Method for producing wood plastic material by using wastes

A wood-plastic material and waste technology, which is applied in the field of domestic waste recycling and recycling, and achieves the effect of environmental friendliness in the process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Preparation of prefabricated wood-plastic composite materials: First, crush the used diapers into 20-mesh powder for use; crush the straw into powder, pass through a 100-mesh sieve for use; recycle polyethylene materials, and crush them into powder body, passed through a 100-mesh sieve for use;

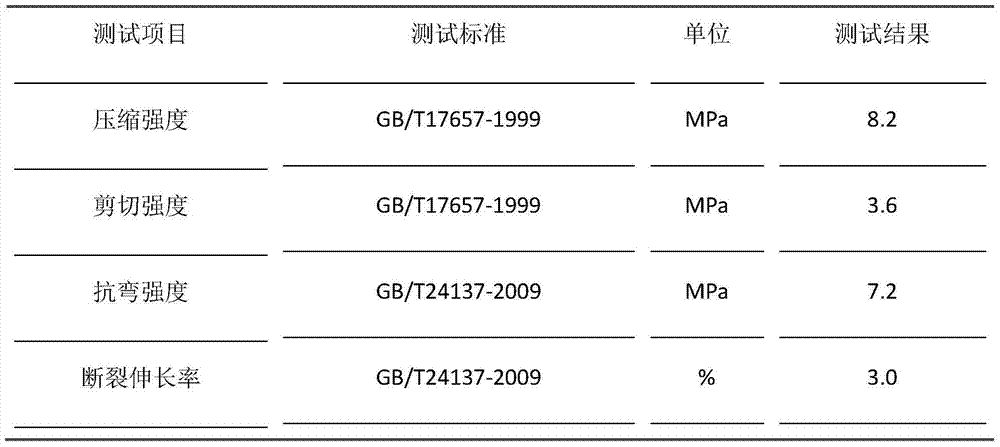

[0023] Preparation of wood-plastic composite material: Take 100 kg of 20 mesh used diaper powder, 25 kg of 100 mesh straw powder, 80 kg of recycled 100 mesh polyethylene powder, and mix evenly , granulation; and then into the twin-screw extruder for extrusion operations. The performance test results of the obtained wood-plastic panels are as follows:

[0024]

Embodiment 2

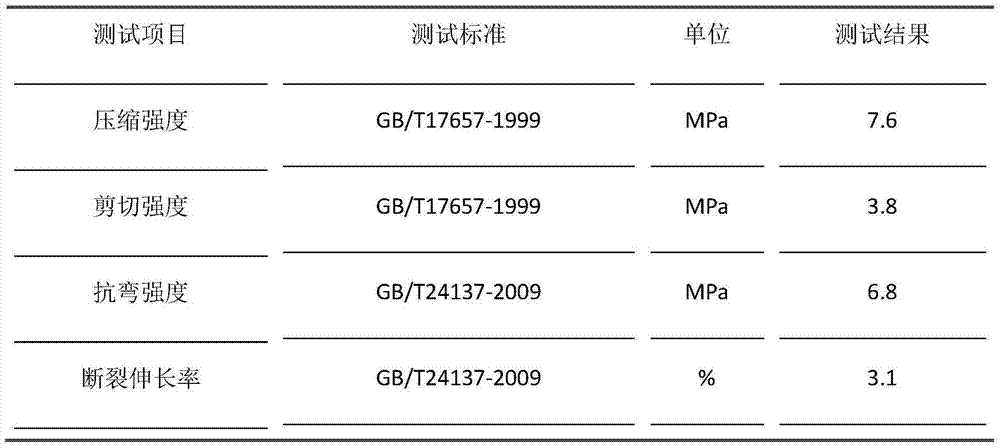

[0026] Preparation of prefabricated wood-plastic composite materials: Firstly, the used diapers are crushed into 25-mesh powder for use; Powder, passed through a 100-mesh sieve for use;

[0027] Preparation of wood-plastic composite materials: Take 100 kg of used diaper powder of 25 mesh, 30 kg of straw powder of 100 mesh, recover 100 kg of polyvinyl chloride powder of 100 mesh, 200 grams of UV-230-200 grams of UV-resistant absorber, Lubricant solid paraffin 8 kilograms is mixed evenly, granulates; Then enters twin-screw extruder to carry out extruding operation. The performance test results of the obtained wood-plastic panels are as follows:

[0028]

Embodiment 3

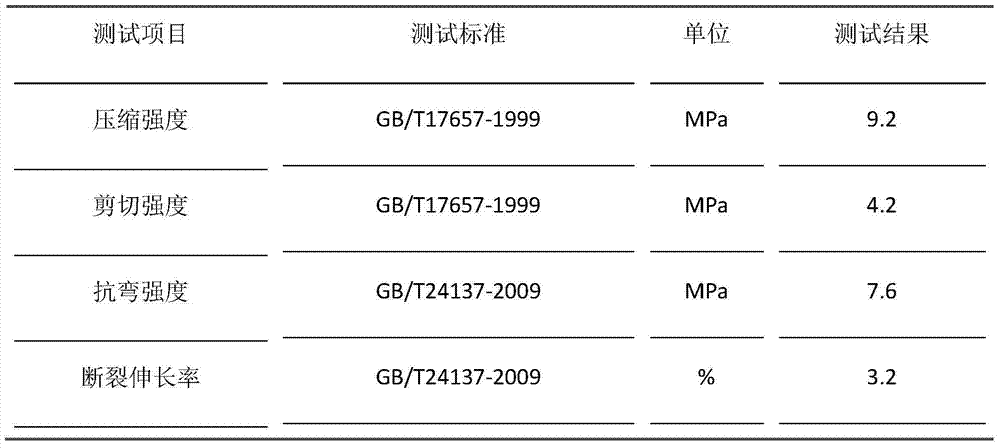

[0030] Preparation of prefabricated wood-plastic composite materials: Firstly, the used diapers are crushed into 25-mesh powder for use; Powder, passed through a 150-mesh sieve for use;

[0031] Preparation of wood-plastic composite materials: Take 100 kg of used diaper powder of 25 mesh, 20 kg of straw powder of 150 mesh, 80 kg of high-density polypropylene powder, 200 g of UV‐230 and 200 g of UV absorber, lubricant Mix 5 kilograms of solid paraffin evenly, then put it into a stainless steel mold prepared in advance, and carry out molding operation under a certain temperature and pressure. The performance test results of the obtained wood-plastic panels are as follows:

[0032]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com