Brown's gas-burning solid organic waste pyrolyzing furnace

A technology of organic waste and Brown gas, applied in the direction of combustion method, combustion type, coke oven, etc., can solve the problems of incomplete cracking, lower flame temperature, increase furnace humidity, etc., to improve energy utilization rate and heating efficiency High and low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

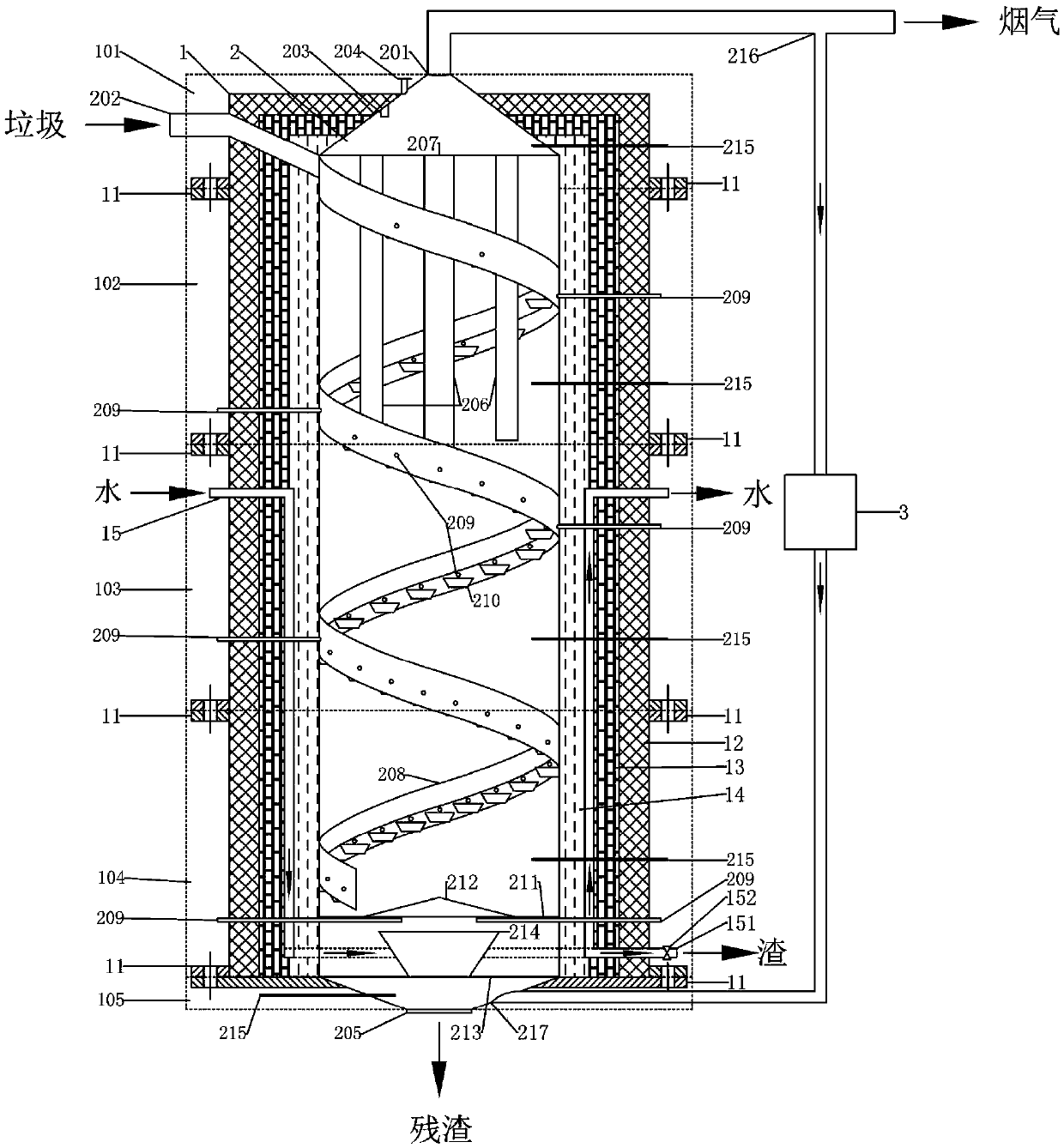

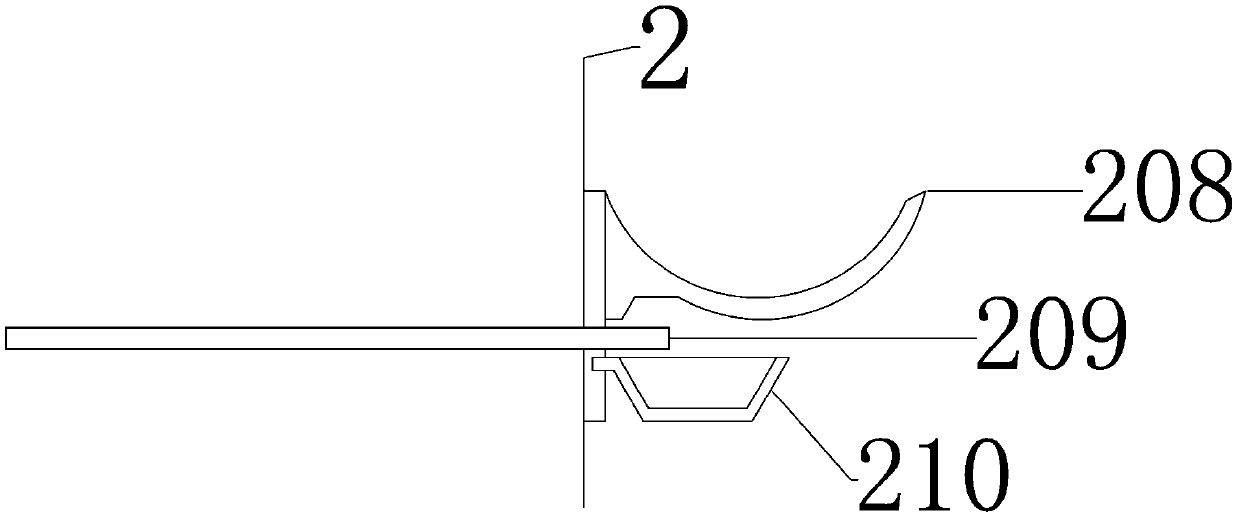

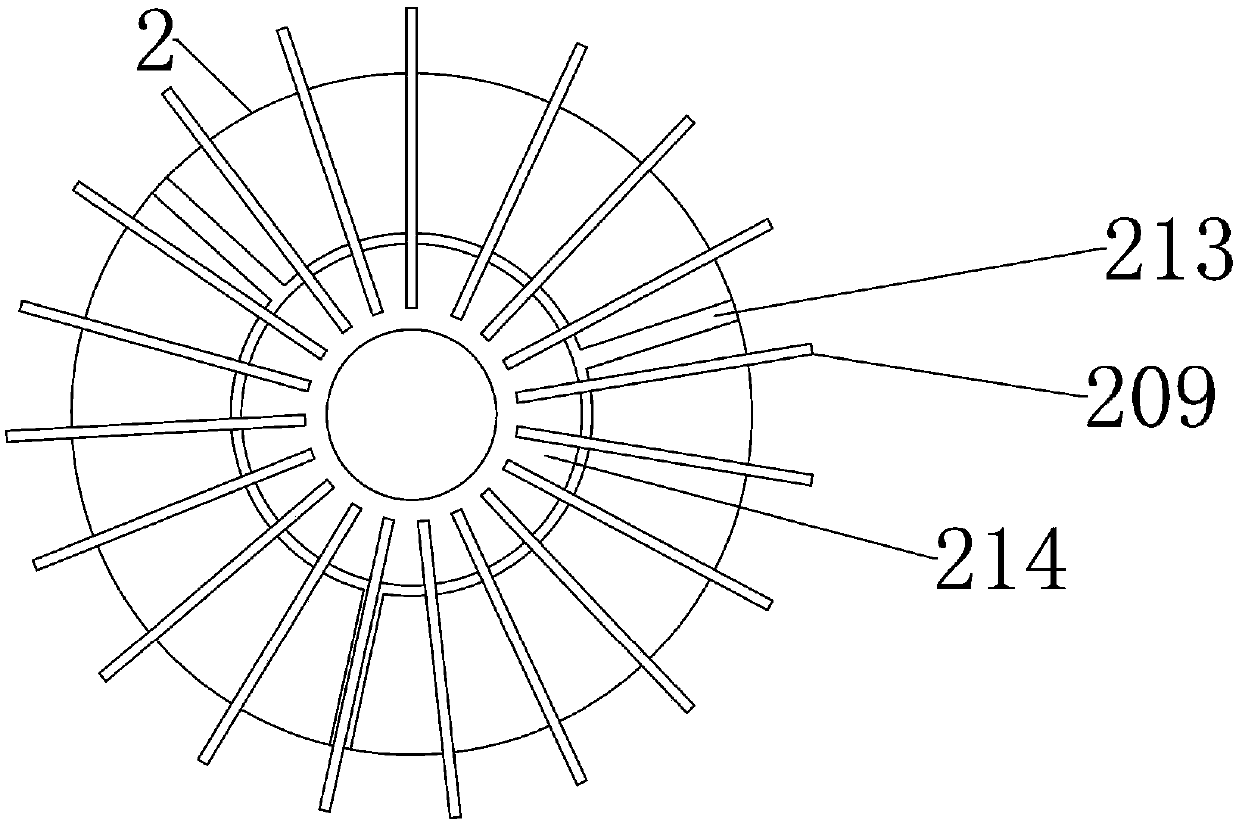

[0036] like Figure 1~3, 4, and 6, a solid organic waste pyrolysis furnace that burns Brown gas includes a shell 1 and a cavity 2 inside the shell 1, and the top of the shell 1 is provided with a main exhaust port 201, a pressure detector 203, a super pressure discharge valve 204, the bottom is provided with quantitative inductive ash discharge electric valve 205, and the upper part of the side is provided with feed port 202; the upper part of cavity 2 is provided with such Figure 4 The five upright hollow smoke guide columns 206 fixed by the first bracket 207 are shown; the cavity 2 is welded with a material guide groove 208 that revolves downward along the inner wall of the cavity 2, and the inner wall of the cavity 2 below the material guide groove 208 is set There are a plurality of Brown gas burners 209 and the wall-mounted crucible 210 below the Brown gas burner 209; like Image 6 As shown in the conical surface heat conducting plate 212 whose middle portion is upward...

Embodiment 2

[0053] This embodiment is different from embodiment 1, as Figure 5 As shown, the upper part of the cavity 2 is provided with an upright hollow smoke guide column 206 fixed by the first bracket 207, and the bottom of the shell 1 is provided with a timing inductive ash discharge electric valve 205. The bottom of material guide trough 208 is provided with second support 211 fixing such as Figure 7 The shown curved heat conducting plate 212 has an upwardly arched middle. The heat conducting plate 212 is made of tungsten steel. Metal material copper is housed in the wall-mounted crucible 210 and the crucible basin 214 . The material of the insulation layer 13 is a refractory brick layer, and the heat conduction layer 14 is a ceramic coating.

Embodiment 3

[0055] The difference between this embodiment and Embodiment 1 is that the metal material inside the wall-mounted crucible 210 and the crucible basin 214 is a combination of tungsten carbide alloy and copper. The material of the insulation layer 13 is a combination of a high-priced aluminum insulation cotton layer and a refractory brick layer, and the heat conduction layer 14 is a combination of a carbon steel layer and a ceramic coating.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com