Bioreactor for producing ethanol by using lignocellulose materials with high solid content

A lignocellulose, high solids content technology, applied in liquid production bioreactors, solid-phase fermentation bioreactors, special-purpose bioreactors/fermenters, etc., to achieve the effect of improving conversion rate and enhancing metabolic capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

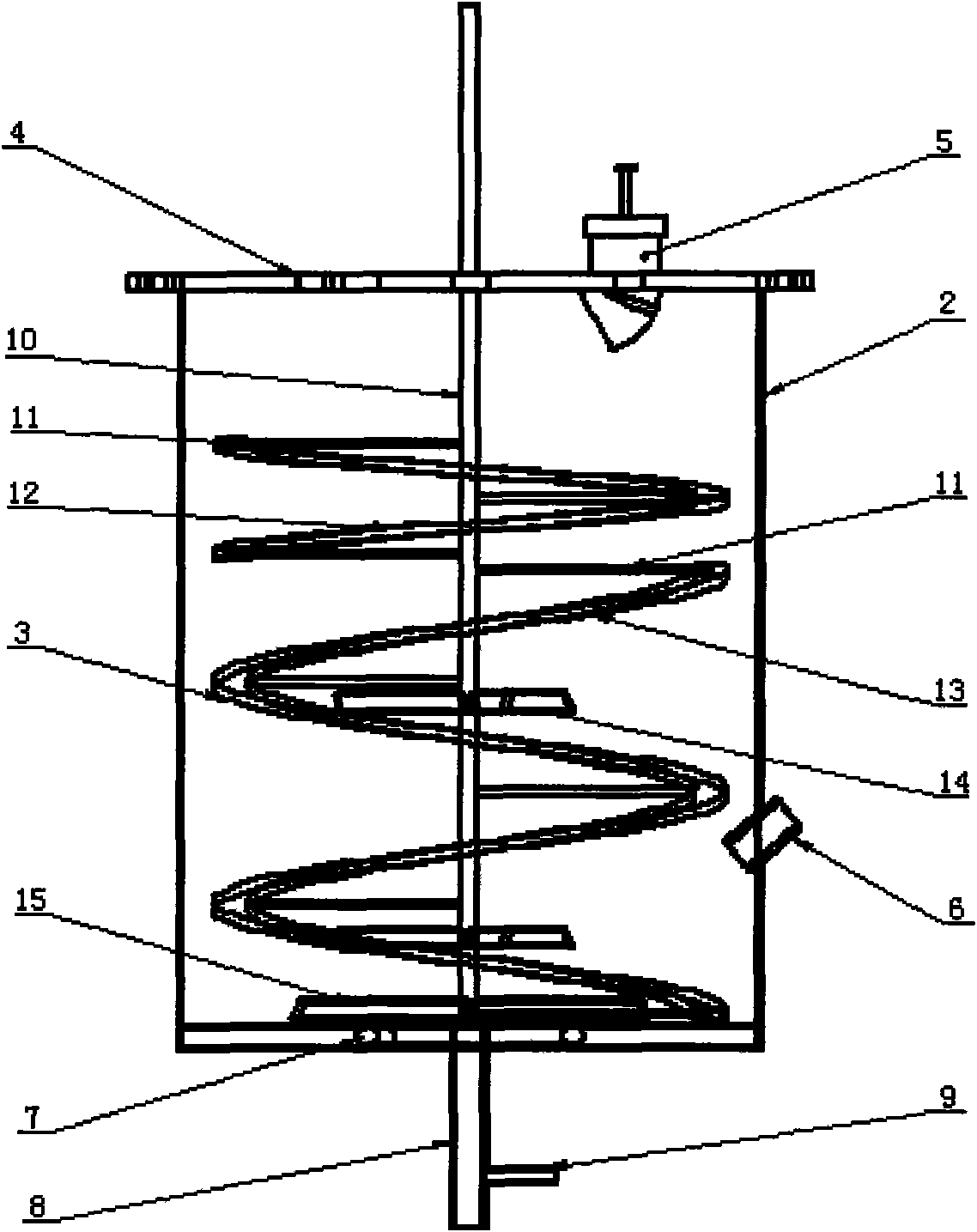

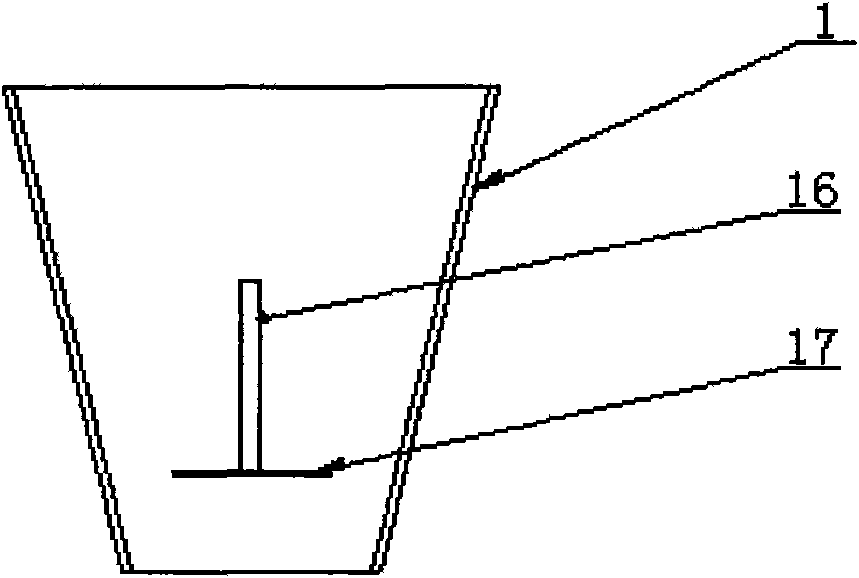

[0026] A specific embodiment of a reactor for producing ethanol by fermenting lignocellulosic raw materials with high solid content of the present invention is provided below.

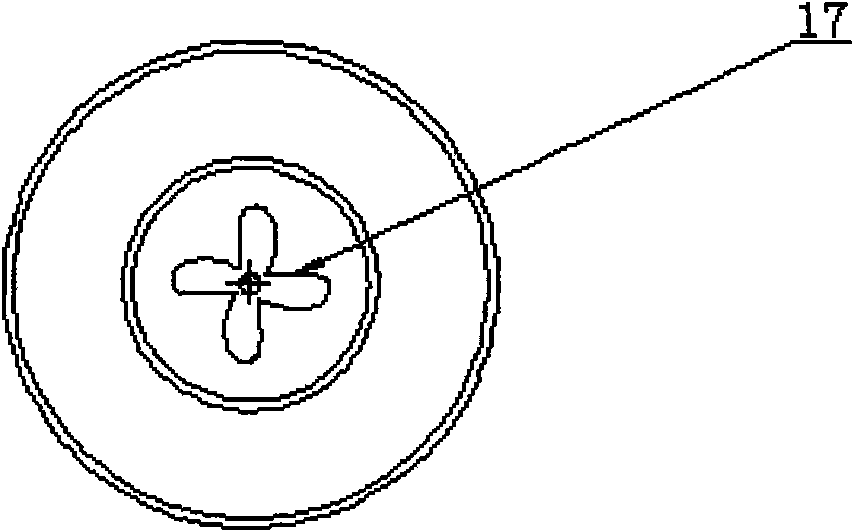

[0027] Please see attached Figure 1-3 , a high solid content lignocellulosic raw material fermentation ethanol production reactor, at least including a tank 2; the upper end of the tank 2 is provided with a feeding port 5 and a tank cover 4, the lower end is provided with a discharge port 8, and the tank body 2 is provided with There are sensor jacks 6 and combined stirring paddles 3; the combined stirring paddles 3 include a positive spiral propeller 13, a turbine / airfoil stirring impeller 14 and a bottom propeller 15; the positive spiral propeller 13 is fixed on the stirring shaft 10 through a support rod 11 and circle around the stirring shaft 10 from top to bottom to form a frame; On the stirring shaft 10 between the ends, the number of layers of the turbine / airfoil stirring paddle 14 is 1 to 3 l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com