Patents

Literature

40results about How to "Mass processing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for synchronization adaptation of asynchronous digital data streams

InactiveUS7035215B1Less signal processingMaintain transmission qualityError preventionTransmission systemsSample rate conversionDigital data

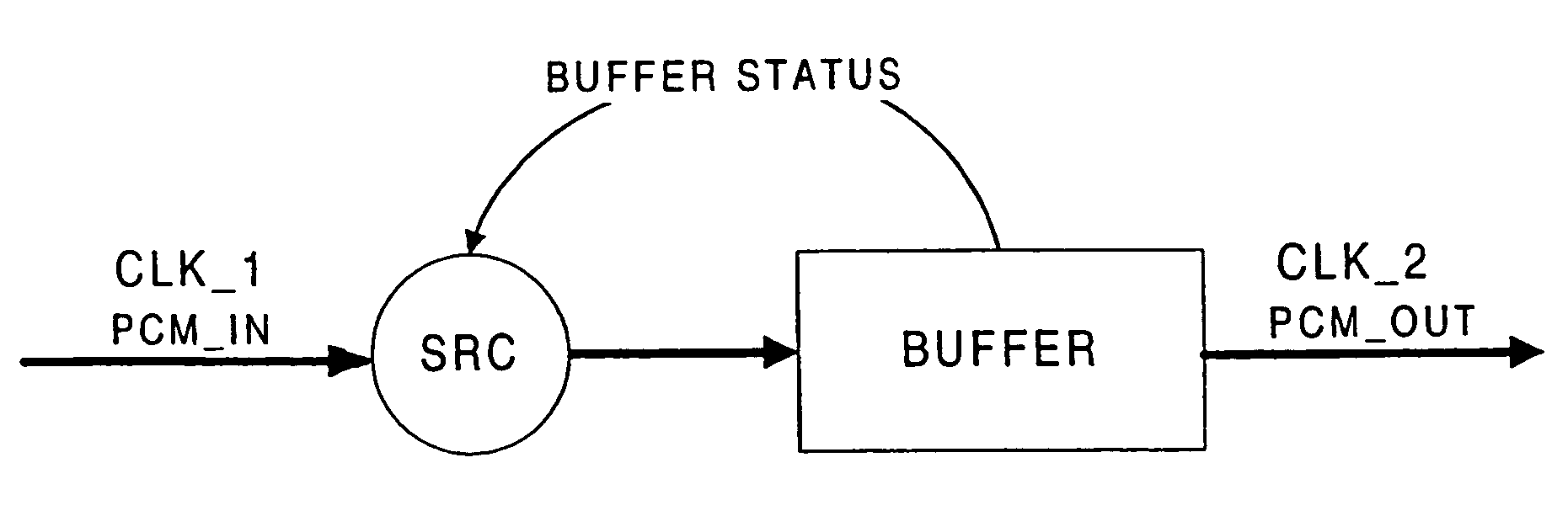

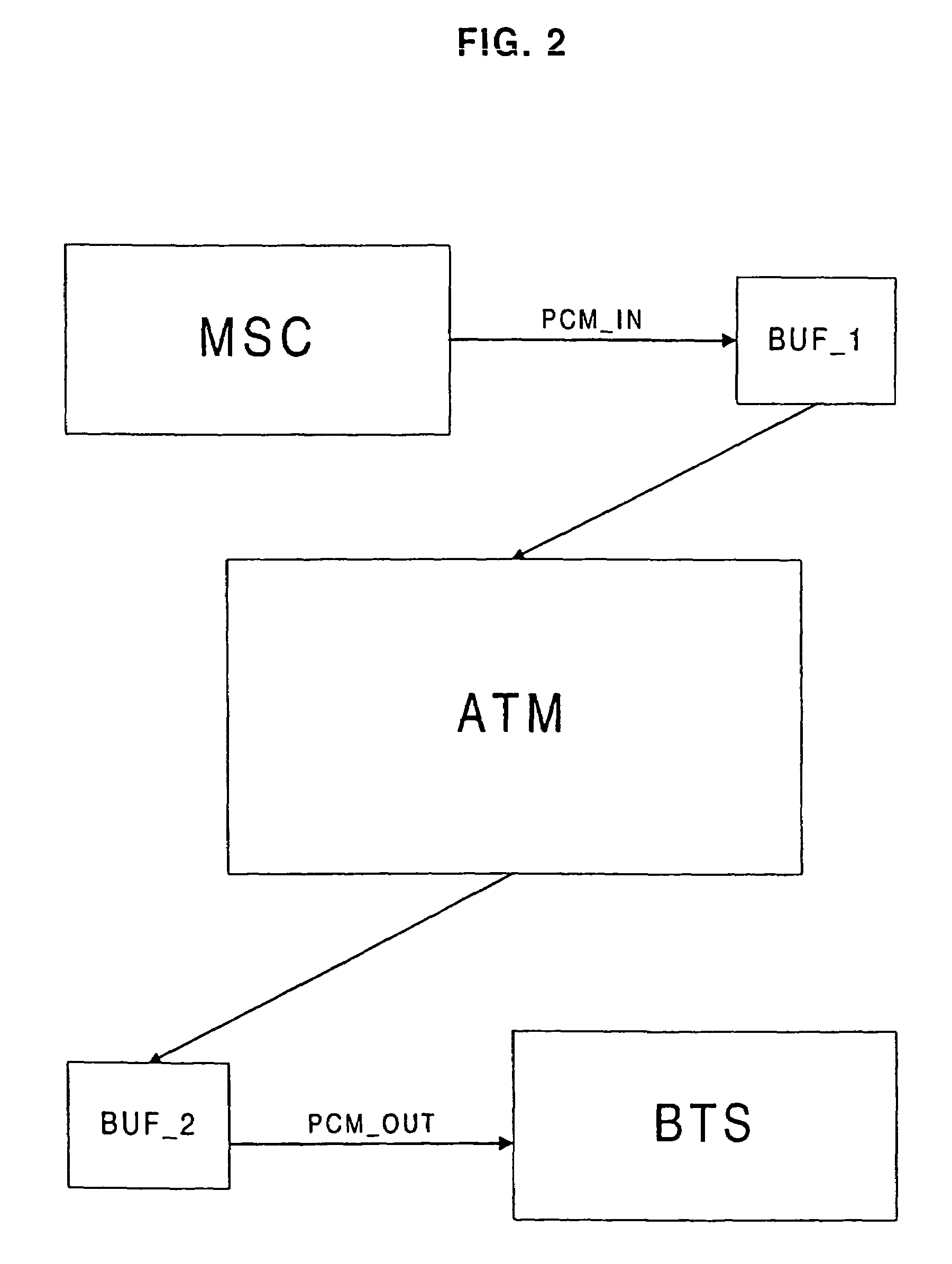

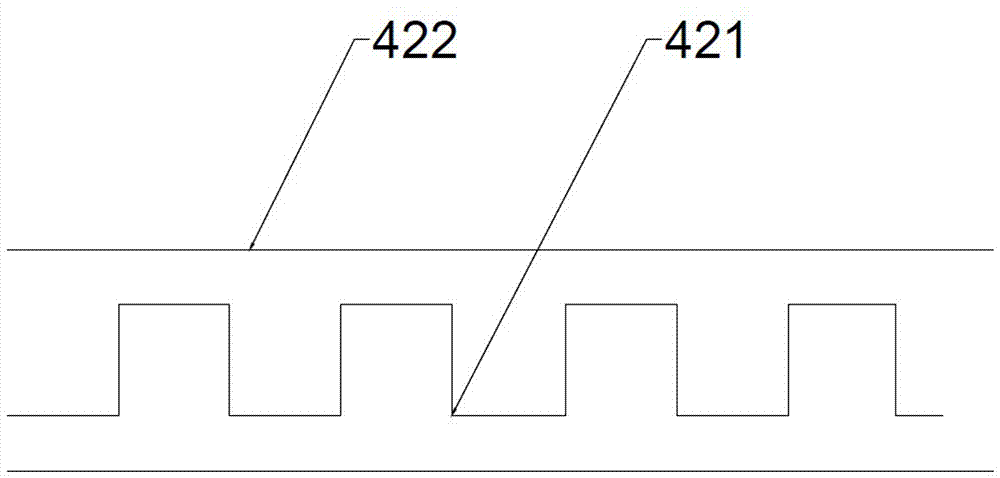

The present invention proposes a method for synchronization adaptation of asynchronous digital data streams comprising the steps of providing a first digital data stream (PCM_IN) at a first sample rate (CLK—1); inputting said first digital data stream (PCM_IN) to a sample rate conversion means (SRC); supplying data output from said sample rate conversion means (SRC) to a processing element (BUFFER); storing said supplied data into said processing element (BUFFER); and outputting said data stored in said processing element as a second digital data stream (PCM_OUT) at a second sample rate (CLK—2), with said first and said second sample rates (CLK—1, CLK—2) being different from each other; and is characterized by the further steps of detecting a state (BUFFER_STATUS) of said processing element (BUFFER); and controlling said sample rate conversion means (SRC) dependent on the detected state of said processing element. The present invention also proposes a device for synchronization adaptation of asynchronous digital data streams, operating according to such a method.

Owner:NOKIA NETWORKS OY

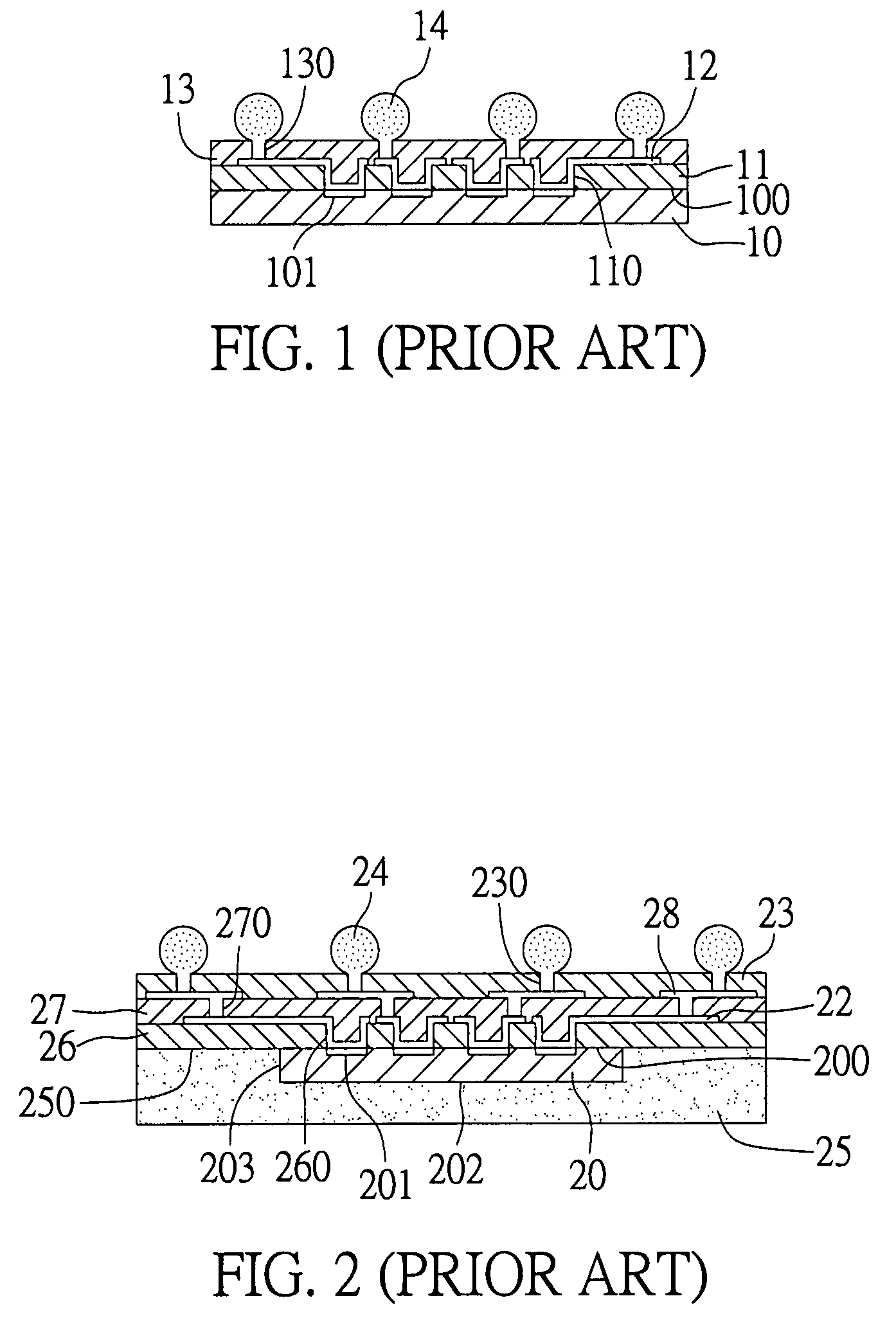

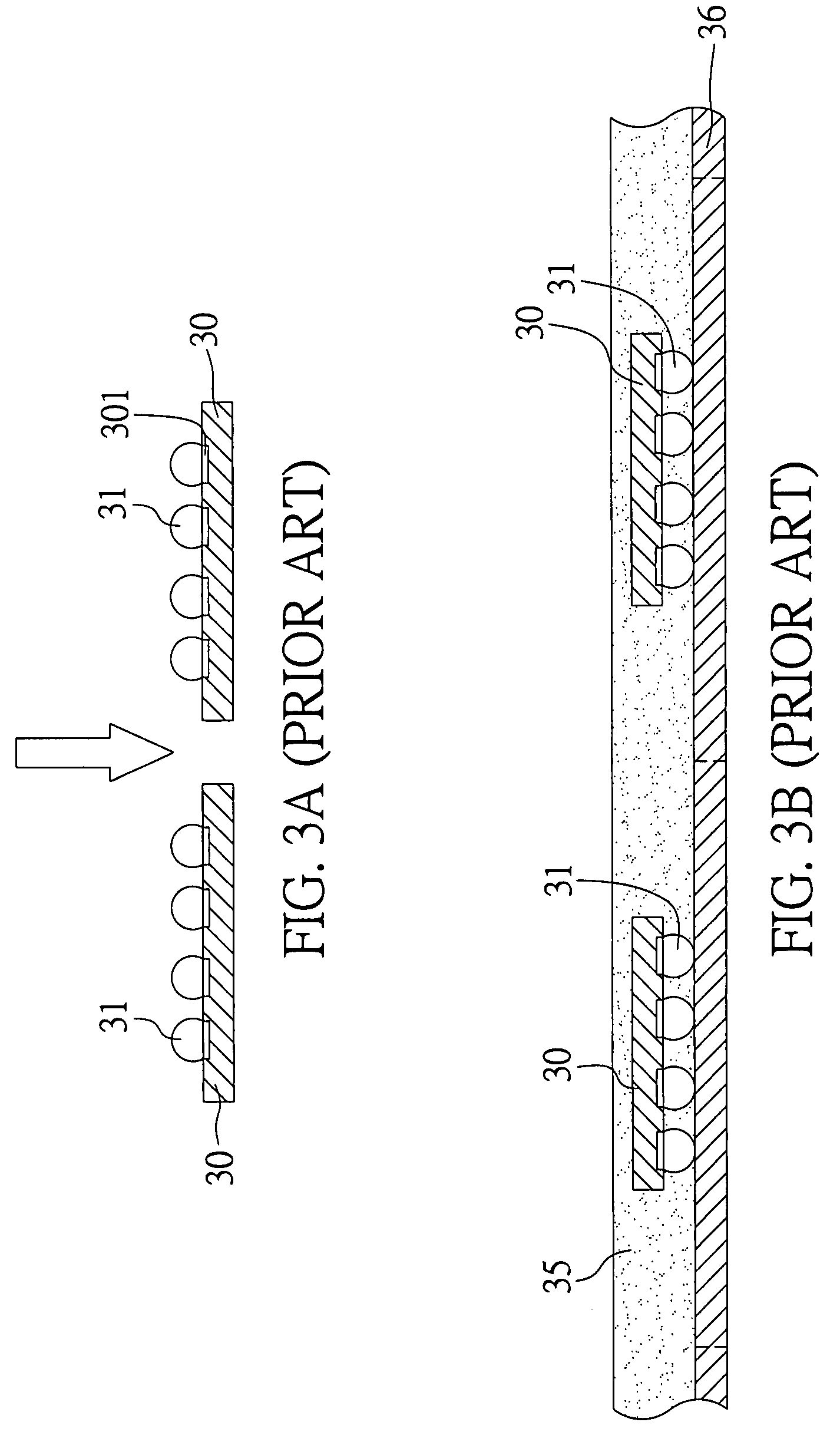

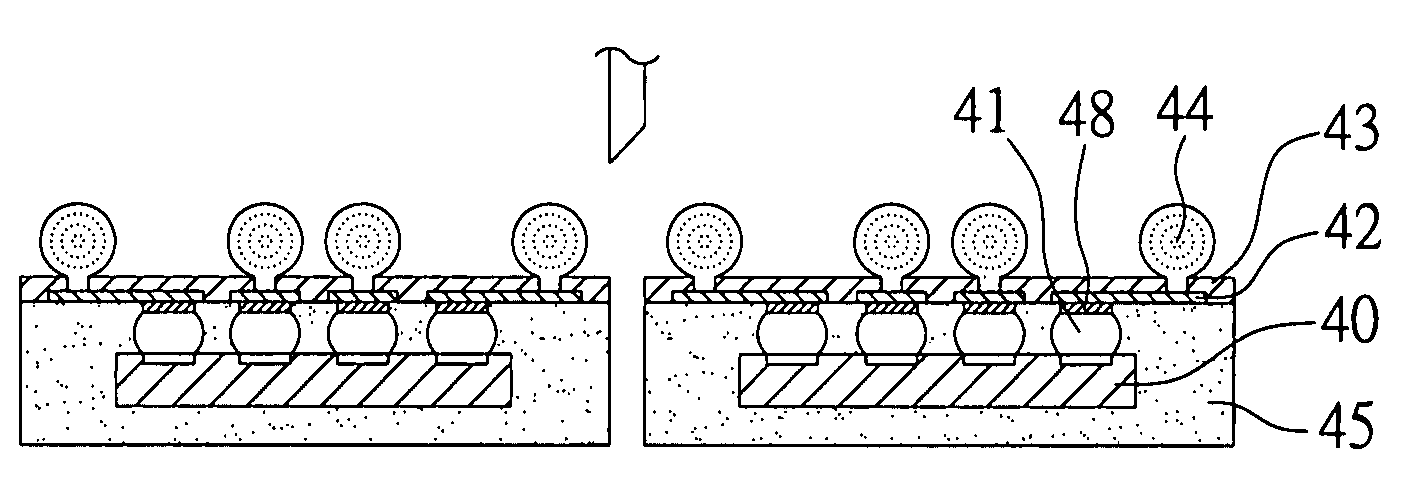

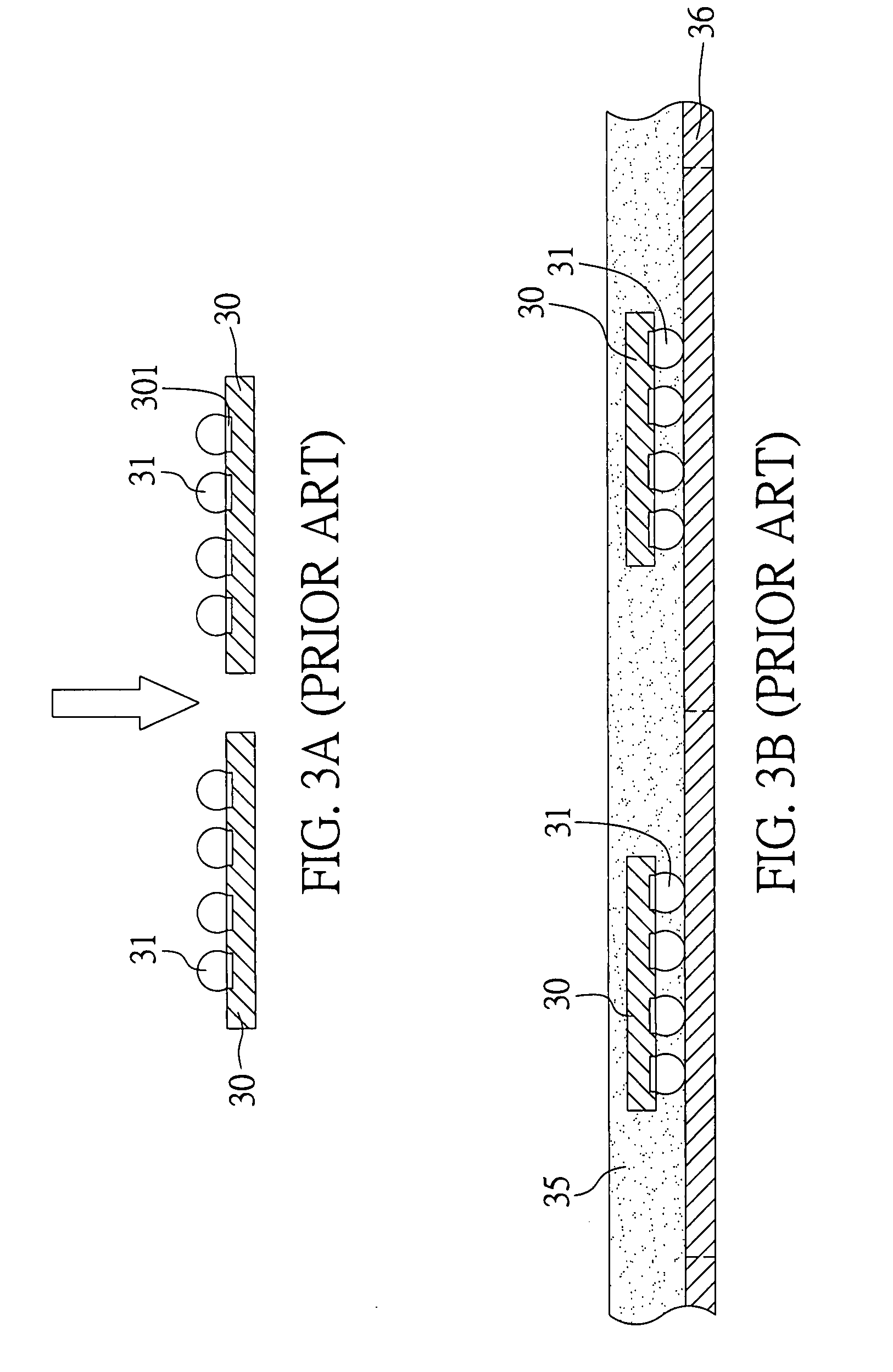

Chip scale package structure with metal pads exposed from an encapsulant

ActiveUS7750467B2Low costMass processingSemiconductor/solid-state device detailsSolid-state devicesSolder maskEngineering

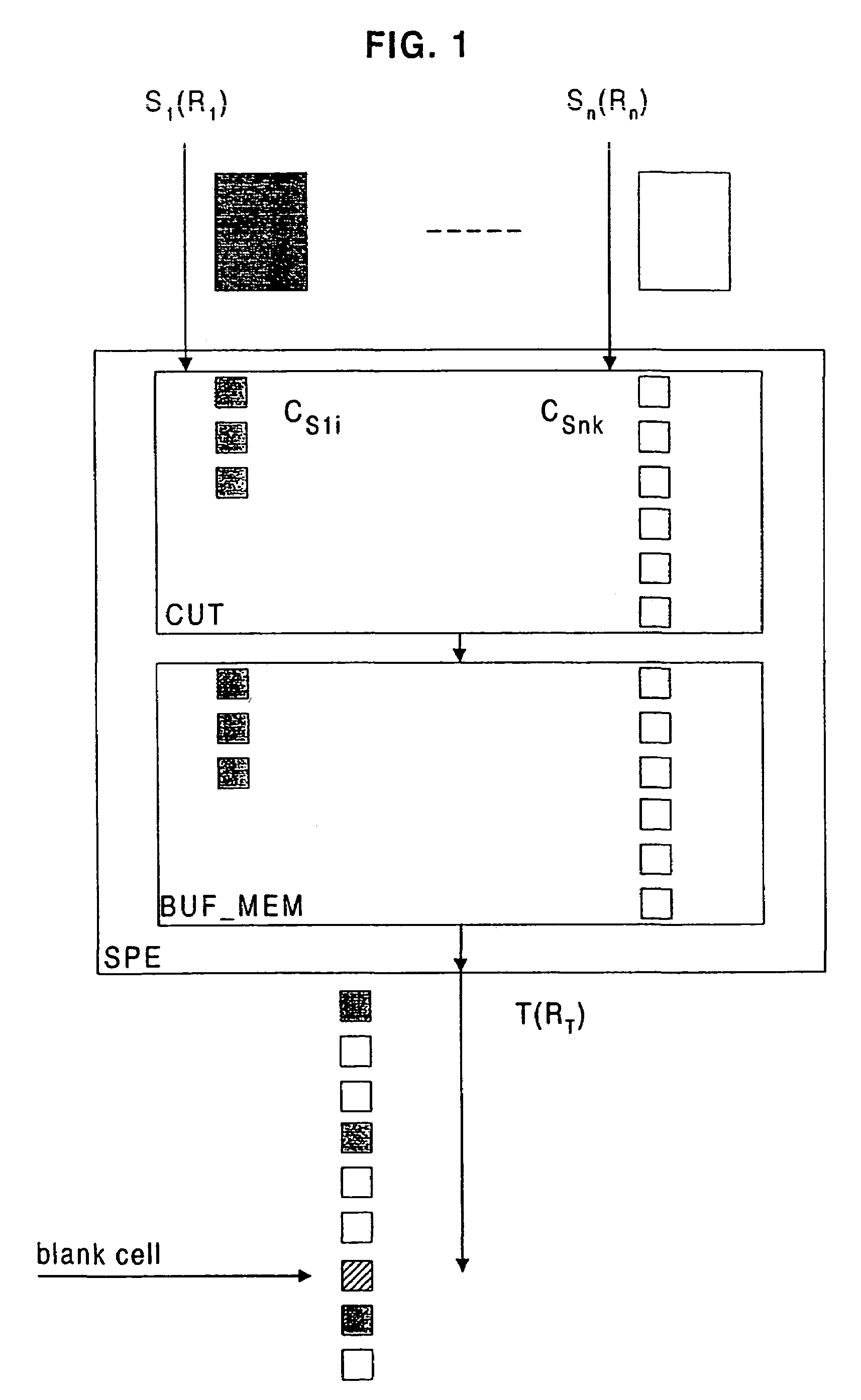

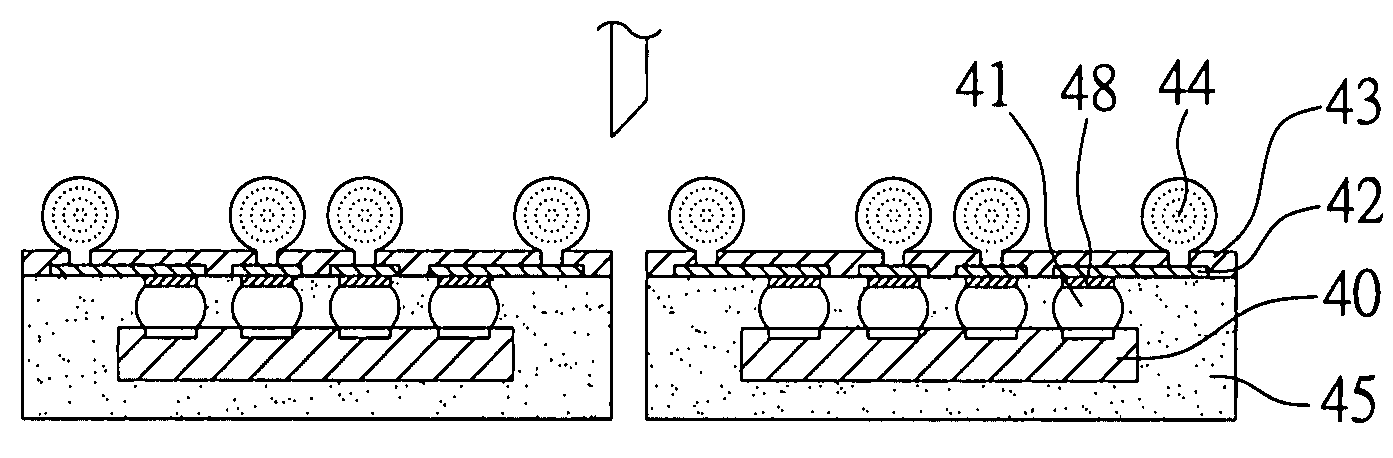

A chip scale package structure and a method for fabricating the same are disclosed. The method includes forming metal pads on a predetermined part of a carrier; mounting chips on the carrier, each of the chips having a plurality of conductive bumps soldered to the metal pads; forming an encapsulant on the carrier to encapsulate the chips and the conductive bumps; removing the carrier to expose the metal pads and even the metal pads with a surface of the encapsulant; forming on the encapsulant a plurality of first conductive traces electrically connected to the metal pads; applying a solder mask on the first conductive traces, and forming a plurality of openings on the solder mask to expose a predetermined part of the first conductive traces; forming a plurality of conductive elements on the predetermined part; and cutting the encapsulant to form a plurality of chip scale package structures.

Owner:SILICONWARE PRECISION IND CO LTD

Chip scale package structure and method for fabricating the same

ActiveUS20080138935A1Increase flexibilityImproved heat dissipation efficiencySemiconductor/solid-state device detailsSolid-state devicesSolder maskEngineering

A chip scale package structure and a method for fabricating the same are disclosed. The method includes forming metal pads on a predetermined part of a carrier; mounting chips on the carrier, each of the chips having a plurality of conductive bumps soldered to the metal pads; forming an encapsulant on the carrier to encapsulate the chips and the conductive bumps; removing the carrier to expose the metal pads and even the metal pads with a surface of the encapsulant; forming on the encapsulant a plurality of first conductive traces electrically connected to the metal pads; applying a solder mask on the first conductive traces, and forming a plurality of openings on the solder mask to expose a predetermined part of the first conductive traces; forming a plurality of conductive elements on the predetermined part; and cutting the encapsulant to form a plurality of chip scale package structures.

Owner:SILICONWARE PRECISION IND CO LTD

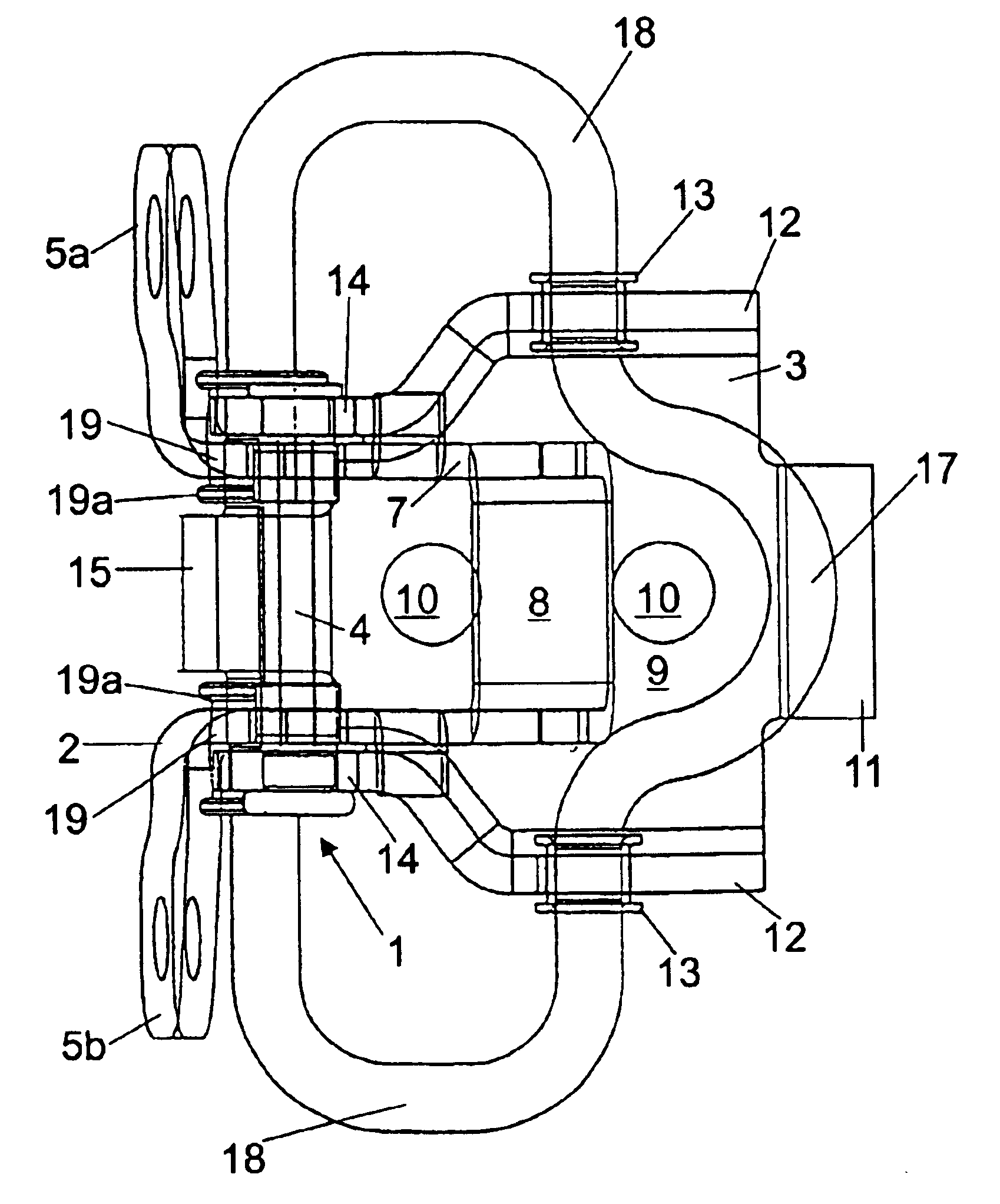

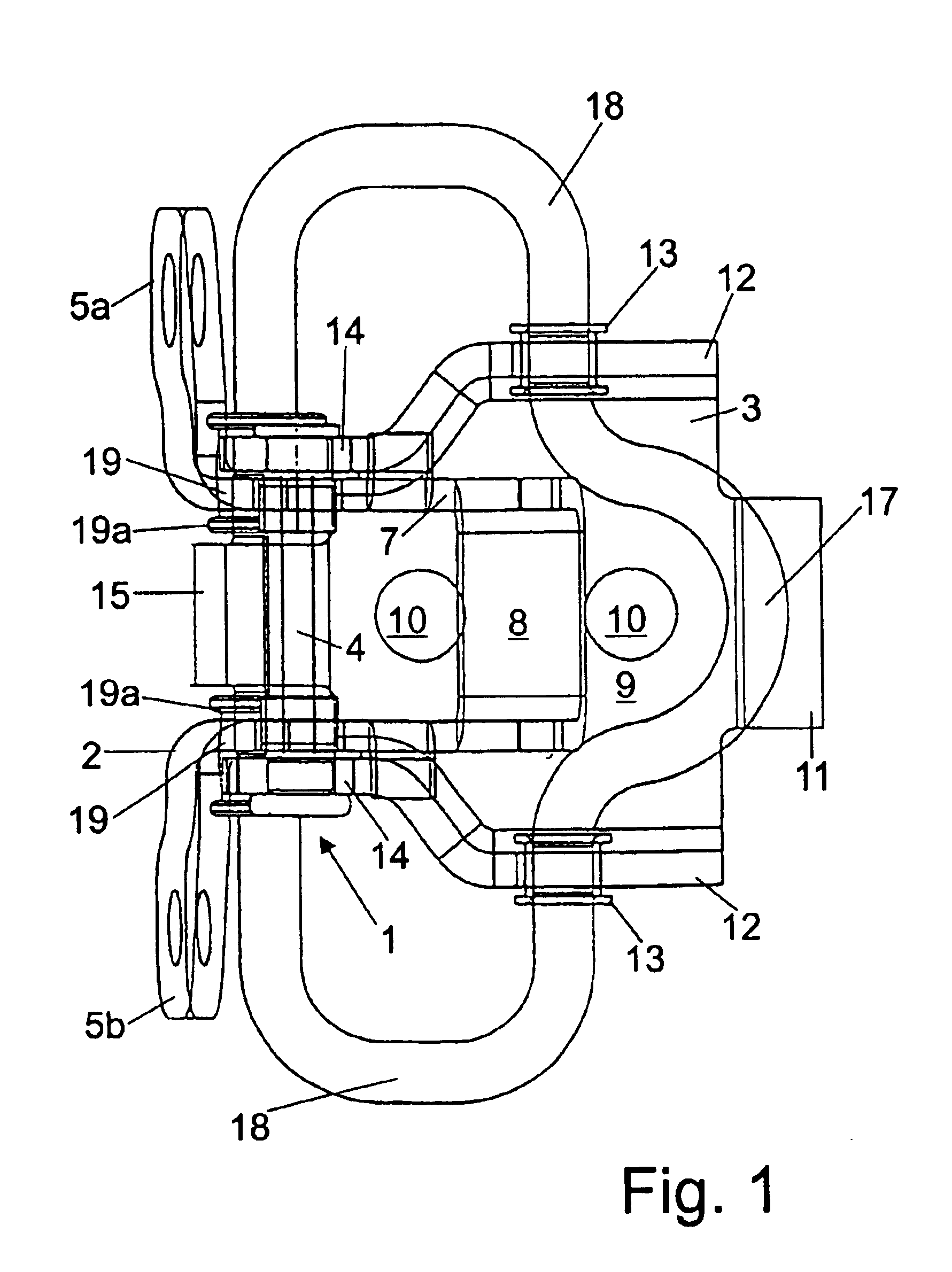

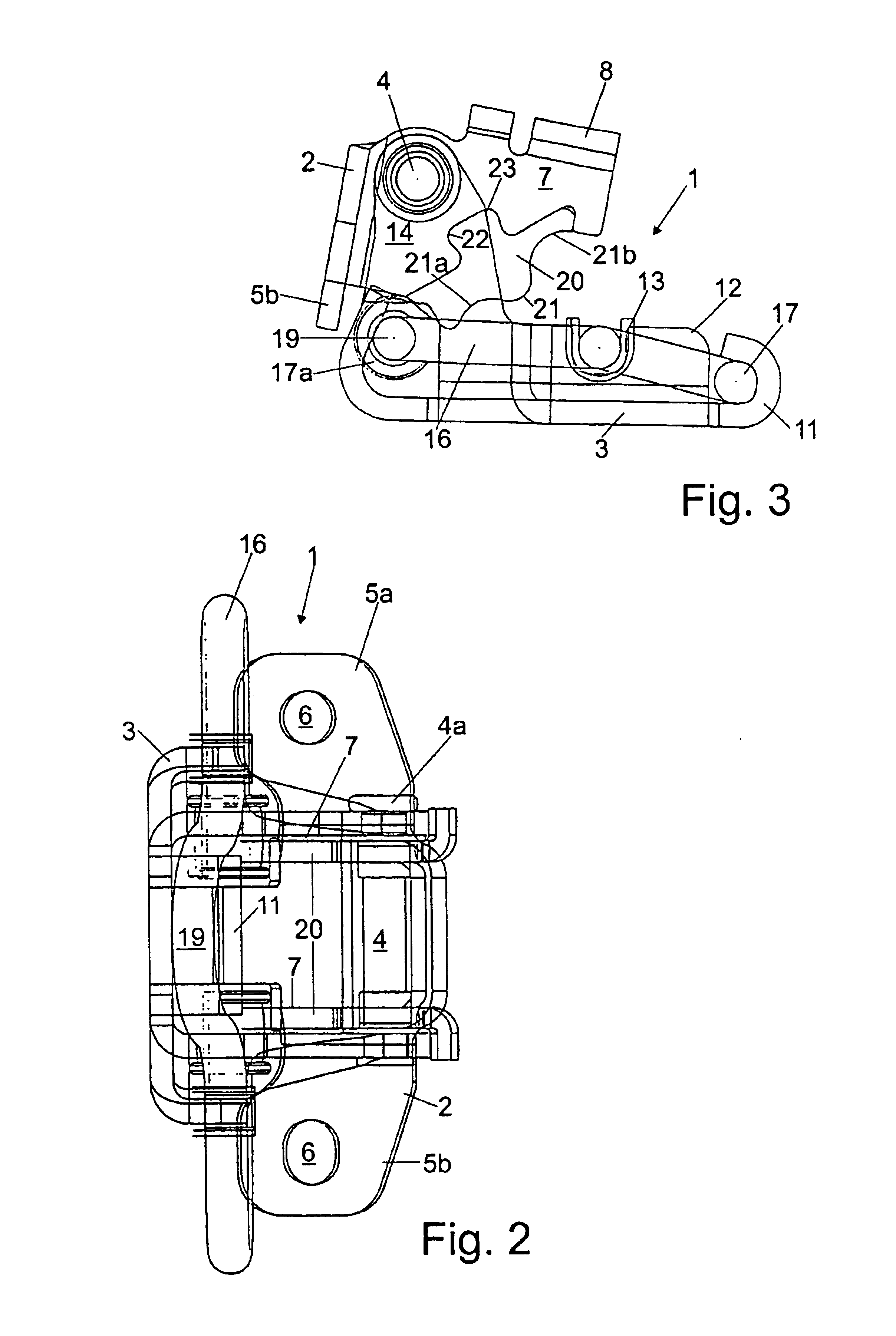

Door hinge

InactiveUS6851159B1Reliably permitCompact structureHingesWing openersEngineeringElectrical and Electronics engineering

Owner:EDSCHA AG

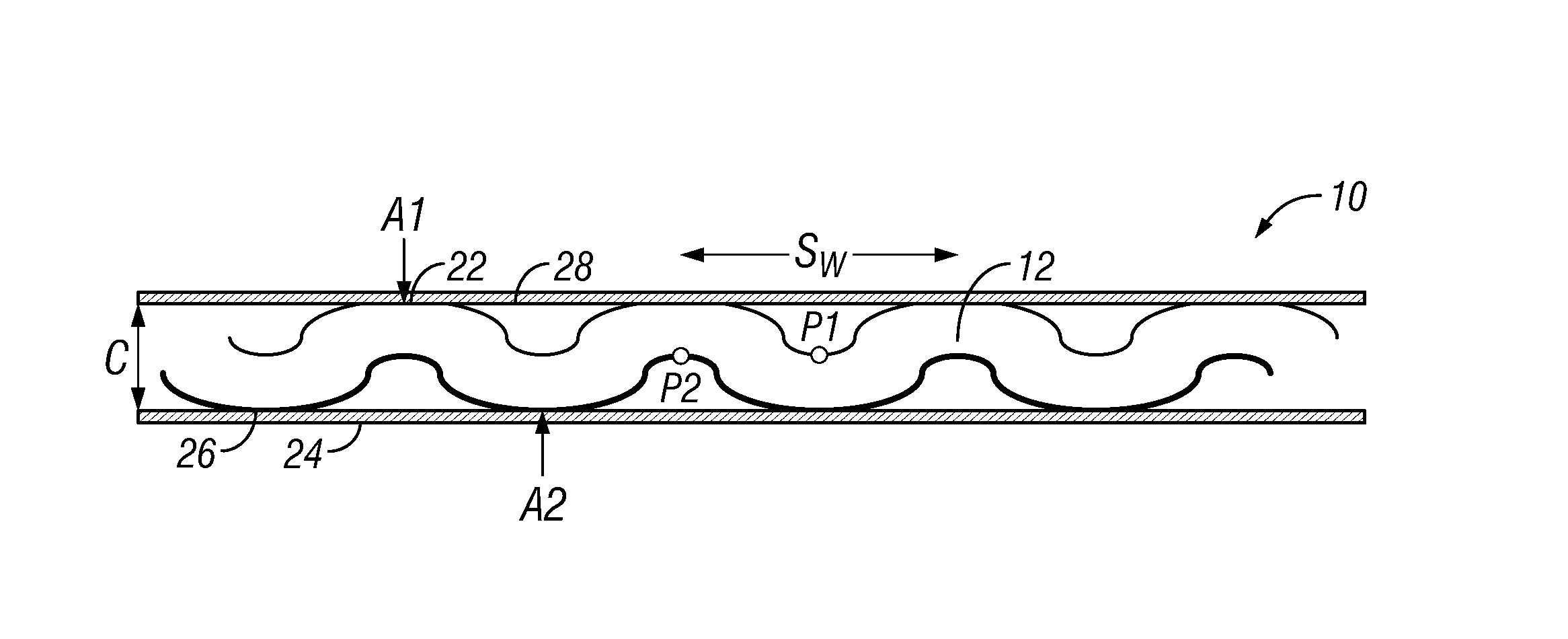

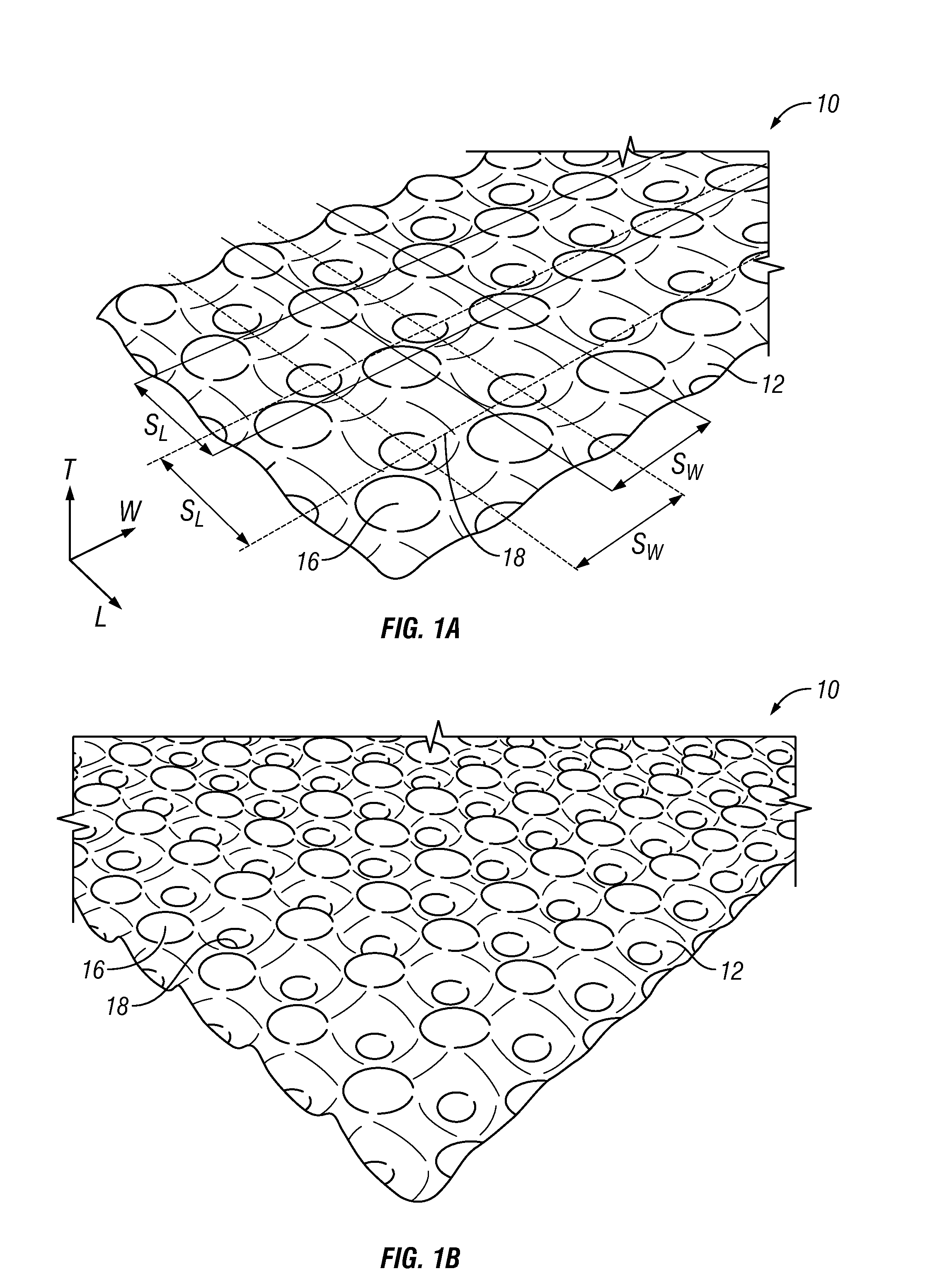

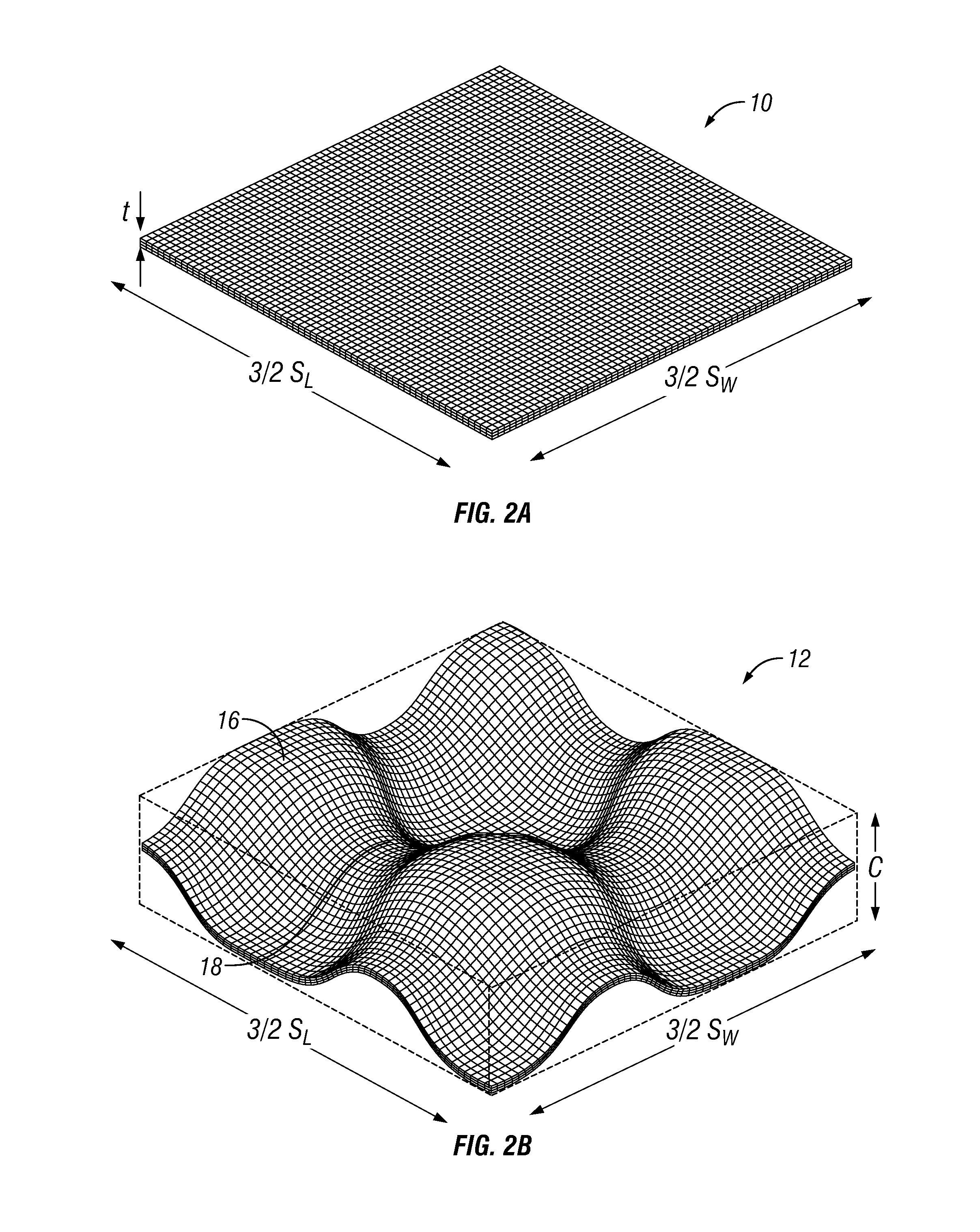

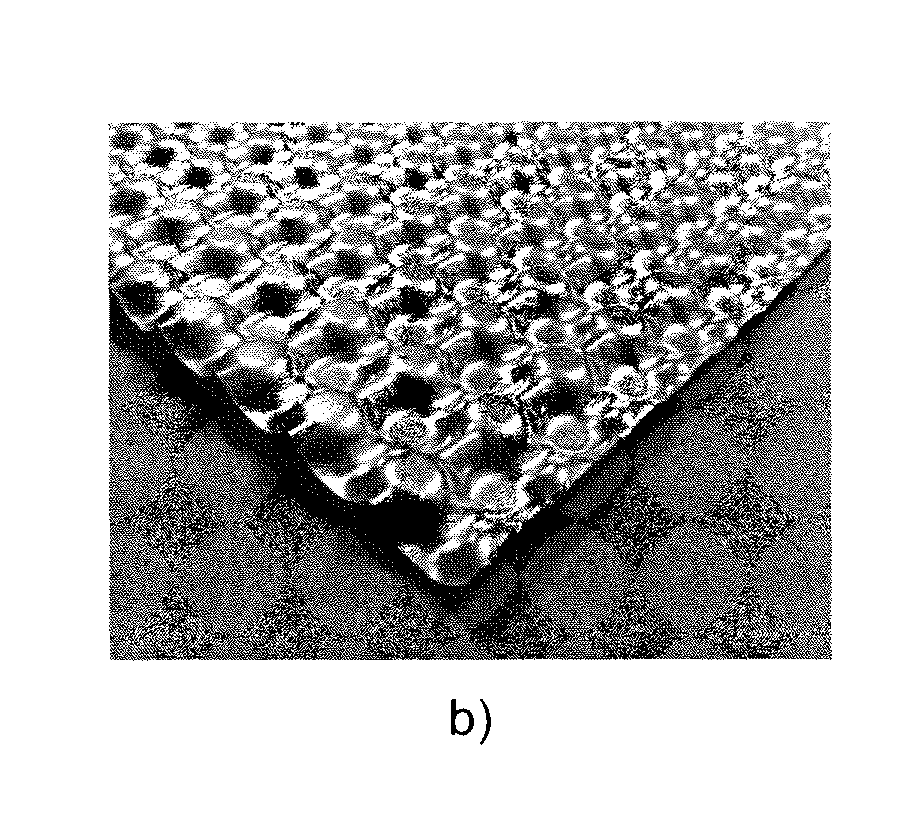

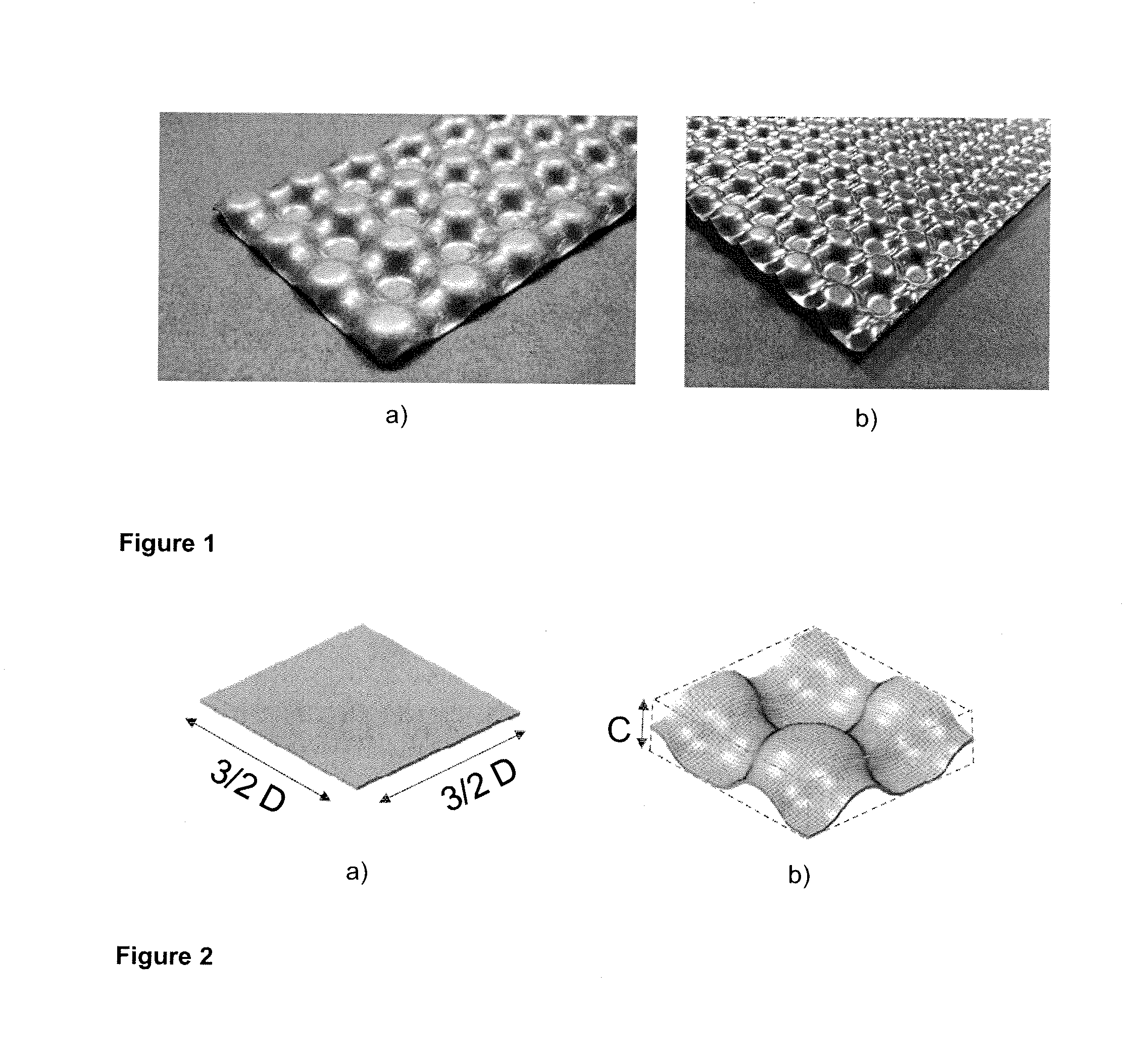

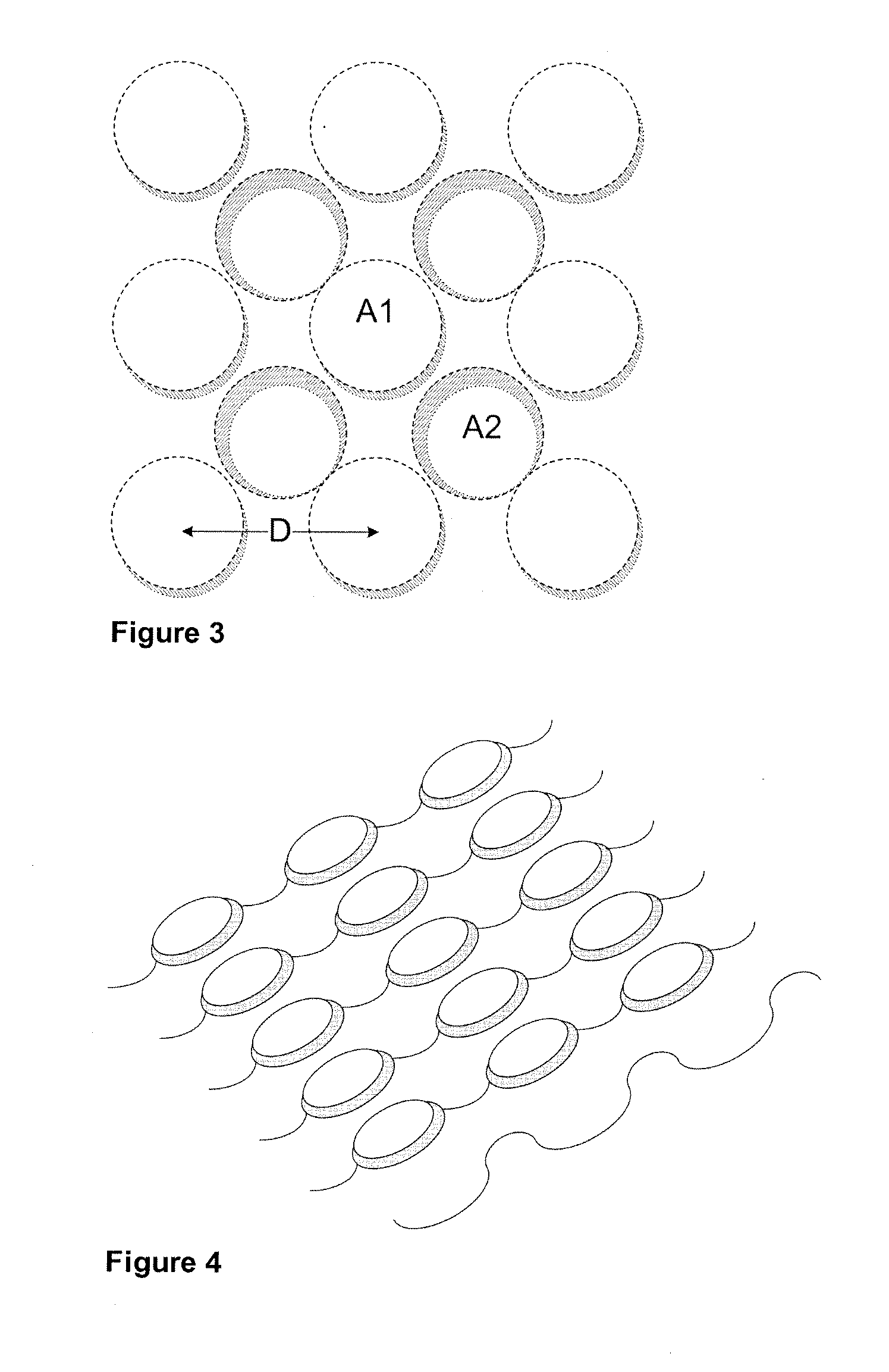

Optimal sandwich core structures and forming tools for the mass production of sandwich structures

ActiveUS20130330521A1Mass processingCost-effectiveThin material handlingMetal layered productsEngineeringSeries production

Owner:CELLTECH METALS INC

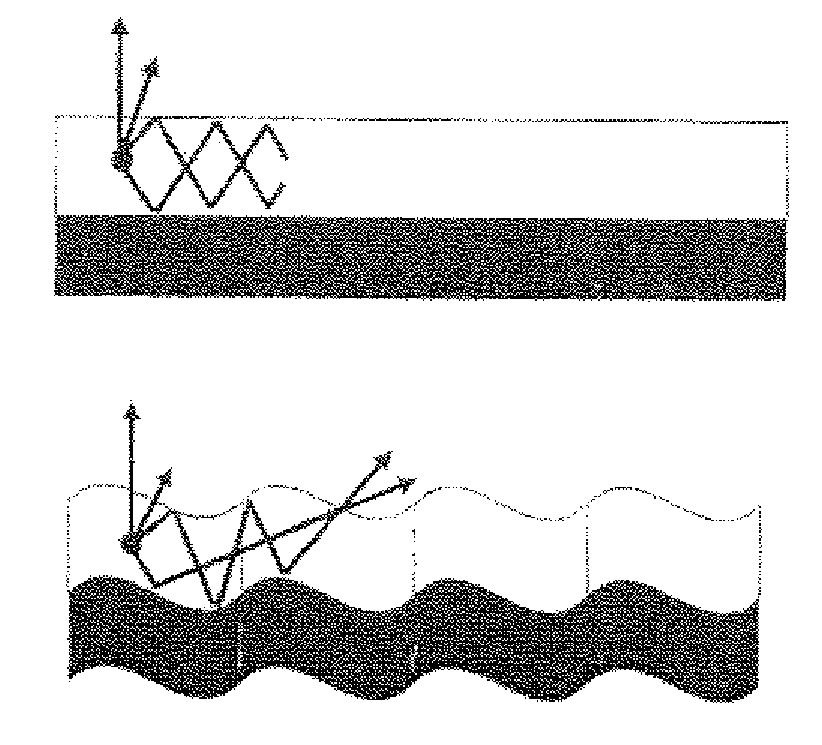

Top-Emitting Device and Illumination Device

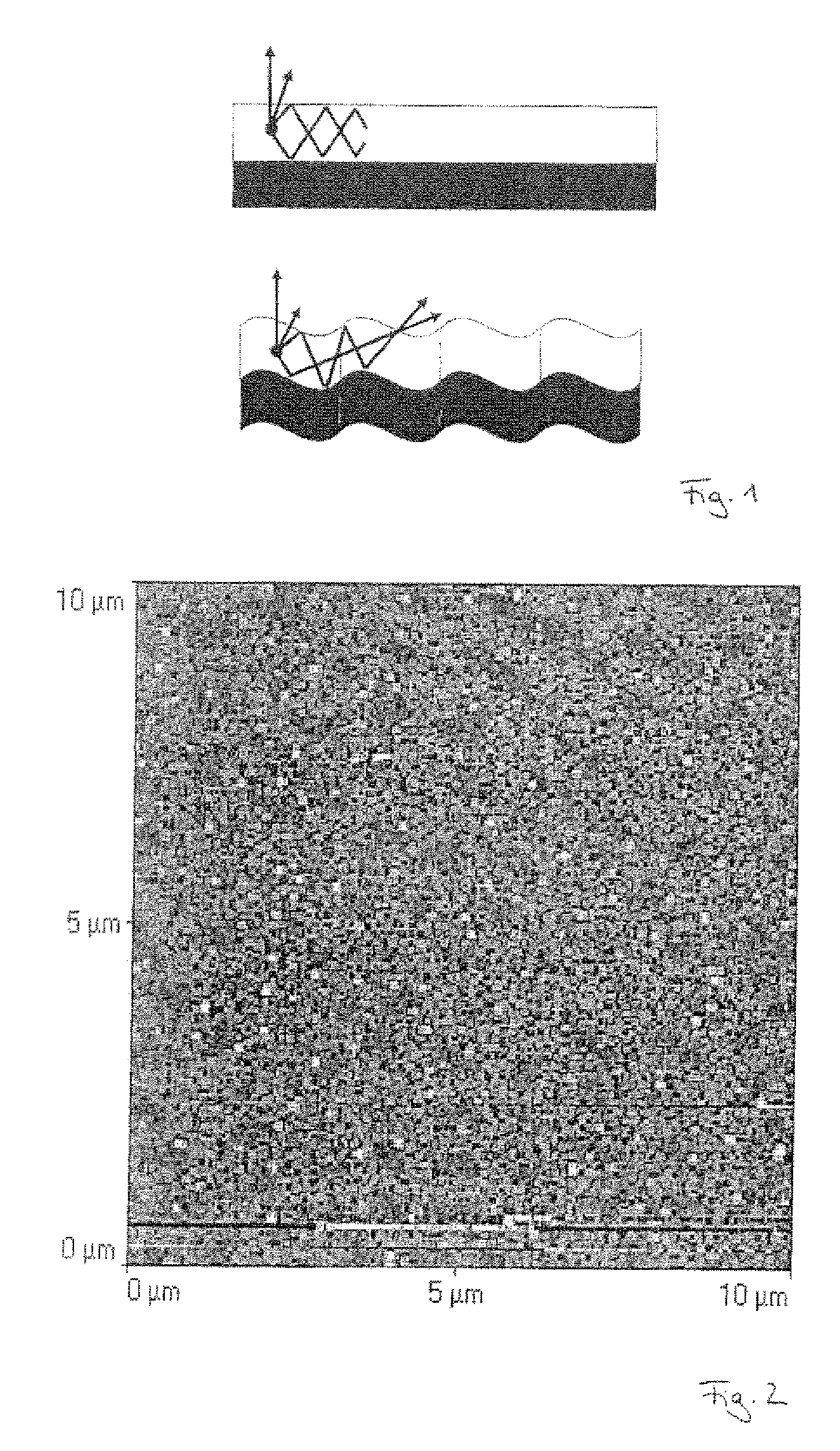

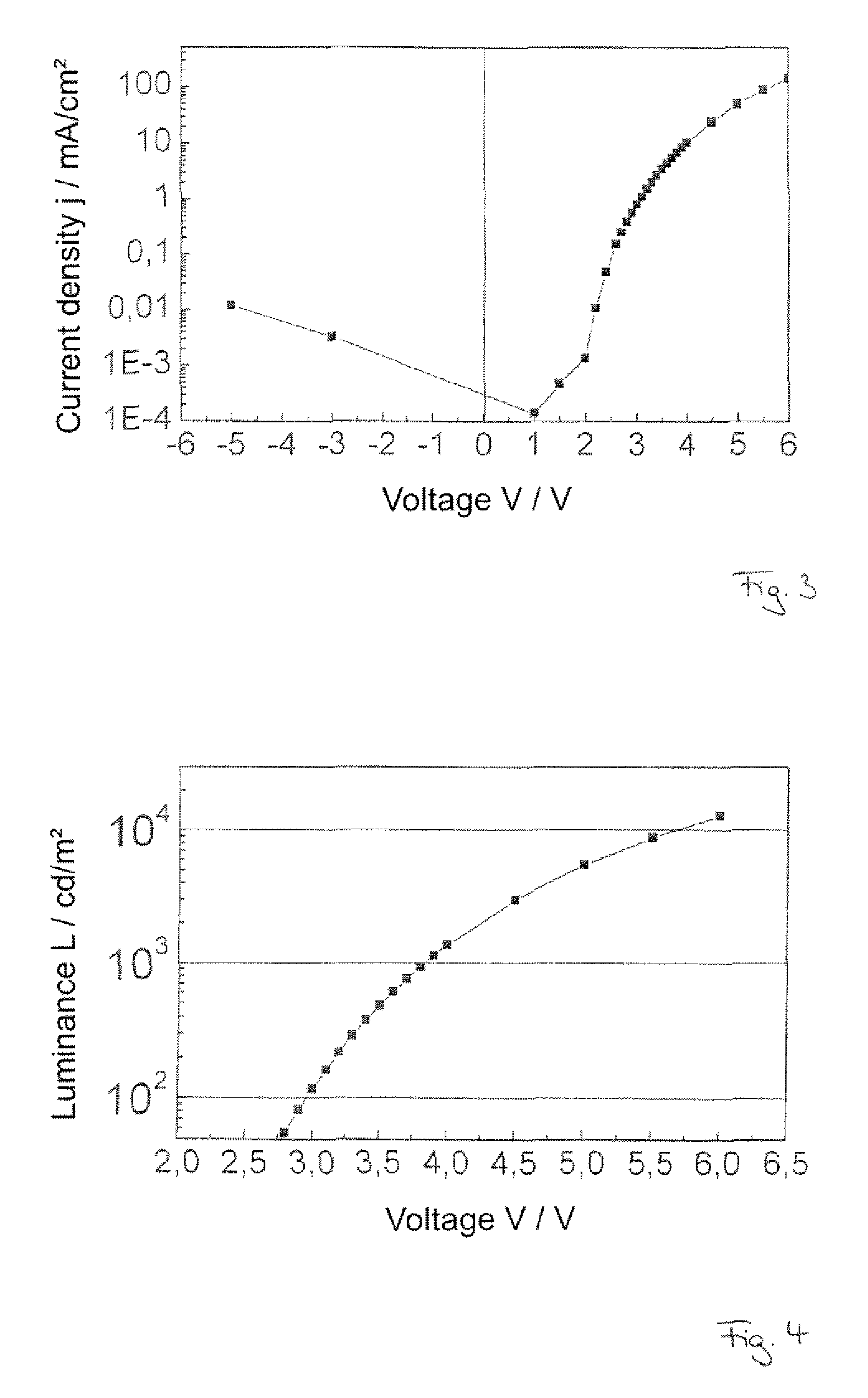

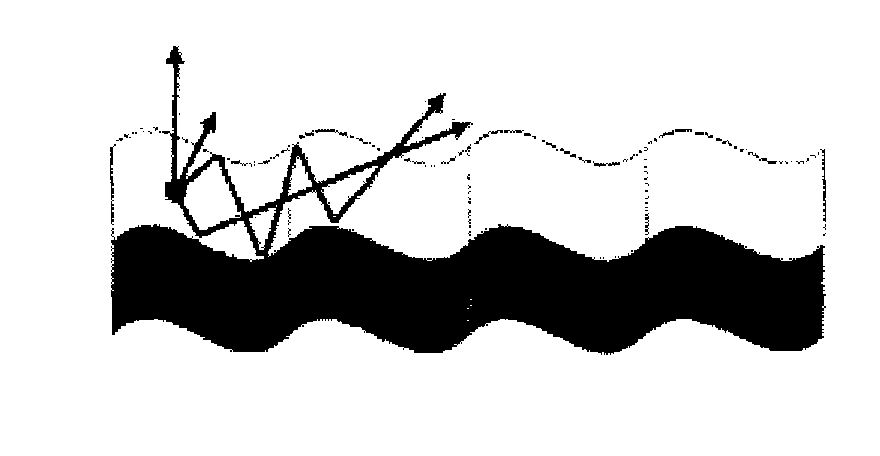

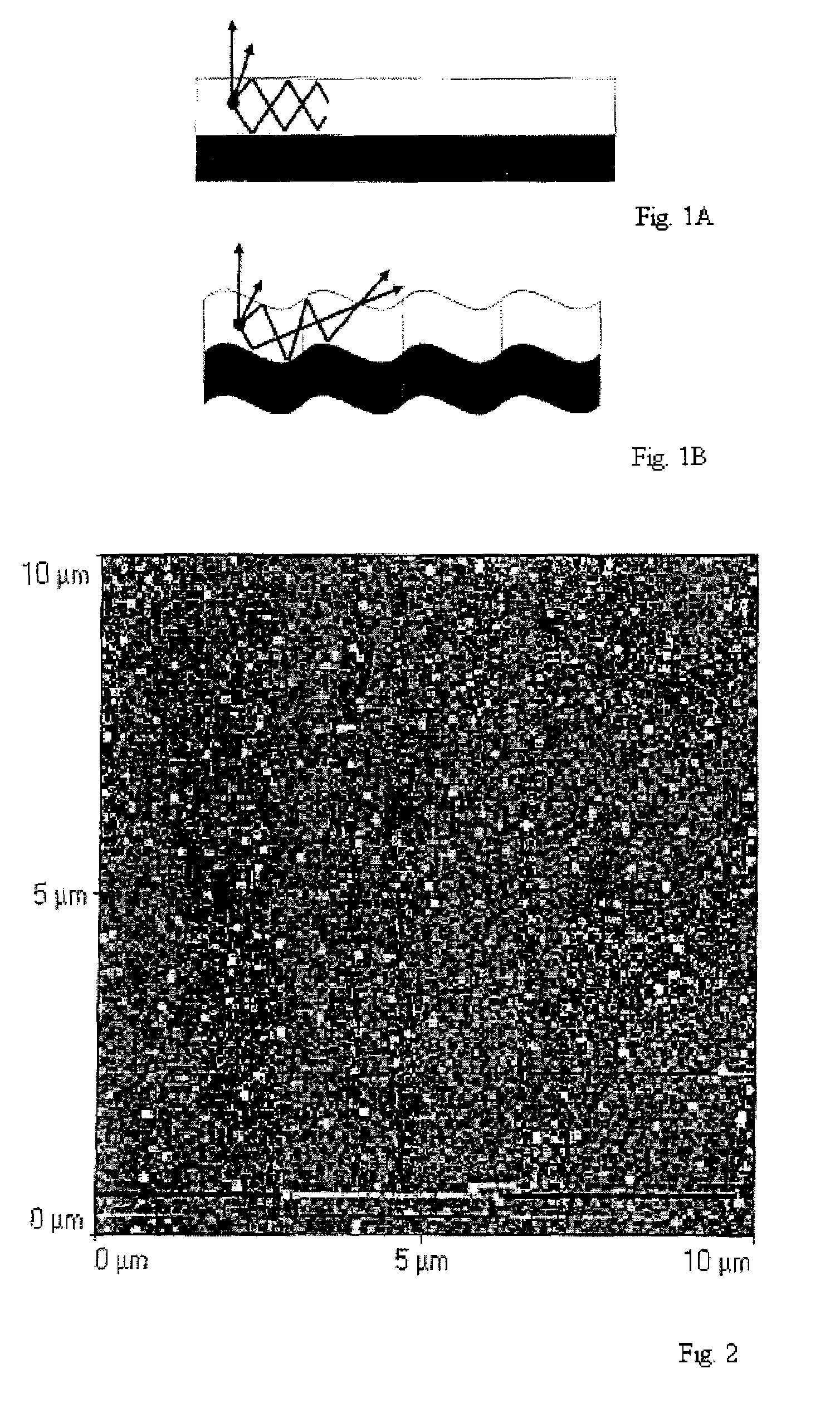

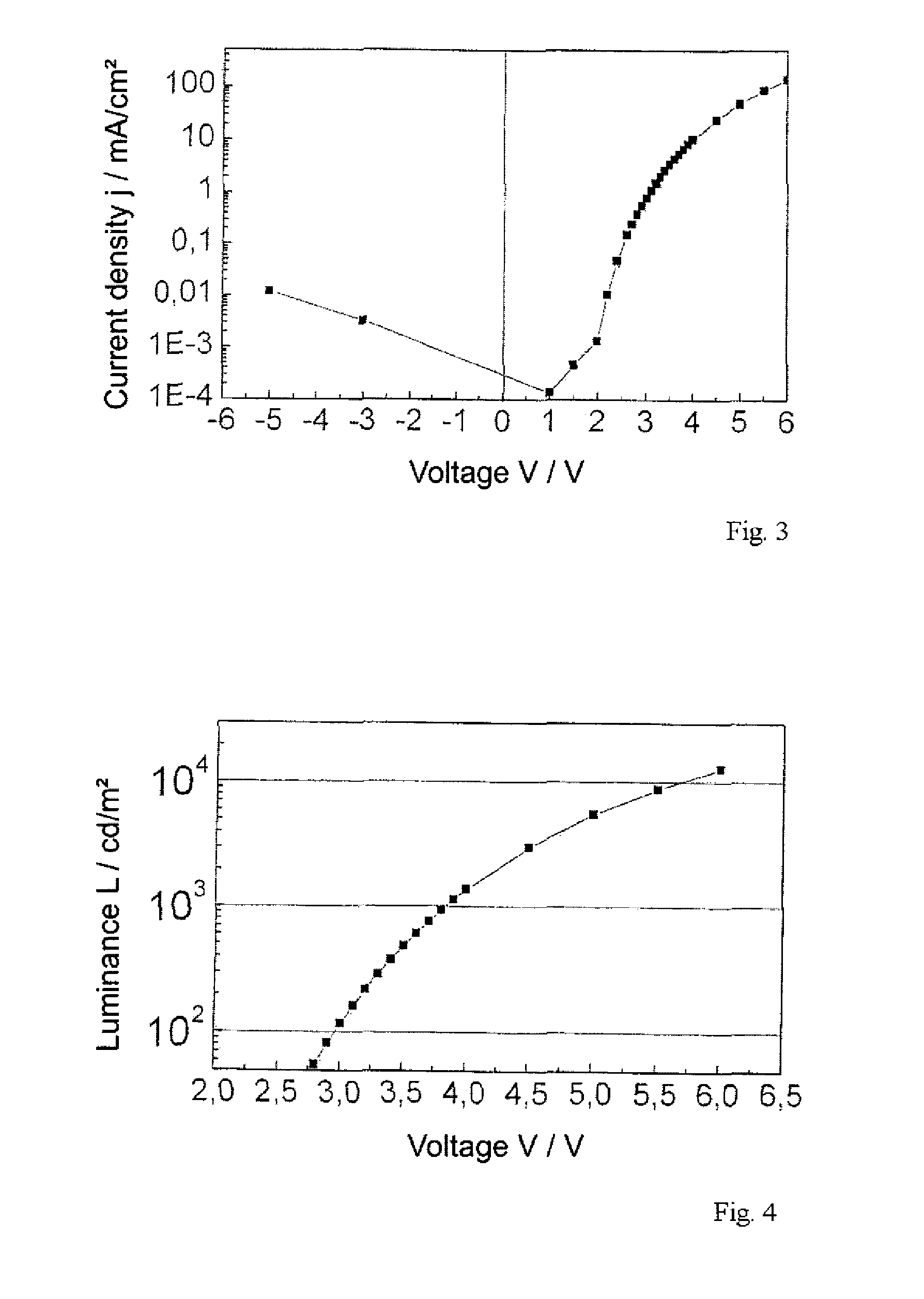

ActiveUS20070035236A1Improve light extractionProduced economicallyDischarge tube luminescnet screensElectroluminescent light sourcesOrganic layerSurface structure

The invention refers to a top-emitting device, particularly organic light-emitting diode having a layer arrangement applied on a substrate, which layer arrangement comprises a bottom electrode arranged on the substrate and a top electrode through which a light emission is effected, and also a stack of organic layers arranged between the bottom electrode and the top electrode where, at the bottom electrode, a surface facing towards the stack of organic layers is formed in light-reflecting fashion at least in a partial region and being provided with a surface structure that defines a reflection of light generated in the stack of organic layers at the bottom electrode, and where the surface structure is formed by means of mechanical shaping.

Owner:NOVALED GMBH

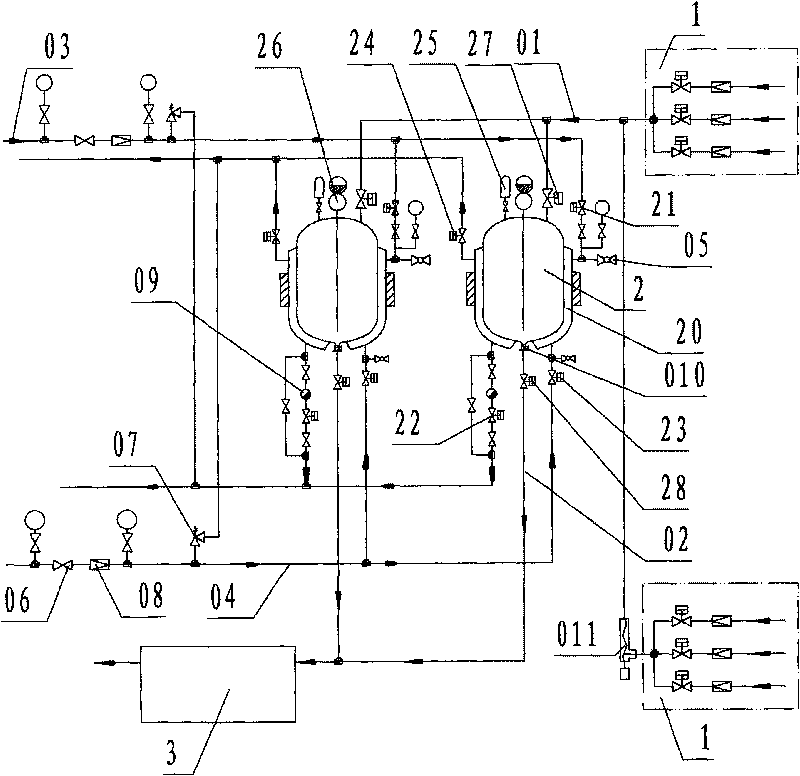

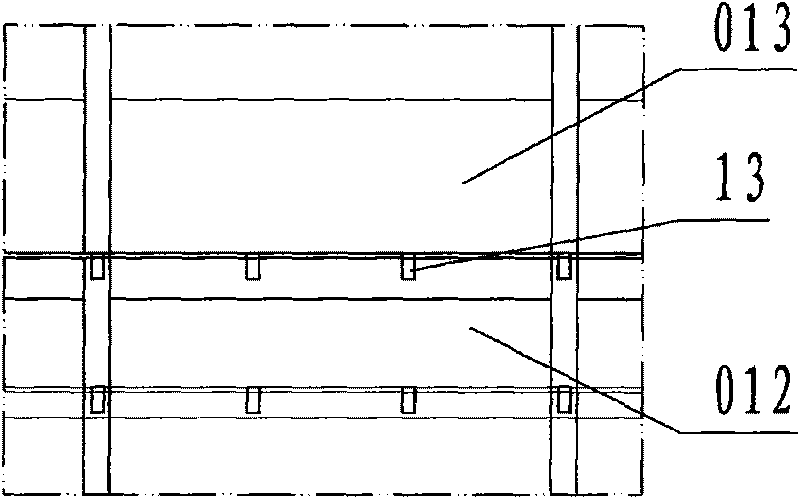

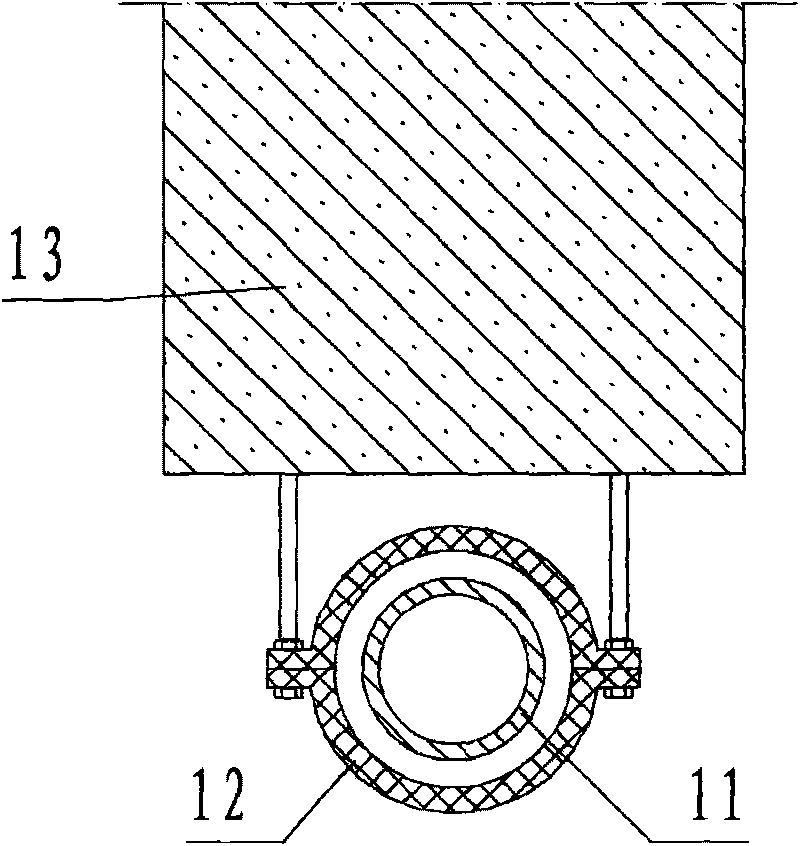

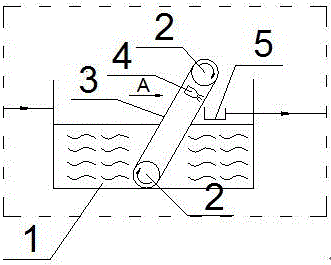

Pathogenic microorganism waste liquor treatment system

InactiveCN101691247ATimely processingThe overall collection and processing of the processing station is timelyWater/sewage treatment by heatingLiquid wastePathogenic microorganism

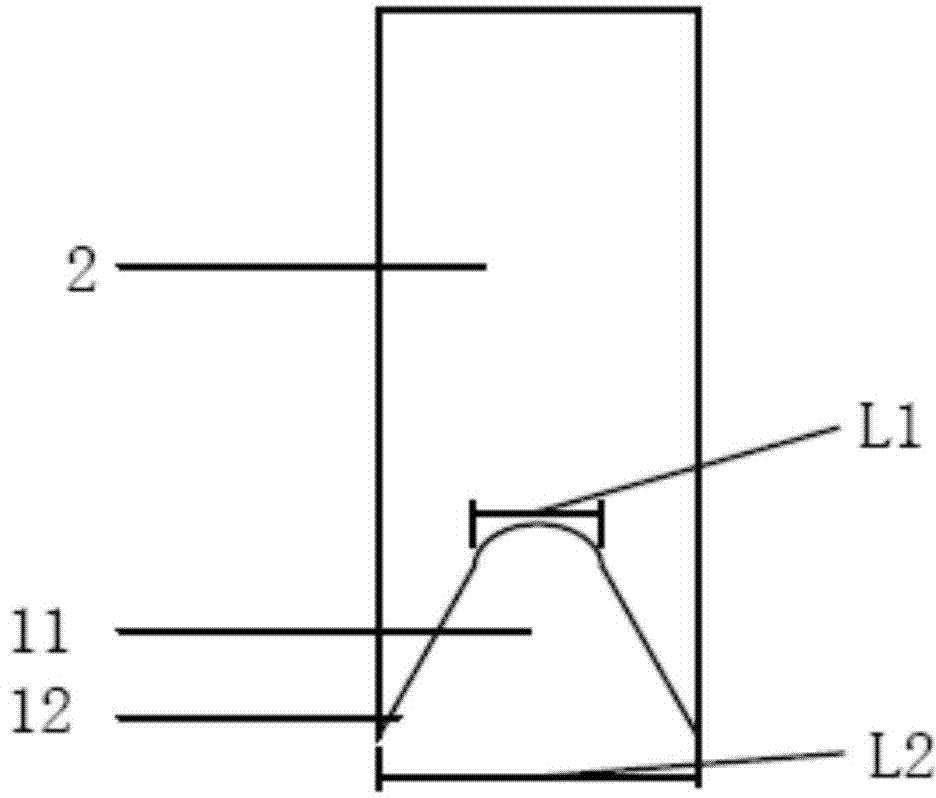

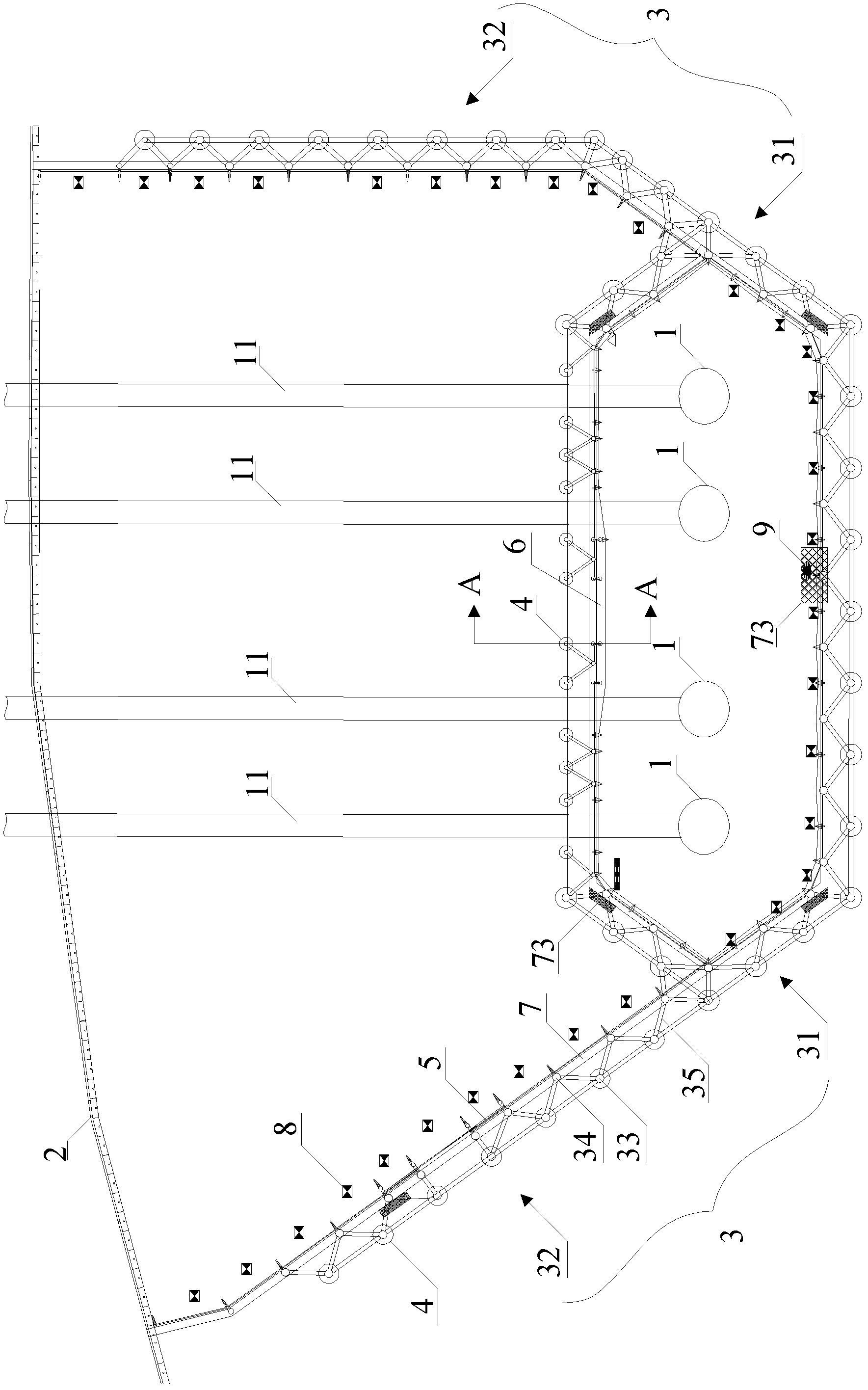

The invention discloses a pathogenic microorganism waste liquor treatment system, which comprises a waste liquor collecting pipeline system (1), a waste liquor sterilizing tank (2) and a sewage treatment station (3). The invention adopts a technical scheme that waste liquor is integrally collected and treated through the waste liquor collecting pipeline system, the high-temperature steam bath waste liquor sterilizing tank and the sewage treatment station special for the waste liquor so as to overcome the defects that the liquor collecting vehicle and liquor collecting bucket mode in the prior art has low waste liquor treatment capacity, occupation of on-site space of a clean area for transit storage, indefinite sterilization effect and easy chemical pollution to environment. The pathogenic microorganism waste liquor treatment system provided by the invention directly conveys the waste liquor generated by various viable bacteria and live virus areas of buildings to the waste liquor sterilizing tank for high-temperature steam sterilization, and then conveys the waste liquor to the common sewage treatment station for physicochemical treatment through a pipeline so as to achieve the aims of timely, massively, highly efficiently and reliably treating the pathogenic microorganism waste liquor with low cost, and reducing the chemical pollution.

Owner:NINGBO RONGAN BIOLOGICAL PHARMA

Optimal sandwich core structures and forming tools for the mass production of sandwich structures

InactiveUS20130244006A1Mass processingCost-effectiveMechanical working/deformationRotary pressesStructure of the EarthEngineering

Owner:CELLTECH METALS INC

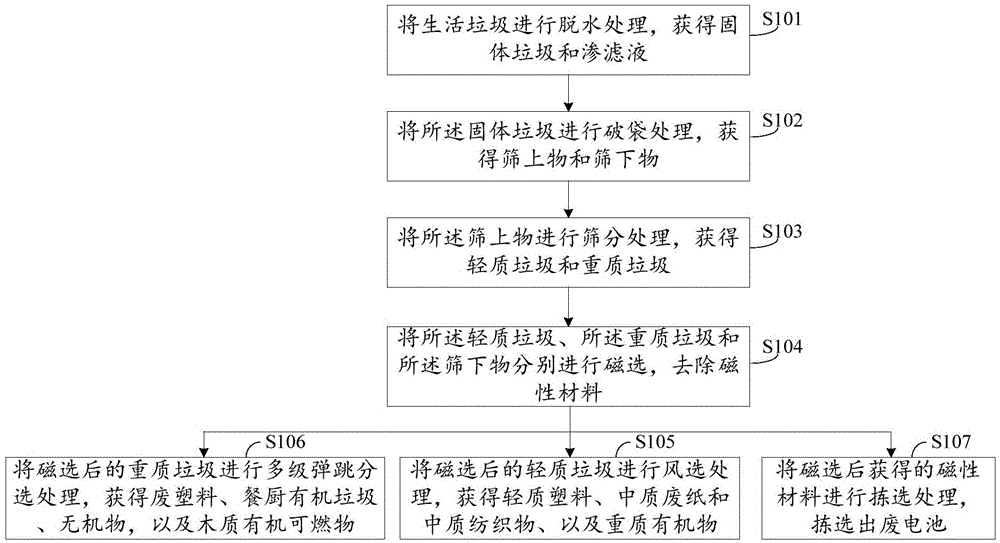

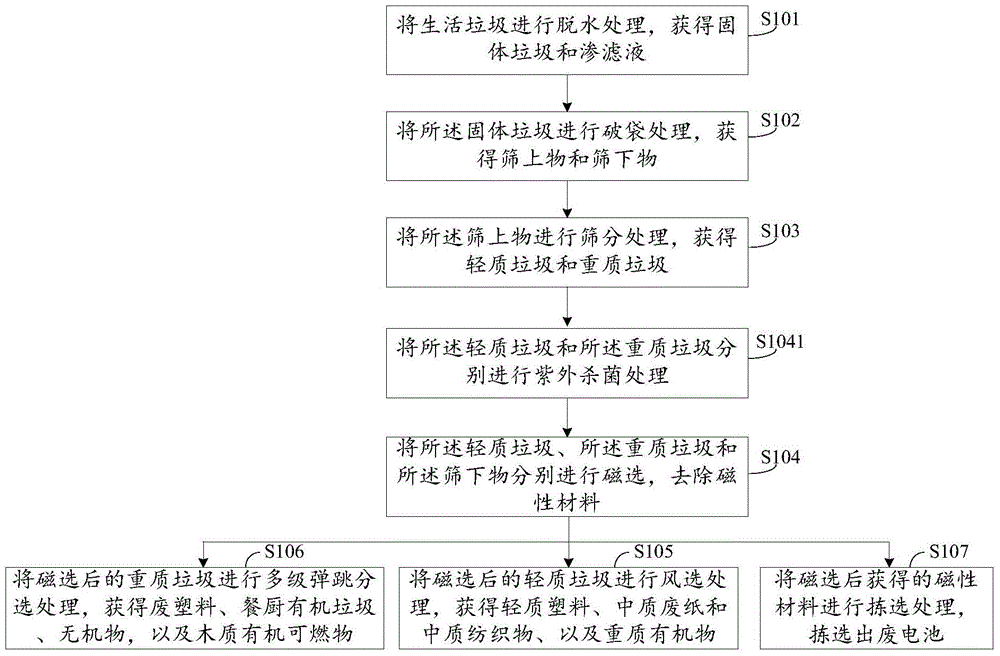

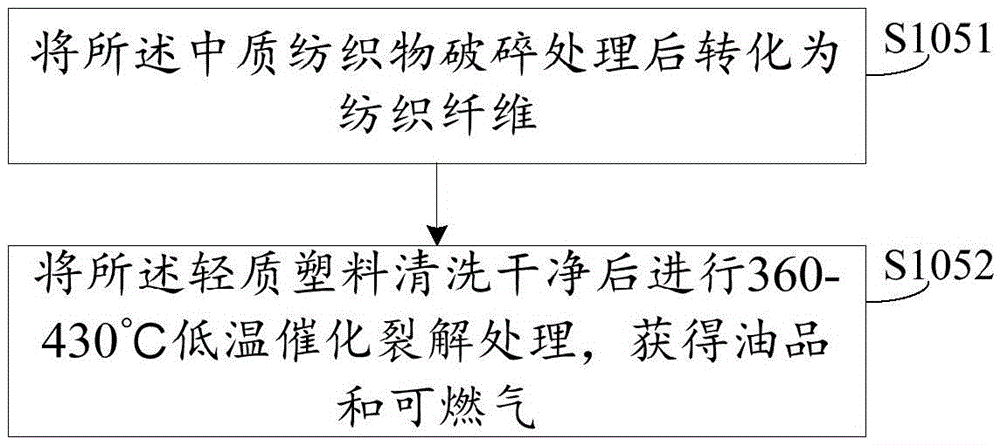

Method for sorting household garbage

InactiveCN105521986AMass processingEasy to handleSolid waste disposalMagnetic separationResource recoveryLitter

The invention relates to the field of garbage disposal, in particular to a method for sorting household garbage. The method classifies household garbage in detail by adopting the following steps: dehydration treatment, bag breaking, screening, magnetic separation, winnowing, multistage bouncing sorting and picking treatment. The final sorting efficiency of a variety of materials achieves more than 85 percent, the sorting effect is good, the disposal capacity is large, and manpower is saved. After sorting, according to the properties of materials, the classified household garbage is respectively recycled to be reused, deeply reprocessed or harmlessly treated. Thus, the household garbage is largely and quickly disposed, the value-maximized resource recovery of household garbage is realized. The method has great economic value and environmental benefits.

Owner:SHENZHEN HUAYUN DIGITAL CO LTD

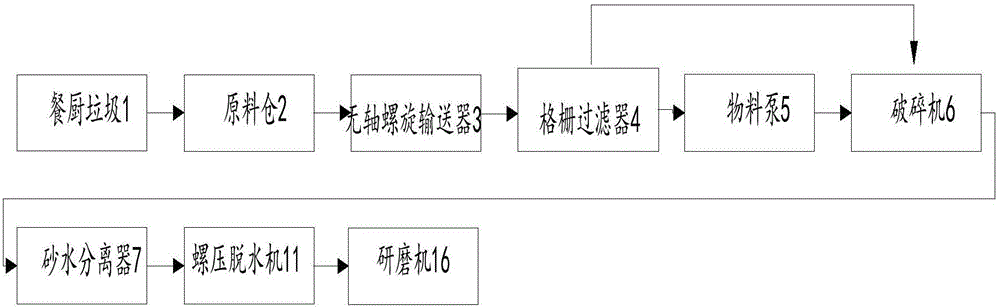

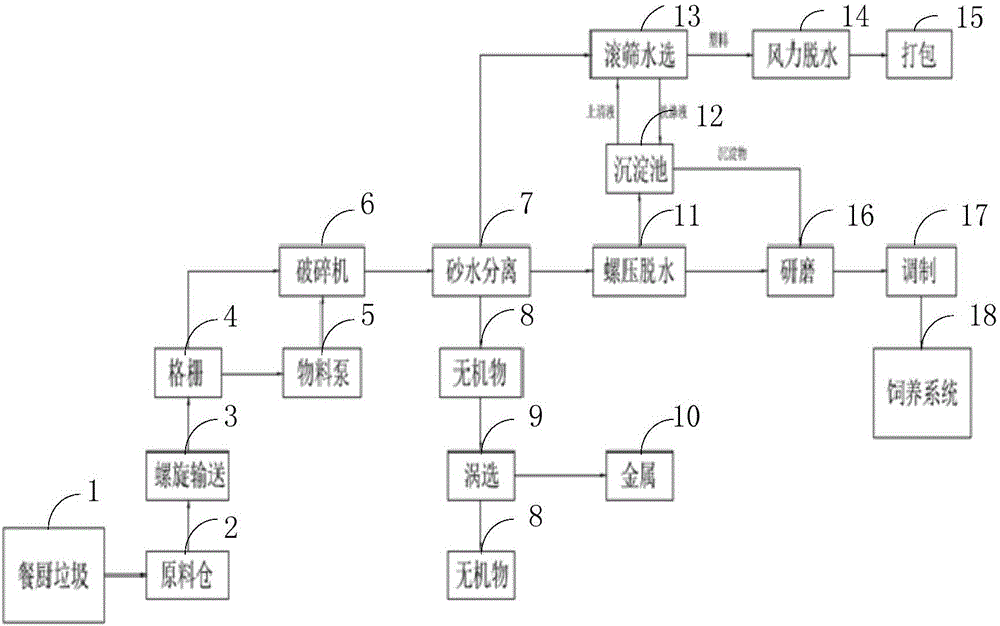

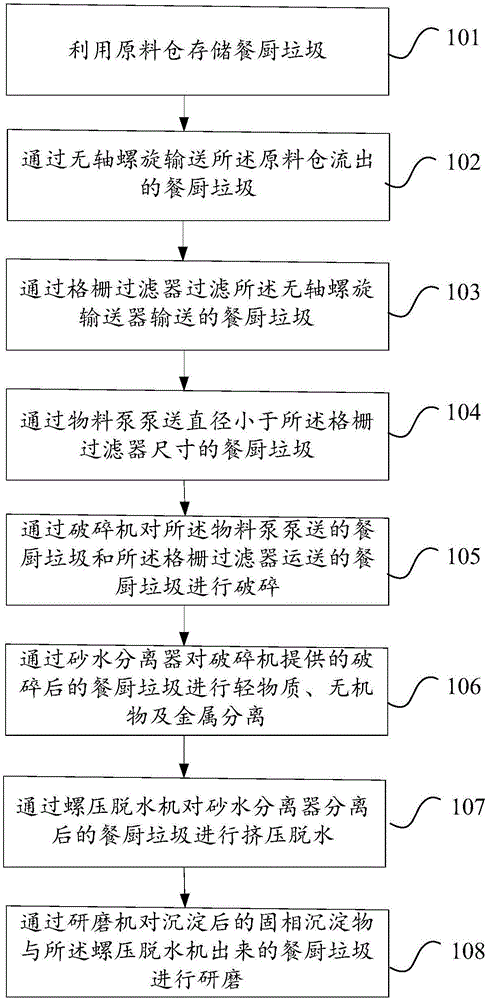

Garbage pretreatment system and method using kitchen garbage to feed insects

InactiveCN106269811AEasy to handleMass processingSolid waste disposalGrain treatmentsLitterHandling system

The invention relates to the field of garbage treatment, in particular to a garbage pretreatment system and method using kitchen garbage to feed insects. The system comprises a raw material bin, a shaftless spiral conveyor, a grid filter, a material pump, a crusher, a sand-water separator, a screw compression dewatering machine and a grinding machine, wherein the shaftless spiral conveyor is arranged at the bottom of the raw material bin; the grid filter is arranged at the bottom of the raw material bin and connected with the shaftless spiral conveyor; the material pump is arranged at the bottom of the raw material bin and connected with the grid filter; the crusher is connected with the grid filter and the material pump; the sand-water separator is connected with the crusher; the screw compression dewatering machine is connected with the sand-water separator; the grinding machine is connected with the screw compression dewatering machine. The garbage pretreatment system has the advantages that the kitchen garbage is filtered first, conveyed separately and crushed, impurities are sorted, a large amount of the kitchen garbage can be treated, equipment blocking can be avoided, continuous normal operation of equipment can be guaranteed, high-quality insect protein can be obtained, and high economic value is achieved.

Owner:深圳华云智能装备科技有限公司

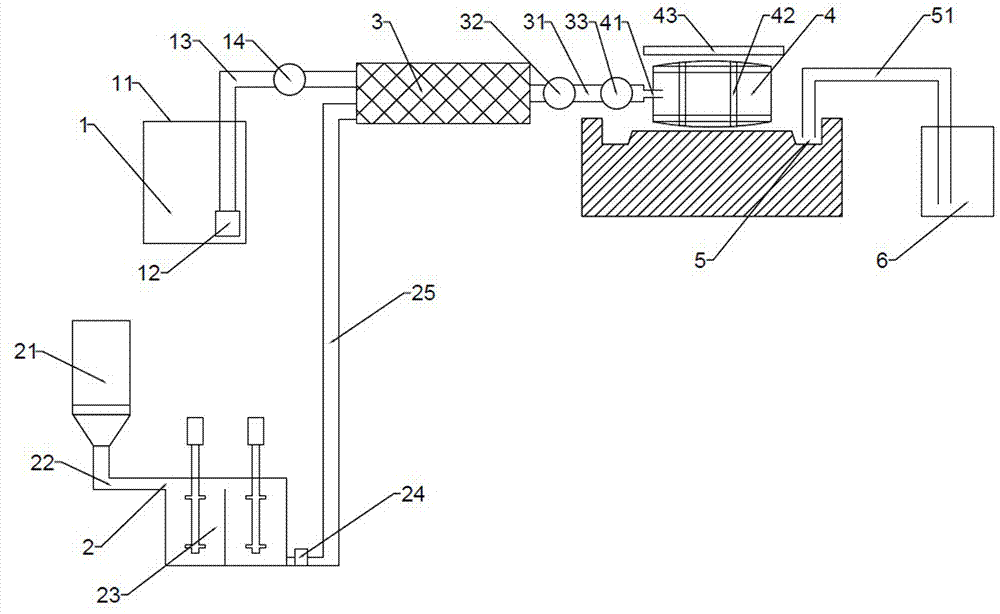

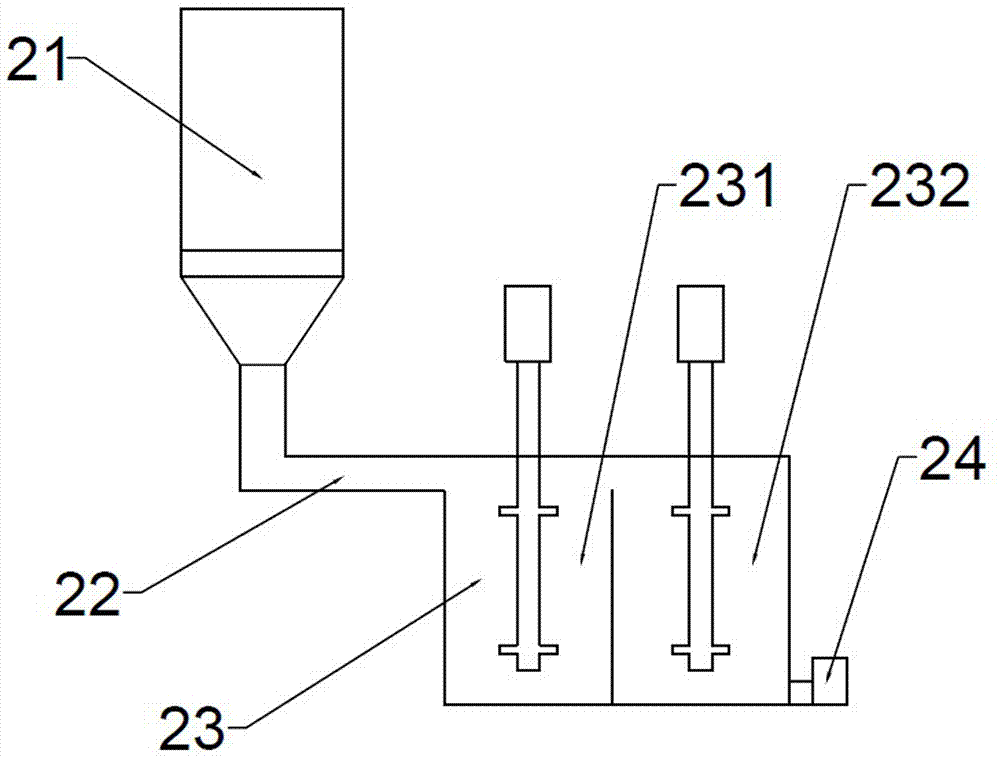

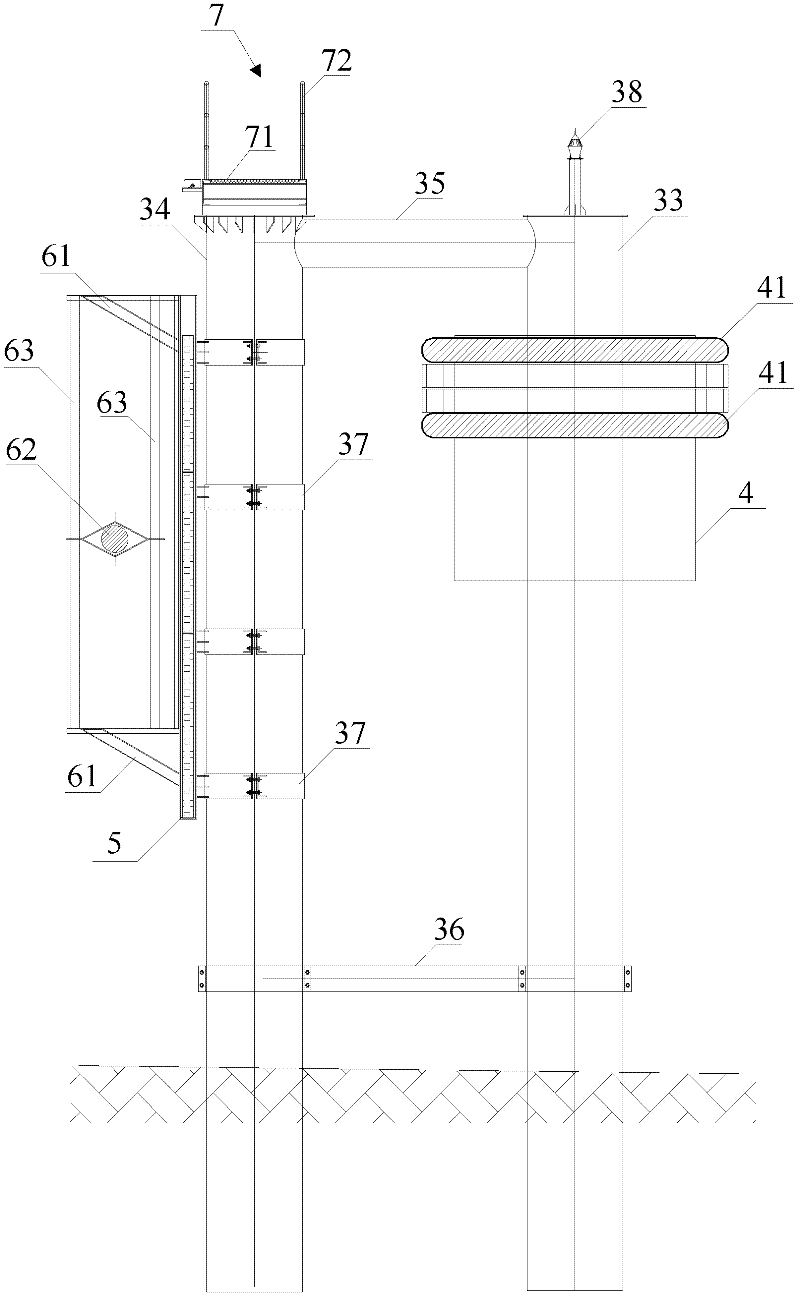

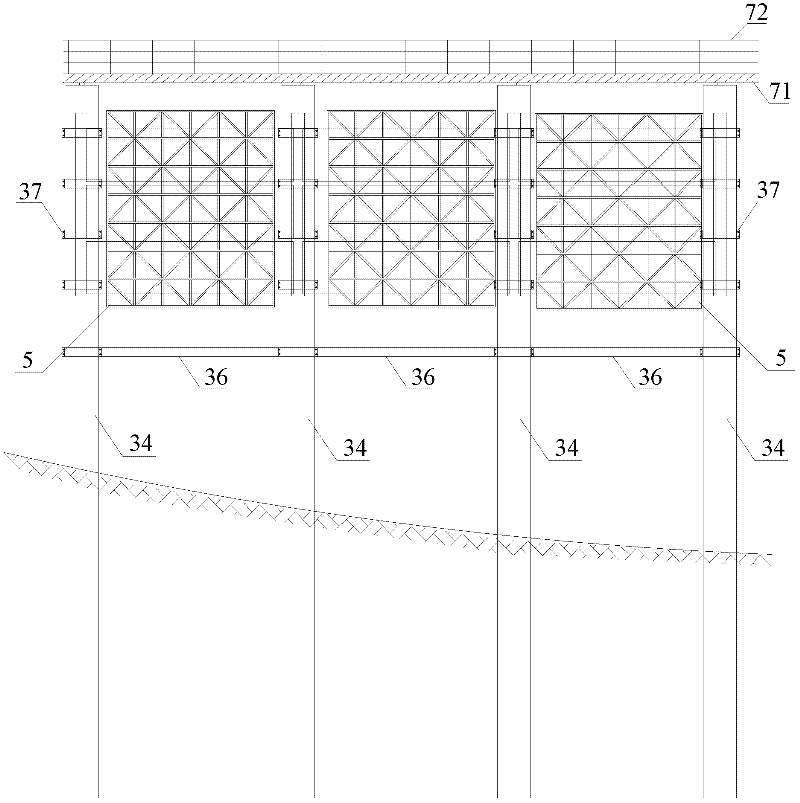

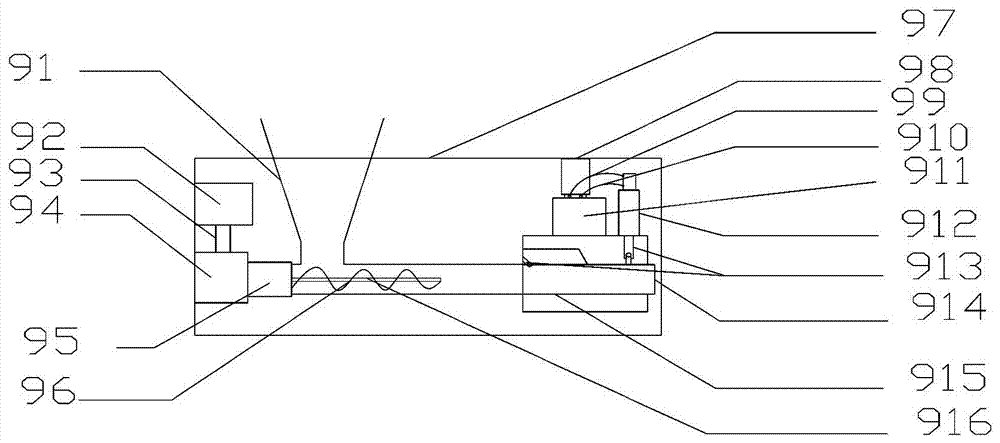

Dehydration and curing device for river channel silt

InactiveCN106927661AReduce energy consumptionFast mud dischargeSludge treatment by de-watering/drying/thickeningWater treatment parameter controlFiltrationControl system

The invention discloses a dehydration and curing device for river channel silt. The device comprises a silt treatment and conveying system, a coagulant stirring and conveying system, a pipeline mixer, dehydration filter bags, a water collecting groove, a drainage well and a control system, wherein the silt treatment and conveying system comprises a silt impurity-removing pool, and a silt pumping and conveying device is arranged in the silt impurity-removing pool; the coagulant stirring and conveying system comprises a coagulant storage device, a coagulant conveying device, a coagulant stirring device and a coagulant pumping and conveying device; the pipeline mixer is connected with the multiple dehydration filter bags, each dehydration filter bag is provided with a drainage device in the circumferential and / or in the longitudinal direction, and a height control device is arranged above each dehydration filter bag. According to the dehydration and curing device for the river channel silt, by the utilization of the filtration function of the dehydration filter bags, in combination with the addition of corresponding flocculating agents, power consumption produced by mechanical dehydration can be greatly reduced, the silt discharging speed is high, the silt discharging amount is large, the dehydration and curing device is very suitable for treating a large amount of silt, simple in structure and easy to operate, no much manual operation needs to be carried out in the usage process, and the labor cost is saved.

Owner:浙江中呈科技有限公司

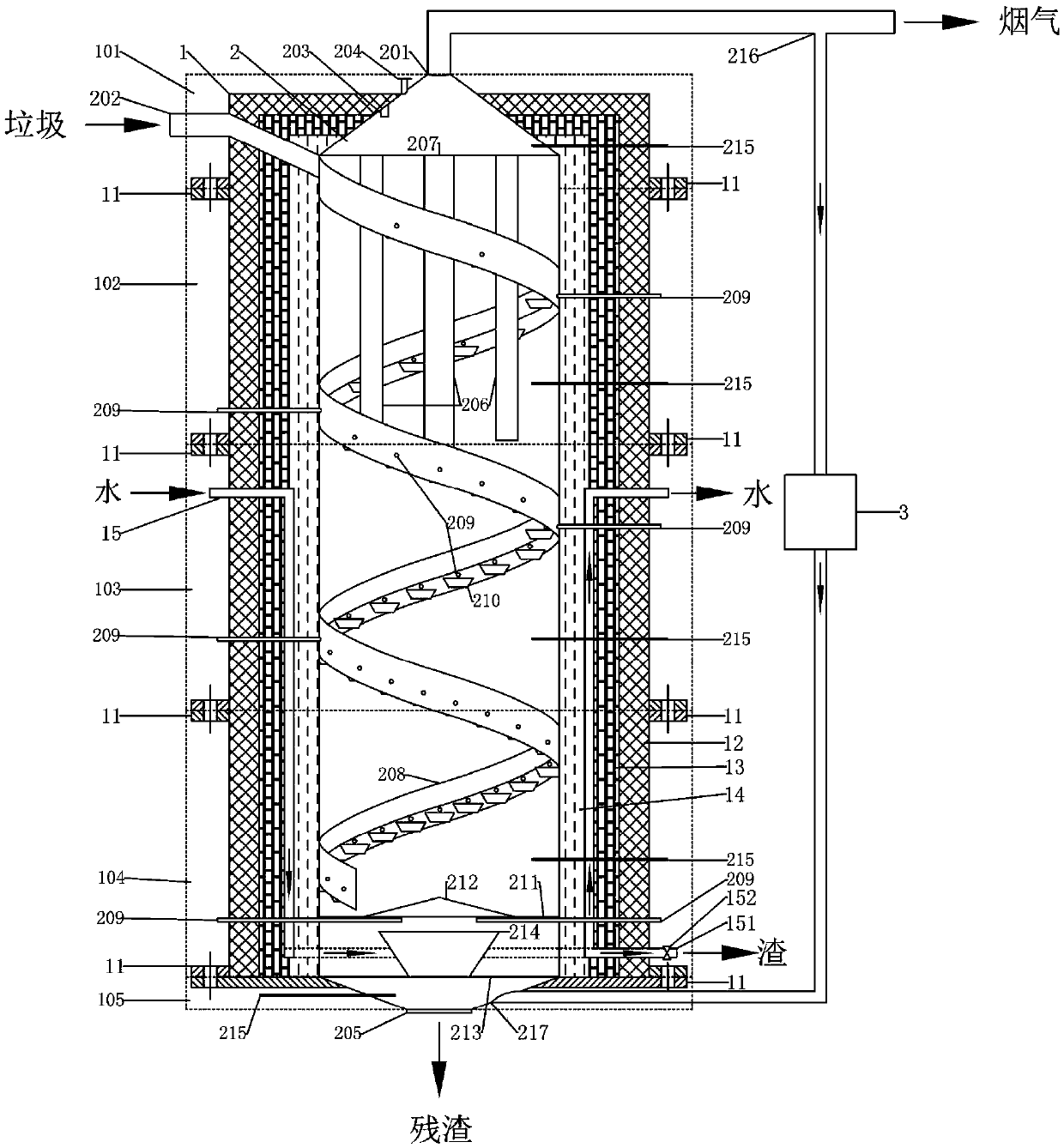

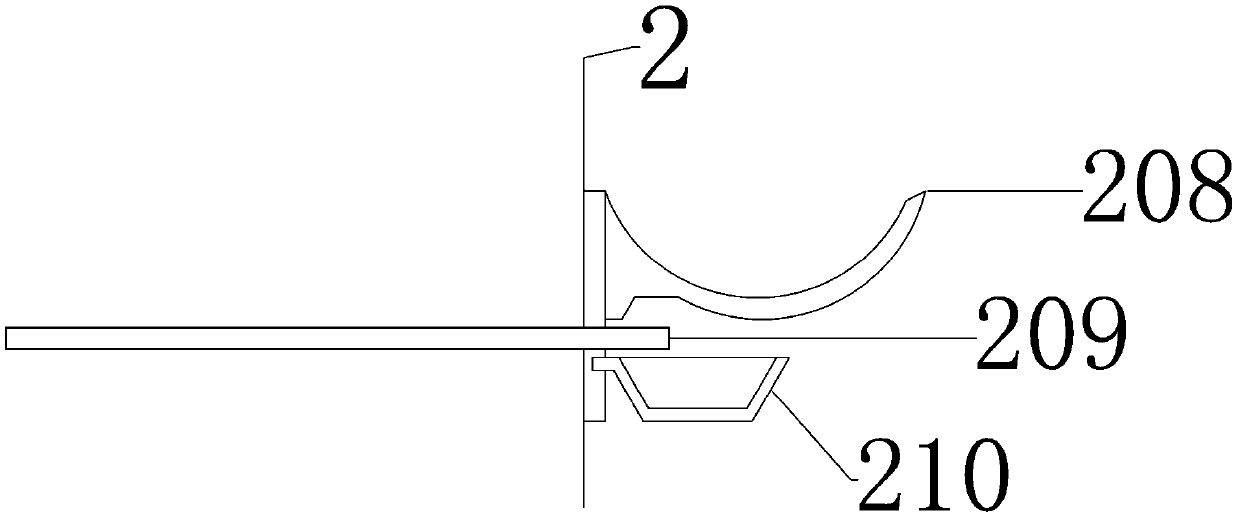

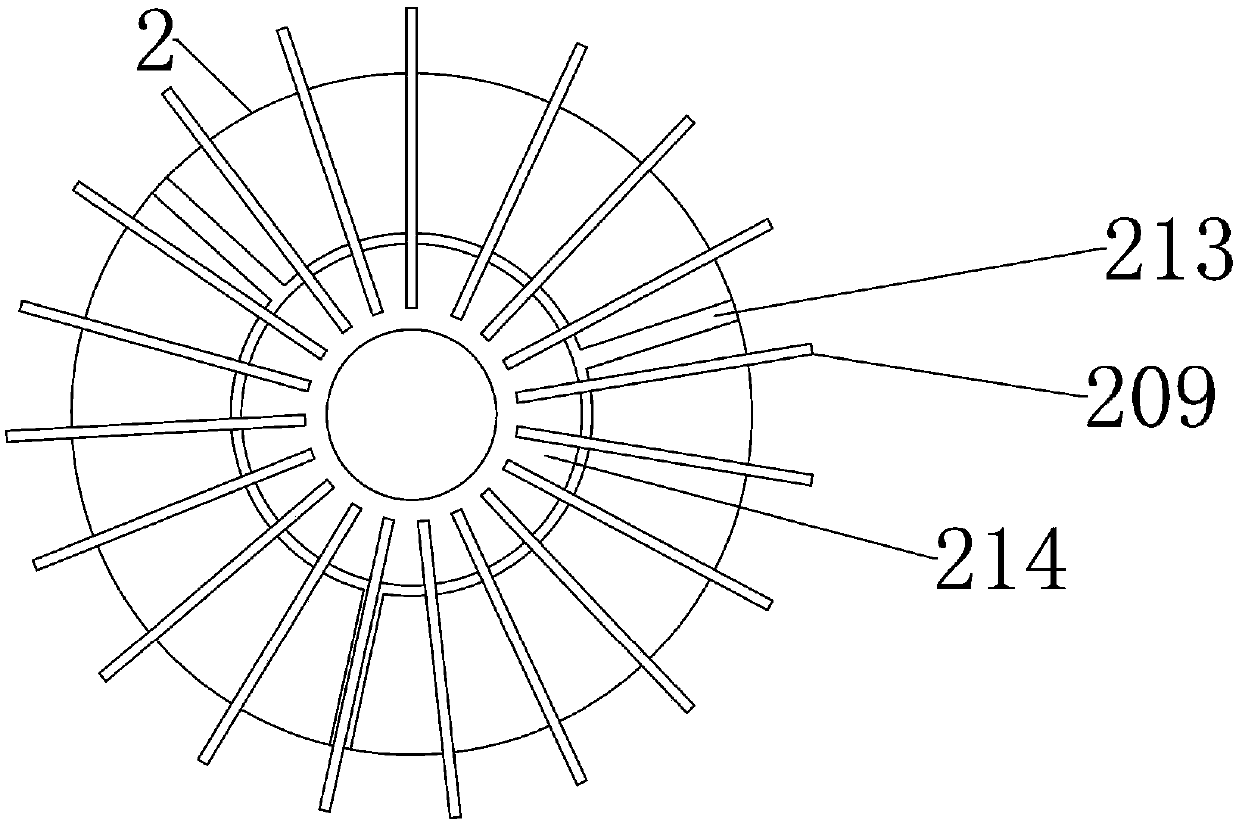

Brown's gas-burning solid organic waste pyrolyzing furnace

ActiveCN109681884ALow costInhibitionSpecial form destructive distillationIncinerator apparatusHeat conductingCrucible

The invention relates to the field of solid waste pyrolyzing devices, and discloses a Brown's gas-burning solid organic waste pyrolyzing furnace which comprises a housing and a cavity positioned inside the housing, wherein the housing is equipped with a main gas exhaust port, a pressure detector, an overpressure relief valve, an inductive ash-discharging electric valve and a feeding port; the cavity is equipped with smoke-guiding gas columns, a guiding chute, Brown's gas burning guns, wall-hanging crucibles, a heat conducting plate and a crucible basin; the wall-hanging crucibles and the crucible basin are filled with a metal material; and through an external fan of the Brown's gas-burning solid organic waste pyrolyzing furnace, part of burnable gas generated from the pyrolyzing process can flow back to the Brown's gas-burning solid organic waste pyrolyzing furnace. A kind of clean burning energy, namely Brown's gas, is utilized for the Brown's gas-burning solid organic waste pyrolyzing furnace; and the Brown's gas-burning solid organic waste pyrolyzing furnace has the advantages that the environment-friendly property is achieved, the cost is low, the occupied area is small, and solid organic waste can be efficiently, continuously and massively treated.

Owner:广东蓝新氢能源科技有限公司

Top-emitting device and illumination device

ActiveUS7589463B2Improve light extractionProduced economicallyDischarge tube luminescnet screensLamp detailsOrganic layerSurface structure

The invention refers to a top-emitting device, particularly organic light-emitting diode having a layer arrangement applied on a substrate, which layer arrangement comprises a bottom electrode arranged on the substrate and a top electrode through which a light emission is effected, and also a stack of organic layers arranged between the bottom electrode and the top electrode where, at the bottom electrode, a surface facing towards the stack of organic layers is formed in light-reflecting fashion at least in a partial region and being provided with a surface structure that defines a reflection of light generated in the stack of organic layers at the bottom electrode, and where the surface structure is formed by means of mechanical shaping.

Owner:NOVALED GMBH

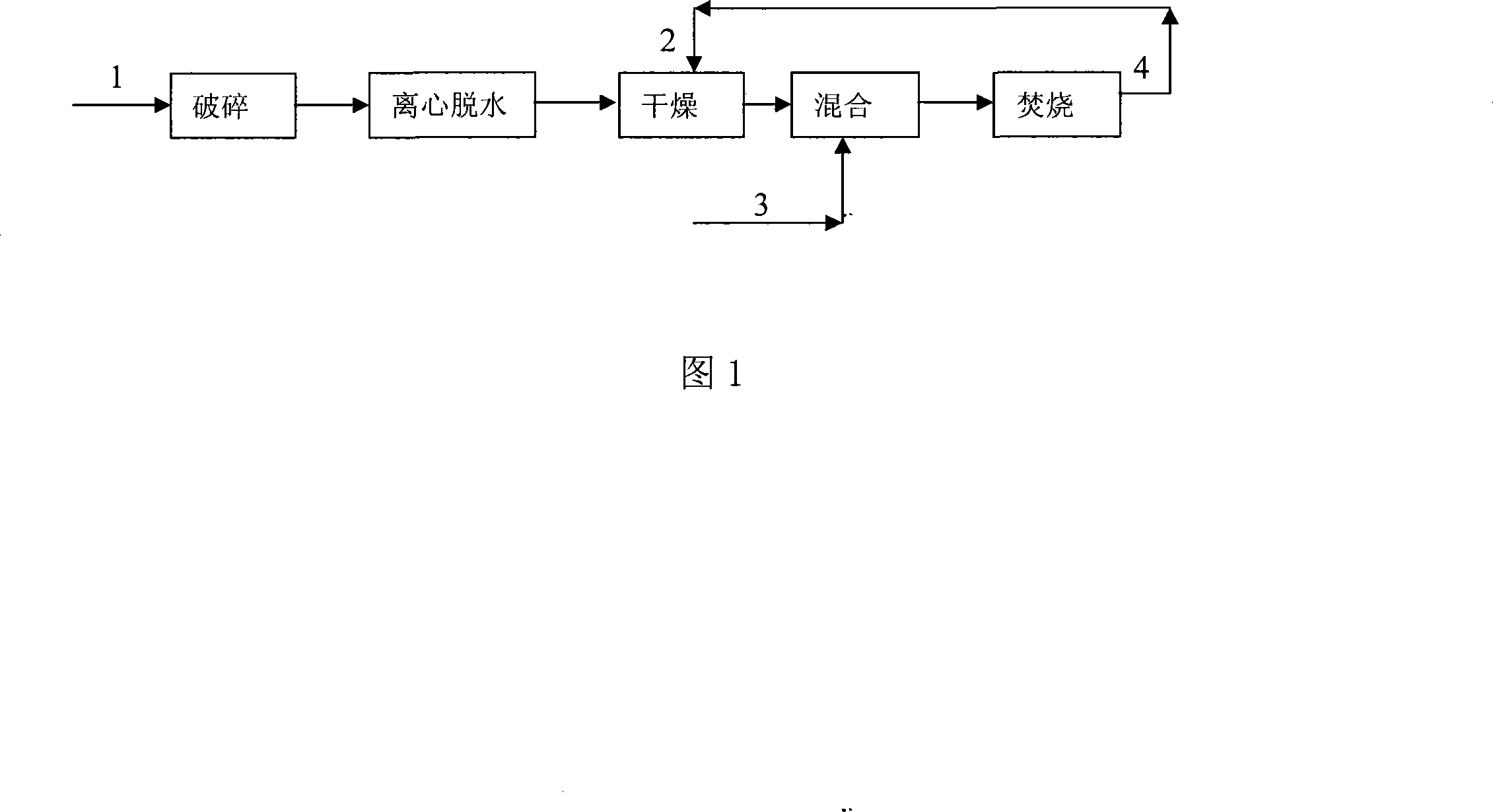

Burning processing method for hyacinth

The invention discloses a burning disposal method used for burning hyacinths, belonging to the biological matter burning technique field of environment protection engineering. The method mainly includes the following steps: firstly, newly collected hyacinths are transferred to a crusher for being crushed and the crushed hyacinths are transferred to a centrifuge spin-drier for being spin-dried and then are transferred to a drier for being dried, after being dried, the hyacinths contain 60 to 70 percent of water; assistant fuel coals with a mass ratio of 5 to 10 percent against the processed newly collected hyacinths are mixed into the dried hyacinths to get mixed fuel; finally the mixed fuel is delivered into an incinerator for carrying out burning disposal. In the invention, the heat supply used for drying the hyacinths comes from the heat of the hot off-gas generated by the incinerator so as to realize the heat recycling of heat and the adding ratio of the assistance fuel coal is low. The invention provides the method for the mass, quick and collective final disposal of the hyacinths.

Owner:BEIJING JIAOTONG UNIV

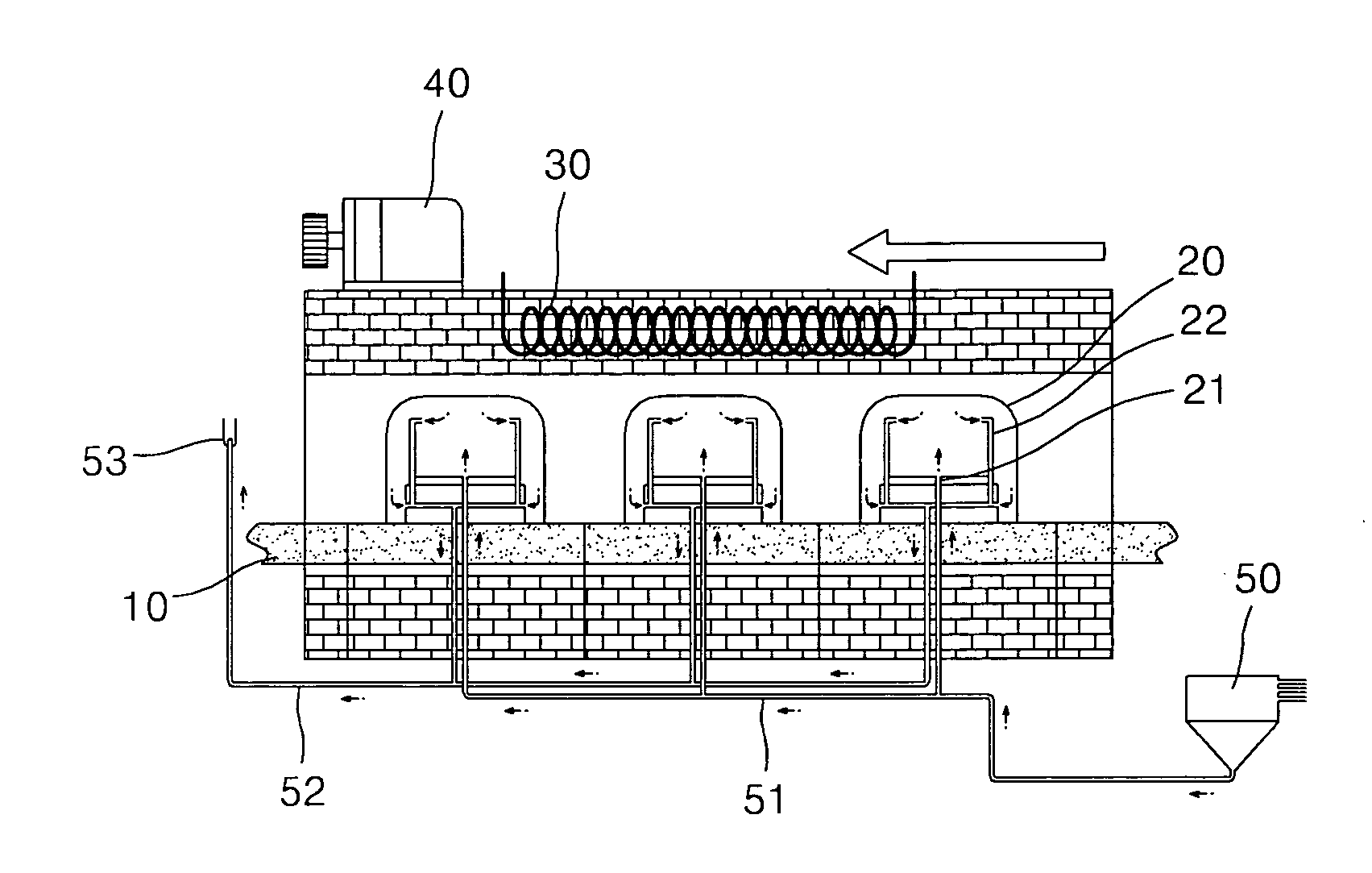

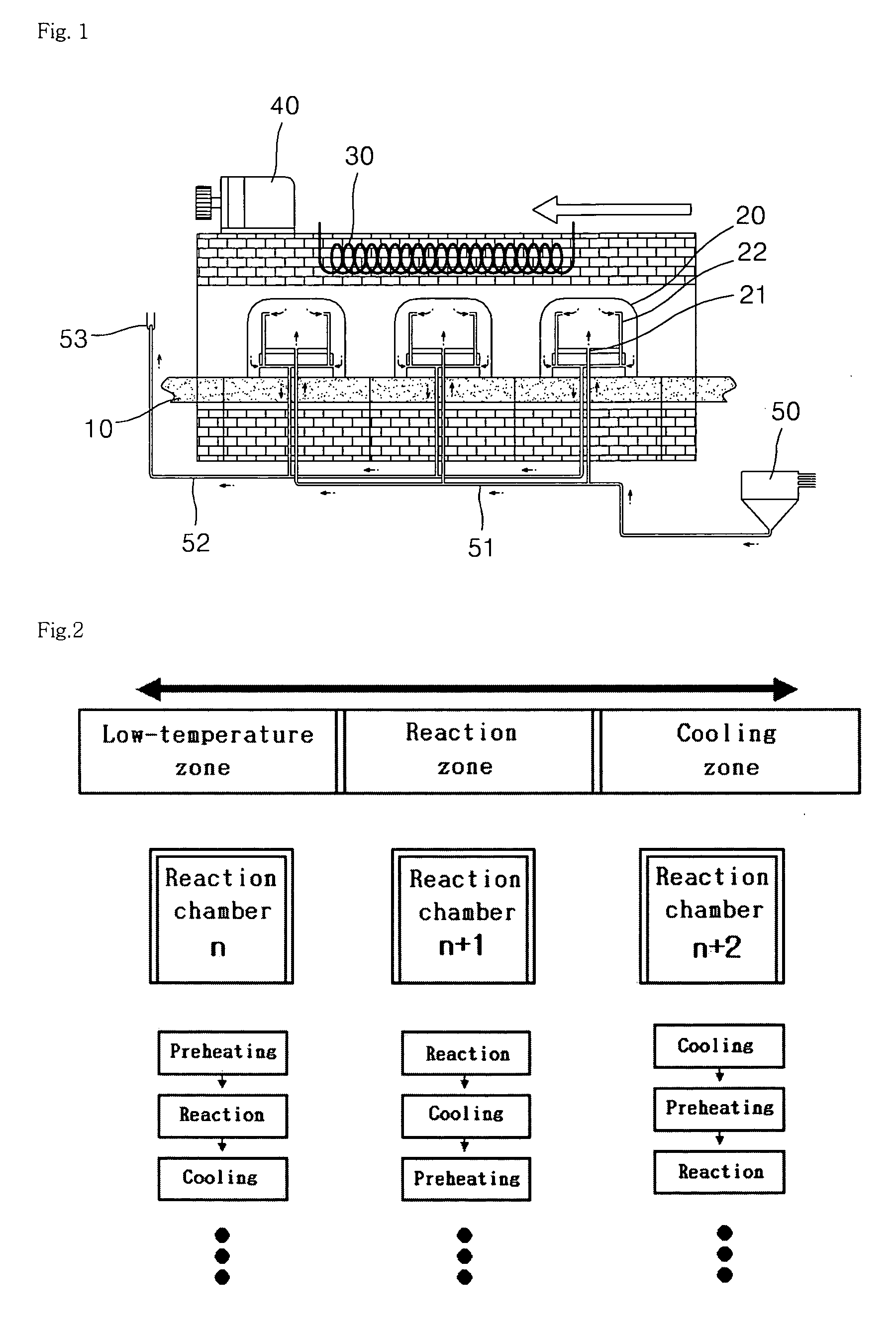

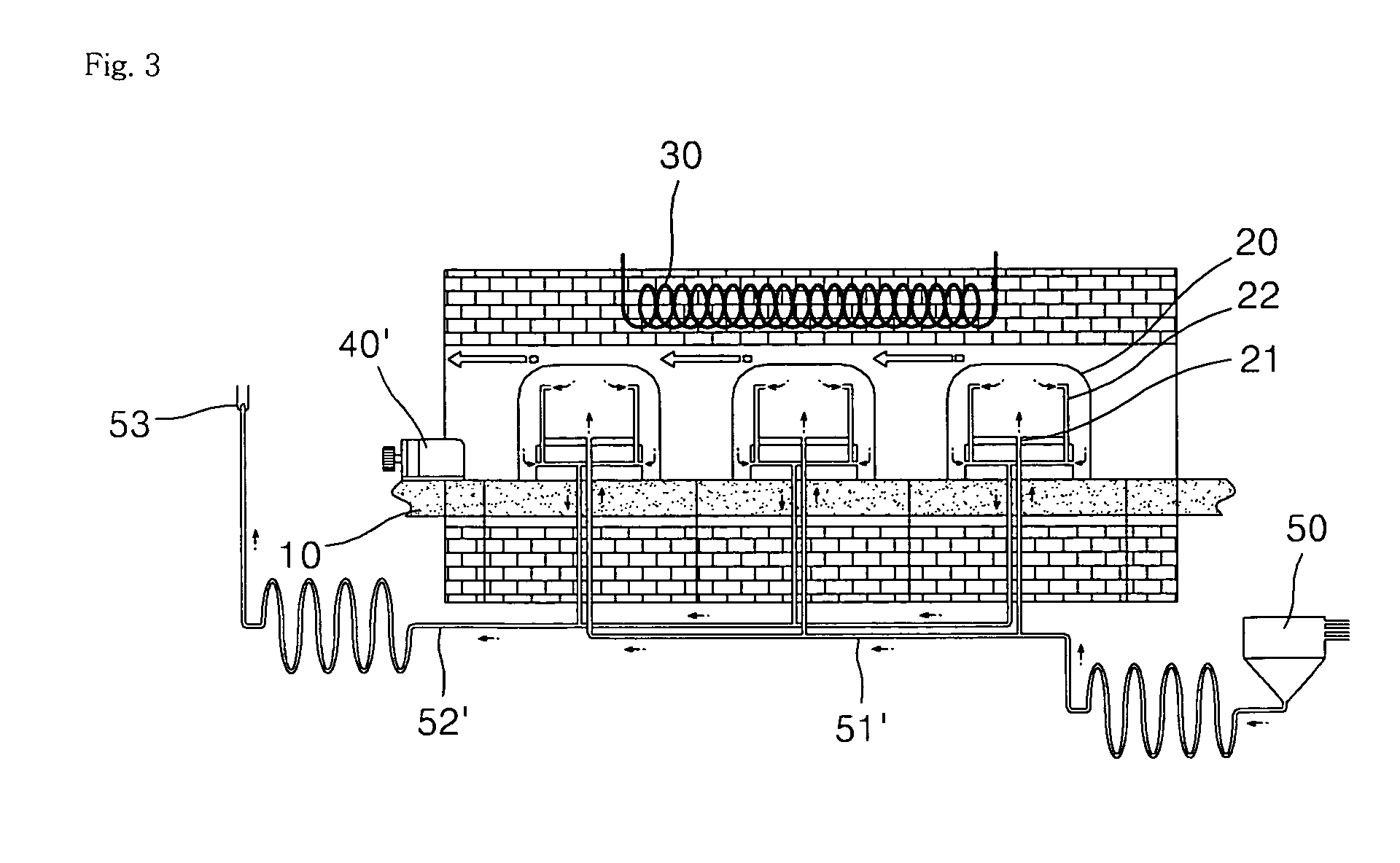

Apparatus and method for mass production of carbon nanotubes

InactiveUS20060269468A1Guaranteed uptimeMass processingMaterial nanotechnologyGaseous chemical processesCarbon nanotubeReaction temperature

The present invention relates to an apparatus and method for mass production of carbon nanotubes. More specifically, it relates to an apparatus and method for mass production of carbon nanotubes, which are capable of achieving mass synthesis of carbon nanotubes and simultaneous production of various structures of carbon nanotubes, by a manner that a plurality of independent reaction chambers are configured, and a heater supplying temperatures necessary for reaction in the corresponding reaction chambers is configured to have a plurality of reaction temperature sections, such that the heater moves according to reaction steps in the respective reaction chambers under different reaction steps and matches reaction temperature sections to thereby continuously provide proper reaction temperatures to the respective reaction chambers and at the same time, to stably supply and discharge reaction gases and stabilizing gases necessary for the respective reaction steps to and from respective reaction chambers, in order to continuously produce carbon nanotubes.

Owner:VIKO

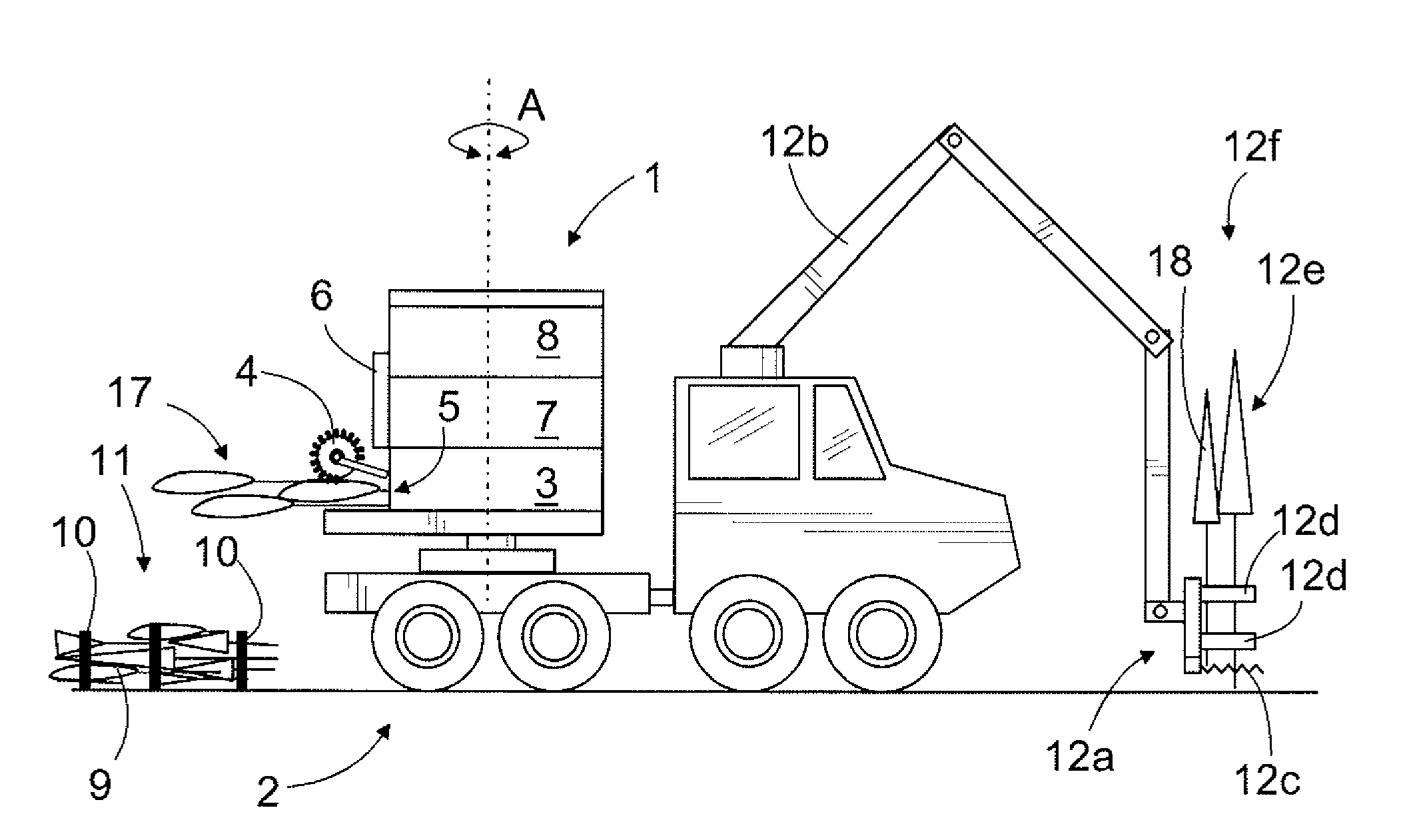

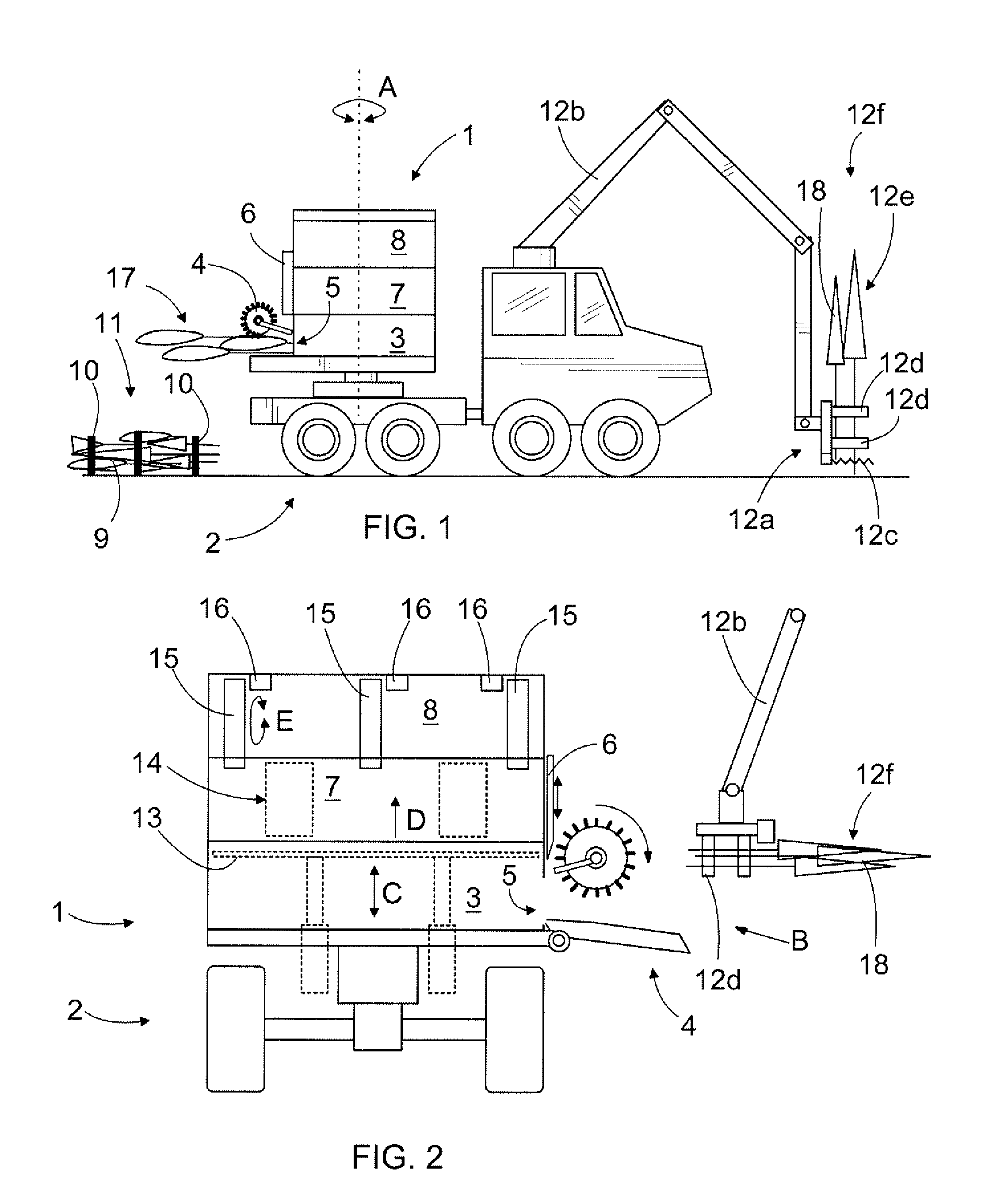

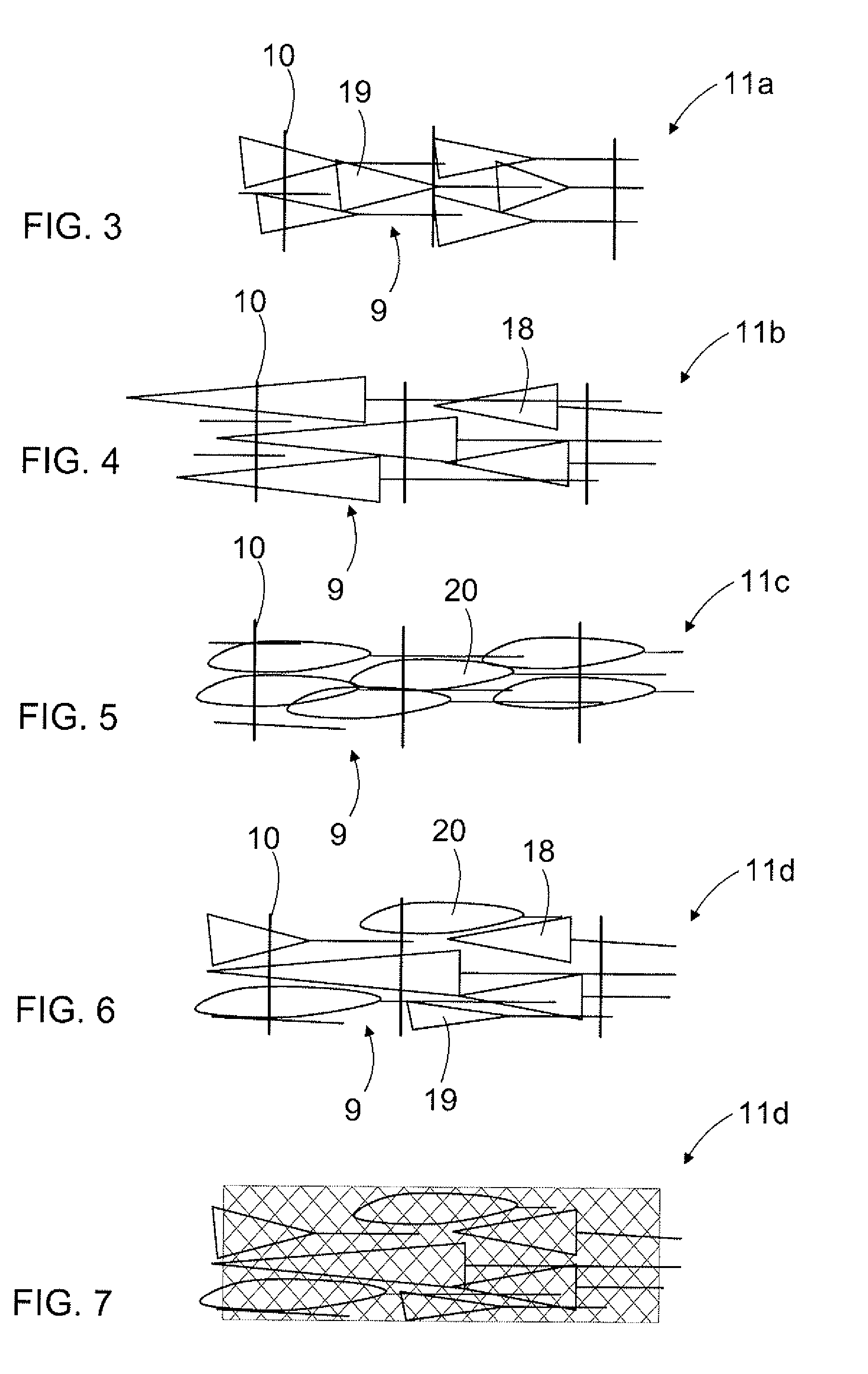

Method and arrangement for harvesting

InactiveUS20100024921A1Cost effectiveness of harvesting improvesIncreased cost-effectivenessTree debarkingChemical debarkingPulp and paper industryRaw material

A method for harvesting and an arrangement for processing wood. In a harvesting area, a baler (1) is used to bale small-dimensioned wood into bales belonging to different bale classes, wherein a compressed wood bundle (9) is bound by means of a binding member (10). Energy bales (11d) and raw material bales (11a to 11c) may be created in a forest. The raw material bales may be processed in a debarking device (21), wherein the wood contained by the bale is divided into a pulp fraction (26) and an energy fraction (25). The pulp fraction may be used in the manufacture of raw material, and the energy fraction may be used as fuel.

Owner:FIXTERI

Method for treating high-fat wastewater of food industries

InactiveCN106277597AEconomic treatmentEasy to handleTreatment involving filtrationWaste based fuelFiltration membraneUltrafiltration

The invention relates to a method for treating high-fat wastewater of food industries. The method comprises the following steps: (A) after wastewater flows through multiple grids, pumping the wastewater into a bending-flow type hydrolysis reactor for treating, introducing the wastewater into an anaerobic aeration tank, and carrying out anaerobic treatment; (B) introducing the wastewater into a coagulating tank for coagulation, regulating the pH to 7.5-8.5, firstly carrying out solid-liquid separation, and carrying out floating separation; (C) carrying out oxidation treatment on the wastewater by virtue of ultrasonic compound supercritical water, filtering by virtue of activated carbon, and carrying out sedimentation; and (D) sequentially carrying out security filtering, micro-filtration membrane filtering, ultrafiltration membrane filtering and reverse osmosis membrane filtering, so as to obtain discharged water meeting the environmental protection standards. Compared with the prior art, the method has the advantages that the organic matters in the high-fat wastewater of the food industries can be effectively degraded, the acidity of the wastewater is reduced, suspended solids such as COD and grease, metal oxides, colloids, bacteria and the like can be effectively removed, the wastewater can be economic, efficient and bulk treatment of the wastewater can be realized, the operation is simple, the operation cost is low, the occupied area is reduced, and the treating effect is remarkable.

Owner:潘纪鸿

Ex-situ decontamination method for low-permeability contaminated soil

InactiveCN108941185AEfficient removalMass processingContaminated soil reclamationChemical reactionSoil treatment

The invention discloses an ex-situ decontamination method for low-permeability contaminated soil, and belongs to the field of contaminated soil treatment. The ex-situ decontamination method is characterized in that a plurality of electrodes which can conduct electricity and water are horizontally arranged at certain intervals and in parallel to form an electrode group, the electrode group and contaminated soil layers are stacked alternately, and the polarity of the direct current power supply to which any electrode is connected is opposite to the polarity of the direct current power supply towhich at least one of the electrodes surrounding the contaminated soil layers is connected; direct currents applied by the electrodes generates an electric field in the contaminated soil, meanwhile appropriate liquid is injected through the electrodes to regulate and control the chemical reaction environment in the contaminated soil, the pollutants in the contaminated soil migrate to the electrodes under the action of the electric field and are carried out by water via a water-filled pipeline of the electrodes, and the pollutants are removed from the contaminated soil. The ex-situ decontamination method can carry out the treatment of large-volume contaminated soil and can remove a variety of pollutants in the contaminated soil at the same time, the treatment time is short, and land occupation for construction is less.

Owner:BEIJING ZHONGYAN DADI TECH CO LTD

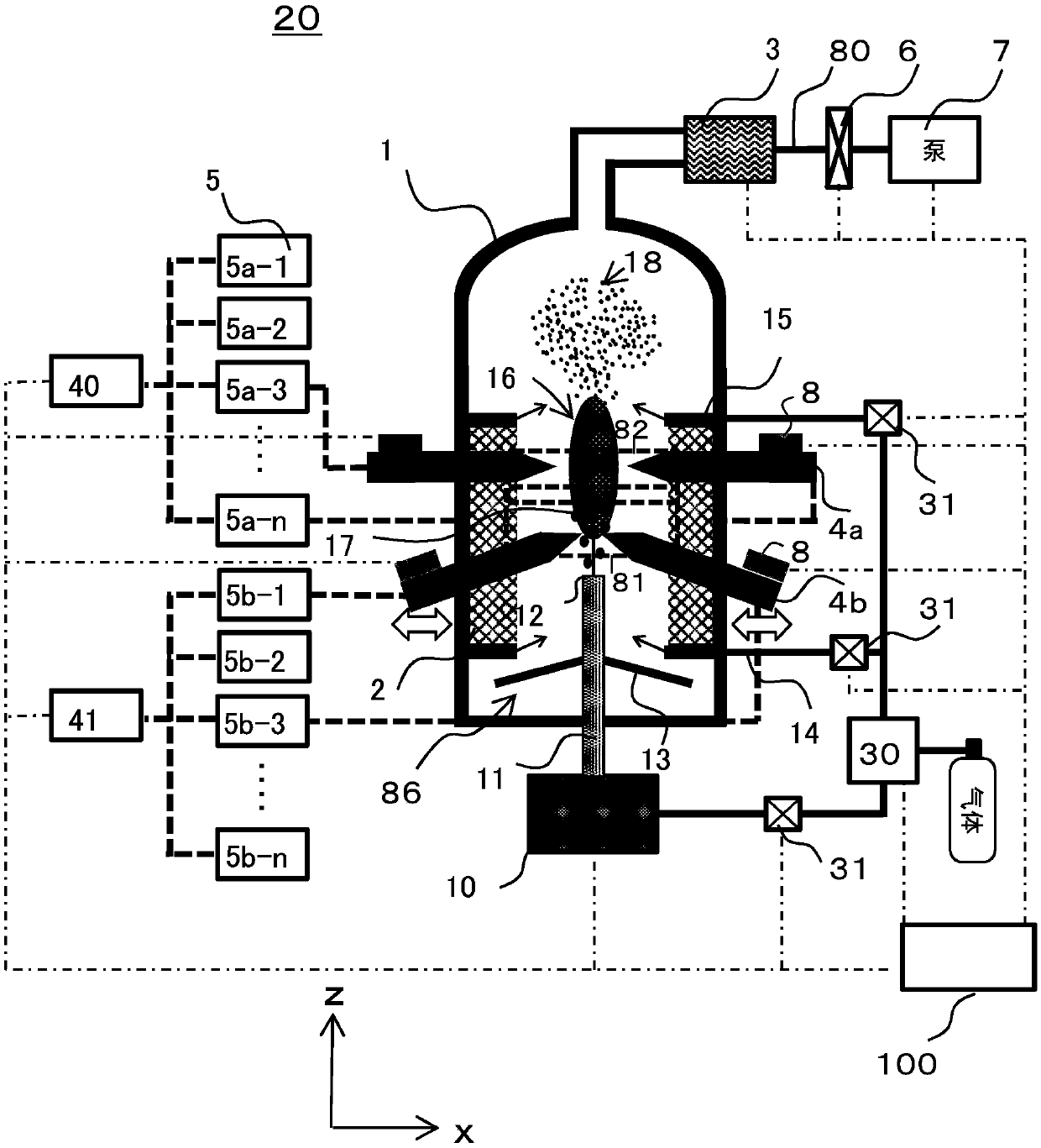

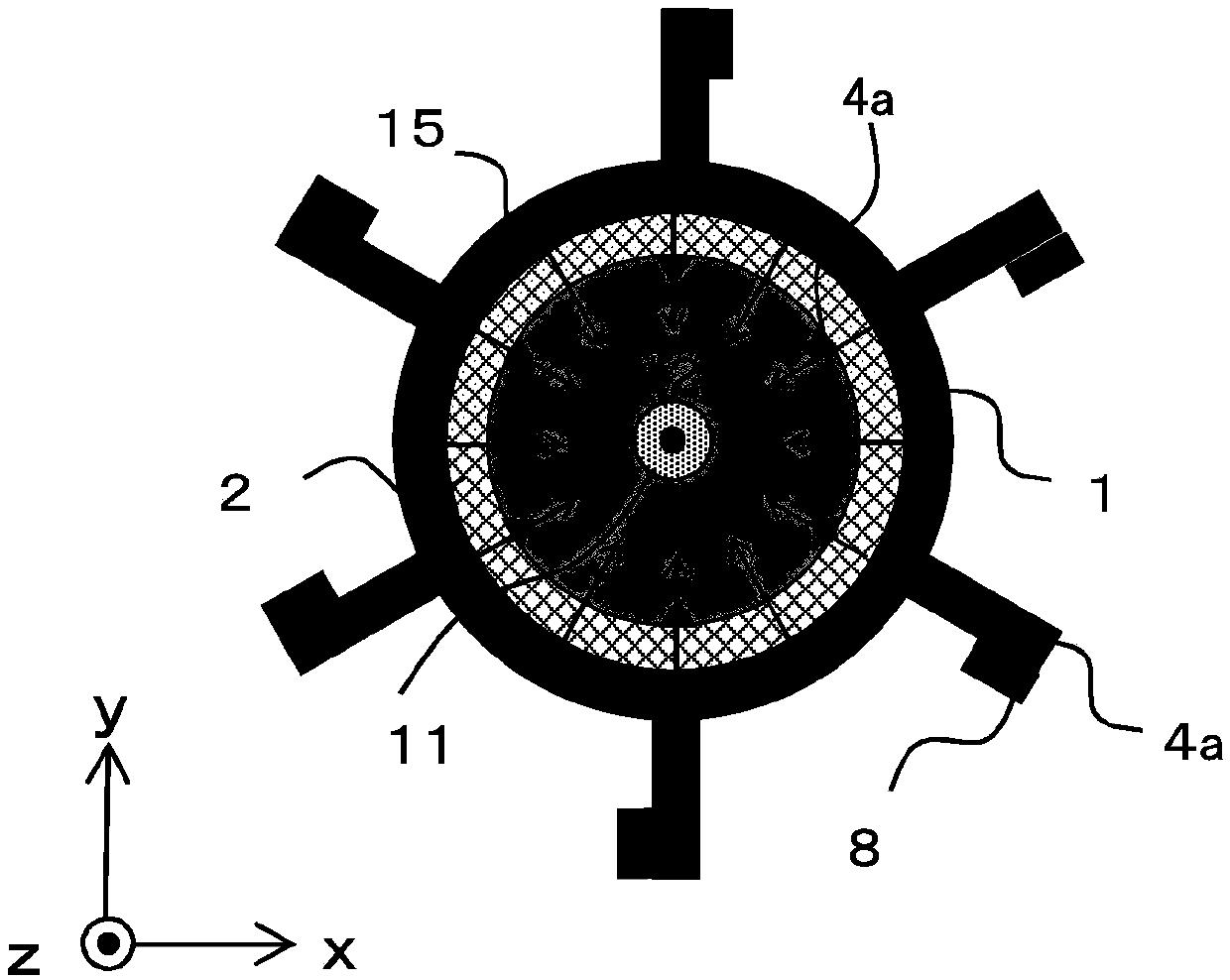

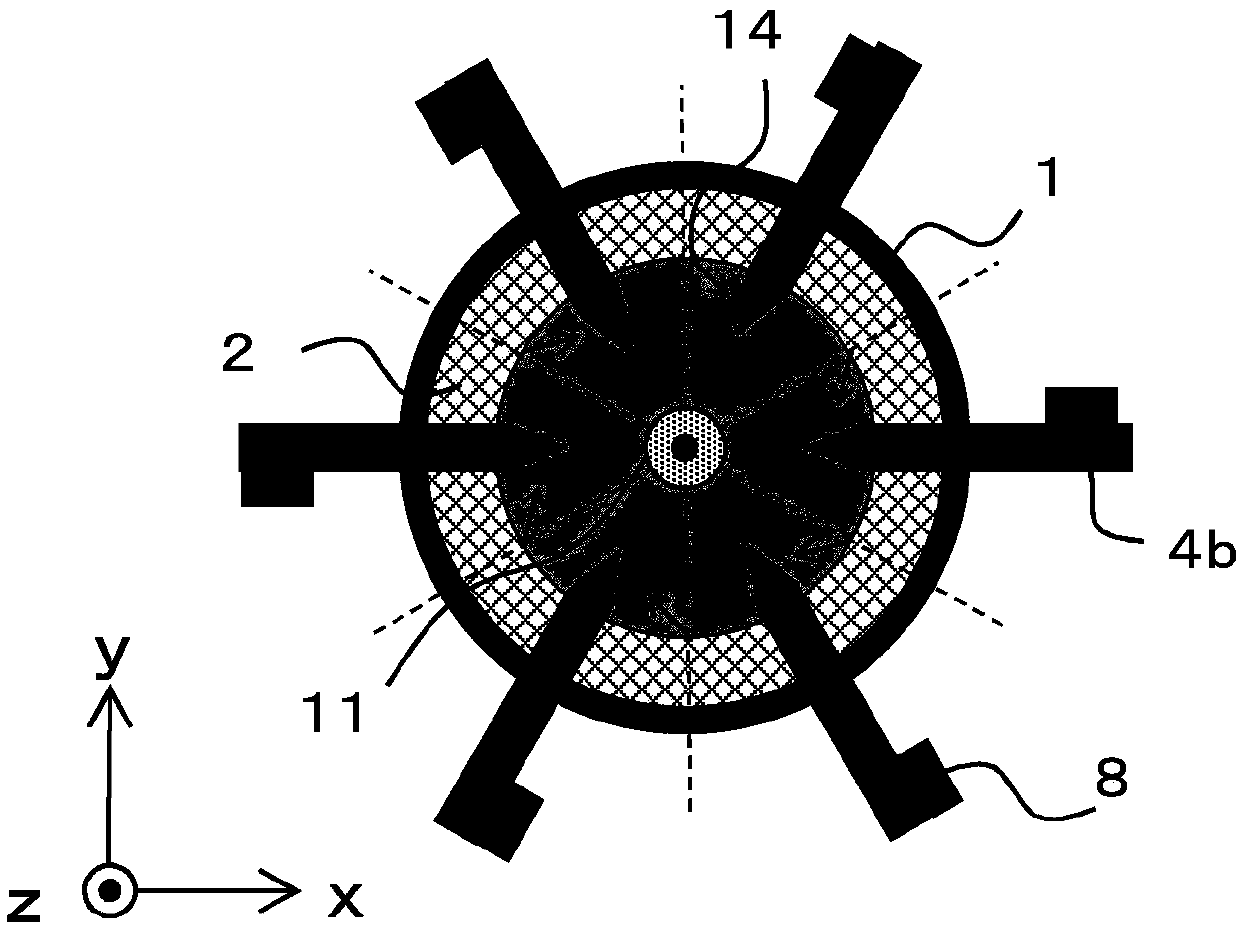

Microparticle manufacturing device and microparticle manufacturing method

ActiveCN110124599AImprove evaporation efficiencyHigh yieldProcess control/regulationTransportation and packagingMicroparticleAlternating current

The present invention provides a microparticle production device and a microparticle manufacturing method. The device includes a reaction chamber that extends from the lower side to the upper side inthe vertical direction; a material supply device that supplies material particles to the reaction chamber from a material supply port to the vertical direction; a first electrode arrangement region having a plurality of lower electrodes on an inner peripheral wall of the reaction chamber; a second electrode arrangement region having a plurality of upper electrodes on the part closer to the vertical direction on the inner peripheral wall of the reaction chamber than the first electrode arrangement region; a recycling part connected to the other end side of the vertical upper side in the reaction chamber to collect microparticles; a power source which is capable of changing the frequency of the alternating current power applied to at least one of the lower electrode and the upper electrode;and a control unit which set the frequency of the alternating current power applied to the lower electrode to be the frequency higher than the frequency of the alternating current power applied to theupper electrode. Arc discharge is generated through the lower electrode and the upper electrode, so plasma is generated in the reaction chamber, and microparticles are generated from the material particles.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

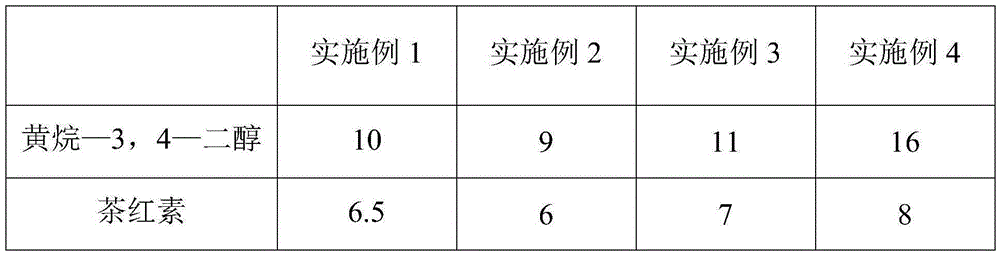

Water body restoration method

The present invention provides a water body restoration method using a water body restoration agent for restoration, and the water body restoration agent comprises the following components in parts by weight: 6 to 16 parts of flavan-3,4-diol, 5 to 8 parts of thearubigin, 7 to 12 parts of theaflavin, 0.5 to 1 part of violet essence, 1 to 2 parts of mink oil amide propyl betaine and 1 to 9 parts of Ca-Al hydrotalcite. The water body restoration method is simple to operate, only the water body restoration agent is poured into water without follow-up operation, the water body restoration method is wide in application range, and capable of processing a large number of all kinds of sewage, and the sewage can be effectively processed.

Owner:TIANJIN OUPAN TECH DEV CO LTD

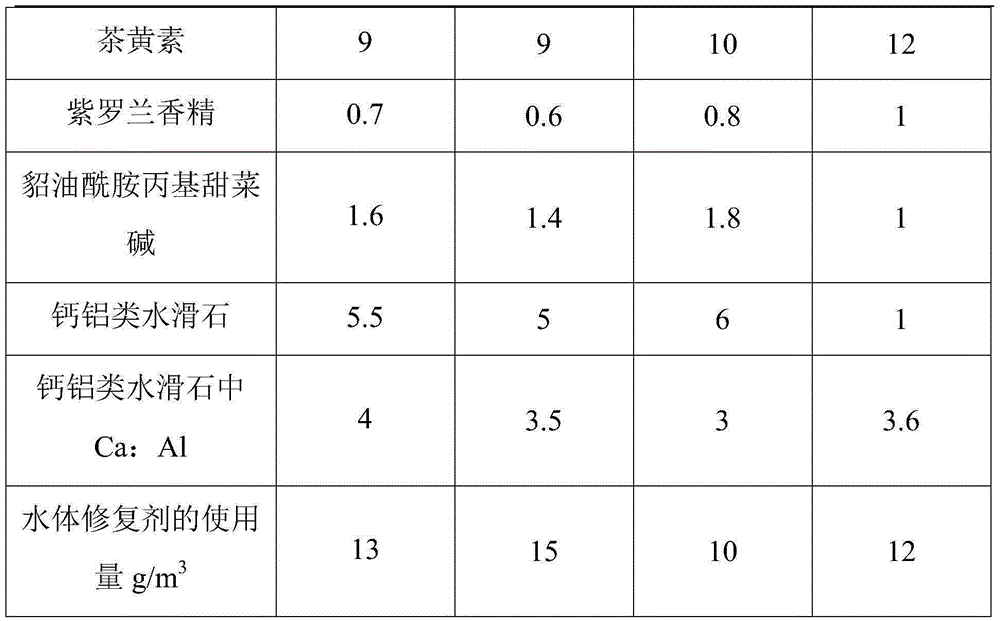

Sudden oil pollution pre-treatment system for large water intake port

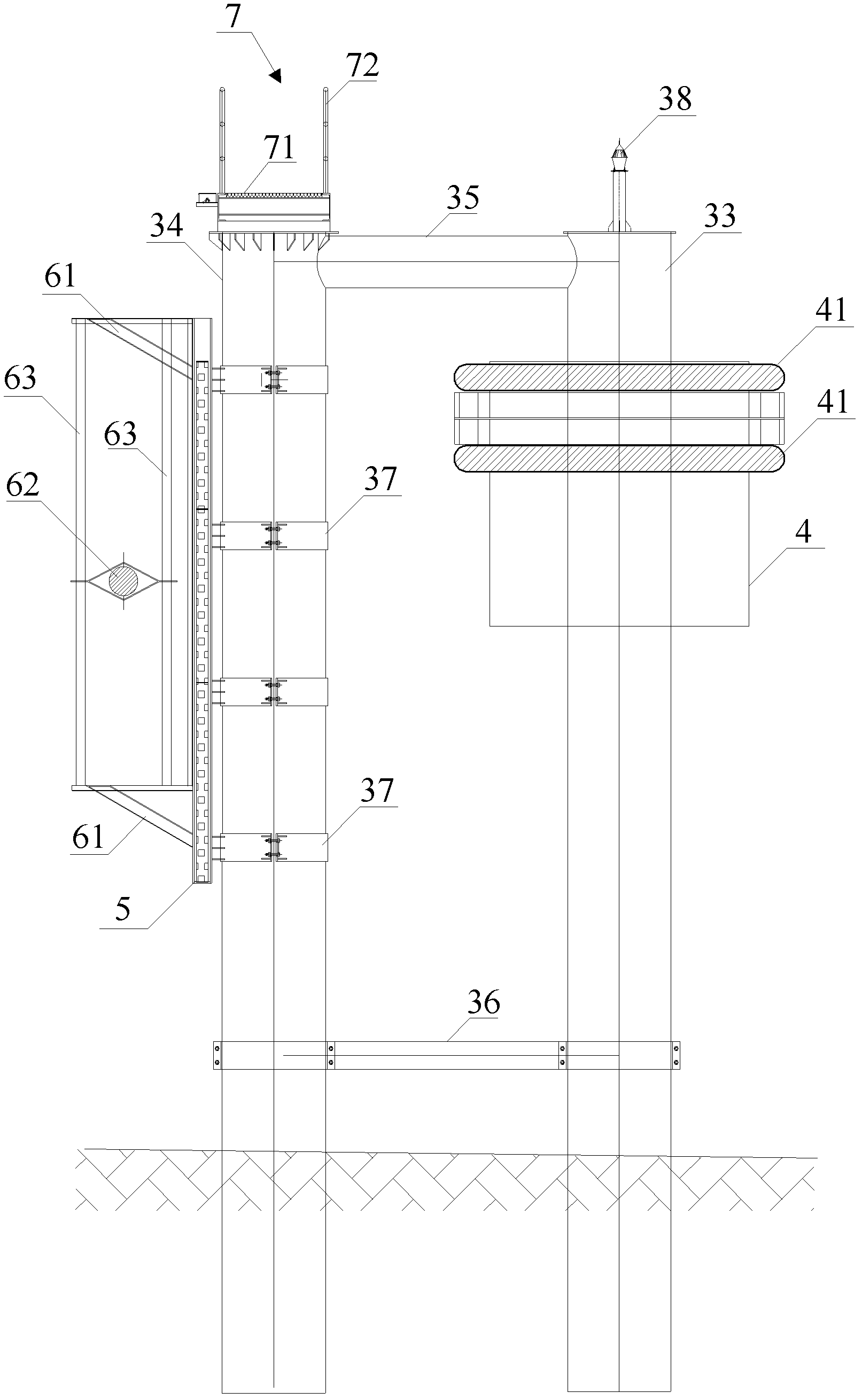

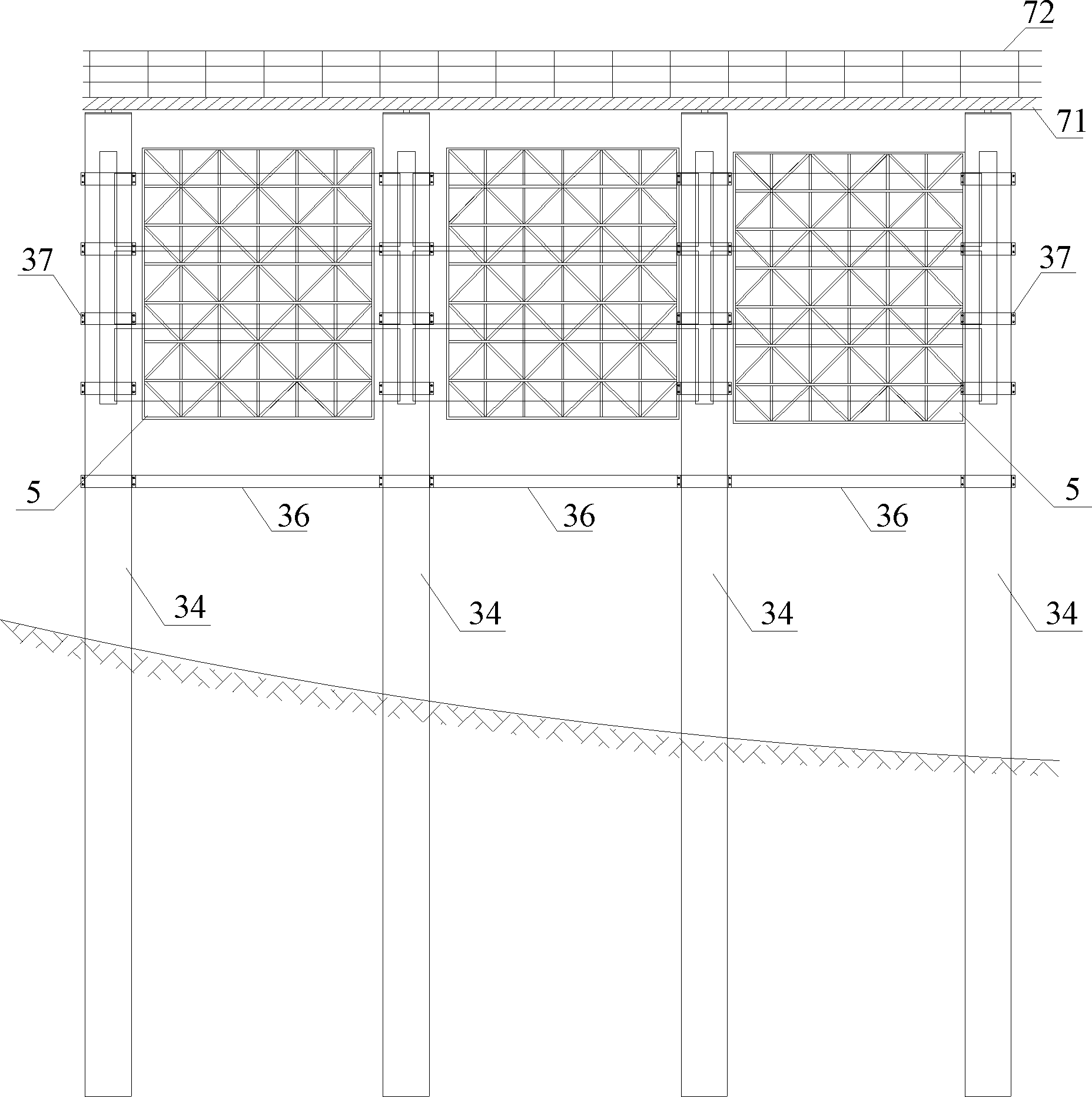

ActiveCN102518097ADifficult to solveEasy to handleWater cleaningGeneral water supply conservationUnderwaterSewage

The invention provides a sudden oil pollution pre-treatment system for a large water intake port. The pre-treatment system comprises a main body framework, an anti-collision device, a sewage blockage net, an oil enclosure device and a repair walkway. The main body framework is connected with a flood control wall to form an enclosed fence structure, consists of a main body fence and a side wing fence and comprises an outer column and an inner column fixedly compacted in water, and the outer column and the inner column are fixedly connected with an underwater connecting beam and an overwater connecting beam; the anti-collision device is movably connected with the outer column to float on water; the sewage blockage net is arranged in a surrounding way along the extension direction of the main body framework and is fixedly arranged on the inner column; and the oil enclosure device is fixedly arranged on the inner column of the main body framework, and the repair walkway is arranged at the top end of the inner column. By adopting the layout of the sudden oil pollution pre-treatment system, the problems of large oil pre-treatment capacity of the large water intake port of a tidal river and difficulties in treatment as a result of changes in the tidal flow and tidal range can be solved.

Owner:SHANGHAI CHENGTOU RAW WATER

Belt-type magnetic separation equipment

InactiveCN106315780AHigh magnetic recovery efficiencyEasy to separateWater/sewage treatment by magnetic/electric fieldsWater/sewage treatment apparatusThin slabDrive motor

The invention discloses belt-type magnetic separation equipment, including the magnetic separation pool. The magnetic separation pool has back washing equipment, belt-type magnetic filter cloth, mud collection tank and two drive motors with waste water. Rotating roller is respectively set up in each drive motor, on which the belt-type magnetic filter cloth is installed. The belt-type magnetic filter cloth is rotating along with the rotation of rotating roller. One drive motor is set underneath the waste water and another one is set above. The mentioned belt-type magnetic filter cloth successively contains upper stainless steel sheet, soft rubber magnetic fabric and lower stainless steel sheet with several filtering holes evenly opened from outside to inside. The invention solves high moisture content, large sludge quantity and low magnetic recovery efficiency of sludge in current loading magnetic precipitation technique, which is beneficial for magnetic refining and magnetic separation with simple structure, going green and environment-friendly.

Owner:安徽清普环保装备有限公司

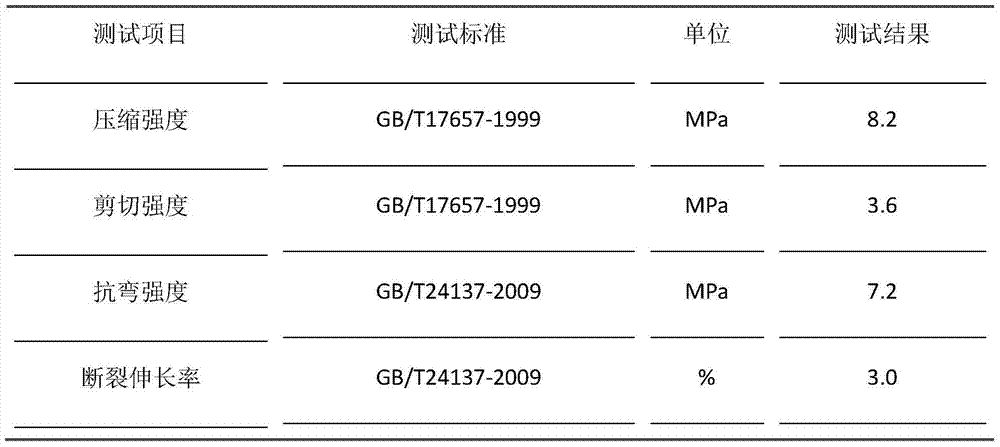

Method for producing wood plastic material by using wastes

The invention discloses a method for producing a wood plastic material by using wastes, which belongs to the field of living waste garbage resource recycling. The method is characterized by comprising the following steps: 1) crushing diaper waste into solid grains or powder, wherein the granularity of the solid grains or the powder is 10-250 meshes, crushing polyvinyl chloride, polyethylene or polypropylene recycled from the waste into resin powder, wherein the granularity of the resin powder is 100-150 meshes, and crushing straw into 100-200 meshes powder; 2) uniformly mixing 100 parts by weight of the diaper waste grains or powder, 20-30 parts by weight of the resin powder, 20-30 parts by weight of the straw powder and 1-10 parts by weight of auxiliary agent, wherein the mixing temperature is 100-110 DEG C; 3) pelleting; 4) forming so as to obtain the wood plastic plate material. By adopting the method, a great deal of used diapers can be rapidly and efficiently treated, and moreover modes such as combustion and burying which can generate harm to the environment, are not used in the treatment process, so that the method is environment-friendly, and moreover the used diapers are turned into wealth, and the requirement of construction of a great amount of municipal facilities, roads and viaducts is met.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

Method for recycling and reutilizing plastic

InactiveCN107263767AHigh purityReduce pollutionPlastic recyclingMechanical material recoveryEngineeringMechanical engineering

The invention belongs to the technical field of plastic processing, and provides a method for recycling and reutilizing plastic. The method comprises the steps that (1) household garbage is sorted, and household garbage plastic is obtained; (2) the sorted garbage plastic is subjected to granulating; and (3) a compatilizer, a coupling agent and filler are added into plastic granules to be stirred for 20 min to 30 min, modification is carried out, and plastic granules are manufactured. The method for recycling and reutilizing the plastic is relatively simple, pollution to the environment is small, and resources are saved.

Owner:HEFEI WANZHIJING DOORS & WINDOWS CO LTD

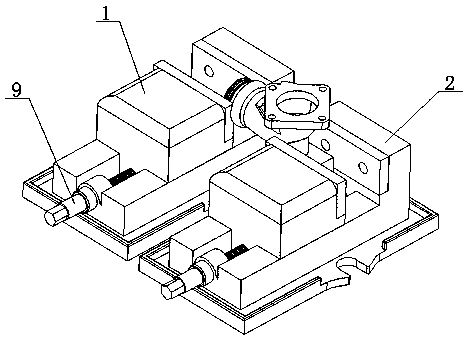

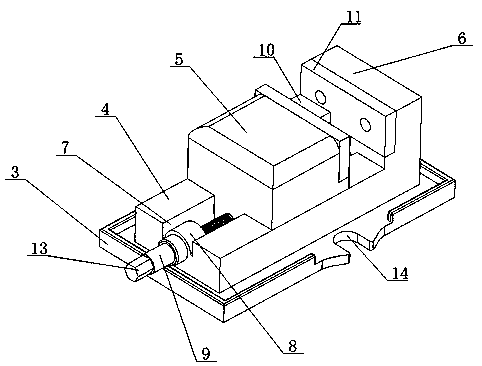

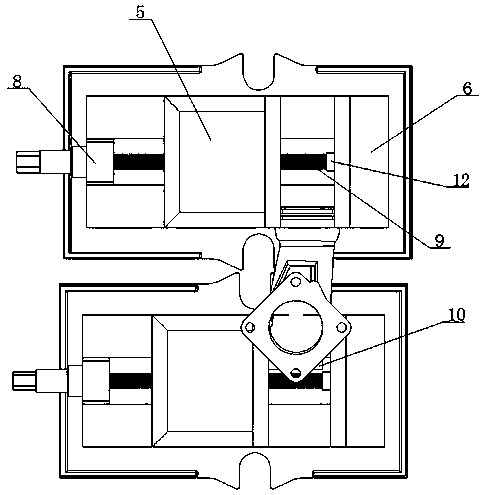

Eccentric parallel shaft special-shaped part clamp

PendingCN108942318AWide adaptabilityEasy to useWork holdersPositioning apparatusEngineeringMechanical engineering

The invention provides an eccentric parallel shaft special-shaped part clamp. The eccentric parallel shaft special-shaped part clamp comprises a first clamping device and a second clamping device, wherein the first clamping device and the second clamping device both comprise base plates, bases, movable blocks and fixed blocks, wherein the bases are fixedly arranged at the tops of the base plates,the fixed blocks are fixedly mounted at the tops of one ends of the bases, sliding grooves are formed in the tops of the bases, the bottoms of the movable blocks are located in the sliding grooves, abearing is fixedly mounted at one end, far away from the corresponding fixed block, of each sliding groove, external threads are arranged on the outer side wall of each propelling screw rod, a screw hole is formed in the position, opposite to the corresponding bearing, of each base, inner threads are arranged on the inner side wall of each screw hole, one end of each propelling screw rod is fixedly installed in the corresponding bearing, and a supporting cushion block is arranged at the portion, between the corresponding fixed block and the corresponding movable block, of the top of each basethrough bolts. The eccentric parallel shaft special-shaped part clamp has the advantages of being reasonable in design, convenient to use and capable of machining a large number of special-shaped parts.

Owner:贵阳华恒机械制造有限公司

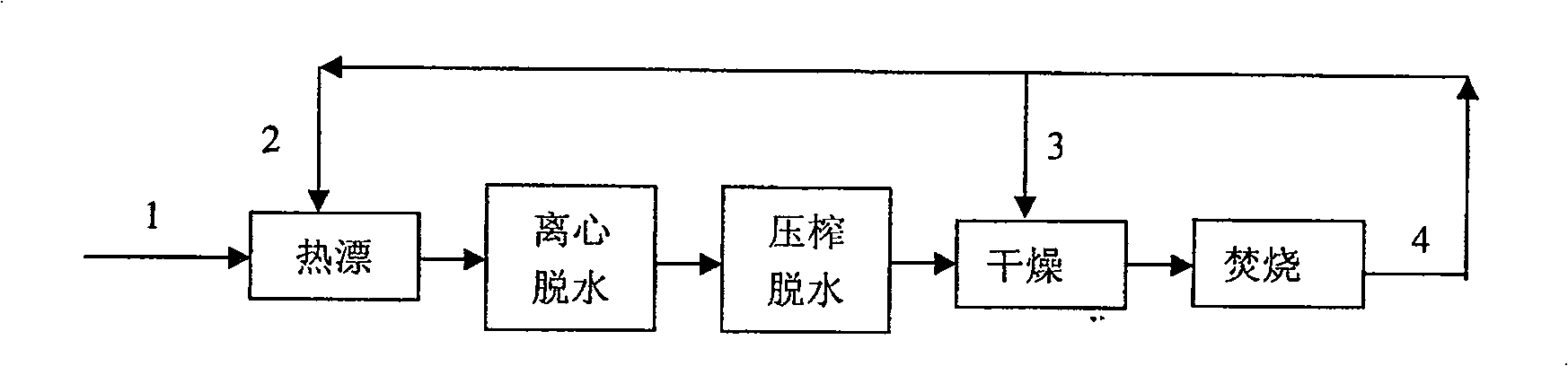

Water hyacinth resource processing method

InactiveCN100535522CSave energyMass processingLandfill technologiesSolid waste disposalLiquid wasteResource utilization

The invention discloses a resourced processing method for common water hyacinths, belongs to the technical field of environment protection projects, which comprises steps as follows of hot-bleaching the fresh common water hyacinths collected, dehydrating the common water hyacinths in a centrifuge and then dehydrating in a compressor. When the rate of water content is >=40% after pressing and dehydrating, the water hyacinths can be directly sent into a incinerator for burning, when the rate of water content is >40%, drying the common water hyacinths in a drier until the rate of water content is between 25% and 40% after drying, then sending into the incinerator for burning. Heat source for hot bleaching and drying comes from heat of flue gas produced in the incinerator. Heat produced by burning the common water hyacinths can be used for power generation, providing steam for heat user, further waste liquid can be used for producing organic liquid fertilizer and ash produced in the incinerator can be used for fertilizer addition agent. During the process of burning, an auxiliary fuel does not need to be added, thereby providing a method for overall utilization of the common water hyacinths. The resourced processing method makes waste profitable, realizes resourced utilization of the common water hyacinths.

Owner:BEIJING JIAOTONG UNIV

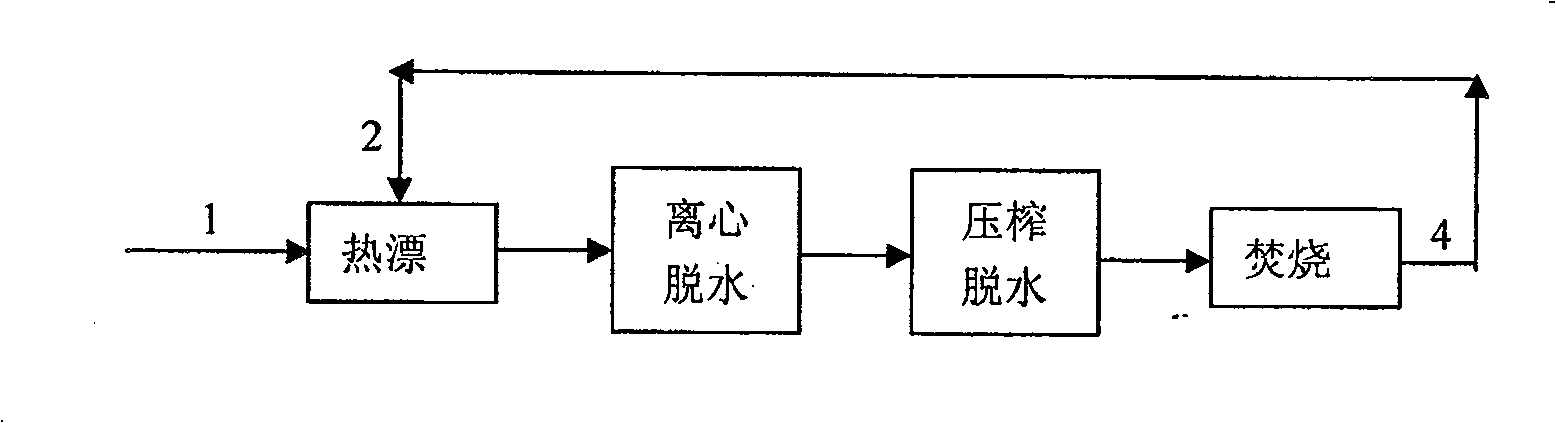

Device and method for adding drugs to feed kelp for sea cucumber and abalone

ActiveCN104322417ALow costEasy to operateClimate change adaptationPisciculture and aquariaMaricultureEngineering

The invention relates to a device for adding drugs to feed kelp for sea cucumber and abalone and belongs to the field of mariculture. The device comprises a perforated nail plate, a separating sieve plate, a concave supporting plate and backing plates, wherein the perforated nail plate is provided with steel nails, one end of the separating sieve plate is connected with the concave supporting plate by hinges, the separating sieve plate and the concave supporting plate are controlled to be closed or opened by the hinges, the concave supporting plate is provided with an open groove with an open front end, and the front end of the concave supporting plate means the end, opposite to the end connected with the separating sieve plate, of the concave supporting plate; the separating sieve plate is of a steel grid shape, and the steel nails on the perforated nail plate can penetrate through gaps among grids on the separating sieve plate and reach the bottom of the open groove of the concave supporting plate; the backing plates are fixedly connected to the lower part of the concave supporting plate. The special device provided by the invention is low in cost, simple in operation, high in hole efficiency and convenient to carry and maintain; meanwhile, by the device provided by the invention, the utilization ratio of the drugs can be increased, so that the incidence of diseases is lowered, and the survival rate of culture is increased.

Owner:YELLOW SEA FISHERIES RES INST CHINESE ACAD OF FISHERIES SCI

Sudden oil pollution pre-treatment system for large water intake port

ActiveCN102518097BDifficult to solveEasy to handleWater cleaningGeneral water supply conservationUnderwaterSewage

Owner:SHANGHAI CHENGTOU RAW WATER

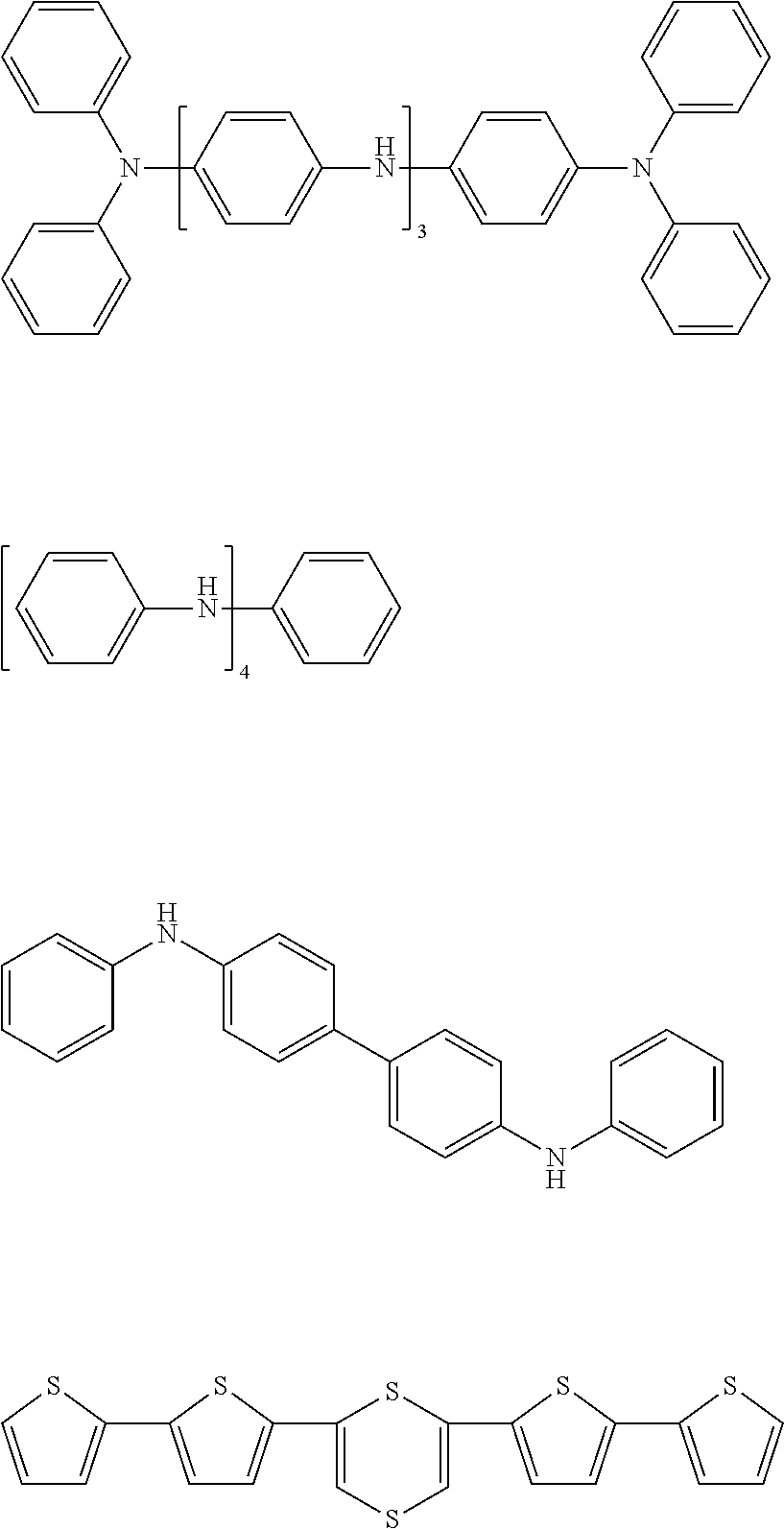

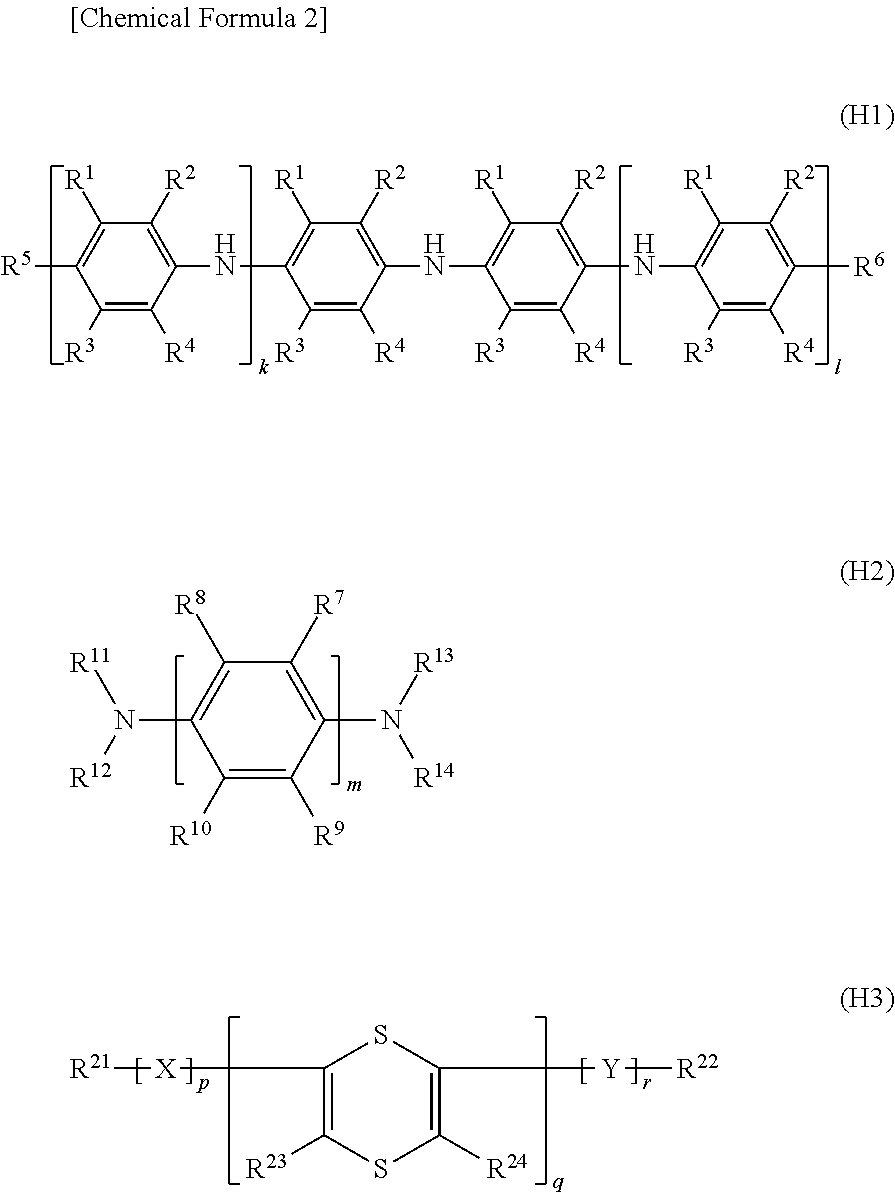

Composition for forming hole collecting layer of photosensor element, and photosensor element

ActiveUS20180114915A1High Photoelectric Conversion EfficiencyReduce dark currentSolid-state devicesSemiconductor/solid-state device manufacturingOrganic solventThiophene derivatives

A photosensor element that is capable of achieving a good balance between high photoelectric conversion efficiency and low dark current is able to be obtained by using a composition for forming a hole collecting layer of a photosensor element, which contains an organic solvent and a charge-transporting material that is composed, for example, of an aniline derivative or thiophene derivative represented by one of formulae (AA)-(DD) and having a molecular weight of 200-2,000.

Owner:NISSAN CHEM IND LTD

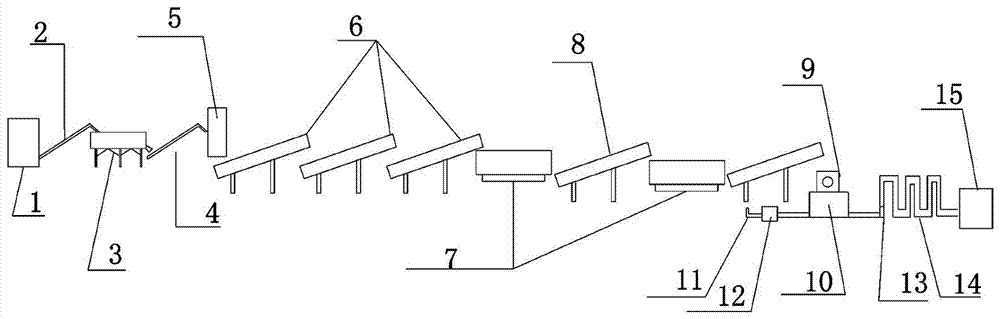

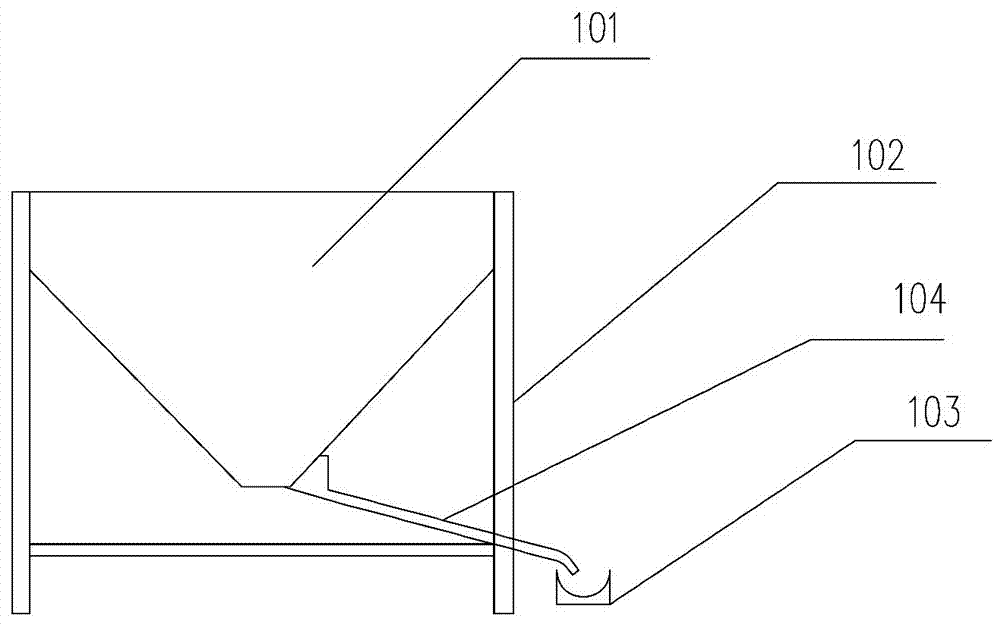

A kind of production equipment and preparation process of waste plastic film particles

ActiveCN104494008BIncrease productivityContinuous processingPlastic recyclingMechanical material recoveryPlasticulturePlastic mulch

The invention discloses production equipment for waste and old mulching film granules. The production equipment comprises a shredding machine, a conveying belt I, a roll separation machine, a conveying belt II, a crusher, a high-speed frictional cleaning device, a primary bleaching device, a conveying auger, a secondary bleaching device, an extruding and drying machine, a dispersing machine, a fan, a heating bag, a suctioning fan, a drying pipeline, and a storage bin, wherein one end of the shredding machine is connected with the conveying belt I; the other end of the conveying belt I is connected with the roller separation machine which is connected with the crusher by the conveying belt II; the primary bleaching device is arranged at the rear side of the high-speed frictional cleaning device and is connected with the secondary bleaching device which is connected with the extruding and drying machine; the lower side of the extruding and drying machine is connected on the dispersing machine; the secondary bleaching device and the dispersing machine are connected with the fan and the heating bag; and the suctioning fan and the drying pipeline are connected between the dispersing machine and the storage bin. A preparation process comprises the following steps: cleaning, frictional cleaning, bleaching, extruding and drying, dispersing, drying, aggregating the granules, plasticized filtering, cutting into the granules, dewatering and bagging.

Owner:巴州汇丰塑业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com