Electrochromic device including a meshing

A technology of electrochromic and electrochromic materials, applied in the direction of instruments, nonlinear optics, coatings, etc., to achieve the effect of easy bending

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

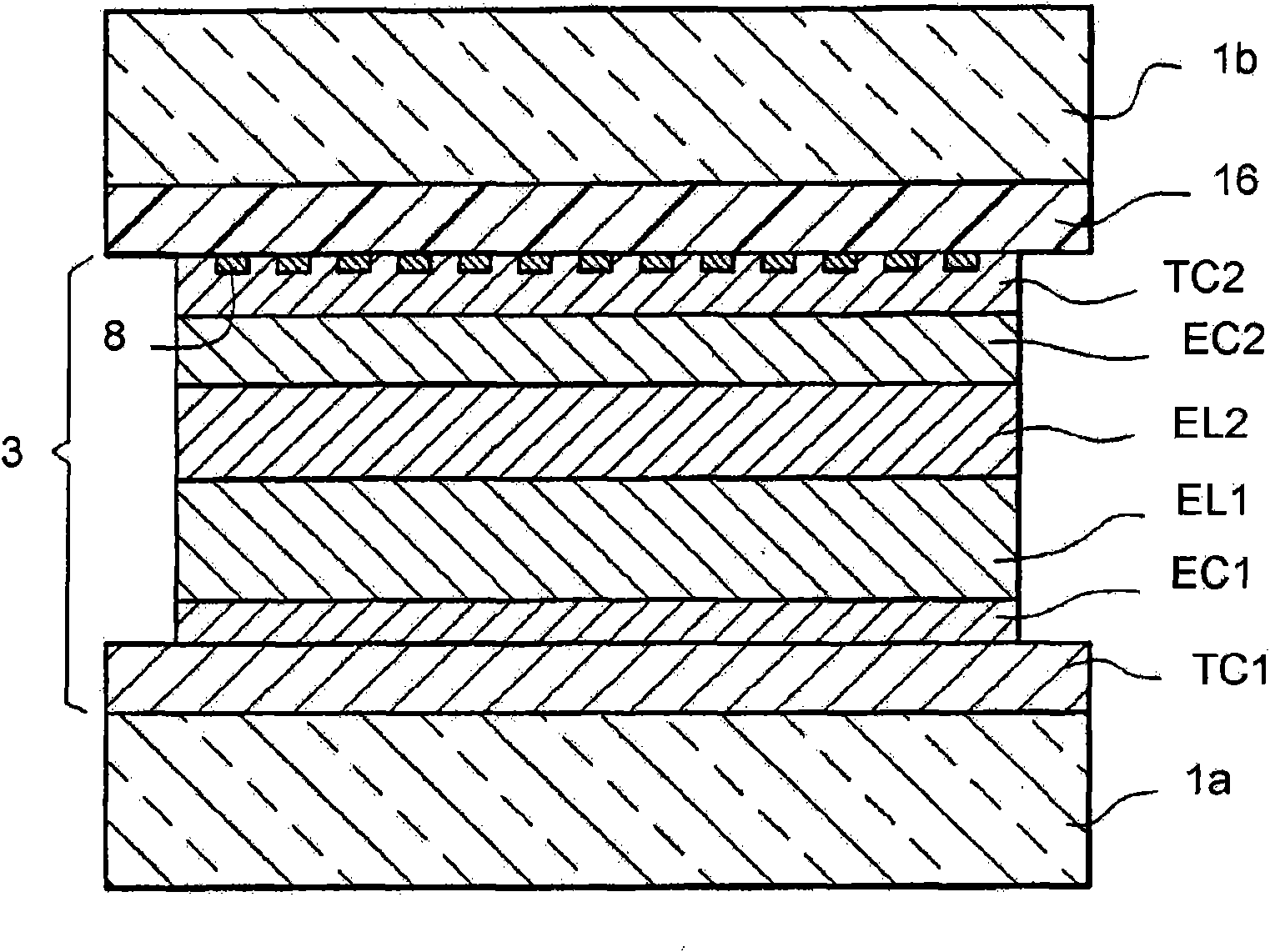

[0045] figure 1 Represented in is an electrochromic device with controlled transparency according to the invention, which is particularly intended for application in the production of automotive glazing units for which it is desirable to be able to adjust the transparency and control the curvature.

[0046] Typically, such devices are formed by functional layer stacks known as "all solid state" stacks, the structure of which includes an electrochromic function of the type EC1 / EL1 / EL2 / EC2 between the conductive layers TC1 and TC2 system, the functional layer stack is located between the carrier substrate 1a and the opposite substrate 1b. In such a device:

[0047] - The two outermost layers TC1 and TC2 of the stack are metal or made of In 2 o 3 :Sn(ITO), SnO 2 : TCO (transparent conductive oxide) type conductive layer made of F, ZnO:Al. They can also be layers of the TCO / metal / TCO type, the metal being chosen especially from silver, gold, platinum, copper, or layers of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com