Nuclear reactor fuel element failure analysis method based on meshless method

A technology for nuclear reactor fuel and failure analysis, applied in chemical process analysis/design, instrumentation, design optimization/simulation, etc., can solve problems such as grid distortion and grid method that are difficult to consider eutectic mass transfer and chemical reaction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0216] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

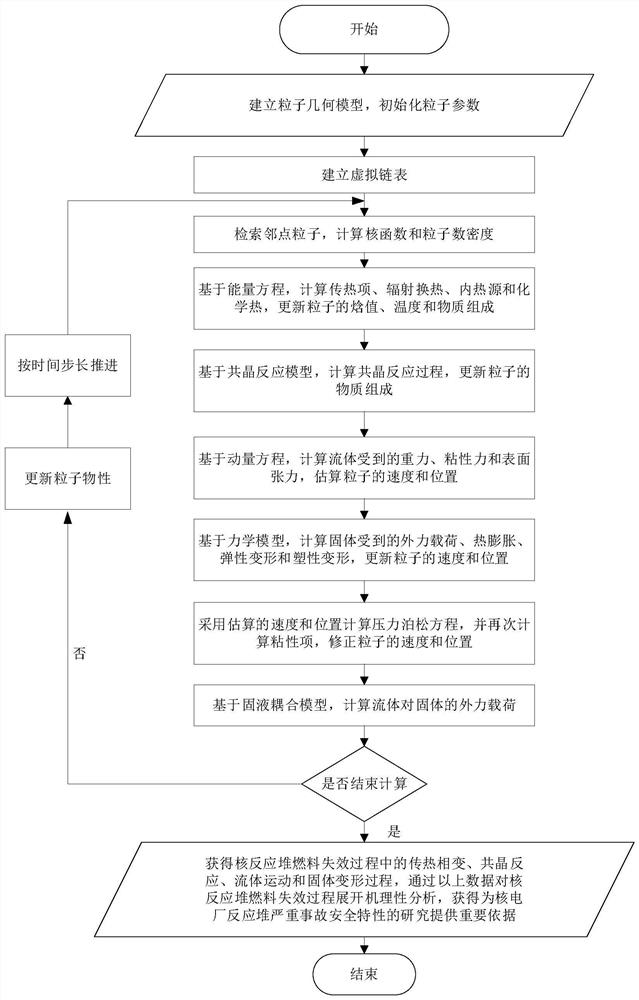

[0217] The present invention is based on the nuclear reactor fuel failure analysis method of gridless method, such as figure 1 As shown, the following takes the failure process analysis of a single fuel rod in a lead-based nuclear reactor as an example, and the steps are as follows:

[0218] Step 1: Carry out three-dimensional particle modeling of a single fuel rod in a lead-based nuclear reactor. The length of the built model is 2.2 meters, and the core block is simplified into a cylinder with a diameter of 9 mm. Stainless steel structural materials are used to fix the whole fuel rod in the lead-bismuth coolant; the definitions of No. 1, 2 and 3 particles represent the liquid phase, solid-liquid mixed phase and solid phase of the fuel element pellets, and the definitions of No. 11, 12 and 13 Particles characterize the liquid phase, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com