A kind of production equipment and preparation process of waste plastic film particles

A technology of production equipment and preparation process, which is applied in the field of waste mulch granule production equipment and its preparation, can solve the problems of easy generation of harmful gas, low cost, high moisture content, etc., and achieve reduction of labor intensity of workers, production cost and production efficiency of enterprises High, highly automated effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

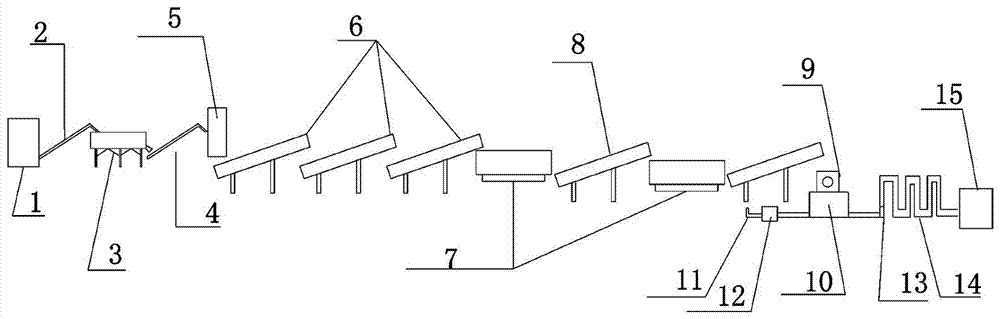

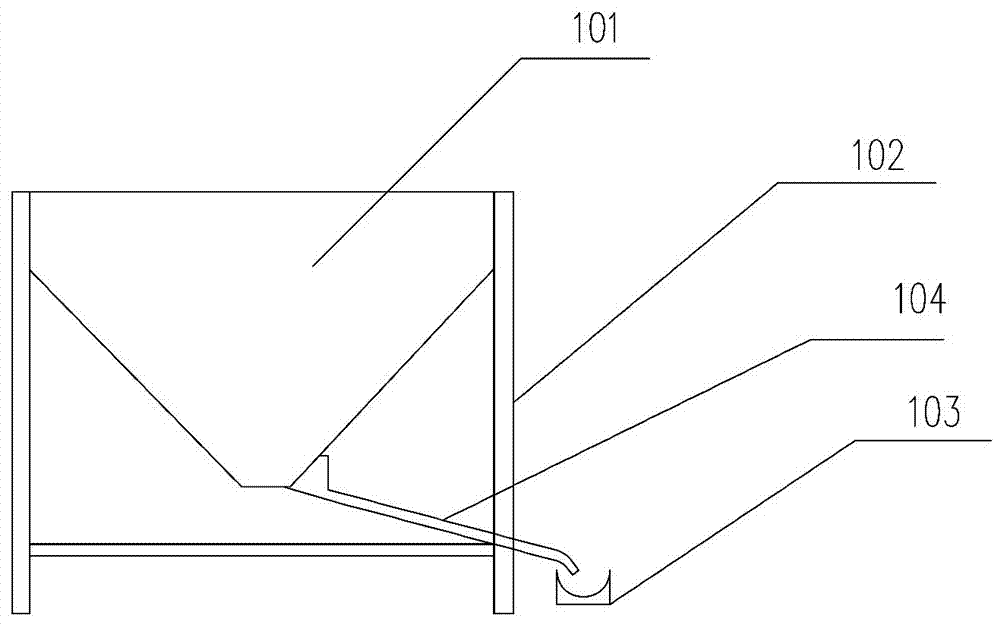

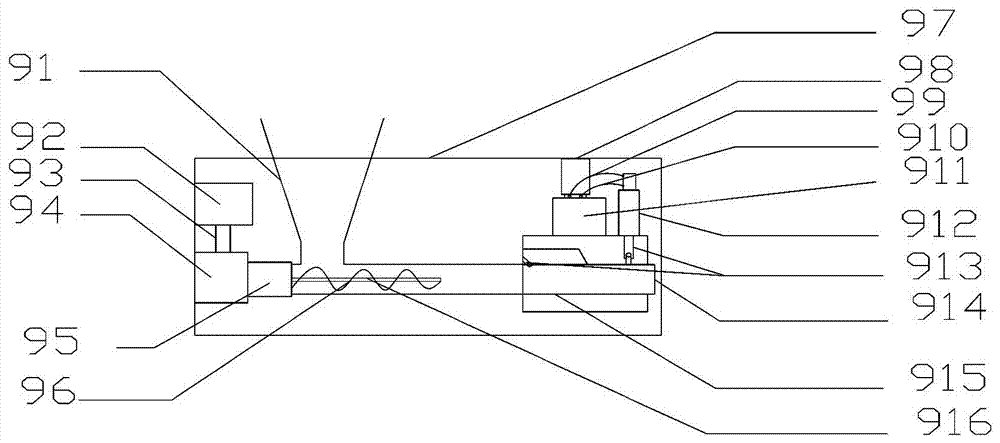

[0025] Such as Figure 1-3 As shown, a kind of production equipment for waste plastic film particles, including a shredder 1, a conveyor belt 2, a drum separator 3, a conveyor belt 2 4, a crusher 5, a high-speed friction cleaning device 6, a primary rinsing device, and a conveying auger 8. Second washing and rinsing device, material lifting screw, squeeze dryer 9, breaker 10, fan 11, heating pack 12, suction fan 13, drying pipeline 14, storage bin 15, and one end of the shredder is connected to a conveyor Belt one 2, the other end of the conveyor belt one 2 is connected with a drum separator 3, the drum separator 3 is connected with the crusher 5 through the conveyo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com