Super-hydrophobic and super-oleophilic copper wire mesh free of low surface energy material modification and preparation method thereof

A low-surface-energy substance and super-hydrophobic technology, which is applied in separation methods, chemical instruments and methods, and immiscible liquid separation, can solve problems such as poor thermal stability, reduced super-hydrophobic performance, and environmental pollution, and achieve the ability to improve, The effect of ease of processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

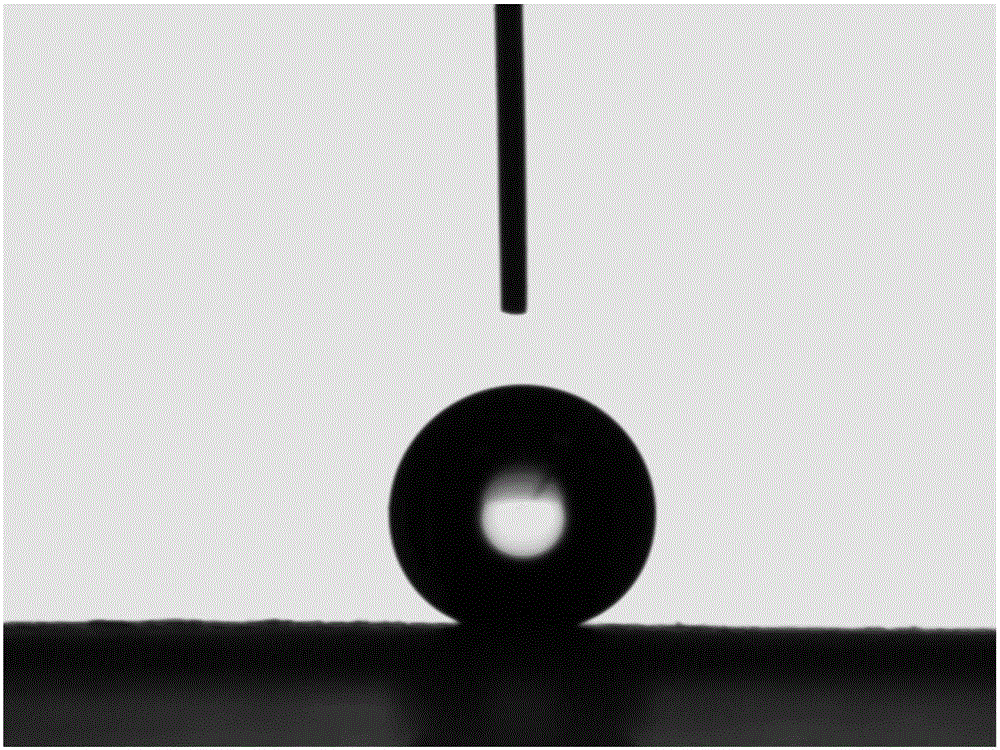

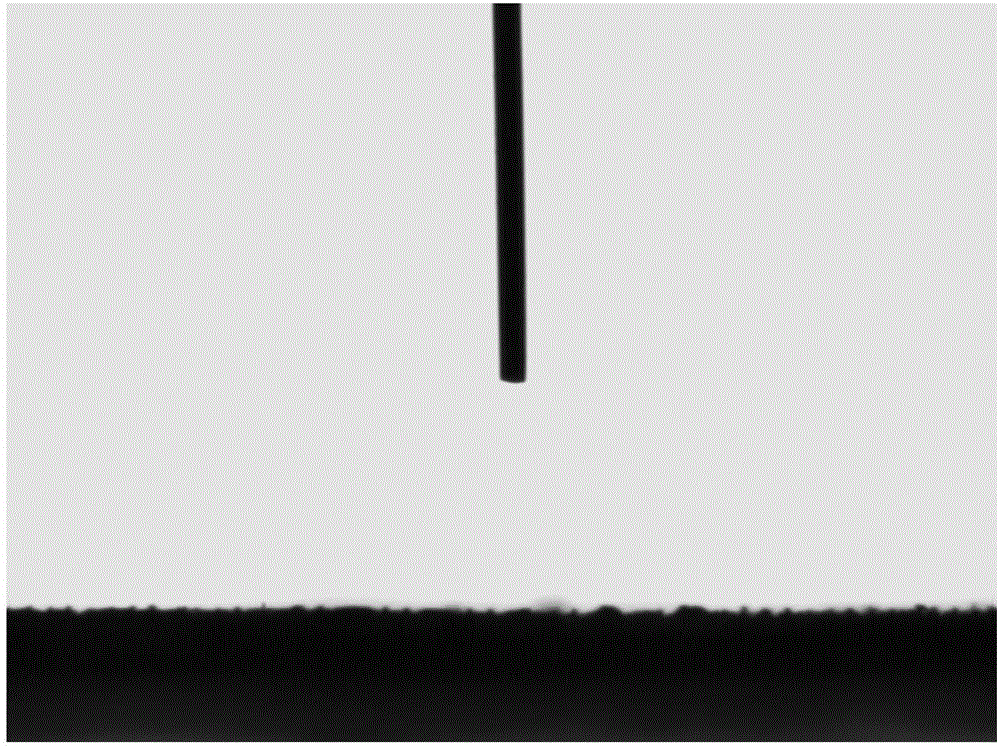

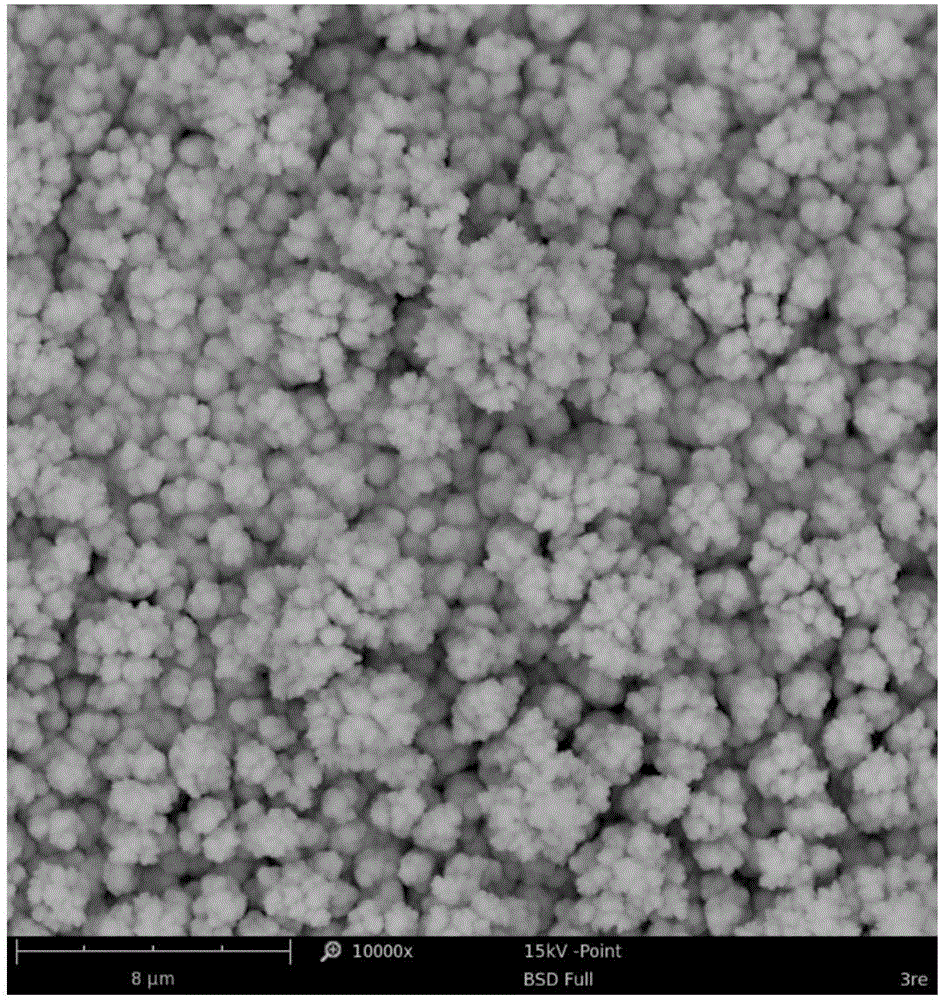

[0029] 180-mesh copper mesh with a size of 50×30, after surface pretreatment, electrodeposition and high-temperature drying, a super-hydrophobic and super-oleophilic surface with outstanding structural characteristics is obtained, specifically including the following steps and process conditions:

[0030] (1) Copper sheet pretreatment: ultrasonically clean the copper mesh with acetone, alcohol, and deionized water for 5 minutes at room temperature, and blow dry with a hair dryer to remove oil and impurities on the surface;

[0031] (2) Plating solution configuration: Dissolve thioacetamide, disodium edetate and copper sulfate pentahydrate in deionized water, wherein the concentration of thioacetamide is 0.1mol / L, ethylenediaminetetraacetic acid di The concentration of sodium is 0.2mol / L, and the concentration of copper sulfate pentahydrate is 0.02mol / L;

[0032] (3) Electrodeposition: take two pretreated copper grids as the poles of alternating current respectively, take 100ml...

Embodiment 2

[0036] The 120-mesh brass mesh with a size of 50×30 is subjected to surface pretreatment, electrodeposition and high-temperature drying to obtain a super-hydrophobic and super-oleophilic surface with outstanding structural features, specifically including the following steps and process conditions:

[0037] (1) Copper sheet pretreatment: ultrasonically clean the brass mesh with acetone, alcohol, and deionized water for 2 minutes at room temperature, and blow dry with a hair dryer to remove oil and impurities on the surface;

[0038] (2) Electroplating solution configuration: dissolve thioacetamide, disodium edetate and copper sulfate pentahydrate in deionized water, wherein the concentration of thioacetamide is 0.05mol / L, ethylenediaminetetraacetic acid di The concentration of sodium is 0.4mol / L, and the concentration of copper sulfate pentahydrate is 0.08mol / L;

[0039] (3) Electrodeposition: use two pretreated copper nets as the poles of alternating current respectively, tak...

Embodiment 3

[0043] The 300-mesh phosphorus copper mesh with a size of 50×30, after surface pretreatment, electrodeposition and high-temperature drying, obtains a super-hydrophobic and super-oleophilic surface with outstanding structural characteristics, specifically including the following steps and process conditions:

[0044] (1) Copper sheet pretreatment: ultrasonically clean the phosphor copper mesh with acetone, alcohol, and deionized water for 10 minutes at room temperature, and blow dry with a hair dryer to remove oil and impurities on the surface;

[0045] (2) Electroplating solution configuration: Dissolve thioacetamide, ethylenediaminetetraacetic acid disodium and copper sulfate pentahydrate in deionized water, wherein the concentration of thioacetamide is 0.18mol / L, ethylenediaminetetraacetic acid di The concentration of sodium is 0.1mol / L, and the concentration of copper sulfate pentahydrate is 0.06mol / L;

[0046] (3) Electrodeposition: take two pretreated copper grids as the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com