Liquid crystal display

A liquid crystal display, display panel technology, applied in instruments, nonlinear optics, optics, etc., can solve problems such as affecting the quality of transmission signals, scratches, and easy bending damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] Examples of exemplary embodiments of the present invention will now be described in detail with reference to the accompanying drawings of the present invention.

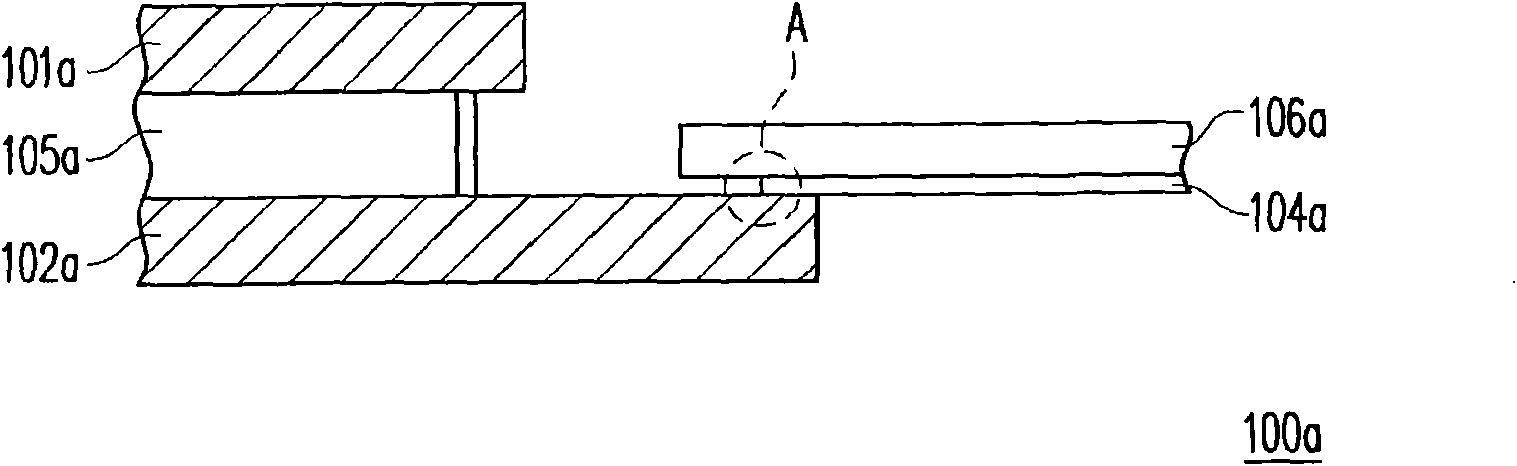

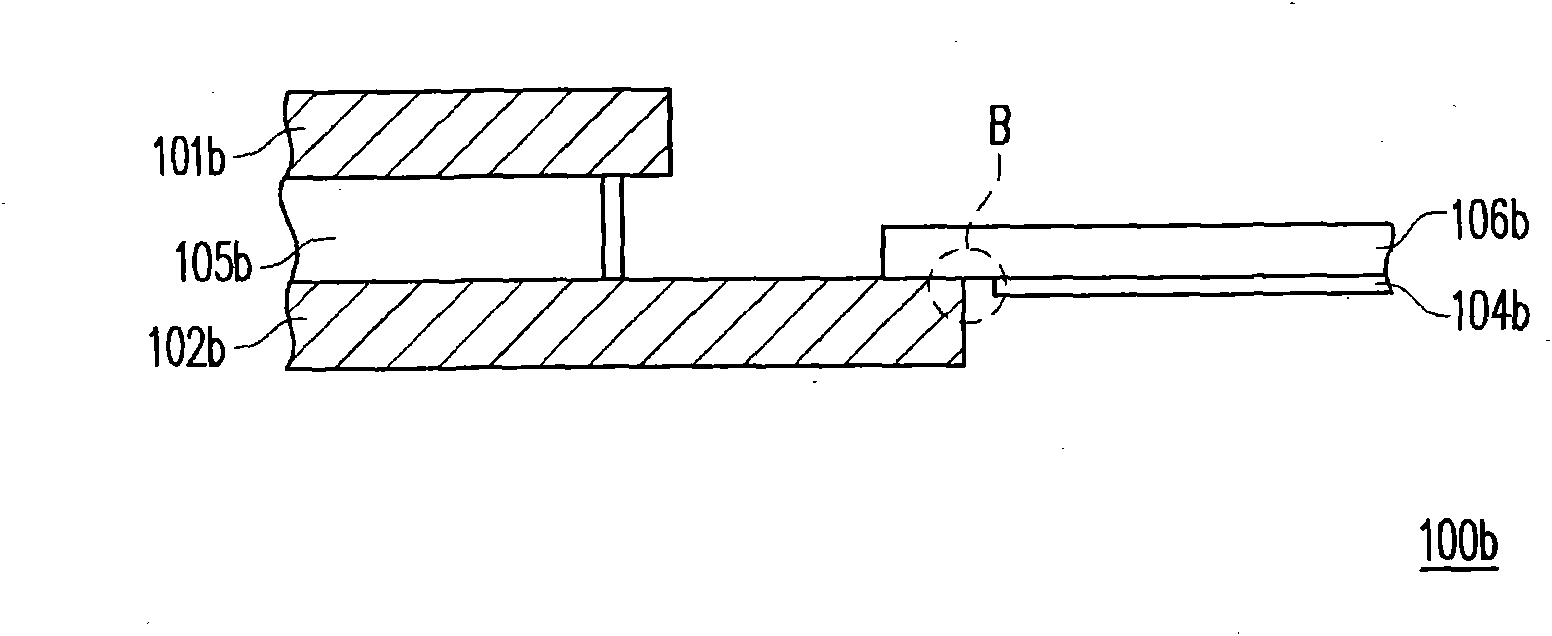

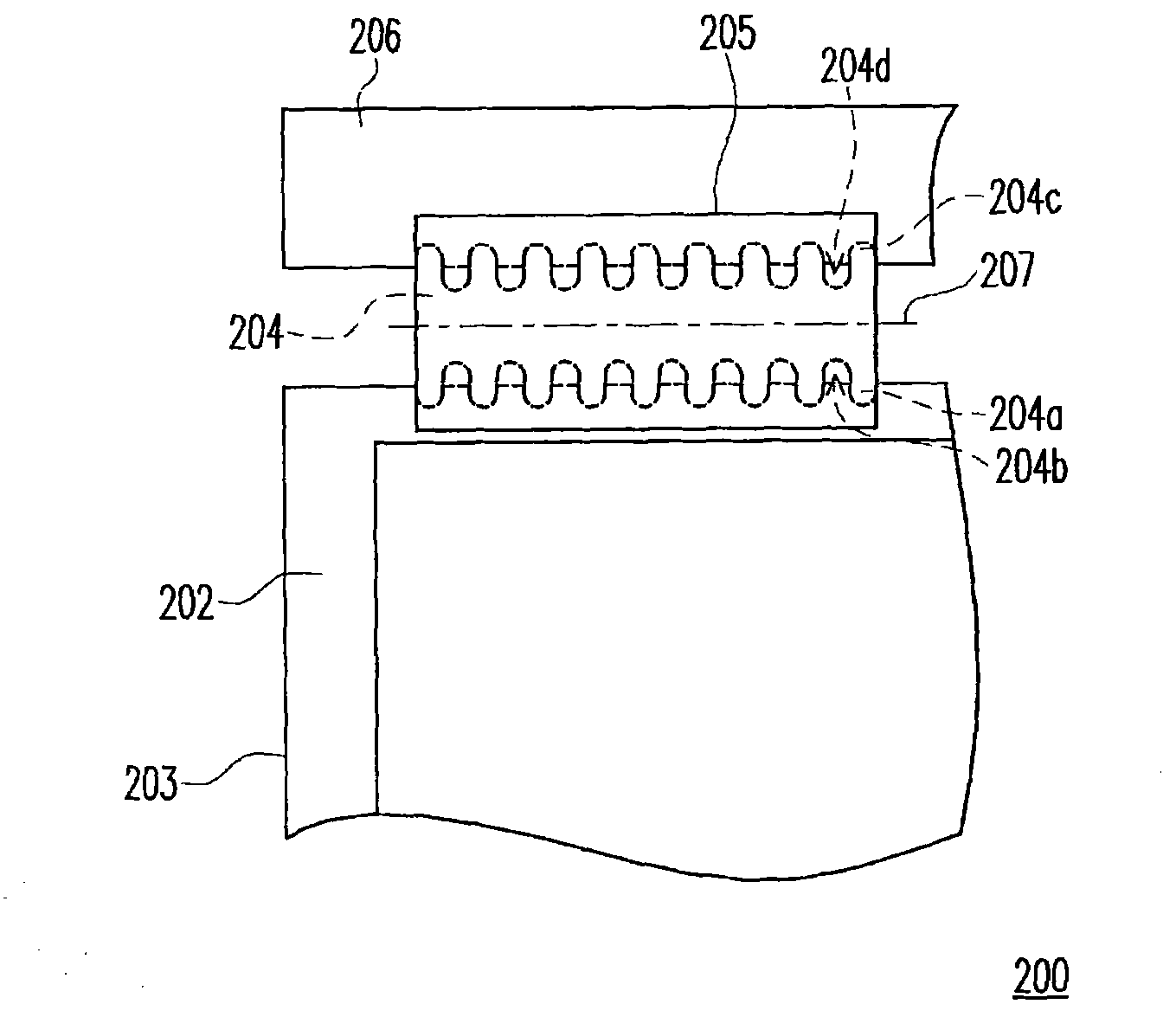

[0047] Figure 2A It is a schematic partial top view of a liquid crystal display in an exemplary embodiment of the present invention. Figure 2B for further targeting Figure 2A A schematic top view of the flexible substrate 205. Please refer to Figure 2A and Figure 2B The liquid crystal display 200 of this exemplary embodiment includes a display panel 203 having a substrate 202 and a flexible substrate 205 having a protective layer 204 (Protective Layer or Solder Resistor). Wherein, the substrate 202 can be a glass substrate or a quartz substrate, and a plurality of contact pads (Pads) are arranged on it, and can be connected with the flexible substrate 205 by pasting an adhesive film, such as an anisotropic conductive adhesive film (ACF). Metal wires (or conductive pins (Lead)) are electrically connec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com