Light thin plate glue-containing rolling forming coupling modeling and quality prediction method

A quality prediction, fluid-solid coupling model technology, applied in the direction of instruments, electrical digital data processing, geometric CAD, etc., can solve the problems of high forming accuracy, mesh distortion, calculation divergence, etc., to improve the forming prediction accuracy, improve Prediction accuracy and the effect of optimizing process parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

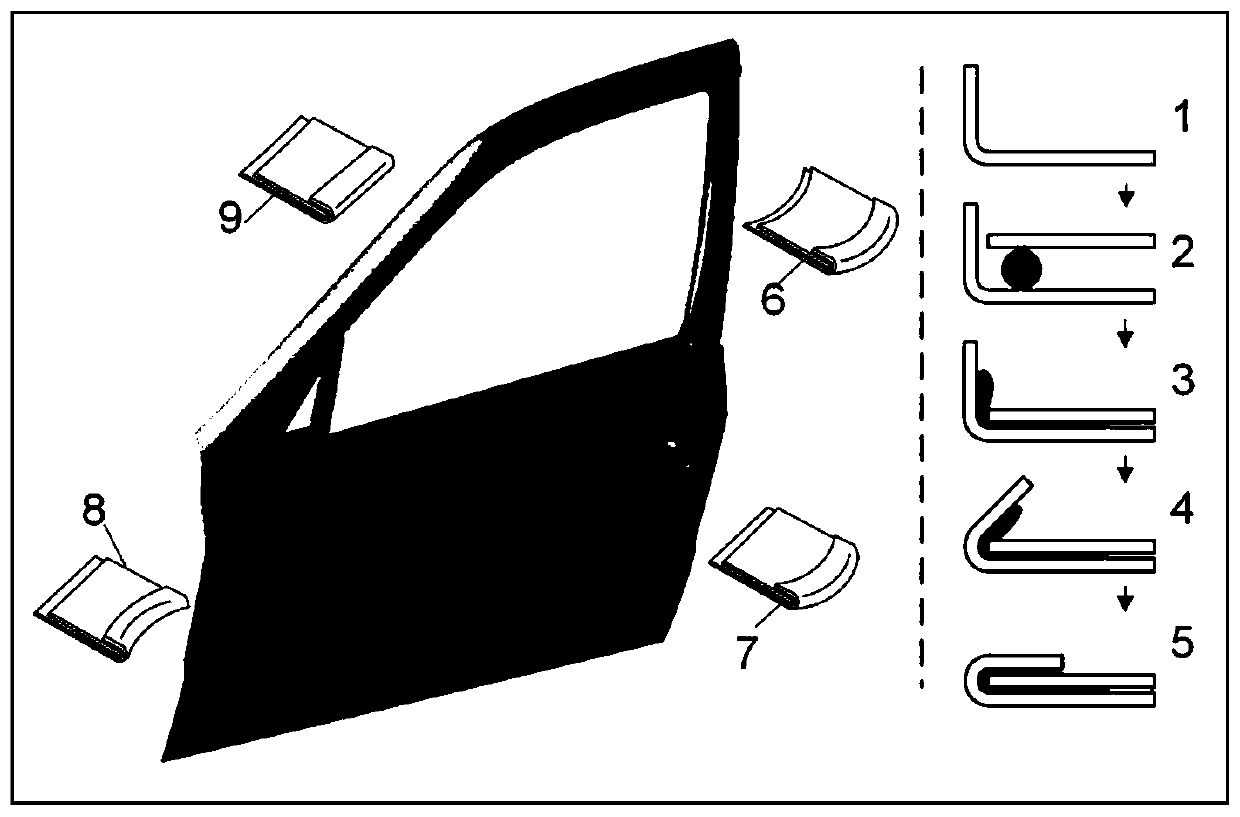

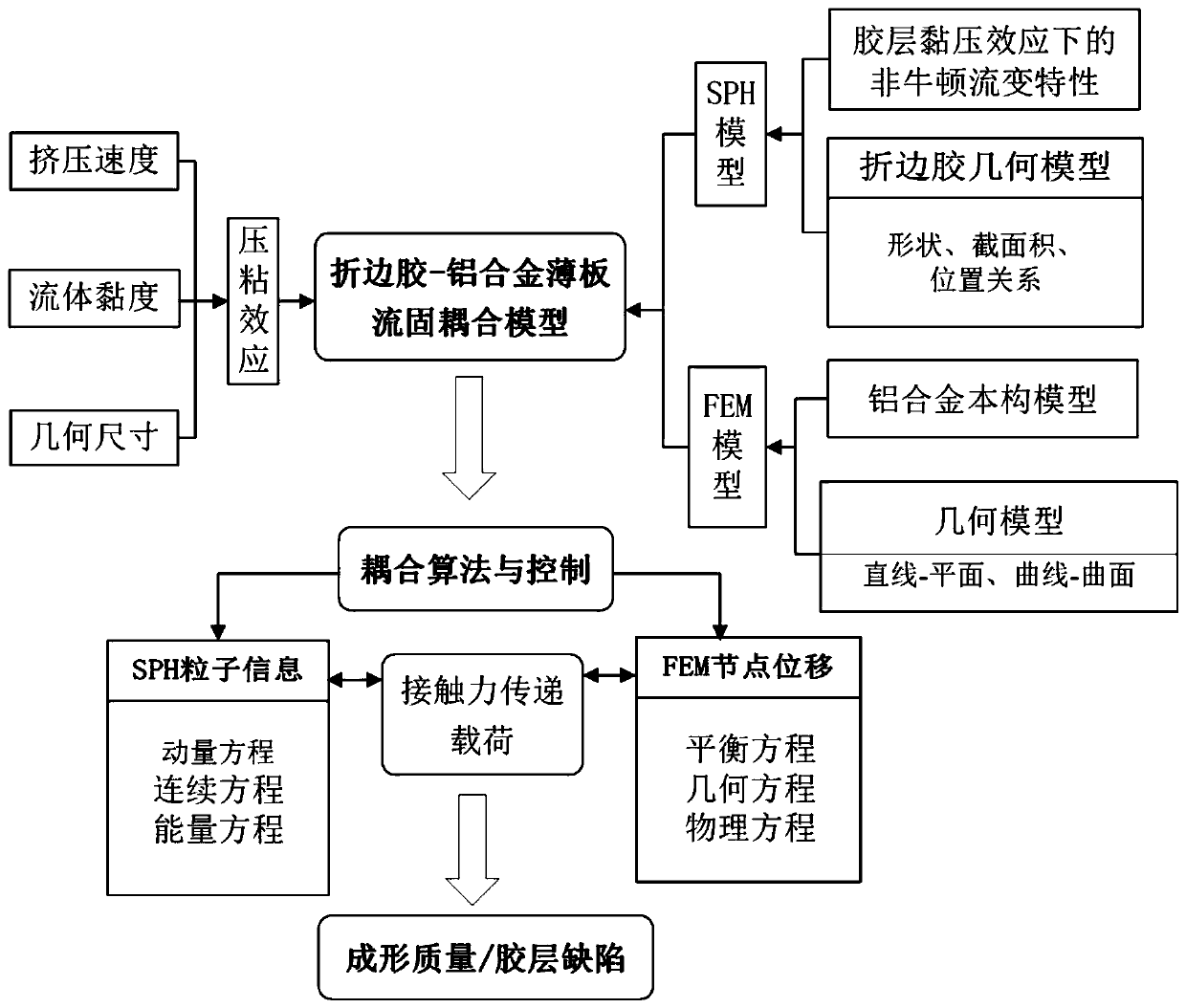

[0051] like figure 1 As shown in , the complex structure of the car door is complex, with various structural forms, such as curved surface-curve rolling structure 6, flat-convex rolling structure 7, flat-concave rolling structure 8, flat-linear rolling structure 9, etc. .

[0052] According to the rolling process, there are mainly 5 steps, and the sequence is: flanging, gluing, gluing, pre-flanging, and final flanging.

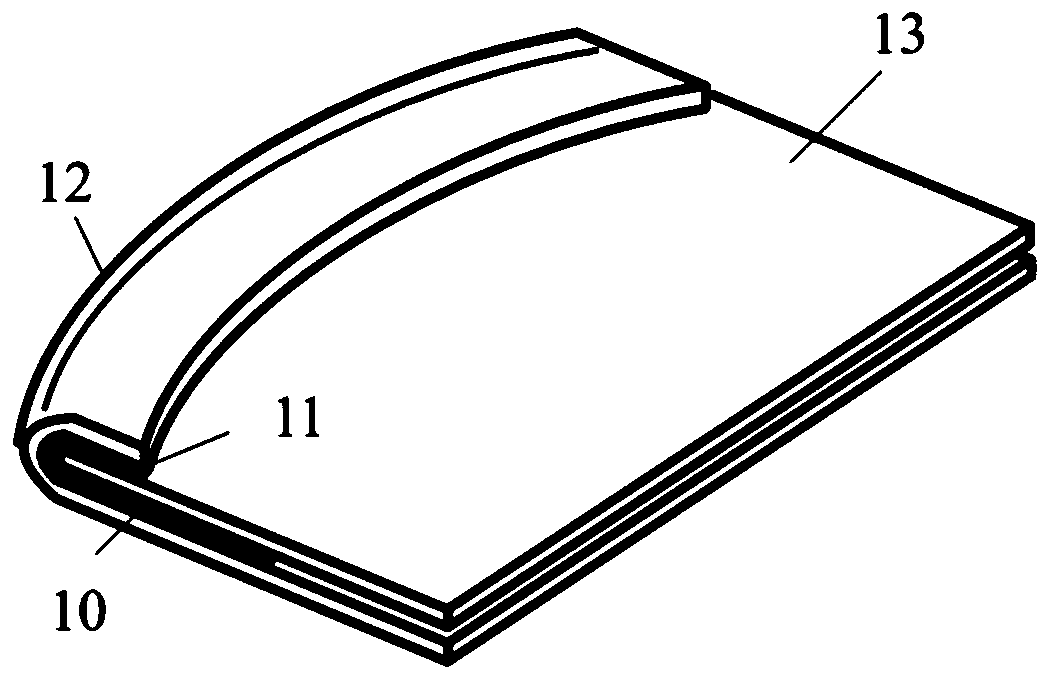

[0053] as figure 2 The shown planar curved aluminum alloy sheet with adhesive roll-in structure is an example:

[0054] (1) Adhesive material characteristics

[0055] Use a rotational viscometer to measure the relationship between the dynamic viscosity of the adhesive and the shear rate, such as image 3 As shown, then according to the curve, the rheological model is determined to be a power-law non-Newtonian fluid, and the constitutive model is:

[0056] τ=K·γ^n

[0057] (2) Material tensile test

[0058] Using a universal material stretching machine,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com