Patents

Literature

88 results about "Mesh free" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

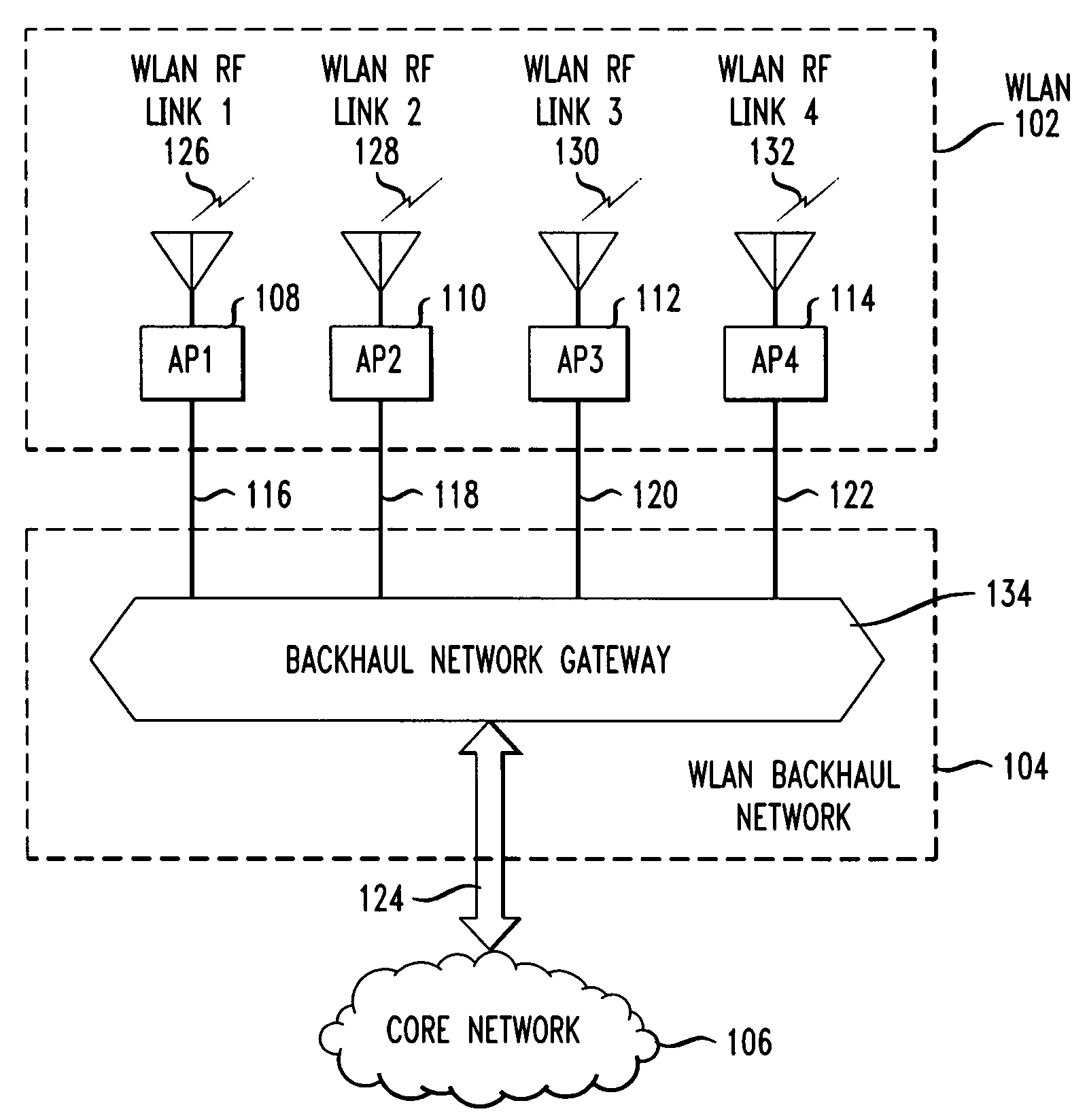

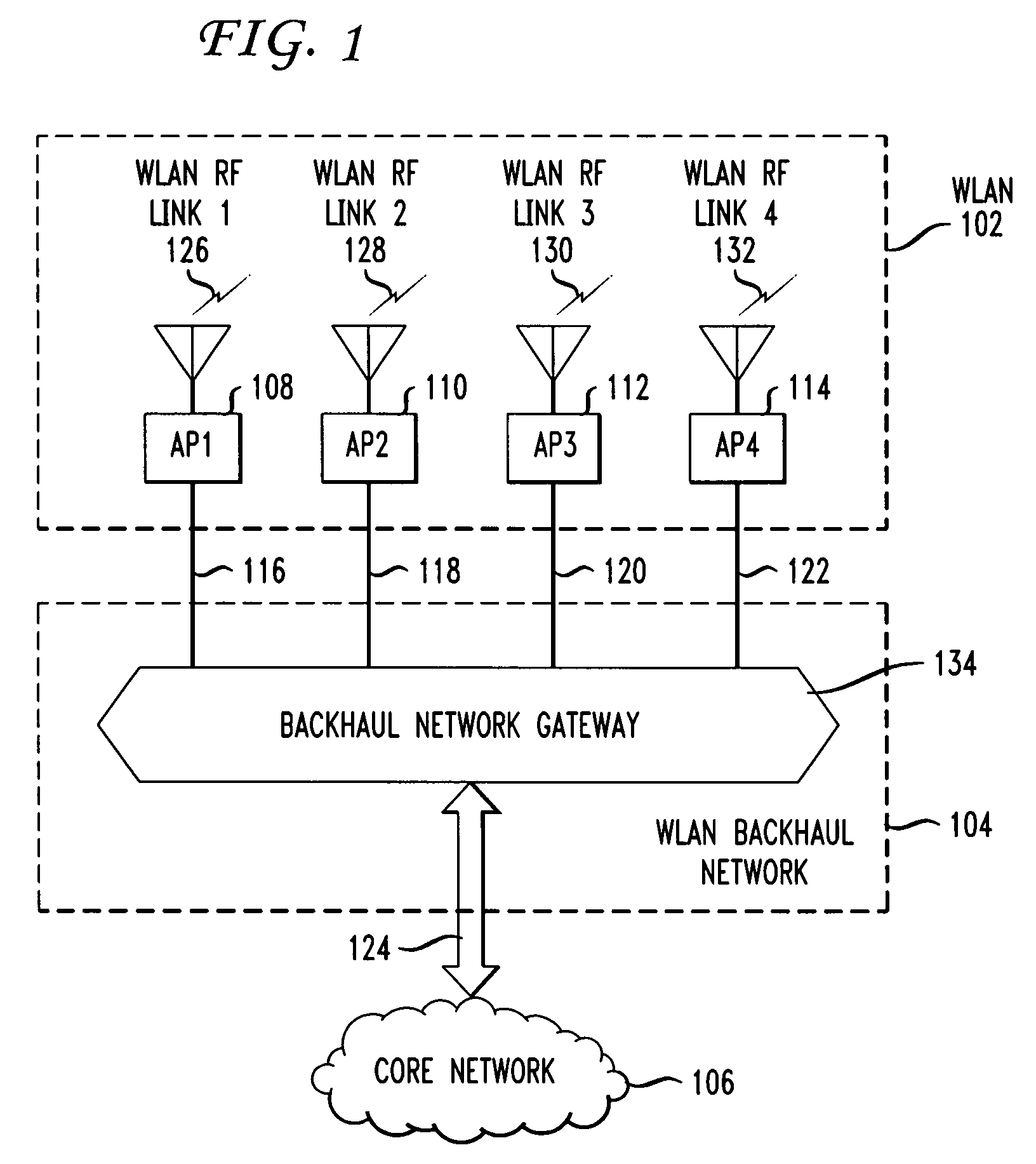

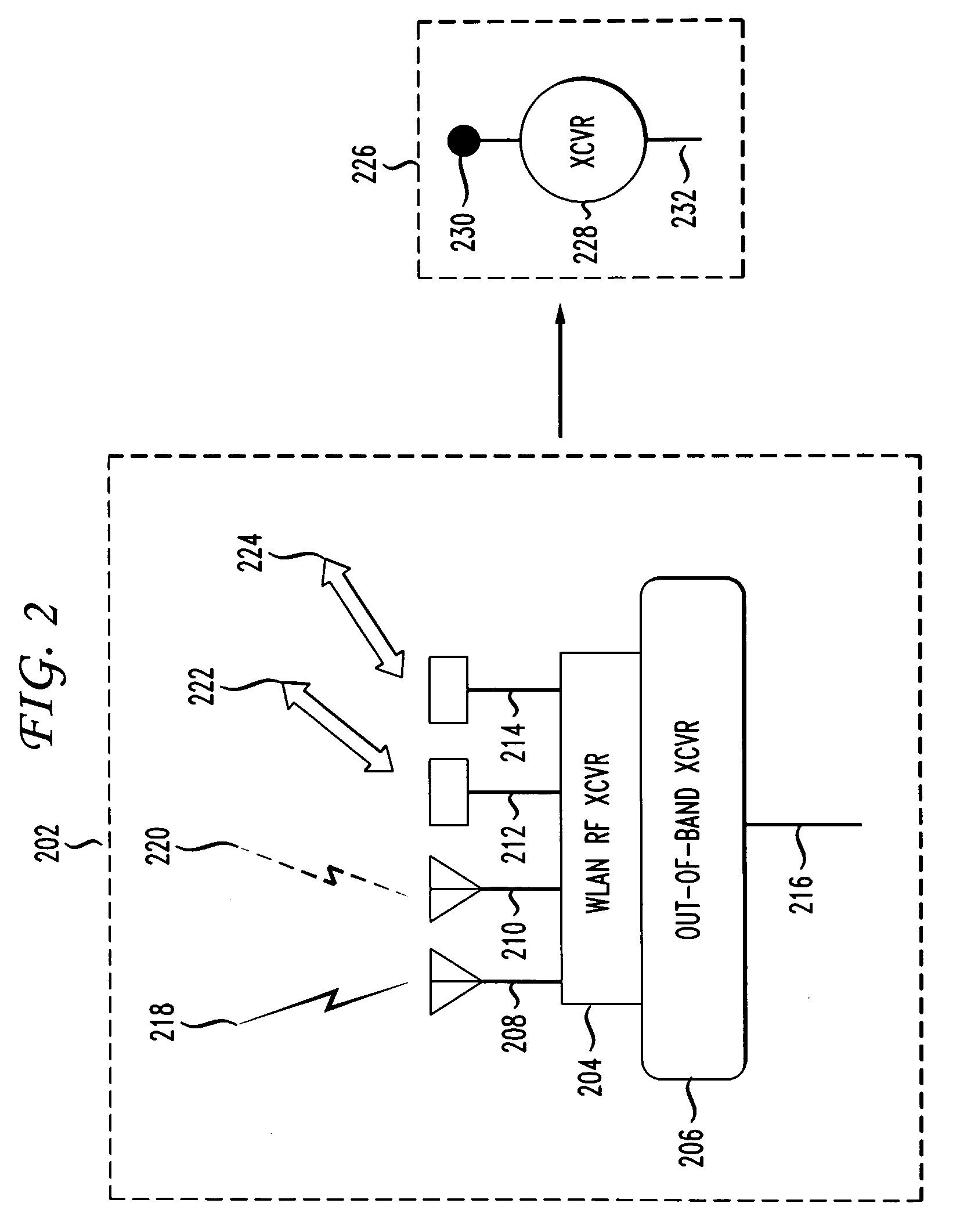

Mesh free-space optical system for wireless local area network backhaul

InactiveUS20080304831A1Improve network reliabilityOptimize networkNetwork topologiesElectromagnetic transmissionCoaxial cableHigh density

In wireless local area networks (WLANS) with a large number of access points, the provisioning and capacity of the WLAN backhaul network connecting the access points to a core network becomes a major issue in network design. Some network services call for access points to be deployed in high densities in a wide range of environments, including outdoor environments. Traditional backhaul networks using fixed media such as twisted pair cable, coax cable, or optical fiber, in many instances are not physically or economically viable. Disclosed are method and apparatus for connecting access points via a mesh network using free-space optical links. The free-space optical links may be supplemented with mm-wave links to increase reliability and capacity.

Owner:AT&T LABS

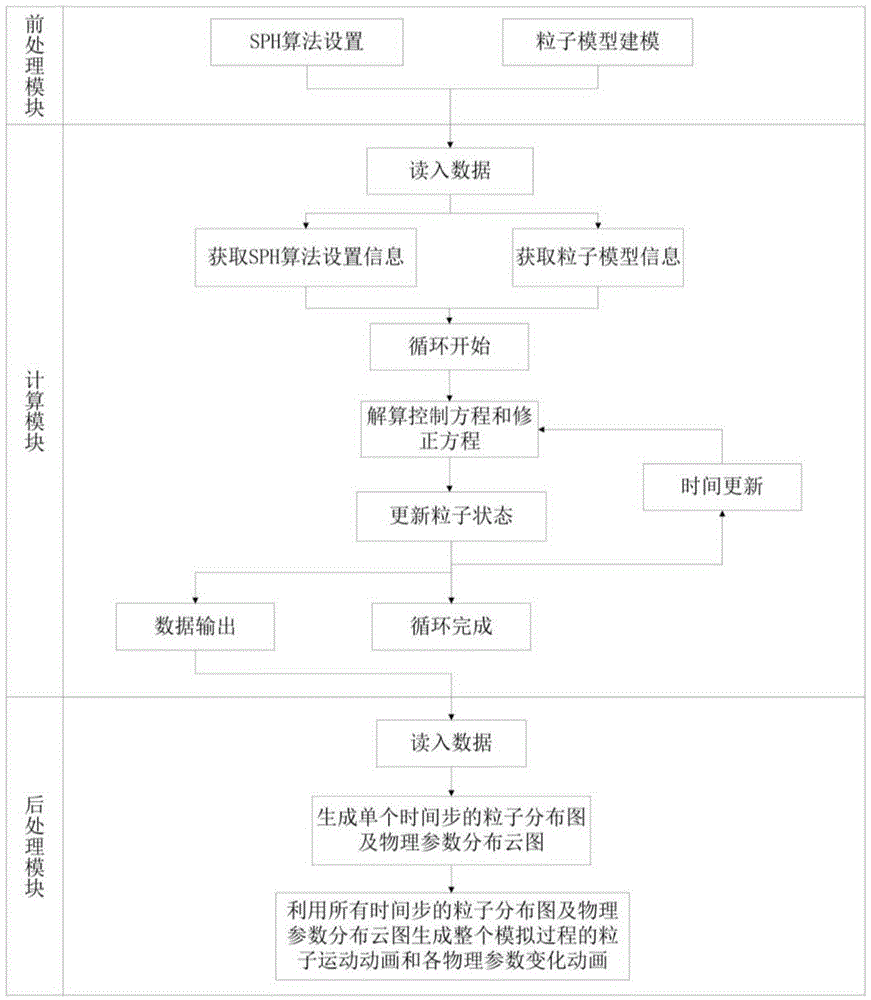

Fluid thermal motion simulation system based on SPH algorithm

InactiveCN104143027AImprove stabilityImprove calculation accuracySpecial data processing applicationsThermodynamic simulationGraphics

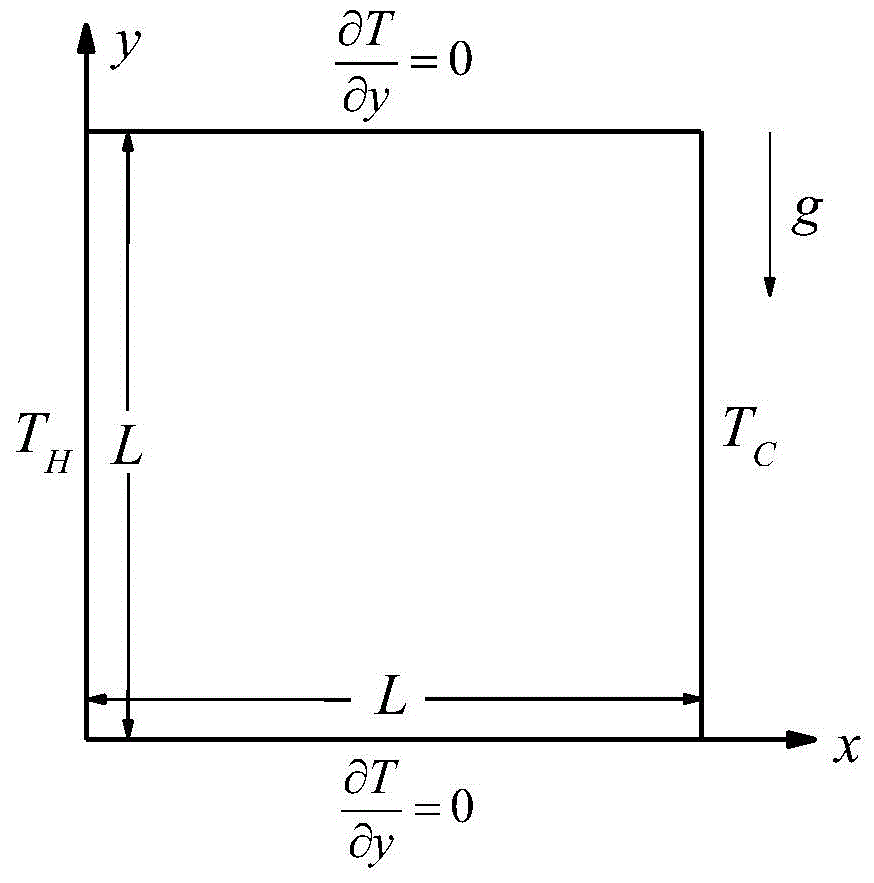

The invention relates to a fluid thermal motion simulation system based on the SPH algorithm and belongs to the field of thermodynamics simulation and visual flowing. The method comprises the steps of conducting modeling on fluid according to calculation examples and calculation requirements, solving a fluid control equation and a modified equation based on the SPH algorithm to achieve analogue simulation of fluid Lagrange thermal motion, and finally showing the thermal motion process of fluid visually in the form of graphs and animations by means of the visual processing technology. Compared with an existing meshing CFD simulation system, the fluid thermal motion simulation system has the advantage that a more reasonable simulation result can be obtained when the system is used for simulating certain advanced non-linear problems such as the jet flow problem, the ocean motion problem, the dam break problem and the dynamic boundary problem. Compared with an existing mesh-free CFD simulation system, the fluid thermal motion simulation system has the advantages that calculation stability and calculation accuracy are improved, and the gap of fluid thermal motion simulation and turbulent flow simulation is filled.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Simulation Method of Soft Tissue Deformation Based on Meshless Galerkin and Particle Spring Coupling

InactiveCN102262699AImprove continuityImprove stabilitySpecial data processing applicationsComputation complexitySoft tissue deformation

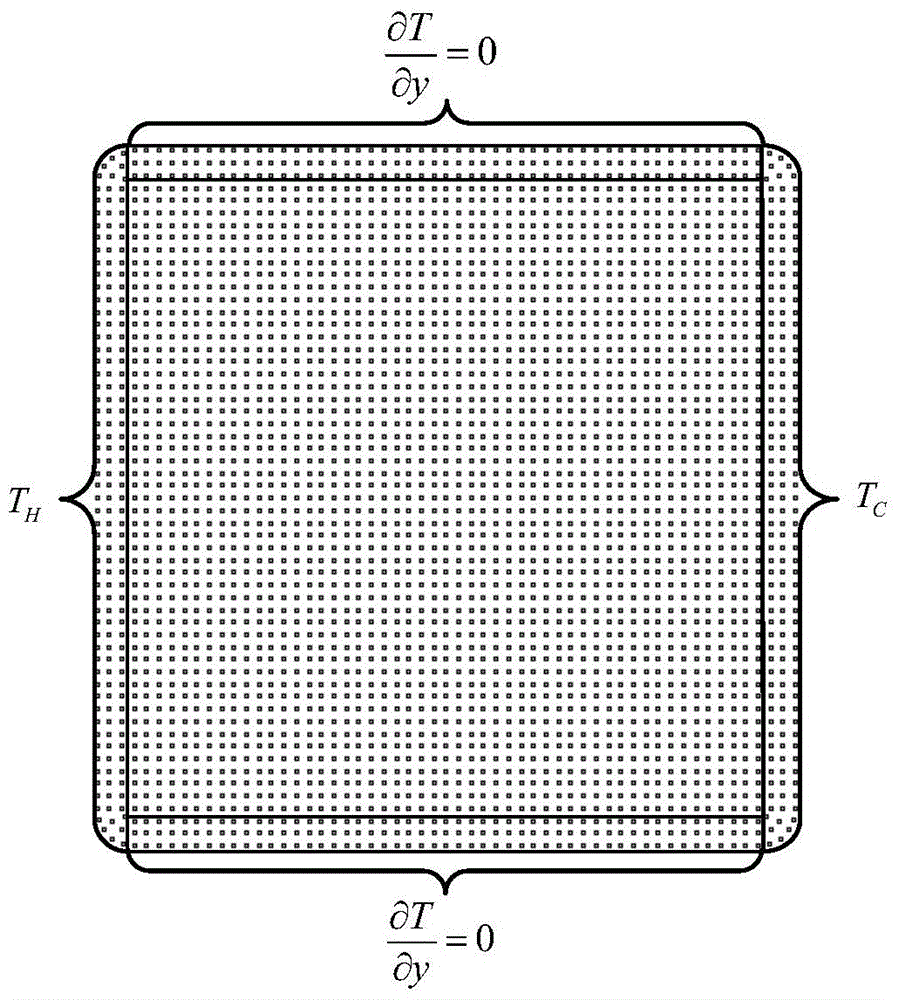

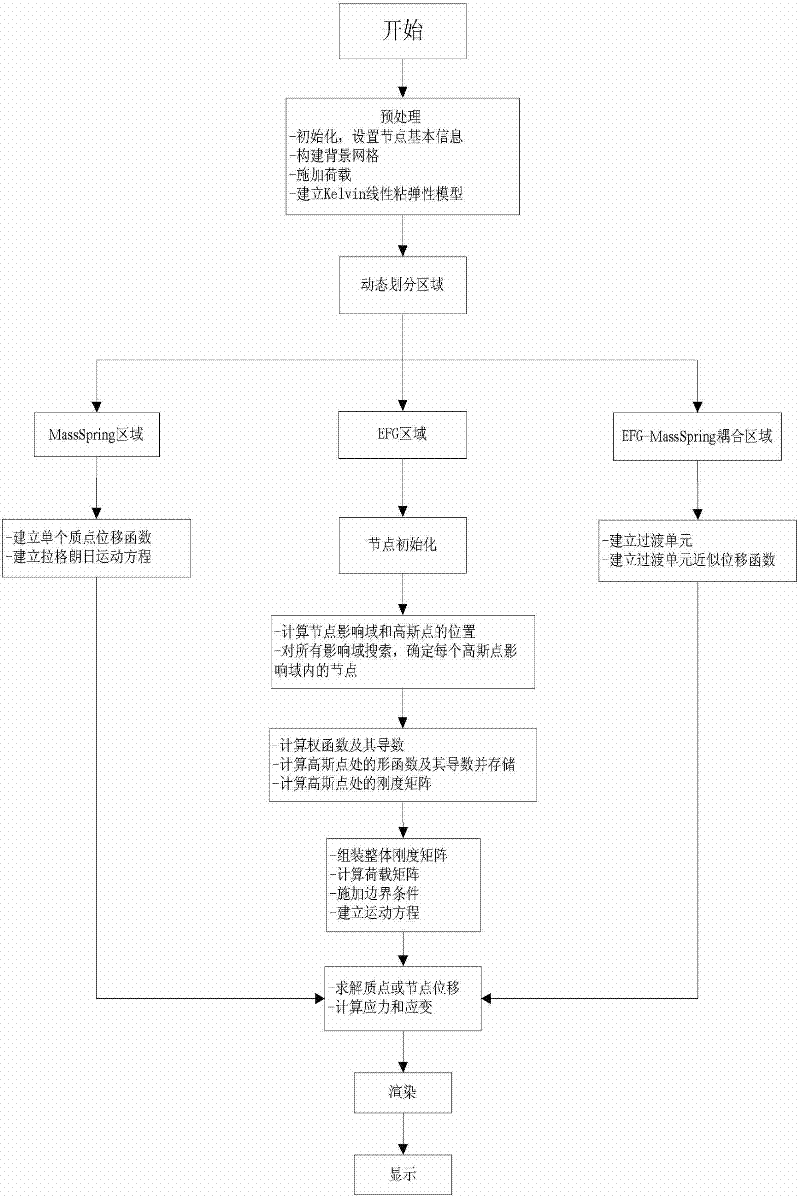

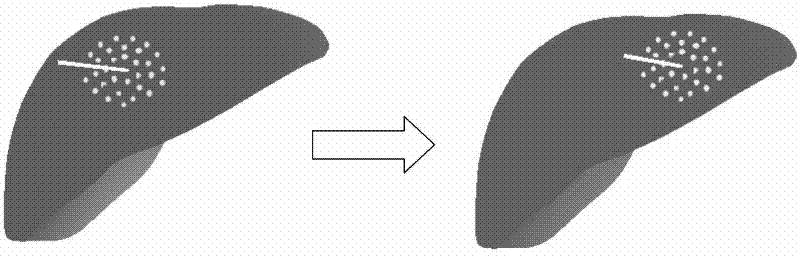

The invention relates to an object deformation real-time simulation graphic processing technique, particularly a soft tissue deformation simulation method based on coupling of mesh-free Galerkin and mass spring, which comprises the following steps: in the pretreatment process, establishing a linear viscoelasticity biomechanical model for soft tissues; in the deformation computation process, dynamically partitioning a mesh-free region and a mass spring region according to the load carried by the soft tissues, establishing a transitional unit of the connection region between the mesh-free region and mass spring region, and constructing a transitional unit approximation displacement function, thereby implementing self-adapting coupling of a mesh-free Galerkin method and a mass spring method;and in the after-treatment process, outputting the state of the mass or node of each time step in the deformation process onto a screen, carrying out illumination rendering, and finally displaying the real-time deformation process of the soft tissue organ under stressed conditions on the screen, thereby implementing visualization effect of dynamic deformation. By utilizing the advantage of high efficiency in the mass spring method and the advantages of high precision and no need of mesh reconstruction in the mesh-free Galerkin method, the invention overcomes the defect that the Galerkin method is not suitable for solving a large-scale problem, thereby effectively lowering the complexity of computation in the soft tissue deformation simulation and enhancing the operation efficiency.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

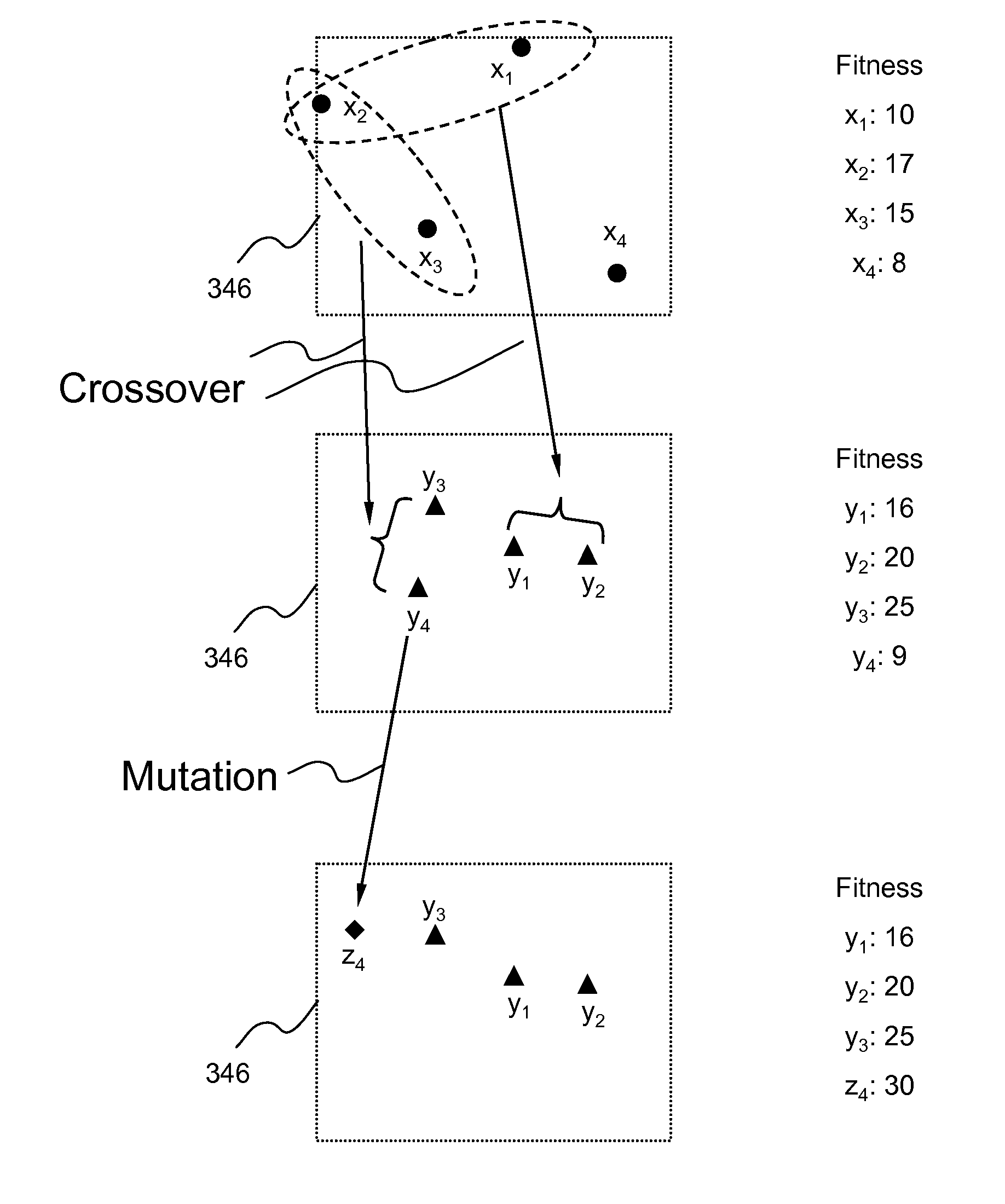

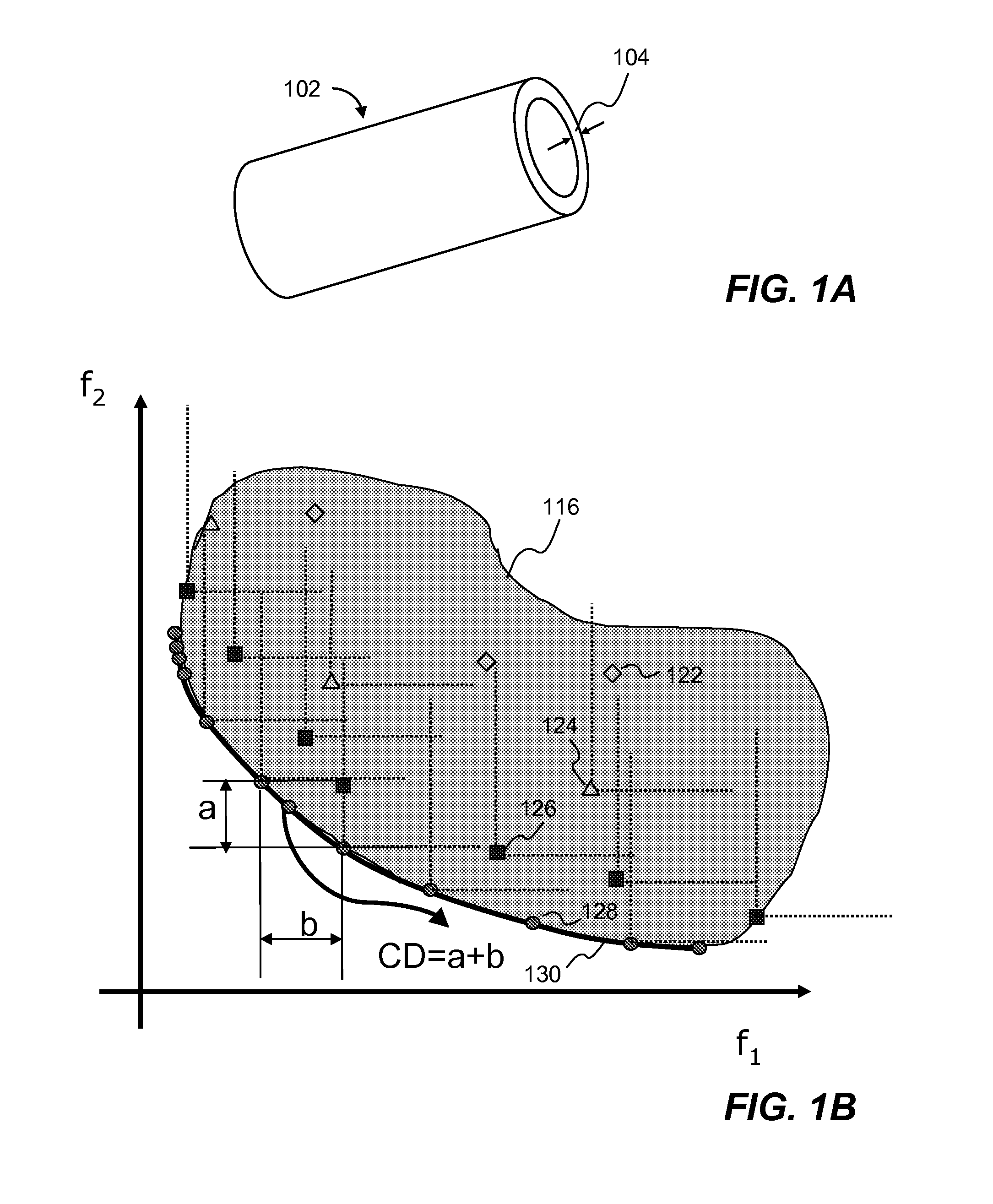

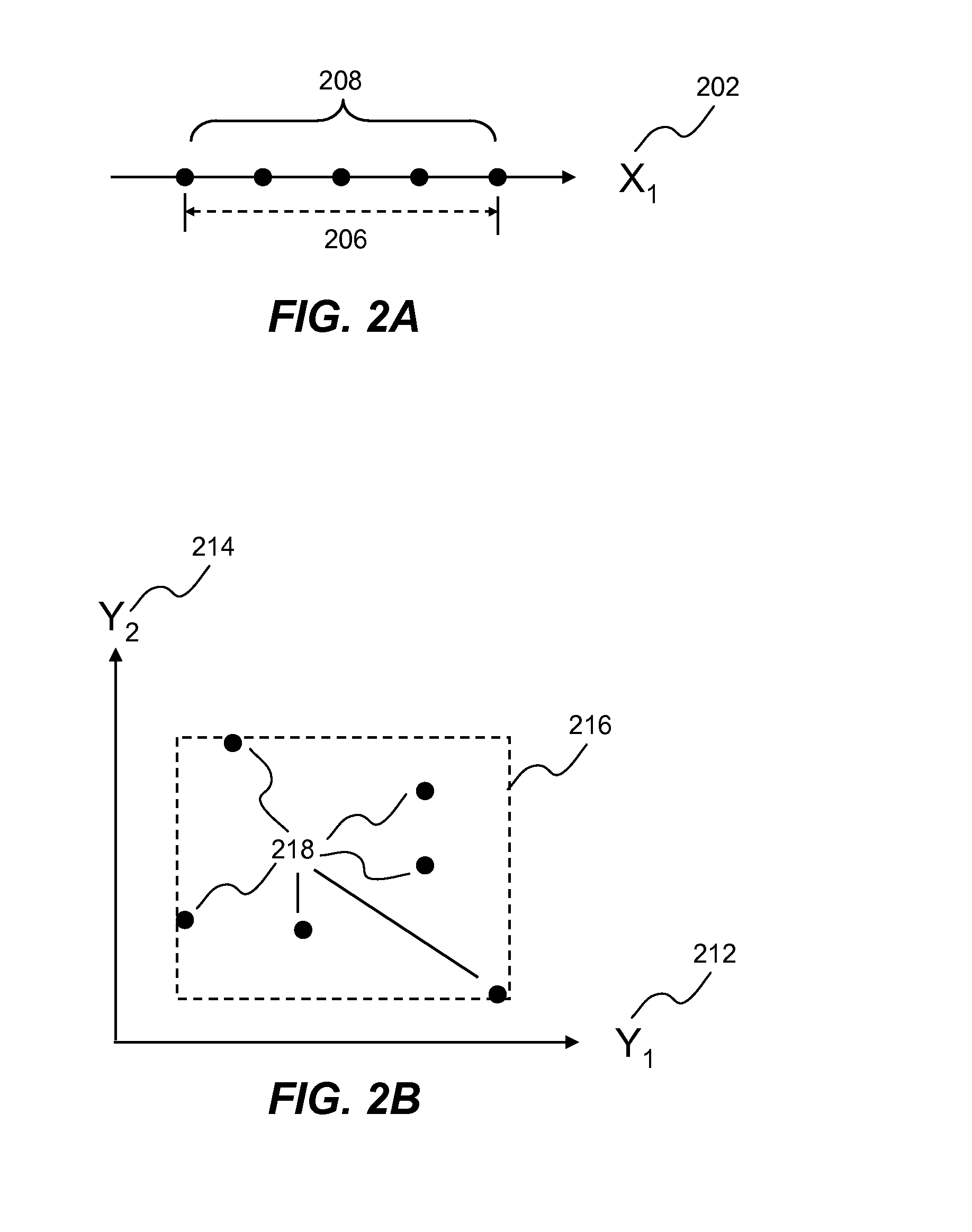

Sampling Strategy Using Genetic Algorithms in Engineering Design Optimization

InactiveUS20090319453A1Digital computer detailsDesign optimisation/simulationAlgorithmElement analysis

A sampling strategy using genetic algorithms (GA) in engineering design optimization is disclosed. A product is to design and optimize with a set of design variables, objectives and constraints. A suitable number of design of experiments (DOE) samples is then identified such that each point represents a particular or unique combination of design variables. The sample selection strategy is based on genetic algorithms. Computer-aided engineering (CAE) analysis or analyses (e.g., finite element analysis, finite difference analysis, mesh-free analysis, etc.) is / are performed for each of the samples during the GA based sample selection procedure. A meta-model is created to approximate the CAE analysis results at all of the DOE samples. Once the meta-model is satisfactory (e.g., accuracy within a tolerance), an optimized “best” design can be found by using the meta-model as function evaluator for the optimization method. Finally, a CAE analysis is performed to verify the optimized “best” design.

Owner:LIVERMORE SOFTWARE TECH

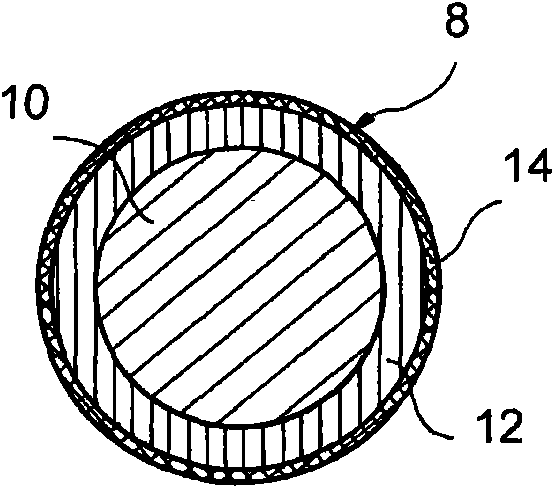

Filter element and method of making

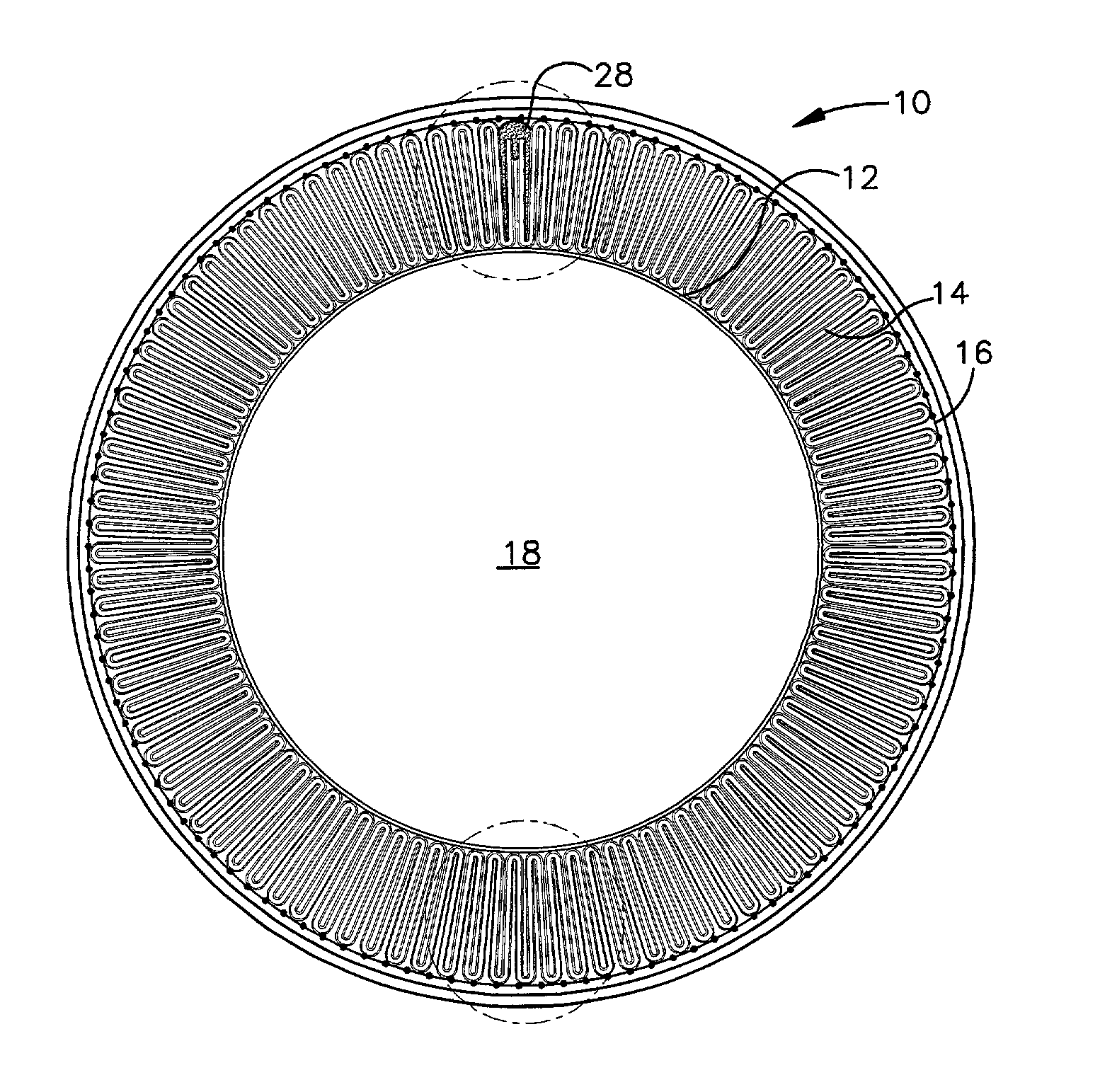

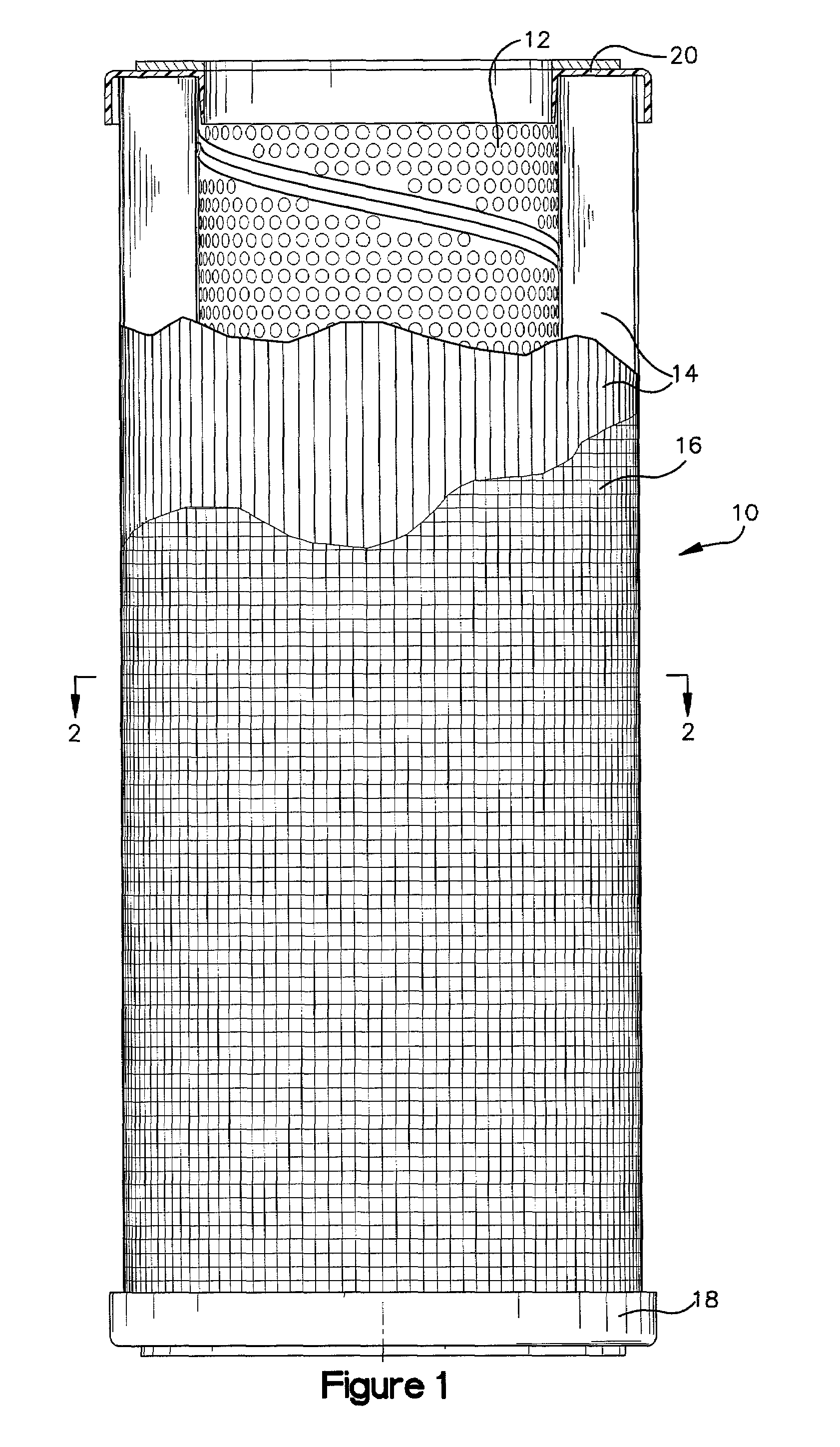

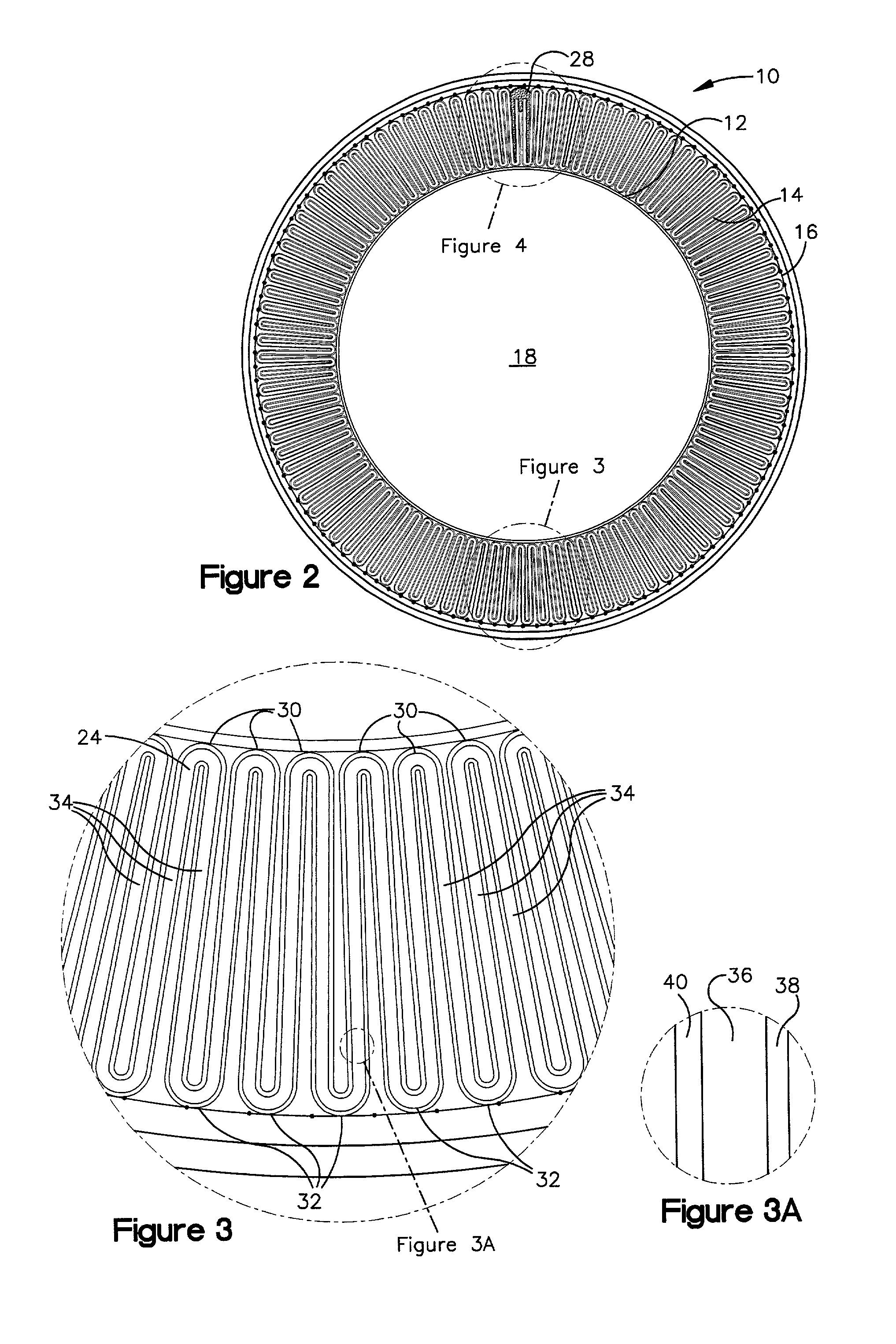

InactiveUS7438812B2Solution to short lifeImprove efficiencyDispersed particle filtrationLiquid suspension thickening by filtrationFilter mediaCellulose fiber

A filter element (10) is provided which can be used to remove microsize contaminant particles (i.e., about 0.5 μm to about 25.0 μm) from aviation fuel. The filter element (10) includes a cylindrical pleated filter media (14) and an exoskeleton support structure (16) supporting the filter media (14). The filter media (14) has a pleat density of about eight to about thirteen pleats per inner diameter inch and is formed only from cellulose-fiber-free and woven-mesh-free layers. The exoskeleton support structure (16) is a screen which is thermally bonded to the pleats' peaks in such a manner that the filter media (14) is sufficiently supported without conventional endoskeleton support layers.

Owner:PARKER INTANGIBLES LLC

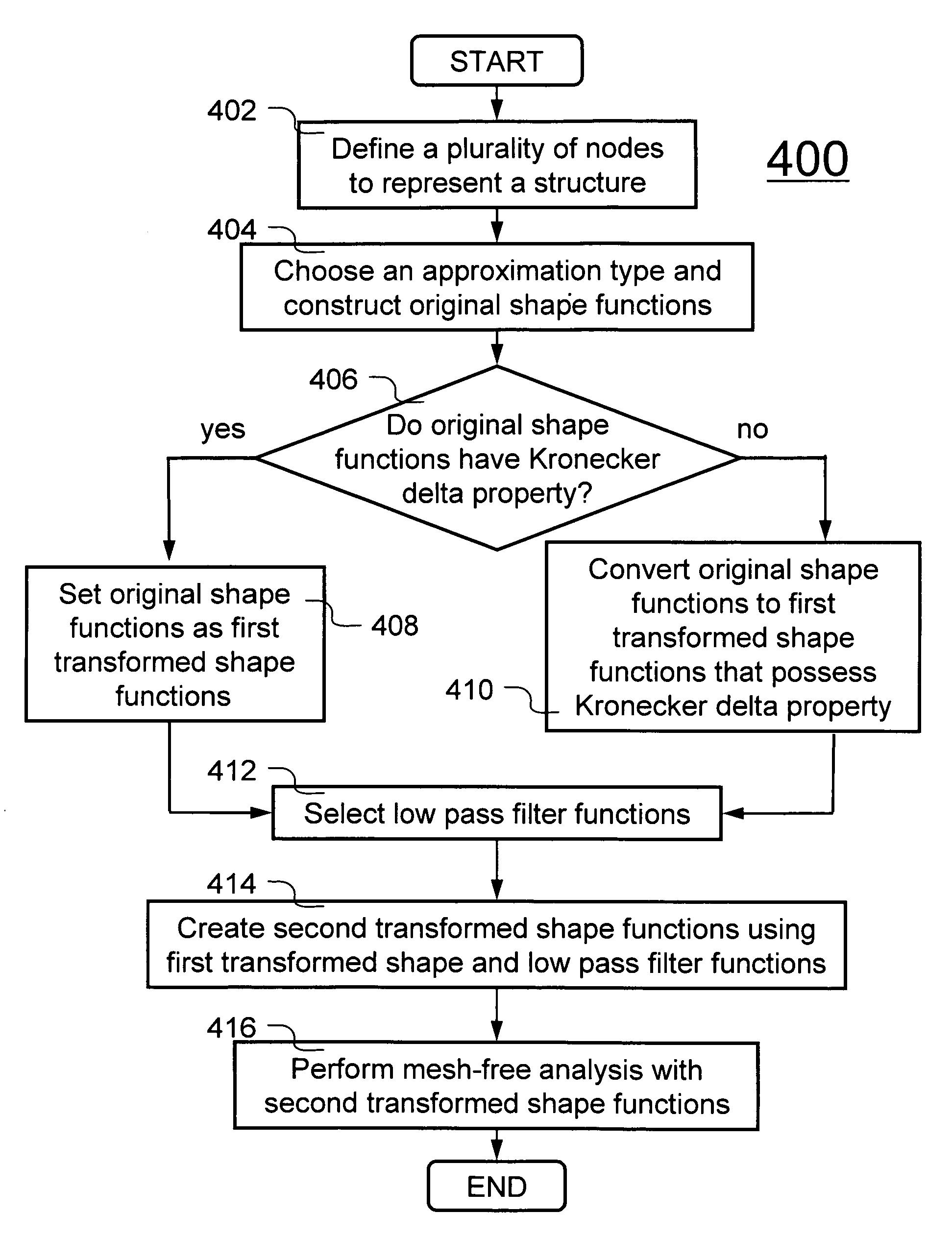

Practical fast mesh-free analysis

ActiveUS7660480B1Method is fastSimple conditionsCharacter and pattern recognitionComputation using non-denominational number representationIntegration ruleLow-pass filter

A two-level transformation scheme to enable a practical fast mesh-free method is disclosed. The first level transformation transforms the original chosen mesh-free shape function to a first transformed mesh-free shape function that preserves Kronecker delta properties. The first transformed mesh-free function allows the essential boundary conditions to be imposed directly. The second-level transformation scheme employs a low pass filter function served as a regularization process that filters out the higher-order terms in the monomial mesh-free approximation obtained from the first-level transformation scheme with desired consistency and completeness conditions. This integration scheme requires only a low-order integration rule comparing to the high order integration rule used in the traditional mesh-free methods. The present invention simplifies the boundary condition treatments and avoids the usage of high-order integration rule and therefore is more practical than the traditional mesh-free methods.

Owner:ANSYS

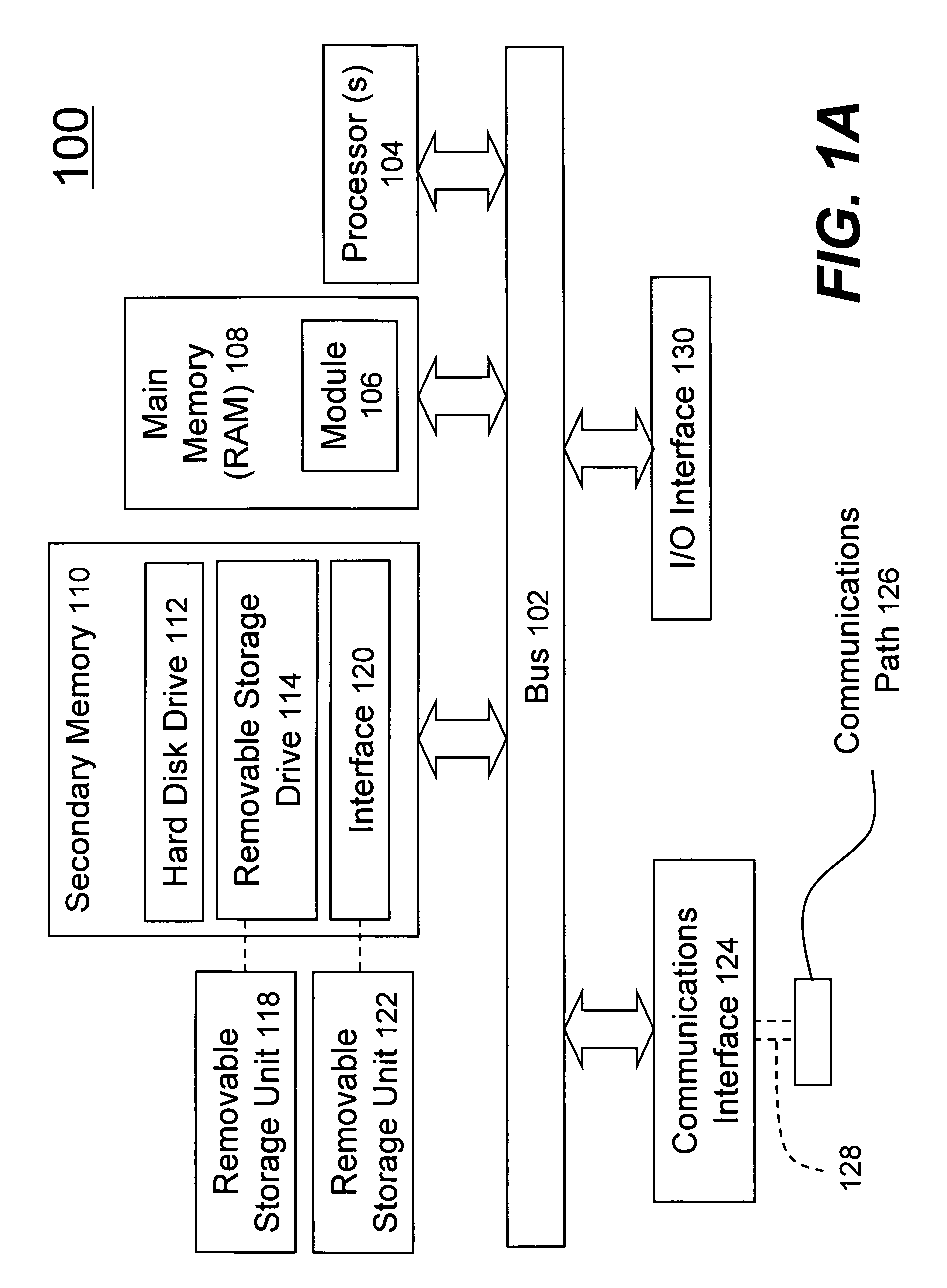

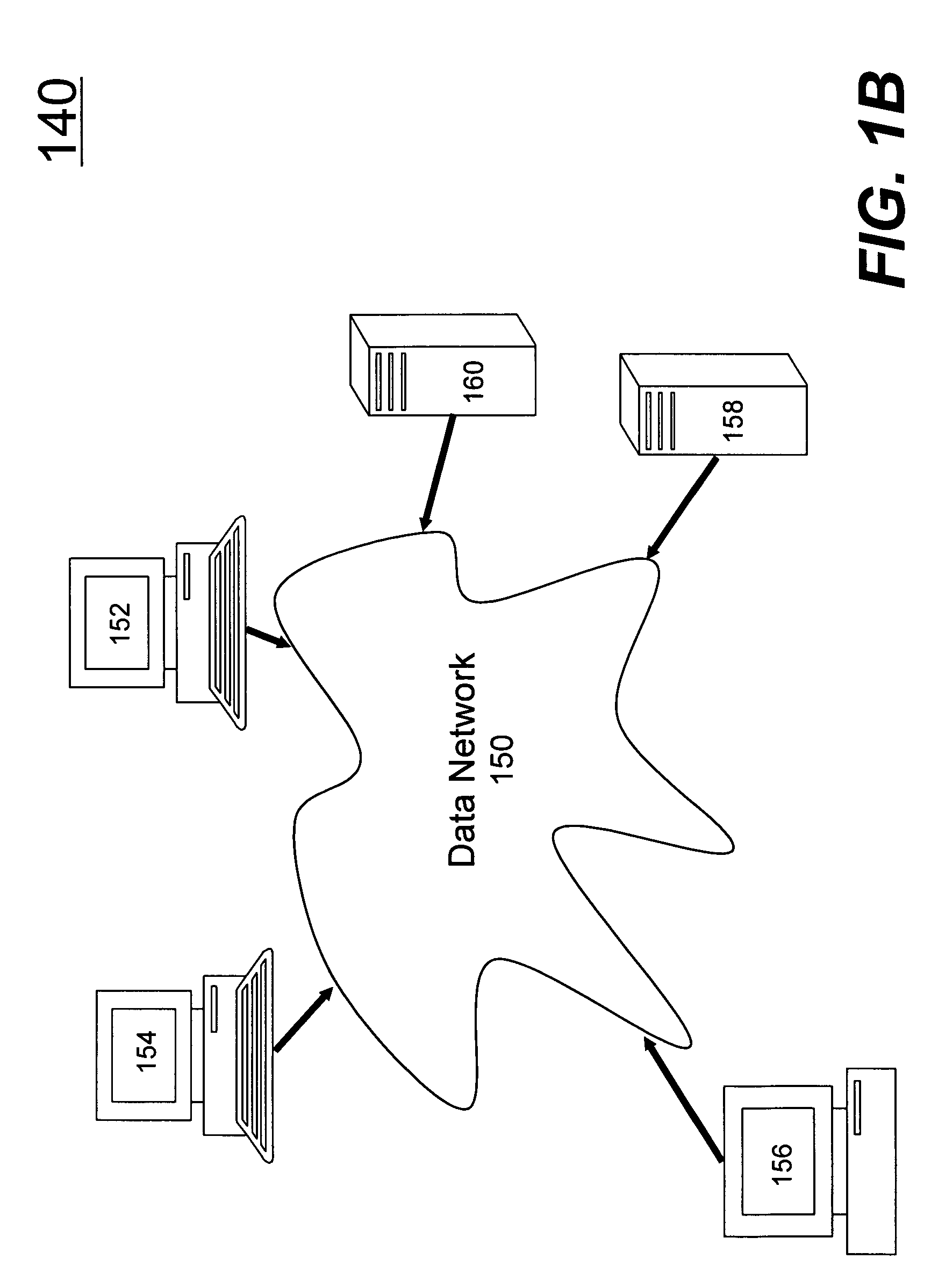

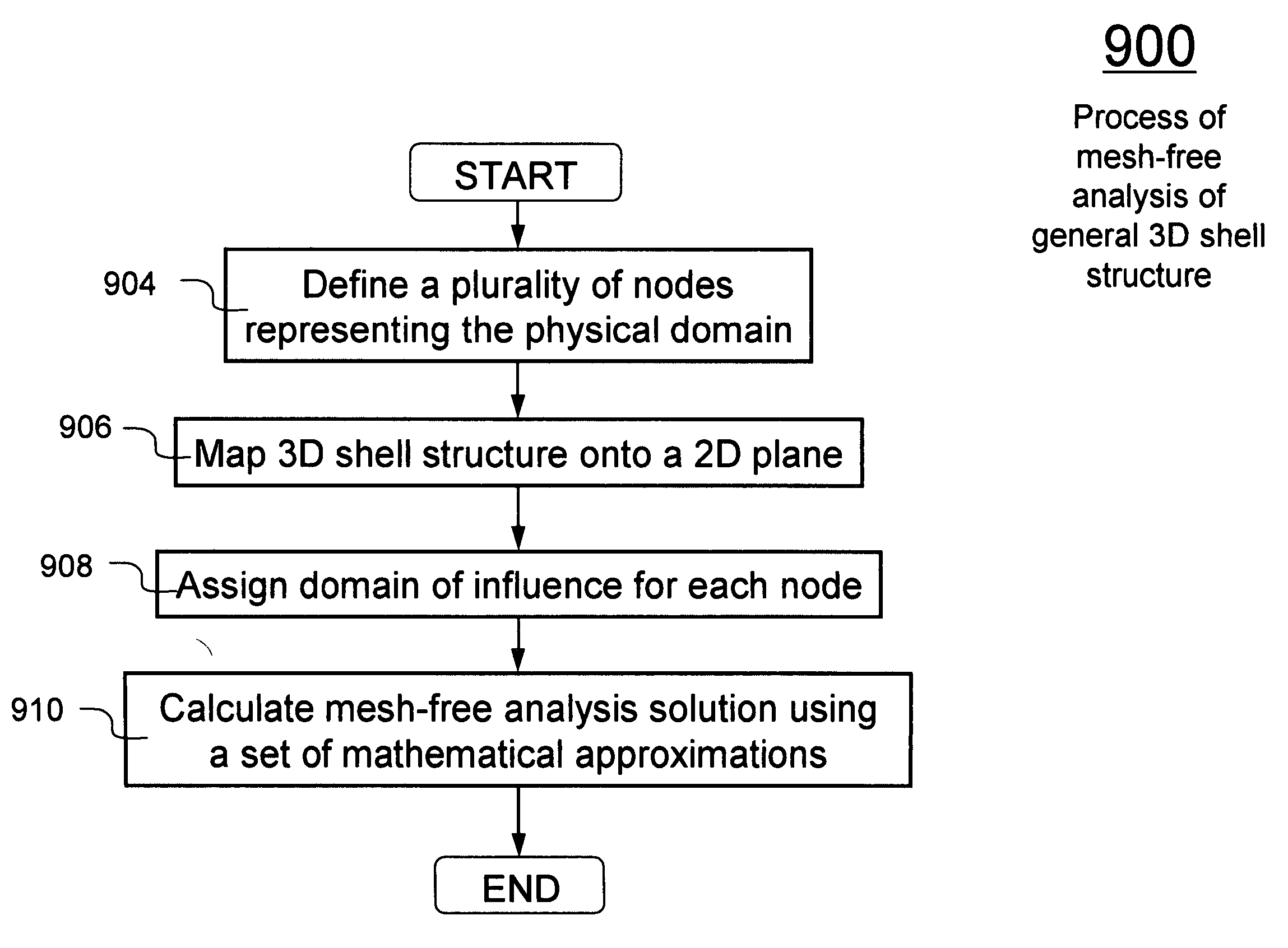

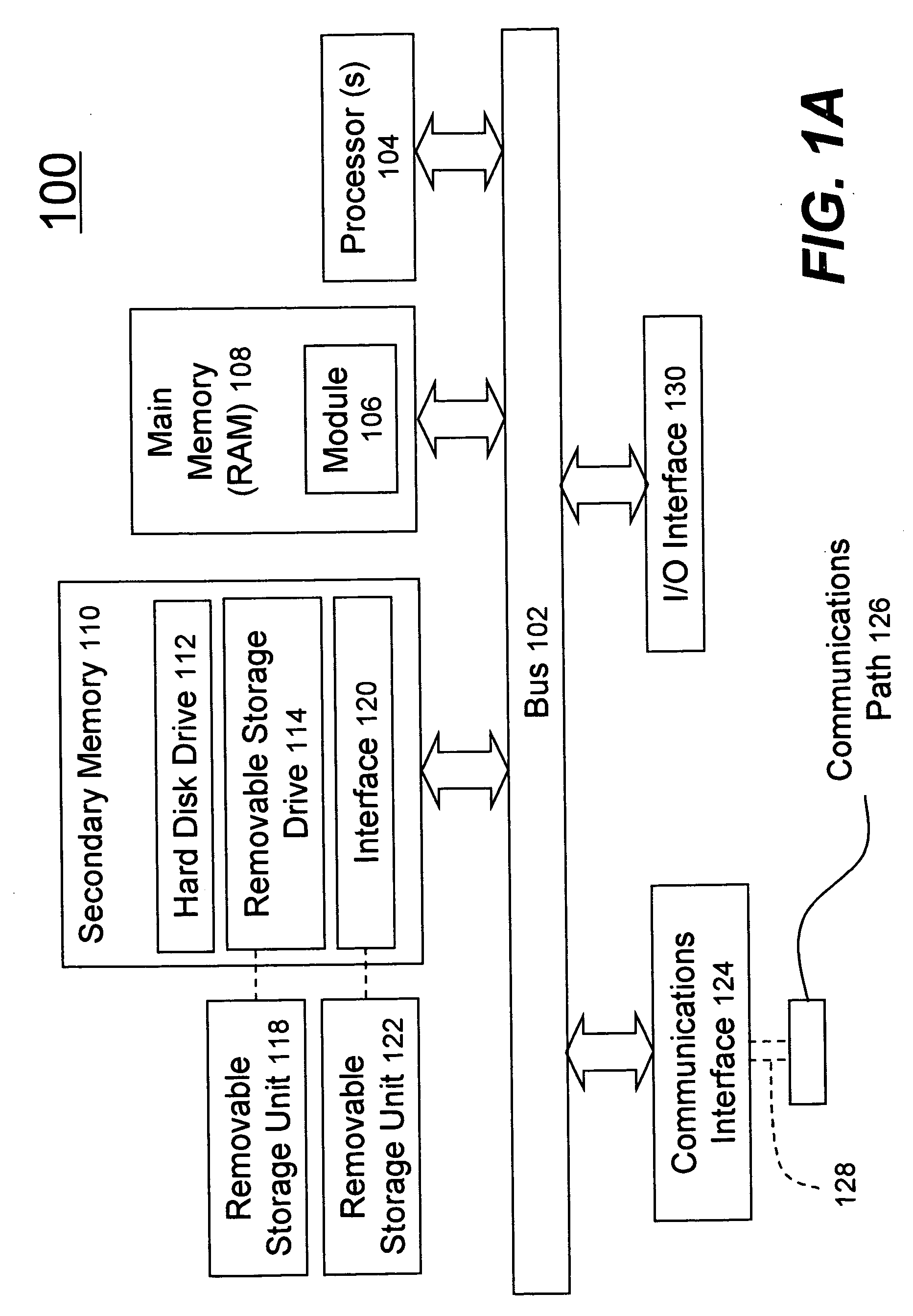

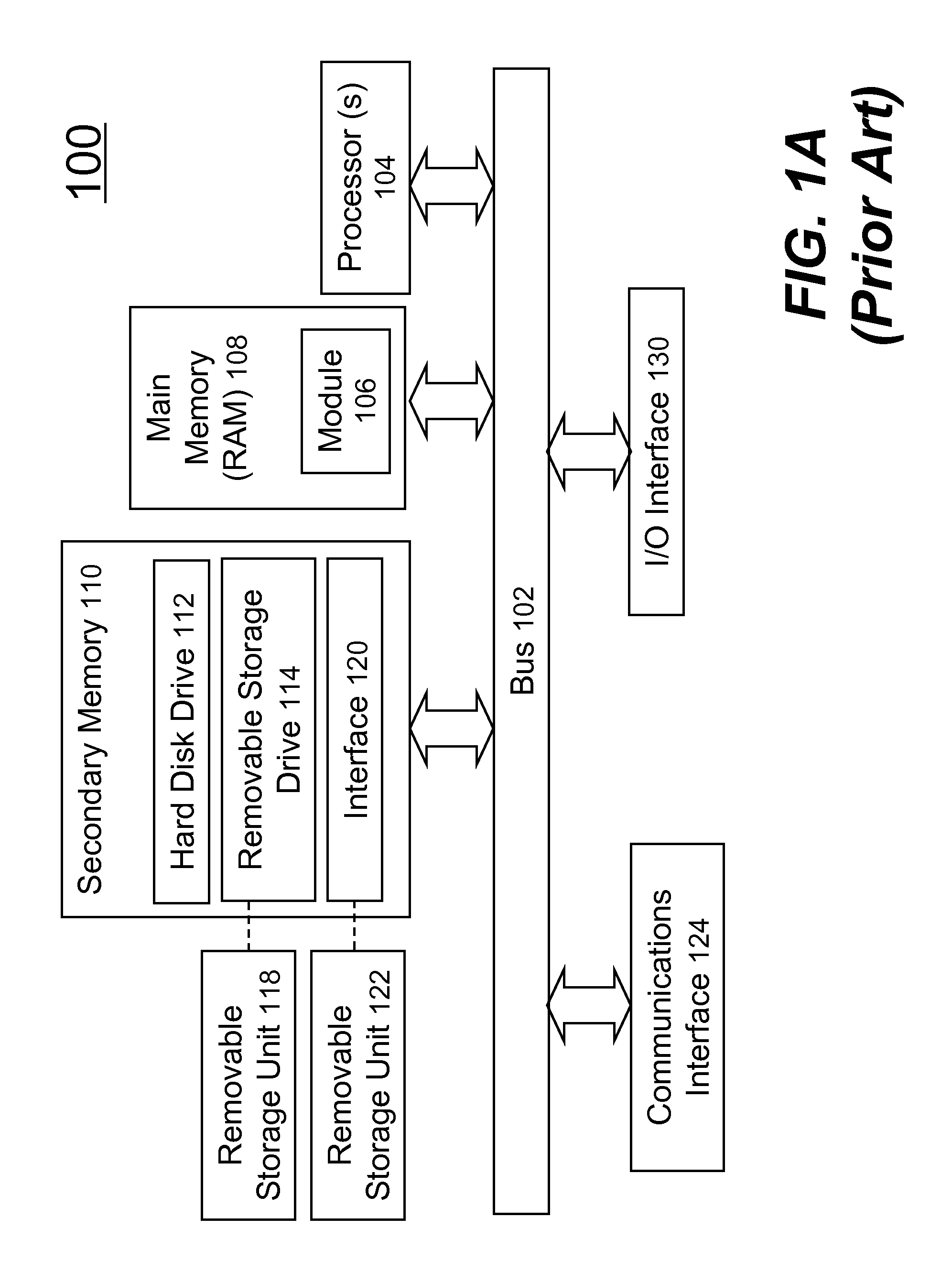

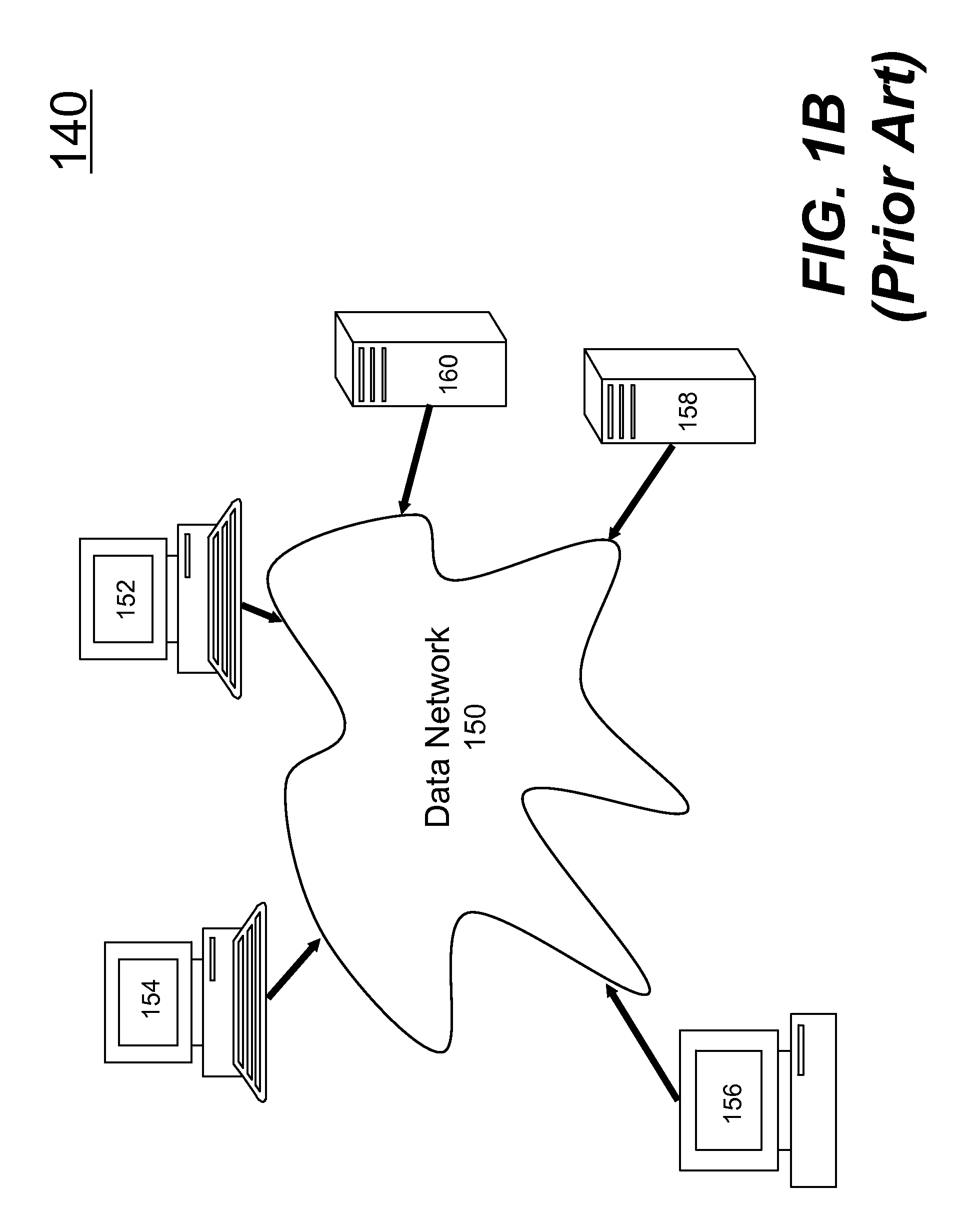

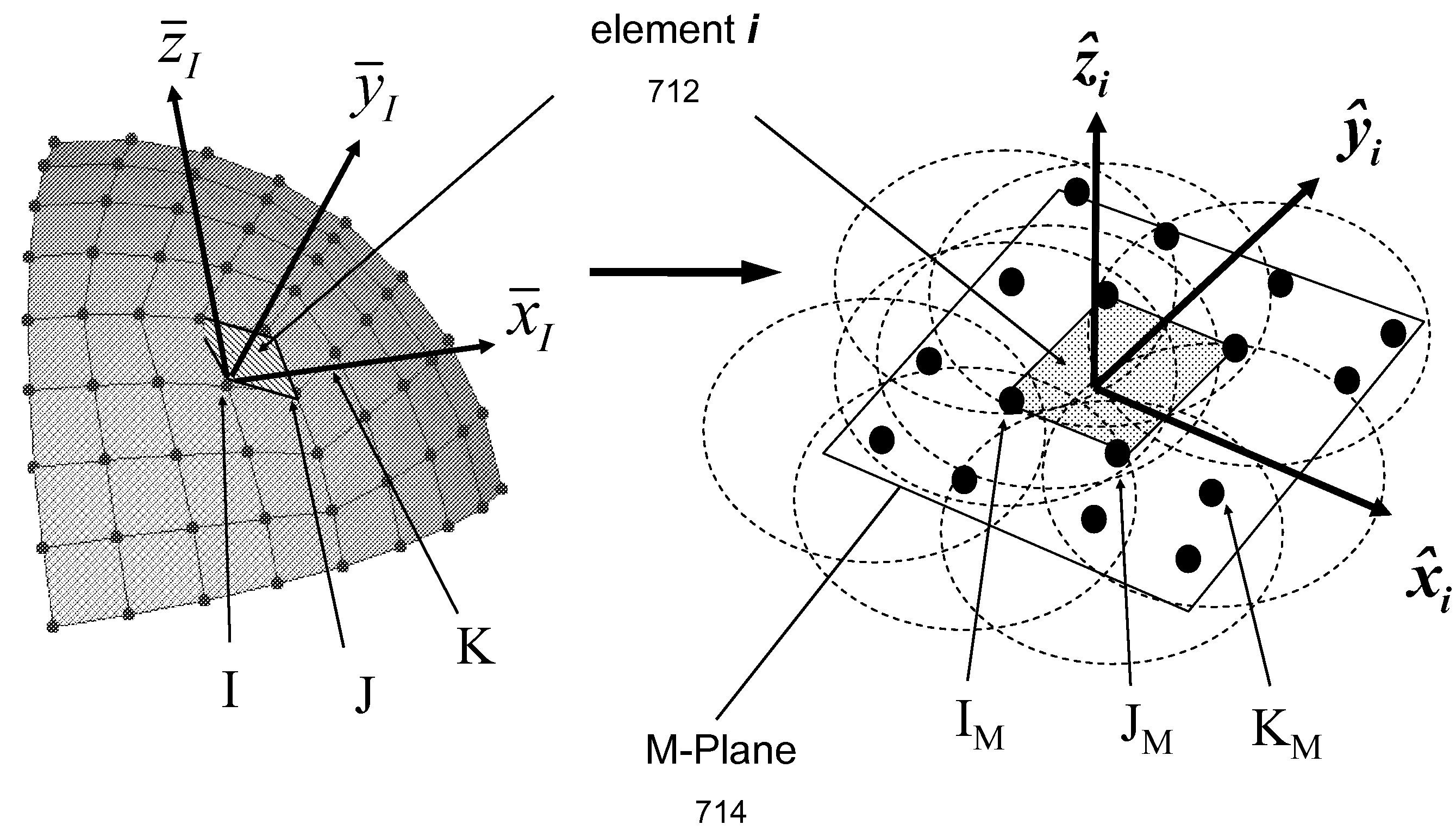

Method and system for mesh-free analysis of general three-dimensional shell structures

ActiveUS20060103648A1Computation using non-denominational number representationDesign optimisation/simulationThree-dimensional spaceComputer science

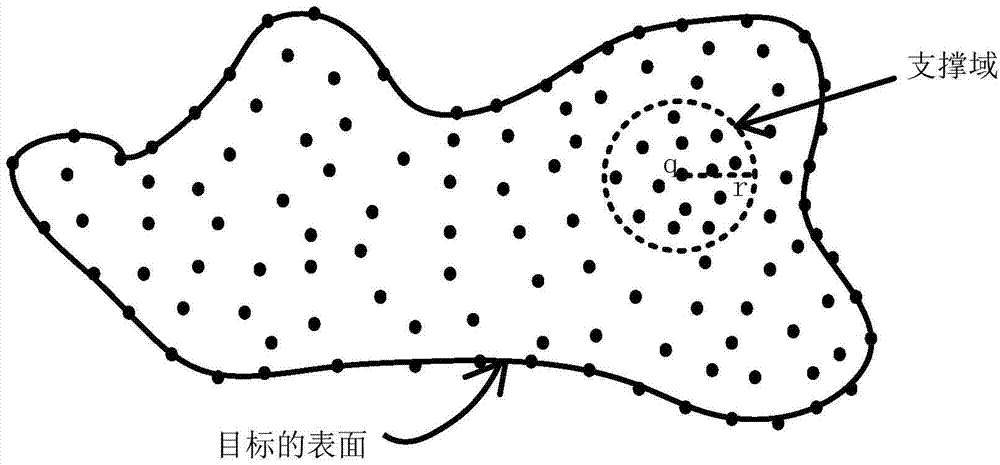

A method, system and computer program product pertained to engineering analysis of a general three-dimensional (3-D) shell structure using the mesh-free technique is disclosed. The structural responses are solved with mesh-free technique after the 3-D shell structure is mapped to a two-dimensional plane. According to one aspect, the present invention is a method for mesh-free analysis of a general three-dimensional shell structure, the method comprises: defining the general shell structure as a physical domain represented by a plurality of nodes in a three-dimensional space, creating a plurality of projected nodes by mapping the plurality of nodes in the three-dimensional space onto a two-dimensional plane, assigning a plurality of domain of influences, one for each of the plurality of projected nodes, and calculating a solution of the physical domain using a set of mathematical approximations pertaining to each of the plurality of projected nodes.

Owner:ANSYS

Method and system for adaptive mesh-free shell structures

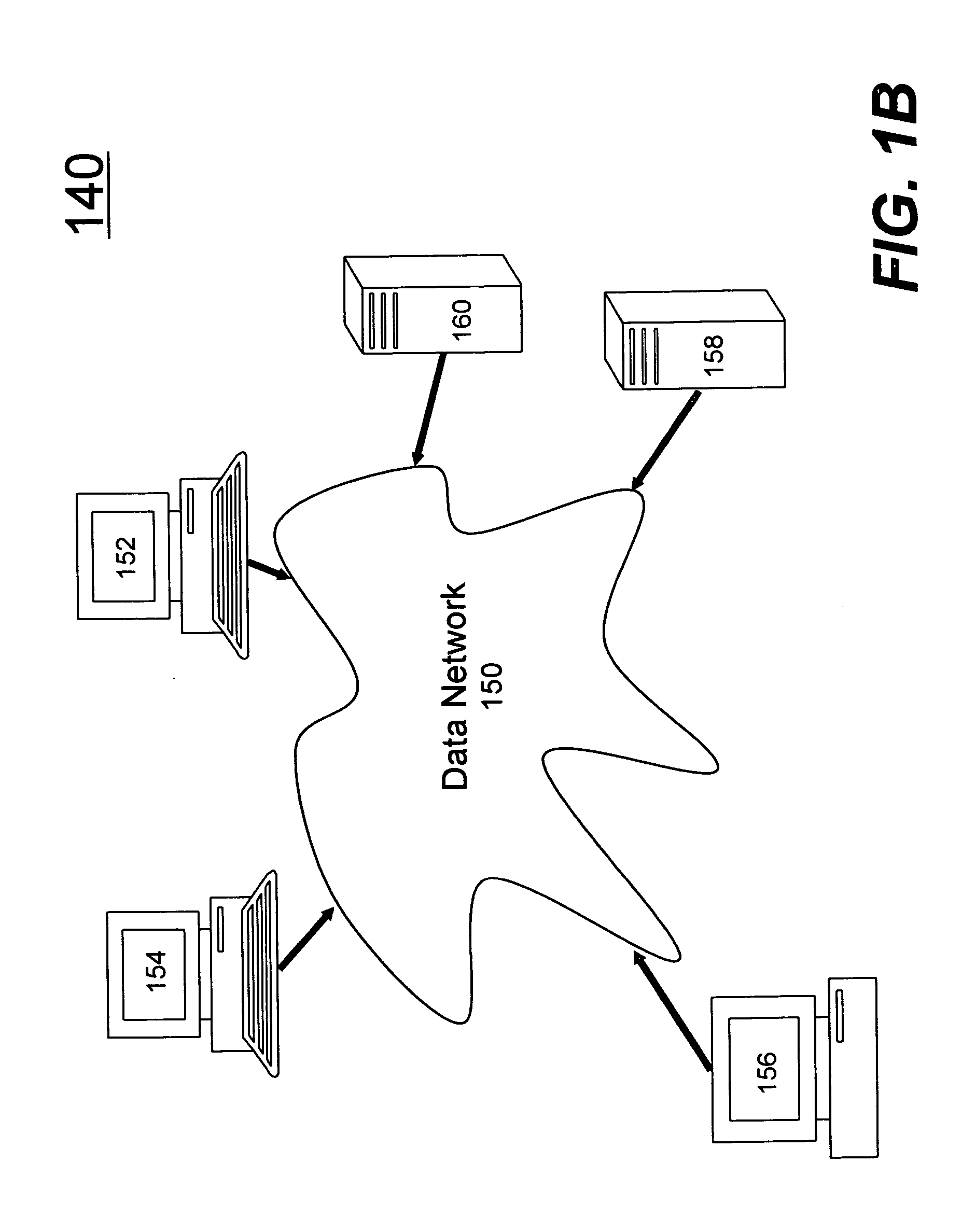

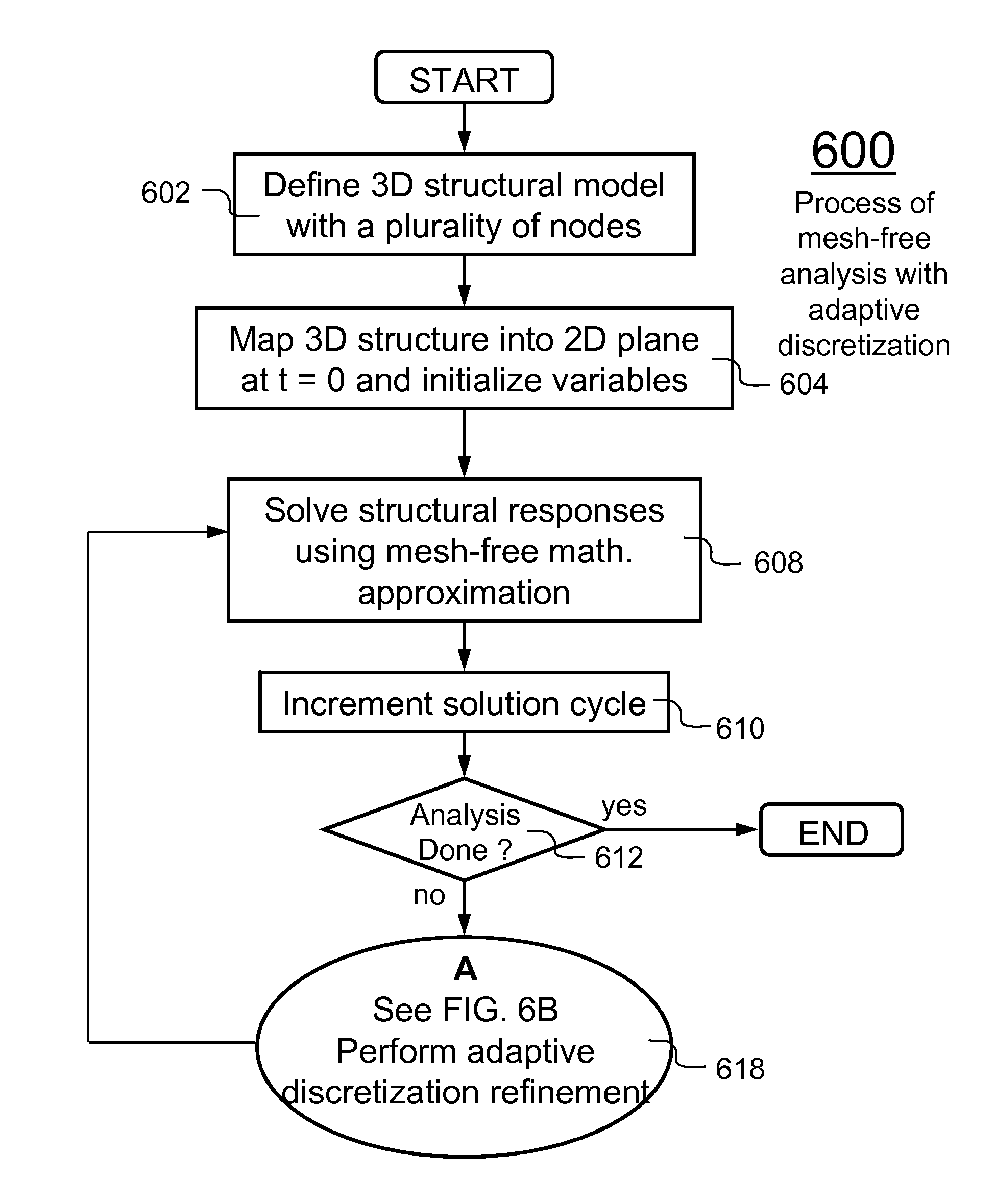

ActiveUS7702490B1Efficient analysisRealistic analytical resultComputation using non-denominational number representationDesign optimisation/simulationComputational scienceTime domain

A method, system and computer program product pertained to adaptive discretization refinement of shell structure is disclosed. The adaptive mesh-free model is based on a technique for dividing the critical area into a finer model. The present invention is a method for enabling adaptive mesh-free shell structure in a time-domain analysis, the method comprises: defining the mesh-free shell structure by a structural geometry description file including a plurality of nodes and a reference 3-D mesh, which includes a plurality of shell elements, mapping the 3-D reference mesh into a 2-D parametric plane, wherein the 2-D parametric mesh includes a plurality of integration cells corresponding to the plurality of shell elements, solving structural responses at current solution cycle using mesh-free mathematical approximations pertaining to each of the plurality of integration cells, performing adaptive discretization refinement for the plurality of the integration cells.

Owner:ANSYS

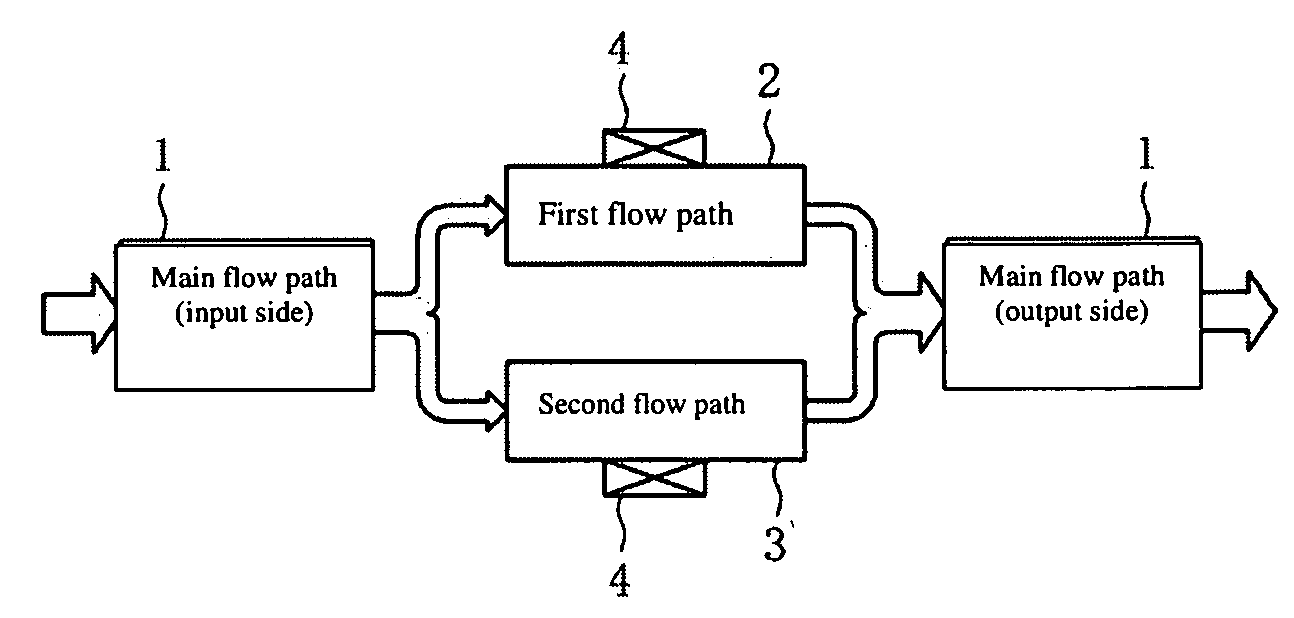

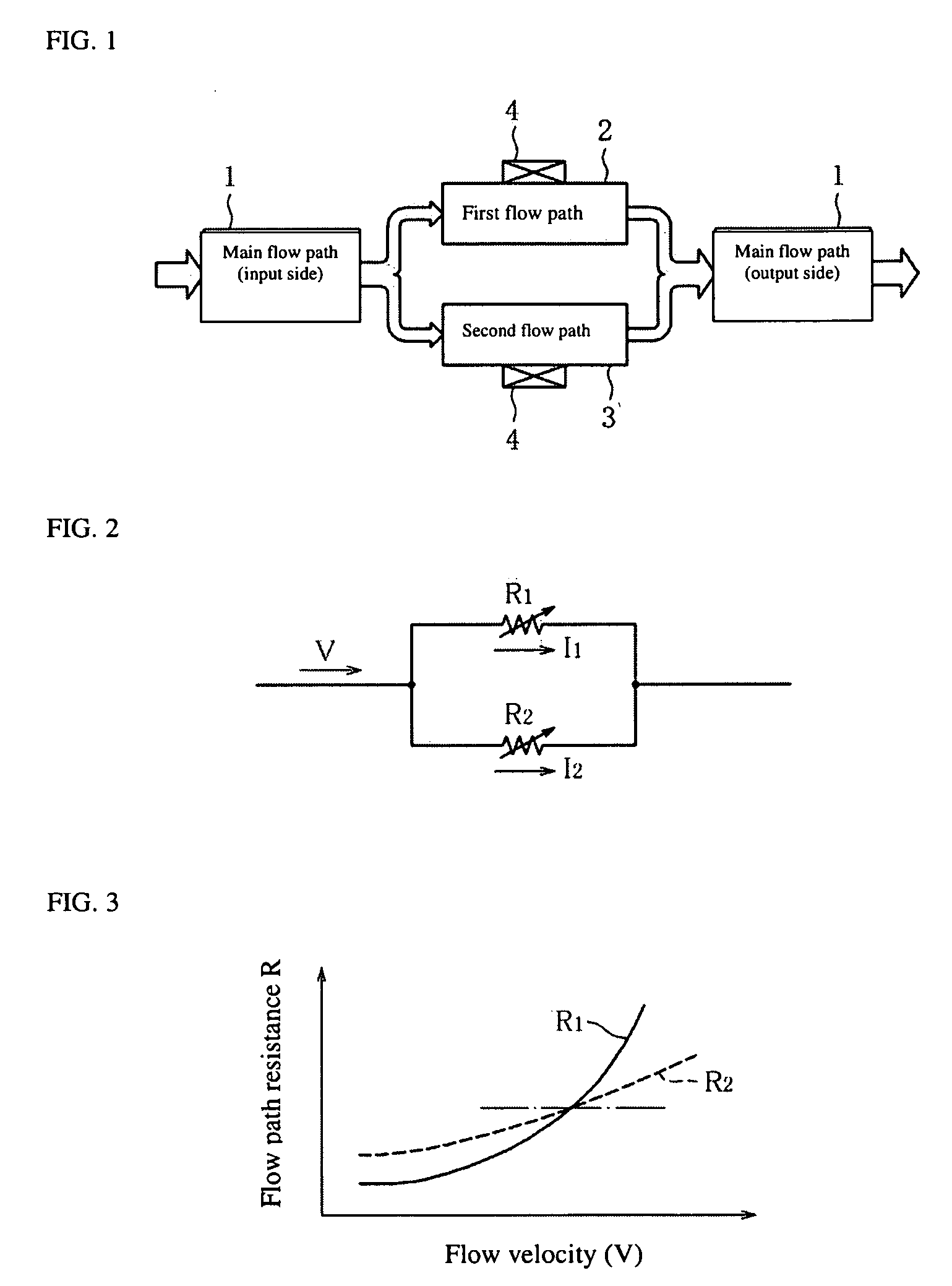

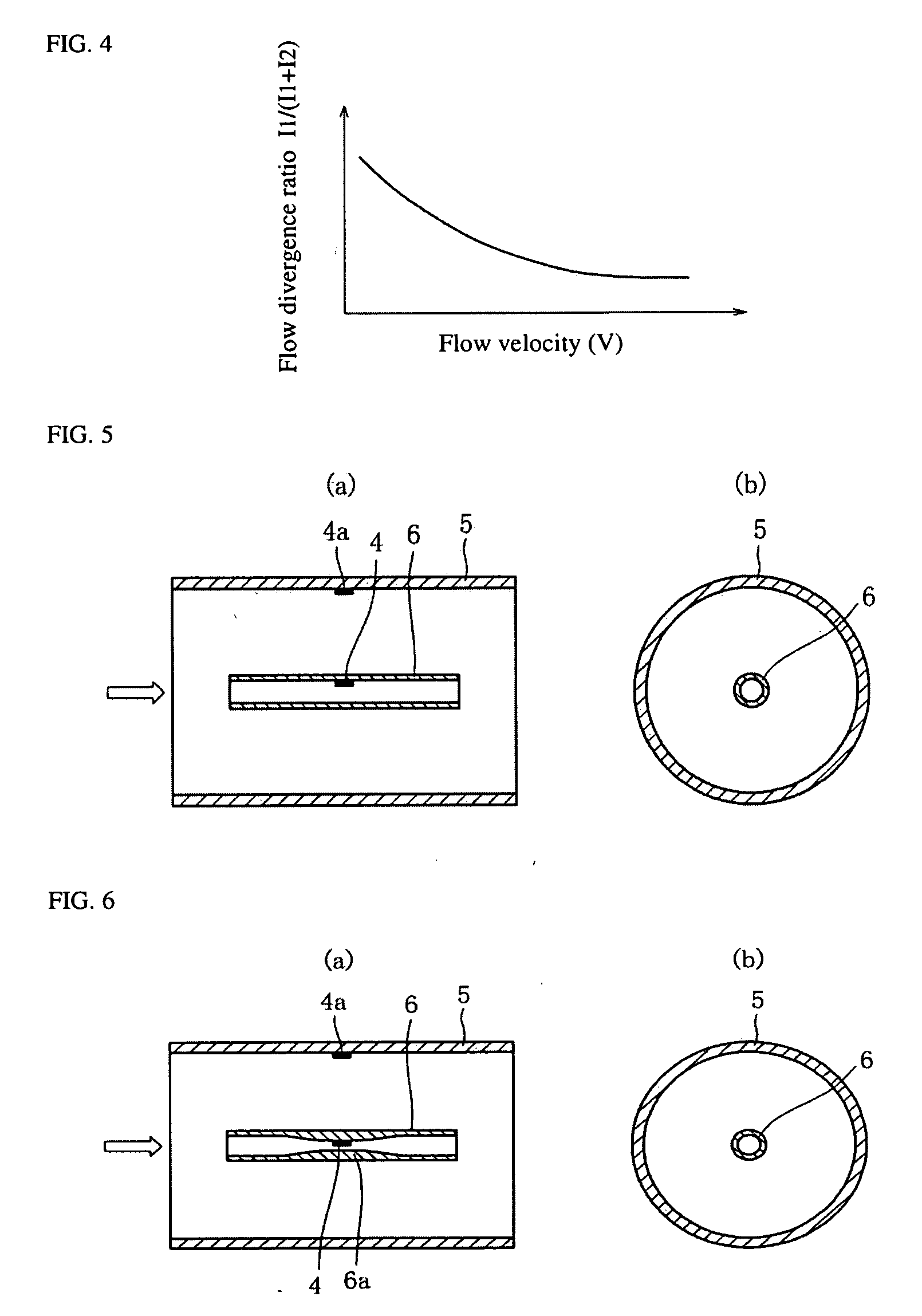

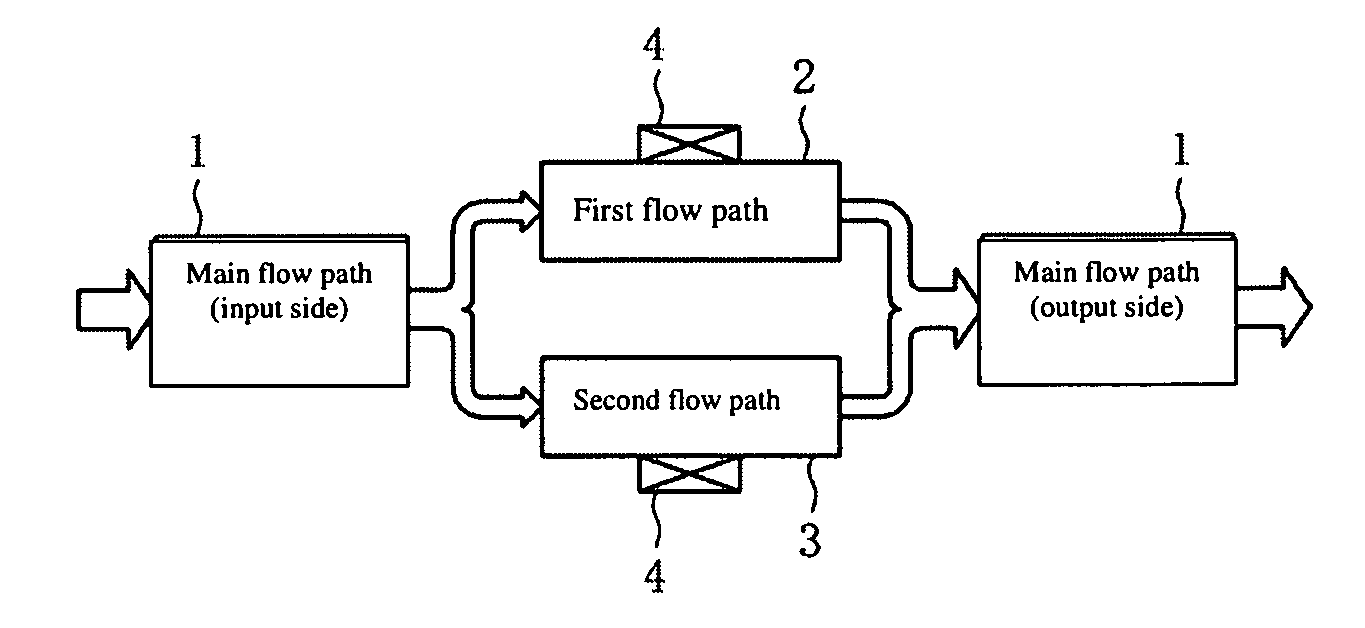

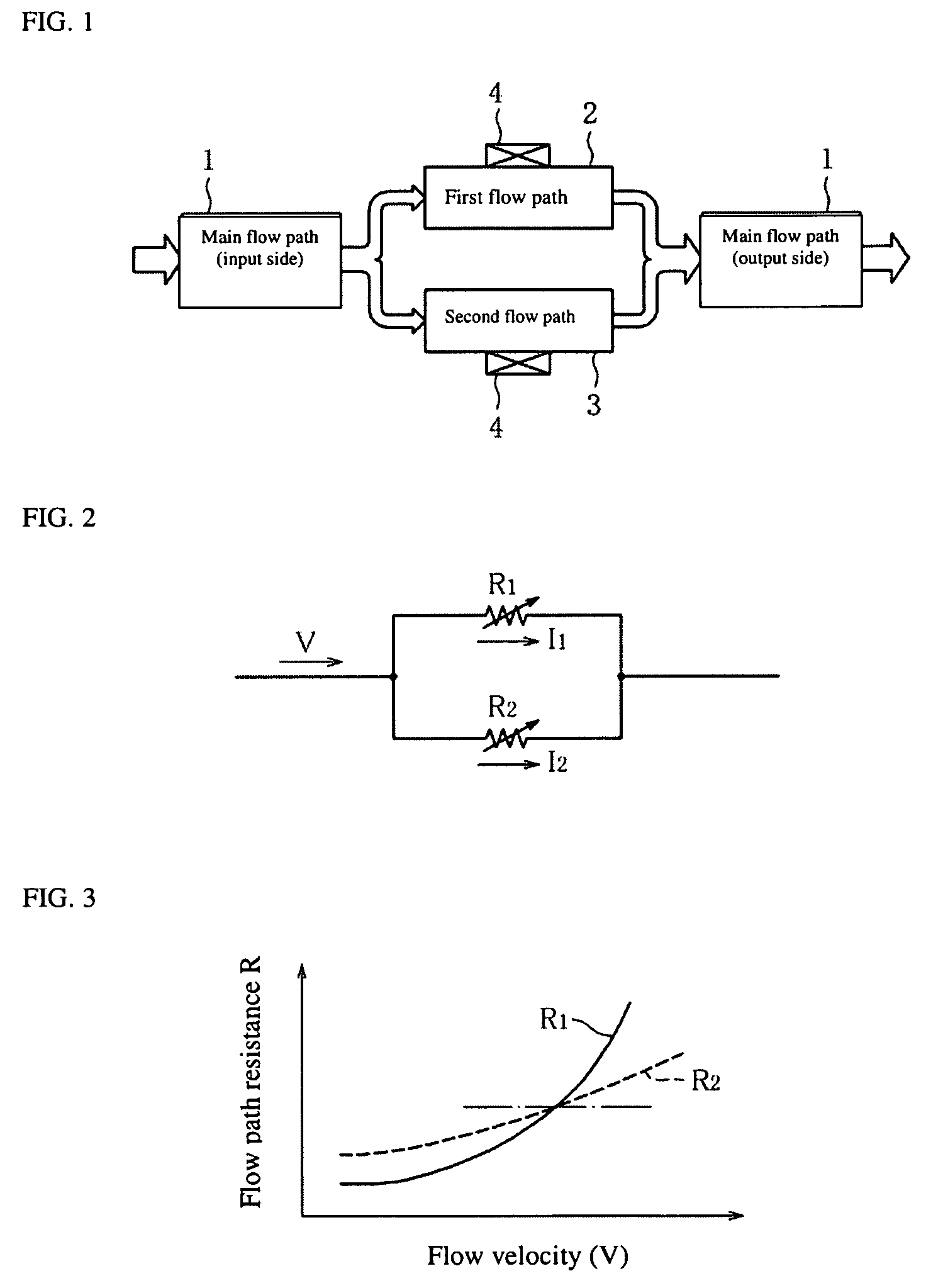

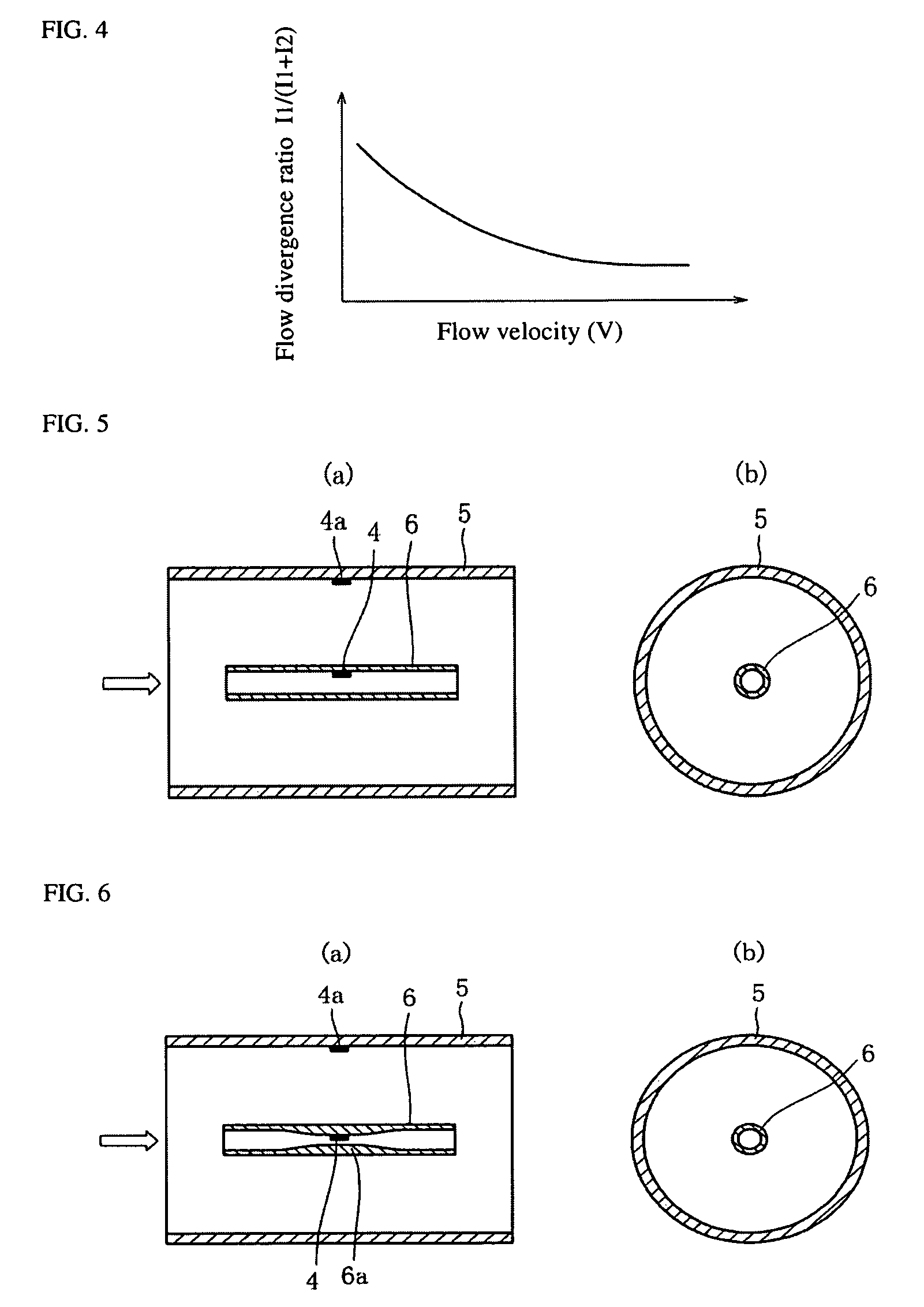

Flow sensor

InactiveUS20090007654A1High detection sensitivityIncrease flow rateVolume/mass flow by thermal effectsVolume flow proportion measurementEngineeringFlow diversion

The flow meter is equipped with first and second flow paths, provided in parallel and through which flows fluid having flowed through and being diverted from a main flow path, the flow diversion ratio among the first and second flow paths changing passively in accordance with the flow rate of fluid through the main flow path, and a flow rate sensor provided on at least one of the first and second flow paths. The first and second flow paths are formed, for example, as flow paths having different flow path cross-sectional areas, or alternatively are formed from mesh elements provided with mesh-free areas on a portion thereof. Alternatively, one of the either the first or second flow path is realized with a paddle mechanism incorporated therein.

Owner:YAMATAKE HONEYWELL CO LTD

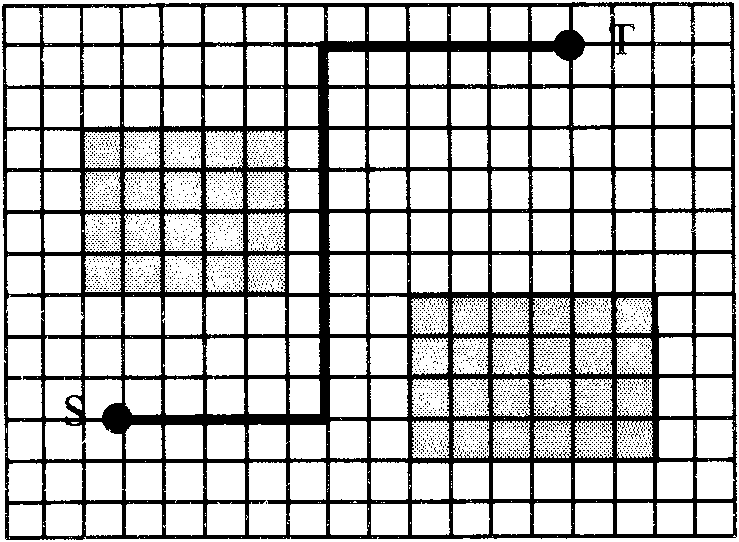

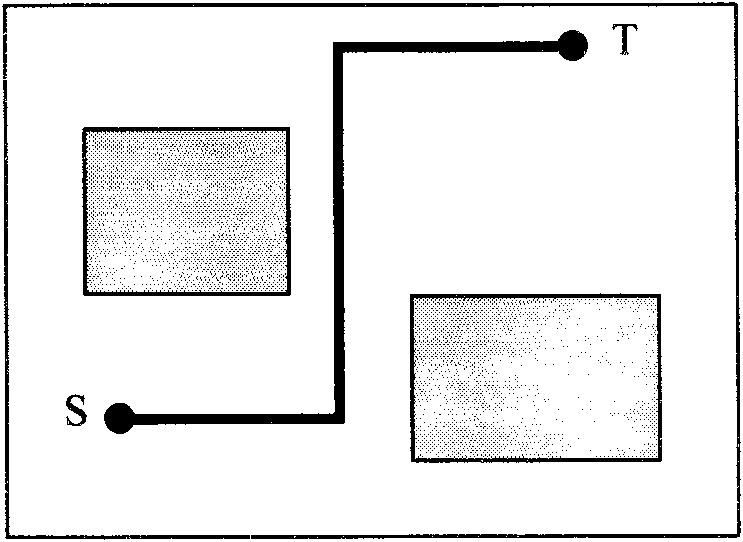

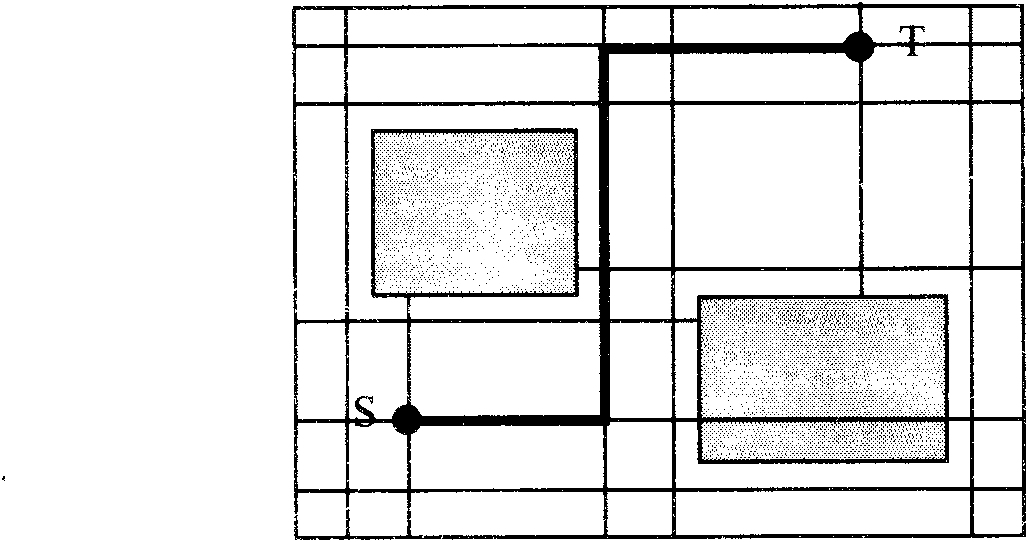

Grid-free model based wiring method of integrated circuit from module to module

InactiveCN101916317AFlexible handlingReduce the numberSpecial data processing applicationsFree modelPoint set

The invention discloses a grid-free model based module-to-module wiring method of an integrated circuit from a, aiming at finding a shortest wiring path of the integrated circuit and enhancing wiring efficiency. The wiring method comprises the following steps of: establishing an obstacle list according to read obstacle information, transforming each polygonal obstacle of the obstacle list into a rectangular obstacle, and also extending the boundaries of the rectangular obstacles to form a two-dimensional nonuniform grid array; then respectively transforming a starting module and a finishing module into a starting point set and a finishing point set; carrying out path searching by adopting an A* algorithm; and finally outputting a searching result. The invention can find the shortest wiring path of the integrated circuit and has high wiring efficiency.

Owner:TSINGHUA UNIV

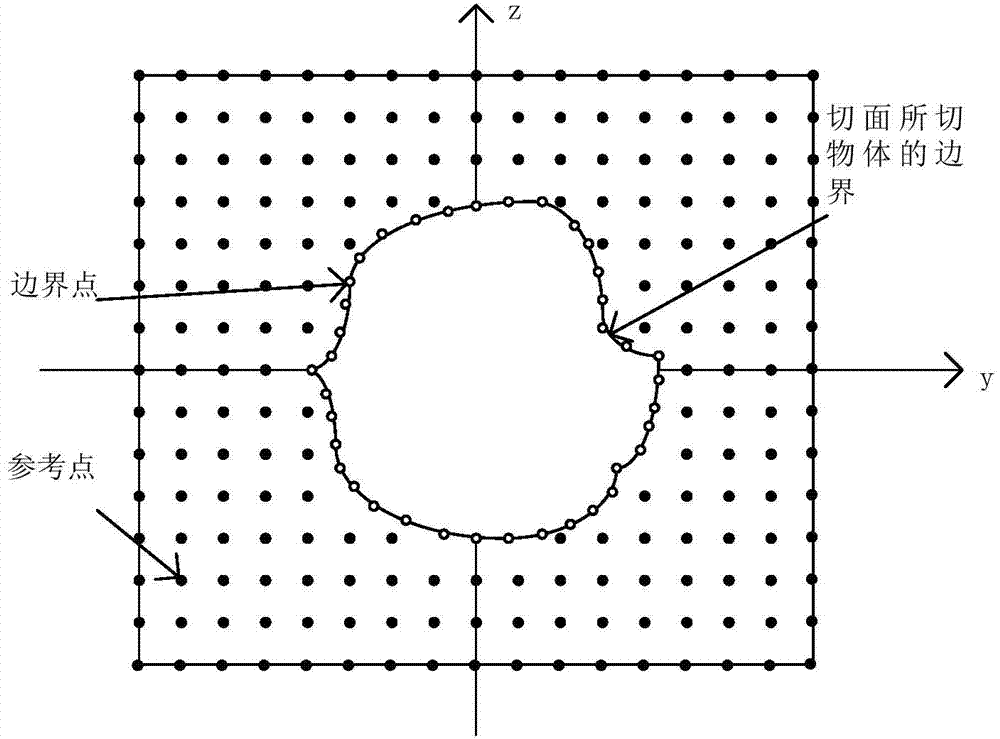

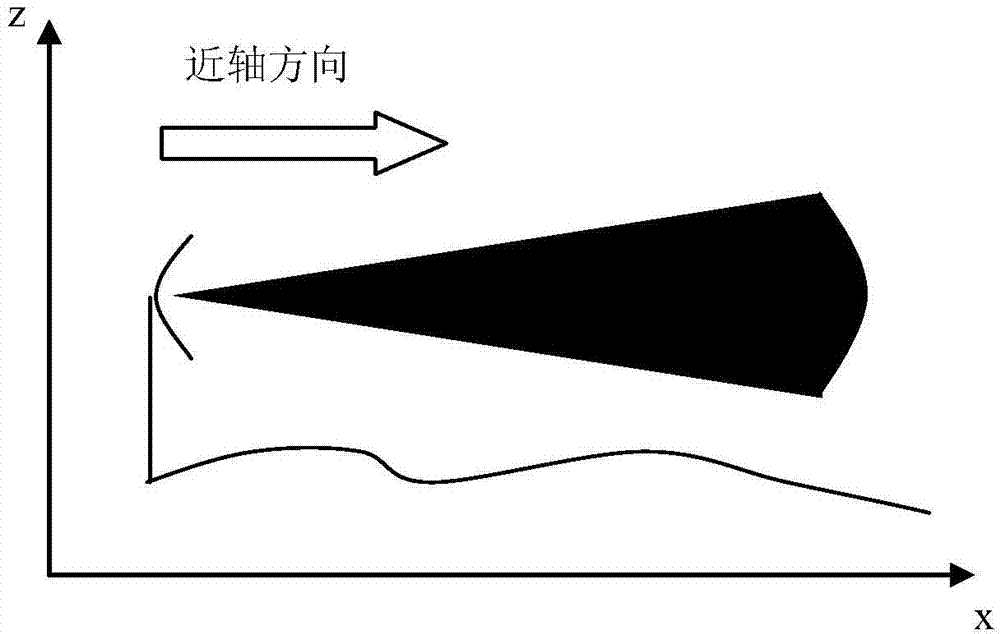

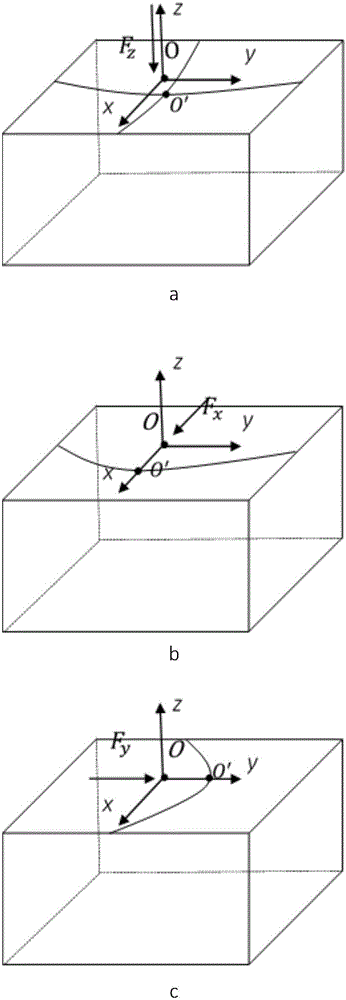

Electromagnetic scattering analysis method of target with cavity on the basis of moment method and parabolic equation

ActiveCN104778151AWell formedQuick and easy to formComplex mathematical operationsAnalysis methodRadar cross-section

The invention discloses an electromagnetic scattering analysis method of a target with a cavity on the basis of a moment method and a parabolic equation. The method comprises the following steps: firstly, filling the cavity body of the target with the cavity with solid metal, establishing a discrete model, determining the axial direction of a parabola as an x axis, and dispersing a target along the axial direction of the parabola by a mesh; in an x-axis direction, utilizing a CN (Crank-Nicolson) difference scheme to obtain a relationship between two adjacent tangent planes; in y-axis and z-axis directions, independently adopting an RPIM (Radial Point Interpolation Method) constructing fractal function and a spatial derivative to construct a matrix equation; successively carrying out recursive solving on a node electric field value on each tangent plane; carrying out solving on a cavity body part in the target separately by a fast multipole algorithm, applying an electric field integral equation to obtain current on the surface of the cavity body, and obtaining the electric field value of each discrete point required by the parabolic equation on an opening surface of the cavity body; and finally, carrying out postprocessing on the electric field on a last tangent plane to obtain a radar scattering sectional area. A meshless parabola and a fast multipole acceleration moment method are combined, and the electromagnetic scattering analysis method has the advantages of being efficient and reliable.

Owner:NANJING UNIV OF SCI & TECH

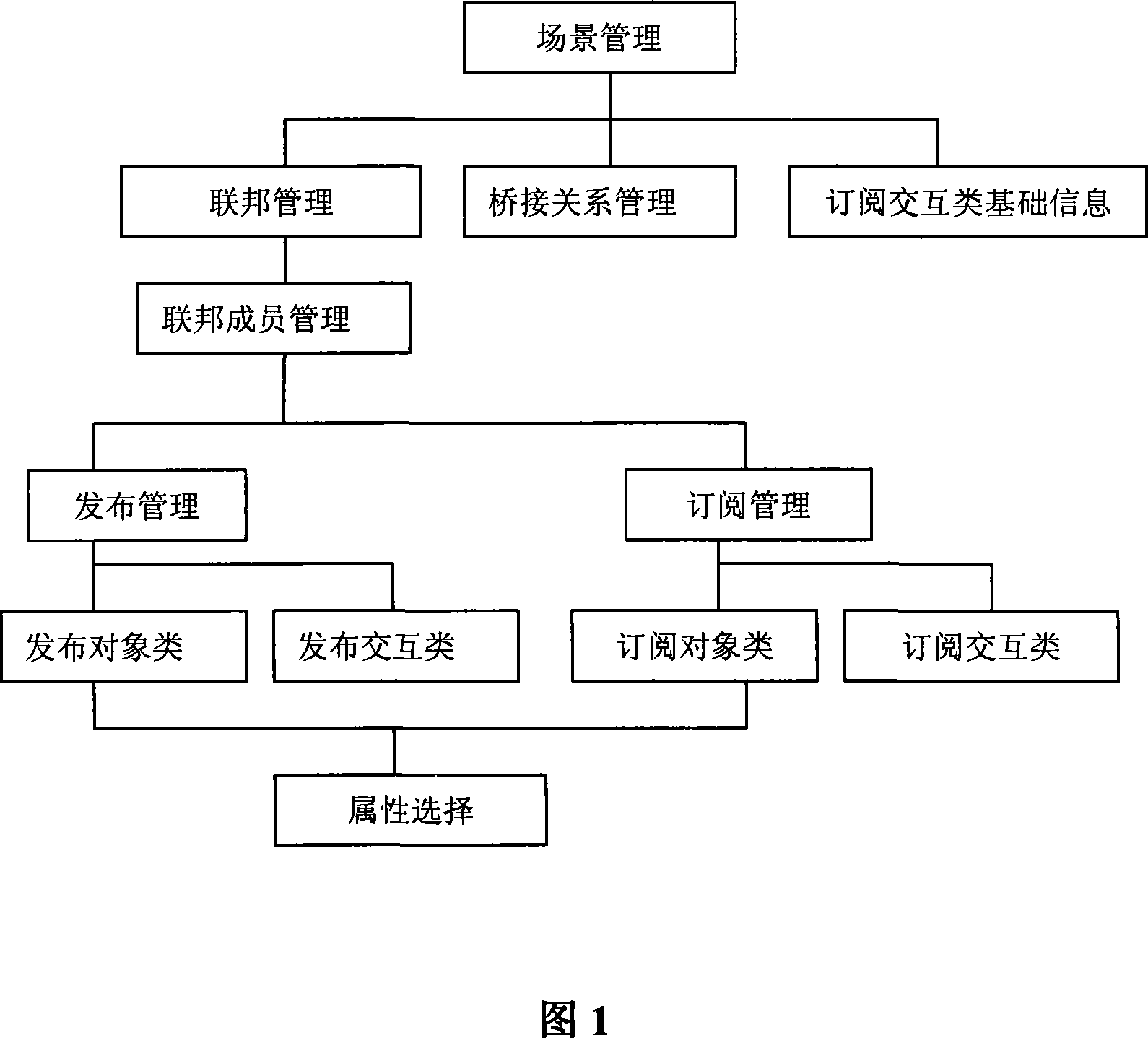

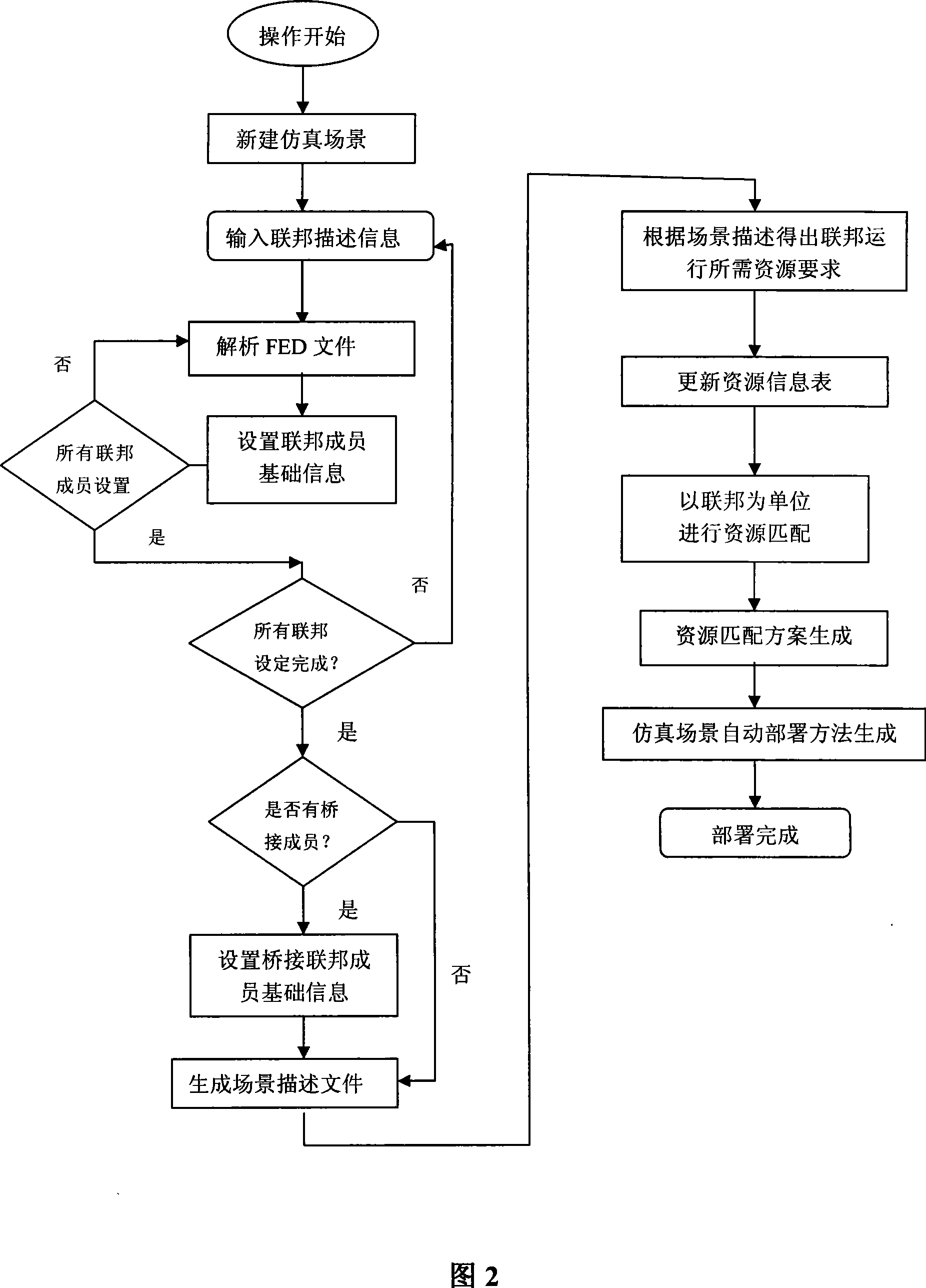

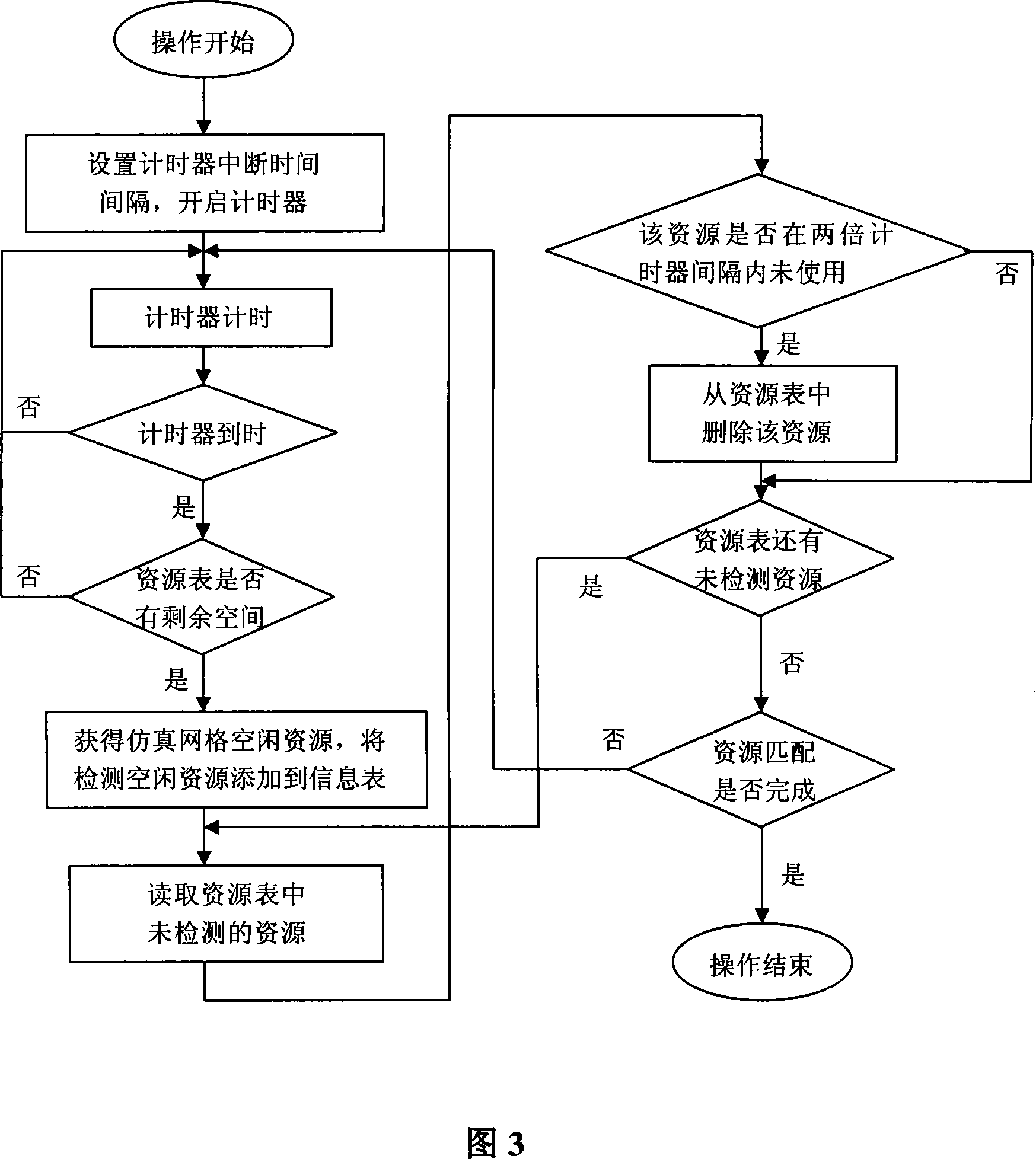

Method for automatically disposing simulation scene based on simulation gridding

InactiveCN101226484AImplement automatic deploymentAvoid Overload SituationsResource allocationSoftware simulation/interpretation/emulationDeployment timeResource utilization

The invention discloses a simulation scene automatic deploy method based on simulation mesh, which comprises (1), describing scene, inputting federation and federation member information, generating a scene description document, (2), using a simulation mesh resource collecting tool to obtain the simulation mesh free resource, adding the checked free resource into an information list, timely refreshing the resource information list, (3), adding the resource match requests into request queue, calling out the requests from queue start and using federation as unit resource to be matched with the resource in the resource information list to generate deploy plan, (4), according to the deploy plan, processing scene automatic deploy. The inventive method can describe the details of simulation scene and support the federation simulation scene constructed by bridging federation members. The inventive method can select suitable simulation resource to simulate the application at macroscopic pint, reduce simulation scene deploy time, improve simulation resource utilization and improve simulation efficiency.

Owner:HUAZHONG UNIV OF SCI & TECH

Method and system for mesh-free analysis of general three-dimensional shell structures

ActiveUS7499050B2Computation using non-denominational number representationDesign optimisation/simulationThree-dimensional spaceComputer science

A method, system and computer program product pertained to engineering analysis of a general three-dimensional (3-D) shell structure using the mesh-free technique is disclosed. The structural responses are solved with mesh-free technique after the 3-D shell structure is mapped to a two-dimensional plane. According to one aspect, the present invention is a method for mesh-free analysis of a general three-dimensional shell structure, the method comprises: defining the general shell structure as a physical domain represented by a plurality of nodes in a three-dimensional space, creating a plurality of projected nodes by mapping the plurality of nodes in the three-dimensional space onto a two-dimensional plane, assigning a plurality of domain of influences, one for each of the plurality of projected nodes, and calculating a solution of the physical domain using a set of mathematical approximations pertaining to each of the plurality of projected nodes.

Owner:ANSYS INC

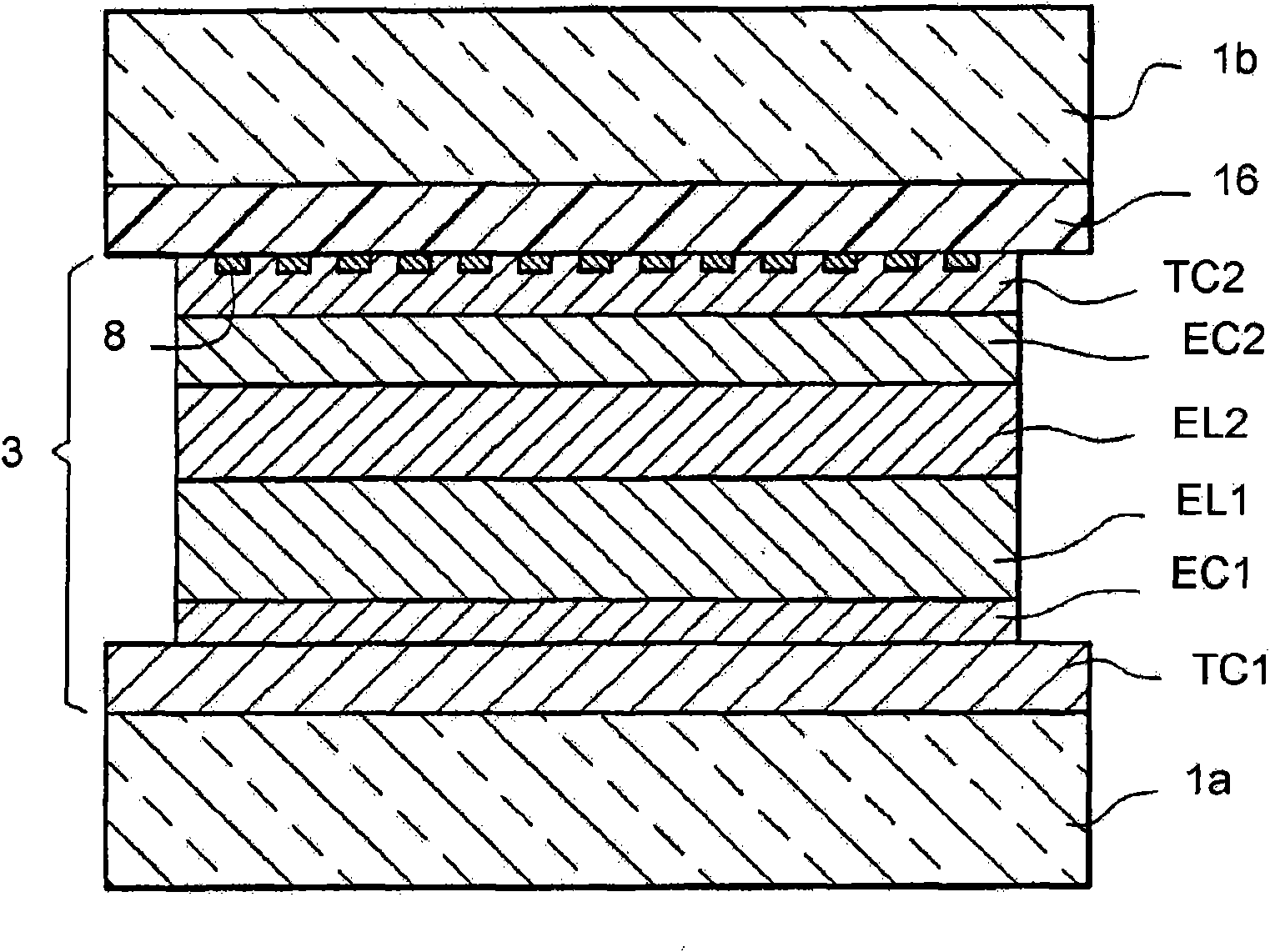

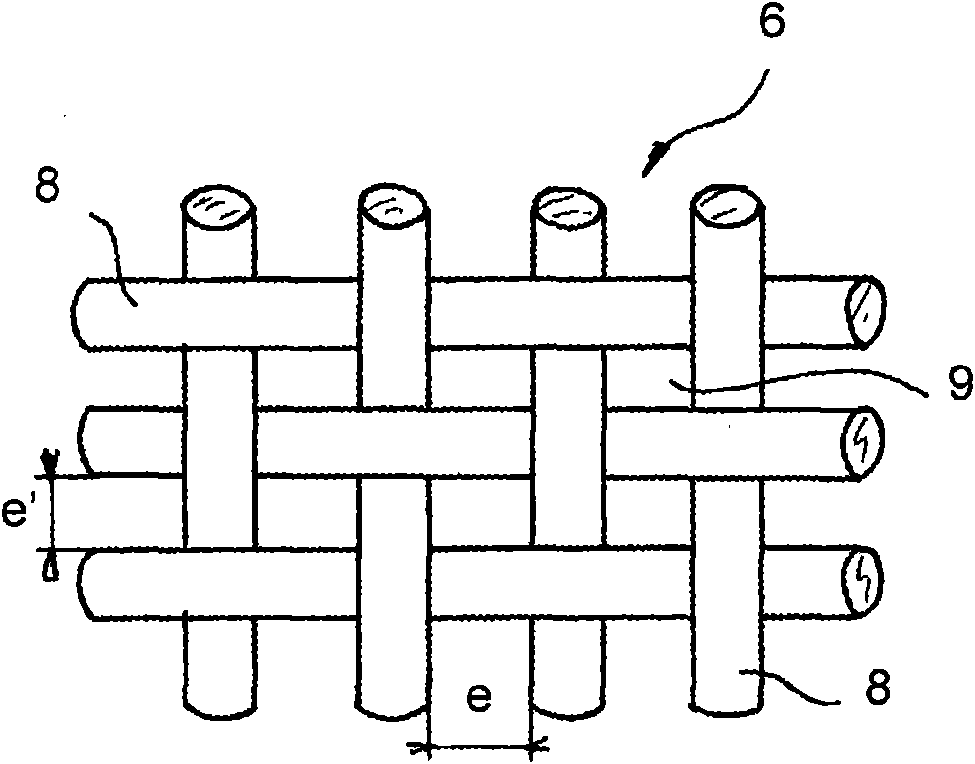

Electrochromic device including a meshing

InactiveCN101981498AFree from scratchesFree from perforationGlass/slag layered productsCoatingsEngineeringMesh free

The invention relates to an electrochromic device with controlled transparency, in particular of the electrically controlled type, that comprises a transparent bearing substrate (1a) and a counter-substrate (1b), at least one stack (3, 3') of functional layers in which the end layers (TC1, TC2; TC1', TC1') include electrically conducting layers, the conductivity of at least one electrically conducting layer (TC2,TC2') not in contact with the bearing substrate (1a) being reinforced by an array of conducting members (8) in contact therewith, characterised in that the array includes a meshing (6, 6') in which the surface area of the inter-mesh free space (9) substantially ranges from 0.04 mm2 to 0.16 mm2 and is preferably about 0.09 mm2.

Owner:SAINT-GOBAIN GLASS FRANCE

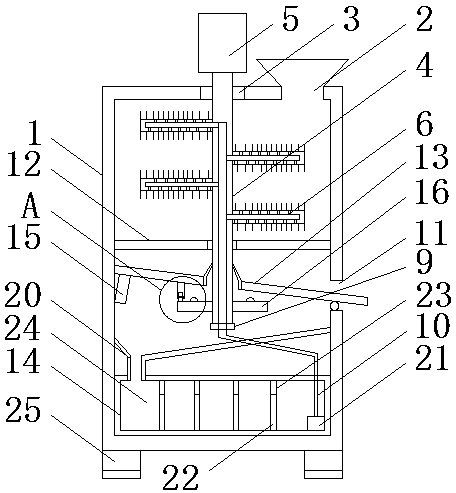

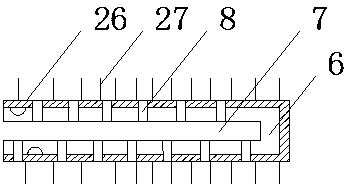

Drum screening machine and application thereof in oil sludge treatment

InactiveCN105688489AEasy to handleEasy to cleanGrain treatmentsMoving filtering element filtersStone particleEngineering

The invention provides a drum screening machine and an application method thereof in oil sludge treatment. The drum screening machine is mainly characterized by comprising a front crushing and tearing device and a rear treatment device, wherein a drum body comprises a screen-mesh-containing drum body and a screen-mesh-free drum body which are connected through subsection welding or through a connecting part, a water spraying device penetrating through the drum body or arranged in a subsection manner is arranged in the drum body, a feeding device is mounted at a feed port in the front end of the drum body, a receiving hopper capable of separating light and heavy impurities is mounted at an impurity discharge port in the rear end of the drum body, and a discharge hopper is mounted at a qualified material discharge port in the lower part of the screen-mesh-containing drum body. The drum screening machine has the advantages that the operation is simple, safe and reliable, oil sludge is sent to the front crushing and tearing device to tear and crush large stone particles, tiles, plastic cloth, woven bags and the like in the material, a to-be-treated material is uniformly sent into the feeding end by a feeding machine, qualified materials discharged from the qualified material discharge end are sent for follow-up treatment, and meanwhile, clean combustible materials with the recovery value are discharged in a classified manner from the impurity discharge end.

Owner:马玉刚

Flow sensor

InactiveUS7614295B2Improve accuracyReliable detectionVolume/mass flow by thermal effectsVolume flow proportion measurementEngineeringFlow diversion

The flow meter is equipped with first and second flow paths, provided in parallel and through which flows fluid having flowed through and being diverted from a main flow path, the flow diversion ratio among the first and second flow paths changing passively in accordance with the flow rate of fluid through the main flow path, and a flow rate sensor provided on at least one of the first and second flow paths. The first and second flow paths are formed, for example, as flow paths having different flow path cross-sectional areas, or alternatively are formed from mesh elements provided with mesh-free areas on a portion thereof. Alternatively, one of the either the first or second flow path is realized with a paddle mechanism incorporated therein.

Owner:YAMATAKE HONEYWELL CO LTD

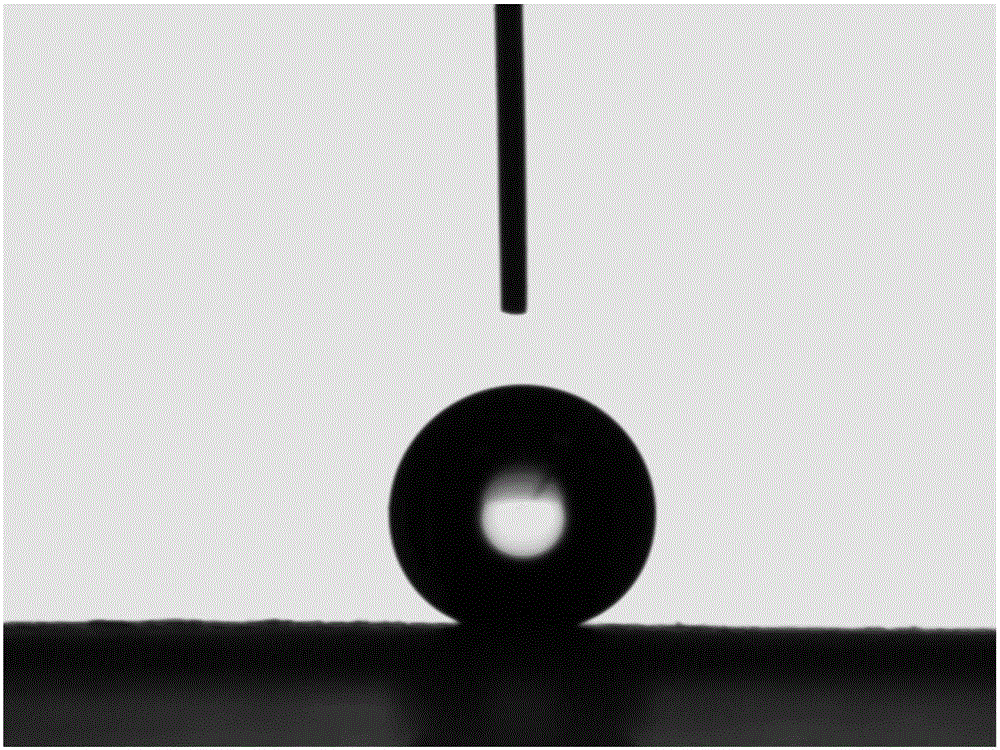

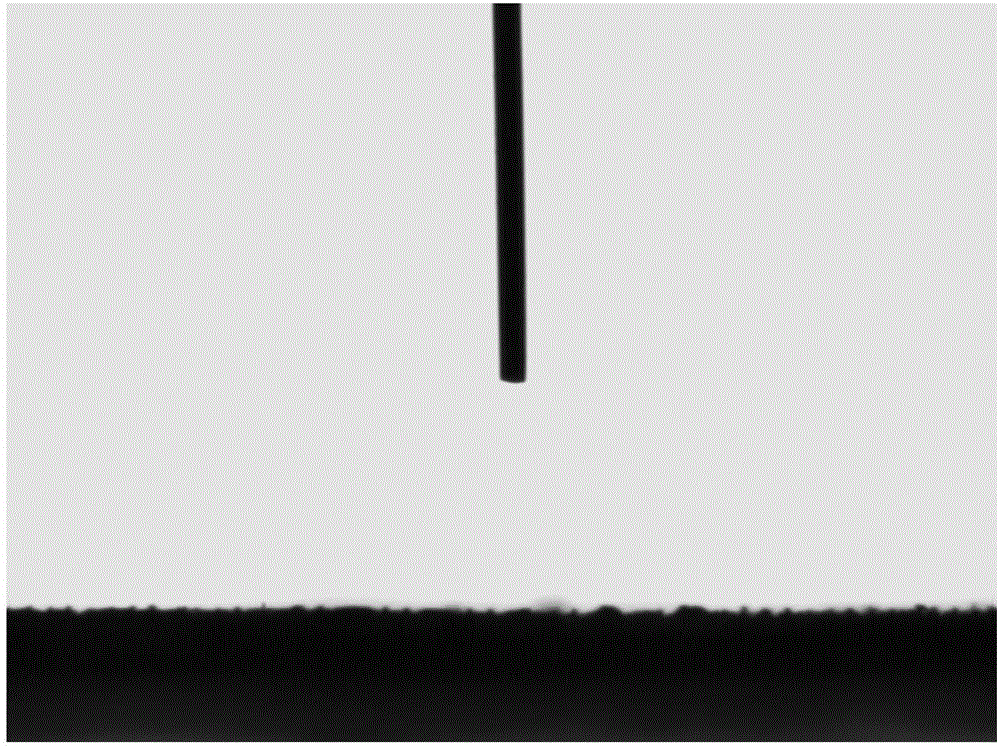

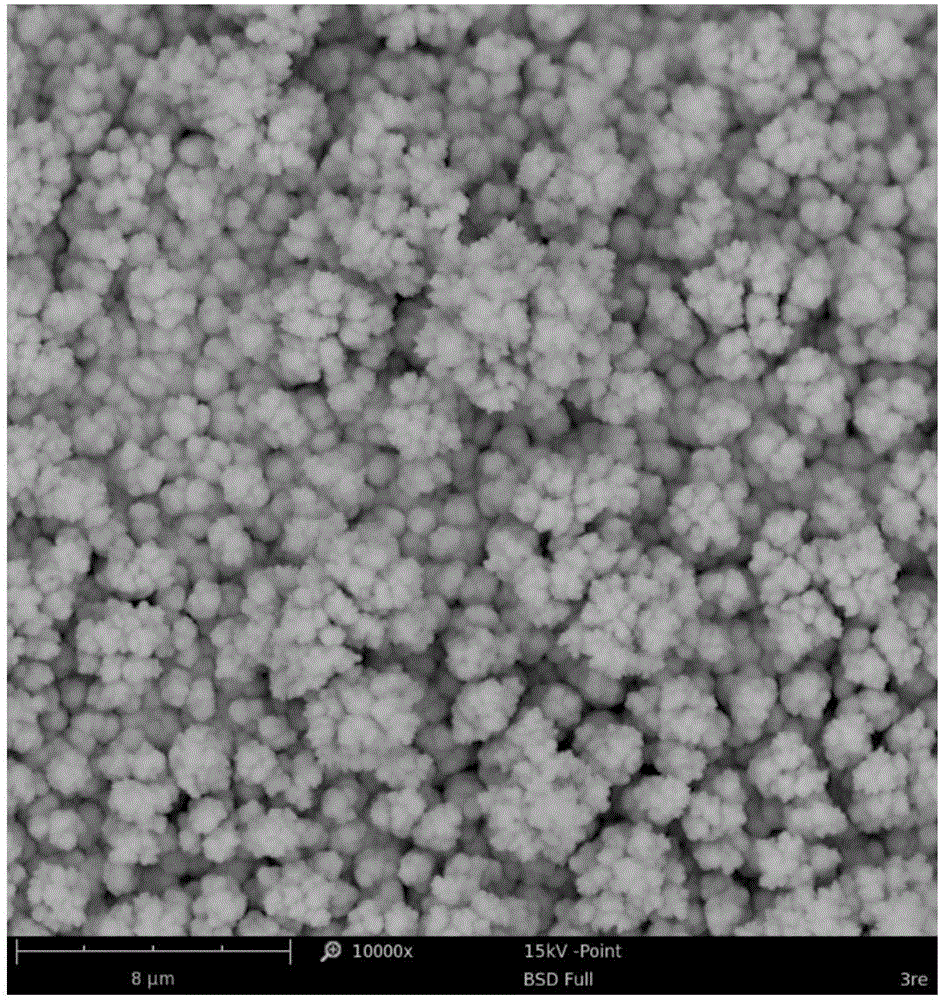

Super-hydrophobic and super-oleophilic copper wire mesh free of low surface energy material modification and preparation method thereof

ActiveCN106823469AFast etchThe process is easy to implementNon-miscible liquid separationCopper wireMetallic materials

The invention belongs to the technical field of metal material surface treatment and discloses a super-hydrophobic and super-oleophilic copper wire mesh free of low surface energy material modification and a preparation method thereof. The preparation method comprises the steps of cleaning and drying the copper wire meshes, and taking two pieces of copper wire meshes as two electrodes of AC separately; carrying out electrodeposition in a deionized water electroplate liquid containing thioacetamide, ethylenediamine tetraacetic acid disodium and copper sulfate pentahydrate; and cleaning the copper meshes subjected to electrodeposition and then carrying out high-temperature drying at 80-200 DEG C to obtain the super-hydrophobic and super-oleophilic copper wire mesh. The two electrodes of the AC can be quickly etched at the same time, and the super-hydrophobic and super-oleophilic copper wire mesh is suitable for large-area production, special equipment does not need to be used, and the treatment process is easy to implement; and the related solution formula does not contain a toxic fluorine-containing or carbon-containing low surface energy material, is free of harm to the environment and a human body, and has good economical and environmental benefits.

Owner:SOUTH CHINA UNIV OF TECH

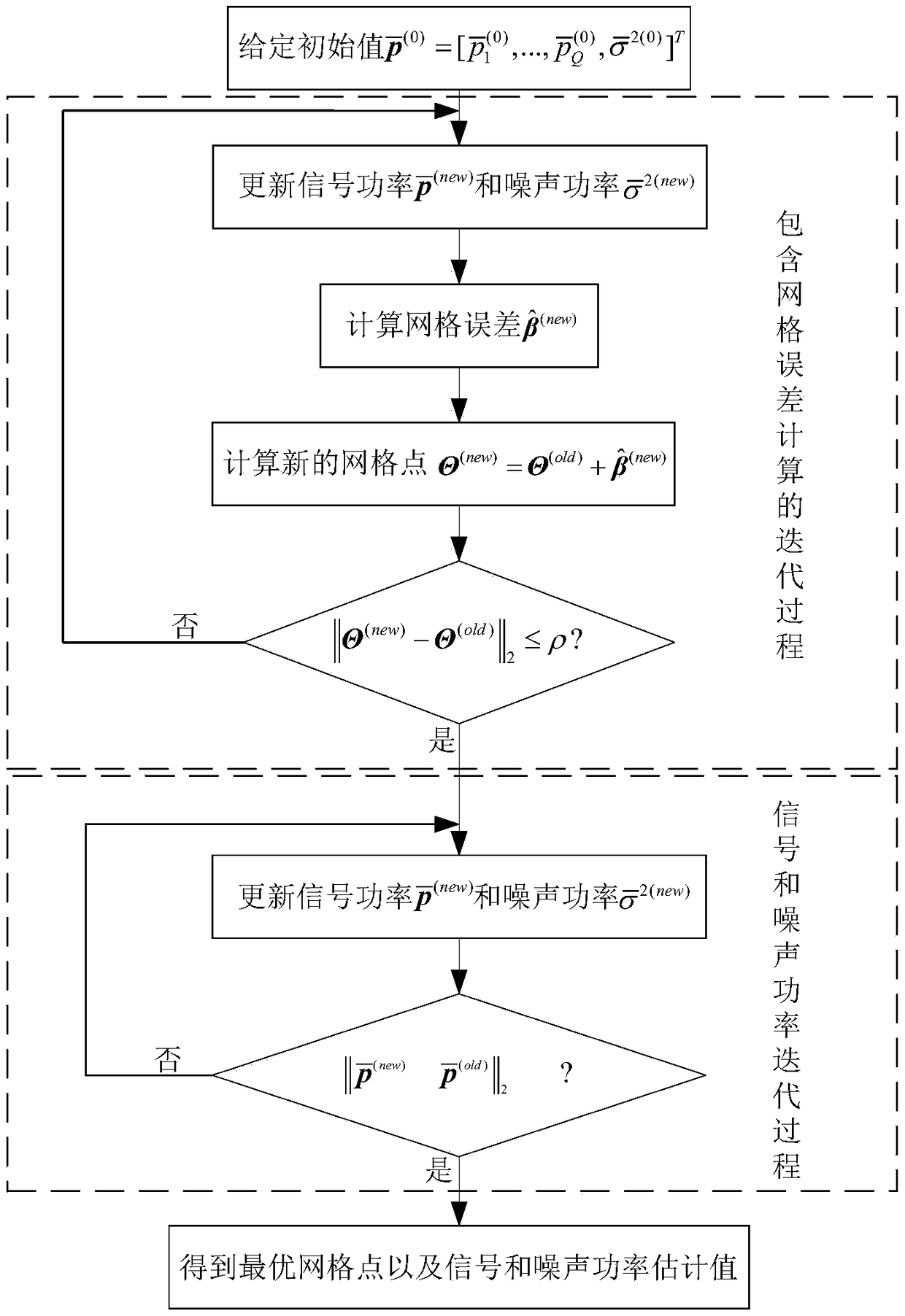

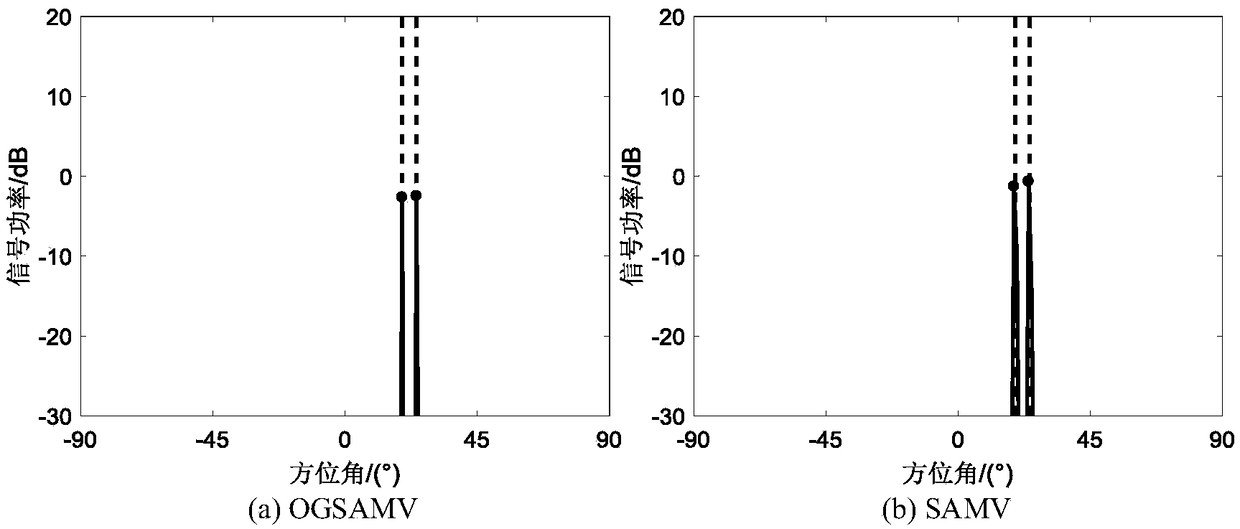

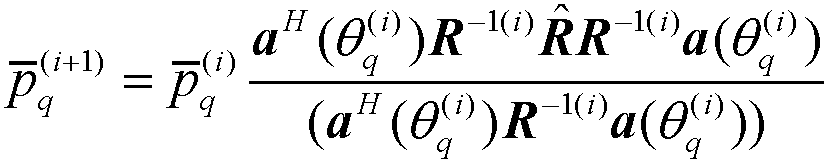

Lattice error model-based mesh-free sparse approximate minimum variance direction of arrival (DOA) estimation method

ActiveCN109307855AHigh positioning accuracyHigh precisionRadio wave direction/deviation determination systemsDirection/deviation determining electromagnetic systemsEstimation methodsTarget signal

The invention relates to a lattice error model-based mesh-free sparse approximate minimum variance direction of arrival (DOA) estimation method. A lattice error model-based array receiving signal model is built, a signal, a noise power and a lattice error are sequentially and iteratively solved according to the model, so that the positioning accuracy of the sparse approximate minimum variance DOAestimation method is free from the limitation of space lattice division accuracy, and relatively high DOA estimation accuracy still can be achieved when DOA of a target signal is not matched with a lattice point.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Plastic product sand removal device and method

InactiveCN108437280ASimple structureEasy to usePlastic recyclingCleaning using liquidsBristleShake up

The invention discloses a plastic product sand removal device and method in the technical field of plastic product sand removal. The device comprises a box body, a rotating rod is inserted in an innercavity of a bearing, cleaning rods are evenly arranged on the left side and the right side of the rotating rod, a first filter net, a second filter net, a hopper and a water box are sequentially arranged in an inner cavity of the box body from top to bottom, cleaning liquid is sprayed out through a water outlet hole through a water pump, plastic product surfaces are washed, the cleaning rods rotate to drive bristles to brush the plastic product, the first filter net separates the cleaning liquid mixed up with gravel and the plastic product, the second filter net separates the cleaning liquidand the gravel, the second filter net shakes up and down, filtering and cleaning of the gravel are facilitated, the cleaning liquid mixed up with fine gravel and dust is precipitated in a precipitation chamber, a mesh-free filter layer filters fine gravel and dust mixed up in the cleaning liquid, through layer-by-layer filtering of the cleaning liquid, circular utilization of the cleaning liquid is achieved, and resource waste is reduced.

Owner:CHENGDU PUJIANG KEXIAN TECH

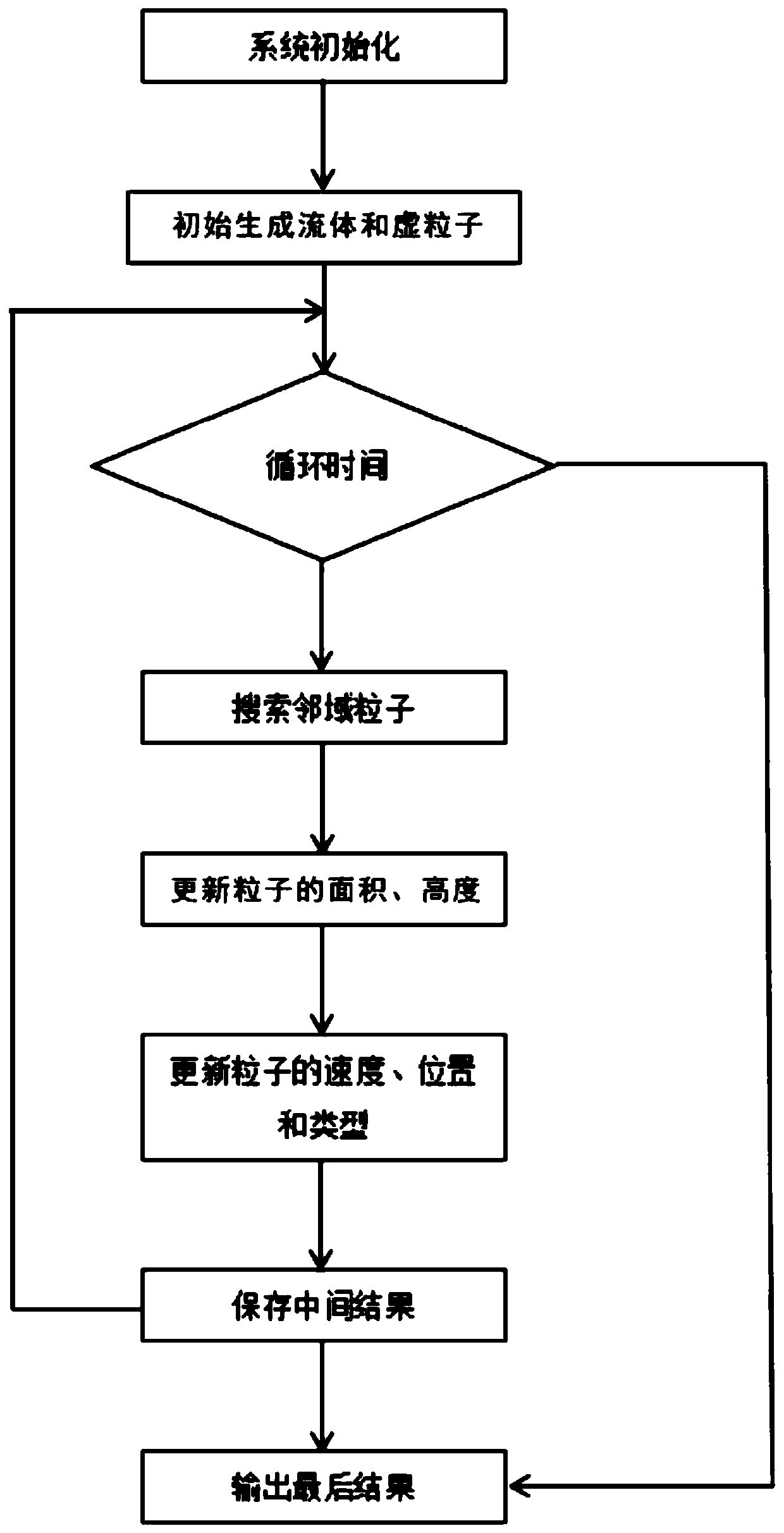

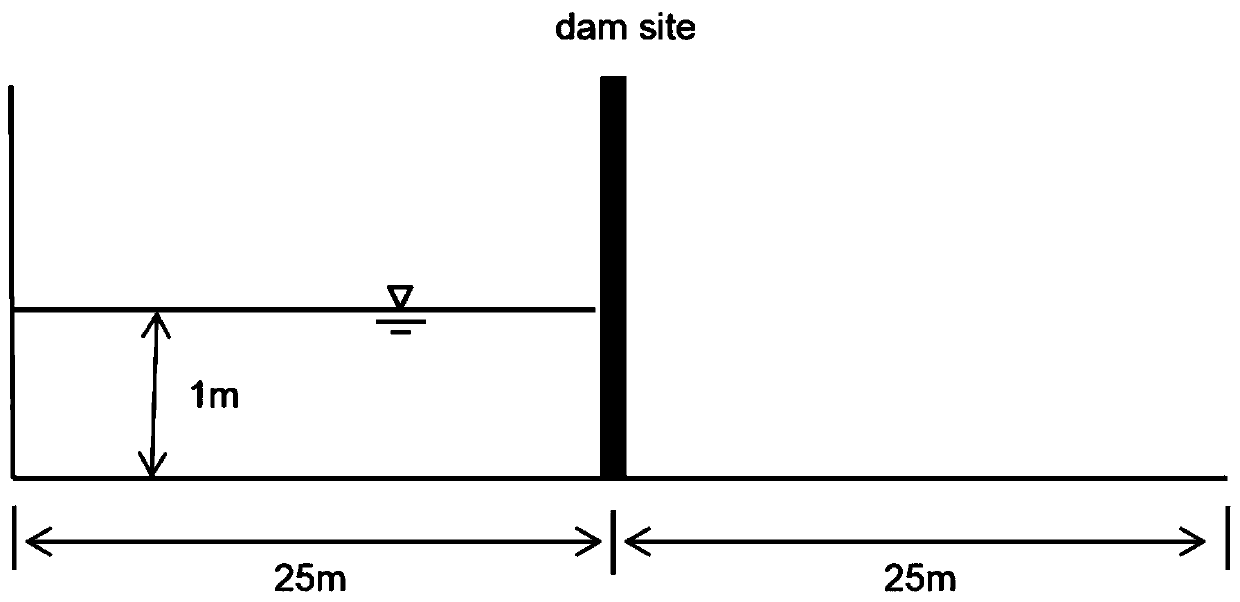

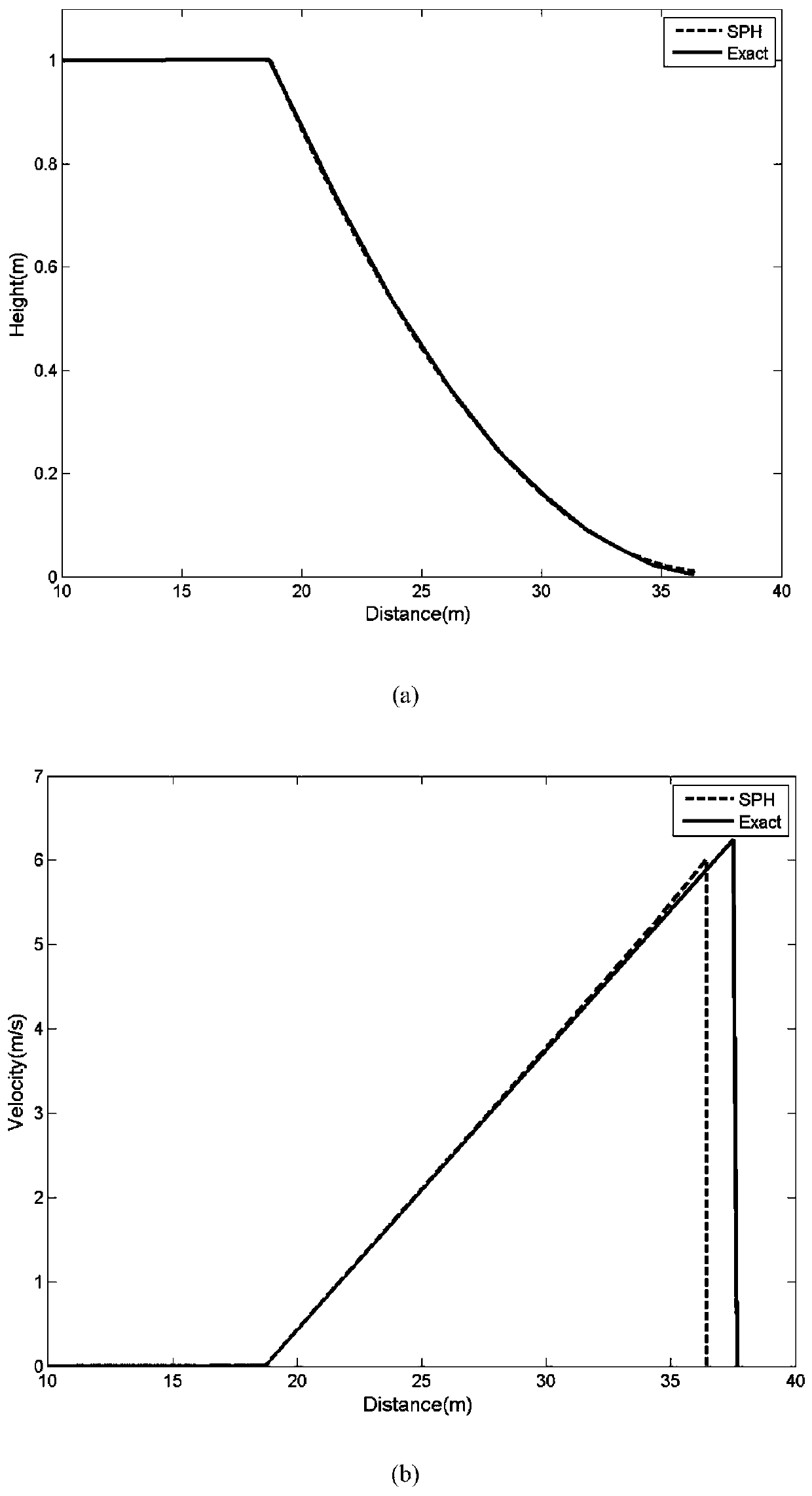

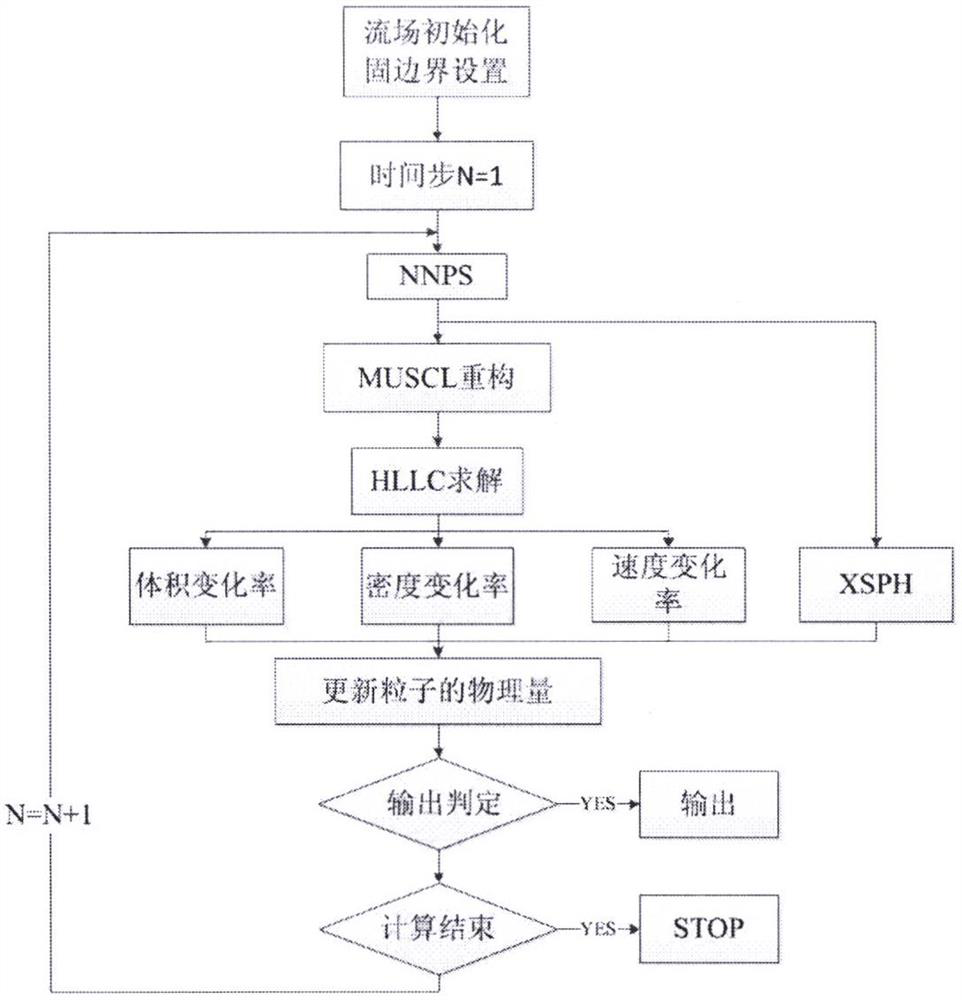

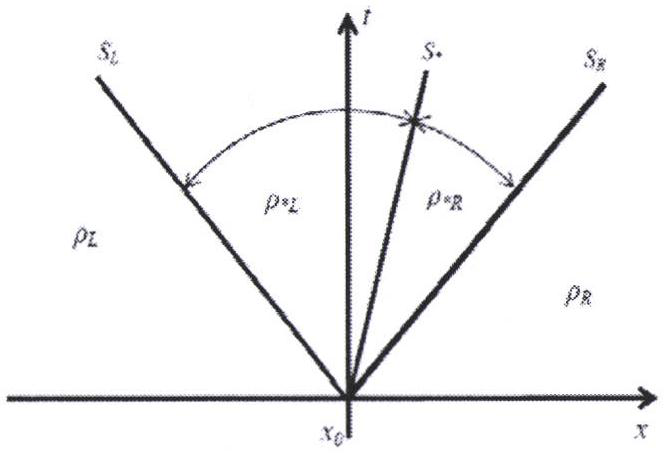

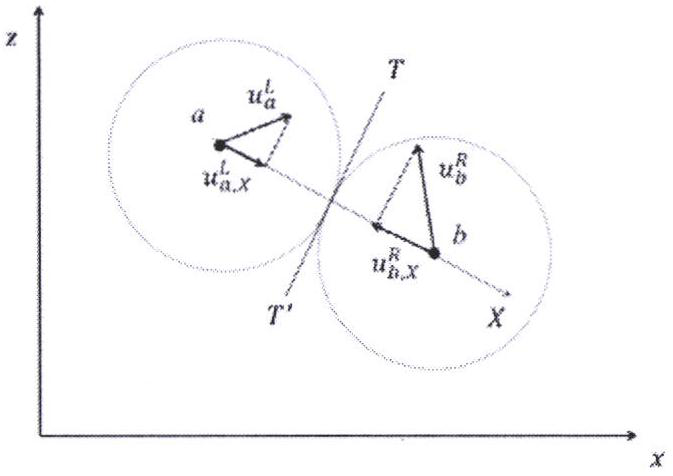

An open channel non-constant flow grid-free particle simulation method containing section change

PendingCN109948109AOvercoming numerical problemsEasy to calculateComplex mathematical operations3D modellingSimulationWater flow

The invention relates to the technical field of fluid mechanics, and provides an open channel non-constant flow mesh-free particle simulation method containing cross section changes to simulate the open channel non-constant flow problem containing the cross section changes. Therefore, the technical scheme adopted by the invention is as follows: the open channel non-constant flow mesh-free particlesimulation method containing the section change comprises the following steps: step 1, initializing related variables and operating parameters of a system; Step 2, generating particle information; Step 3, listing a solving equation and performing iterative calculation; step 4, outputting a result: updating the result every time calculation of one time step is completed, namely simulating the water depth, the cross sectional area and the flow velocity of the open channel water flow at each moment; And completing the circulation of the time step and outputting a final result. The method is mainly applied to an open channel non-constant flow gridless particle simulation occasion.

Owner:TIANJIN UNIV

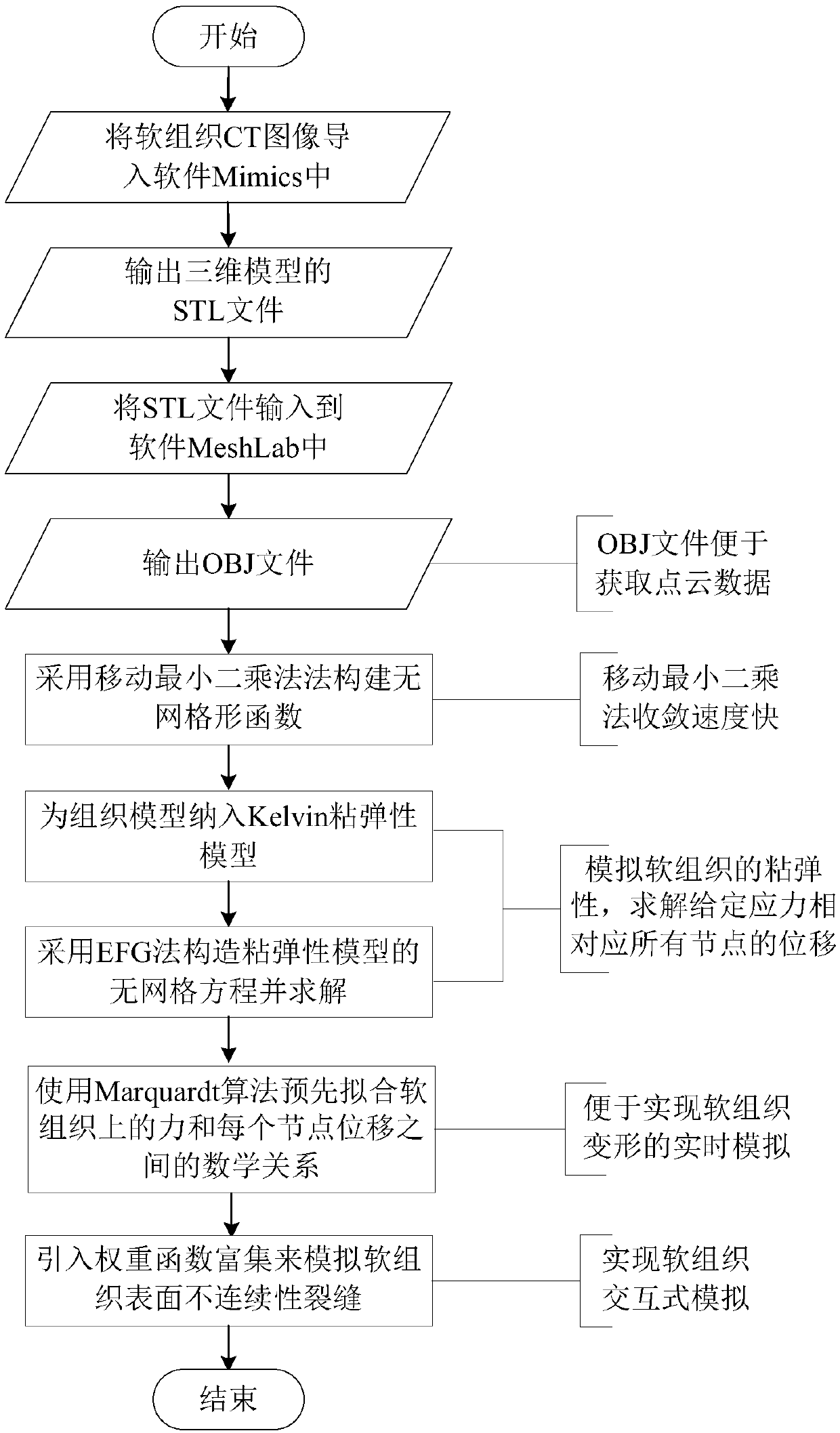

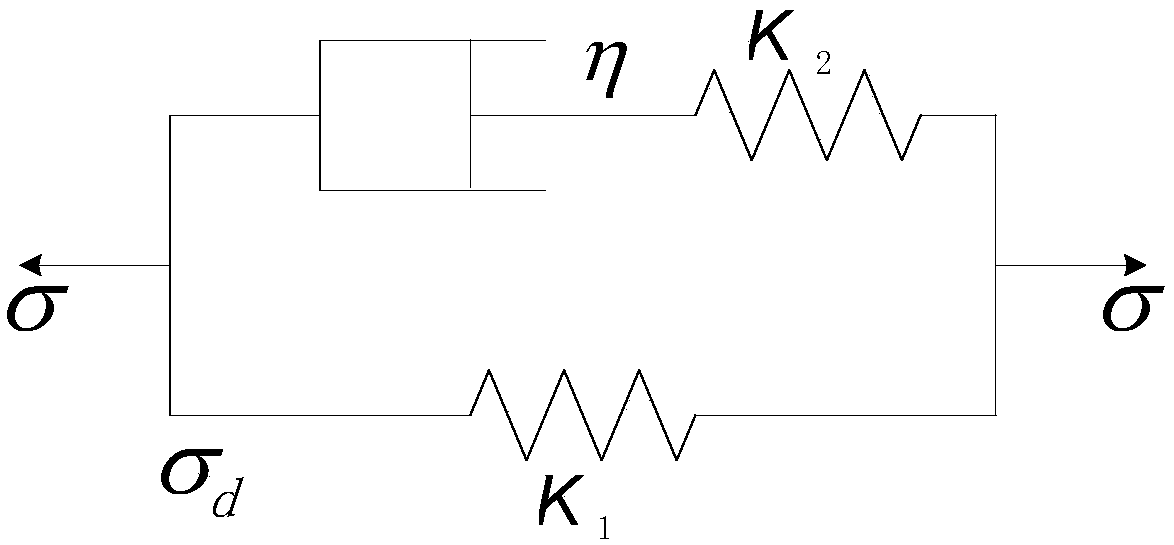

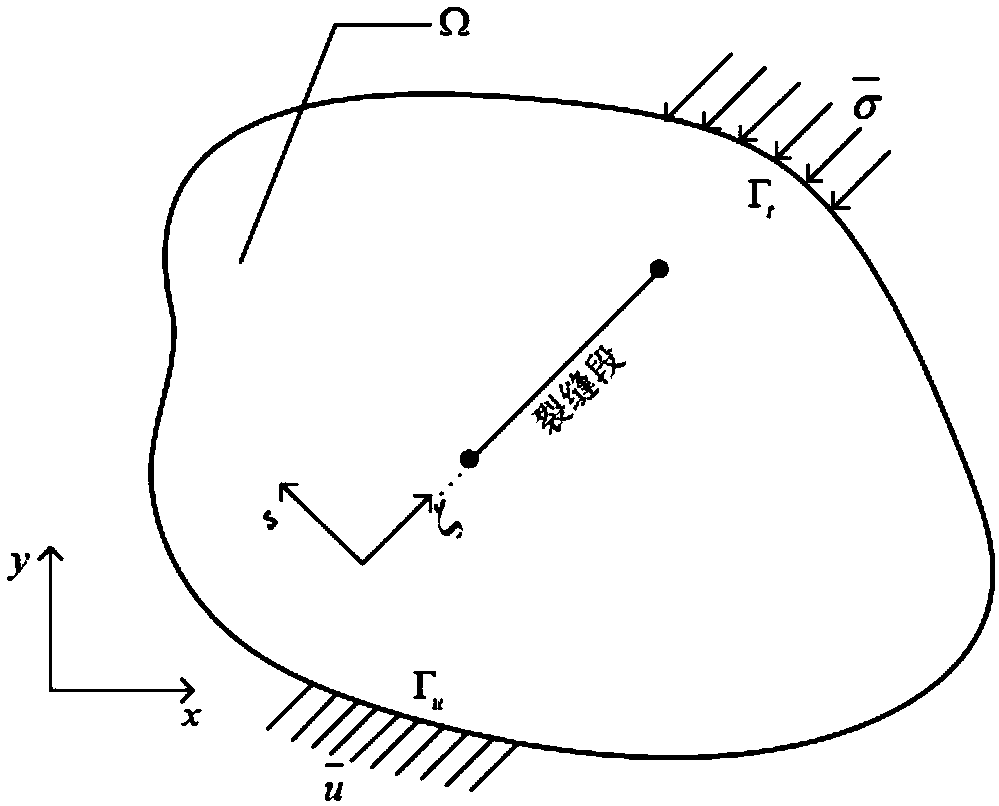

Real-time interaction mesh-free soft tissue deformation simulation method

InactiveCN108710735AViscoelastic performanceImprove real-time performanceDesign optimisation/simulationSpecial data processing applicationsHuman bodySoft tissue deformation

The invention discloses a real-time interaction mesh-free soft tissue deformation simulation method, which comprises the following steps that: (1) transforming the CT (Computed Tomography) image of asoft tissue into an OBJ file to conveniently obtain vertex information; (2) using MLS (Moving Least Squares) to construct a mesh-free function; (3) bringing Kelvin viscoelasticity into a tissue model;(4) according to the displacement of all nodes corresponding to given stress calculated in S(3), using a Marquardt algorithm to pre-fit a mathematical relationship between force on the soft tissue and the displacement of each node; and (5) importing an enrichment function to simulate tissue surface discontinuity cracks caused by operations including segmentation. By use of the method, the Kelvinviscoelasticity model is brought into the human body tissue model, the viscoelasticity of the soft tissue can be more favorably presented, simulation validity is improved, the Marquardt algorithm is used for pre-fitting the mathematical relationship between force on the soft tissue and the displacement of each node, simulation instantaneity is improved, and meanwhile, weight function enrichment isimported to realize the interactive simulation of soft tissues.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

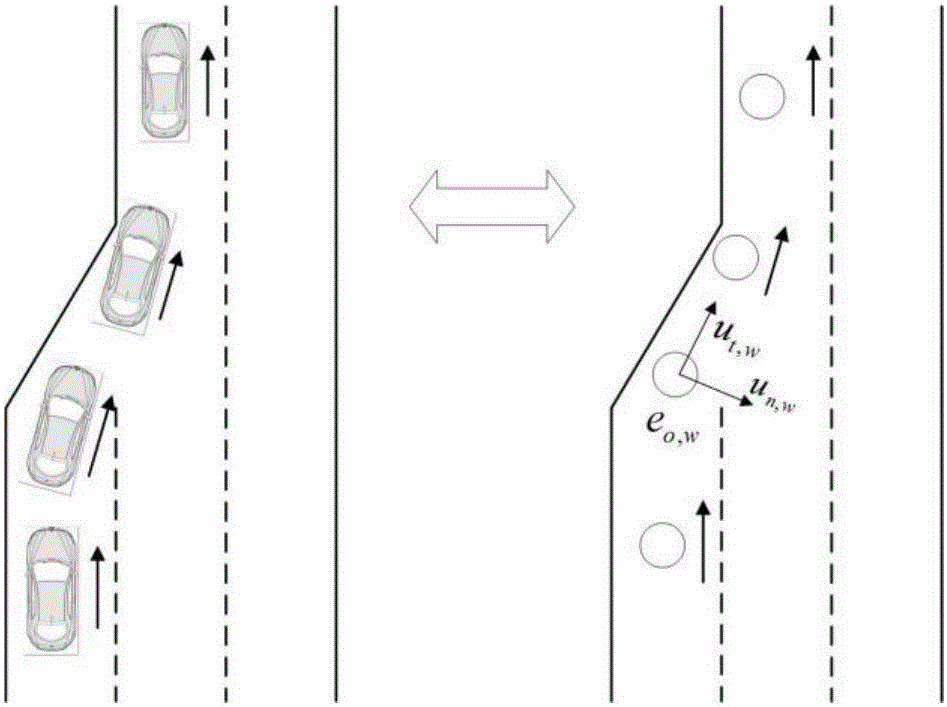

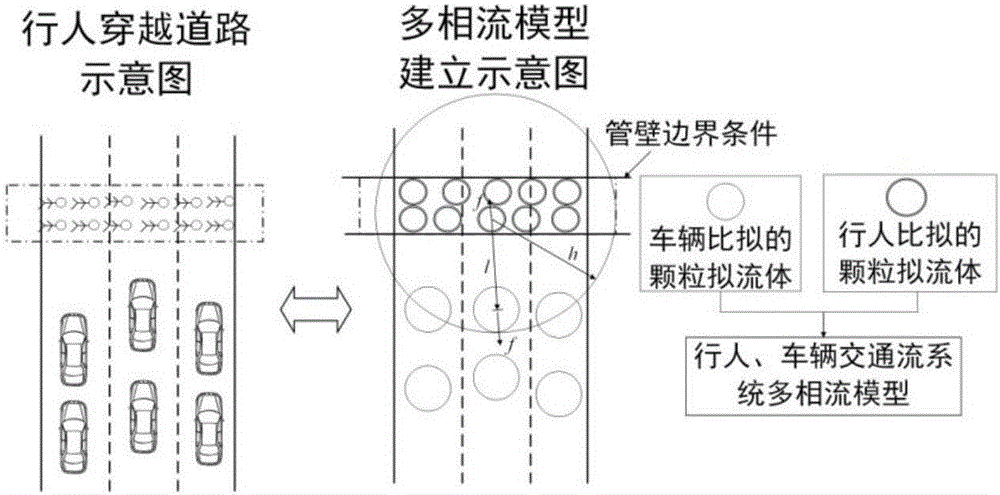

Mesh-free traffic simulation method based on novel traffic simulation model

ActiveCN107180146AActive connectionDesign optimisation/simulationSpecial data processing applicationsTraffic simulationRoad traffic

The invention discloses a mesh-free traffic simulation method based on a novel traffic simulation model. According to the method, a vehicle system simulation model, a power system model of road traffic, a boundary acting force model of a traffic system and a system model of pedestrians and other non-motor vehicles are established; a simulation model of the action of signal lamps on the traffic system and a one-to-one corresponding relation between mesh-free particles and true vehicles are established, and a control equation set used for SPH solving is obtained; and a mesh-free traffic simulation method equation set based on the novel traffic simulation model is obtained. By the adoption of the ideology of a particle fluid system, a traffic system pseudo-fluid model is established; respective advantages of traditional micro, medium and macro models in traffic problem solving can be maintained, respective defects of the models are overcome, and meanwhile the purpose of effectively connecting a micro method, a medium method and a macro method is truly achieved.

Owner:崔曼

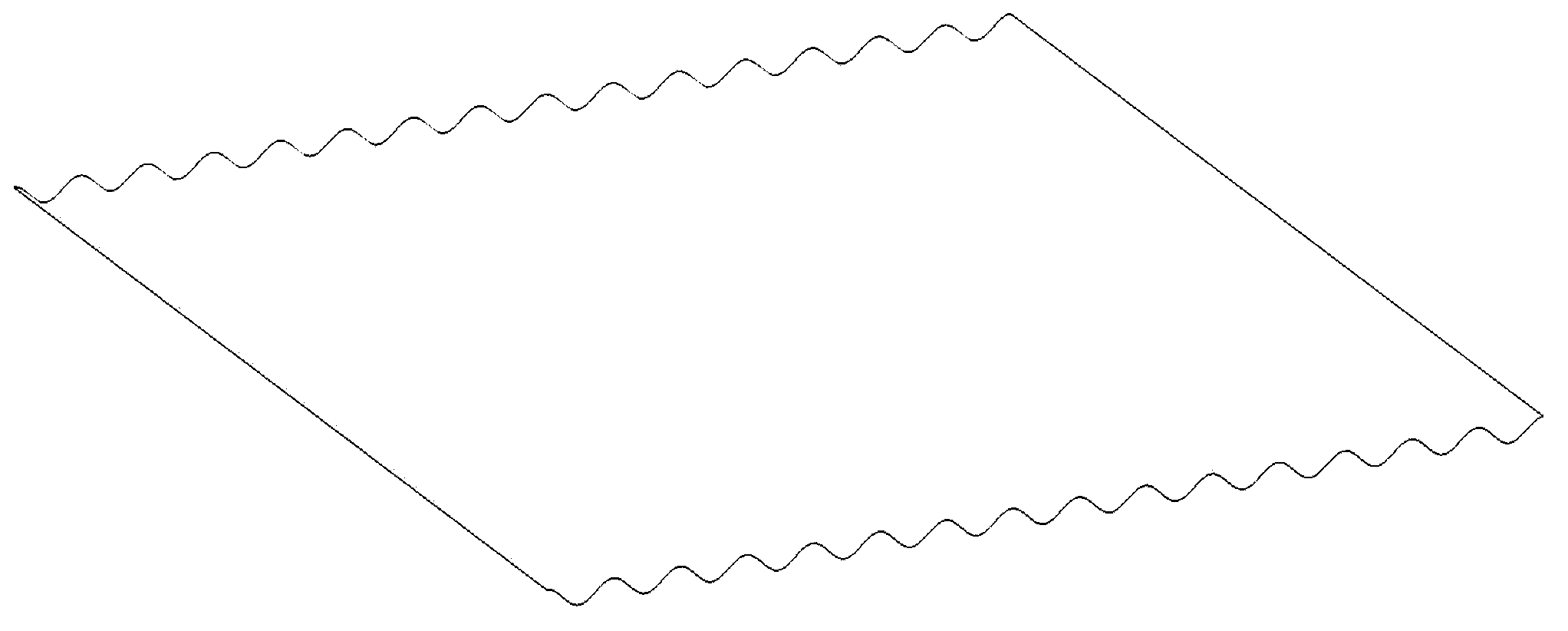

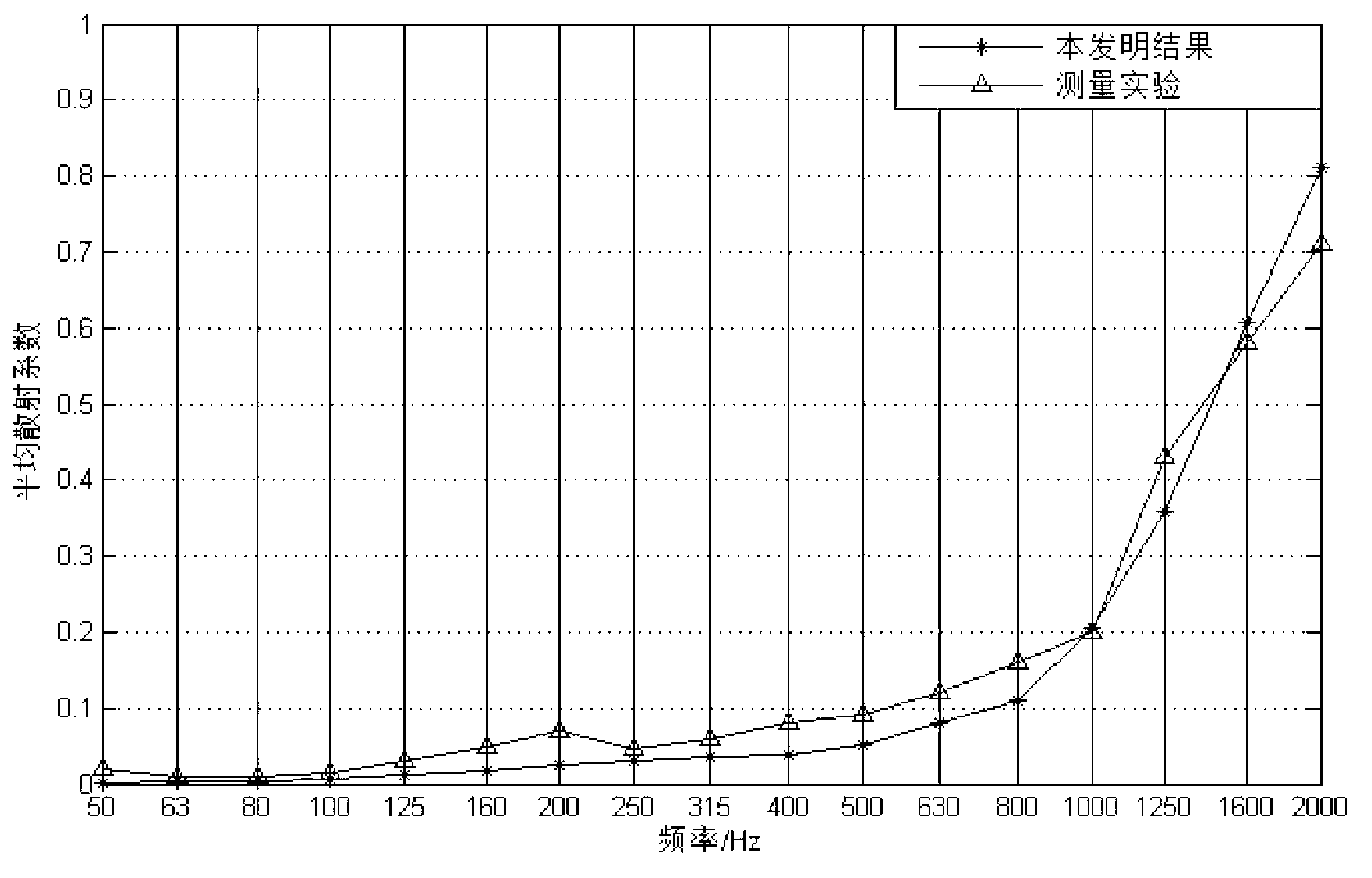

Method for calculating acoustic scattering coefficient of periodic structure plate based on mesh-free model

InactiveCN102938017AAdaptableHigh precisionSpecial data processing applicationsSound pressureComputer science

The invention discloses a method for calculating an acoustic scattering coefficient of a periodic structure plate based on a mesh-free model. The method comprises the following steps: firstly, deducing a system equation which is suitable for calculating sound pressure of nodes of a periodic structure plate; and then, modeling the periodic structure plate and a reference plate of the same dimension through the nodes, and using a moving least square method to construct a shape function; finally, combining the system equation with the shape function to acquire the sound pressure difference at the nodes, so that sound pressure of a receiving point is calculated, and a direction scattering coefficient and a mean scattering coefficient are calculated. According to the method disclosed by the invention, a mesh-free method is introduced to calculate a numerical value of the acoustic scattering coefficient of the periodic structure, so that a series of problems caused by existence of meshes in a conventional numerical method are avoided. The method has good adaptability, and can locally increase node density without re-distributing the model when frequency upper limit is needed to be calculated. Compared with measurement experiment, the method has high precision, and has an extensive application prospect in the calculation of the scattering coefficient value of the periodic structure.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

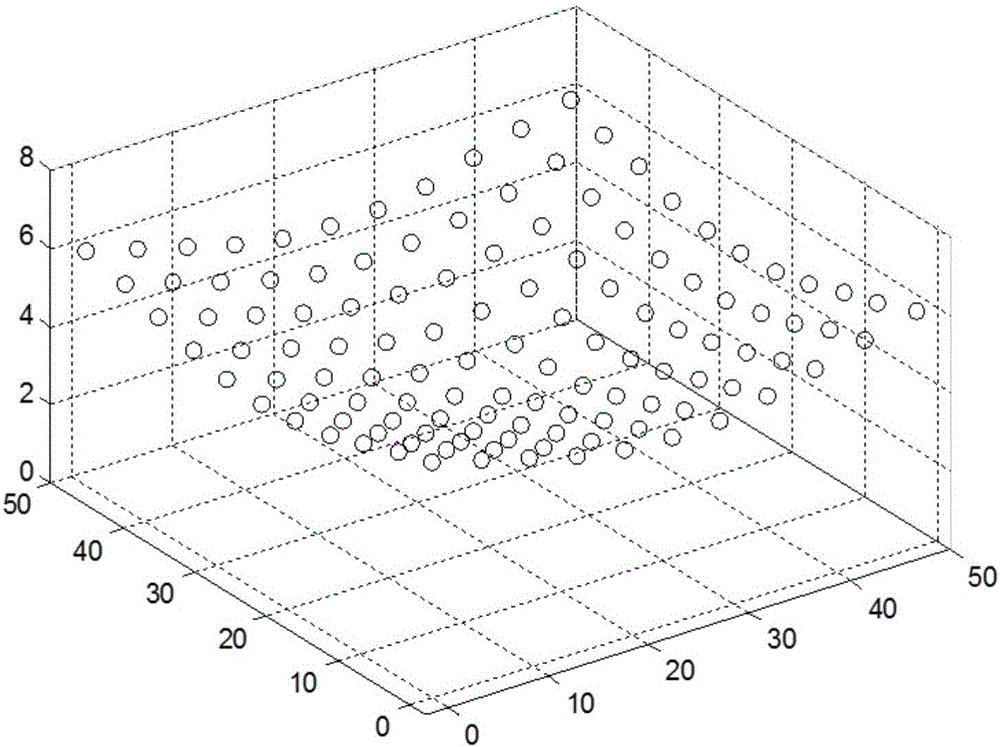

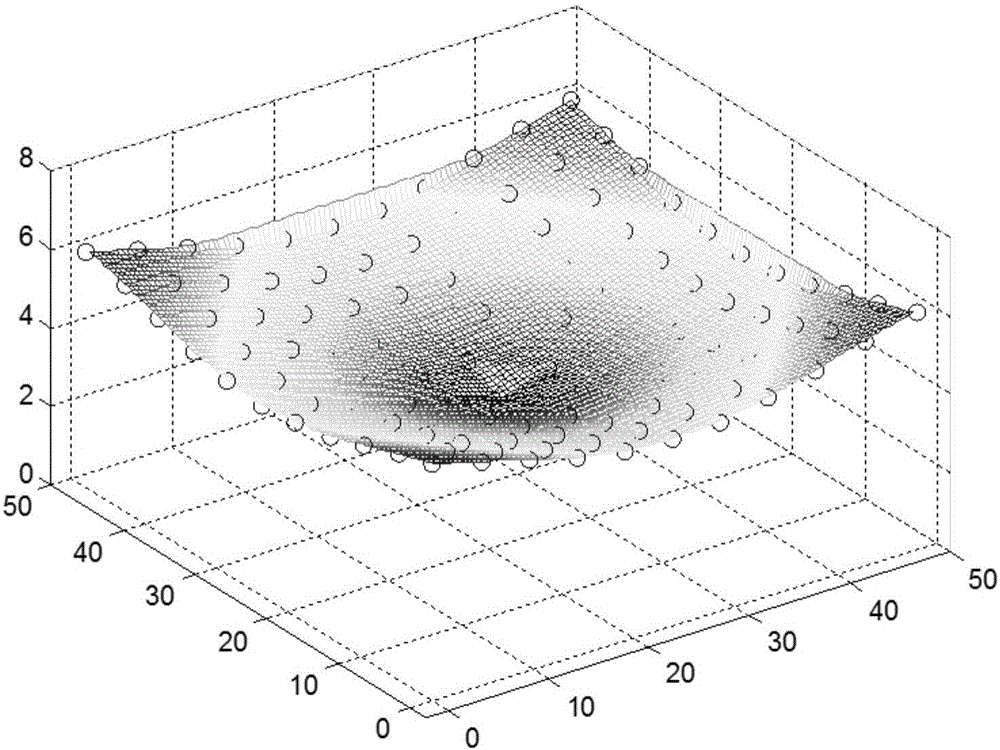

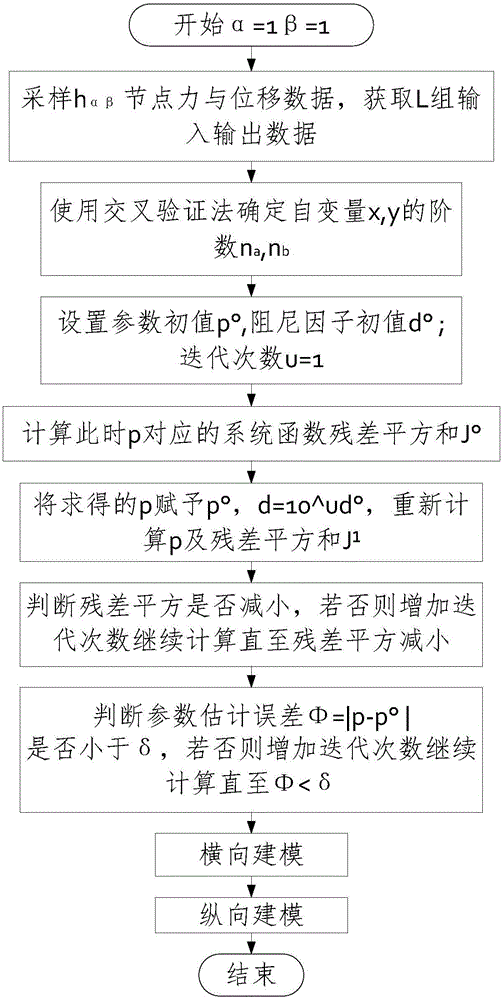

Soft tissue stress deformable model modeling method based on mesh-free radial base data fitting

ActiveCN106570341AAccurate interactionSimple structureMedical simulationSpecial data processing applicationsNODALStress point

Disclosed is a soft tissue stress deformable model modeling method based on mesh-free radial base data fitting. For overcoming the shortcomings of complex structure, poor real-time performance and the like of the existing biological soft tissue physical deformable model, a soft tissue surface nodal force-displacement hook face deformable model is established by the steps of considering isotropic characteristics of the biological soft tissues, taking force as data flow, obtaining stress displacement data through a radial basis mesh-free method in an off-line manner, wherein the stress displacement data takes soft tissue stress points as the center, and a finite number of equal-interval points are on the surface; and finally establishing the deformable model by using a Marquardt method. The model, by combination with the characteristics of a geometric deformable model and a physical deformable model, greatly simplifies a calculation process while the physical characteristic truth property of the deformable model is maintained; in addition, the high real-time property of interaction is ensured; and accurate real-time interaction between the biological soft tissue deformable model and an operator in a virtual operation is realized.

Owner:NANCHANG UNIV

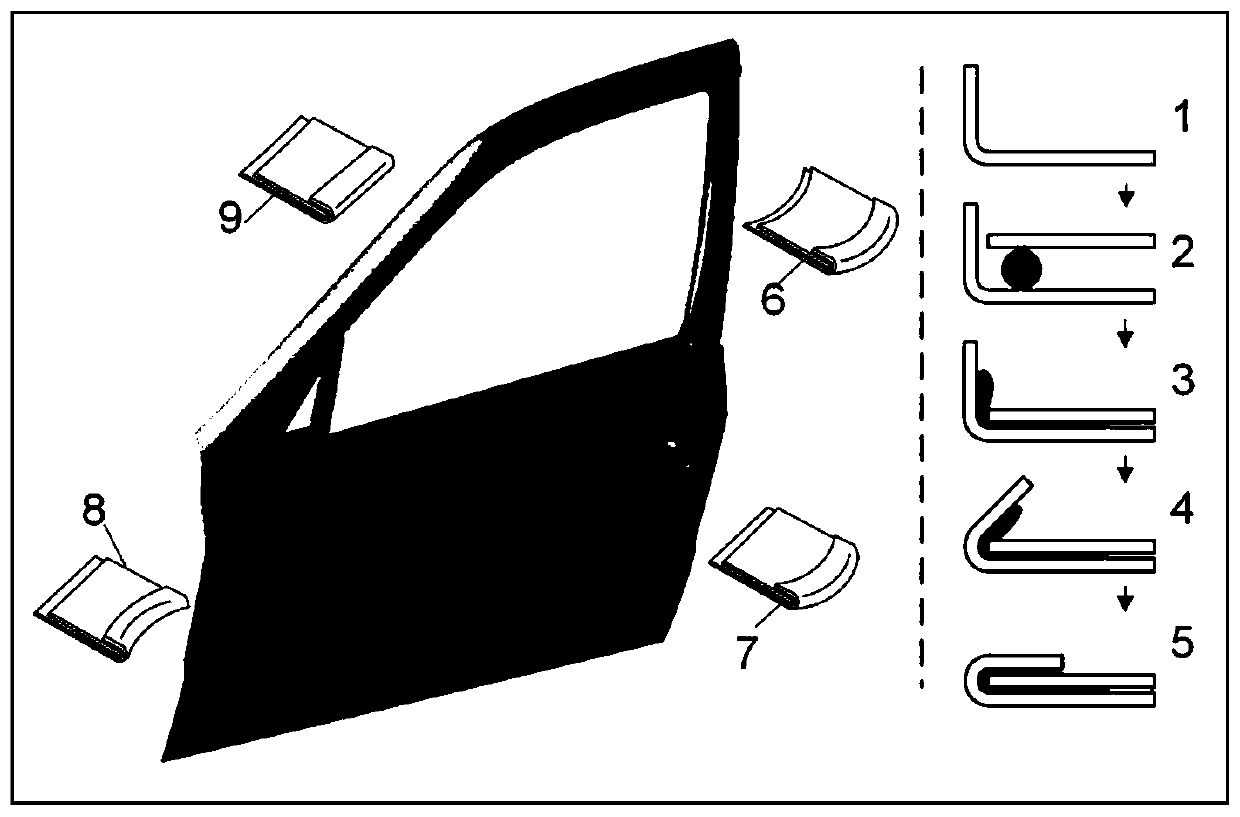

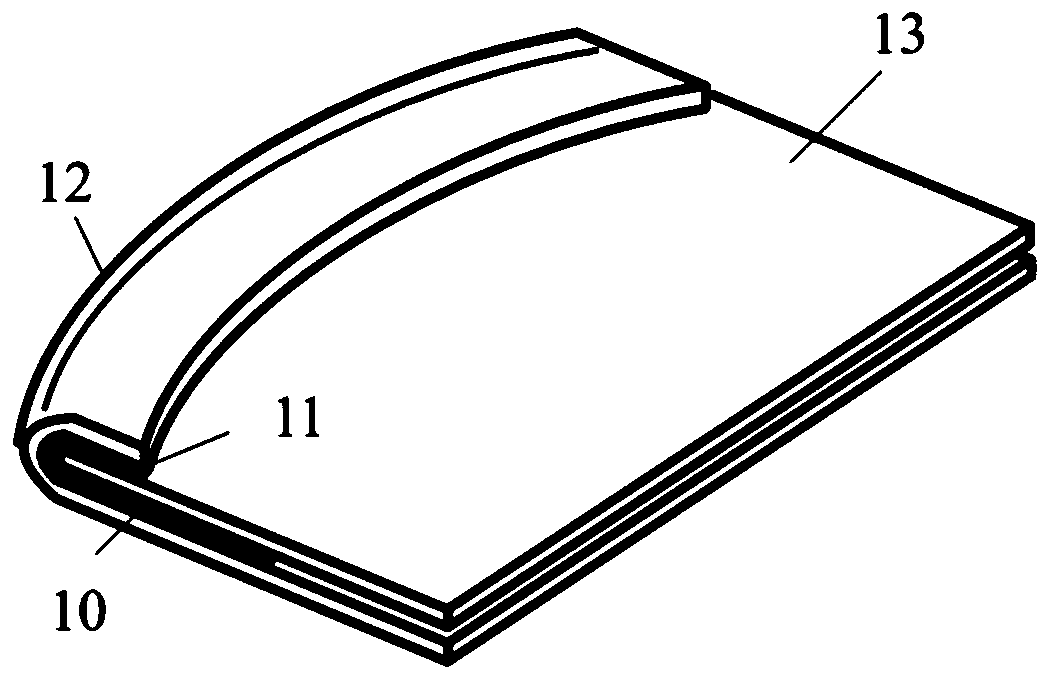

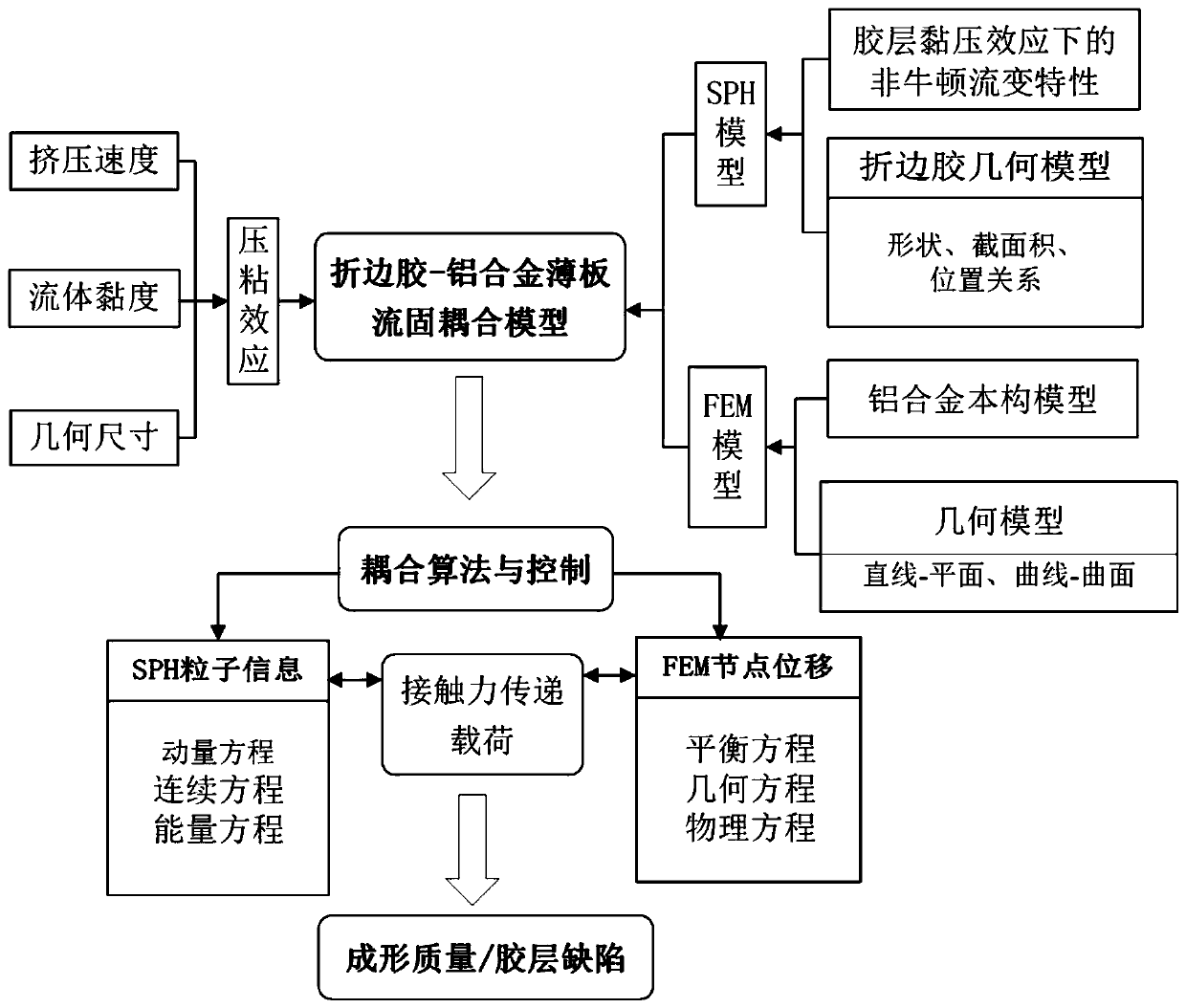

Light thin plate glue-containing rolling forming coupling modeling and quality prediction method

ActiveCN111222273AEasy to optimizeRealistic response to mechanical propertiesGeometric CADDesign optimisation/simulationAdhesive cementGeometric modeling

The invention relates to a numerical modeling and quality prediction method capable of quantifying the influence of an adhesive on rolling forming of a light thin plate, which is beneficial to improving the manufacturing precision and quality of a light door cover part and providing a reference basis for improving and optimizing rolling and pressing process parameters. First, material properties of the adhesive and the lightweight sheet are determined. Then, establishing a geometric model of the adhesive-light thin plate, simulating the adhesive by adopting a meshless smooth particle method SPH, simulating the light thin plate by adopting a finite element method FEM, and establishing a fluid-solid coupling model of the SPH-FEM; and finally, under boundary and load constraint conditions, finishing rolling process simulation and quality prediction of the light sheet containing the adhesive. Compared with the prior art, the method has the following beneficial effects: (1) the optimizationof the constitutive model of the adhesive is facilitated; and (2) the coupling algorithm is beneficial to improving the forming prediction precision of the light thin plate. And (3) the distributionof the adhesive is favorably controlled.

Owner:TONGJI UNIV

Marquardt algorithm based force feedback model construction method for radial-basis meshless soft tissue data

ActiveCN106156537AEfficient modelingSimple structureSystems biologySpecial data processing applicationsStress pointMedicine

The invention provides a Marquardt algorithm based fitting method for radial-basis meshless soft tissue data. The method aims at overcoming defects of complicated structure, large calculated amount and poor real-time performance of a conventional physical model of biological soft tissue, anisotropic characteristics of the soft tissue are taken into consideration, stress displacement data of a finite number of equally spaced points on the surface with a soft tissue stress point as a center are obtained once with a radial-basis meshless method, a soft tissue node force displacement model is fitted with a Marquardt algorithm, and the biological soft tissue model is constructed by forming lines with points and forming planes with lines. The method has the advantages as follows: the structure is concise, the calculation is convenient, precision of the radial-basis meshless method is reserved, meanwhile, the calculated amount is greatly reduced, high real-time performance of virtual interaction is guaranteed, and efficient construction of a soft tissue force feedback model of a virtual surgery system is realized.

Owner:NANCHANG UNIV

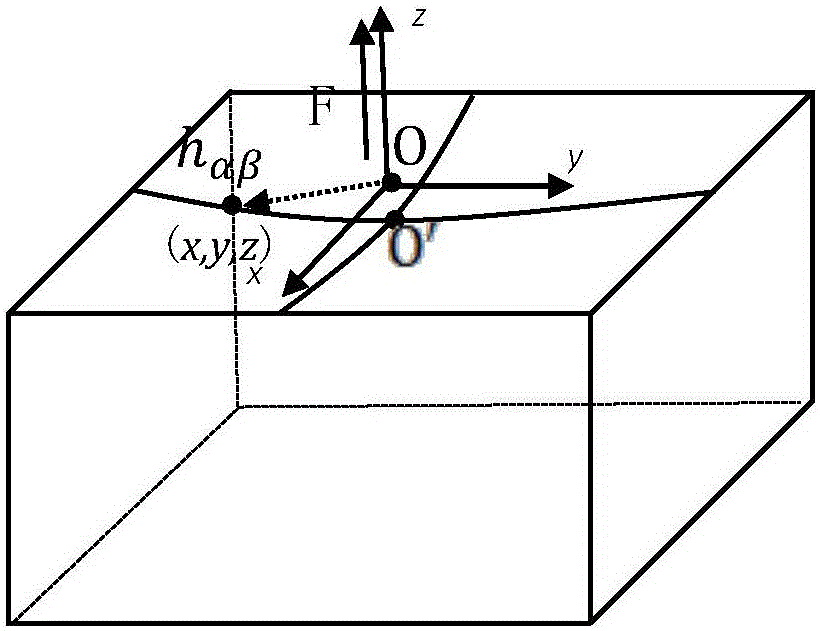

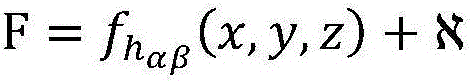

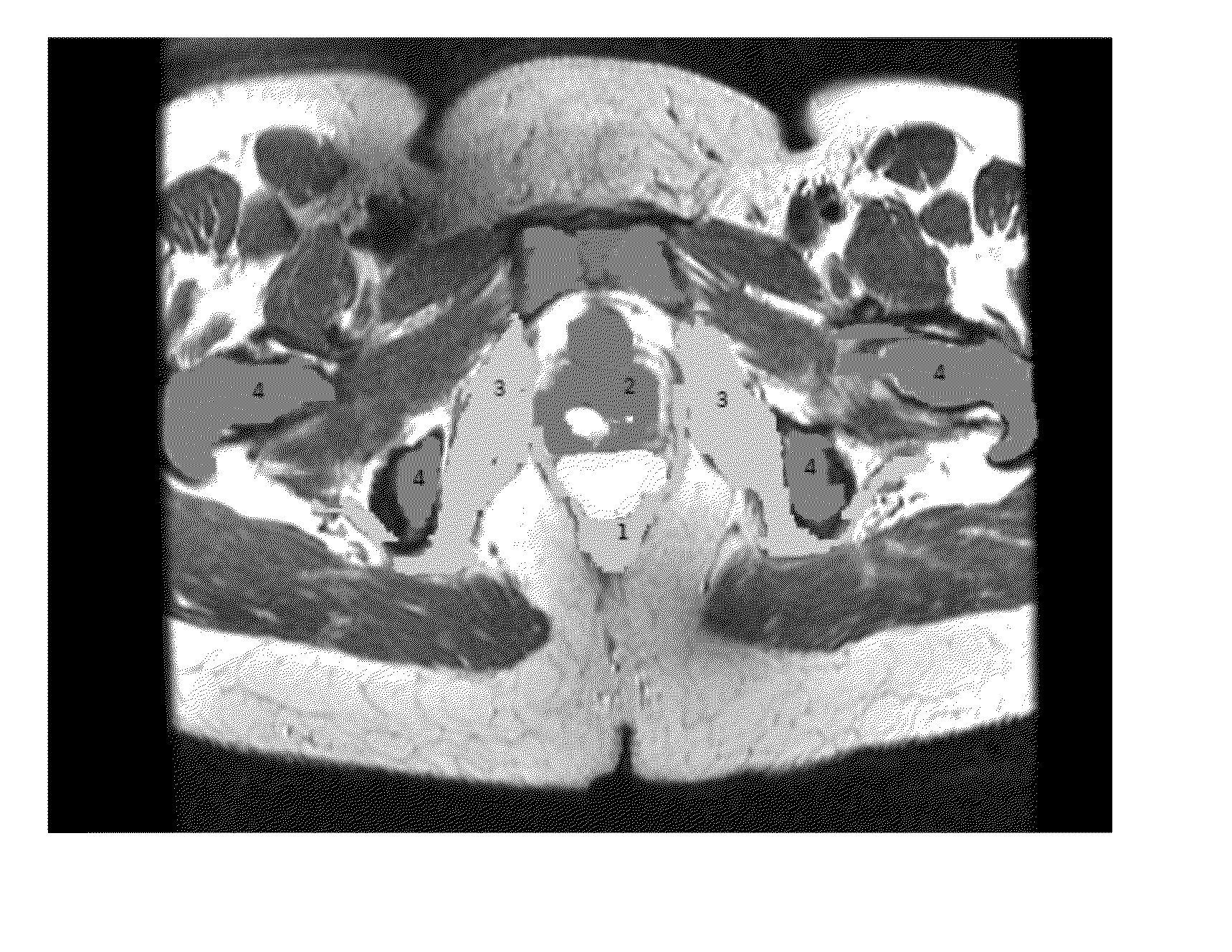

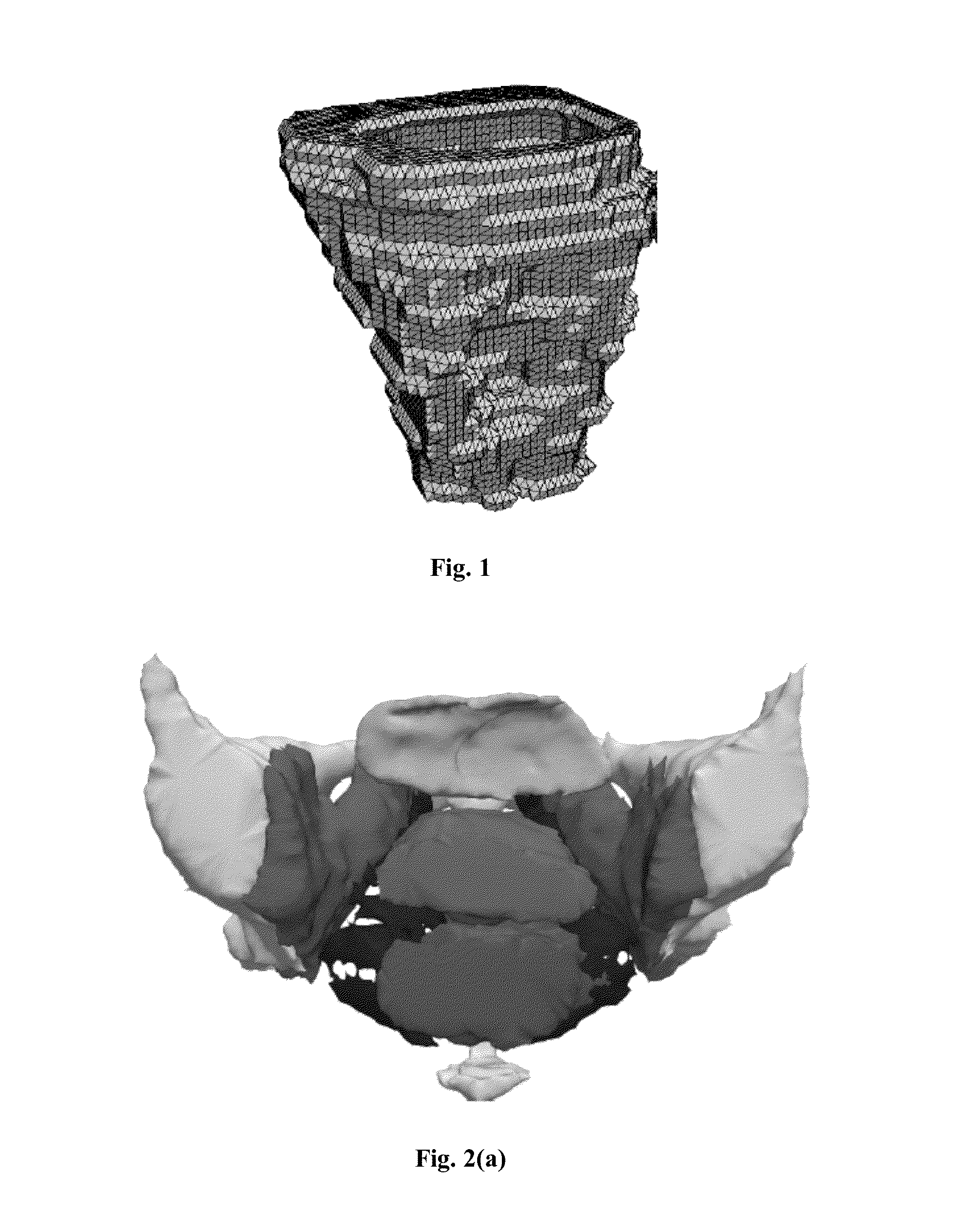

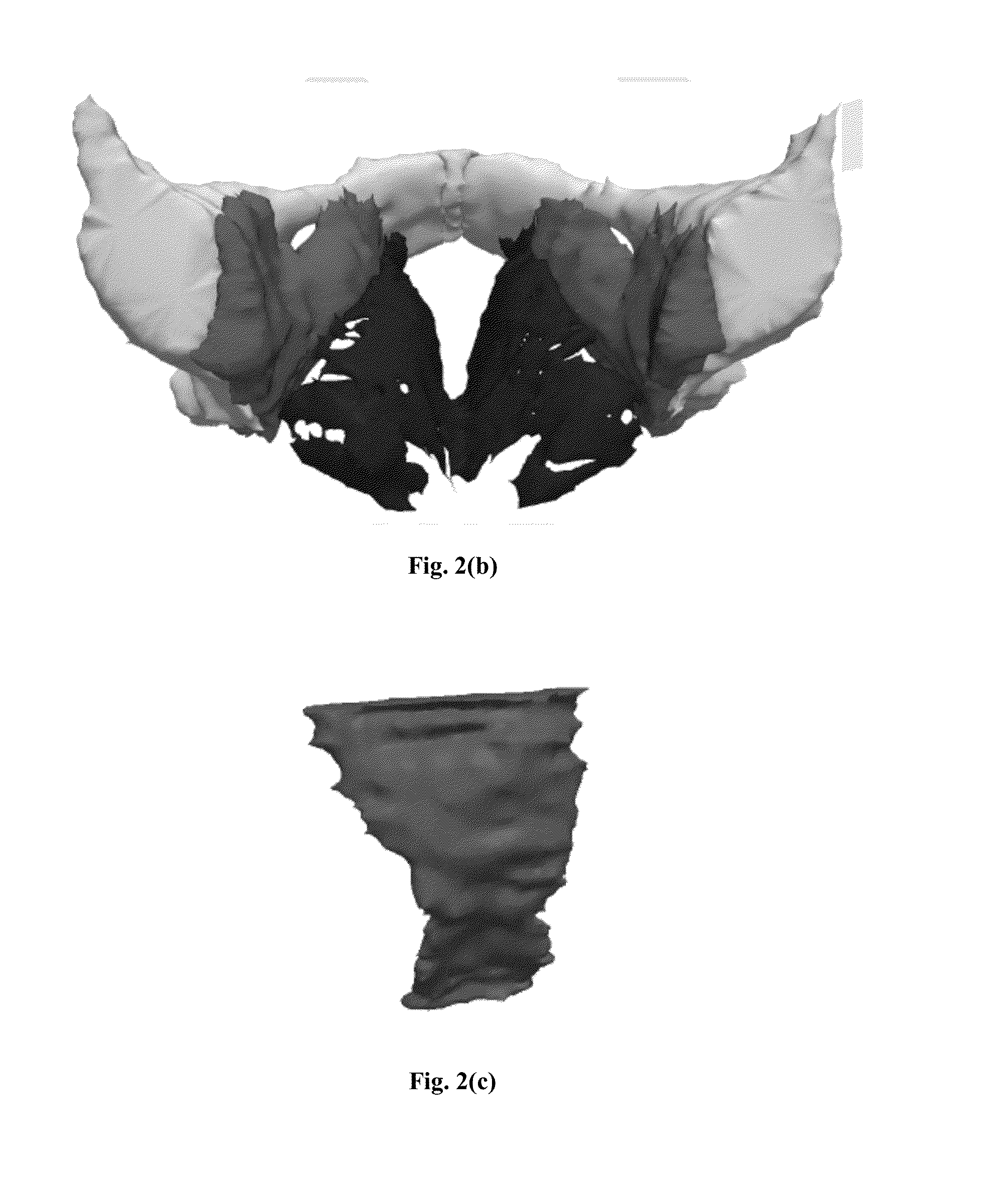

Analysis-suitable geometry from discrete point sets using a mesh-free method

ActiveUS20150332501A1Design optimisation/simulationSpecial data processing applicationsPattern recognitionComputed tomography

The present invention includes a method of creating analysis suitable models from discrete point sets. The proposed methodology is completely automated, requiring no human intervention, as compared to traditional mesh-based methods that often require manual input. The present invention is directly applicable to engineering approaches in medicine where the object to be analyzed is described by discrete medical images, such as MRI or CT scans. Moreover, the present invention is useful in any application where the object of interest is created from digitized imaging technology.

Owner:UNIV OF SOUTH FLORIDA

Simulation method of meshless numerical model

PendingCN112861445AImprove the calculation accuracy of flow field pressureHigh precisionGeometric CADDesign optimisation/simulationNumerical modelsMeshfree methods

The invention discloses a simulation method of a meshless numerical model, computer equipment and a computer readable storage medium. According to the simulation method of the meshless numerical model, the floating body and fluid interaction numerical model of the improved Riemannian solution meshless algorithm is constructed, and compared with a meshless method in the related technology, the influence of strong nonlinear factors such as rolling, breaking and splashing of a water body on a flow field is fully considered; the problems of stress instability, particle pressure field oscillation and low free surface expression precision are solved, the flow field pressure calculation precision is improved, and the effectiveness and precision of high-precision and strong-impact solid-liquid interaction are achieved in the wave making problem. Therefore, the invention can be suitable for simulating scenes where nonlinear waves and floating bodies interact, has a wider application environment, can be applied to the fields of ship and ocean engineering, offshore engineering and the like, and has a higher use value.

Owner:中国船舶重工集团公司第七研究院

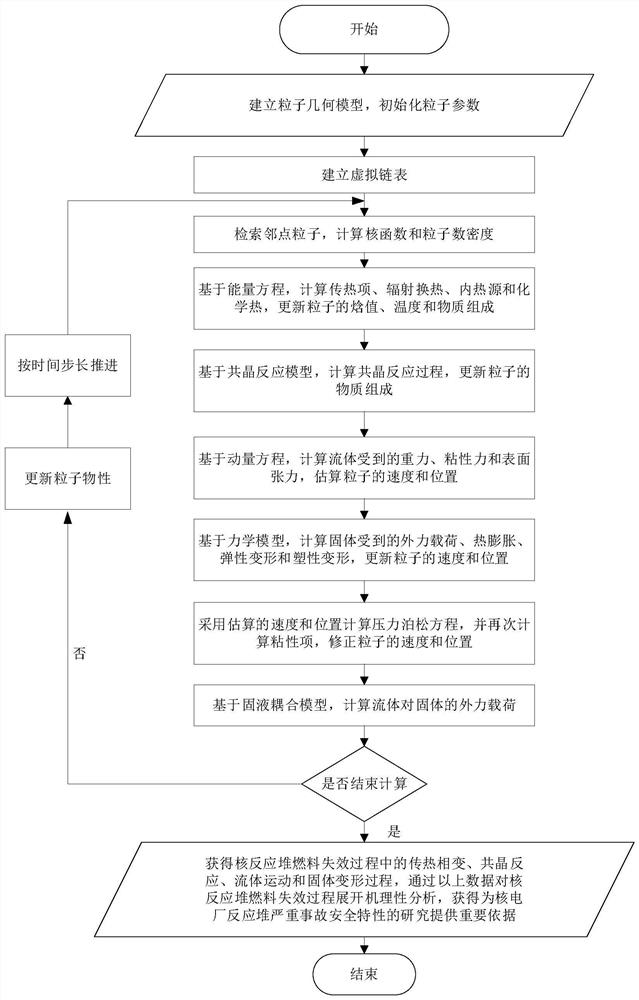

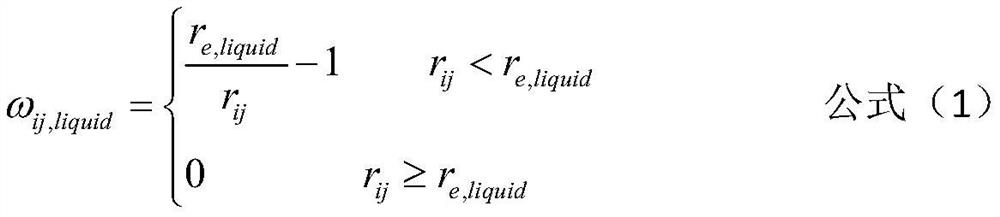

Nuclear reactor fuel element failure analysis method based on meshless method

ActiveCN113191066AEasy to analyzeEfficient analysisNuclear energy generationChemical processes analysis/designEngineeringSolid particle

A nuclear reactor fuel element failure analysis method based on a meshless method comprises the following steps of: 1, establishing a particle geometric model, and initializing particle parameters; 2, updating adjacent point particles, and calculating a weighting function and particle number density; 3, calculating energy conservation, and updating enthalpy values, temperatures and phase states of particles; 4, performing eutectic reaction calculation, updating the content and the physical property of particles, and updating the enthalpy value, the temperature and the phase state of the particles; 6, calculating the gravity, viscosity and surface tension of the fluid, and estimating the speed and position of fluid particles; 7, calculating solid motion, and updating the speed and position of solid particles; 8, correcting viscosity, and updating the speed and the position of fluid particles; 9, updating the load of the fluid on the solid; and 10, outputting data. According to the method, all phenomena in a nuclear reactor fuel element failure process are considered; on the basis of a meshless method, interface changes can be accurately captured, and compared with a grid method, the problem of grid distortion in large deformation is avoided; and the algorithm process is easy to realize large-scale parallel computing.

Owner:XI AN JIAOTONG UNIV

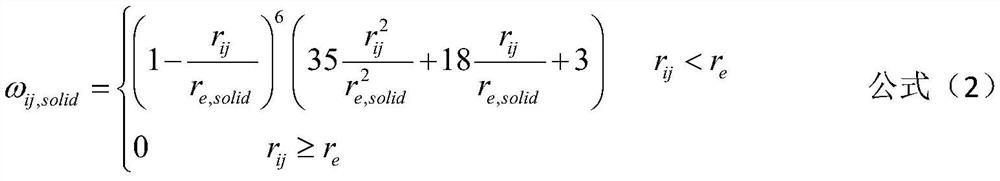

Production method of super-breathability mesh-free cotton and quilt

Disclosed is a production method of super-breathability mesh-free cotton. The method includes: firstly, using a cotton machine to mechanically remove impurities of primary cotton for 10 to 15 minutes; secondly, using a bamboo pole to knock the impurity-removed primary cotton out from the cotton machine, and making the cotton into secondary cotton; thirdly, using a rectangular wood frame as a mould, paving the secondary cotton in the mould to form rectangular ternary cotton, and manually making the ternary cotton into the cotton with the thickness of the middle larger than the thickness of parts close to four sides; fourthly, using a wooden iron to press the ternary cotton in a suspension manner, and then loading the ternary cotton into a mesh. The invention further provides a quilt produced by the method. By the production method, warm keeping effect is good since the middle of the super-breathability mesh-free cotton is thick; the four sides are thin, so that load to the aged due to the quilt can be reduced.

Owner:江西鼎鼎家纺有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com