Drum screening machine and application thereof in oil sludge treatment

A drum screening machine and sludge sludge technology, which is applied in grain processing, filtration separation, separation methods, etc., can solve the problems of restricting the development of sludge sludge, unable to process sludge in time, and poor treatment effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

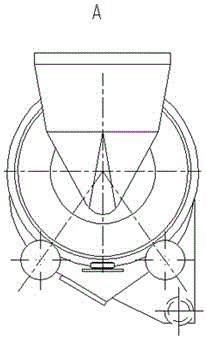

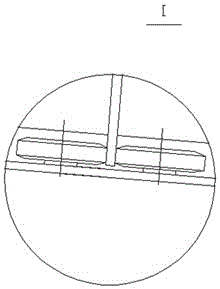

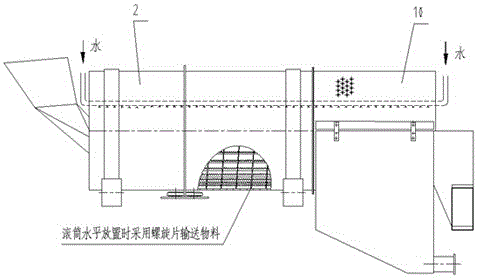

[0017] Below in conjunction with accompanying drawing this embodiment will be further described

[0018] Figure 1~3 It can be seen that, from the oblique installation view of the roller of the present invention, the roller is of equal diameter or variable diameter, or a combination of straight cylinder and conical cylinder. The rotary drive mode is gear transmission, or friction wheel transmission, or chain transmission. The positioning and rotation of the drum is realized by installing two sets of supporting wheels 8 and an additional axial limit wheel 4 under the cylinder body 2 . There are two types of internal structure of the drum. Firstly, a continuous or discontinuous helical piece coaxial with the drum is installed close to the inner wall of the drum, which is used to transport the materials to be cleaned and separated in the drum from the feed end to the discharge when the drum rotates. Second, install continuous or misplaced steps arranged in parallel to the axis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com