Processing method for pre-pressing threshed and re-dried tobacco stems and producing cut stems

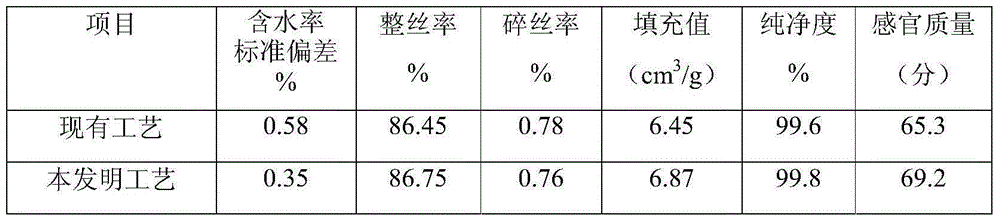

A processing method and technology for re-cured tobacco, which are applied in the directions of tobacco, tobacco processing, application, etc., can solve the problems of poor penetration effect of tobacco stems, uneven quality of cut stems, affecting the quality of cut stems, etc., and achieve good processing effect and shortening Processing time, effect in favor of technical parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

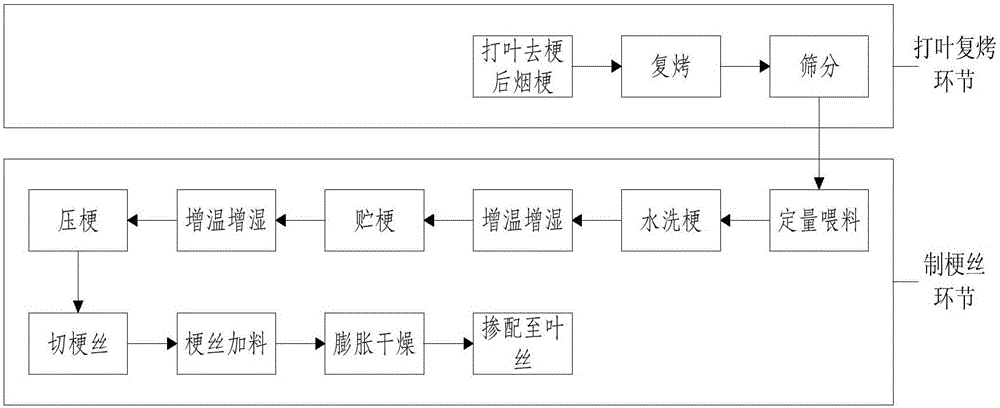

Method used

Image

Examples

Embodiment 1

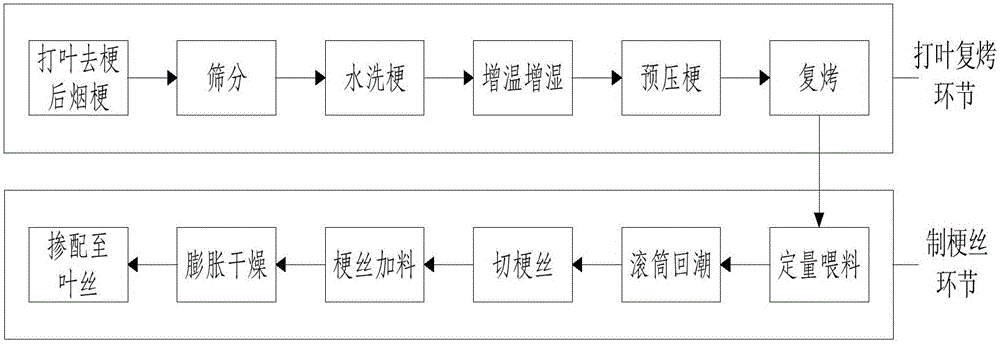

[0029] The equipment used in the processing technology of threshing and redrying tobacco stems for pre-pressing and shredded stems are all general-purpose equipment for tobacco. The processing technology of the present invention is to partially adjust the existing tobacco stem processing technology: (1) Add water-washing stem, warming and humidifying and stem-pressing equipment in the re-drying process; (2) Remove the water-washing stem, stem-pressing and temperature-increasing and humidifying equipment in the stem-making process, and add roller moisture regaining equipment; (3) After moisture regaining Tobacco stalks do not need to be stored, so cut the stalks directly.

[0030] The processing method of threshing and redrying tobacco stems and shredded stems in this embodiment includes sieving, washing stems, warming and humidifying, pre-pressing stems, redrying, quantitative feeding, drum remoisture, cutting stems, cutting stems, and adding Expansion drying steps are as follows...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com