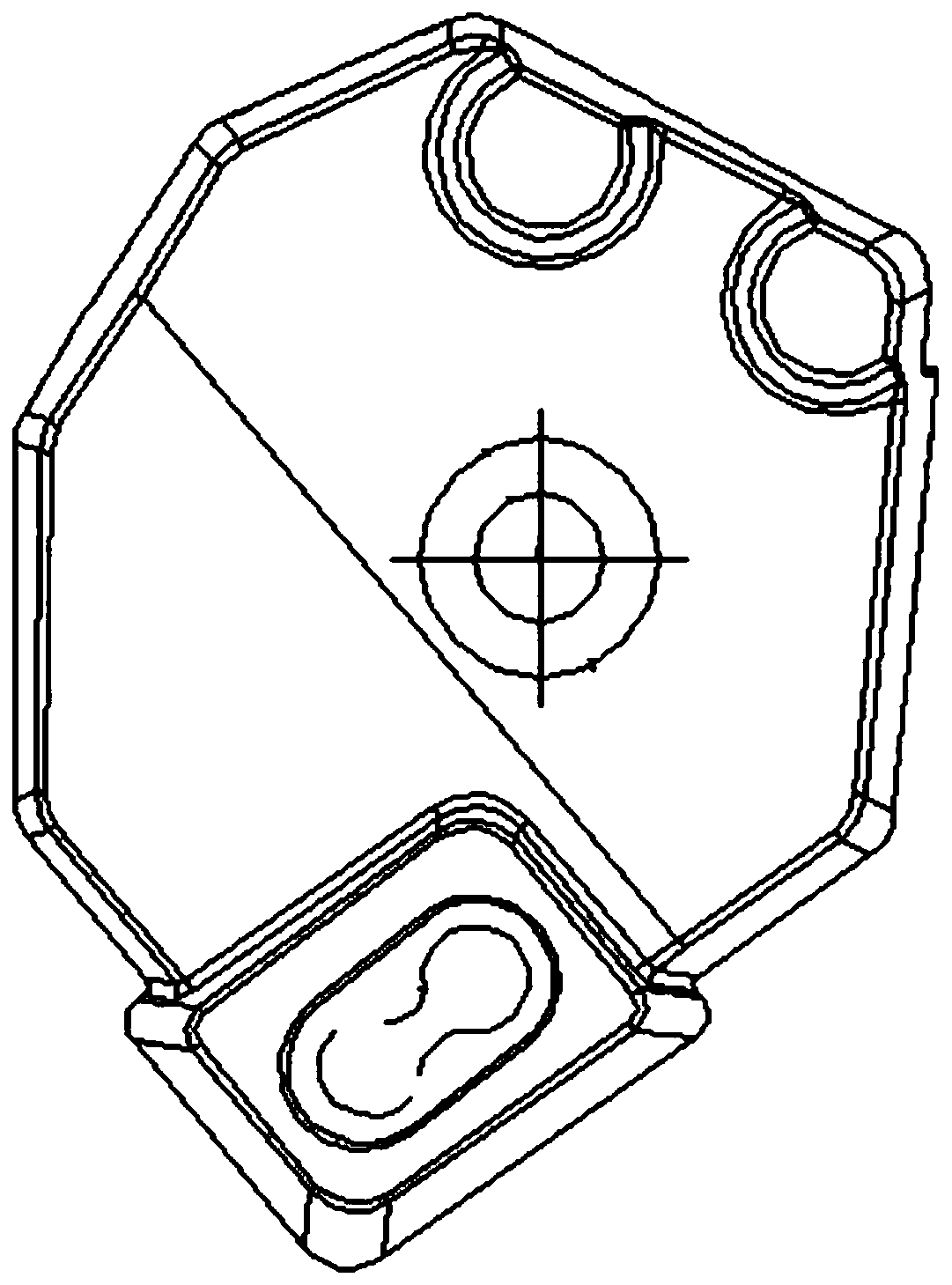

[0073] Embodiment 3 product model 1139865.

[0074] Please fill in the parameters that have changed. The following iron mold is made of sand-coated cold iron with a length of 110mm, a width of 45mm and a thickness of 10mm, and the sand-coated process in the middle; refer to Figure 10 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com