Burning processing method for hyacinth

A treatment method and technology of water hyacinth, applied in the direction of combustion method, incinerator, combustion type, etc., can solve the problems of small processing capacity, long production cycle, difficult disposal of waste residue, etc., and achieve the effect of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

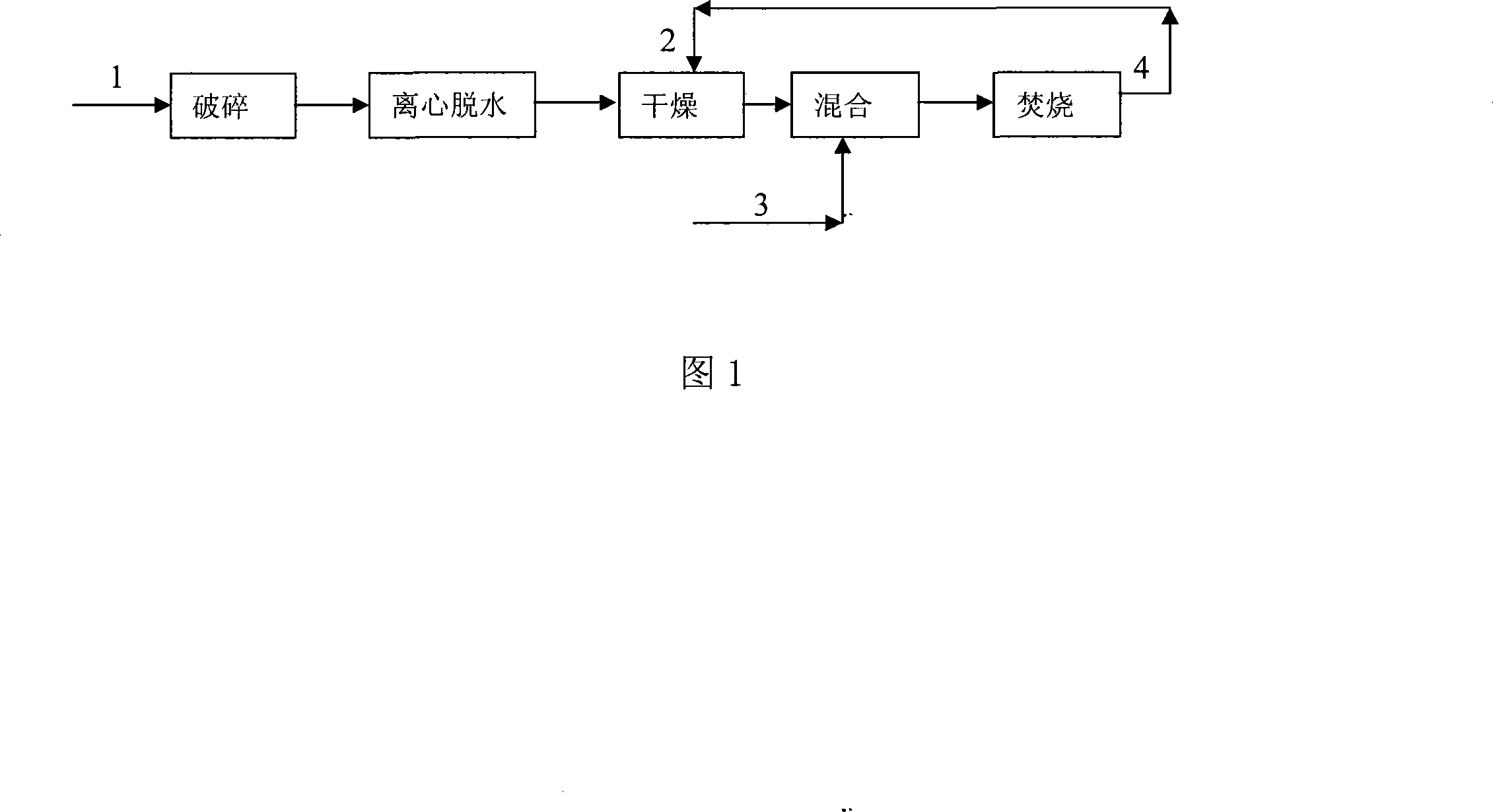

[0025] In step 1, the newly harvested water hyacinth 1 is first sent to a mechanical shear crusher for crushing, and the crushing size is controlled at about 6 cm.

[0026] The purpose of crushing is to improve the dehydration efficiency of the centrifugal dehydrator in the next step and to improve the drying efficiency of the subsequent dryer. The broken water hyacinth should not be too small, too small will easily block the drainage holes of the centrifugal dehydrator and reduce the drying efficiency of the dryer.

[0027] Step 2, sending the broken water hyacinth into a centrifugal dehydrator for dehydration, so as to get rid of free water on the surface and inside of the water hyacinth.

[0028] In step 3, the dehydrated water hyacinth is then sent to a dryer for drying, and the moisture content of the dried water hyacinth is 60%.

[0029] In the process of drying the water hyacinth, the heat source of the dryer is the heat of the hot flue gas produced by the incinerator....

Embodiment 2

[0036] Step is with embodiment one, and its difference is:

[0037] Step 1, the newly harvested water hyacinth is sent to a mechanical shear crusher for crushing, and the crushed size is controlled at about 8cm.

[0038] In step 3, the moisture content of the dried water hyacinth is 70%.

[0039] Step 4, in the dried water hyacinth, mix 10% of the weight of the treated fresh water hyacinth with a calorific value of 5500kCal / kg coal to form a mixed fuel, and the mixed low calorific value is 1700kCal / kg.

[0040] Taking the treatment of 100 tons of fresh water hyacinth per day as an example, after analysis and calculation, when the moisture content of water hyacinth after drying is 60%, the low calorific value of auxiliary fuel coal is 5000kCal / kg, and the amount of coal mixed with fresh water hyacinth is 5% of the weight of the mixed fuel, the low calorific value of the mixed fuel is 1600kCal / kg. The daily consumption of auxiliary fuel coal is 5 tons, and the auxiliary fuel c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com