Production method of super-breathability mesh-free cotton and quilt

A production method and air-permeable technology, applied to bed sheets, blankets, etc., can solve the problems of unable to meet the requirements of the elderly, long-term finishing time, etc., and achieve the effect of improving warmth retention and high warmth retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below through specific embodiments and in conjunction with the accompanying drawings.

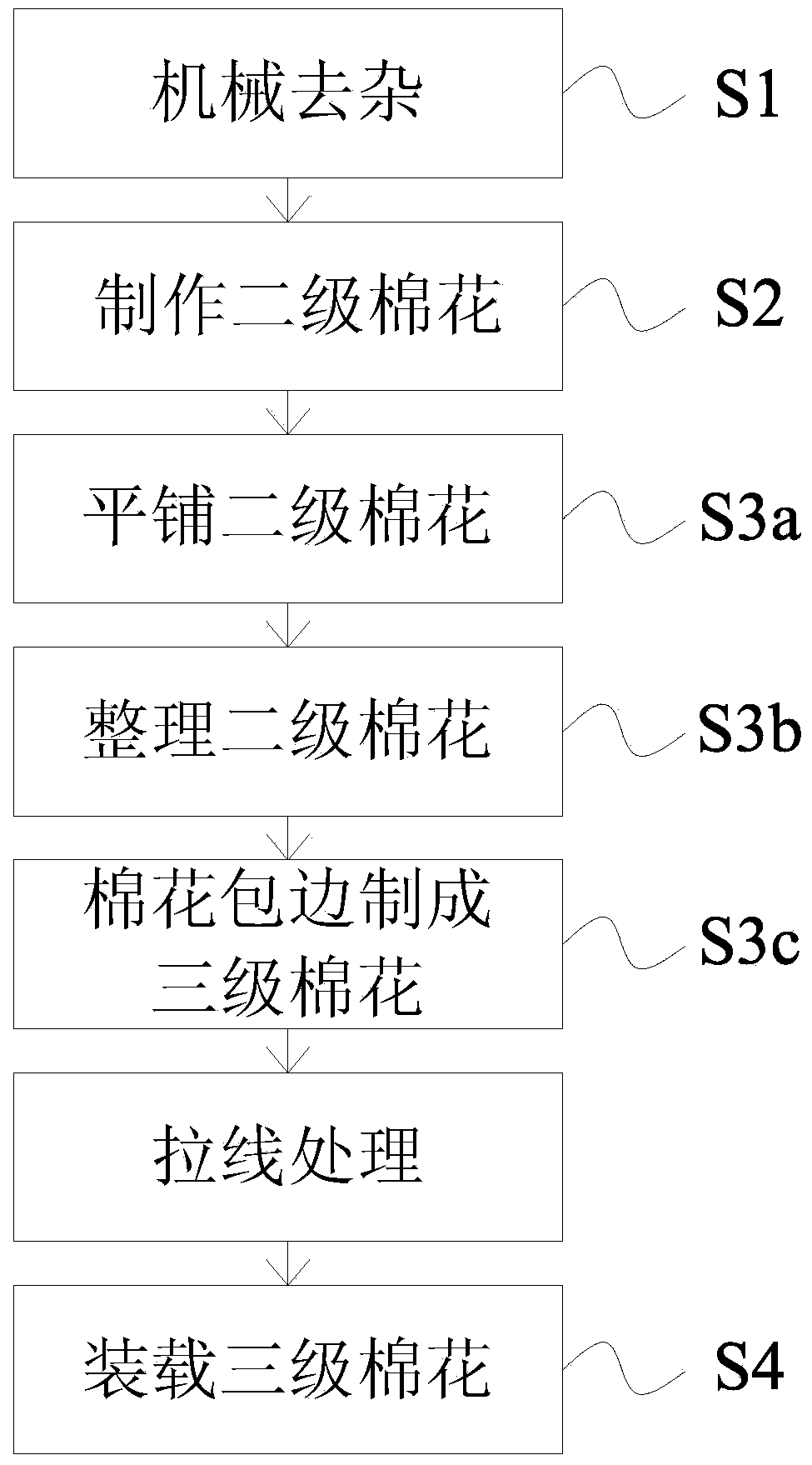

[0029] Please refer to figure 1 , figure 1 It is a flowchart of a method for making super-breathable non-mesh cotton in an embodiment of the present invention.

[0030] The invention provides a method for making super-breathable non-net cotton, comprising steps: S1, mechanically removing impurities, using a cotton machine to mechanically remove impurities from primary cotton, and the time for removing impurities is 10-15 minutes; S2, making secondary cotton Cotton, use bamboo poles to beat out the primary cotton after removing impurities from the cotton machine, and make barrel-shaped secondary cotton; S3, make tertiary cotton, use a rectangular wooden frame as a mold, spread the secondary cotton in the mold and Form the three-grade cotton of rectangle, and make the thickness of the middle position of the three-grade cotton ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com