Belt-type magnetic separation equipment

A magnetic separation and equipment technology, applied in water/sewage treatment equipment, magnetic/electric field water/sewage treatment, water/sewage treatment, etc., can solve the problems of low magnetic recovery efficiency, large amount of sludge, high moisture content of sludge, etc. , to achieve the effect of high magnetic recovery efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

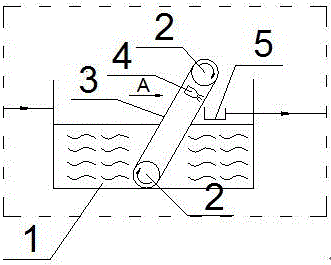

[0021] Such as figure 1 As shown, a belt-type magnetic separation device includes a magnetic separation tank 1, and the magnetic separation tank 1 includes a backwashing device 4, a belt-type magnetic filter cloth 3, a sludge collection tank 5 and two drive motors 2, and the magnetic separation tank 1 Sewage is also loaded in the tank, two drive motors 2 are respectively provided with rotating rollers, and belt-type magnetic filter cloth 3 is installed on the rotating rollers, and the belt-type magnetic filter cloth 3 rotates with the rotation of the rotating rollers, and a driving motor 2 is set Below the sewage, another drive motor 2 is set above the sewage, so that the inclination angle between the belt-type magnetic filter cloth 3 and the horizontal plane between the two drive motors 2 is α, and the belt-type magnetic filter cloth 3 is sequentially arranged from outside to inside Including upper stainless steel sheet, soft rubber magnetic cloth and lower stainless steel sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com