Eccentric parallel shaft special-shaped part clamp

A technology with parallel shafts and special shapes, which is applied in the direction of workpiece clamping devices, metal processing machinery parts, clamping, etc., can solve the problems that parts cannot meet the requirements of use, and achieve the effect of convenient use and wide adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

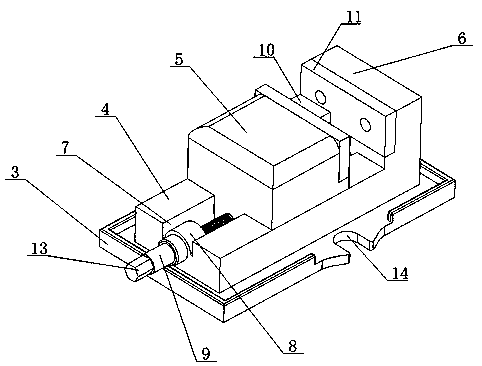

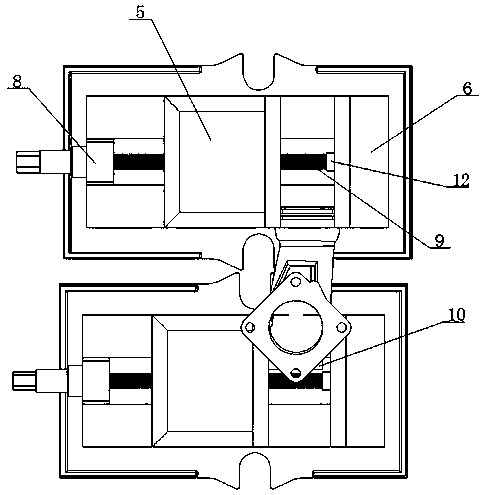

[0020] As a preferred embodiment of the present invention, the opposite sides of the movable block 5 and the fixed block 6 are installed with backing plates 11 through bolts.

[0021] As a preferred embodiment of the present invention, one end of the propulsion screw 9 is welded with a hexagon bolt 13 .

[0022] As a preferred embodiment of the present invention, the other end of the propulsion screw 9 is equipped with a rotating shaft 12, and one end of the propulsion screw 9 with the rotating shaft 12 passes through the screw hole through the external thread and the internal thread and passes through the rotating shaft. 12 is installed on one side of fixed block 6.

[0023] As a preferred embodiment of the present invention, both the front side and the rear side of the chassis 3 are provided with fixing grooves 14 .

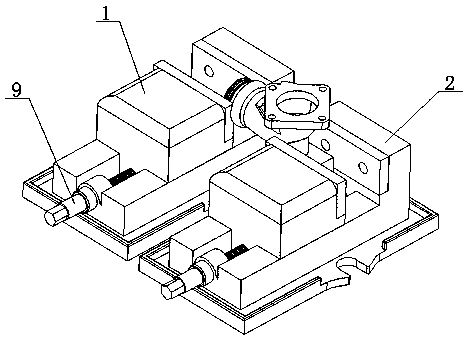

[0024] Working principle: When using this eccentric parallel axis special-shaped parts fixture, the clamping device 1 and the clamping device 2 are fixed in a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com