Papermaking-process tobacco sheet production wastewater pretreatment equipment

A technology for tobacco flakes and waste water production, which is applied in biological water/sewage treatment, water/sewage treatment, water treatment parameter control, etc. It can solve the problems of underutilization of flocculation agents, large dosage of agents, and influence of biochemical treatment, etc. , to achieve the effect of good pretreatment effect, less chemical input and high treatment efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

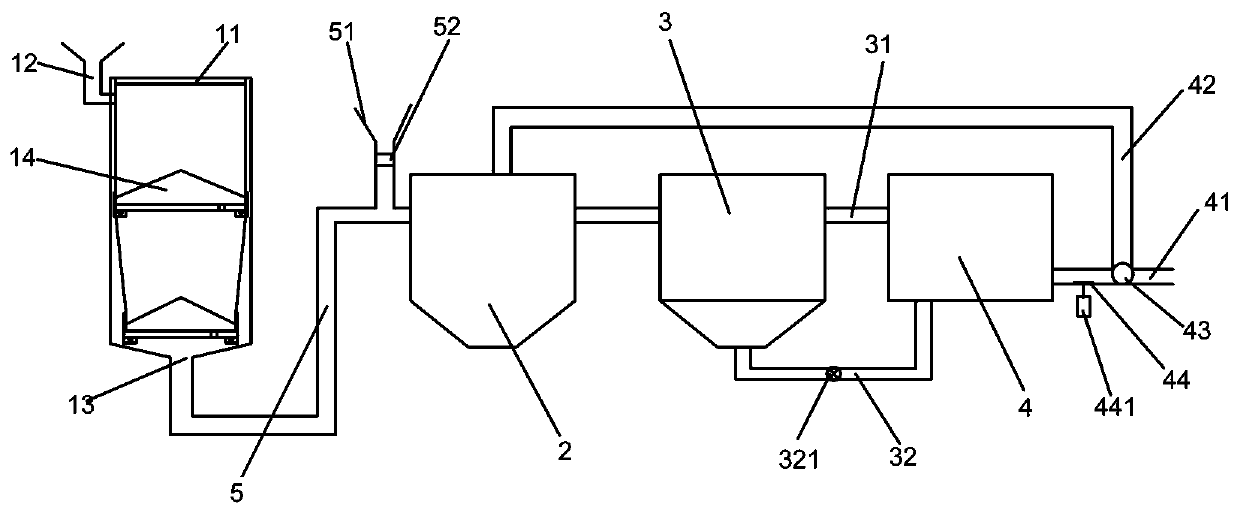

[0026] Example 1: as Figures 1 to 3 As shown, it is only one of the embodiments of the present invention, a papermaking method tobacco sheet production wastewater pretreatment equipment, including a water collection well 1, a flocculation sedimentation tank 2, an air flotation tank 3 and a microsand flocculation sedimentation tank 4, the collection The water well 1 includes a cover body 11 arranged on the upper side of the water collecting well 1, a feeding port 12 arranged on the side wall of the water collecting well 1, a material outlet 13 arranged on the lower side of the water collecting well 1, and a material outlet 13 arranged on the lower side of the water collecting well 1. The filter grid 14 in the water collecting well 1, the discharge port 13 of the water collecting well 1 and the flocculation sedimentation tank 2 are connected by a dosing pipe 5, and the flocculation sedimentation tank 2 is communicated with the air flotation tank 3, The air flotation tank 3 is p...

Embodiment 2

[0031] Embodiment two, still as Figures 1 to 3 As shown, it is only one of the embodiments of the present invention, in order to make the treatment effect of a kind of papermaking method tobacco sheet production wastewater pretreatment equipment of the present invention better, and the degree of stability is higher, the present invention also has the following designs:

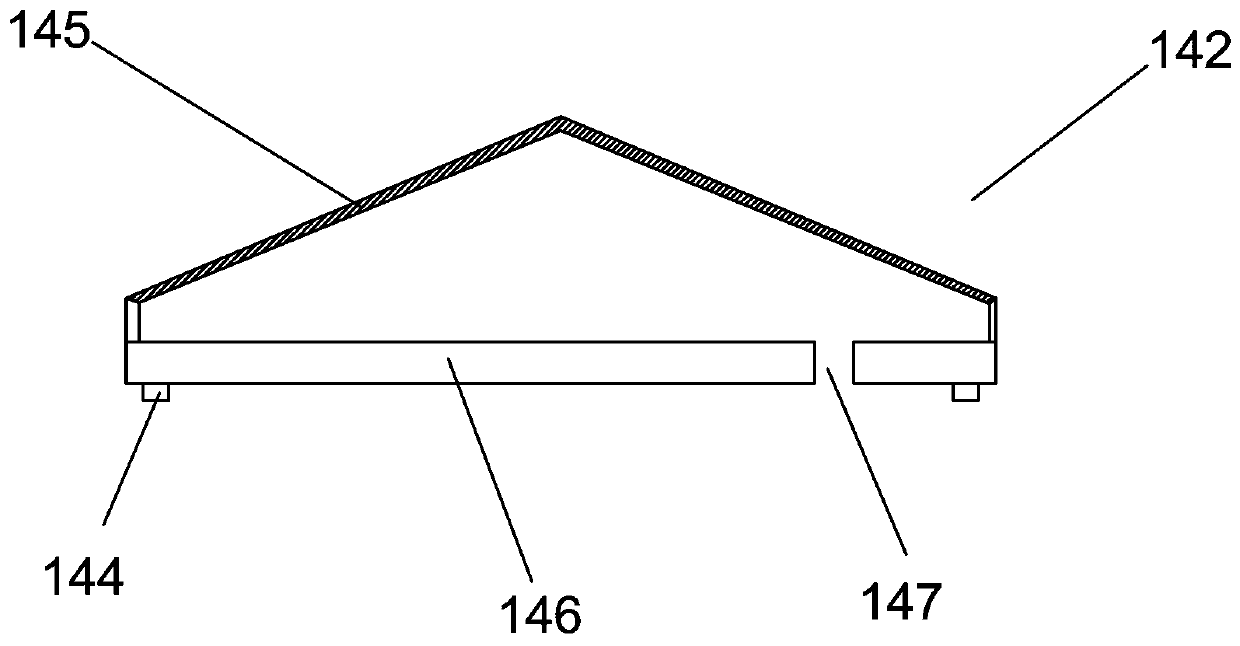

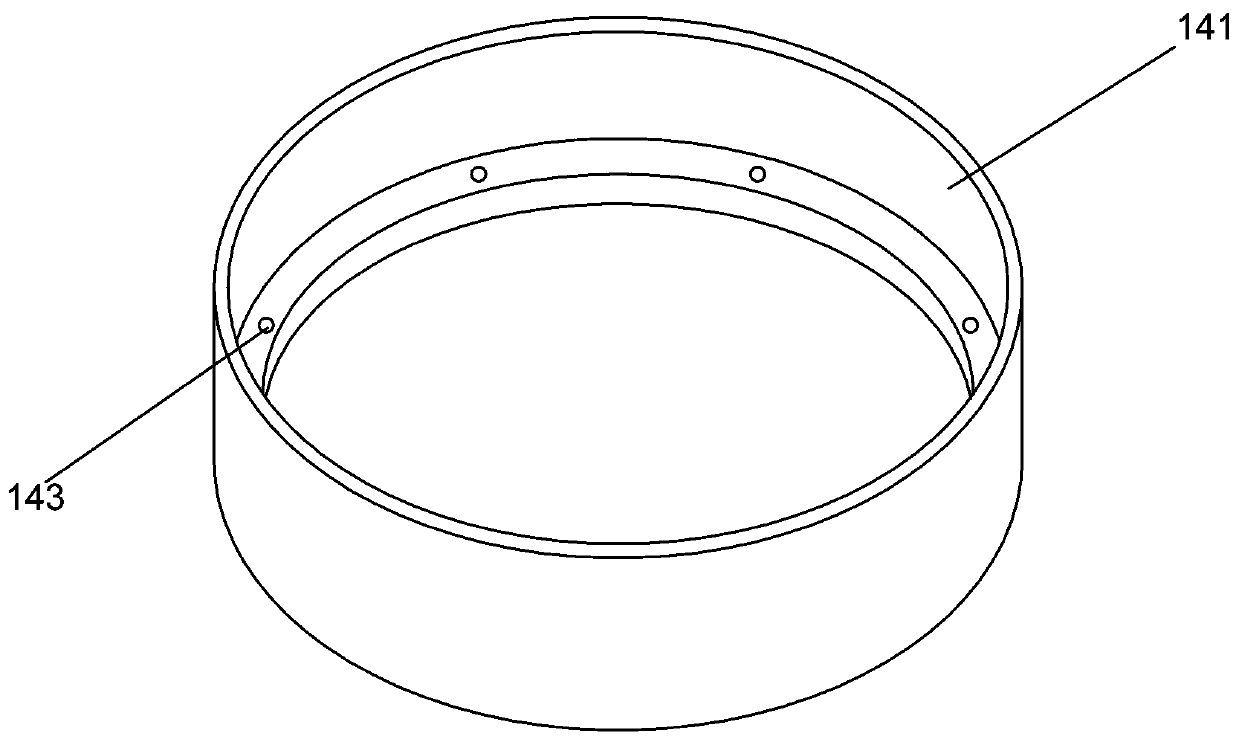

[0032] The first is the filter grid 14 of the water collecting well 1 . The filtering grid 14 includes a rotating ring 141 connected to the inner side wall of the water collecting well 1 and a fence disc 142 connected to the rotating ring 141 . The diameter of the fence disc 142 is larger than The inner diameter of the rotating ring 141 is smaller than the outer diameter of the rotating ring 141 , the rotating ring 141 is provided with a clamping hole 143 , and the lower part of the fence plate 142 is provided with a clamping hole 143 extending in the direction. Post 144 protrudes. Moreover, the inner side w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com