Production process for producing biobase natural gas with coproduction of lignose and microcrystalline cellulose from bamboo processing wastes

A technology of microcrystalline cellulose and production process, which is applied in the directions of lignin derivatives, waste fuels, gas fuels, etc., to achieve great social benefits, realize the utilization of waste resources, and improve the gas production rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

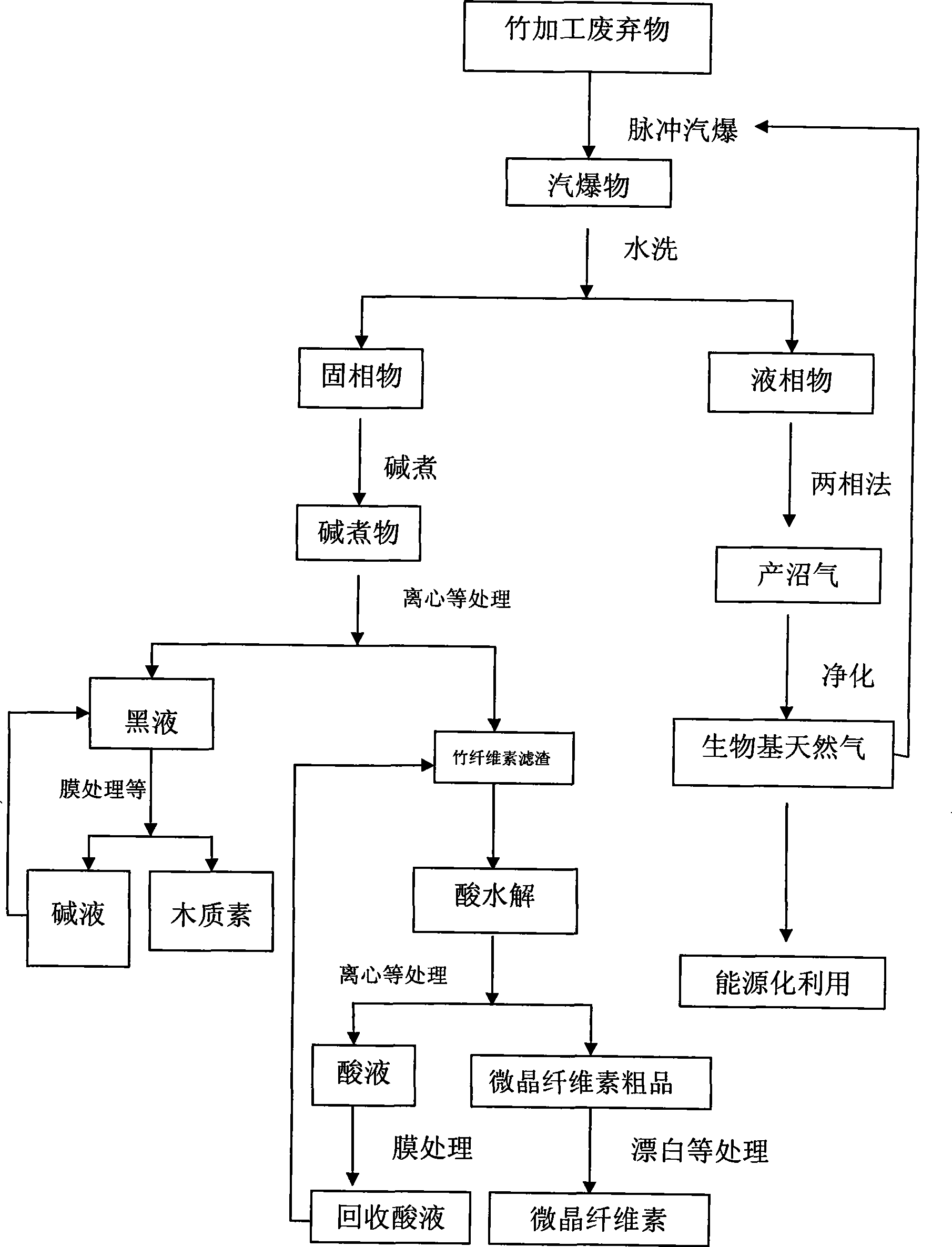

[0041] Referring to Figure 1, the production process of using bamboo processing waste to produce bio-based natural gas, lignin and microcrystalline cellulose includes the following steps:

[0042] A. Steam explosion pretreatment

[0043] Take 100kg of bamboo shavings and fill the explosion chamber of the steam explosion machine in stages, pulse steam explosion conditions: hold the pressure for 9 minutes under a pressure of 1.5MPa to obtain steam explosion materials;

[0044] B. Extraction and separation of steam explosives

[0045] According to the weight ratio of steam explosive: water=1:5, water is added to the steam explosive and fully stirred, and the solid phase and liquid phase are obtained through centrifugal or pressing separation;

[0046] C. The liquid phase is produced by anaerobic fermentation to produce biogas:

[0047]Adjust its pH value to 7.0 with lye, pump it into three methanogenic tanks, and then add 20% swamp mud to carry out anaerobic fermentation. Gas ...

Embodiment 2

[0057] Get 100kg of bamboo chips or bamboo sawdust to fill the explosion chamber of the steam explosion machine in stages, and after holding the pressure for 0.5min (30s) under the pressure of 4.0MPa, carry out pulse steam explosion to obtain steam explosion; according to steam explosion: water = With a weight ratio of 1:10, water is added to the vapor to stir thoroughly, and the solid phase and liquid phase are obtained by centrifugation or pressing. The liquid phase is used for anaerobic fermentation to produce biogas with the same embodiment 1. Add 3 times the volume mass fraction of 1% sodium hydroxide solution to the solid phase, cook at a temperature of 100° C. for 3.5 hours to obtain a cooked product; after cooling the cooked product, centrifuge to obtain about 500 kg of black liquor and about 210 kg of bamboo cellulose filter residue. The black liquor is filtered with a tube membrane to remove suspended matter, and then concentrated with a nanomembrane to remove water ...

Embodiment 3

[0059] Technology and method are the same as embodiment 1, what adopt when just separating lignin in " black liquor " is the method for acetic acid neutralization: promptly add 5%-10% acetic acid solution in black liquor and wherein sodium hydroxide, then 5-10% acetic acid solution is used to adjust the pH value of the solution in the range of 1.5-5.5 to precipitate lignin, separate the precipitated lignin, and use the residue for fermentation to produce bio-based natural gas.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com