Water hyacinth resource processing method

A treatment method and technology of water hyacinth, applied in the direction of combustion method, incinerator, solid waste removal, etc., can solve the problems of small treatment volume, long production cycle, slow treatment speed, etc., and achieve the effect of energy saving and industrialized treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

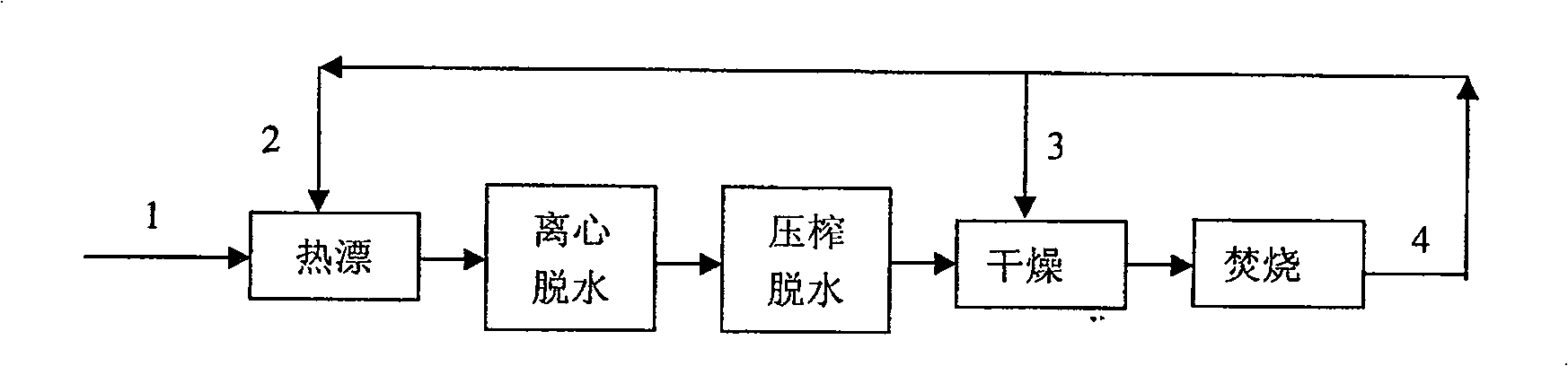

[0032] Embodiment one, such as figure 1 The schematic diagram of the technological process when the water content of the water hyacinth after pressing and dehydration is greater than 40% is shown in the schematic diagram.

[0033] The water content of newly harvested water hyacinth 1 is about 90% to 92%, and its resource treatment method:

[0034] Step 1, heat bleaching the newly harvested water hyacinth 1;

[0035] The water temperature is controlled at 98°C, and the heat bleaching time is 8 minutes.

[0036] The main function of heat bleaching is to make the water hyacinth lose its biological activity, destroy the tissue cell structure of the water hyacinth, and create favorable conditions for subsequent drying and pressing dehydration.

[0037] During the process of bleaching the water hyacinth, the heat source 2 of the bleaching comes from the heat 4 of the hot flue gas produced by the incinerator. The water temperature control and the control of the bleaching time in t...

Embodiment 2

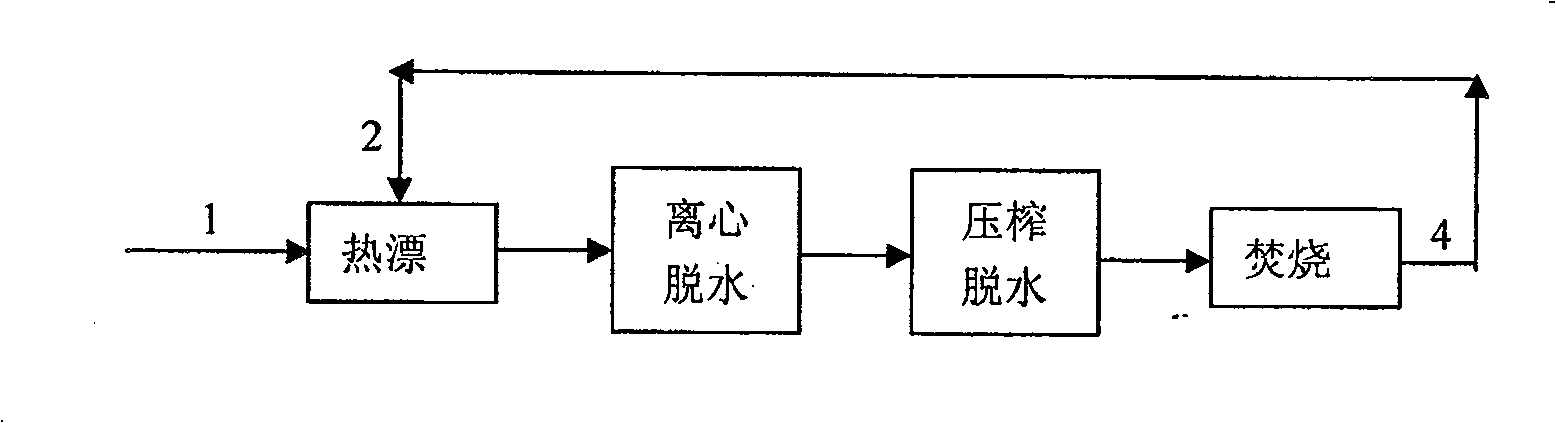

[0044] Embodiment two, such as figure 2 The schematic diagram of the technological process when the moisture content of the water hyacinth after pressing and dehydration is ≤40% is shown in the schematic diagram.

[0045] The water content of newly harvested water hyacinth 1 is about 90% to 92%, and its resource treatment method:

[0046] Step 1, heat bleaching the newly harvested water hyacinth 1;

[0047] The water temperature is controlled at 96°C, and the heat bleaching time is 10 minutes.

[0048] The main function of heat bleaching is to make the water hyacinth lose its biological activity, destroy the tissue cell structure of the water hyacinth, and create favorable conditions for subsequent drying and pressing dehydration.

[0049] During the process of bleaching the water hyacinth, the heat source 2 of the bleaching comes from the heat 4 of the hot flue gas produced by the incinerator. The water temperature control and the control of the bleaching time in the blea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com