Garbage pretreatment system and method using kitchen garbage to feed insects

A food waste and pretreatment technology, applied in the direction of grain processing, solid waste removal, etc., can solve problems such as equipment blockage, achieve the effect of avoiding equipment blockage, ensuring continuous normal operation, and mass processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

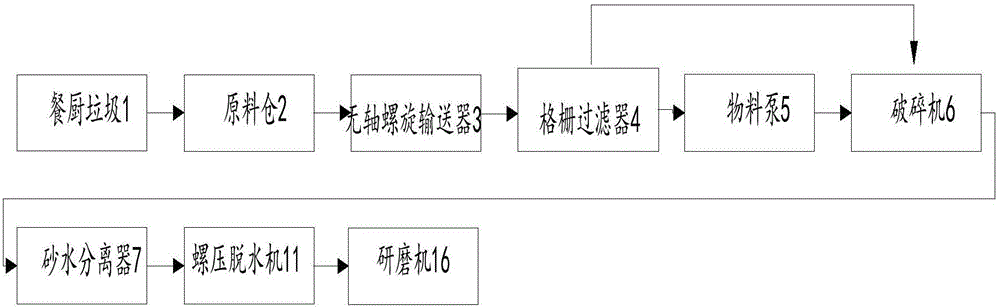

[0037] refer to figure 1 According to an embodiment of the present invention, a waste pretreatment system for using kitchen waste for insect breeding is provided, comprising a raw material bin 2; a shaftless screw conveyor 3 arranged at the bottom of the raw material bin 2; The grid filter 4 at the bottom of the bin 2 is connected to the shaftless screw conveyor 3; the material pump 5 arranged at the bottom of the raw material bin 2 is connected to the grid filter 4; Crusher 6 connected to device 4 and material pump 5; Sand water separator 7 connected to said crusher 6; Screw pressure dehydrator 11 connected to said sand water separator 7; Connected grinder 16.

[0038] The raw material bin 2 is used for storing food waste 1 .

[0039] The shaftless screw conveyor 3 arranged at the bottom of the raw material bin 2 is used to transport the kitchen waste 1 . Shaftless screw conveyor 3 is composed of drive mechanism (motor reducer, transmission shaft), U-shaped groove and brac...

Embodiment 2

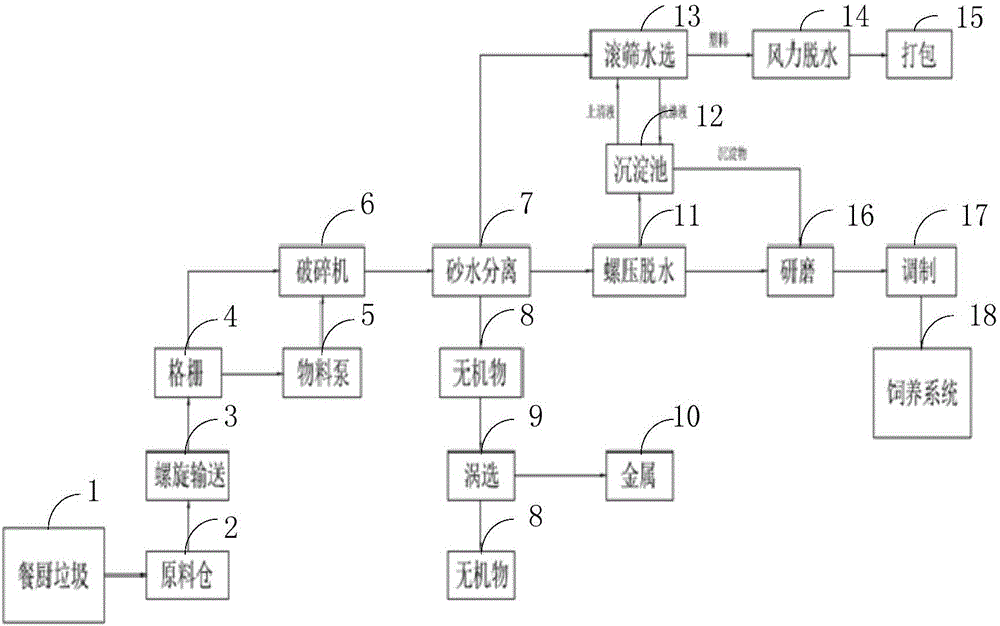

[0054] refer to figure 2 According to an embodiment of the present invention, a waste pretreatment system for using kitchen waste for insect breeding is provided, comprising a raw material bin 2; a shaftless screw conveyor 3 arranged at the bottom of the raw material bin 2; The grid filter 4 at the bottom of the bin 2 is connected to the shaftless screw conveyor 3; the material pump 5 arranged at the bottom of the raw material bin 2 is connected to the grid filter 4; Crusher 6 connected to device 4 and material pump 5; Sand water separator 7 connected to said crusher 6; Screw pressure dehydrator 11 connected to said sand water separator 7; connected grinder 16; brewing tank 17 connected with said grinder 16.

[0055] The raw material bin 2 is used for storing food waste 1 .

[0056] The shaftless screw conveyor 3 arranged at the bottom of the raw material bin 2 is used to transport the kitchen waste 1 . Shaftless screw conveyor 3 is composed of drive mechanism (motor reduc...

Embodiment 3

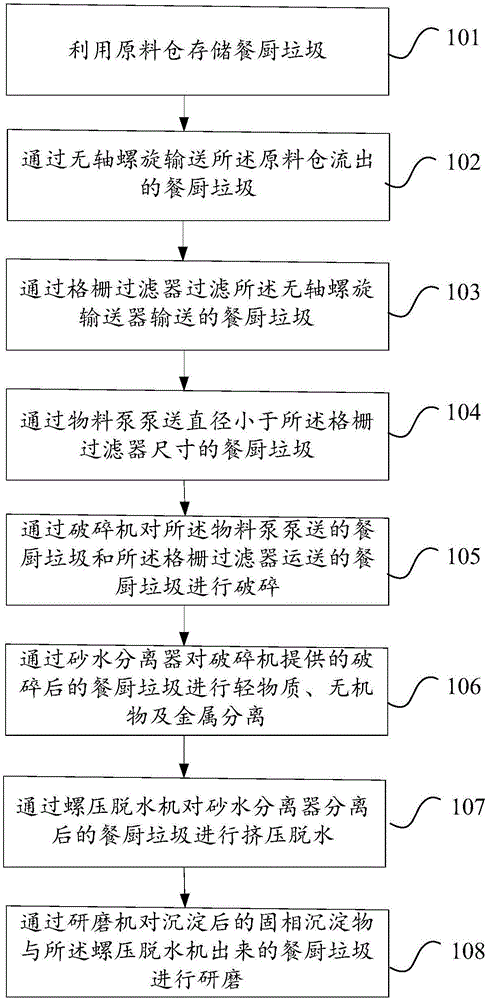

[0075] Such as image 3 As shown, the embodiment of the present invention also provides a garbage pretreatment method for using kitchen garbage for insect breeding, including the following steps.

[0076] Step 101: Use the raw material warehouse to store kitchen waste.

[0077] In some embodiments, a raw material bin can be provided, and the raw material bin can be used to store kitchen waste.

[0078] Step 102: Conveying the kitchen waste flowing out of the raw material bin through a shaftless screw.

[0079] In some embodiments, a shaftless screw conveyor can be set at the bottom of the raw material bin, and the shaftless screw conveys the food waste flowing out of the raw material bin, and the shaftless screw conveyor only plays the role of pushing the food waste forward . However, if the food waste is transferred from the raw material warehouse to other equipment, the shaftless screw conveyor cannot be used, because the food waste has a high fluidity and will flow backw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com