Patents

Literature

33 results about "Contact density" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

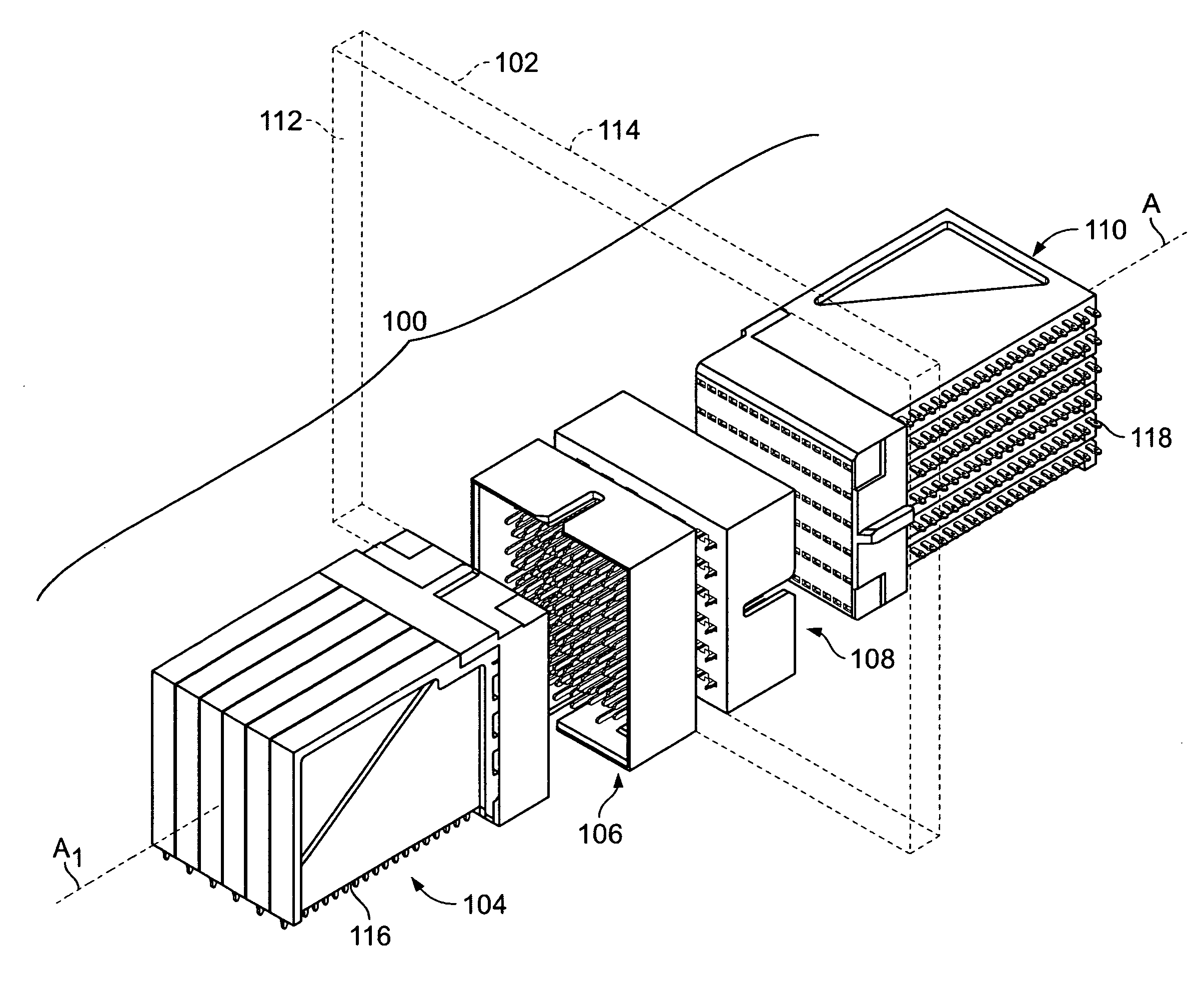

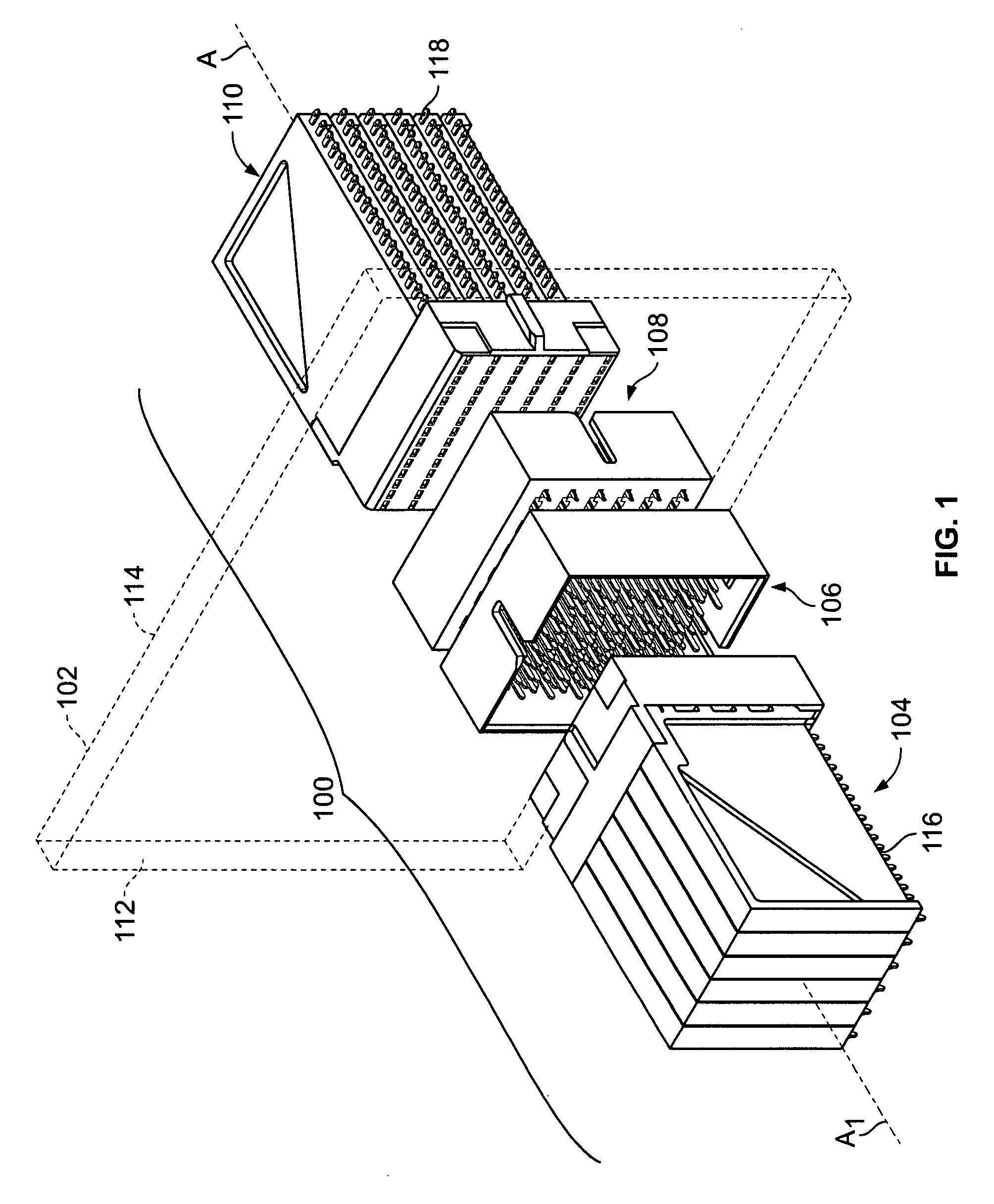

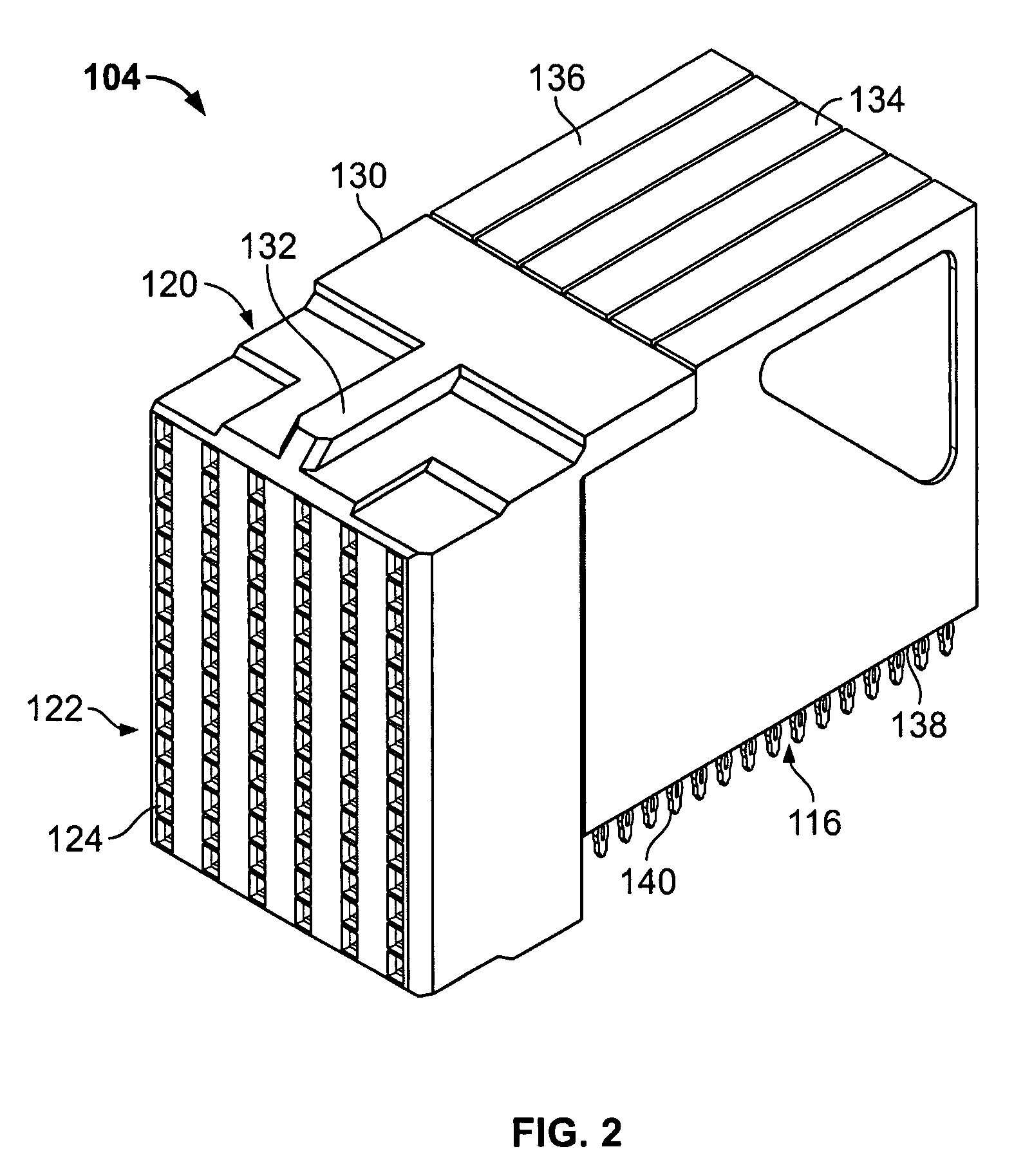

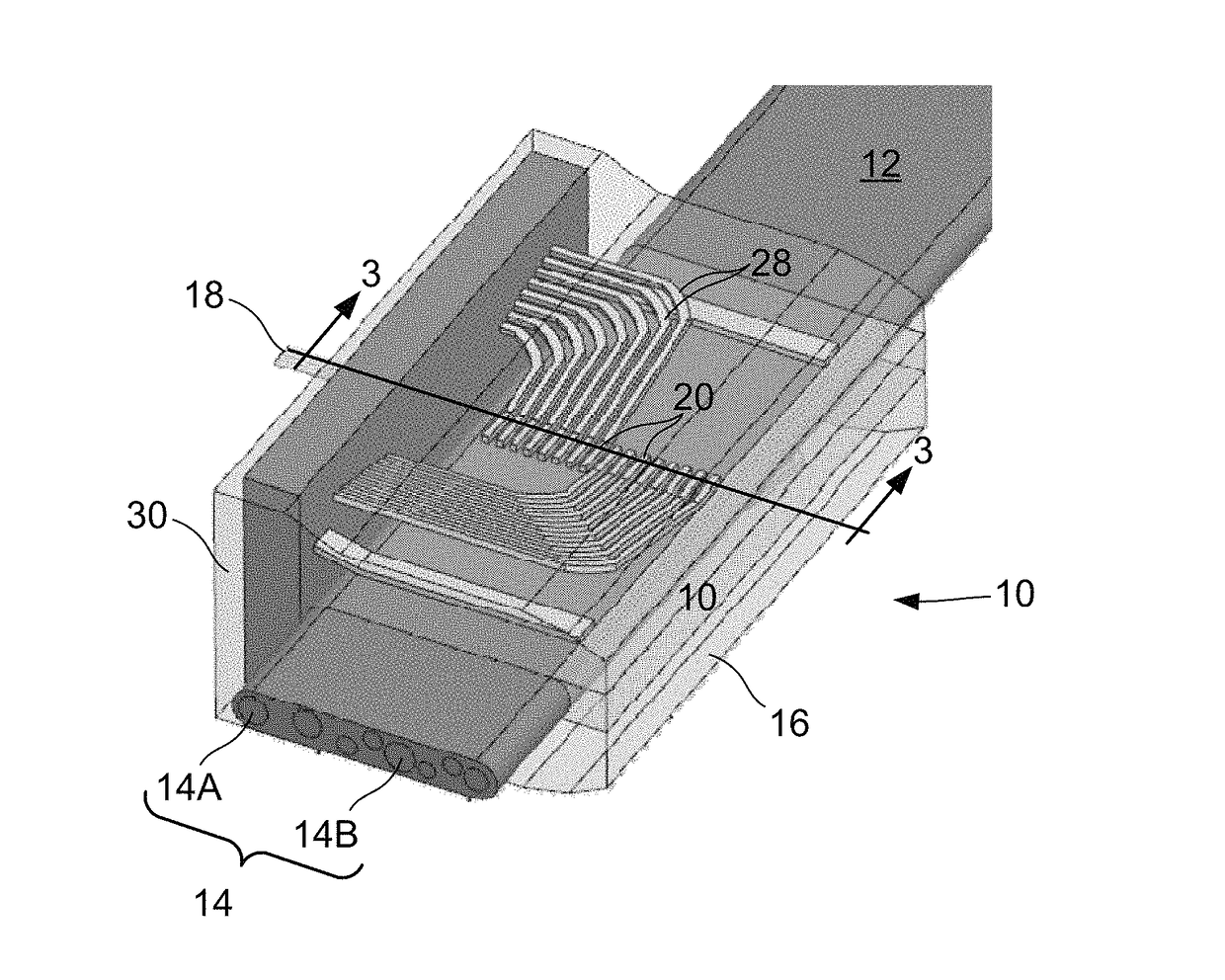

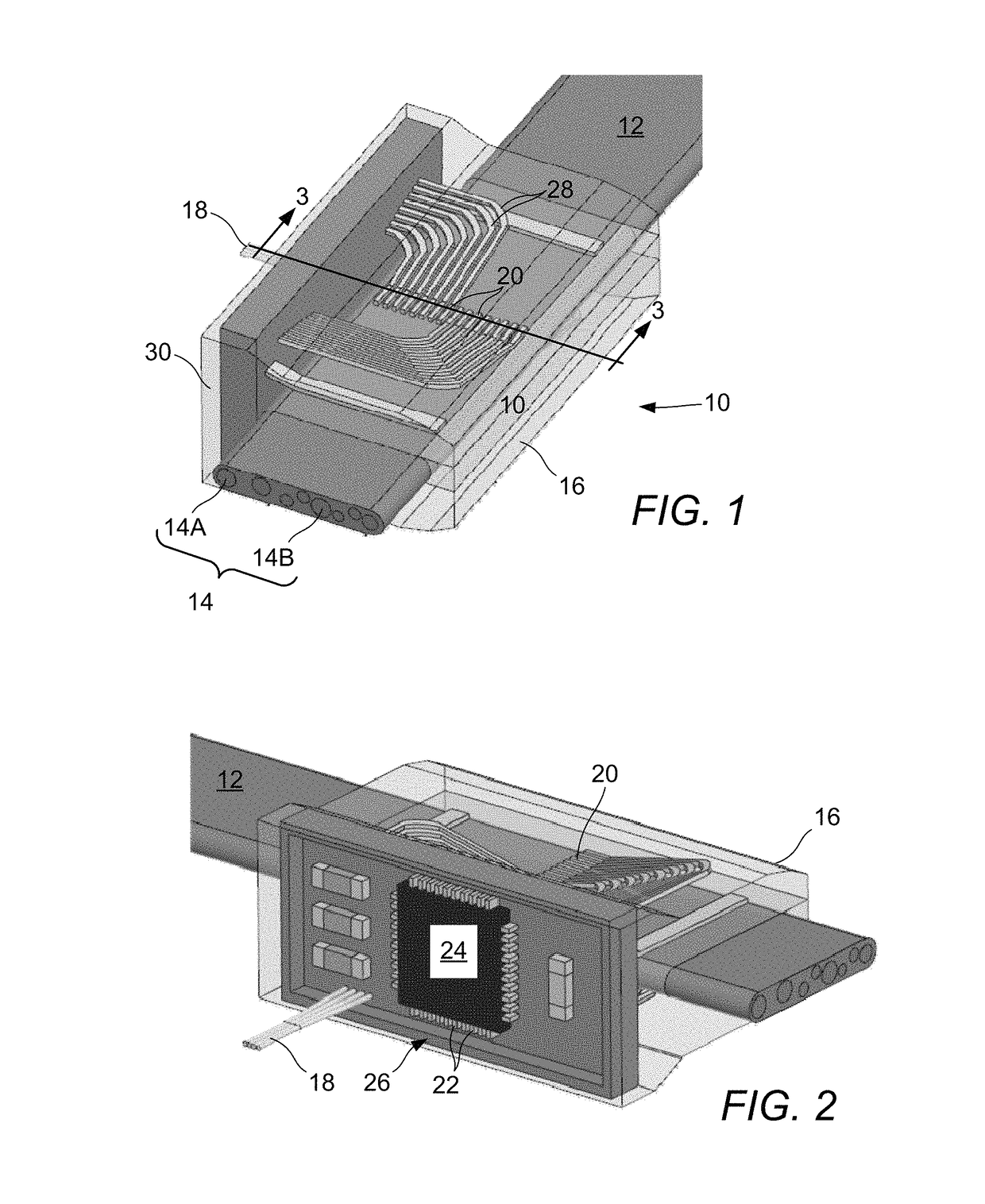

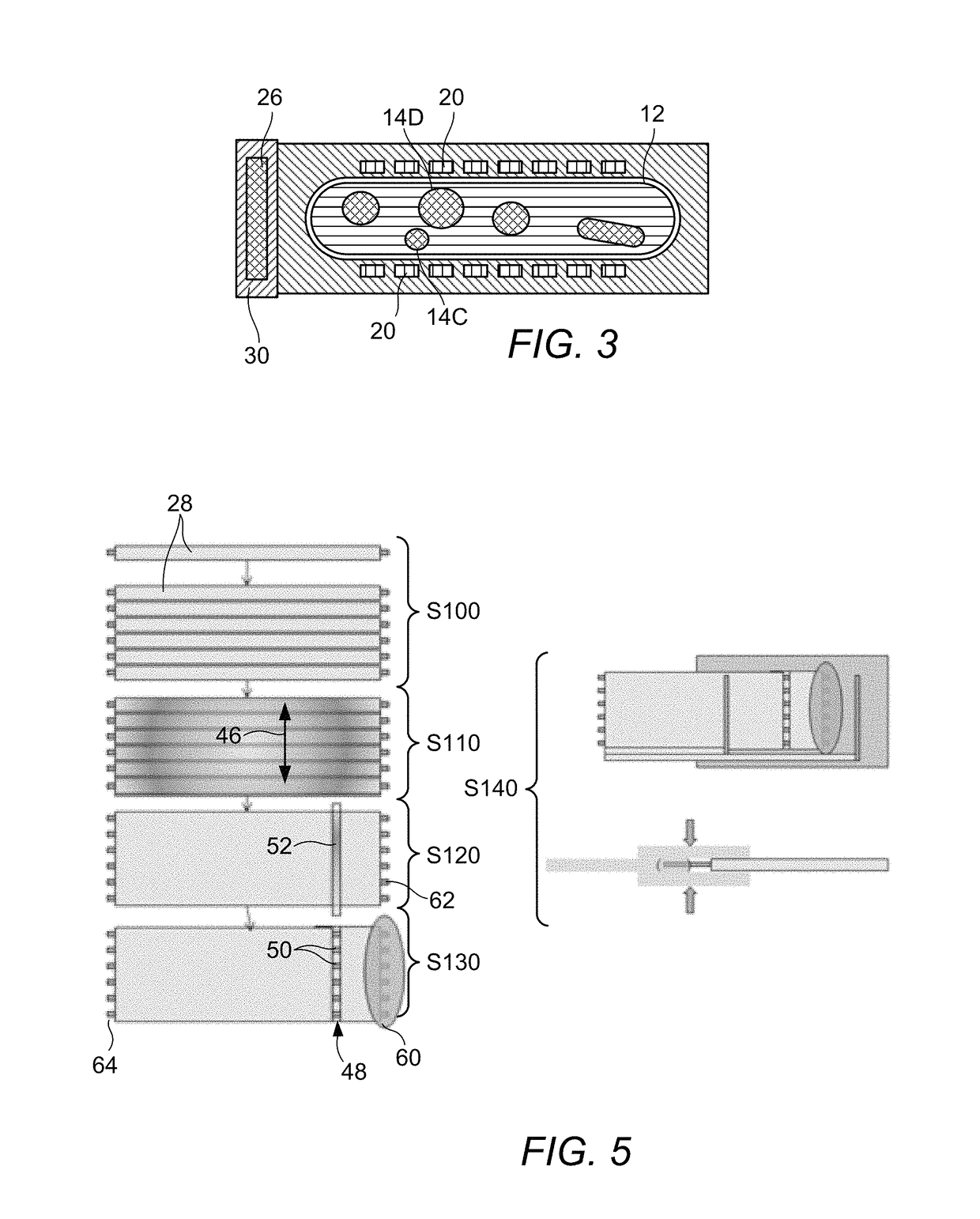

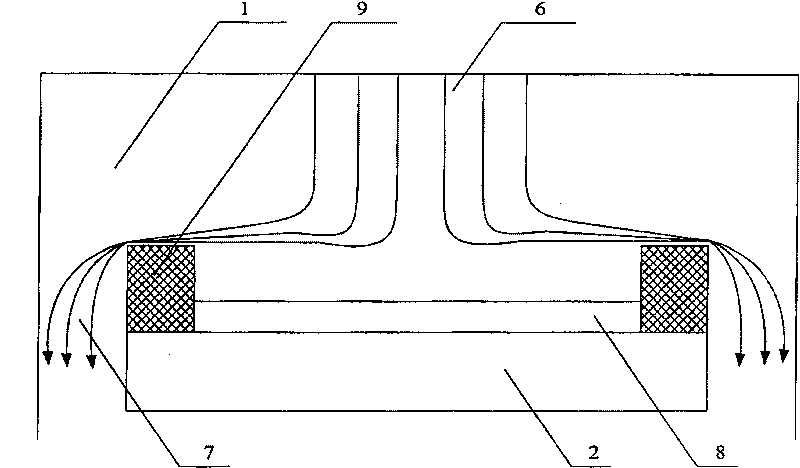

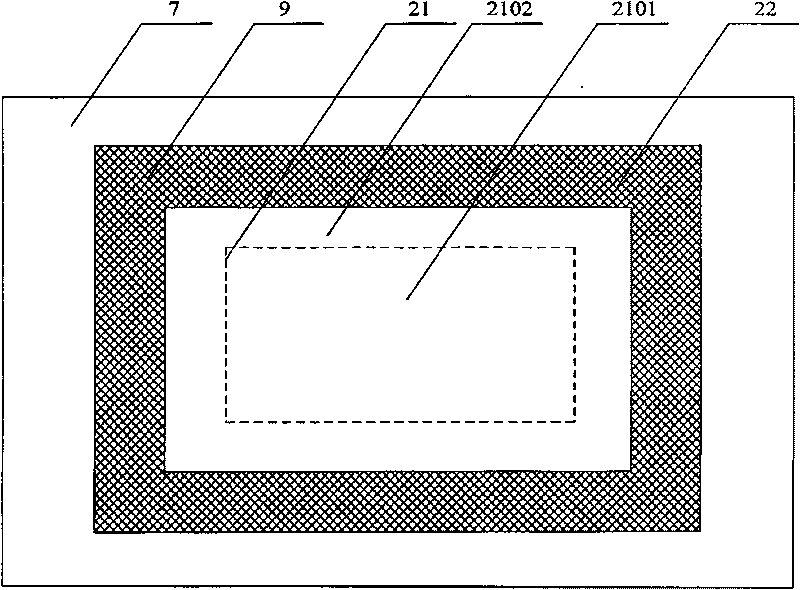

Orthogonal electrical connector with increased contact density

An electrical connector includes a housing that holds signal contacts which are associated as signal contact pairs. The housing has a mounting face and the signal contact pairs are aligned in rows along the mounting face. Each of the rows includes multiple signal contact pairs. Each of the signal contact pairs includes two of the signal contacts aligned on a respective axis. The axes of the signal contact pairs within each row are aligned in a common direction, and the axes of the signal contact pairs in adjacent rows are aligned in respective different directions.

Owner:TE CONNECTIVITY CORP

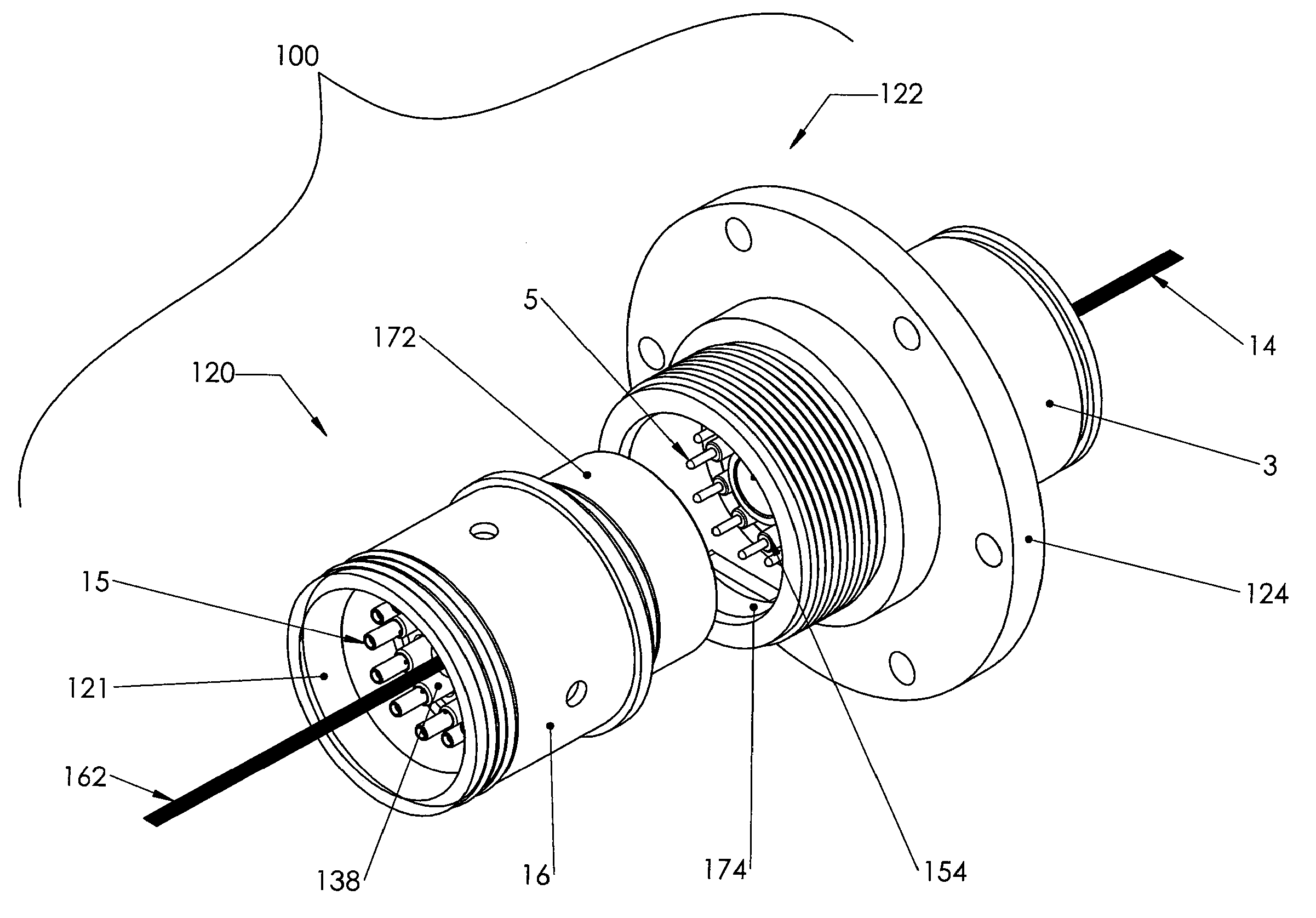

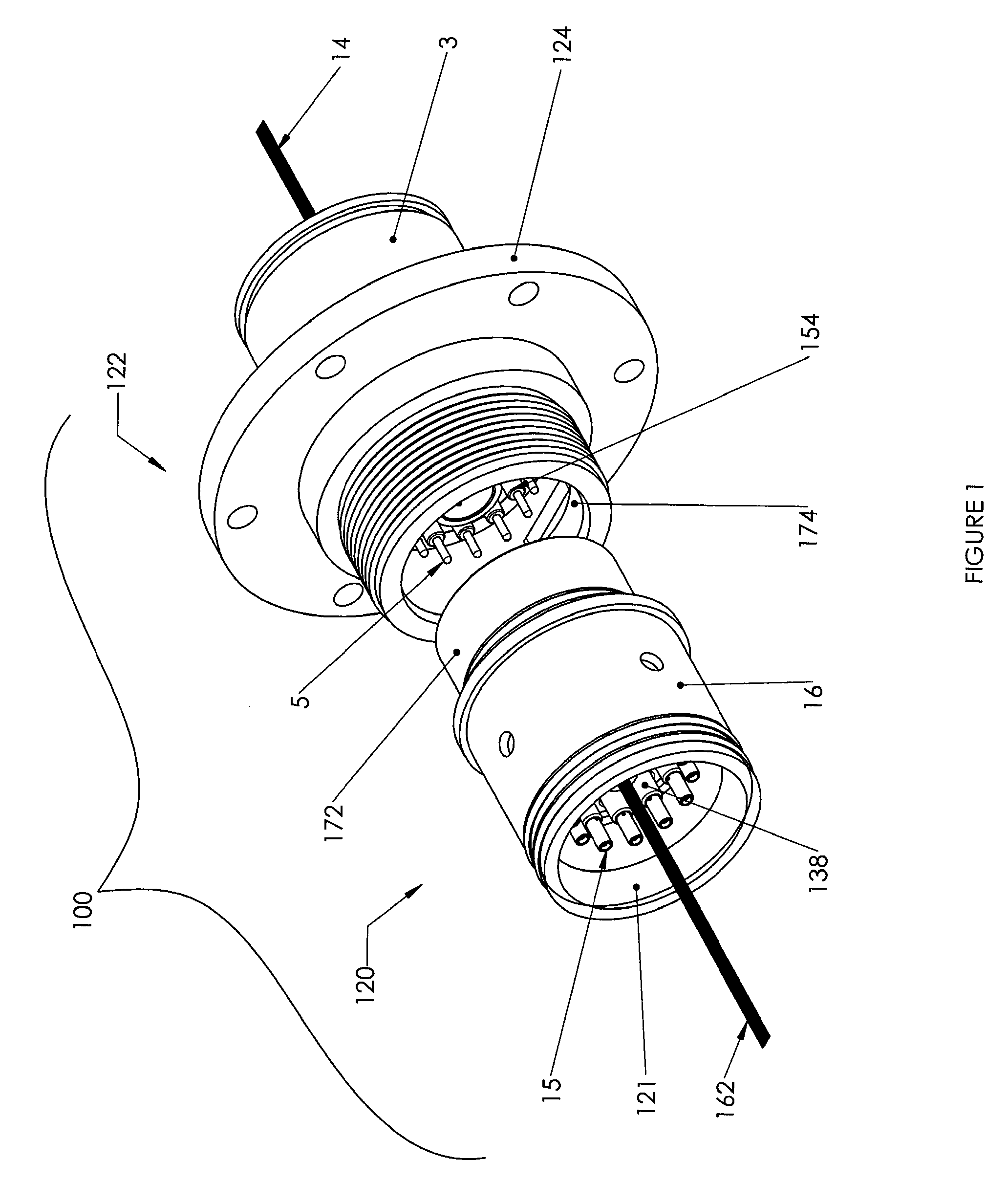

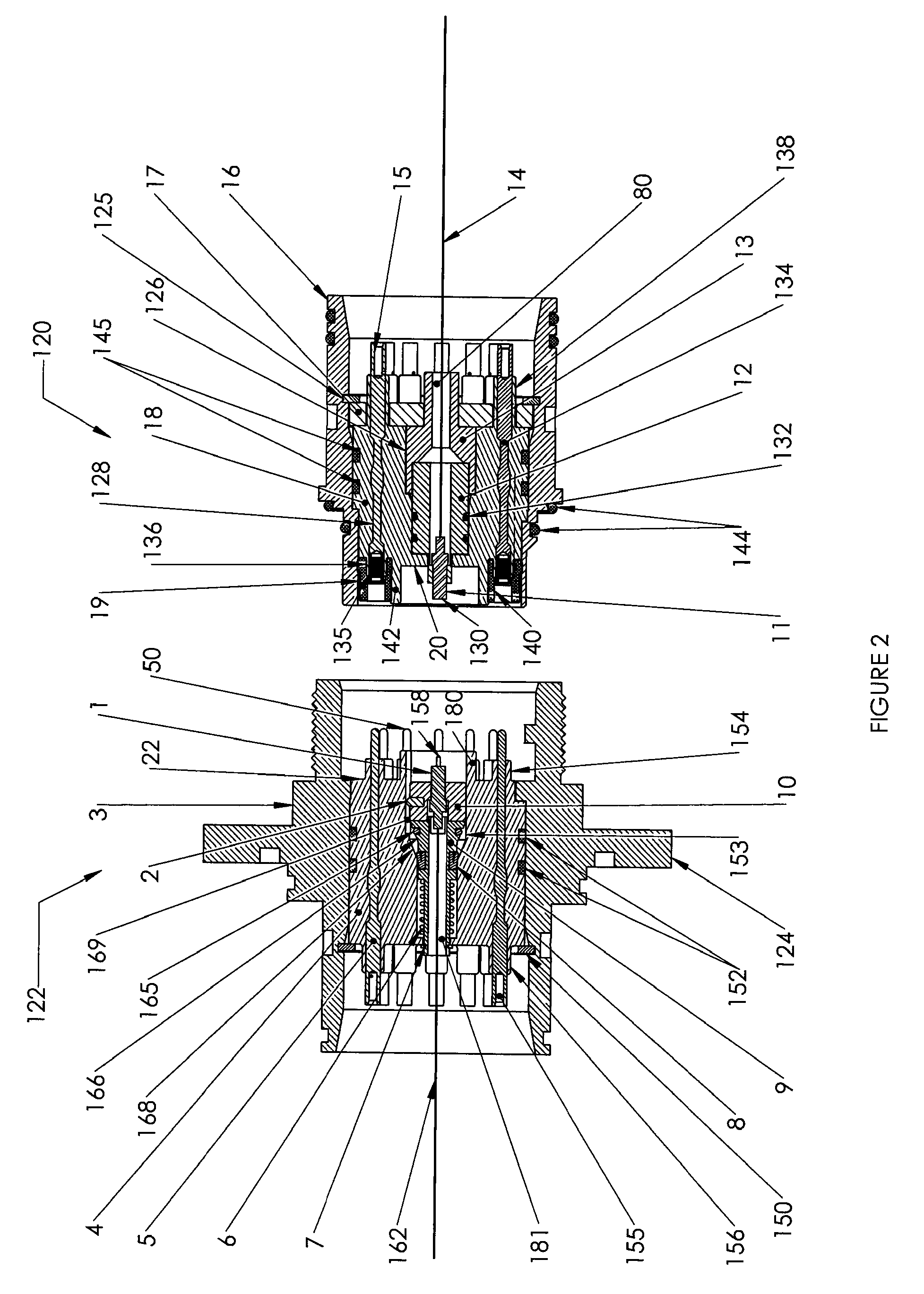

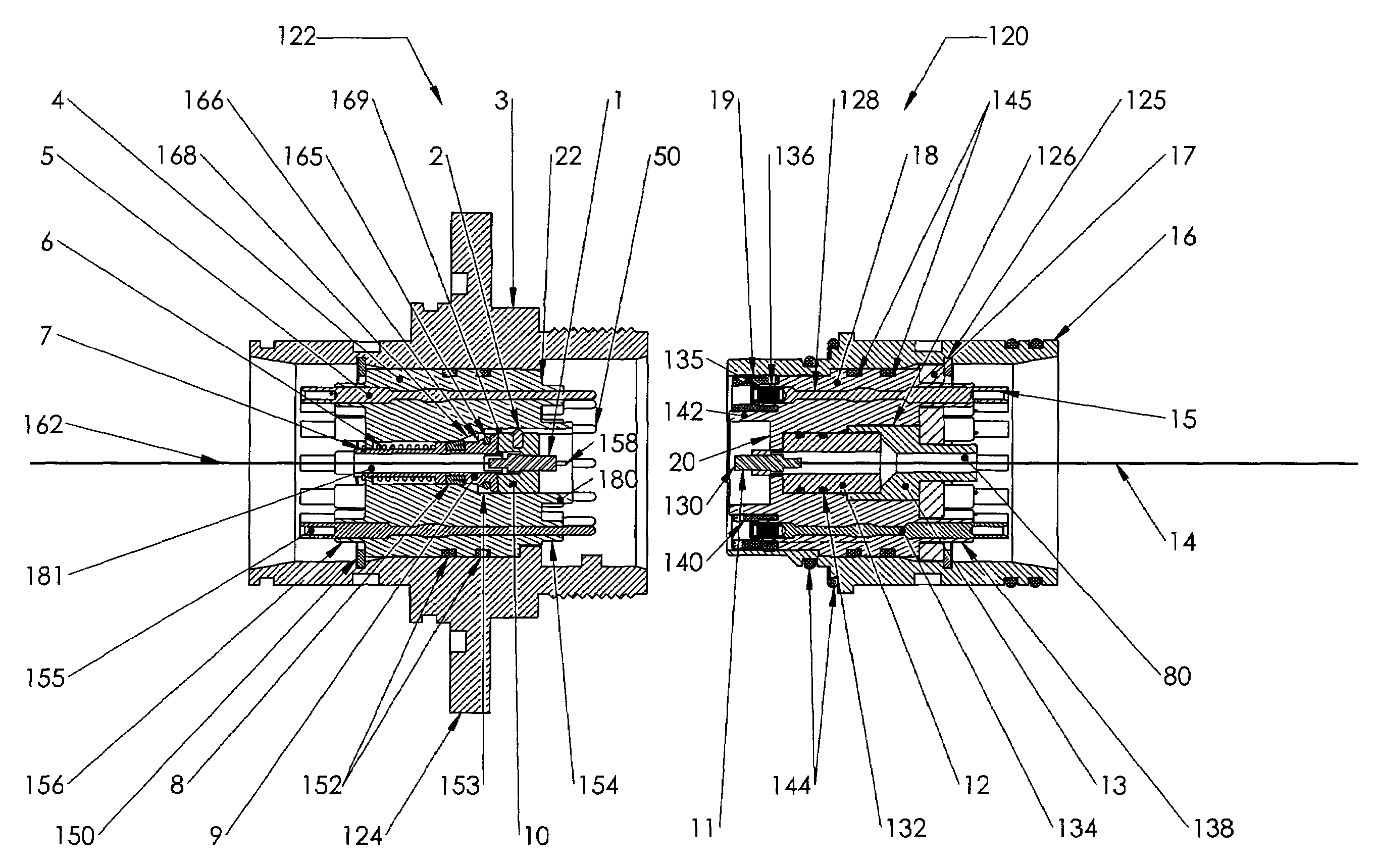

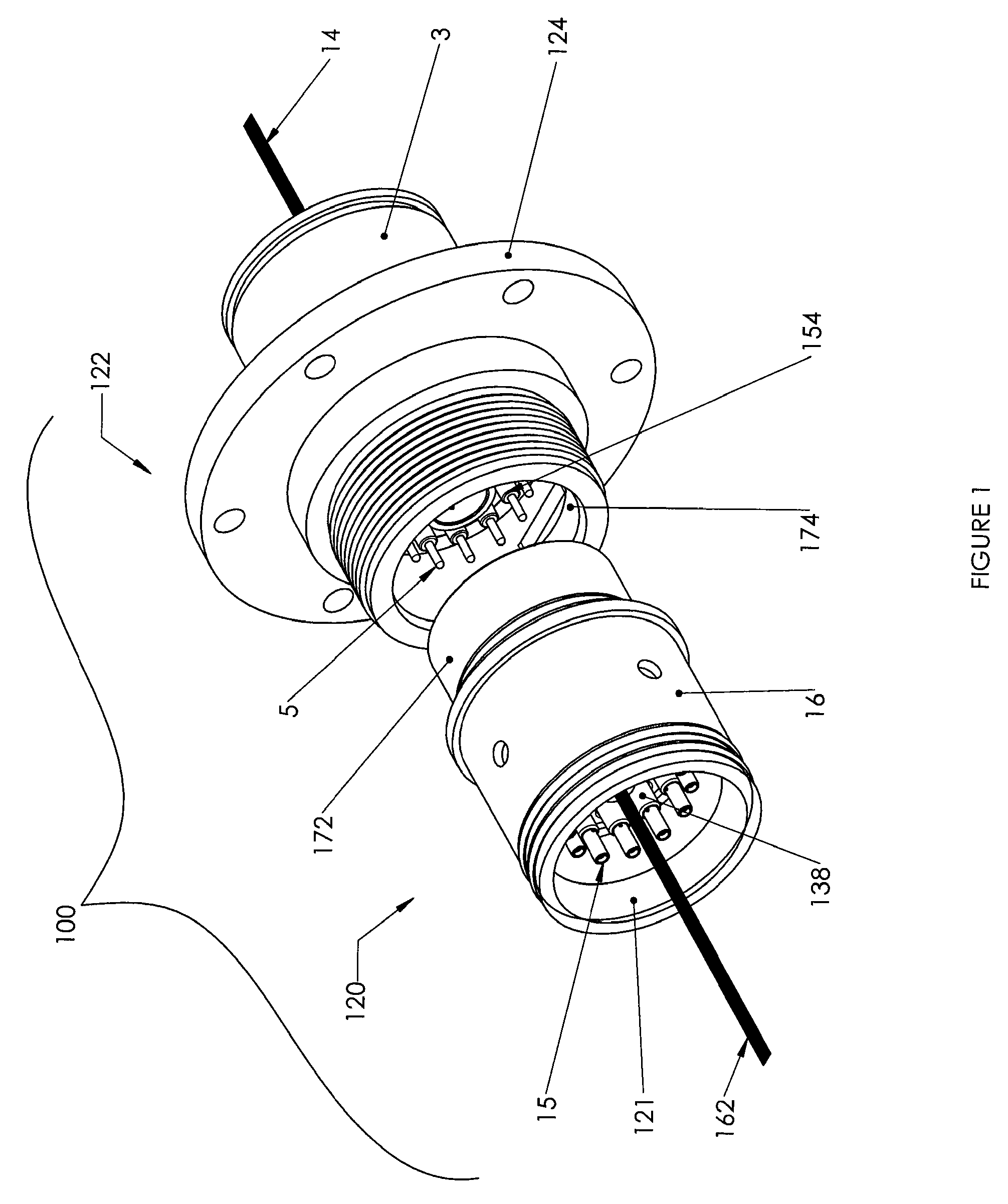

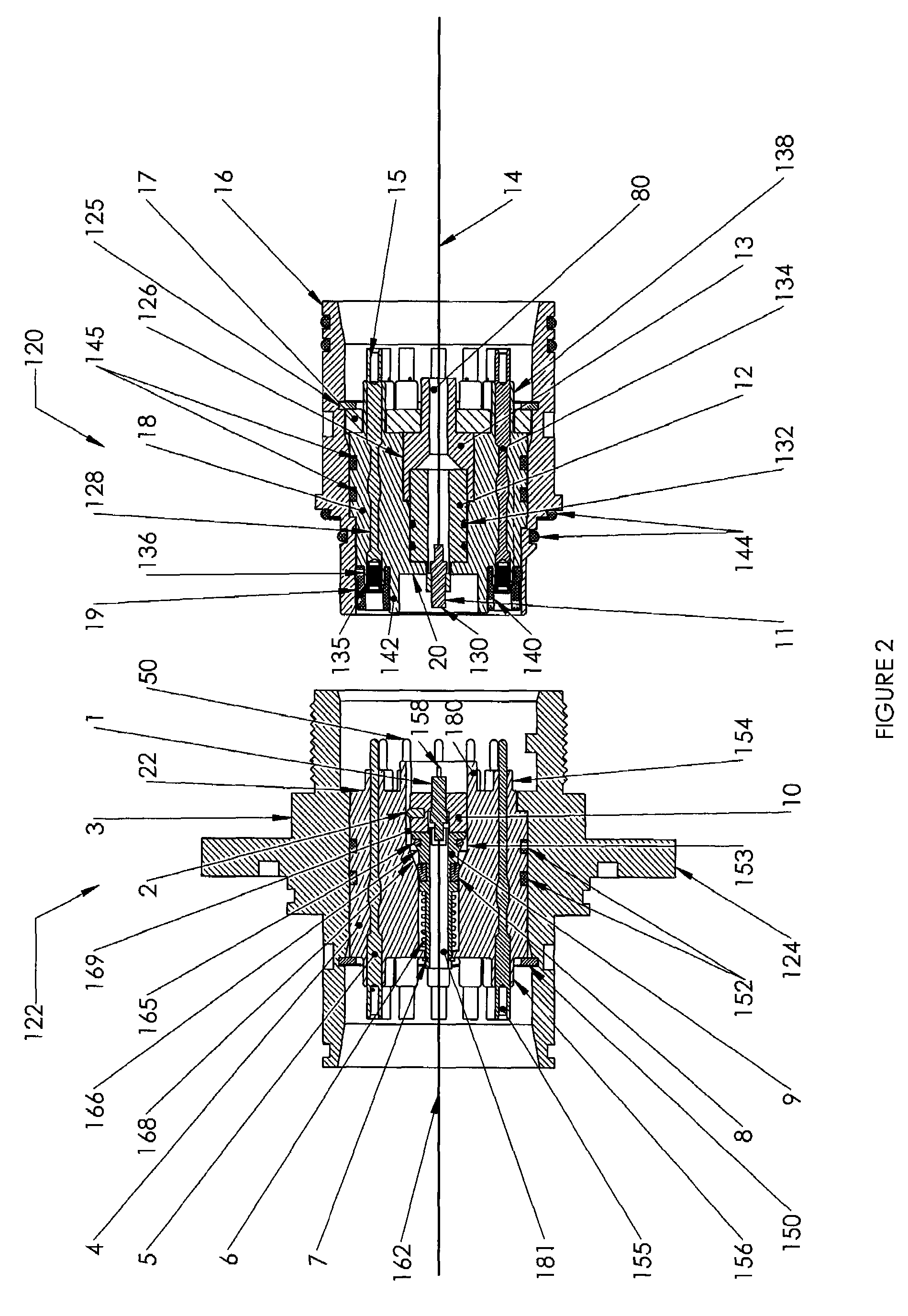

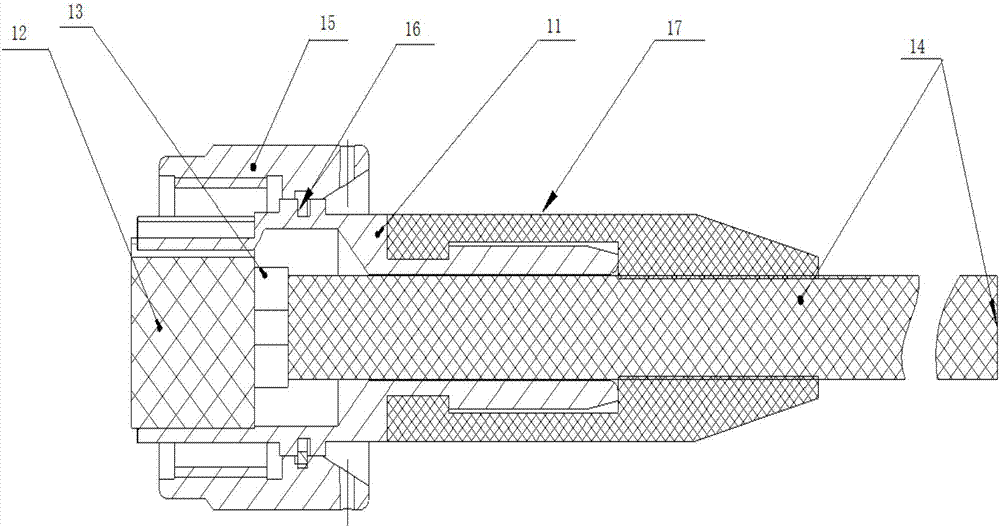

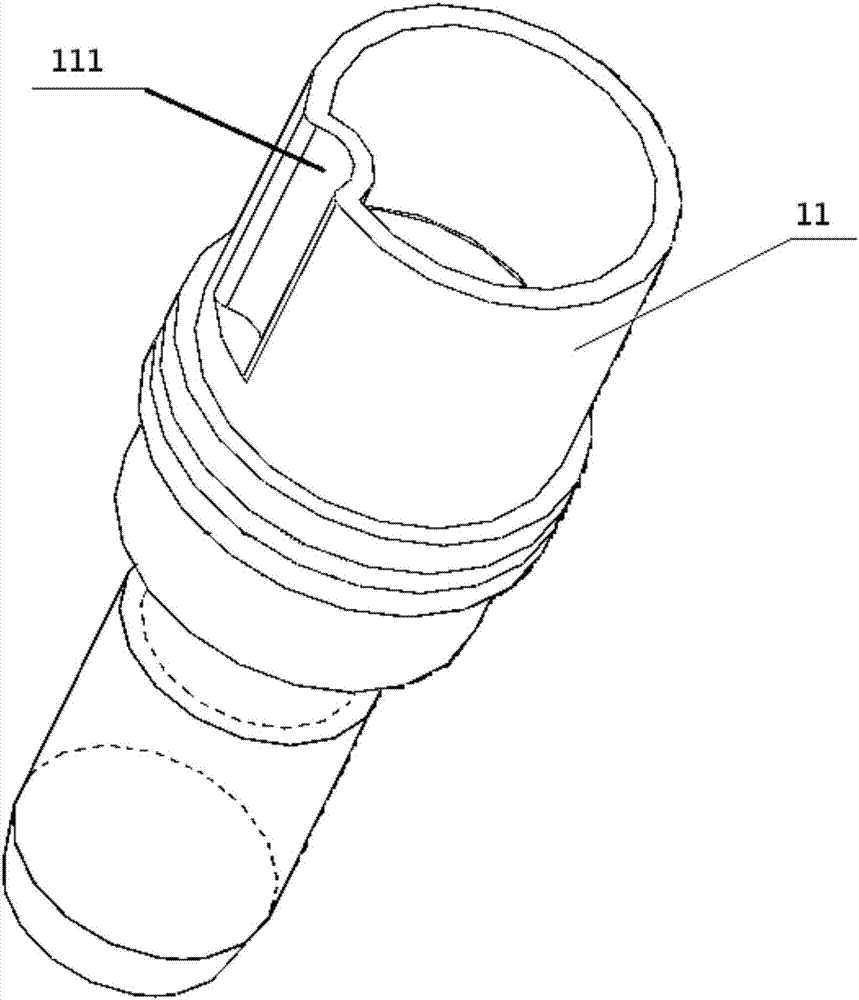

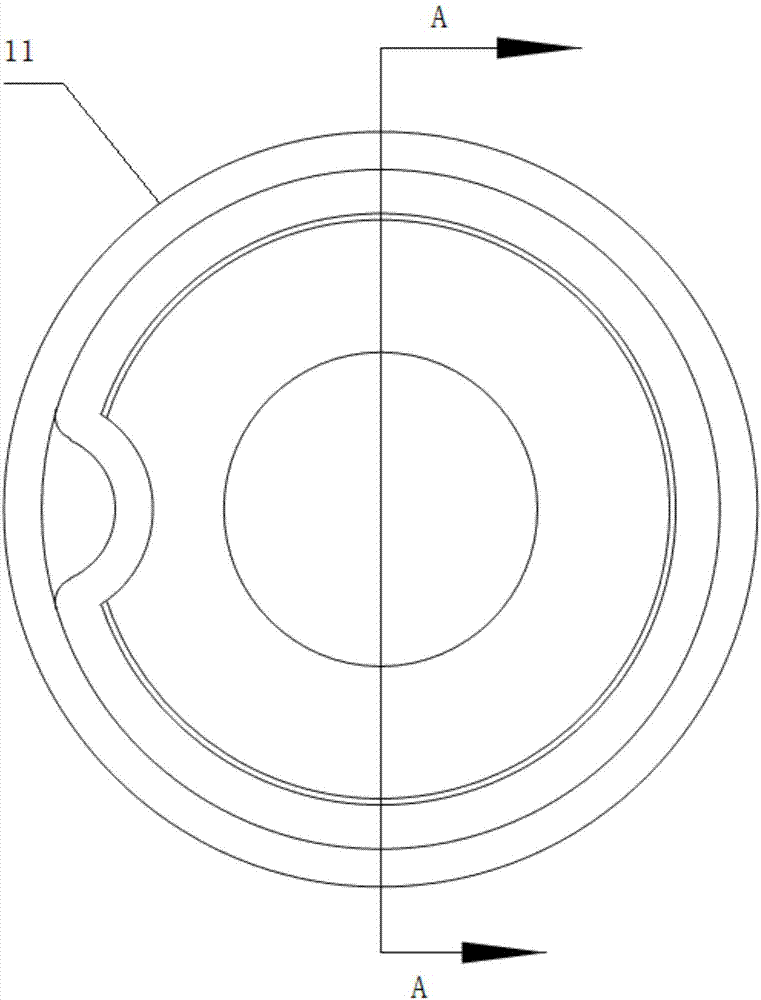

Dry mate connector

ActiveUS20080003868A1Good conditionImprove reliabilitySubstation/switching arrangement detailsCoupling light guidesFiberMating connection

A dry-mate connector has nipples on the front or mating side of the electrical conductors on both the plug and receptacle units which cooperate with an elastomeric seal on the mating end of one of the units to provide an individual seal around each electrical circuit in the mated condition. In a hybrid version of the connector, an optical contact assembly is provided in each unit which has a multi-fiber ferrule at the mating end of the assembly, allowing a high contact density to be achieved in a relatively small space.

Owner:TELEDYNE INSTR INC

Dry mate connector

ActiveUS7481584B2High optical-circuit densityGood conditionSubstation/switching arrangement detailsCoupling light guidesFiberMating connection

A dry-mate connector has nipples on the front or mating side of the electrical conductors on both the plug and receptacle units which cooperate with an elastomeric seal on the mating end of one of the units to provide an individual seal around each electrical circuit in the mated condition. In a hybrid version of the connector, an optical contact assembly is provided in each unit which has a multi-fiber ferrule at the mating end of the assembly, allowing a high contact density to be achieved in a relatively small space.

Owner:TELEDYNE INSTR INC

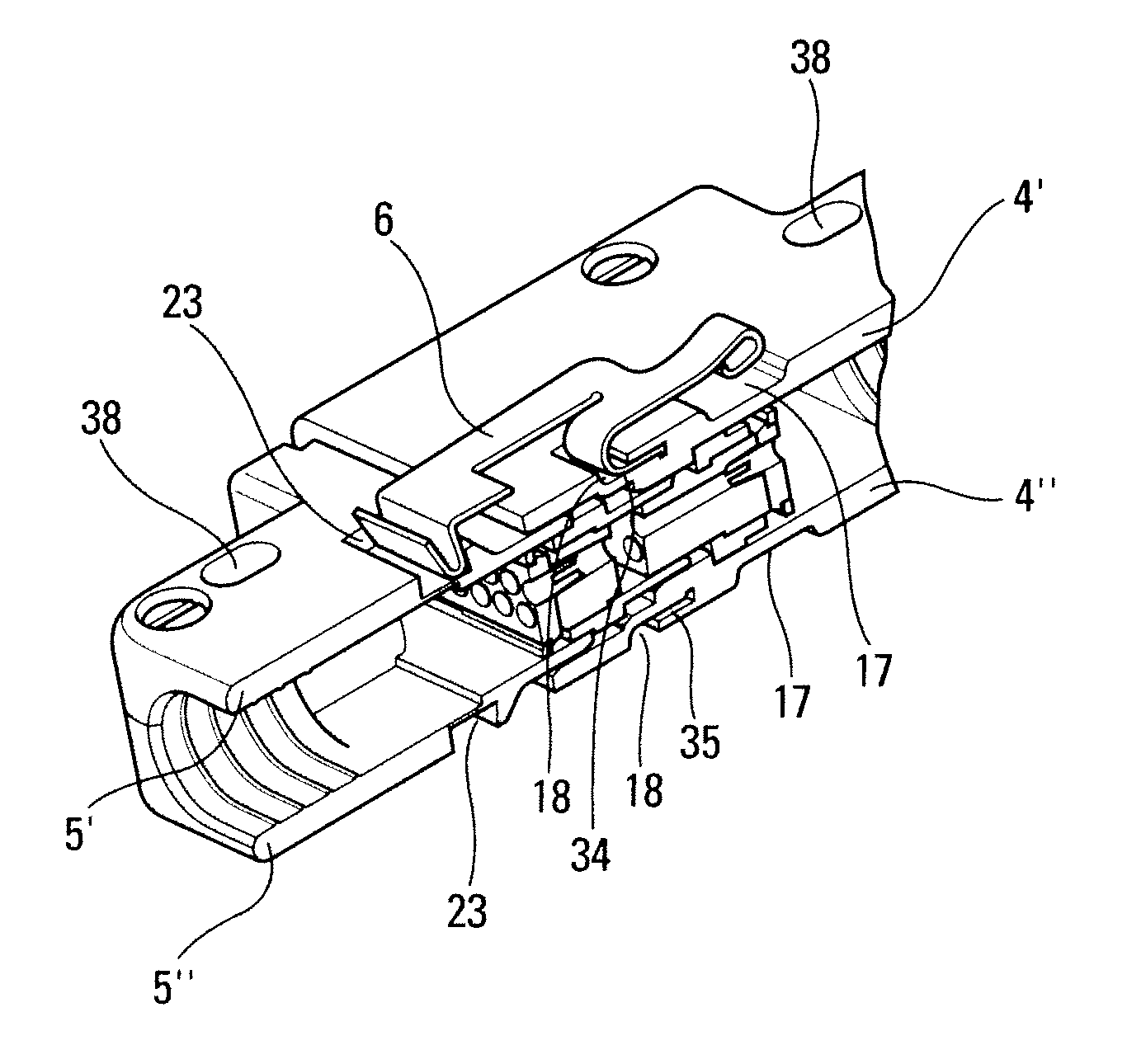

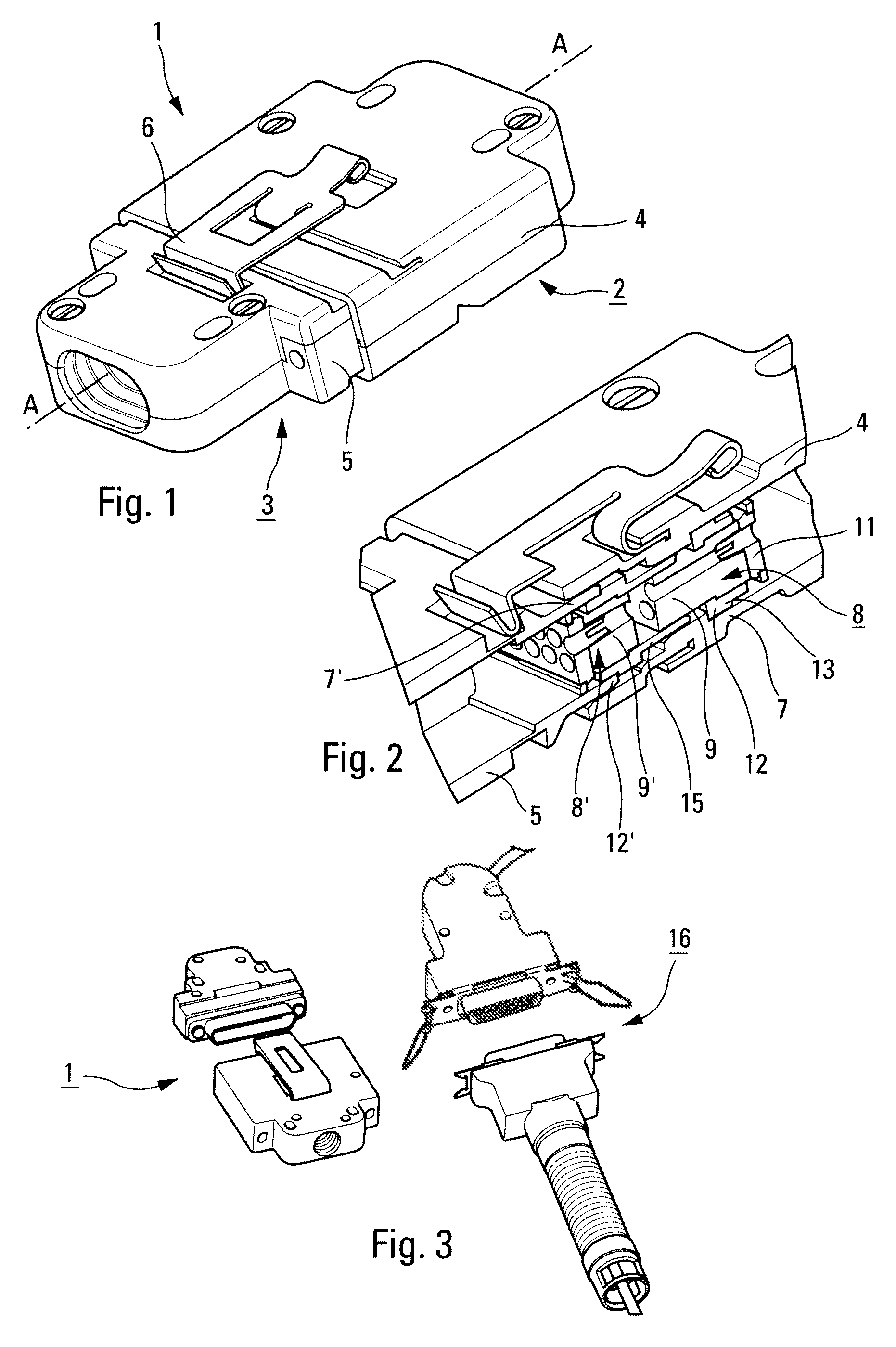

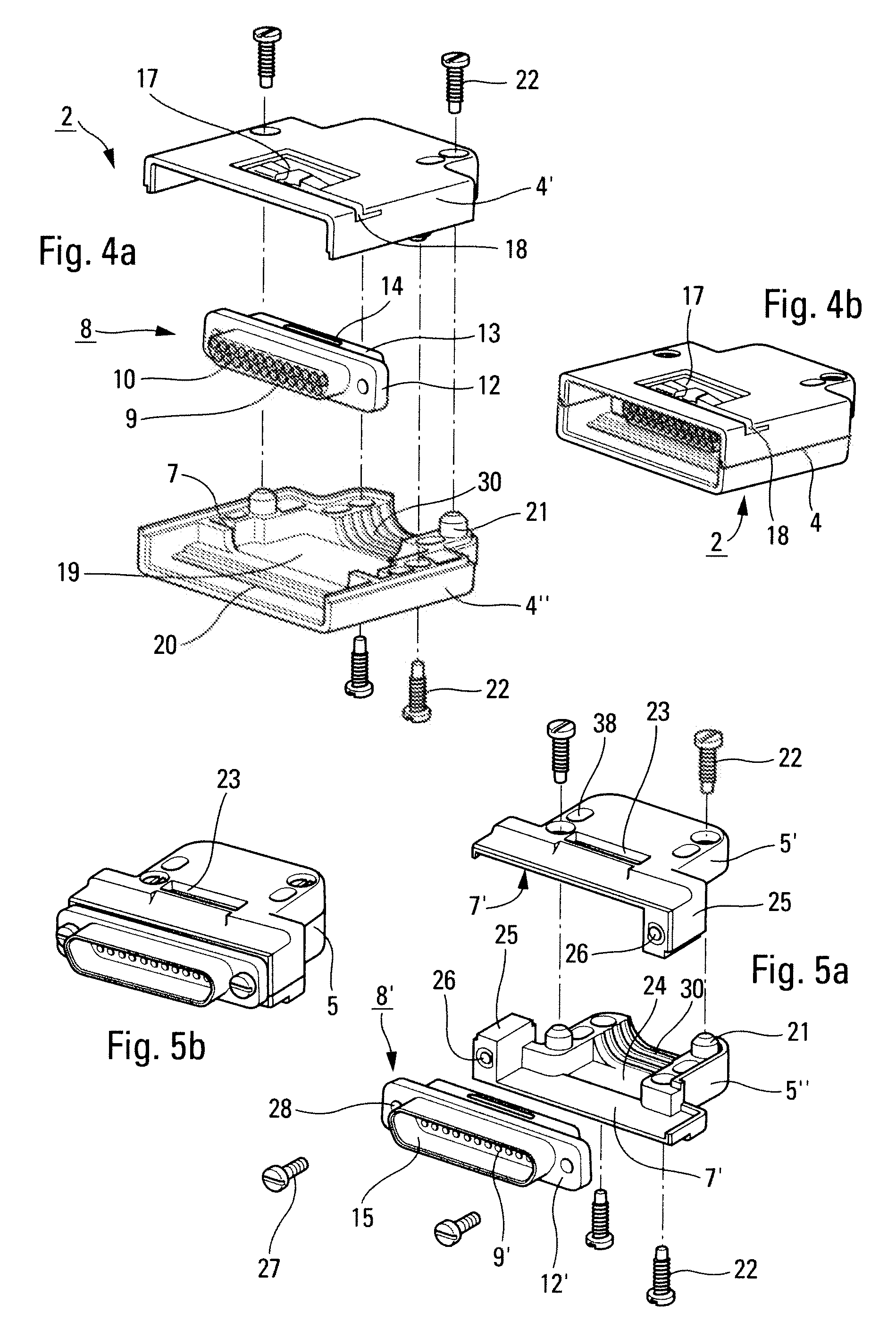

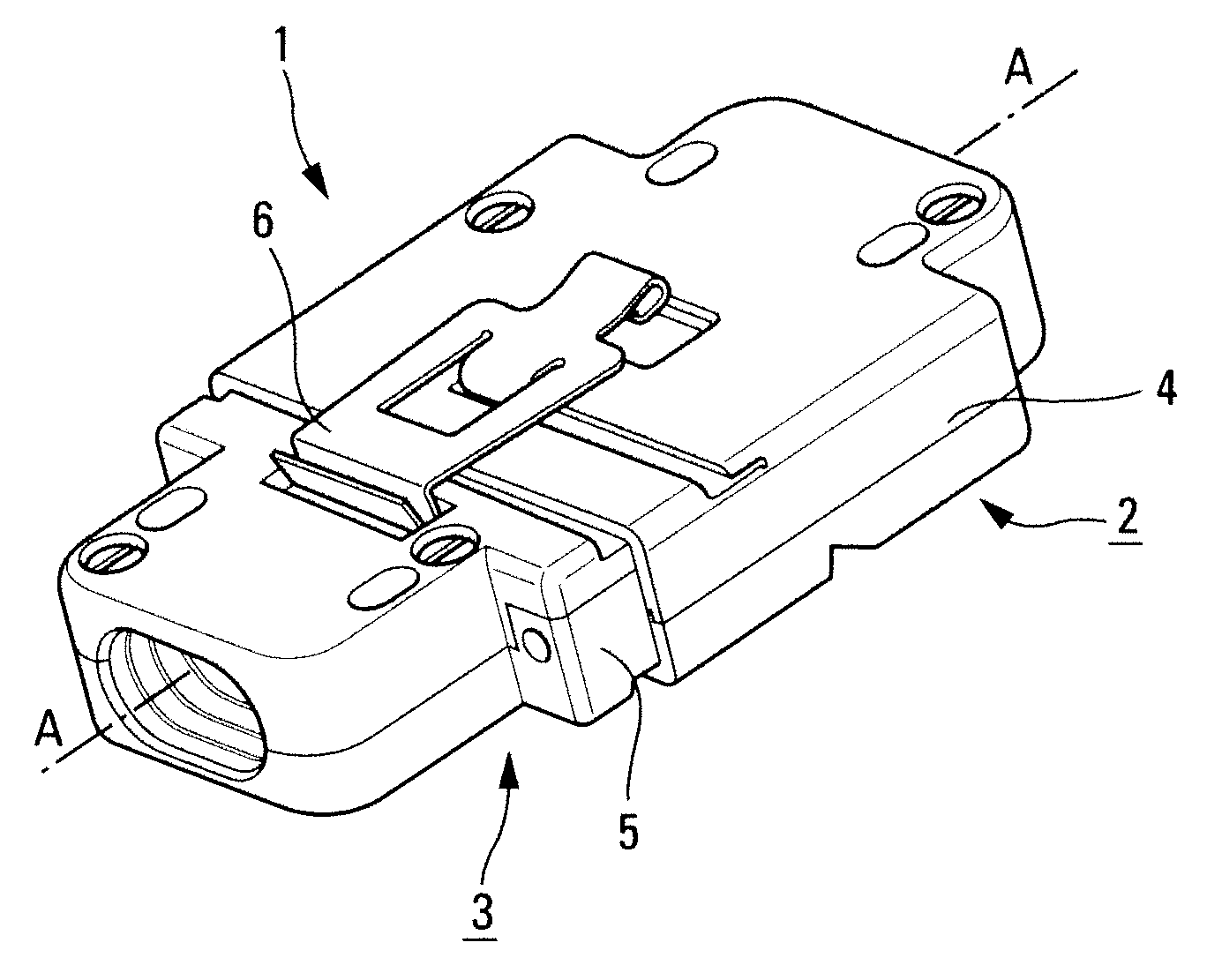

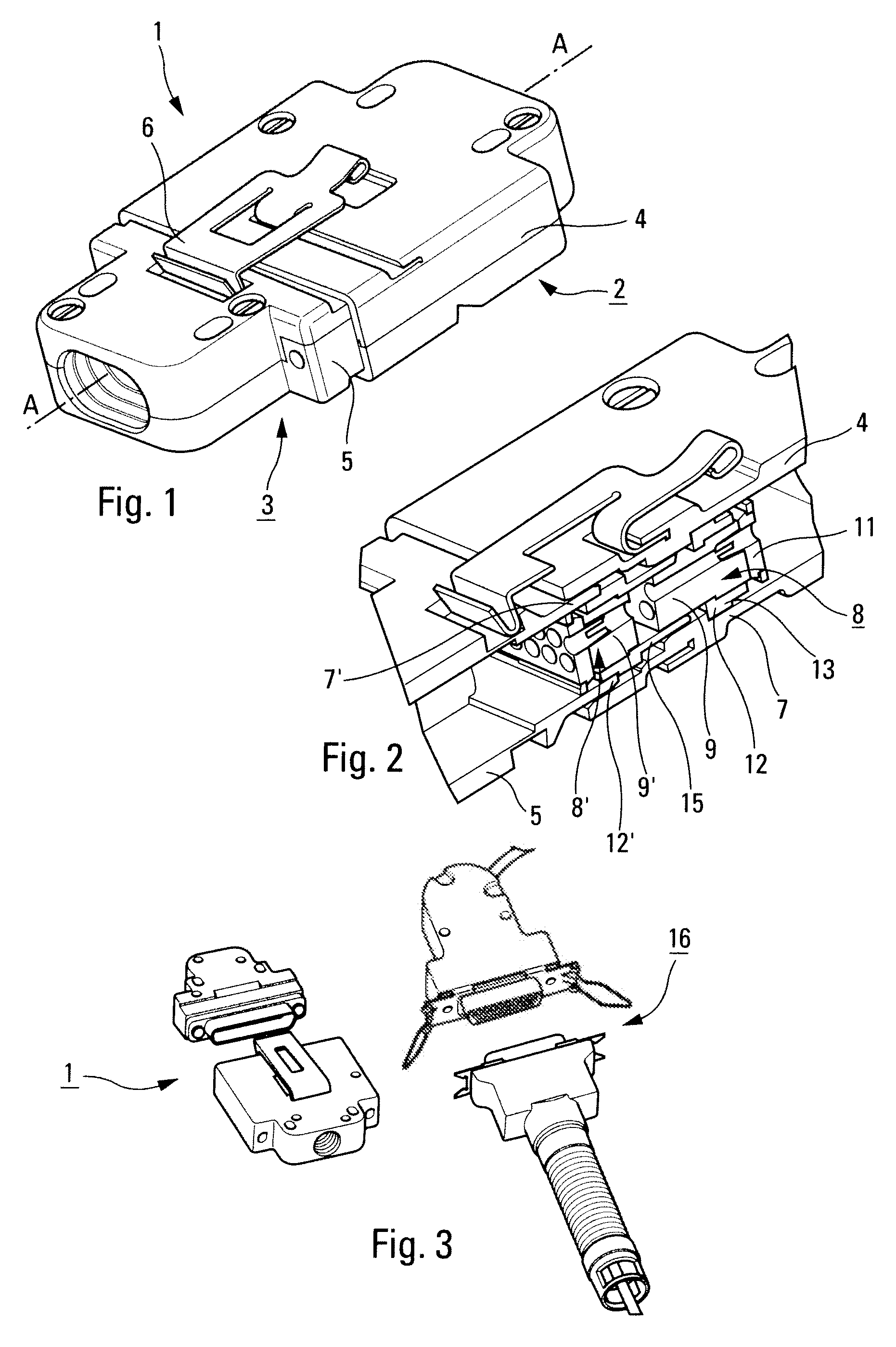

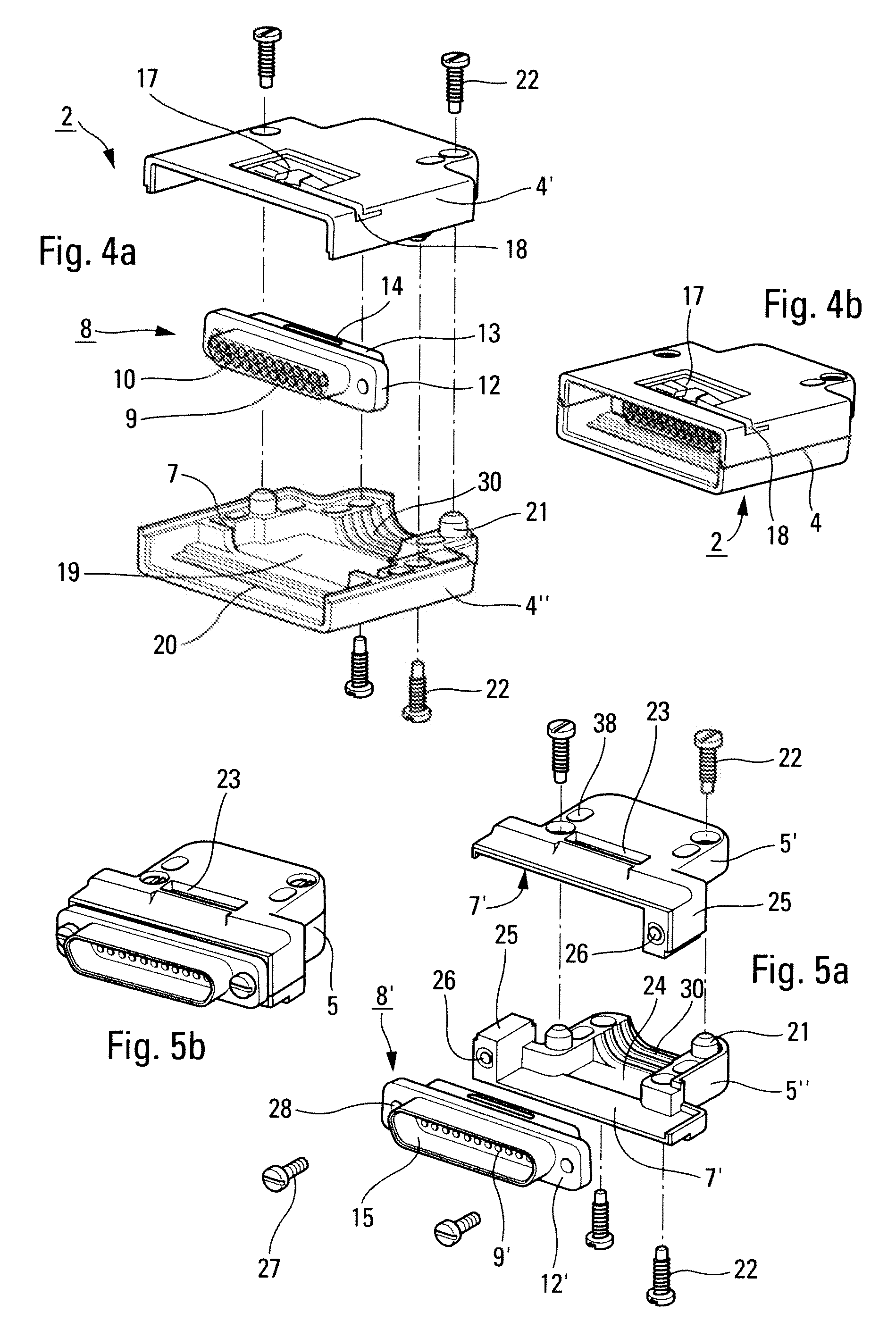

Locking device for a shielded sub-miniature connection assembly

ActiveUS7841889B2Promote recoveryHigh strengthEngagement/disengagement of coupling partsCoupling protective earth/shielding arrangementsEngineeringContact density

Locking device for a shielded sub-miniature connection assembly having two sub-miniature connectors with housings made of two molded thermoplastic half-shells, a high contact density miniature sub-assembly with a molded thermoplastic insulating body provided with contact cavities for the positioning and retention of contacts, wherein one of the housings includes on at least one of its faces a movable metal latch able to co-act with a slot made in at least one of the outside faces of the complementary housing.

Owner:SOURIAU

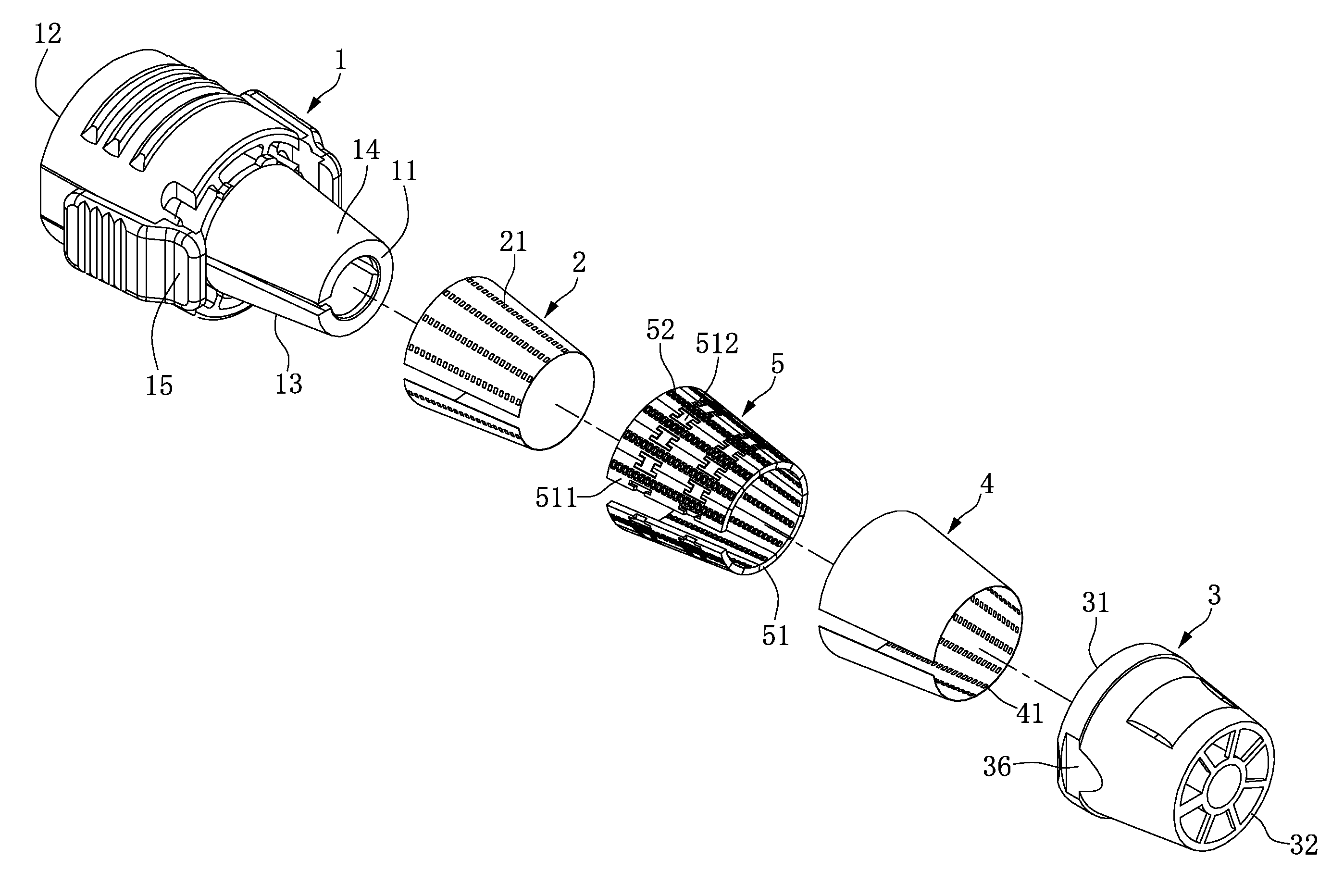

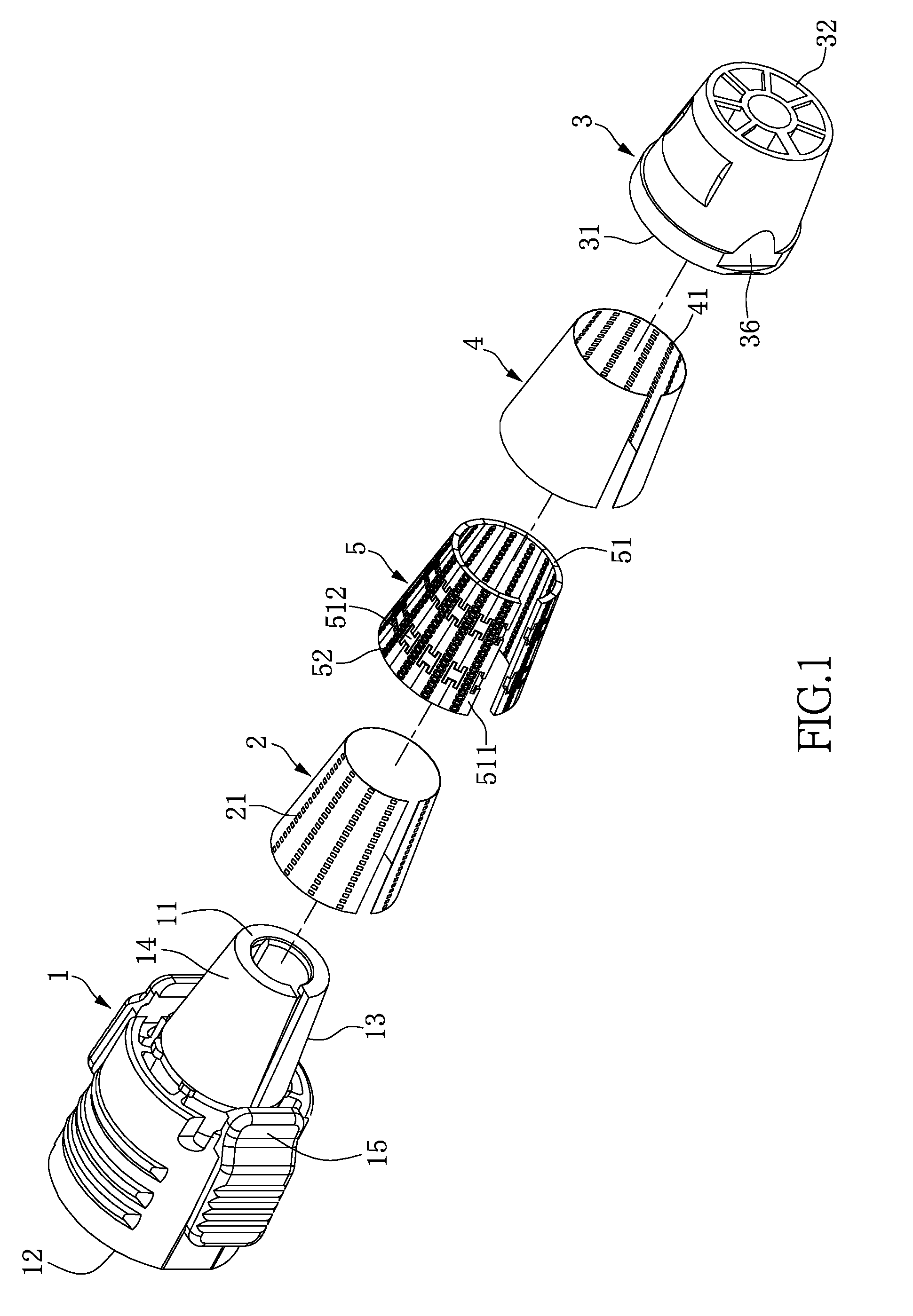

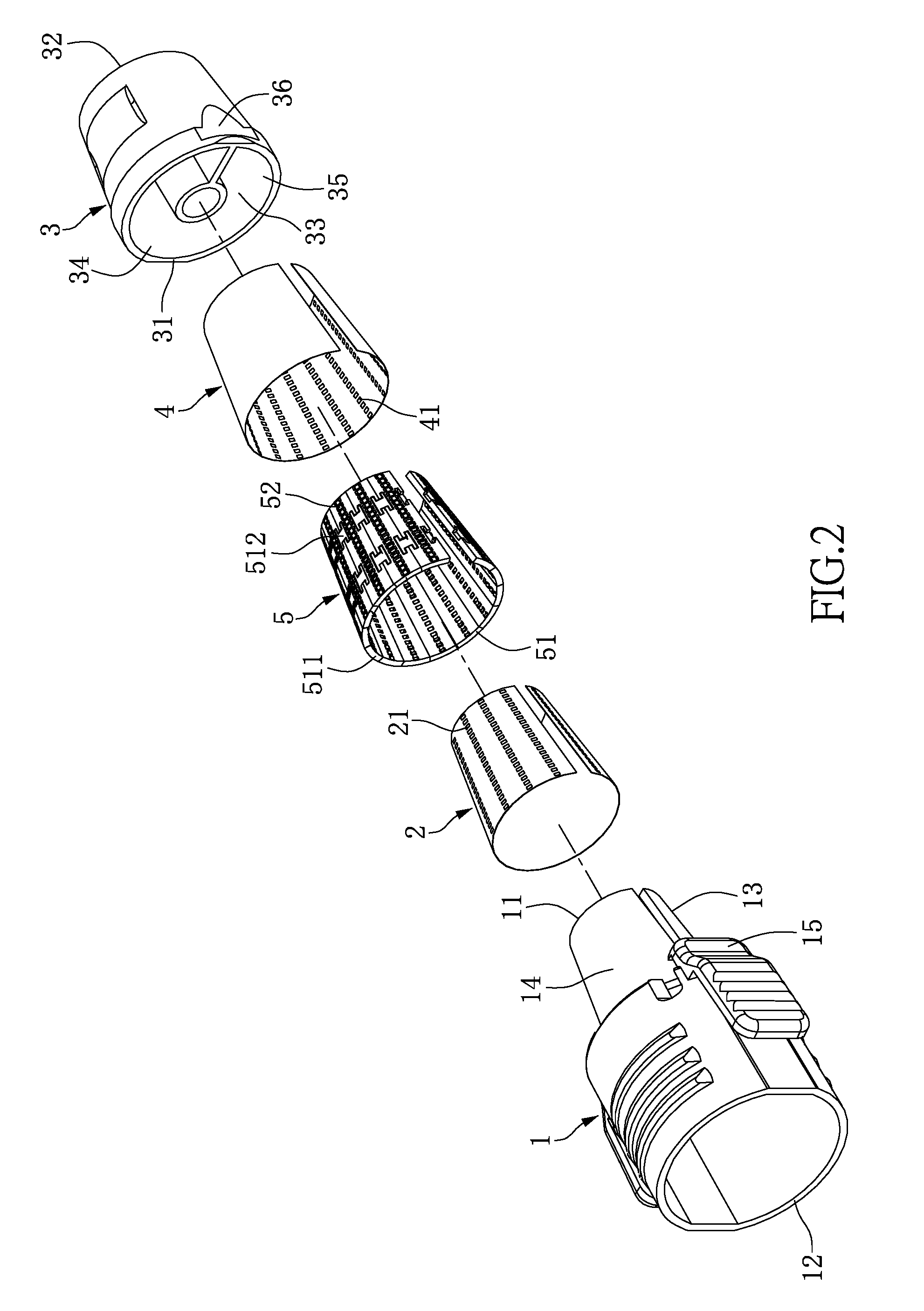

Connector with high contact density

ActiveUS9496638B1High contact densityHigh densityElectrically conductive connectionsIncorrect coupling preventionEngineeringContact density

A connector with high contact density includes interior casing, first contact set, exterior casing, second contact set, and conducting element. The interior casing has a plug portion and a first slope. The first contact set is disposed in the first slope of the interior casing, and the first contact set has a plurality of first contact points. A containing space is formed inside the exterior casing, and the containing space is formed with a second slope, a second contact set is disposed in the second slope and has a plurality of second contact points. A conducting element includes an insulating main body and connecting terminals. The connecting terminals are disposed in the insulating main body and exposed to the exterior and interior of the insulating main body. The plug portion inserts into the containing space, so the first contact points contact the second contact points by the connecting terminals.

Owner:NEXTRONICS ENG CORP

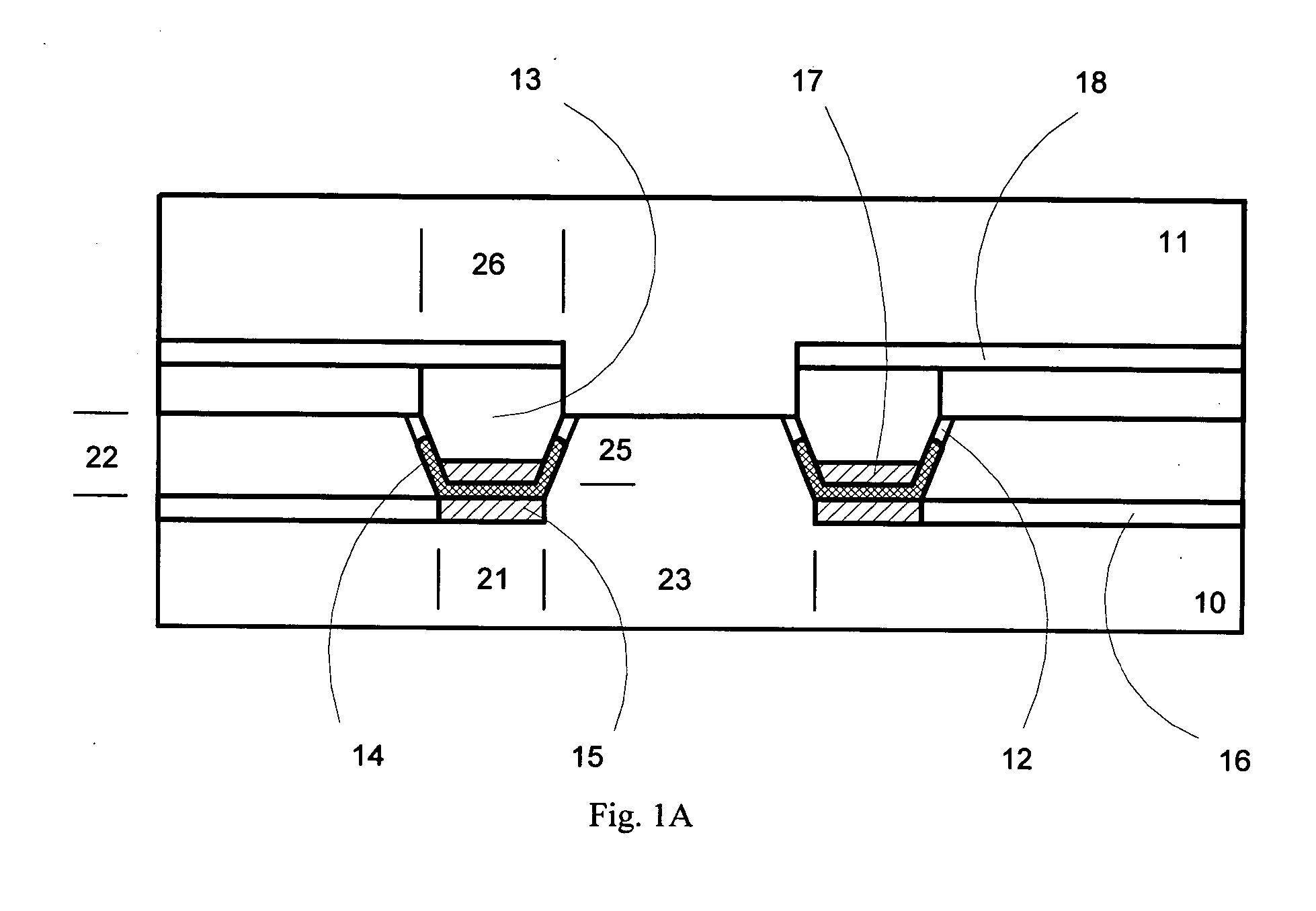

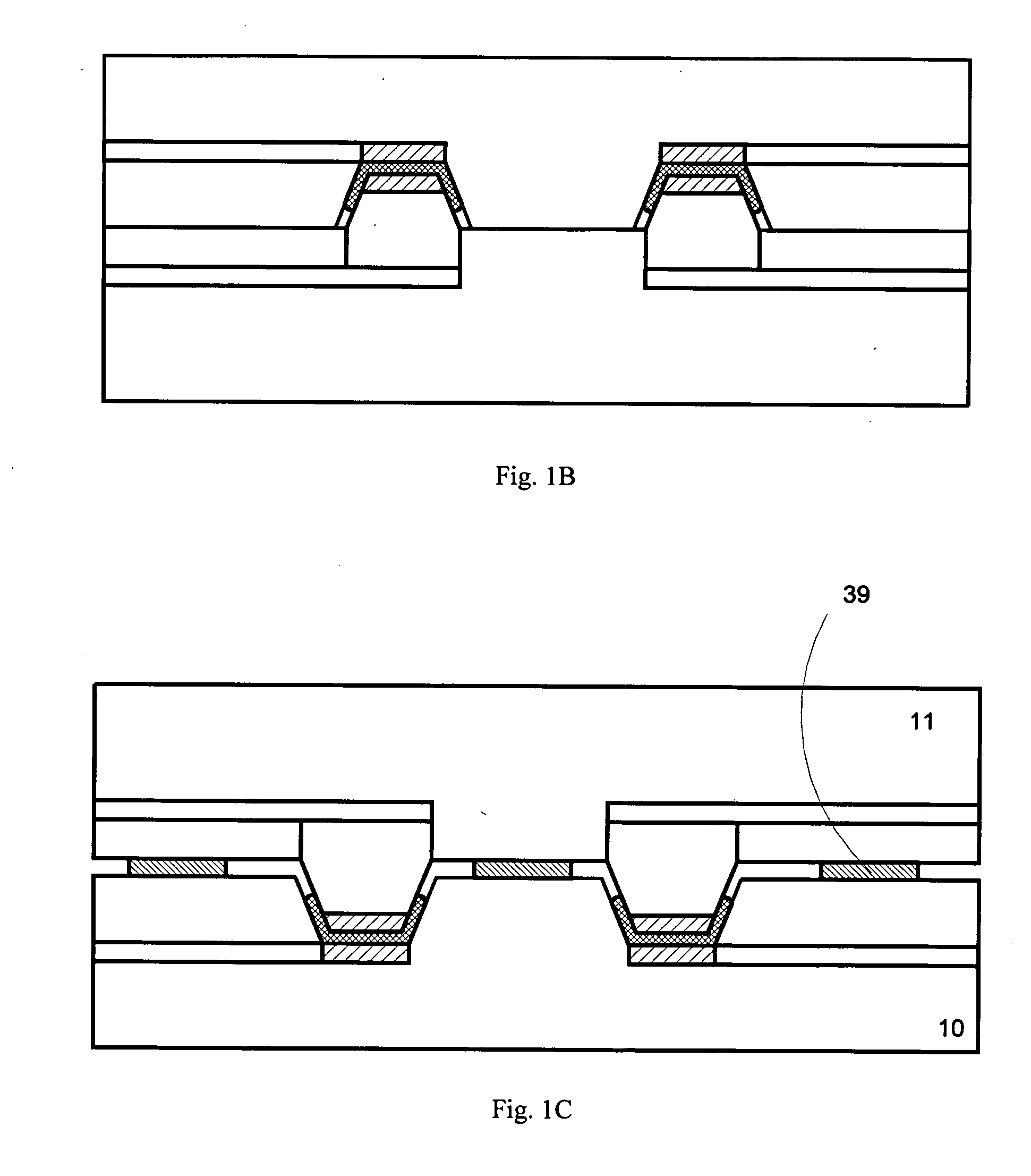

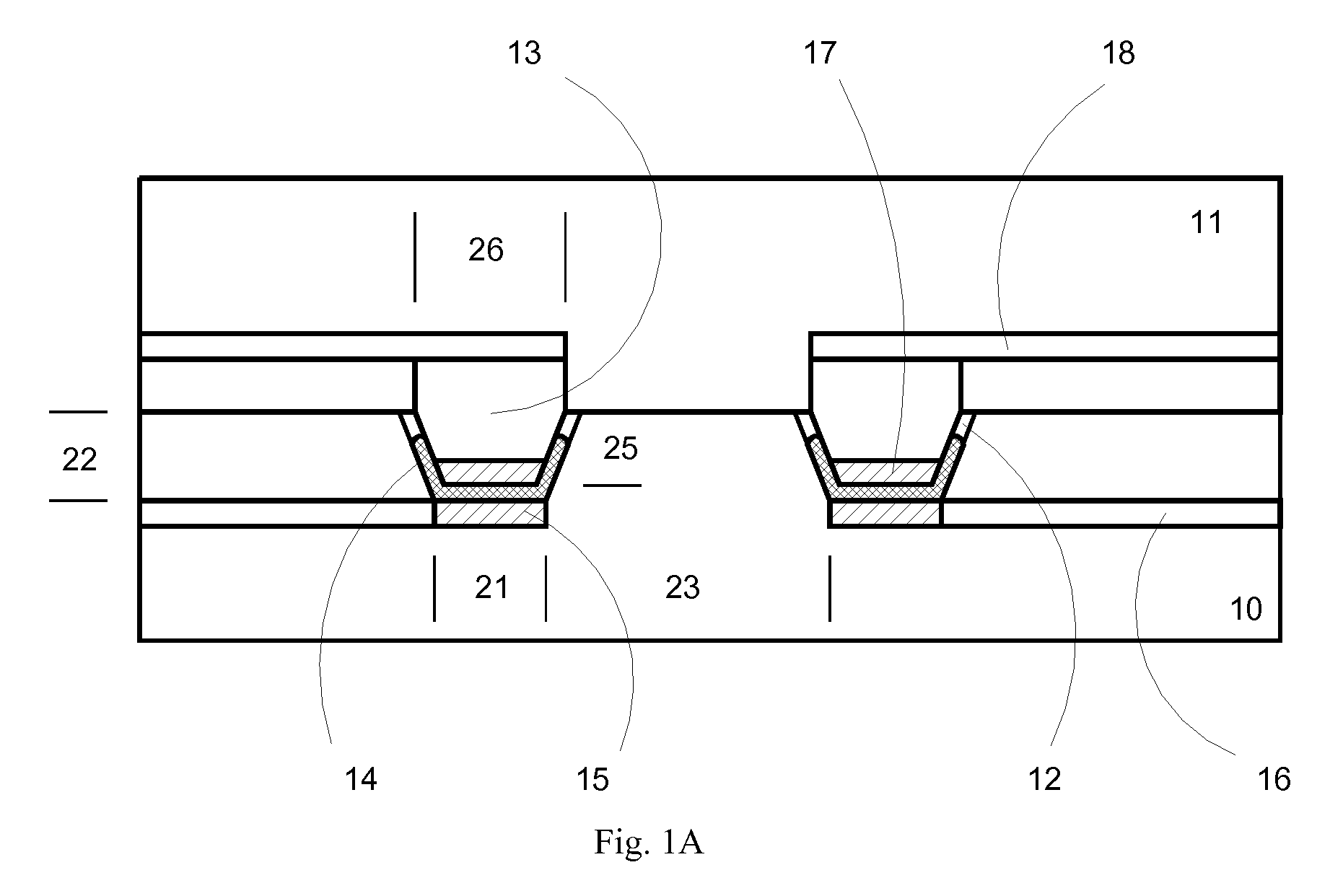

Method of packaging and interconnection of integrated circuits

InactiveUS20070040272A1High densityAdhesionSemiconductor/solid-state device detailsSolid-state devicesMicron scaleContact pad

A semiconductor chip packaging on a flexible substrate is disclosed. The chip and the flexible substrate are provided with corresponding raised and indented micron-scale contact pads with the indented contact pads partially filled with a liquid amalgam. After low temperature amalgam curing, the chip and the substrate form a flexible substrate IC packaging with high conductivity, controllable interface layer thickness, micron-scale contact density and low process temperature. Adhesion between the chip and the substrate can be further enhanced by coating other areas with non-conducting adhesive.

Owner:INTELLEFLEX CORP +1

Locking device for a shielded sub-miniature connection assembly

ActiveUS20080318462A1Avoid placingPromote recoveryCoupling protective earth/shielding arrangementsContact densityElectrical and Electronics engineering

Locking device for a shielded sub-miniature connection assembly having two sub-miniature connectors with housings made of two molded thermoplastic half-shells, a high contact density miniature sub-assembly with a molded thermoplastic insulating body provided with contact cavities for the positioning and retention of contacts, wherein one of the housings includes on at least one of its faces a movable metal latch able to co-act with a slot made in at least one of the outside faces of the complementary housing.

Owner:SOURIAU

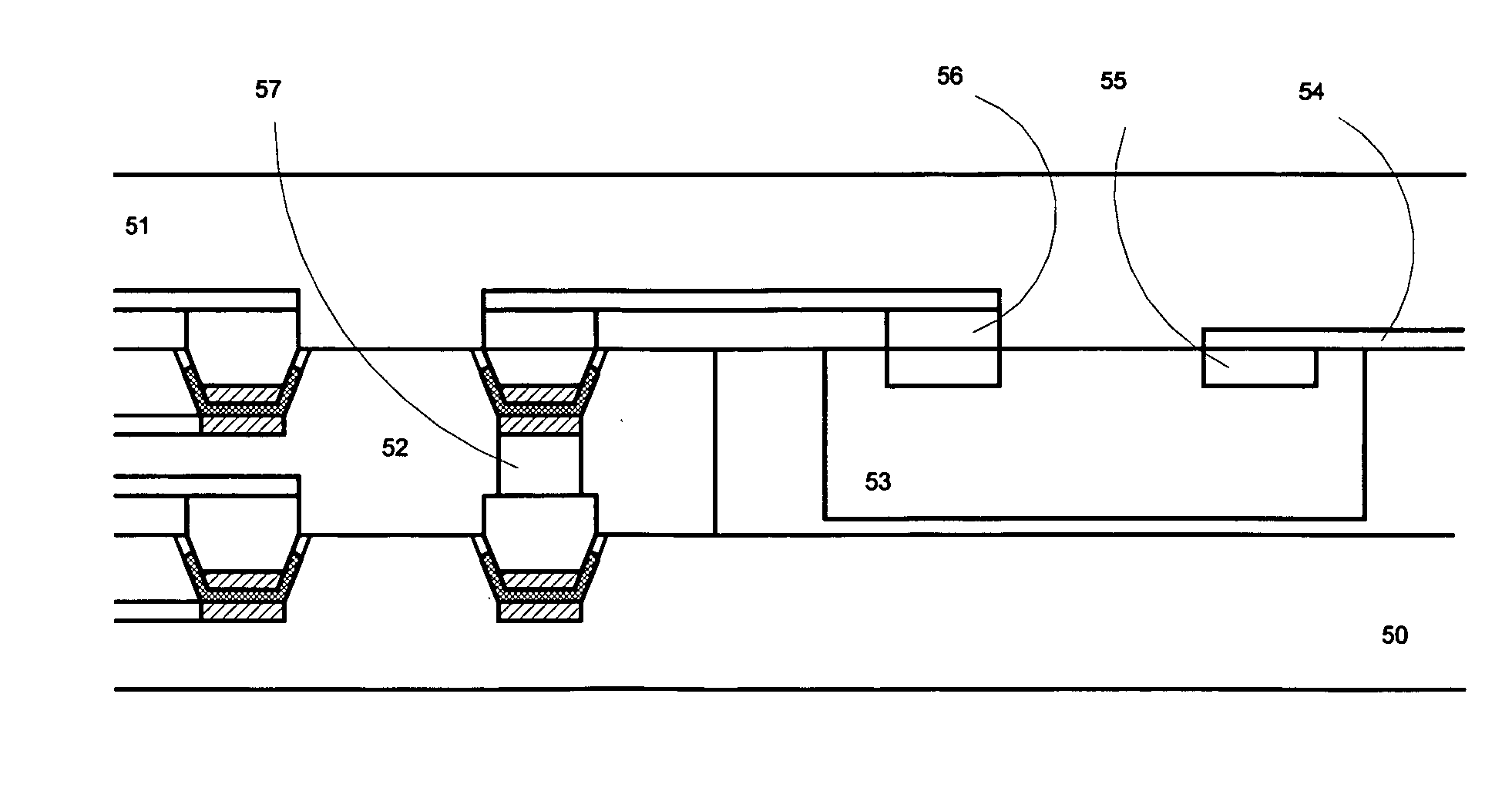

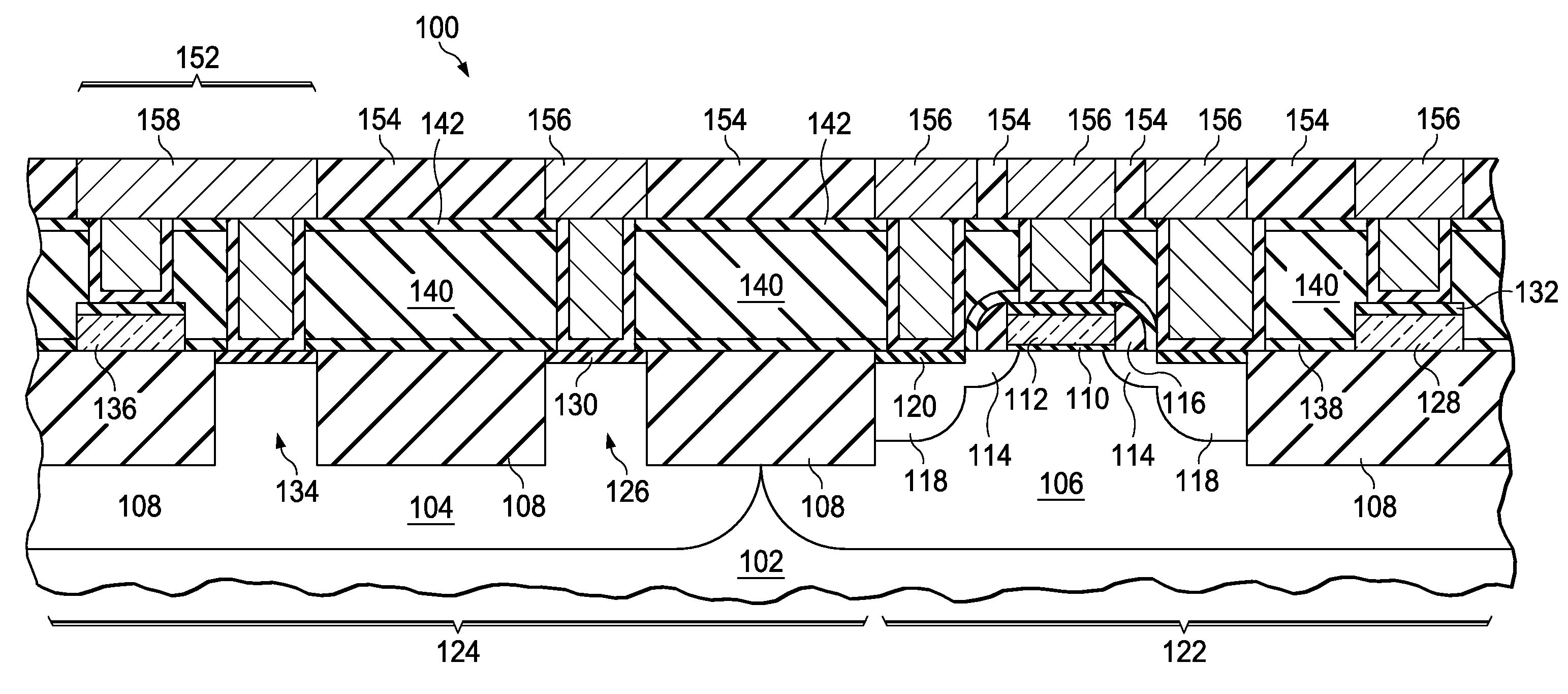

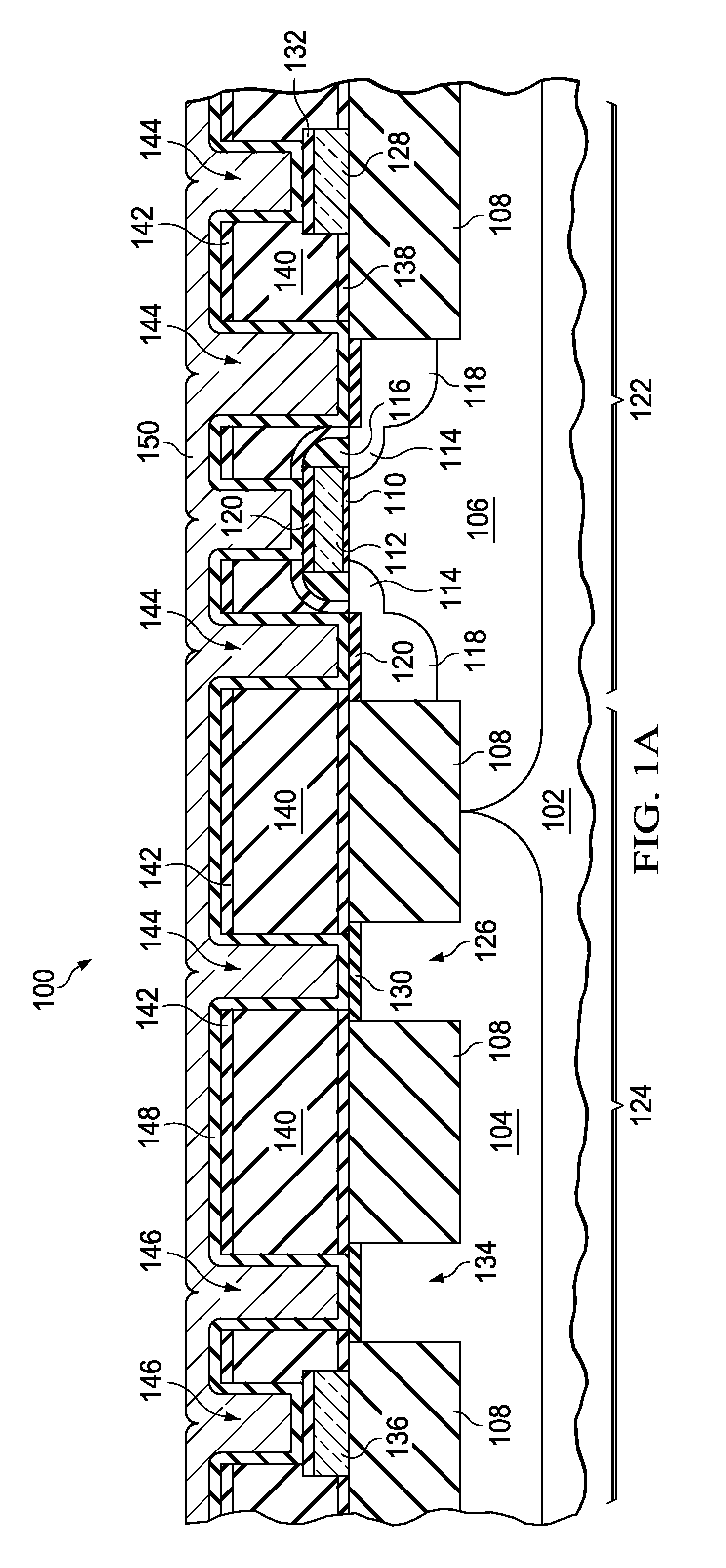

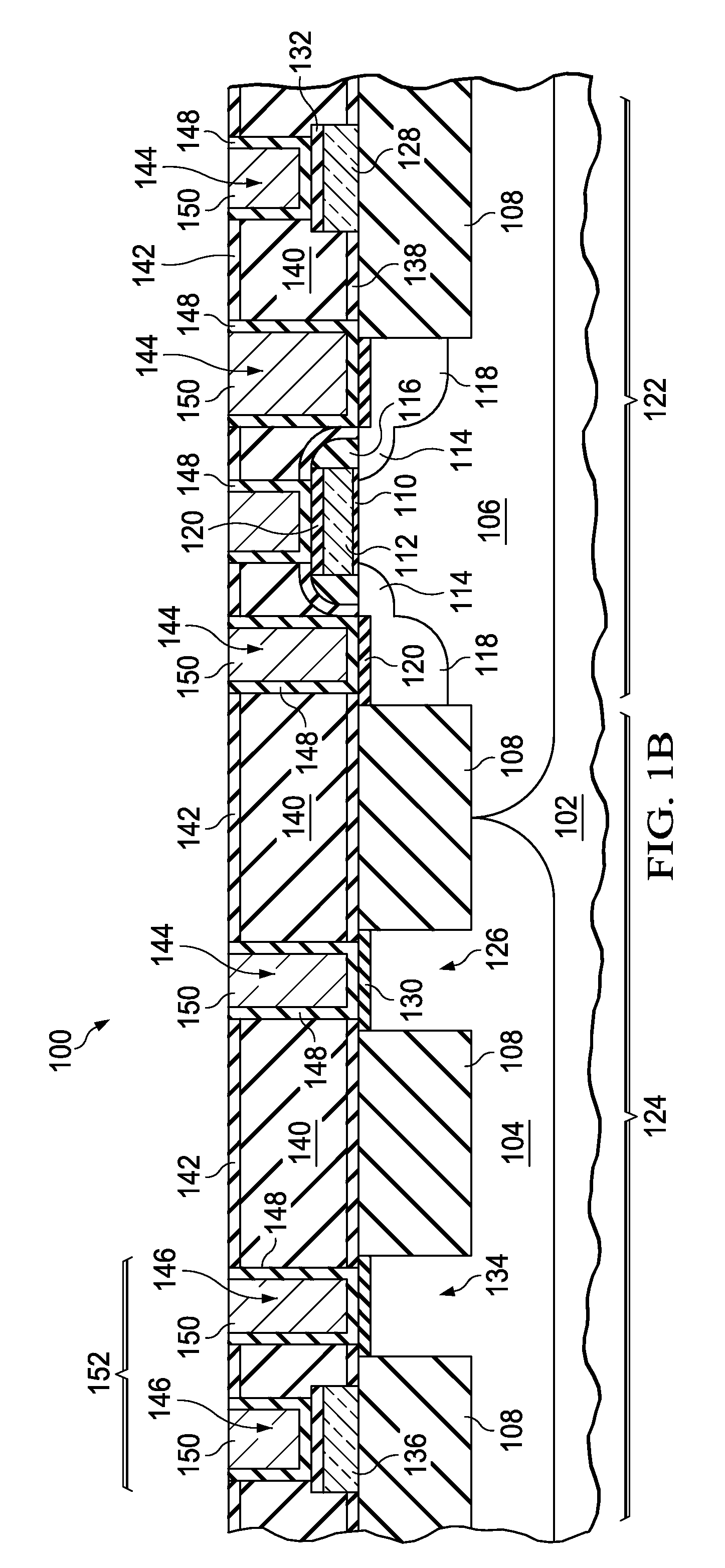

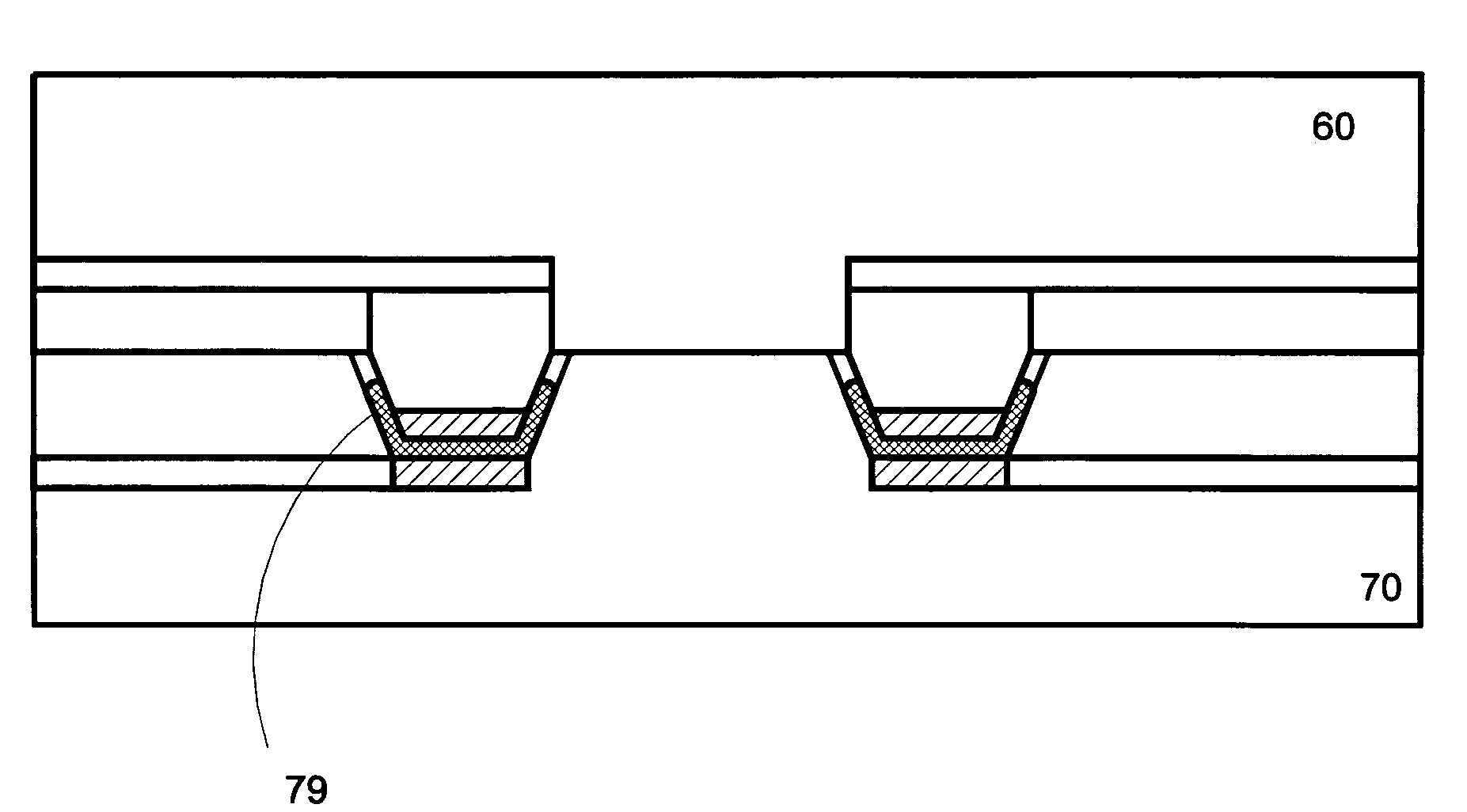

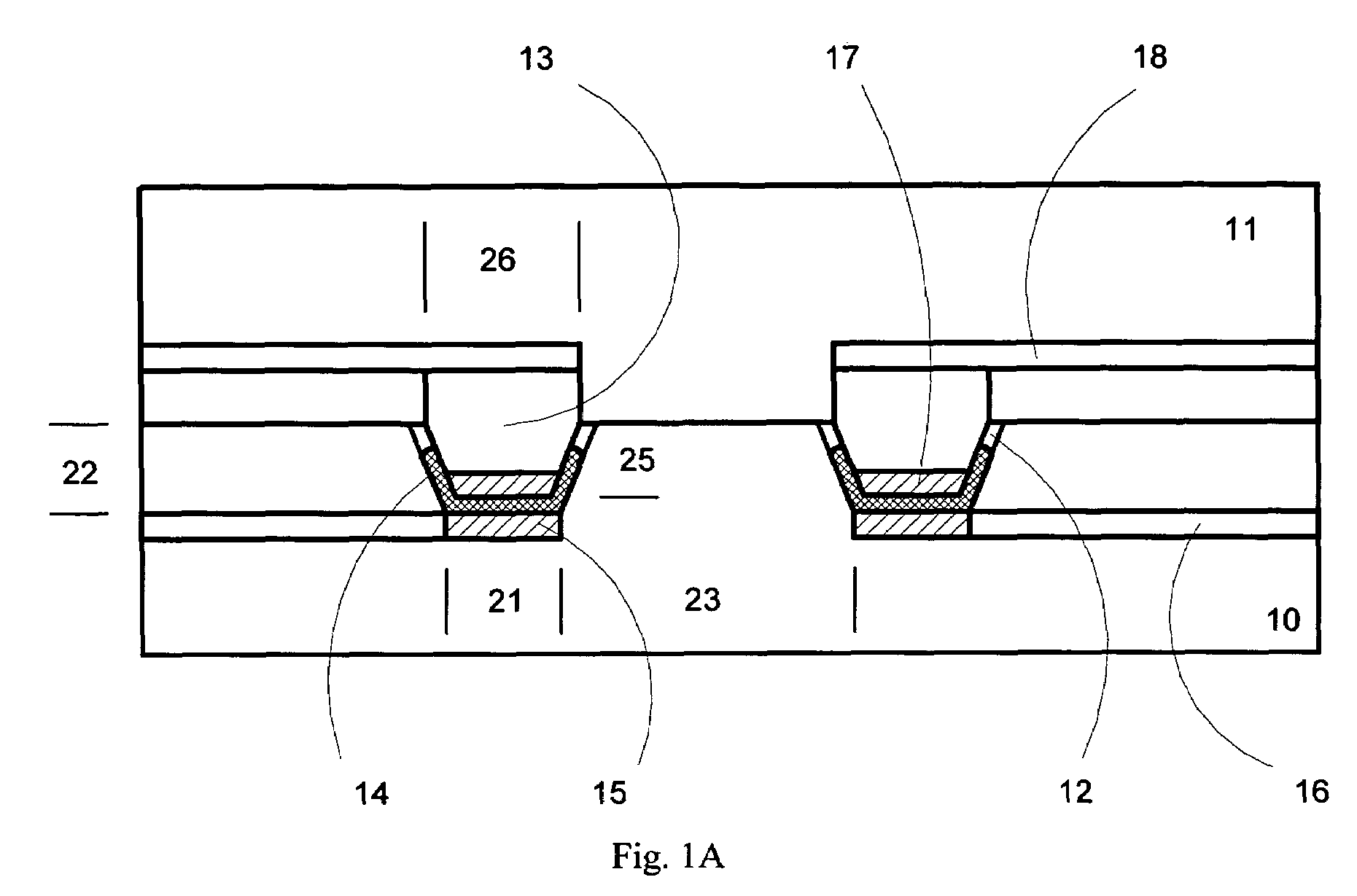

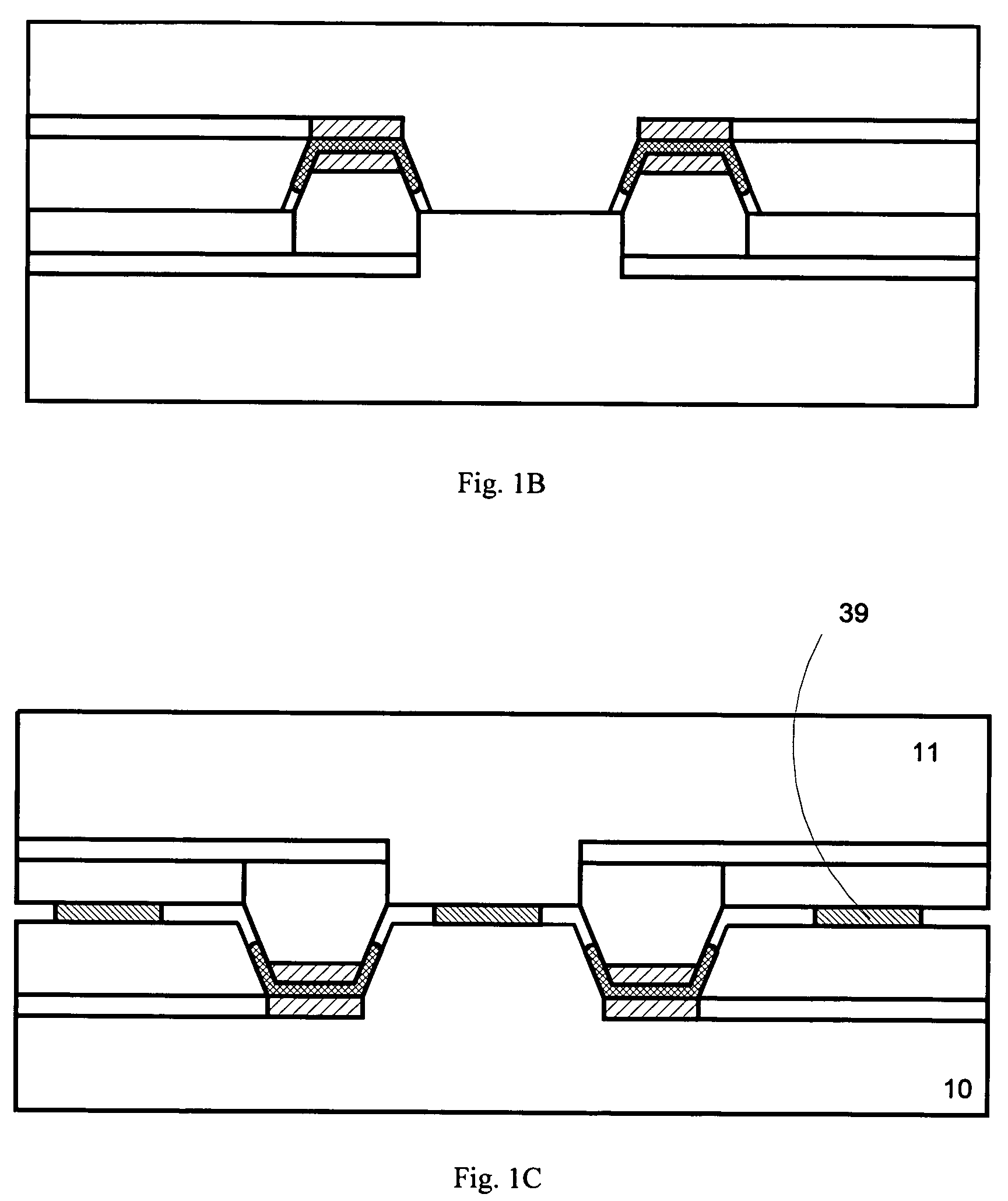

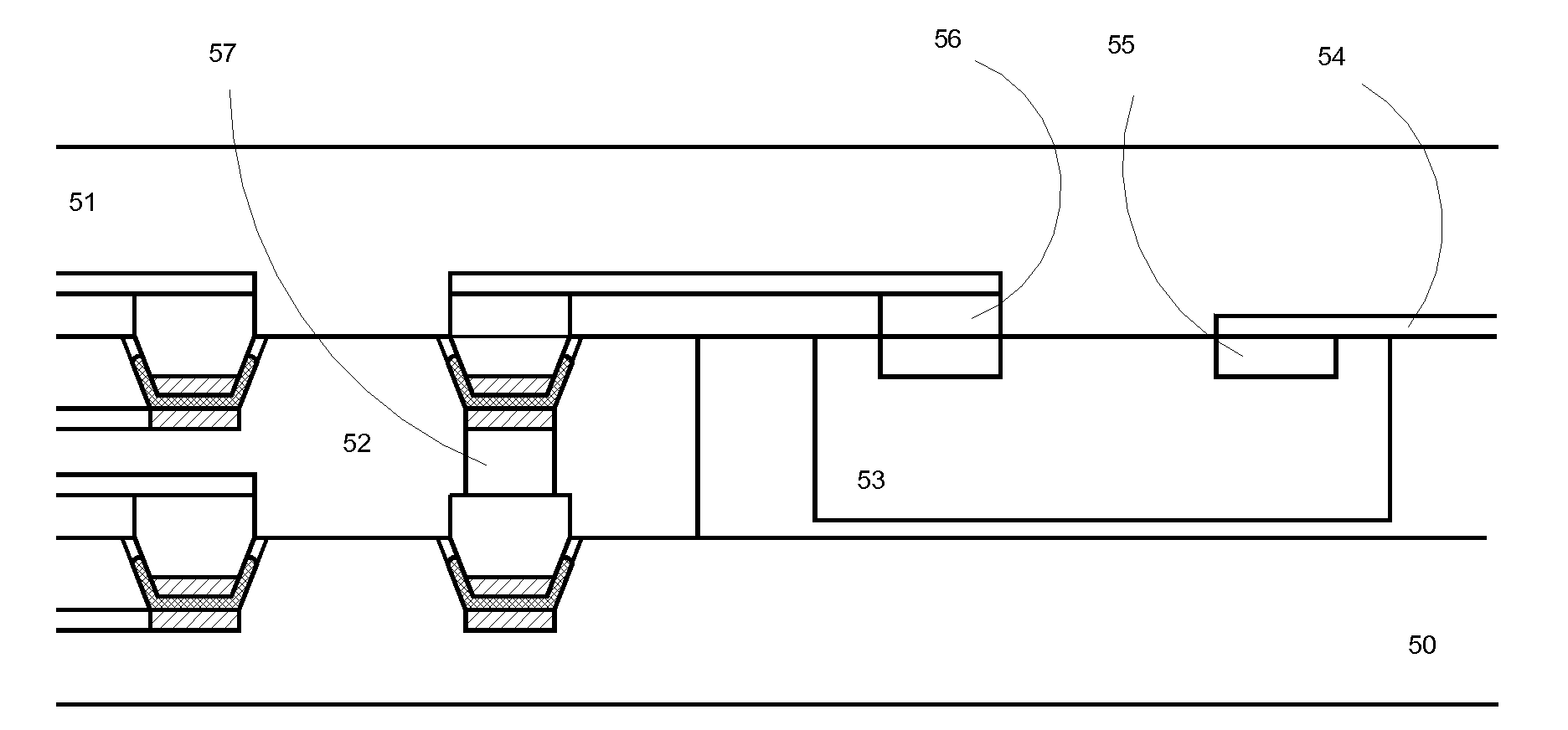

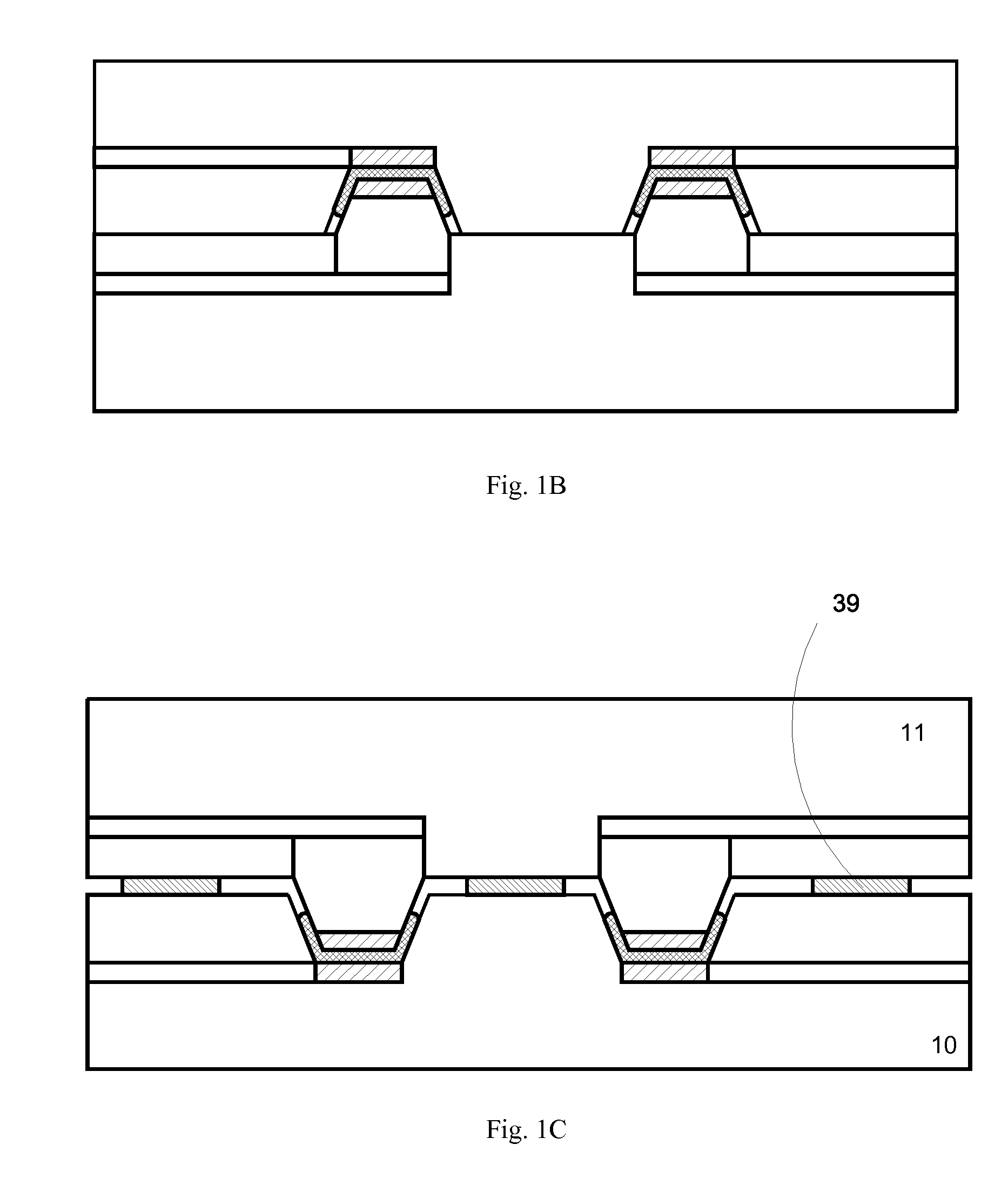

Dummy Contact Fill to Improve Post Contact Chemical Mechanical Polish Topography

InactiveUS20090087956A1Semiconductor/solid-state device detailsSolid-state devicesState of artContact density

State of the art Integrated Circuits (ICs) encompass a variety of circuits, which have a wide variety of contact densities as measured in regions from 10 to 1000 microns in size. Fabrication processes for contacts have difficulty with high and low contact densities on the same IC, leading to a high incidence of electrical shorts and reduced operating speed of the circuits. This problem is expected to worsen as feature sizes shrink in future technology nodes. This invention is an electrically non-functional contact, known as a dummy contact, that is utilized to attain a more uniform distribution of contacts across an IC, which allows contact fabrication processes to produce ICs with fewer defects, and a method for forming said dummy contacts in ICs.

Owner:TEXAS INSTR INC

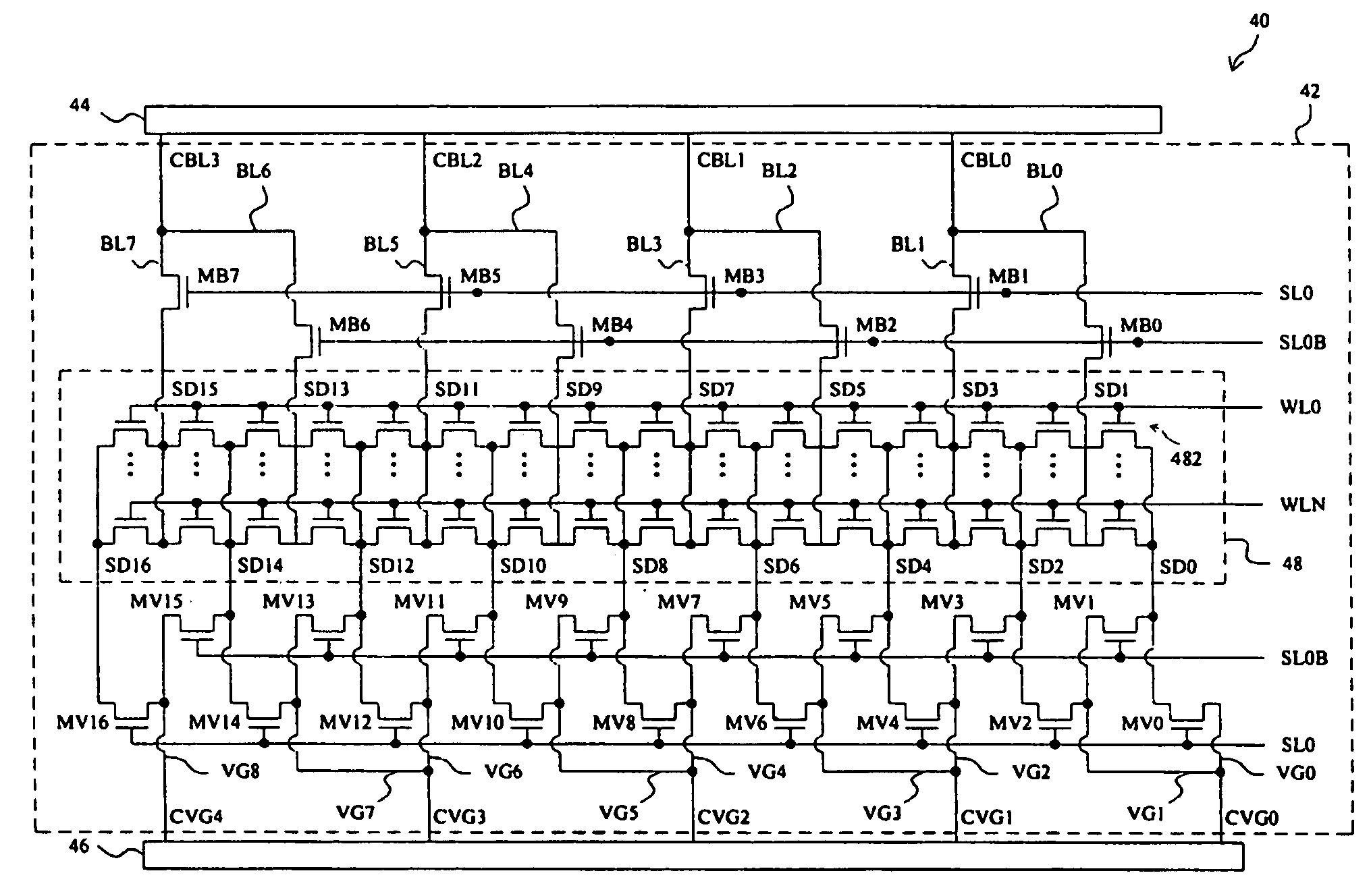

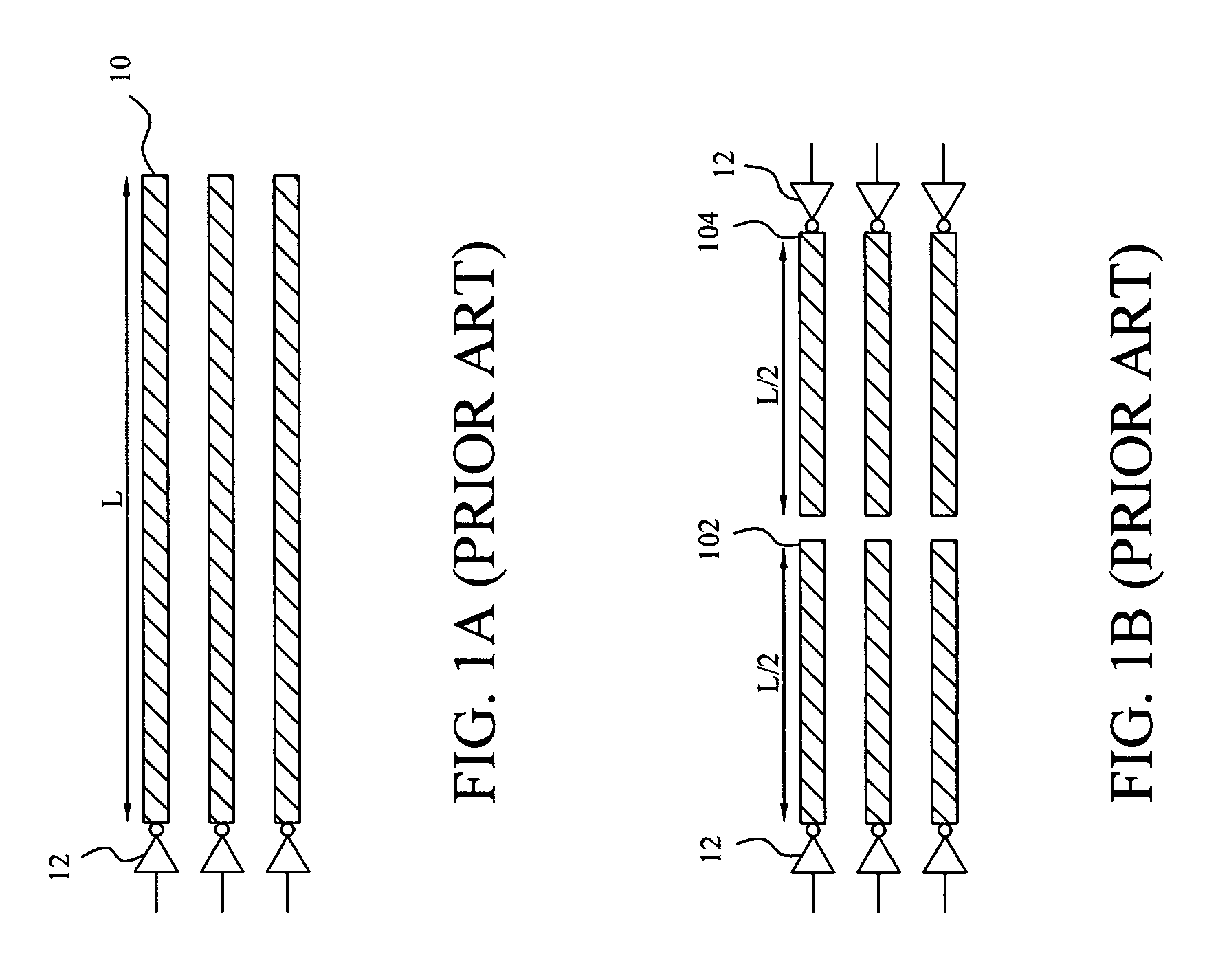

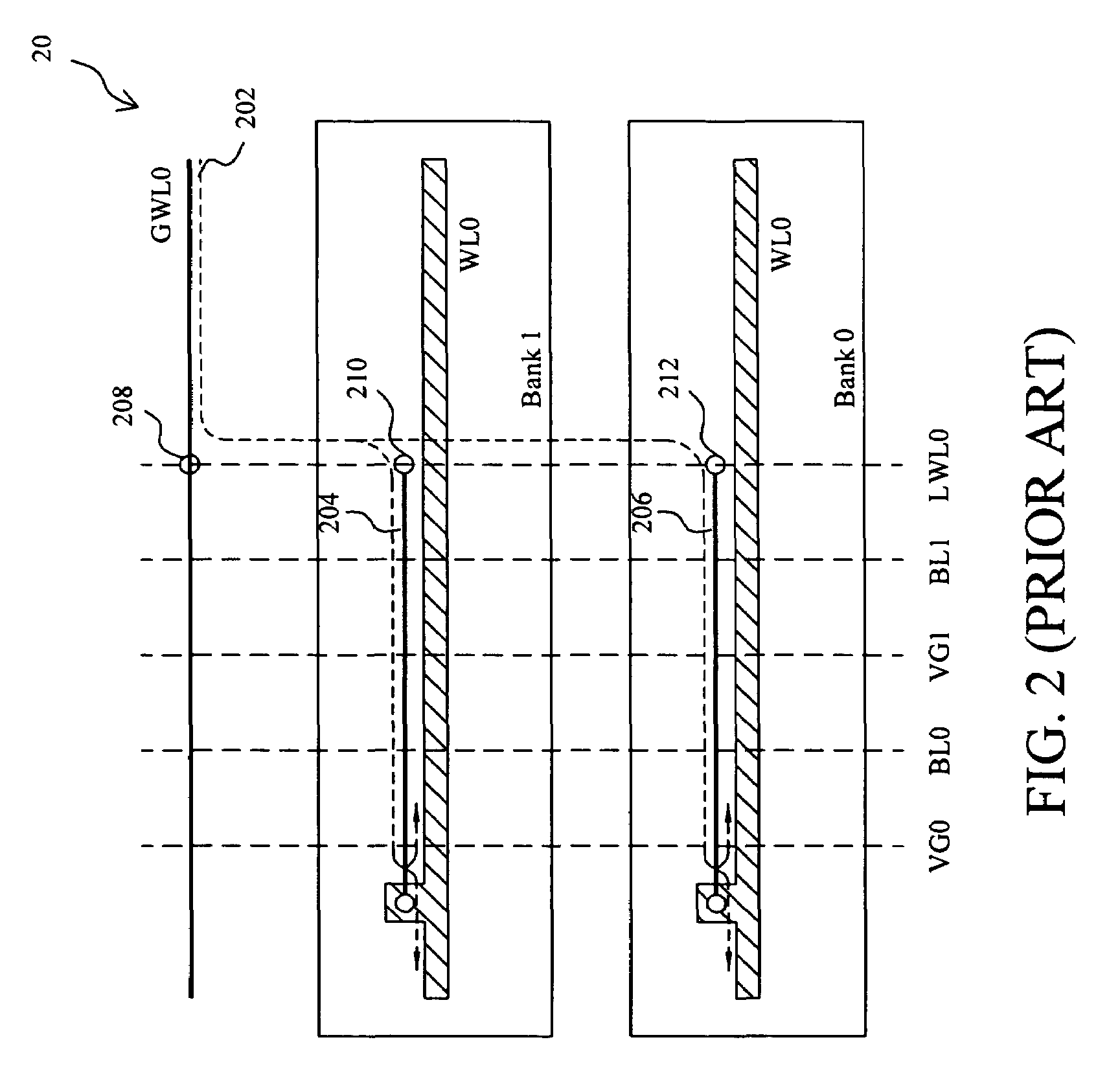

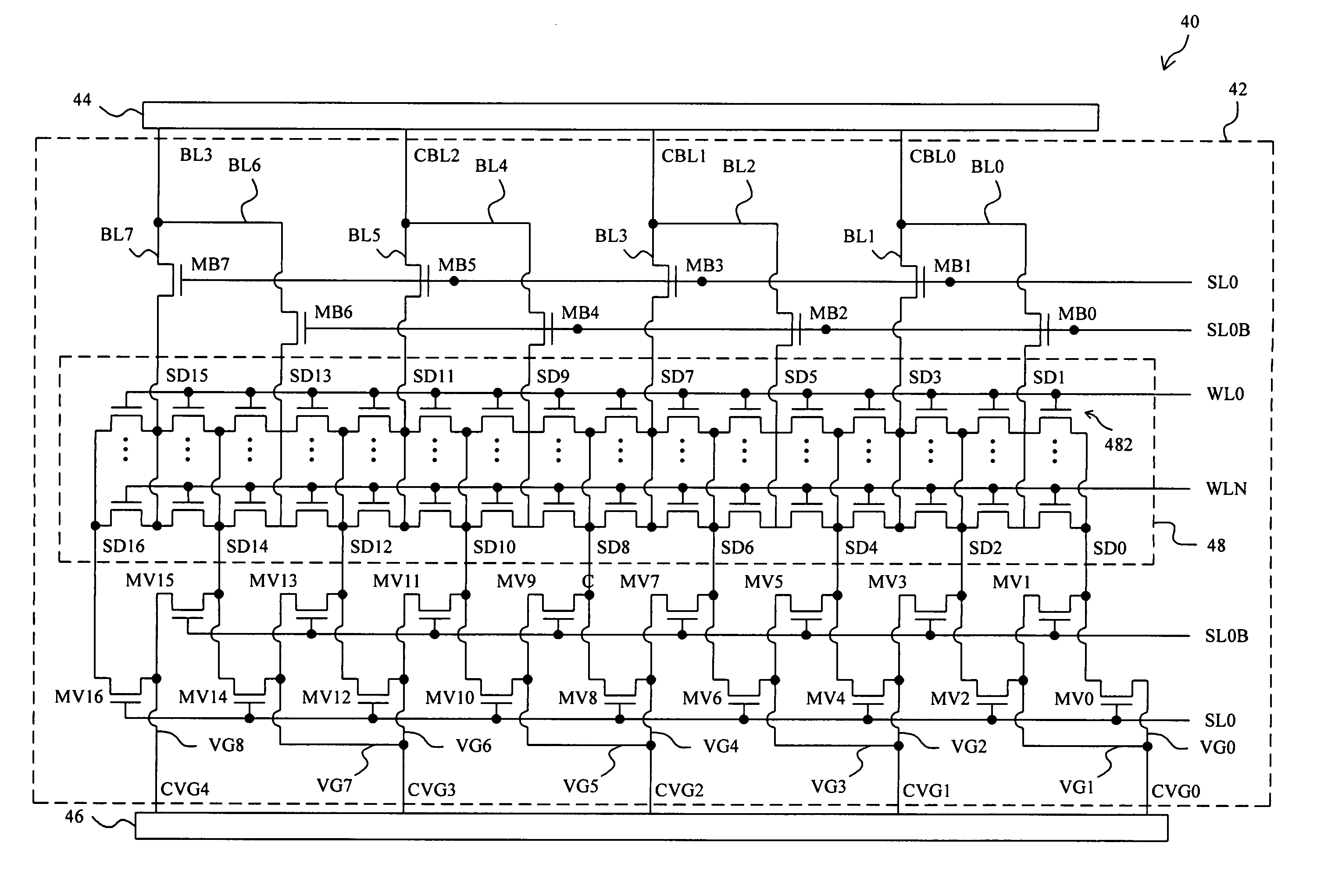

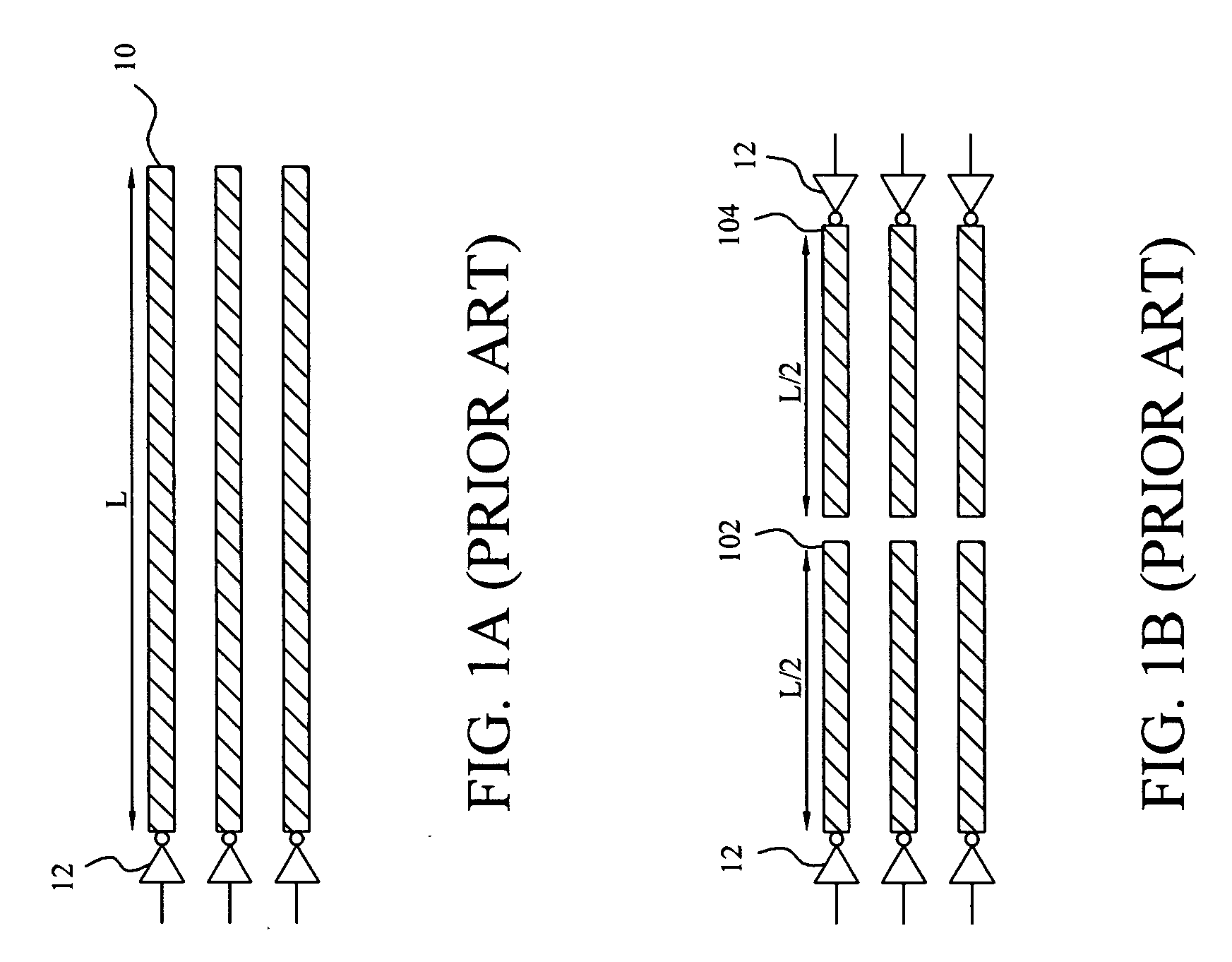

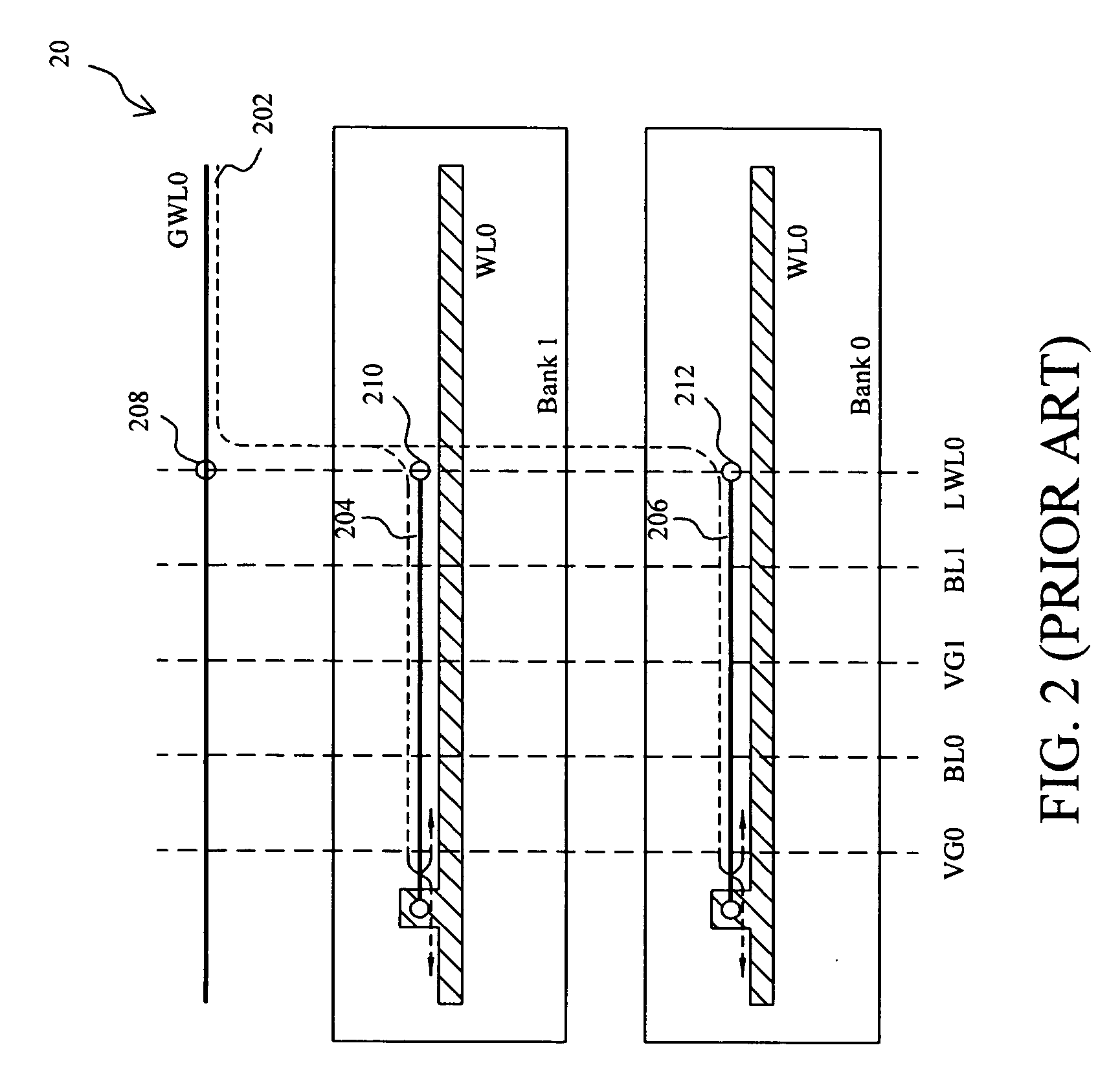

Flat cell read only memory using common contacts for bit lines and virtual ground lines

InactiveUS7436690B2Speeding up the operation of the memory without increasing the layout areaReduce contact densityTransistorSolid-state devicesBit lineEngineering

In a flat cell read only memory, two bit lines or two virtual ground lines share a common contact such that the contact is slightly adjustable in its location for inserting a local metal word line without increasing the layout area to improve the reading speed of the memory. Moreover, two adjacent banks of the memory share common bit lines or virtual ground lines, whereby reducing the contact density and height of the memory.

Owner:ELAN MICROELECTRONICS CORPORATION

Electrical connector having improved electrical characteristics

An electrical connector (70) for mounting on a substrate comprises a housing (76) and a plurality of signal contacts (10) positioned in the housing. Each of the contacts defines a mating end (16) and a mounting end (14). The mating end and the mounting end each define a width. The mounting end comprises a compliant pin section and defines a width that is less than about 60% of the width of the mating end. The connector has a contact density of at least about 90 contacts per square inch. The connector has a worst case multi-aggressor asynchronous differential cross-talk of less than about three percent at an initial rise time of approximately 40 picoseconds.

Owner:TE CONNECTIVITY CORP

Method of packaging and interconnection of integrated circuits

InactiveUS7618844B2High densityAdhesionSemiconductor/solid-state device detailsSolid-state devicesMicron scaleContact pad

Owner:INTELLEFLEX CORP +1

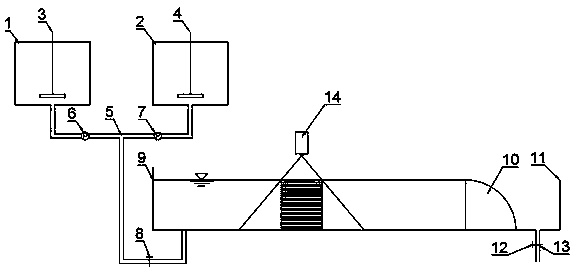

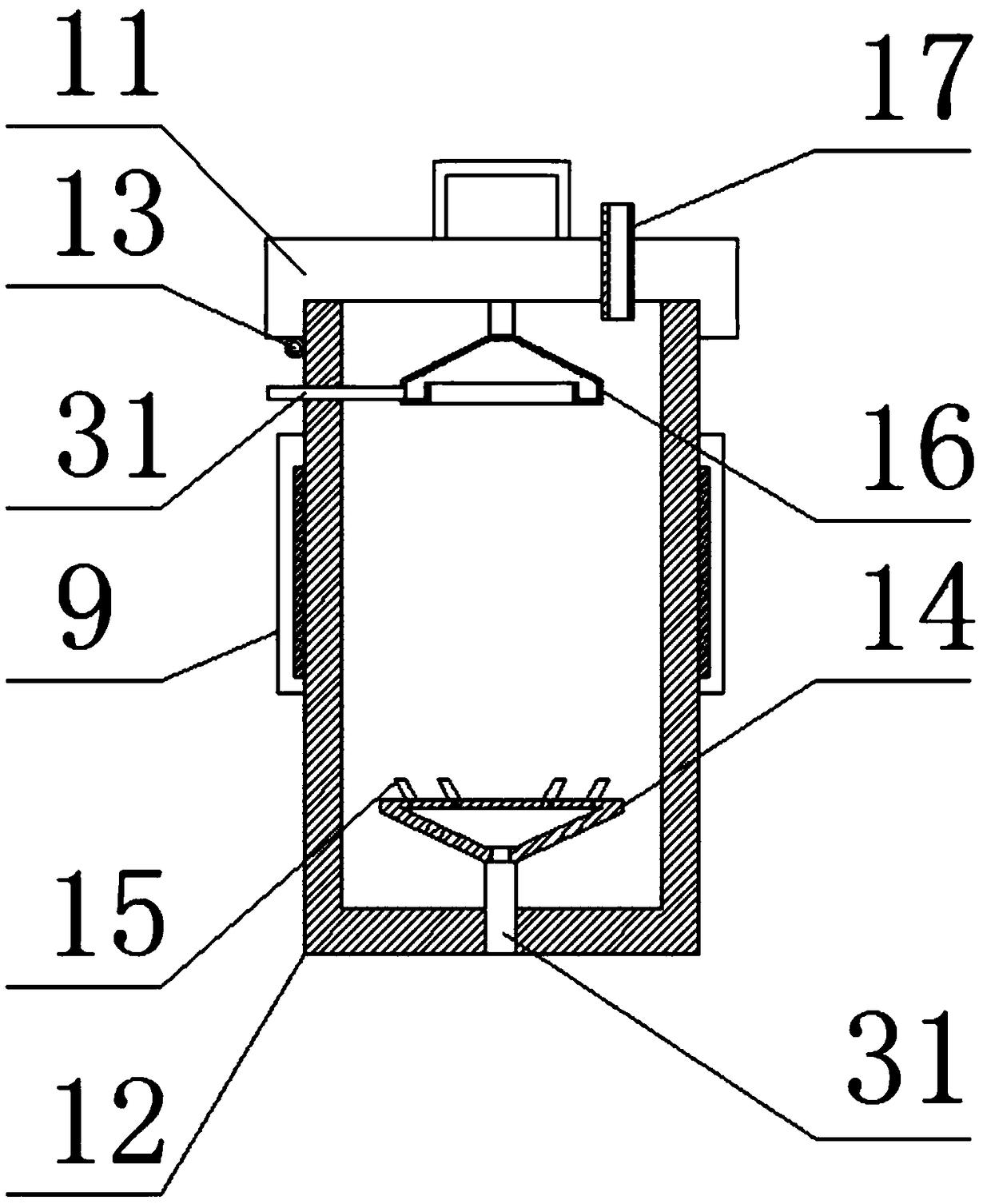

Special transport box for living aquatic products and transport method

InactiveCN102084841AReduce contact densityAvoid mechanical damageClimate change adaptationPisciculture and aquariaTemperature controlAquatic product

The invention discloses a special transport box for living aquatic products and a transport method. The method is characterized in that: the living aquatic products are treated at a low temperature so that the living aquatic products are transported in a dormancy state, the temperature of the transport box adopted during transporting is regulated through a cold-hot exchanger, and the aquatic products are partitioned by using layered trays to reduce the contact density of the aquatic products and avoid mechanical injury. The transport box consists of a box body, a temperature detector, a temperature control electromagnetic valve, a heat exchange valve, a cold exchange valve, the cold-hot exchanger, the layered trays, tray pores, an oxygen content measurement instrument, an oxygen inlet, an air exhaust port, an air inlet, an air inlet electromagnetic valve, an exhaust port electromagnetic valve and an oxygen generator. After the aquatic products are transported to the site, the aquatic products are resuscitated by adding oxygen and fresh seawater. The transport box has the characteristics of reasonable design, high transport number, little mechanical injury of the aquatic products, high survival rate and low cost.

Owner:DALIAN BAIJIA TECH

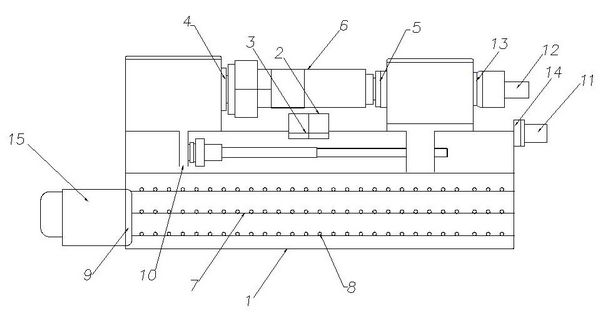

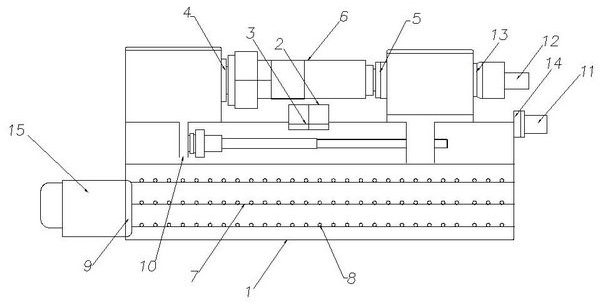

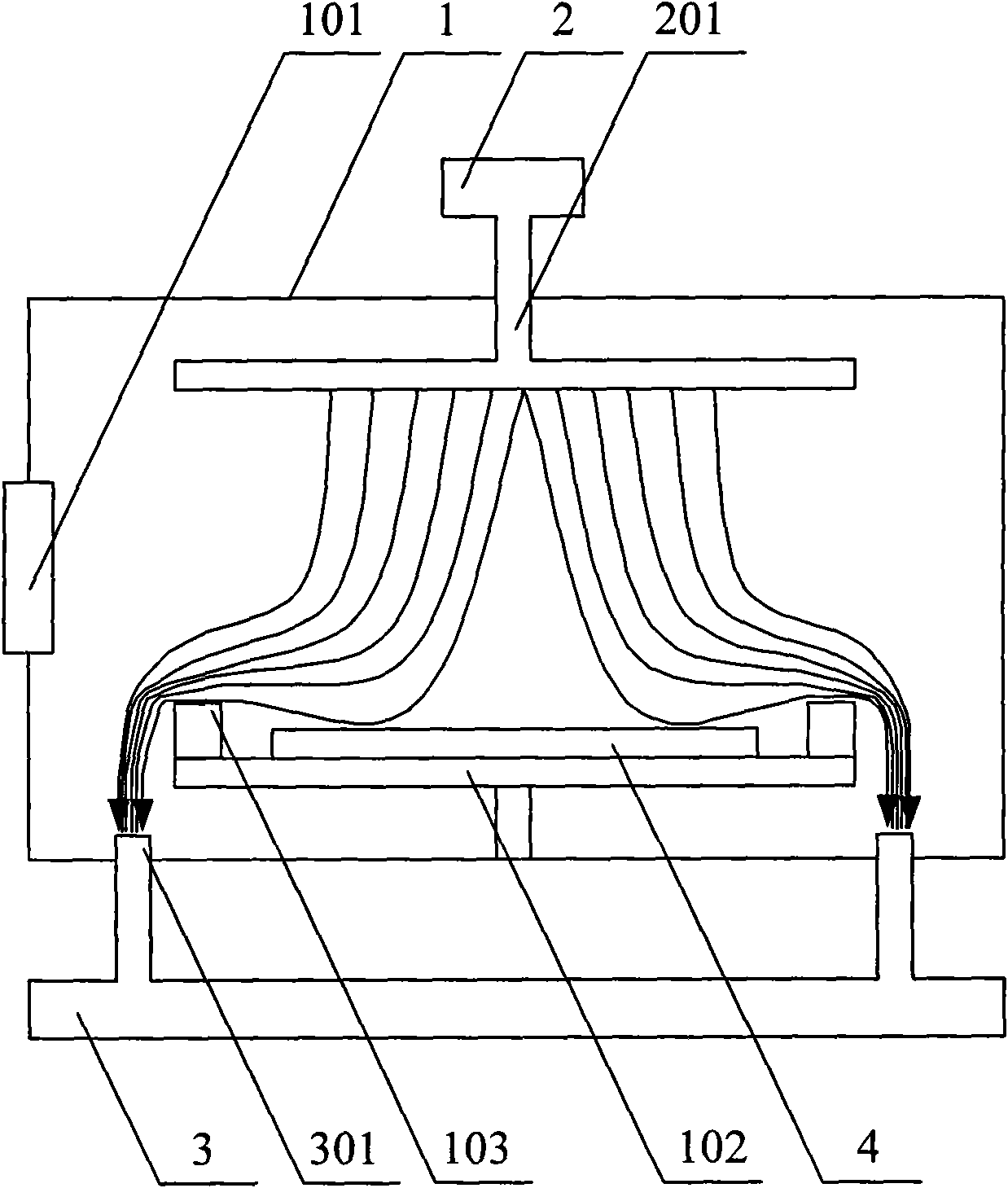

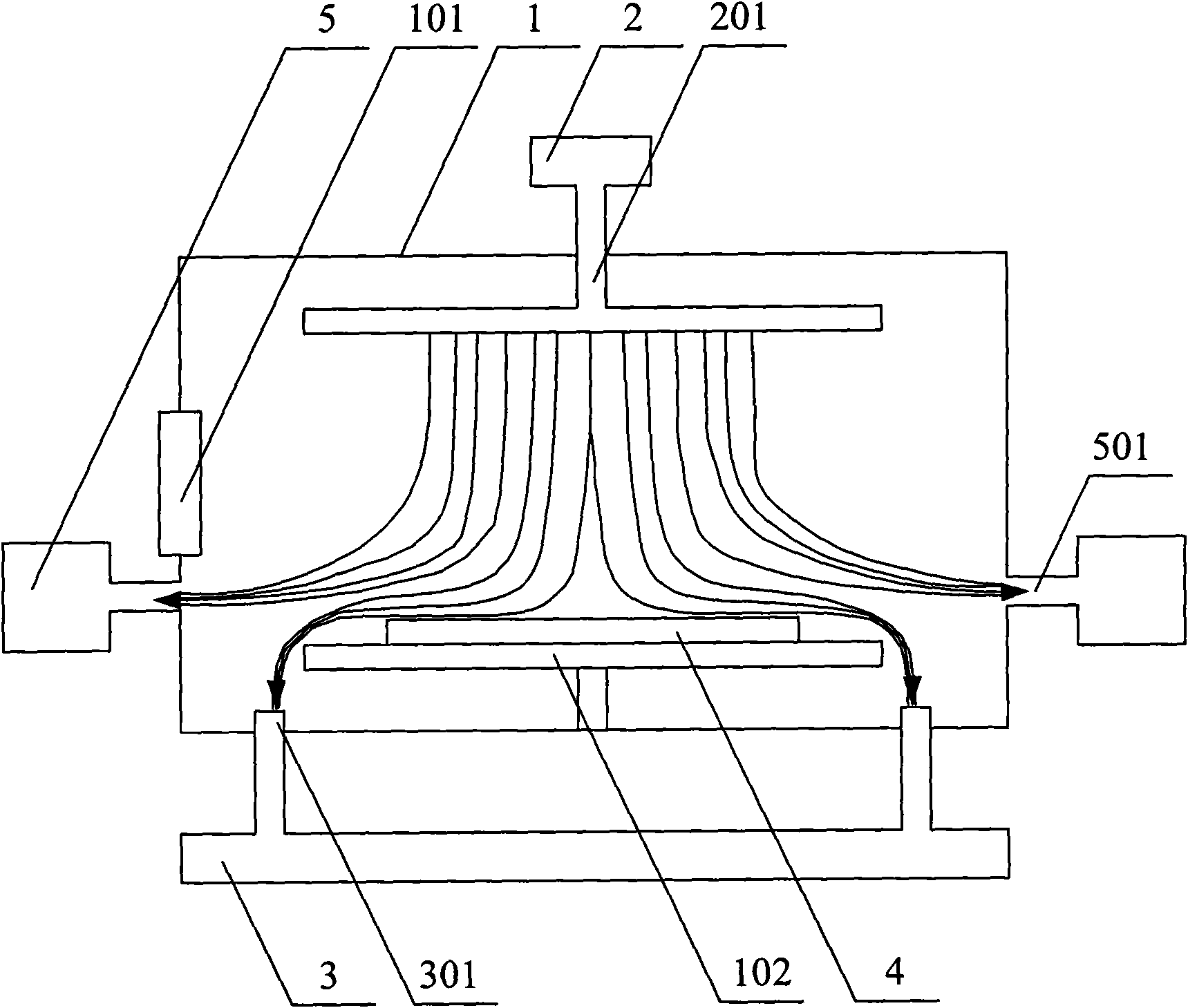

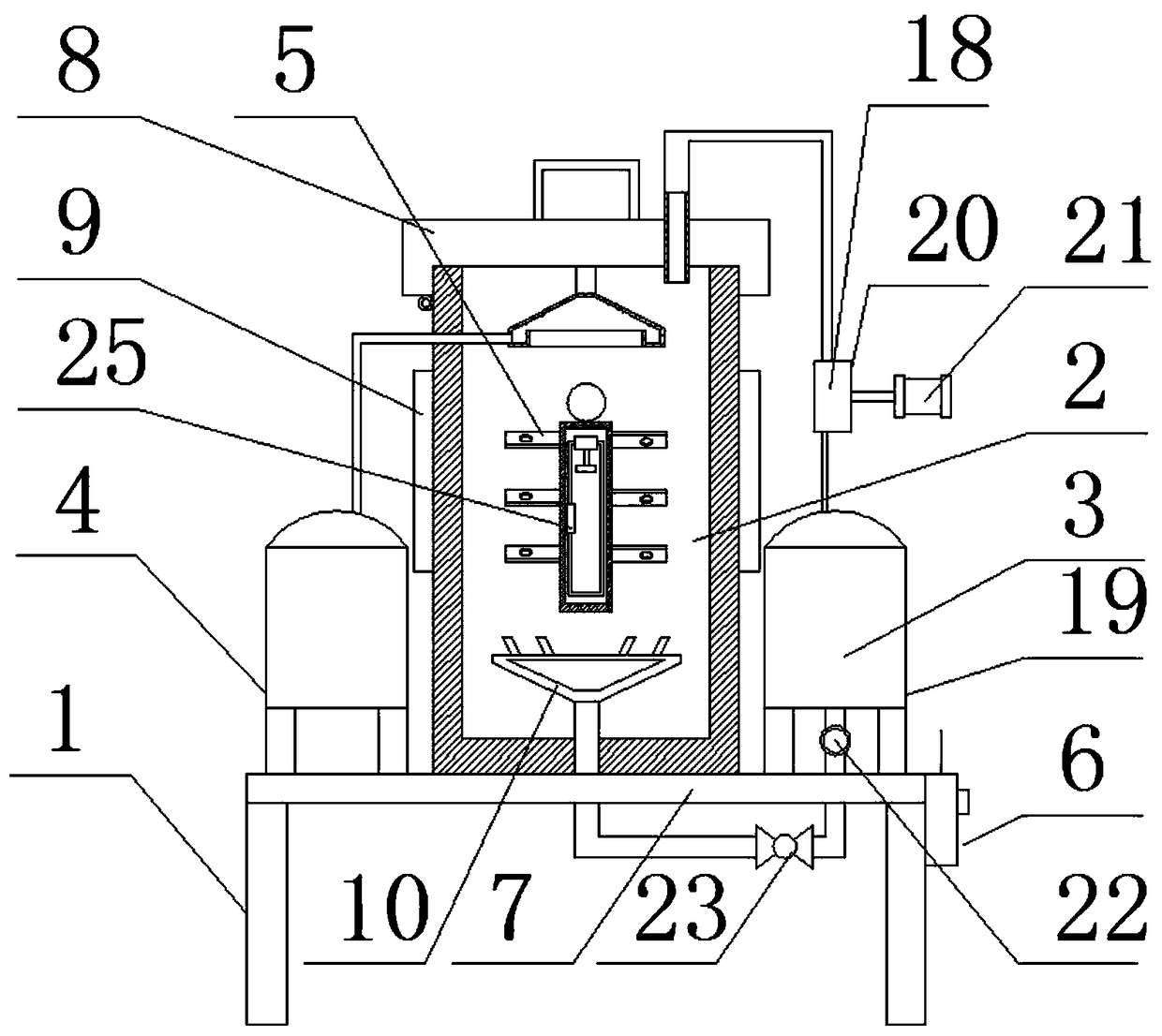

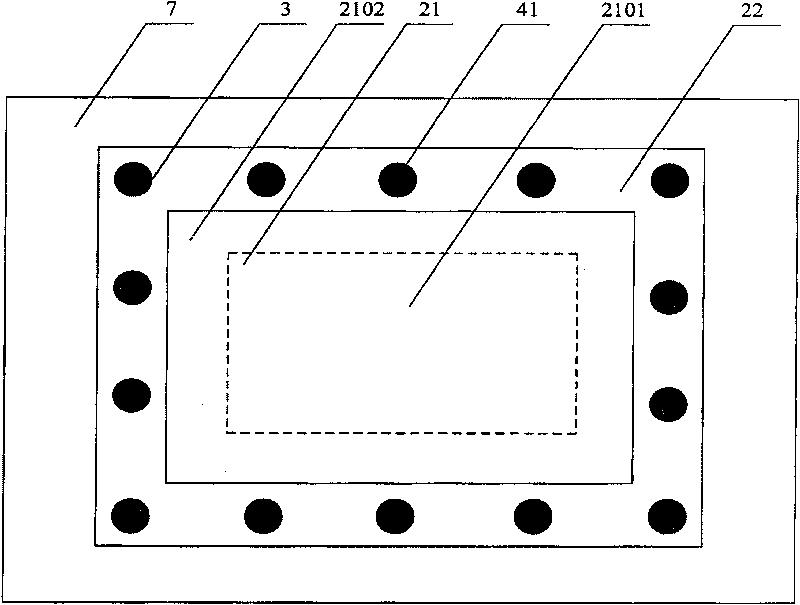

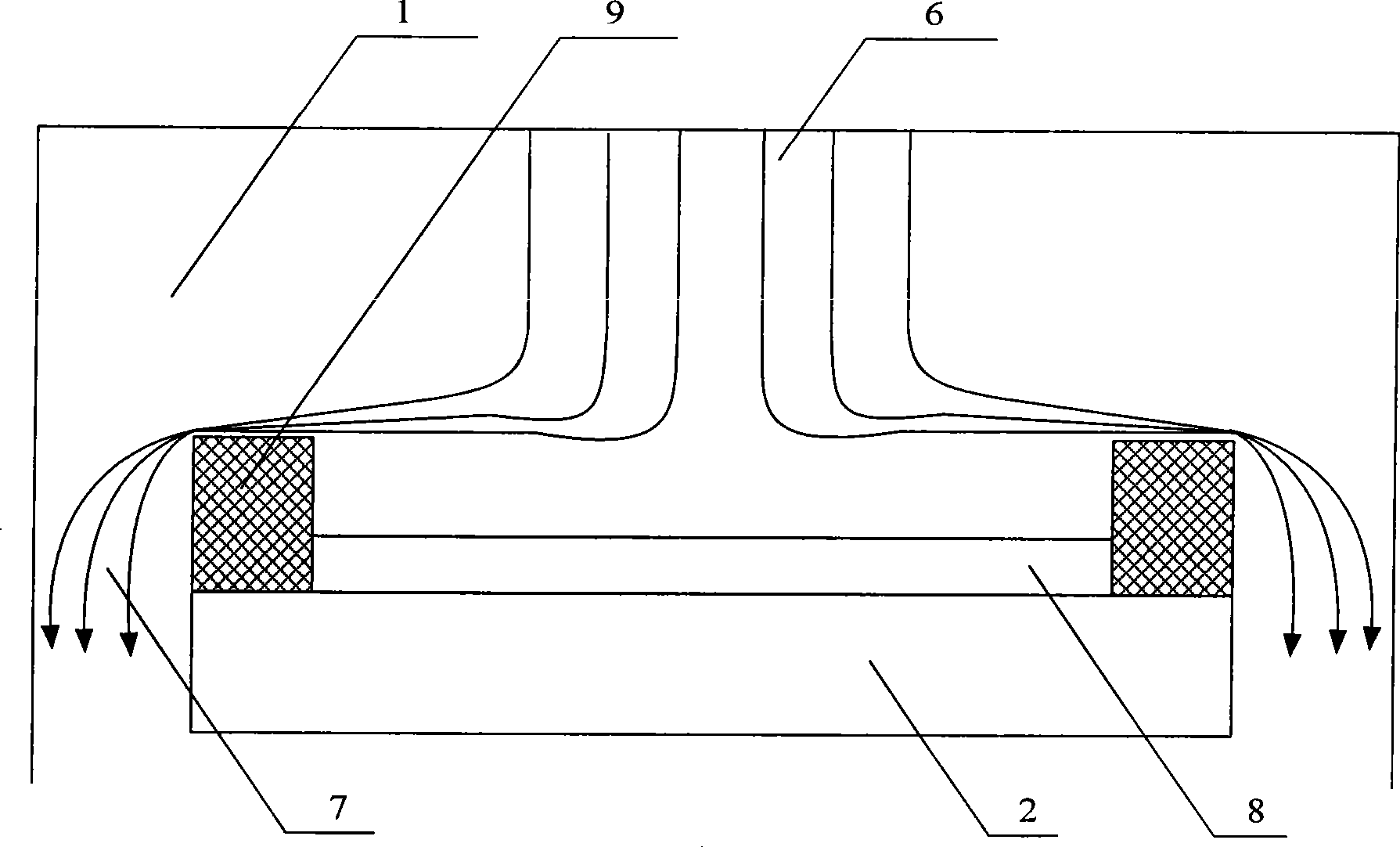

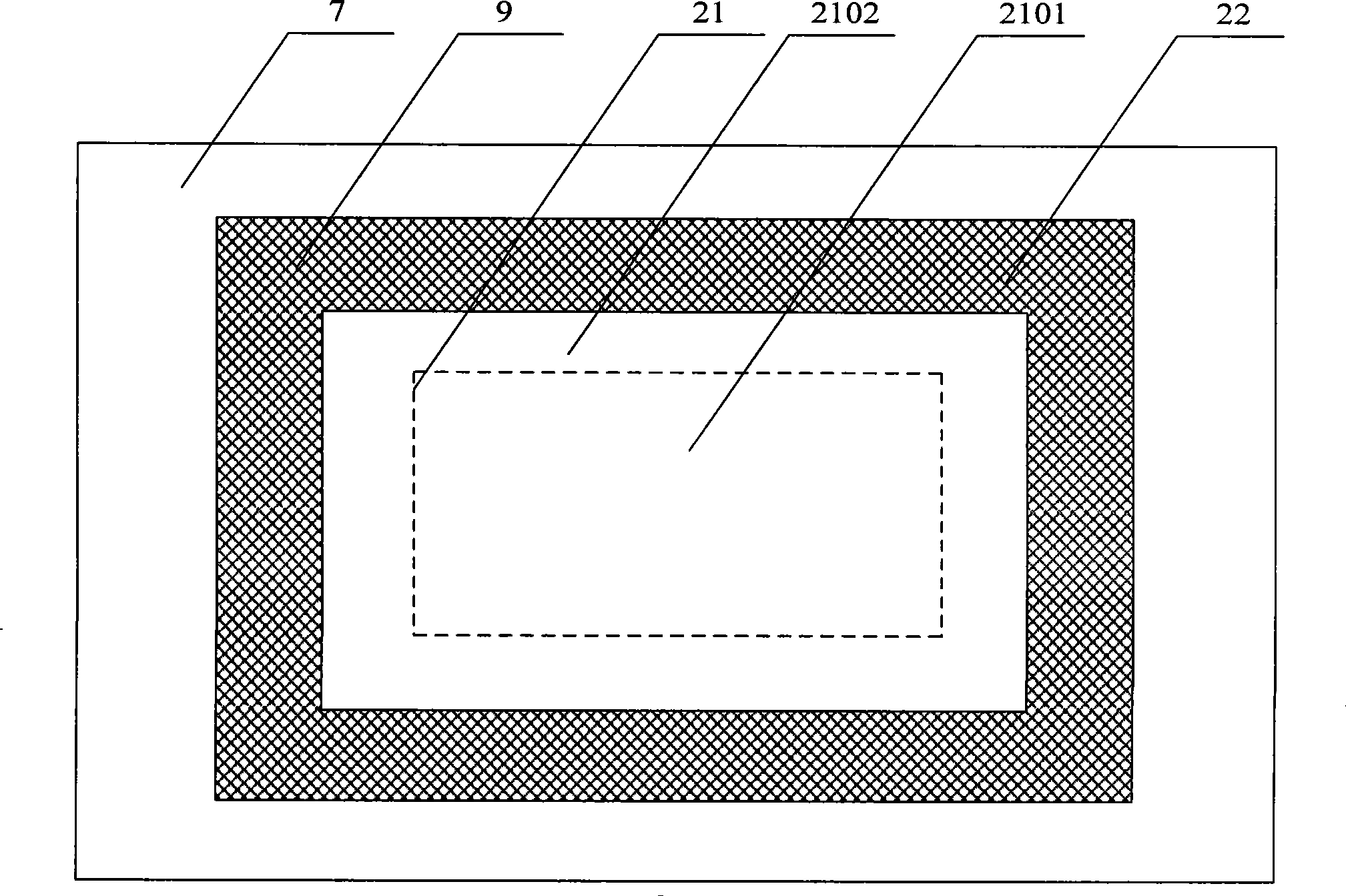

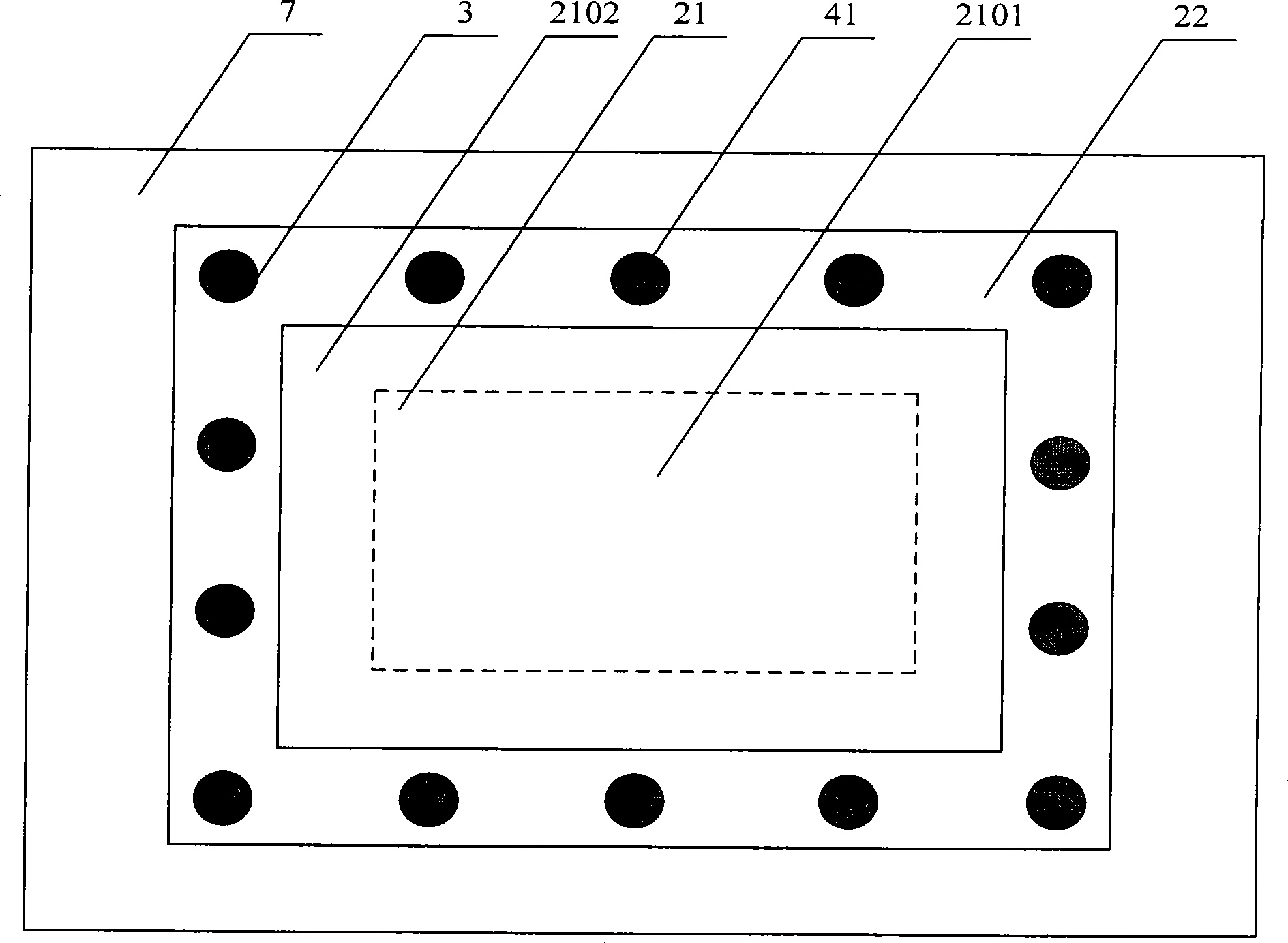

Device for dry etching

ActiveCN101656192AFast etchControl contact densitySemiconductor/solid-state device manufacturingProduct gasContact density

The invention relates to a device for dry etching, which comprises a cavity, a base platform erected at the bottom of the cavity, a gas intake device and a gas extractor. The device also comprises atleast one assistant gas extracting device which is arranged on the lateral surface of the cavity and is used for controlling the contact density of an etching gas and a substrate by pumping the etching gas in the cavity out from the upper part of the base platform. When the device for the dry etching etches the materials of a-Si, SiNx or Mo and the like, the assistant gas extracting device is turned off; when the device etches the materials of Al and the like which are sensitive to the etching gas, the assistant gas extracting device is turned on; besides, the device controls the contact density of the etching gas and the substrate by pumping the etching gas in the cavity out from the upper part of the base platform, thus a gas adjusting seat is not needed to be assembled or disassembled when one device for the dry etching is used for etching various materials, and the production efficiency and the production speed are effectively improved.

Owner:K TRONICS (SUZHOU) TECH CO LTD +1

Tracer-particle-based non-contact density profile measuring method in internal wave experiment

InactiveCN110375952AImprove consistencyAchieve reliabilityHydrodynamic testingMaterial analysis by optical meansParticle densityContact density

The invention discloses a tracer-particle-based non-contact density profile measuring method in an internal wave experiment. A PIV device is arranged at one side of a water tank. Saline water with thedensity lower than that of a tracer particle is placed on the bottom of the water tank and then saline water with the density higher than that of the tracer particle is placed, wherein the saline water contains tracer particles. Laser with the fixed wavelength and the fixed power irradiates the saline water with tracer particles mixed; the PIV device shoots an experimental observation area continuously; the tracer particles are displayed as white light points on an obtained grayscale image and the rest part is displayed in black; and on the basis of the number of white light points in a certain area on the grayscale image, the particle number is estimated by inversion and thus the water density is deduced. According to the method for acquiring velocity field and the density field information of an internal wave simultaneously by the PIV, the data consistency is high. The method can be applied to various marine fluid mechanics experiments.

Owner:ZHEJIANG UNIV

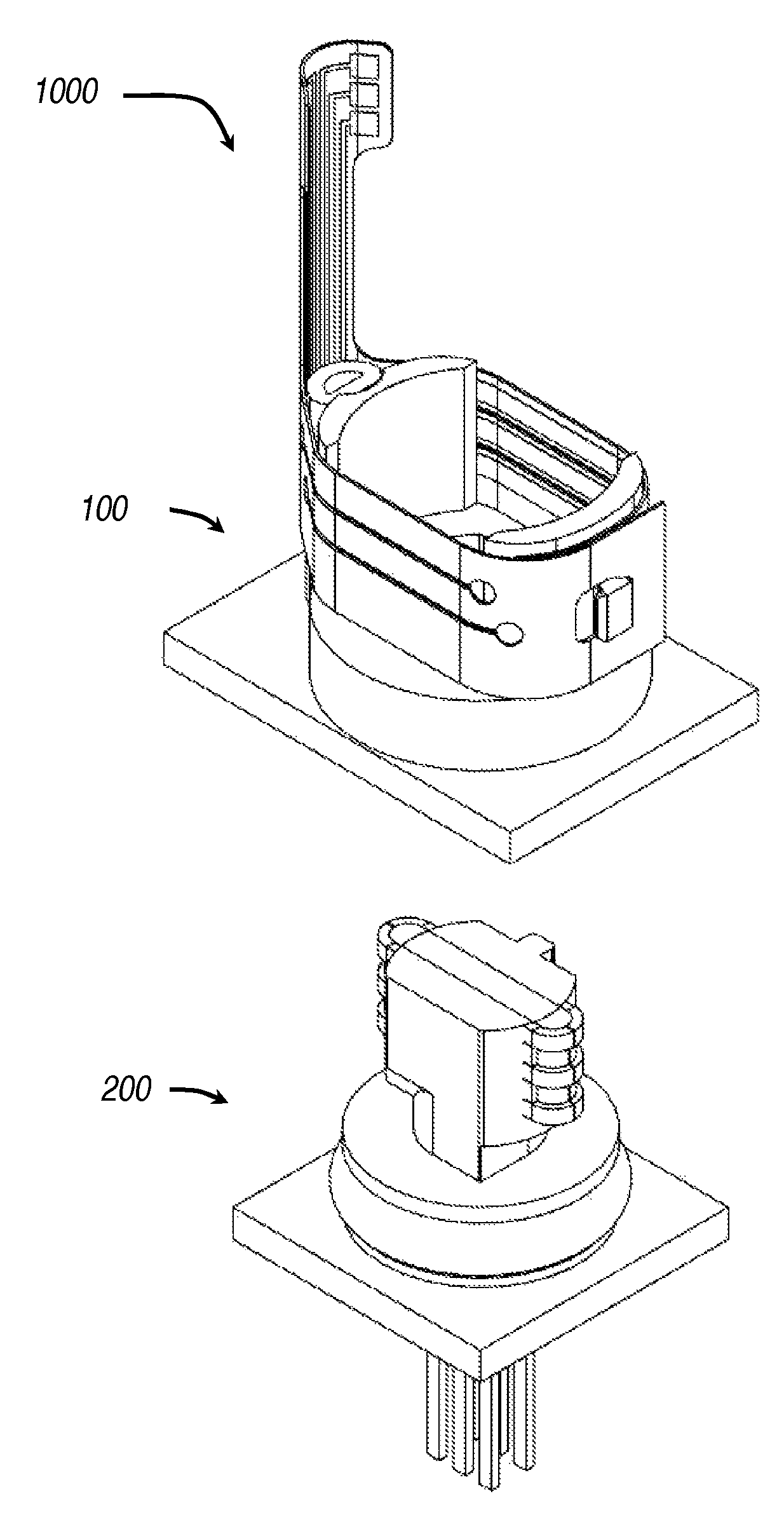

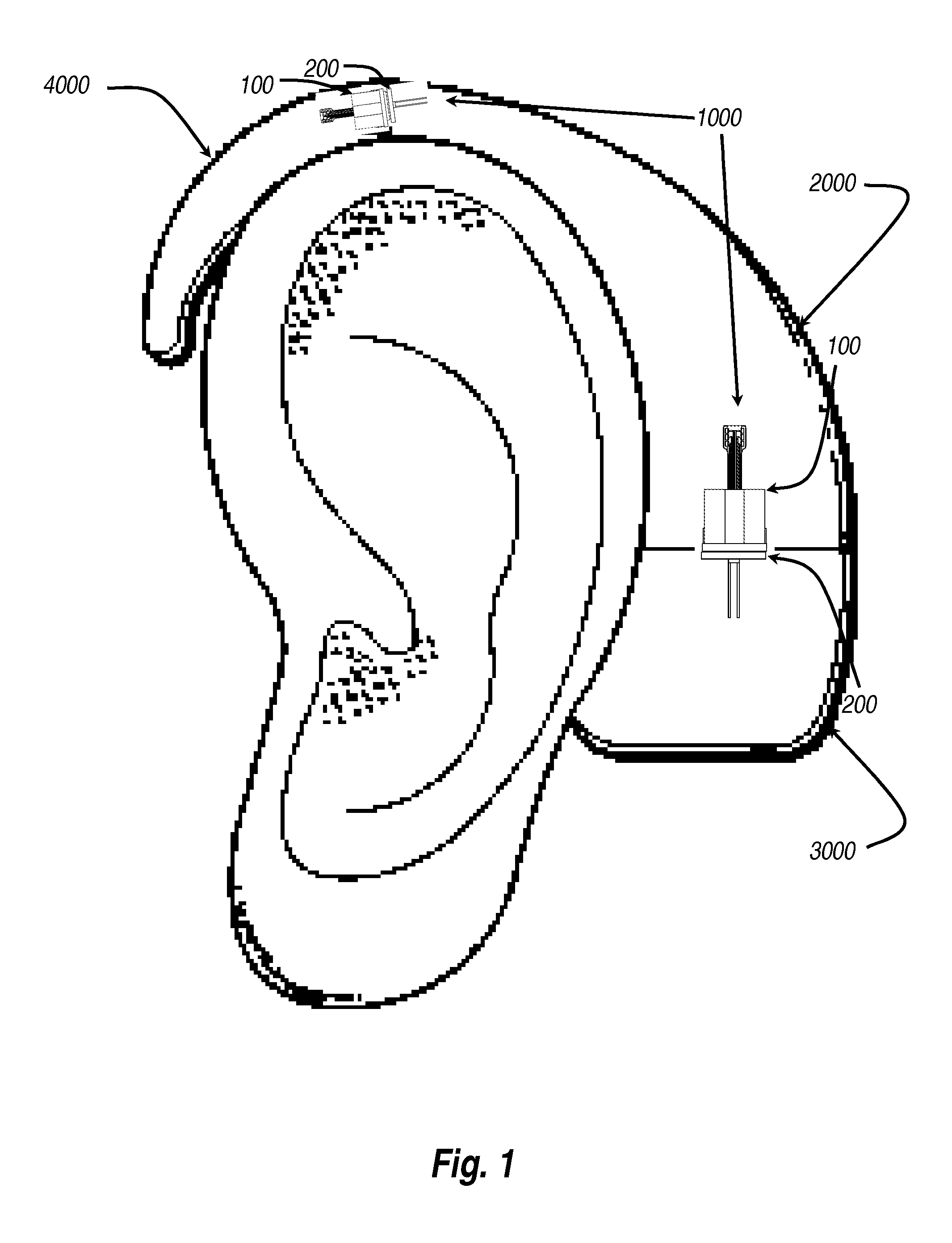

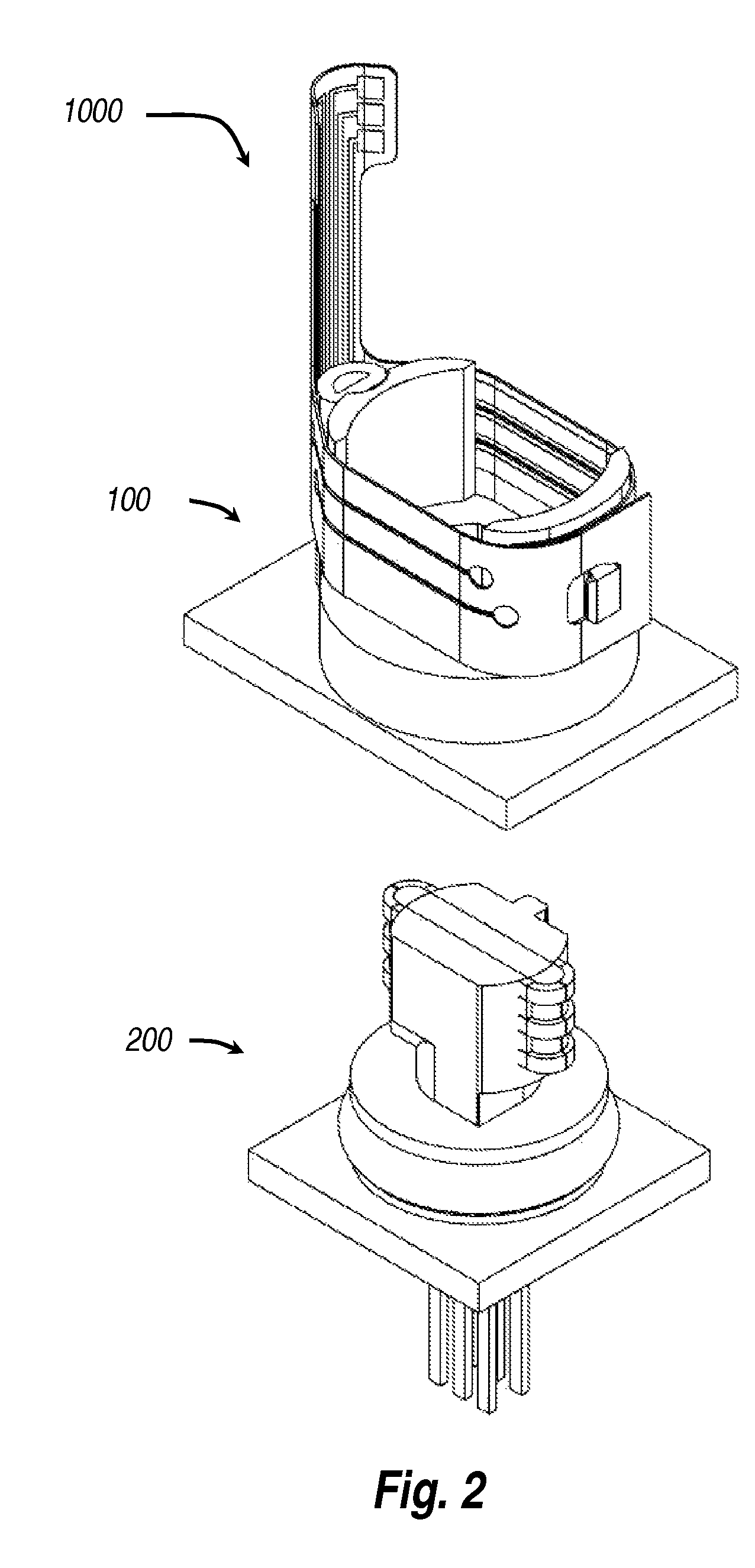

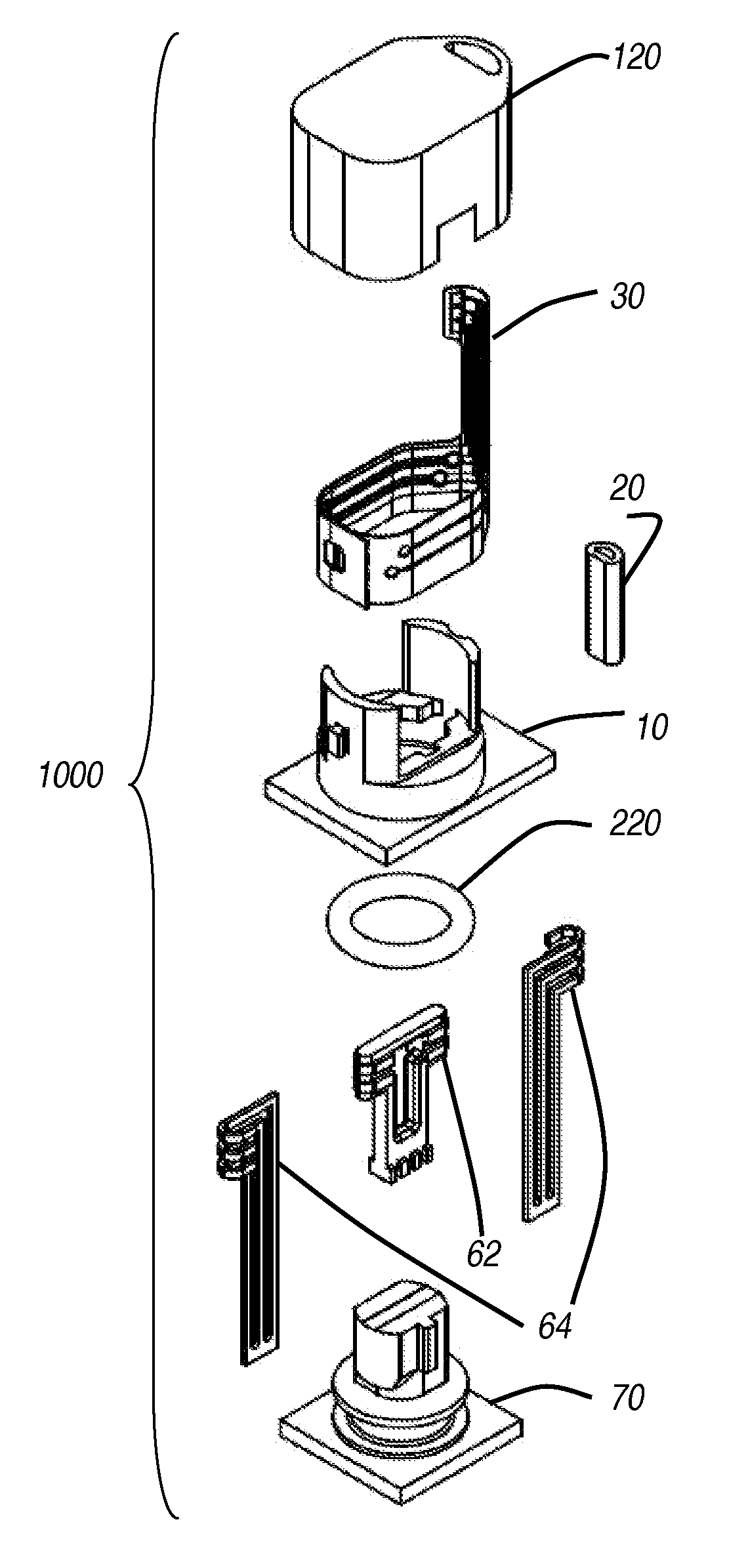

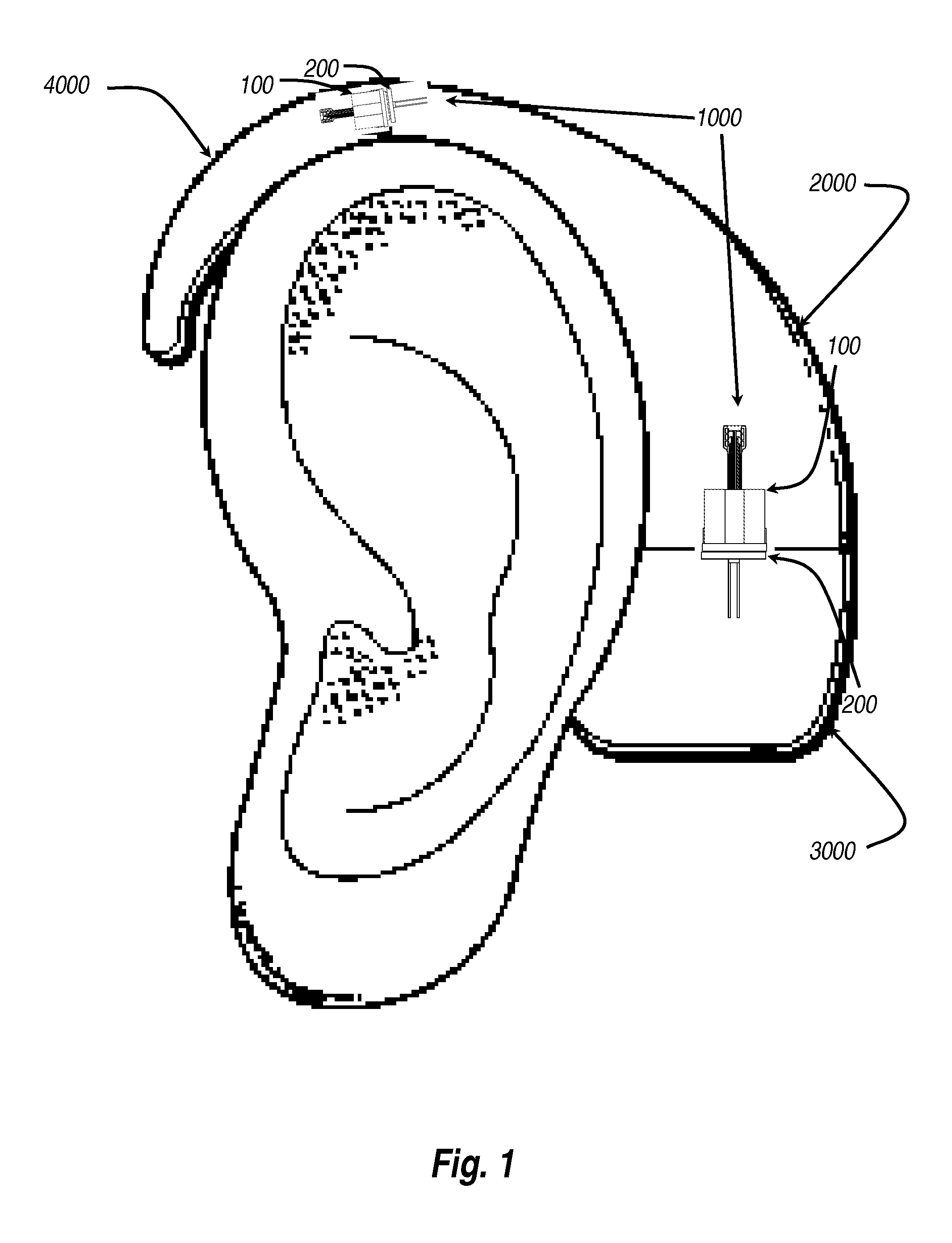

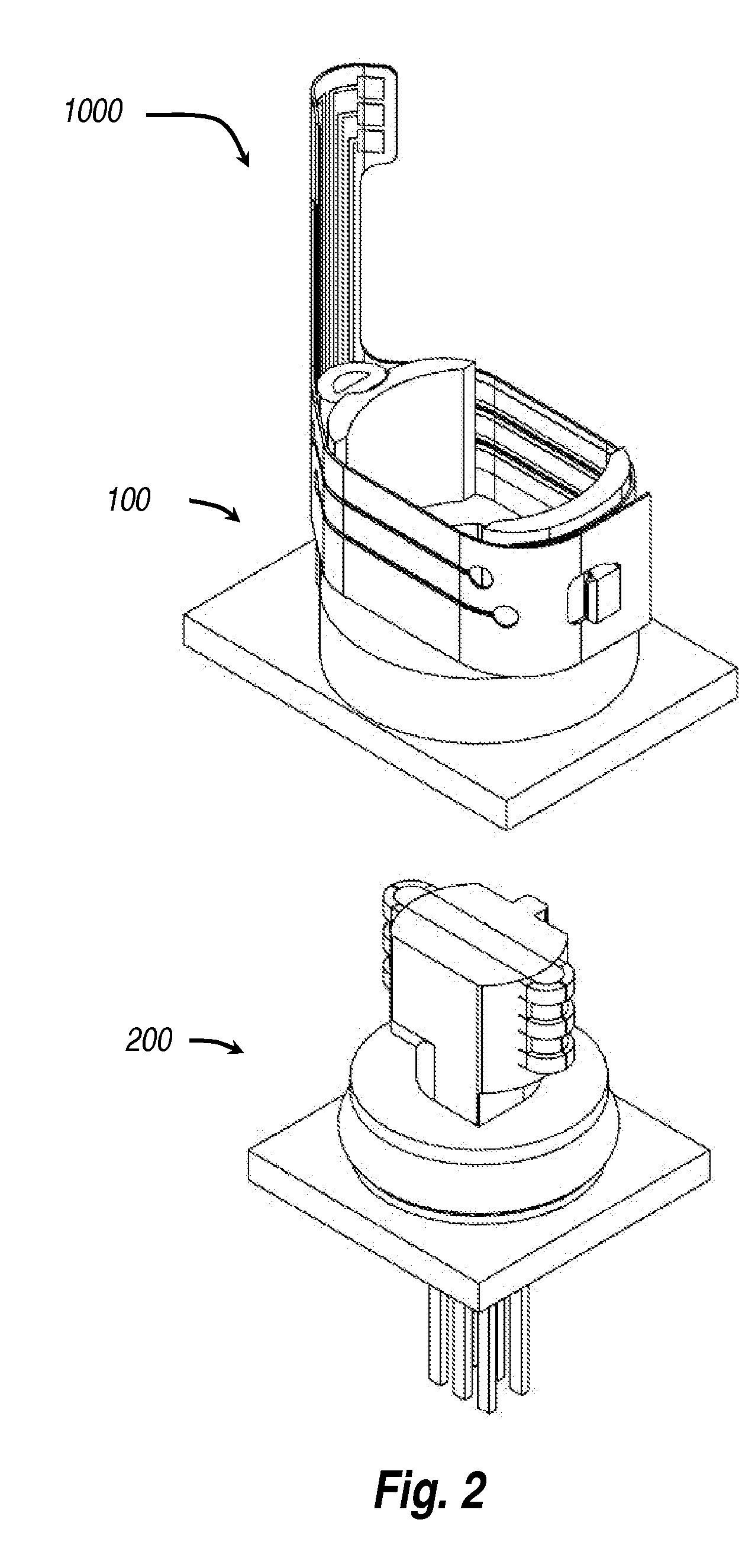

Multi-contact connector system

InactiveUS8591239B2Increase effective lengthIncrease flexibilityContact member manufacturingLive contact access preventionHearing apparatusEngineering

A connector system for Behind-The-Ear (BTE) hearing devices provides a means to detachably connect a variety of accessories to a sound processor, including batteries, earhooks, telecoils, auxiliary microphones, FM receivers, and input jacks for miscellaneous devices. The present invention provides an efficient and economical sealing connection, eliminating the introduction of sweat, body fluid and other contaminants into the connection area, which otherwise would result in corrosion and eventually disable the connected device. A wiping contact formed by a configuration of cam contacts and a flex circuit with a configuration of corresponding contacts is combined with a rotational engagement mechanism to create a vibration-resistant high contact density connector that is moisture proof when engaged.

Owner:ADVANCED BIONICS AG

Multi-Contact Connector System

InactiveUS20120045912A1Increase effective lengthIncrease flexibilityContact member manufacturingLive contact access preventionBody fluidHearing perception

A connector system for Behind-The-Ear (BTE) hearing devices provides a means to detachably connect a variety of accessories to a sound processor, including batteries, earhooks, telecoils, auxiliary microphones, FM receivers, and input jacks for miscellaneous devices. The present invention provides an efficient and economical sealing connection, eliminating the introduction of sweat, body fluid and other contaminants into the connection area, which otherwise would result in corrosion and eventually disable the connected device. A wiping contact formed by a configuration of cam contacts and a flex circuit with a configuration of corresponding contacts is combined with a rotational engagement mechanism to create a vibration-resistant high contact density connector that is moisture proof when engaged.

Owner:ADVANCED BIONICS AG

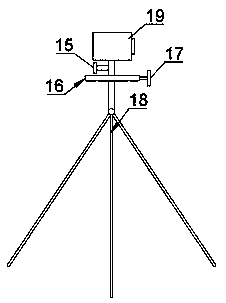

Flotation pulp magnetizer

The invention discloses a flotation pulp magnetizer which comprises a support frame body, a magnetizer body, a vacuum-pumping system, a distilling water storage tank, an air bag suspension stirring device and a control electric box, wherein a support plate is arranged on the support frame body, and the magnetizer body is arranged on the support plate; the vacuum-pumping system is arranged on one side of the magnetizer body and is connected with the support plate, and the distilling water storage tank is arranged on the other side of the magnetizer body and is connected with the support plate;the air bag suspension stirring device is arranged in the inner part of the magnetizer body, and the control electric box is arranged on one side of the support plate; and the magnetizer body comprises a magnetization tank, a magnetization sleeve and an eddy current oxygen exhauster, and the magnetization tank comprises an end cover and a tank body. According to the flotation pulp magnetizer, theair bag suspension stirring device is arranged in the tank body, a magnetic field is generated in the tank body through the magnetization sleeve at the outer part of the tank body, and a conducting loop is arranged in the air bag suspension stirring device in the tank body. The principle of electromagnetic induction is utilized, the air bag suspension stirring device rotates and crushes ores, andthe contact density of magnetized water and the ores is increased.

Owner:内蒙古广利隆能源股份有限公司

Method of packaging and interconnection of integrated circuits

InactiveUS20100038770A1High densityAdhesionSemiconductor/solid-state device detailsSolid-state devicesMicron scaleContact pad

A semiconductor chip packaging on a flexible substrate is disclosed. The chip and the flexible substrate are provided with corresponding raised and indented micron-scale contact pads with the indented contact pads partially filled with a liquid amalgam. After low temperature amalgam curing, the chip and the substrate form a flexible substrate IC packaging with high conductivity, controllable interface layer thickness, micron-scale contact density and low process temperature. Adhesion between the chip and the substrate can be further enhanced by coating other areas with non-conducting adhesive.

Owner:INTELLEFLEX CORP +1

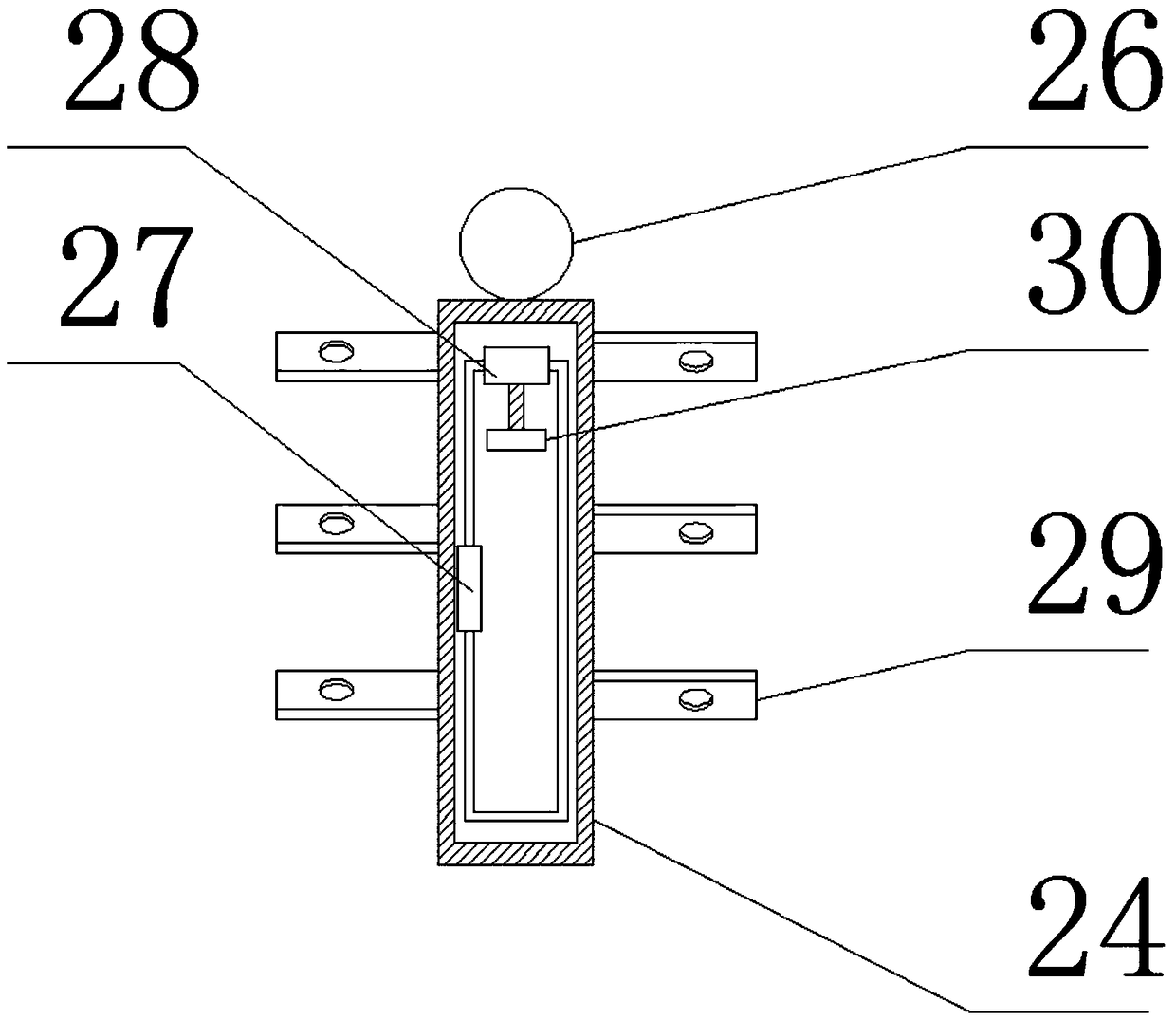

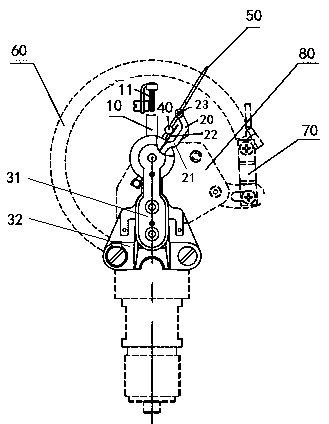

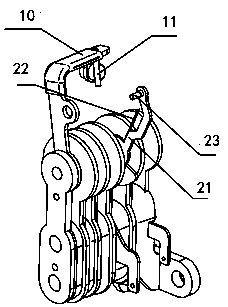

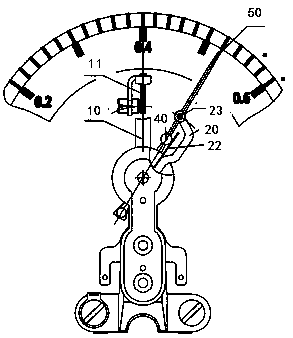

SF6 gas density switch capable of carrying out temperature compensation on multiple different density values

PendingCN110277275AMeet the technical requirements for temperature compensationElectric switchesPressure senseNational standard

The invention discloses an SF6 gas density switch capable of carrying out temperature compensation on multiple different density values, and the switch comprises a pressure sensing element spring tube, wherein a free end of the spring tube is connected with one end of a temperature compensation sheet, the other end of the temperature compensation sheet is connected with a sector gear on a transmission element movement, and a central gear shaft of the movement is provided with a pointer. During working, the temperature compensation is carried out on an SF6 gas density value through the temperature compensation sheet. The SF6 gas density switch is characterized in that the SF6 gas density switch is further provided with an electric contact, a wire spring on the electric contact adopts a bimetallic strip which is bent along with the change of ambient temperature, and temperature compensation of a contact density value is corrected through the bimetallic strip. The multi-point temperature compensation problem of the SF6 gas density switch in use is solved, so that the switch meets the GB / T 22065-2006 national standard and the DL / T 259-2012 electric power industry standard at the same time.

Owner:上海新远仪表厂有限公司

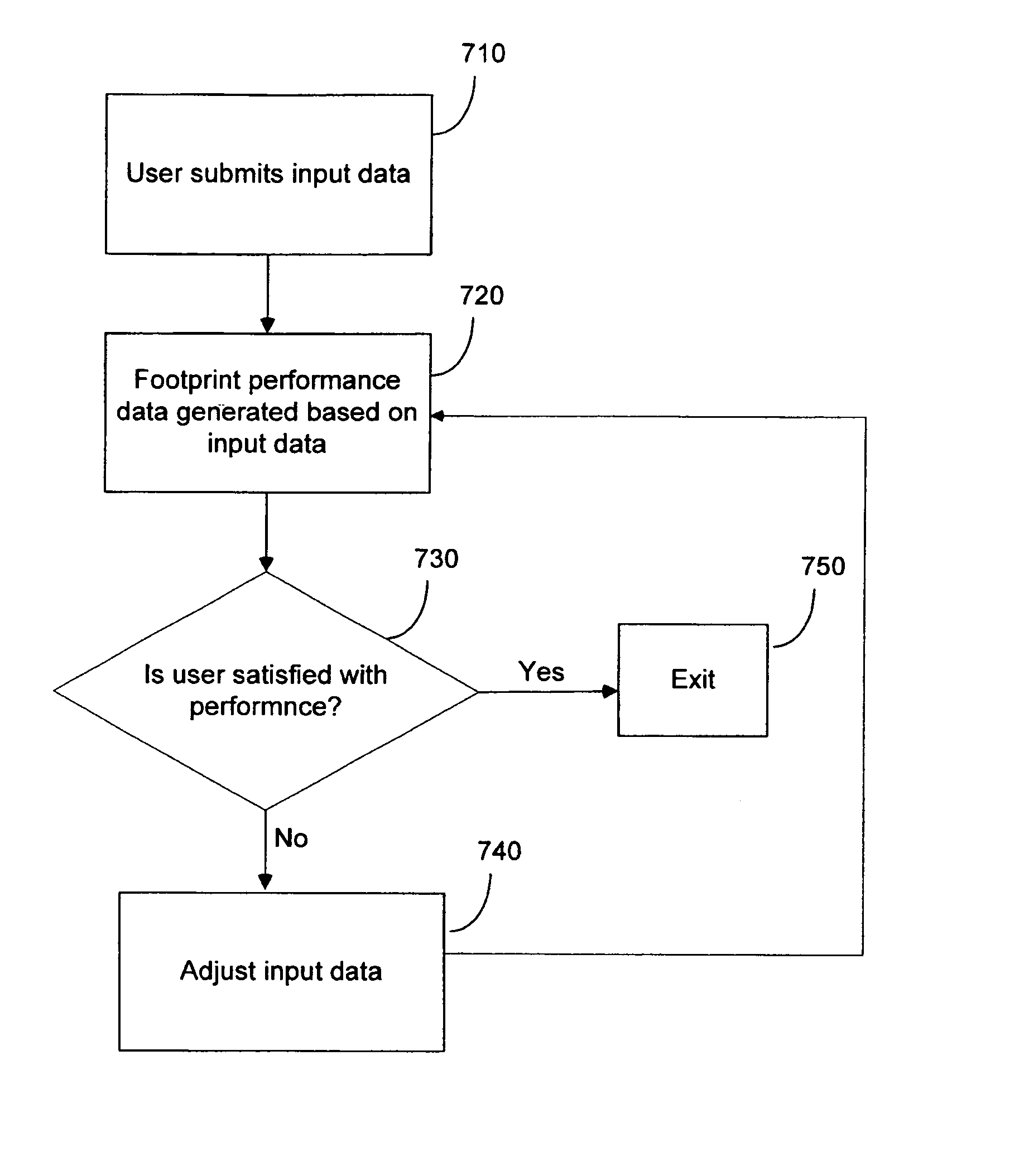

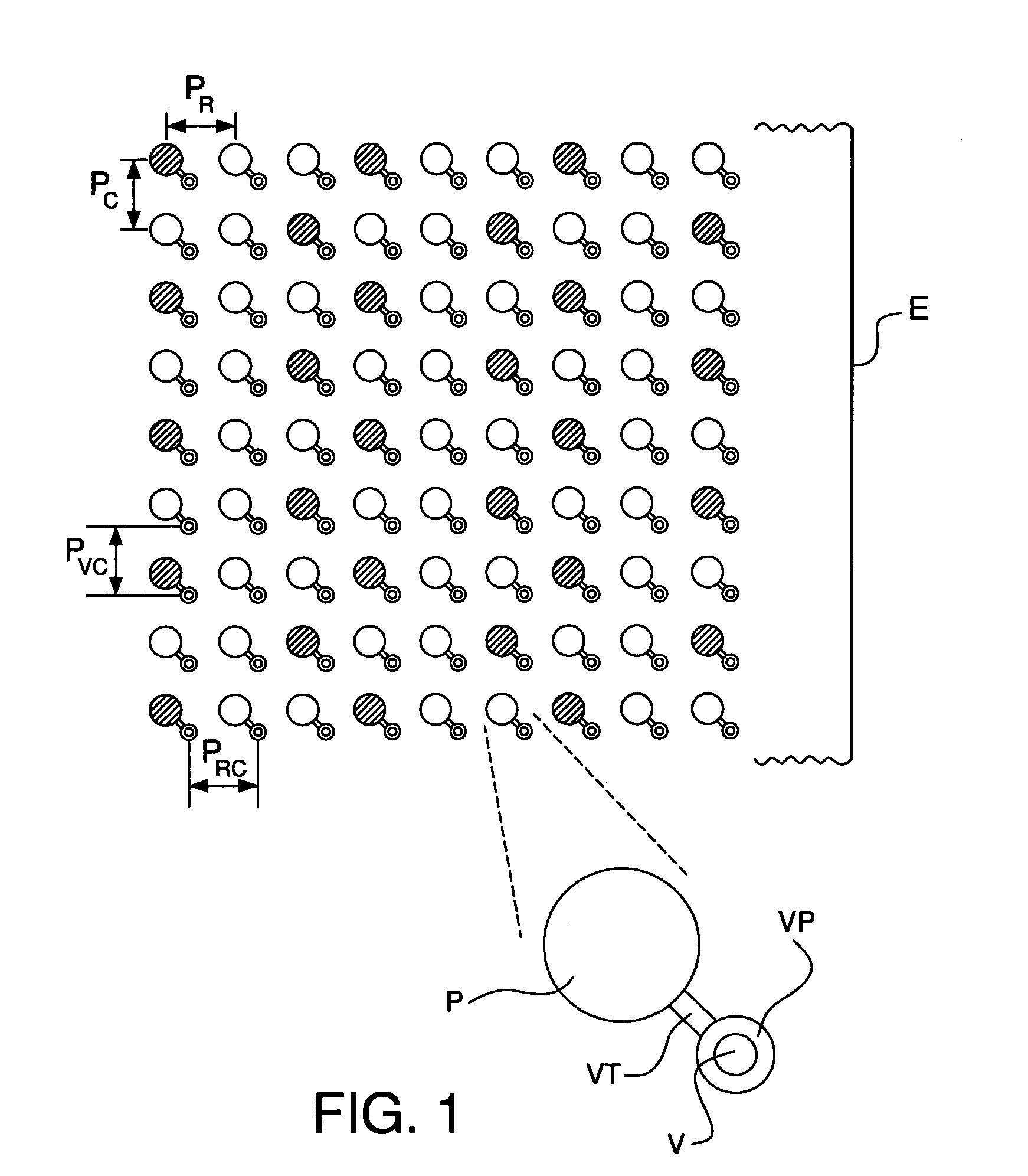

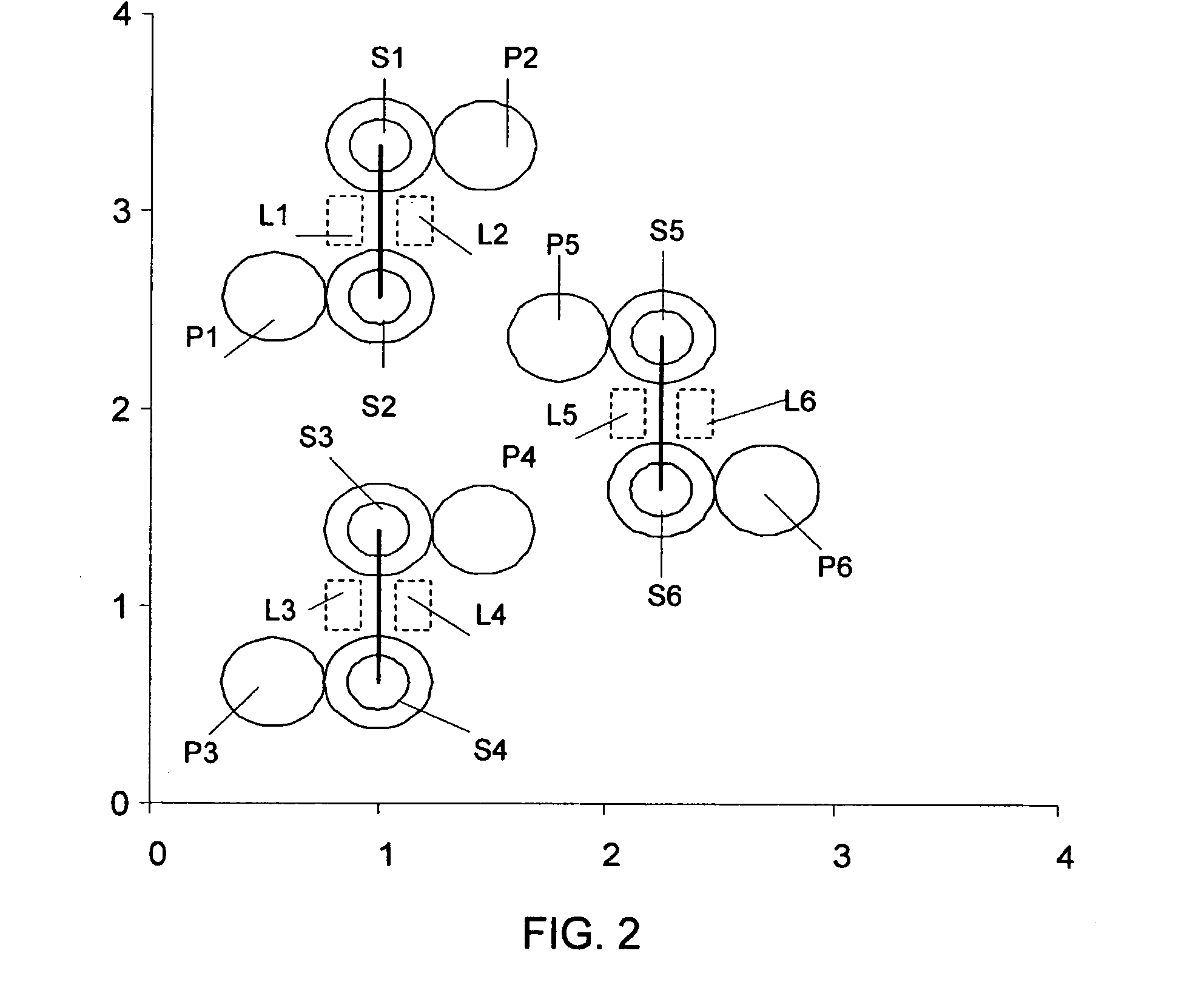

High-frequency, high-signal-density, surface-mount technology footprint definitions

ActiveUS7284221B2Suppress crosstalkHigh contact densitySemiconductor/solid-state device detailsPrinted circuit aspectsElectrical connectionSurface-mount technology

Methods for designing SMT connector footprints are disclosed. A circuit board may have disposed thereon an arrangement of SMT pads and corresponding vias. The arrangement of vias may differ from the arrangement of SMT pads. The arrangement of SMT pads may differ from the arrangement of contacts in a connector the footprint is designed to receive. The terminal ends of the contacts may be jogged or bent for electrical connection with the SMT pads. The SMT pads and vias may be arranged in a number of ways that increase signal contact density of the board, while limiting cross-talk and providing adequate impedance and routing space on the board. An interactive tool for designing such a footprint is disclosed.

Owner:FCI AMERICAS TECH LLC

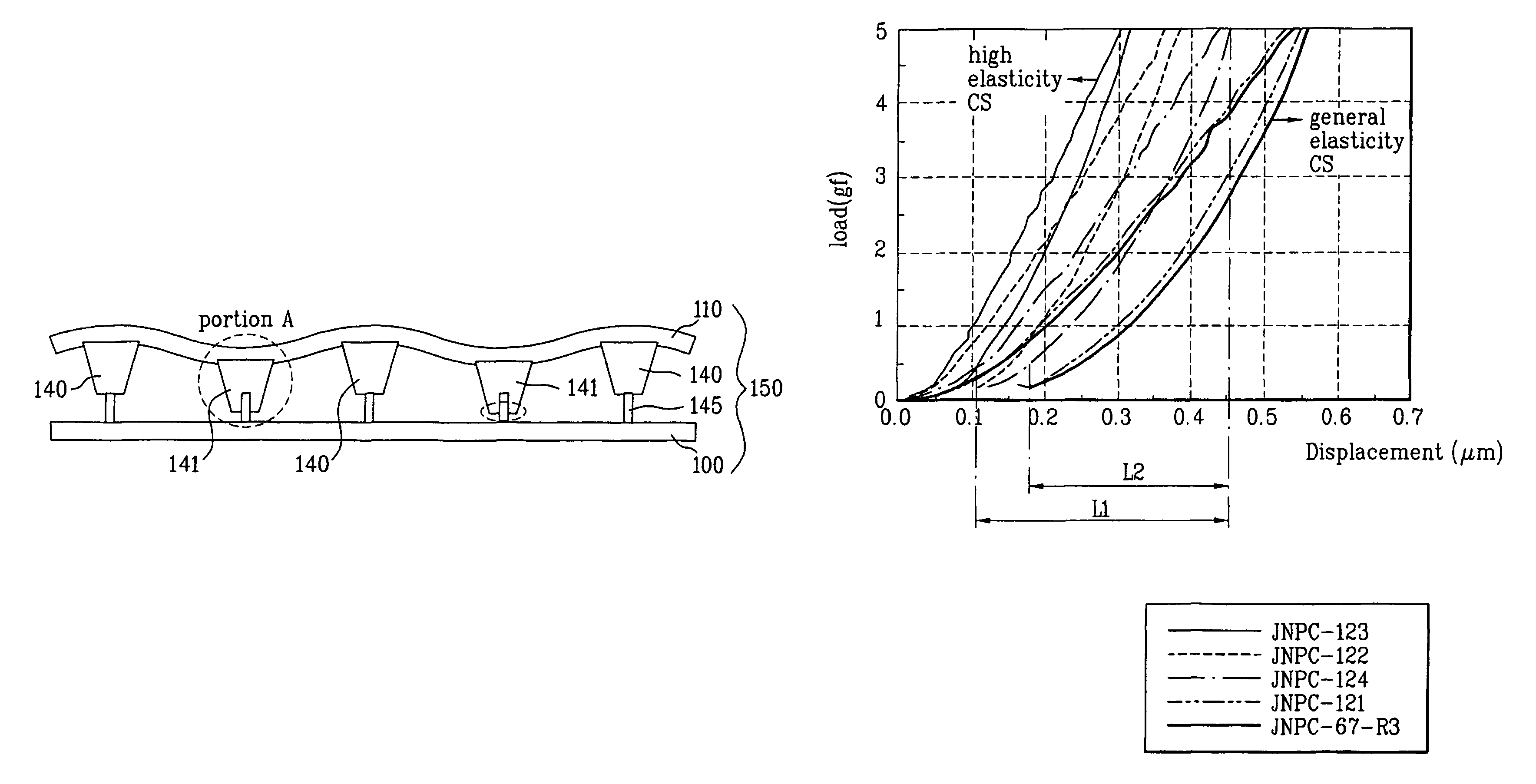

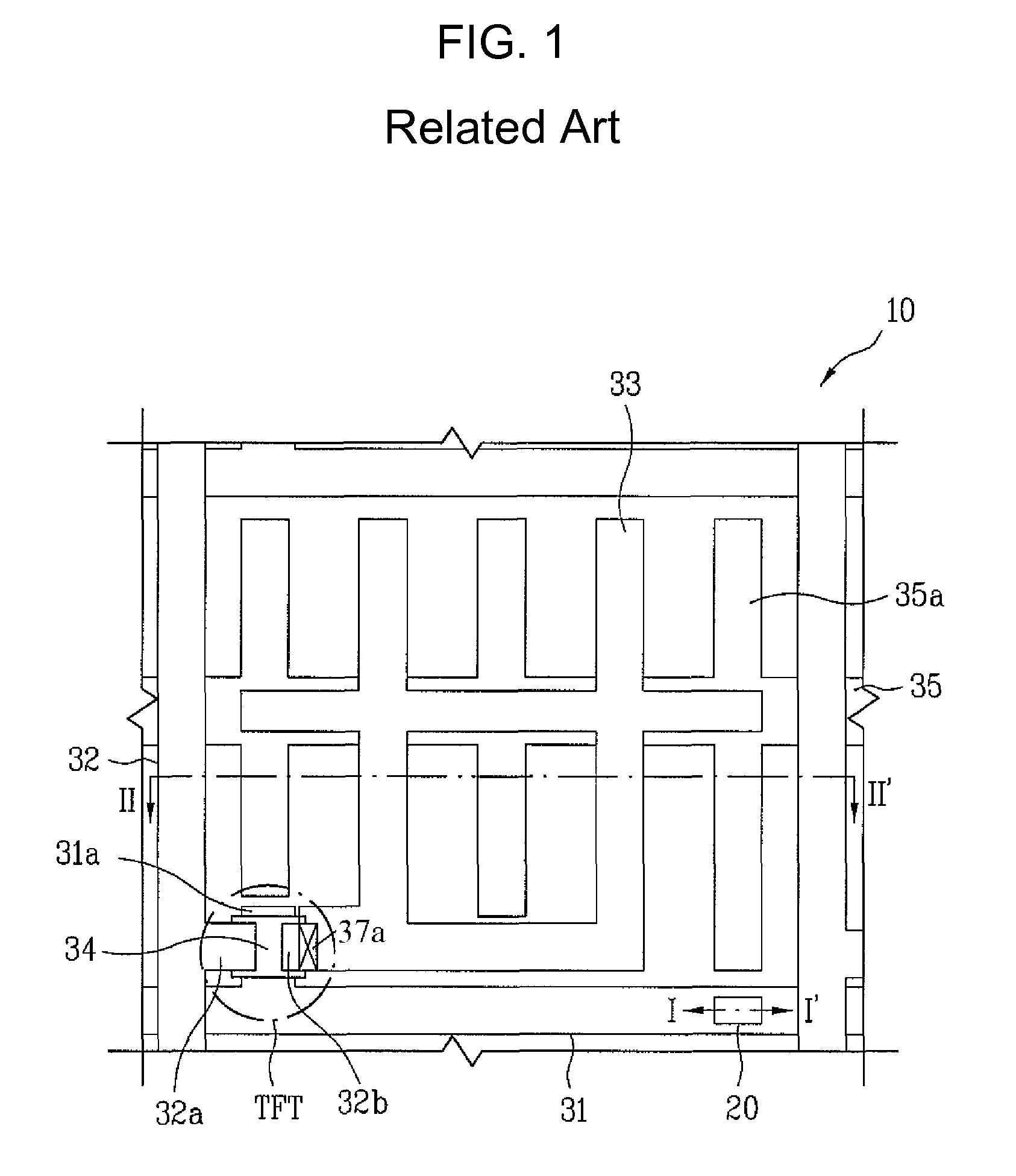

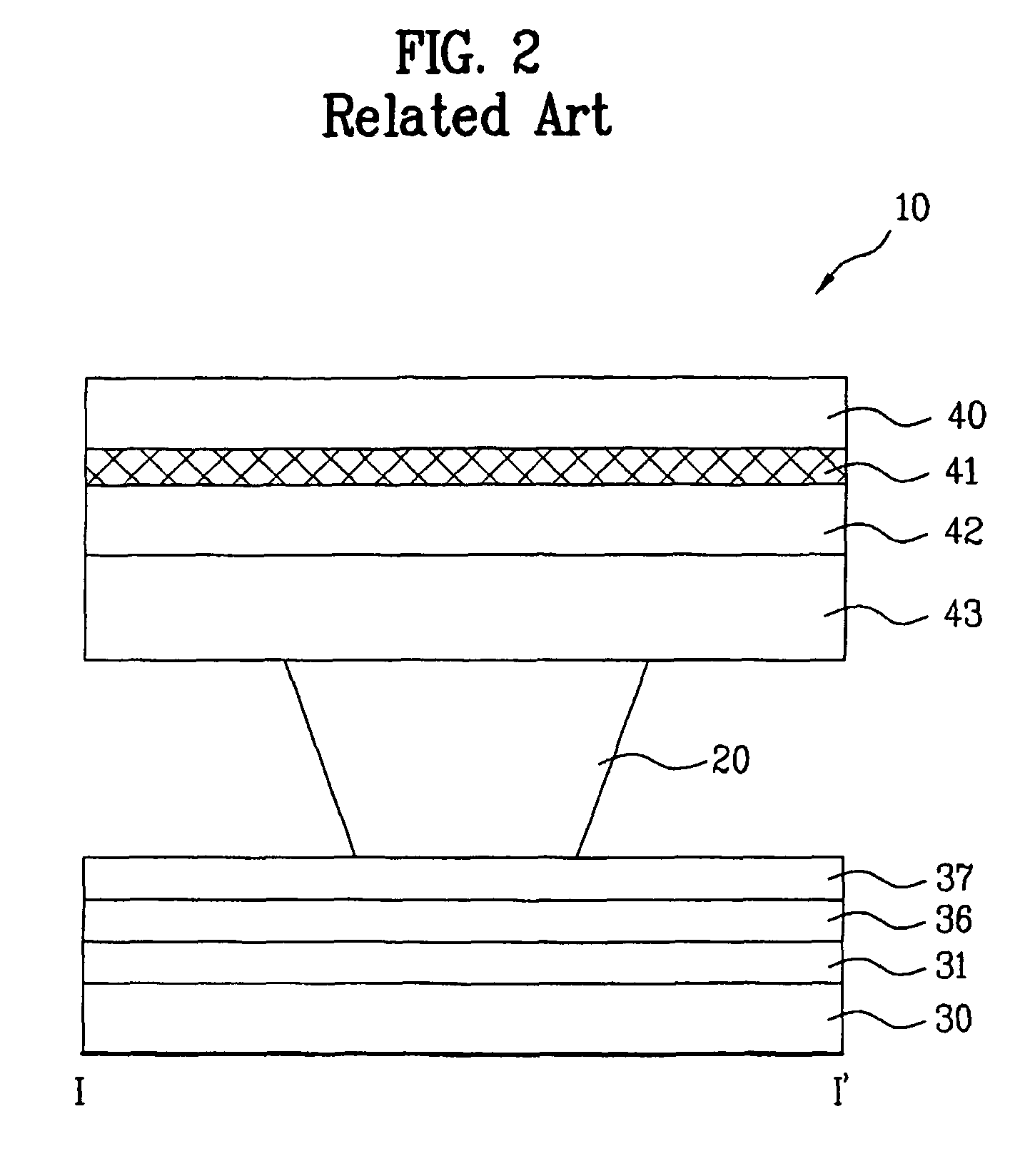

Liquid crystal display device having column spacers and protrusions

ActiveUS8248571B2Reduce touch defectsRelieve substrate wavinessNon-linear opticsLiquid-crystal displayEngineering

Owner:LG DISPLAY CO LTD

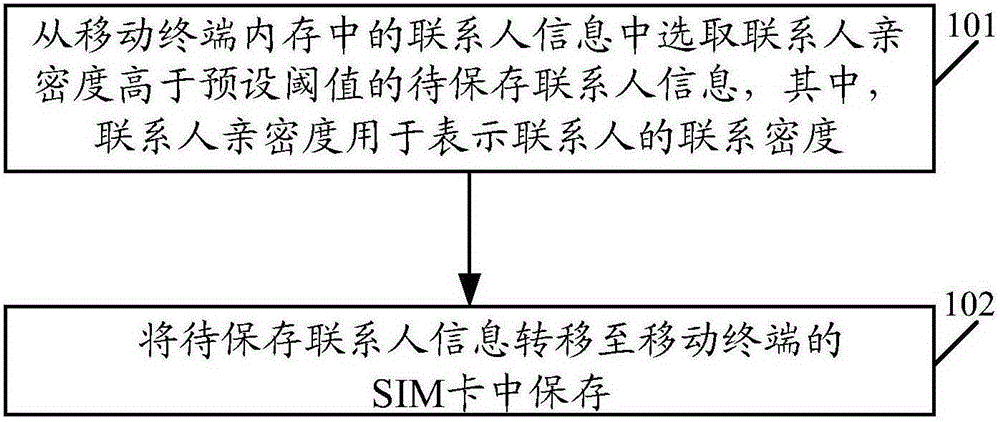

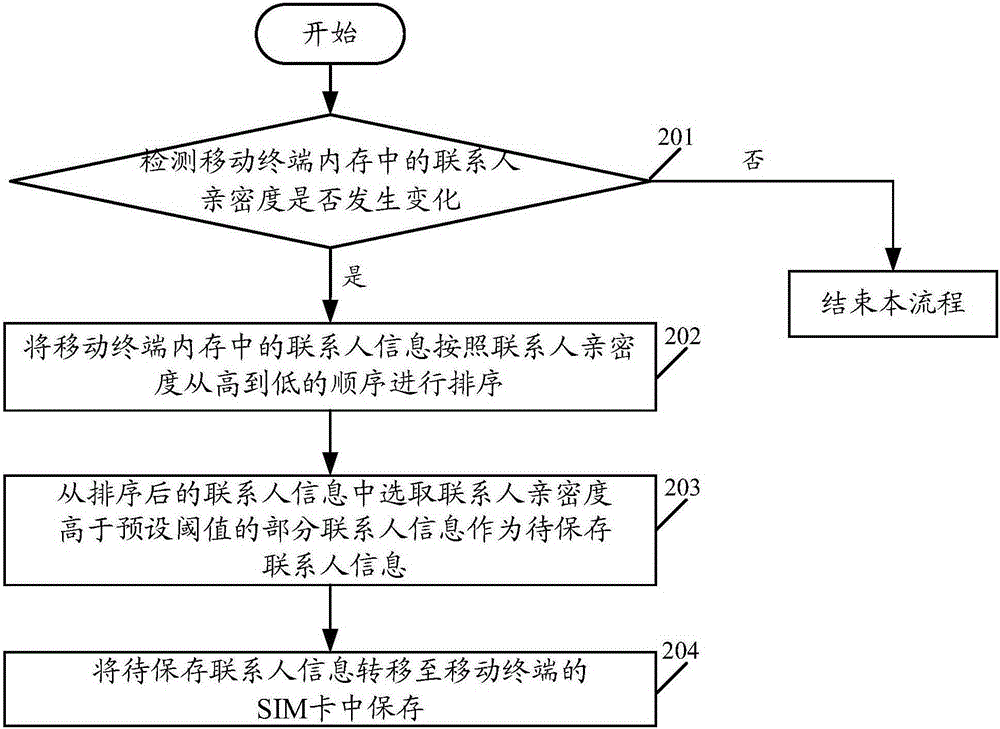

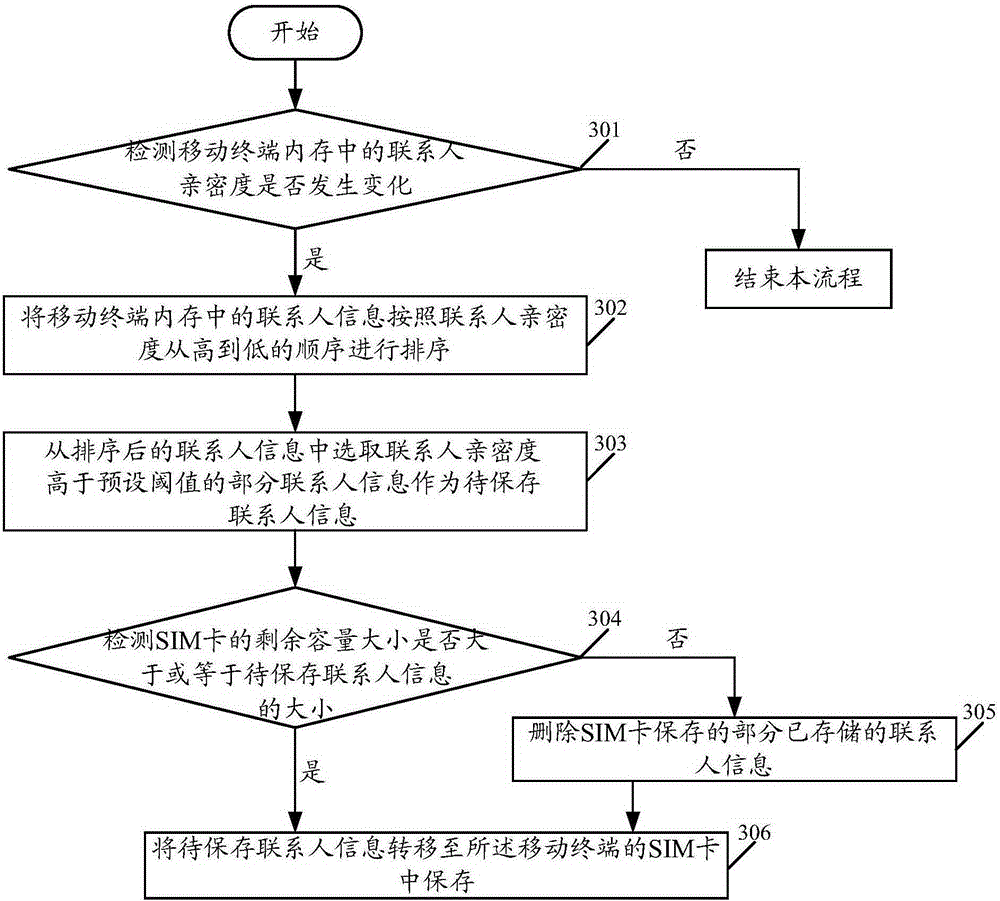

Contact person information storage method and mobile terminal

InactiveCN105554216AImprove storage efficiencyReduce the risk of lossSubstation equipmentContact densityComputer science

The embodiment of the invention relates to the field of the communication technology, and discloses a contact person information storage method and a mobile terminal. The method provided by the invention comprises: selecting contact person information to be stored having a contact person intimacy higher than a preset threshold in the contact person information in a mobile terminal memory, the contact person intimacy is configured to express the contact density of a contact person, and the contact person information to be stored is transferred to the user identification module card of the mobile terminal for storage. The embodiment of the invention is able to improved the storage efficiency of the contact person information and reduce the loss risk of the contact person information.

Owner:DONGGUAN COOLPAD SOFTWARE TECH

Flat cell read only memory using common contacts for bit lines and virtual ground lines

InactiveUS20060176754A1Reduce contact densityReduce the overall heightTransistorSolid-state devicesBit lineMemory bank

In a flat cell read only memory, two bit lines or two virtual ground lines share a common contact such that the contact is slightly adjustable in its location for inserting a local metal word line without increasing the layout area to improve the reading speed of the memory. Moreover, two adjacent banks of the memory share common bit lines or virtual ground lines, whereby reducing the contact density and height of the memory.

Owner:ELAN MICROELECTRONICS CORPORATION

Mini round four-core electric connector and assembly method thereof

PendingCN107994372ASimple structureCompact structureContact member assembly/disassemblyCoupling contact membersElectricityAviation

The invention discloses a mini round four-core electric connector. The mini round four-core electric connector comprises a plug component and a socket component. The plug component comprises a plug shell. A jack base, a jack and a first cable are mounted in the plug shell. A connection ring and a plug bushing sleeve the plug shell. A clamp ring is arranged at the joint between the connection ringand the plug shell. The socket component comprises a socket shell. A pin base is mounted in the socket shell. A pin is fixed to the pin base. A second cable is connected with the pin. An O-ring is arranged on a waist pad of the socket shell. Locking nuts are mounted on two sides of the socket shell. The mini round four-core electric connector shares the features of high contact density and small size with round connectors, has the advantages of high density, lightweight and microminiaturization, can be applied to severe environments with high vibration and impact, is applicable to occasions with special requirements on space and equipment lightweight, and can be widely applied to aviation and spaceflight fields and environments with large environment temperature change.

Owner:MIANYANG CITY JINHUA WESTERN ELECTRIC MFG

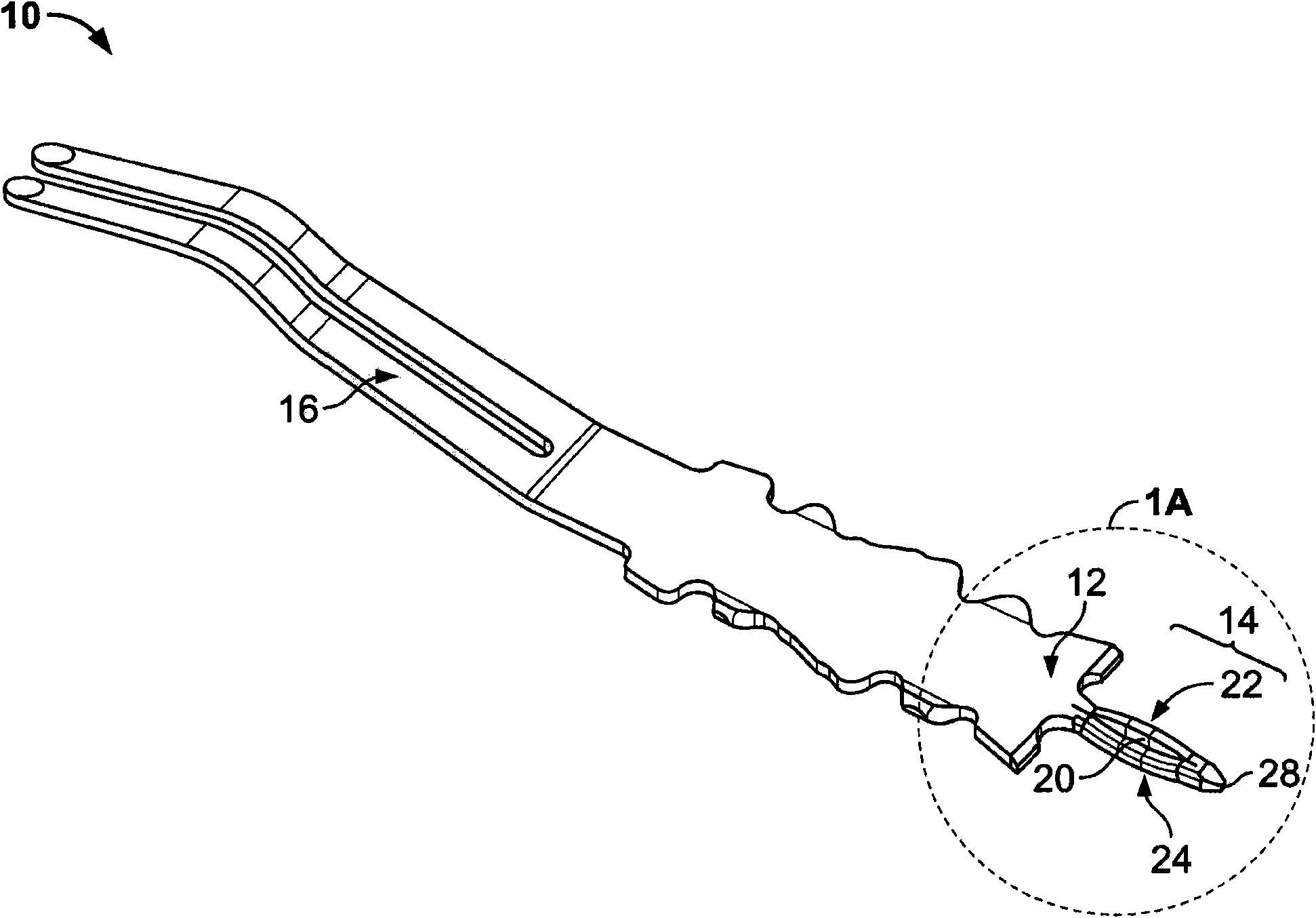

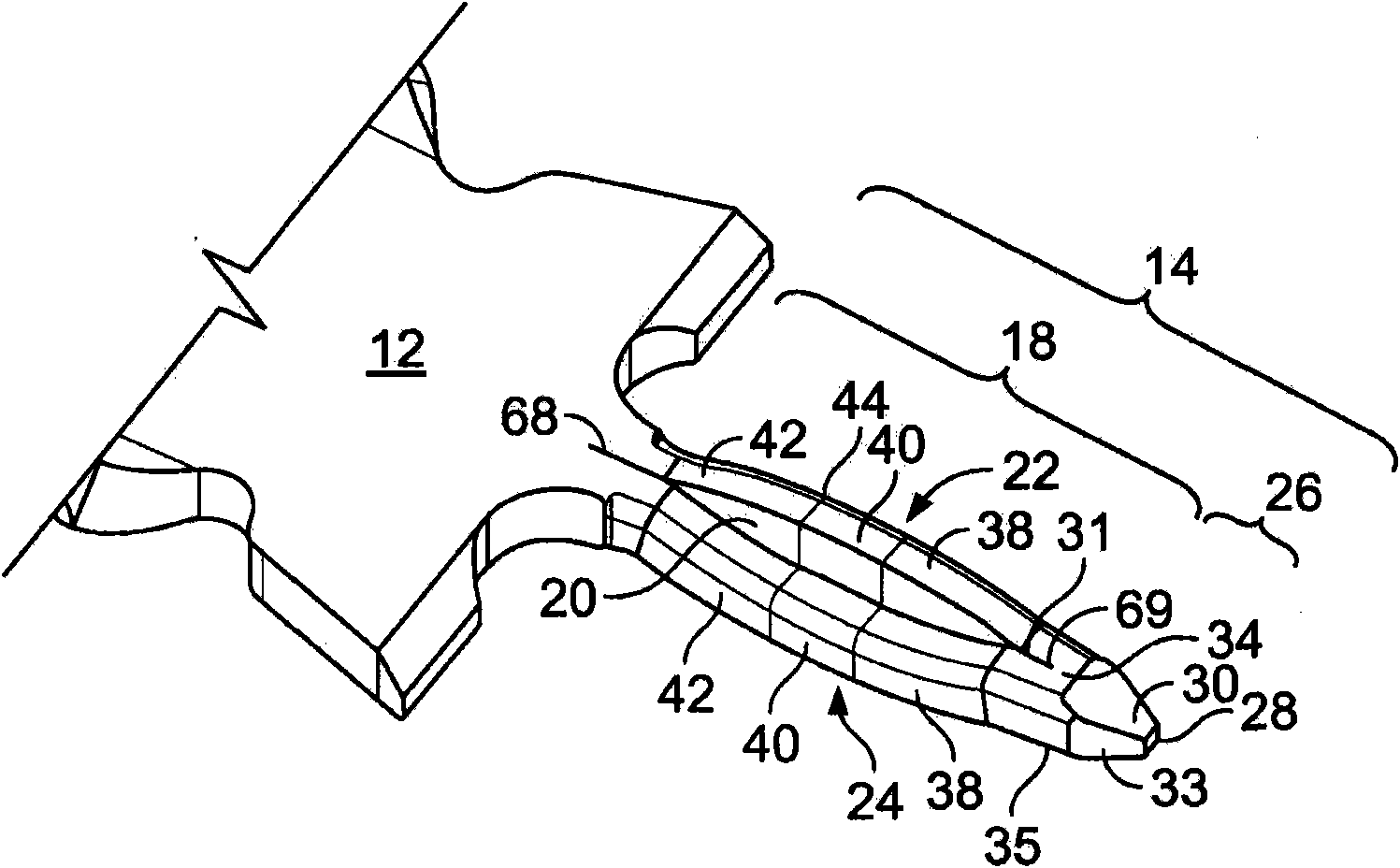

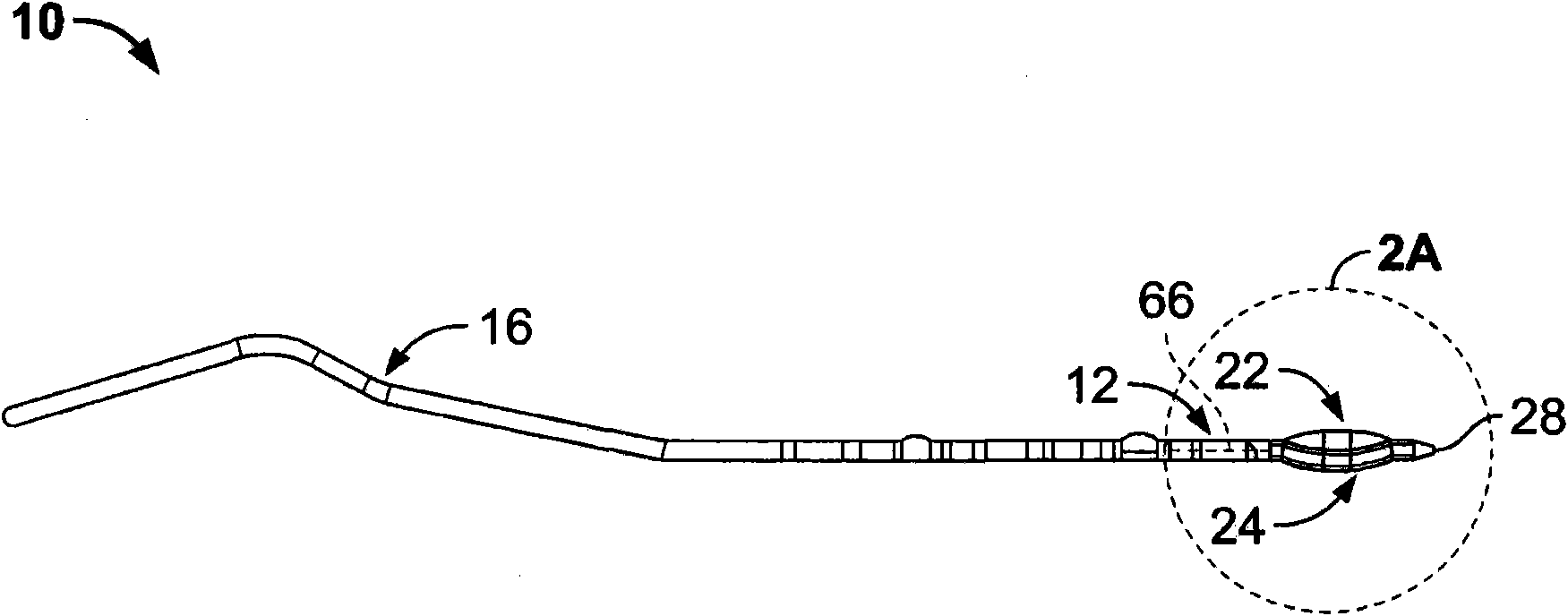

High-contact density electrode and fabrication technique for an implantable cuff design

ActiveUS9980645B1Minimize force impartedMaintain relationshipSpinal electrodesPerson identificationMultiplexingElectricity

A method and an electrode for monitoring electrical activity in a nerve are provided along with a method of fabricating such an electrode. The electrode includes a cuff formed from a chronically-implantable material that, when implanted, extends at least partially around an external periphery of the nerve. A plurality of contacts are supported by the cuff to be arranged adjacent to different regions of the nerve distributed along a transverse direction of the nerve when the cuff is implanted. A multiplexer is coupled to the cuff to be implanted for receiving electrical signals introduced to the contacts by the nerve and multiplexing, in vivo, the electrical signals to be transmitted to an external receiver over a shared communication channel.

Owner:CASE WESTERN RESERVE UNIV

Etching substrates mounted with gas wall

ActiveCN101399166BSolve the defect that cannot be mixedHigh Etch Rate UniformitySemiconductor/solid-state device manufacturingContact densityInjection device

The invention relates to an etching substrate which is provided with a gas wall. The etching substrate is provided with a central region and a peripheral region which is provided with at least one injection device which injects gas to form the gas wall to control the contact density between etching gas in an etching device and the etching substrate. When the invention is used for etching Al, the injection device is opened to form the gas wall, and when other materials are etched, the injection device is closed, therefore, one same etching substrate can be used for etching not only Al but alsoother materials, thus realizing that one etching substrate can etch a plurality of materials of different properties.

Owner:K TRONICS (SUZHOU) TECH CO LTD +1

Etching substrates mounted with gas wall

ActiveCN101399166ASolve the defect that cannot be mixedHigh Etch Rate UniformitySemiconductor/solid-state device manufacturingProduct gasContact density

The invention relates to an etching substrate which is provided with a gas wall. The etching substrate is provided with a central region and a peripheral region which is provided with at least one injection device which injects gas to form the gas wall to control the contact density between etching gas in an etching device and the etching substrate. When the invention is used for etching Al, the injection device is opened to form the gas wall, and when other materials are etched, the injection device is closed, therefore, one same etching substrate can be used for etching not only Al but also other materials, thus realizing that one etching substrate can etch a plurality of materials of different properties.

Owner:K TRONICS (SUZHOU) TECH CO LTD +1

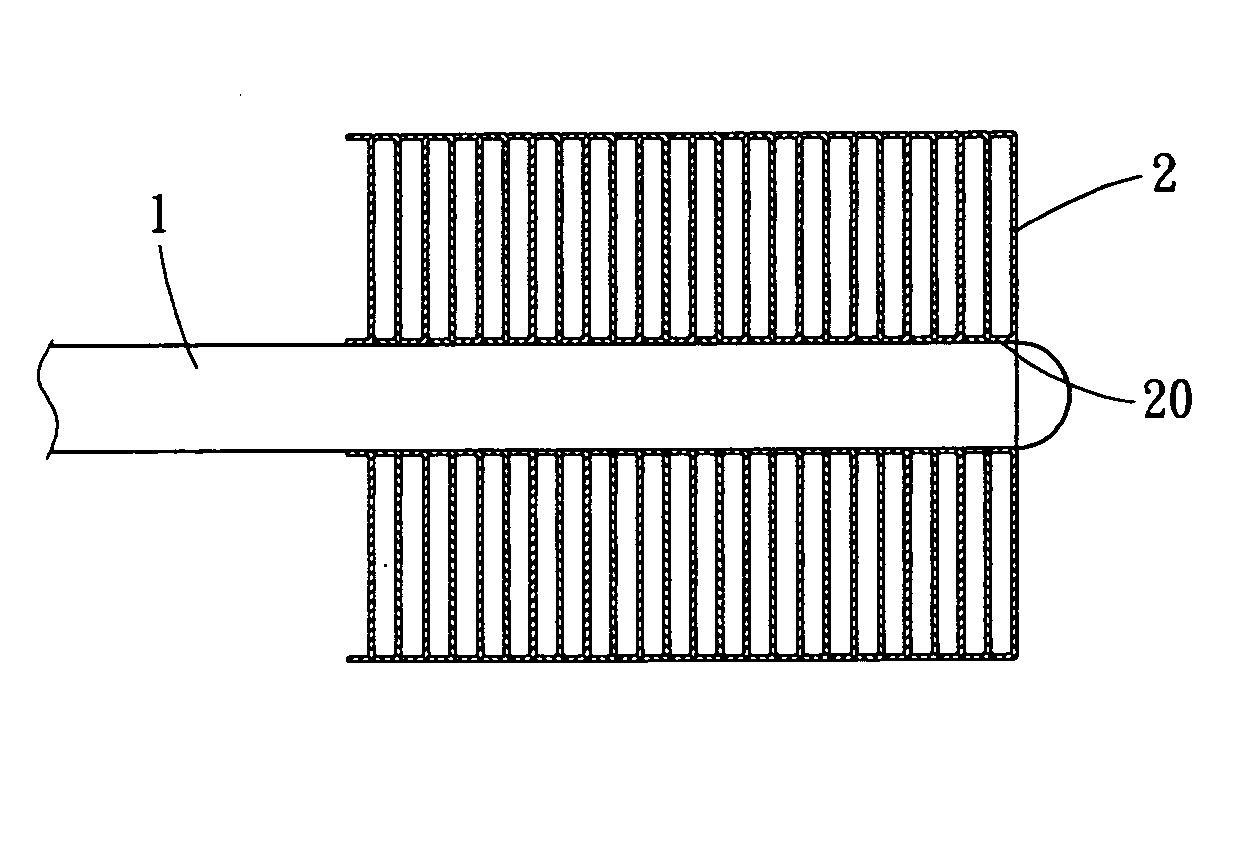

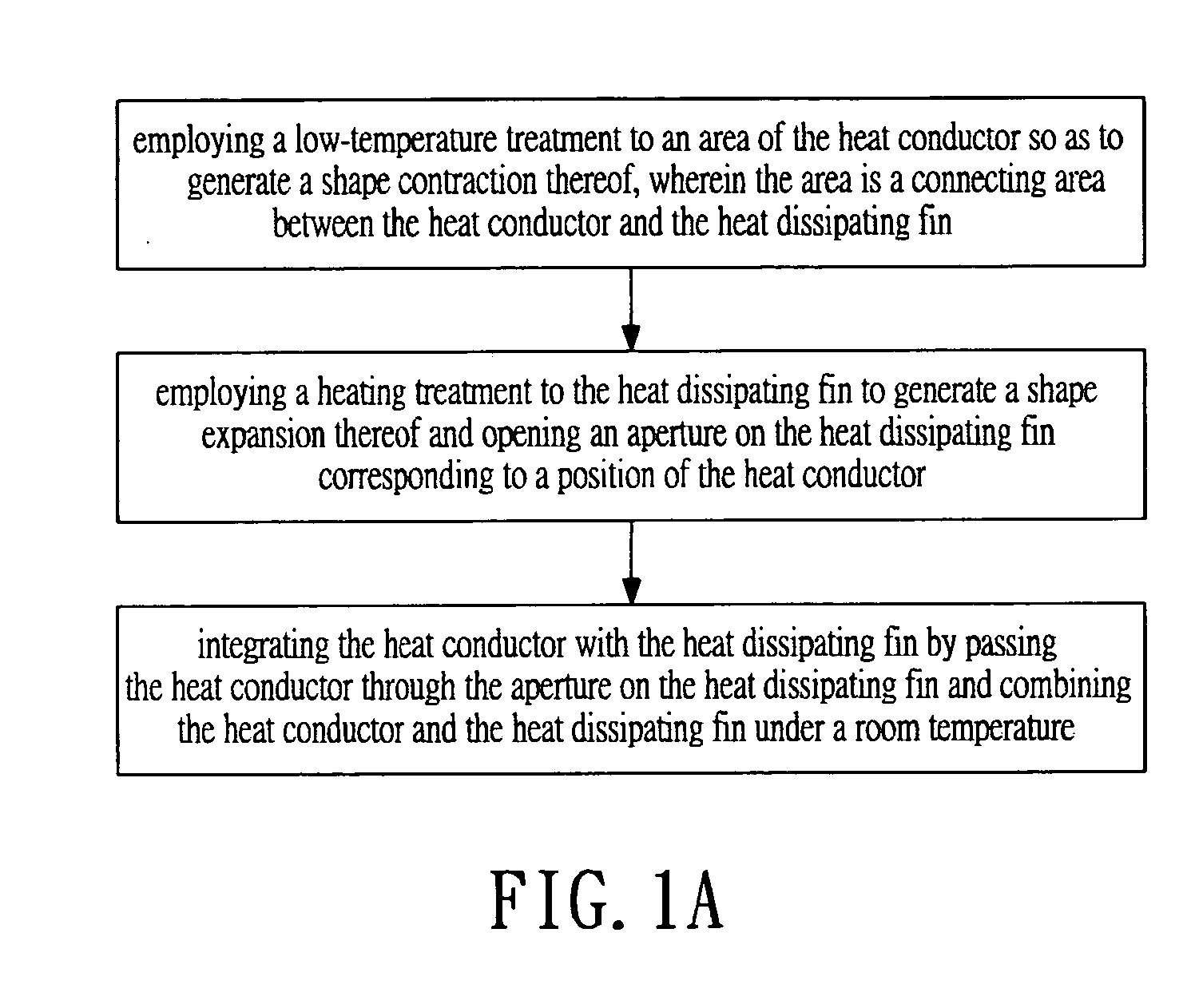

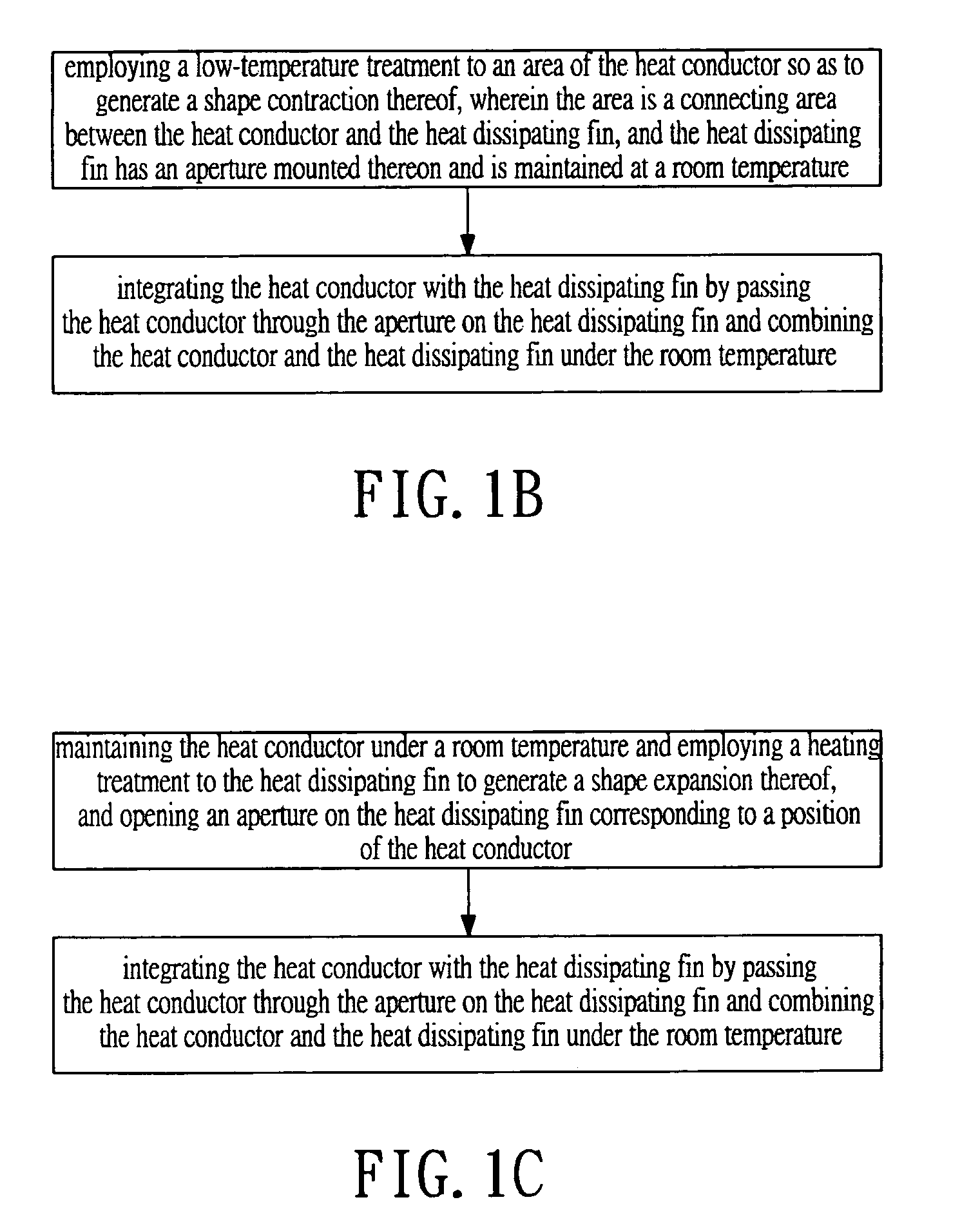

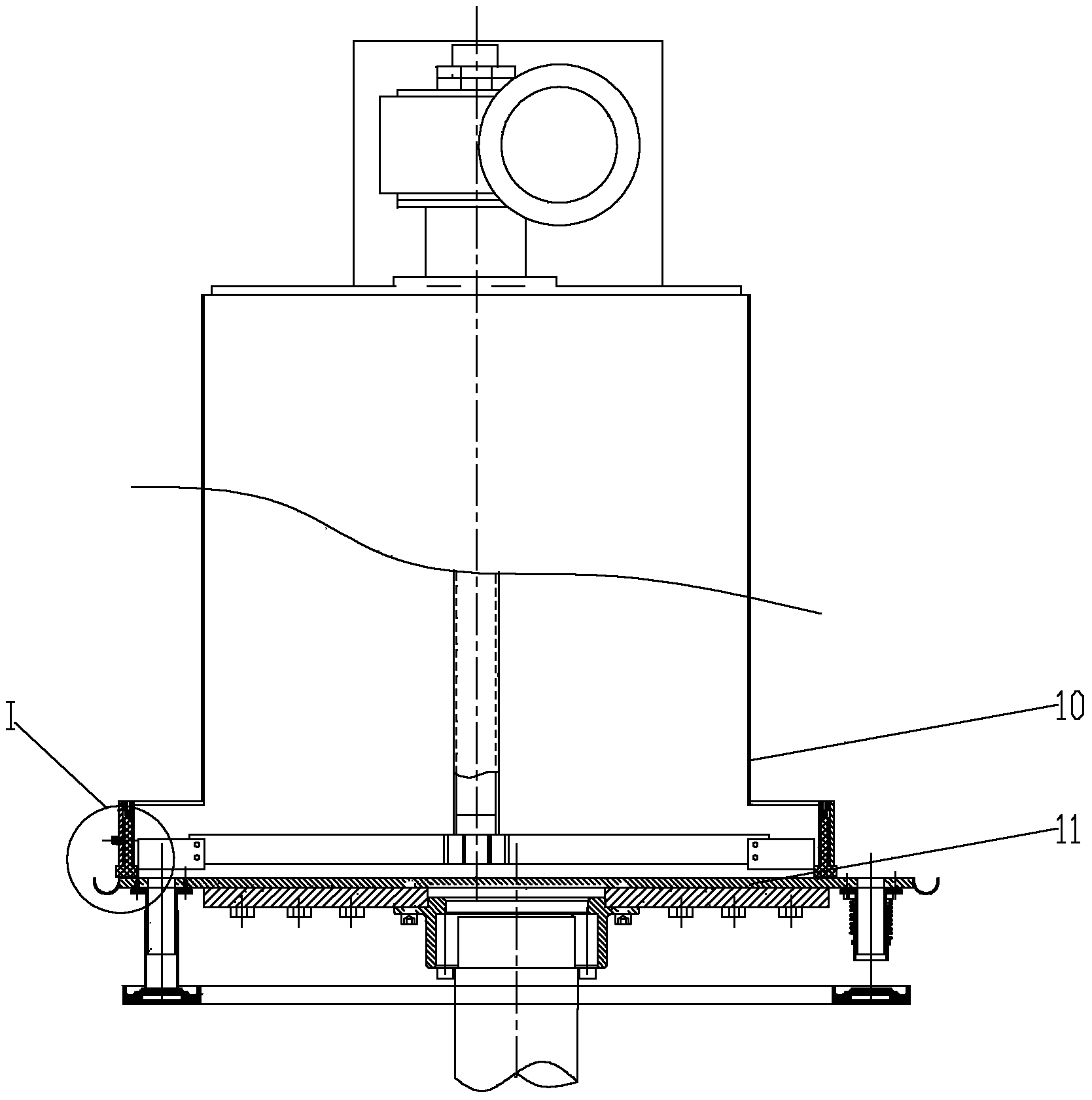

Method for integrating heat conductor with heat dissipating fin

InactiveUS20050193561A1Easy passProne to feverMetal-working apparatusHeat exchanger fasteningElectrical conductorRoom temperature

A method for integrating a heat conductor with a heat dissipating fin is provided. The steps includes: a) employing a low-temperature treatment to an area of the heat conductor so as to generate a shape contraction thereof, wherein the area is a connecting area between the heat conductor and the heat dissipating fin; b) employing a heating treatment to the heat dissipating fin to generate a shape expansion thereof and opening an aperture on the heat dissipating fin corresponding to a position of the heat conductor; and c) integrating the heat conductor with the heat dissipating fin by passing the heat conductor through the aperture on the heat dissipating fin and combining the heat conductor and the heat dissipating fin under a room temperature. Accordingly, the contact density between heat conductor and heat dissipating fin is increased, while the thermal resistance is reduced.

Owner:CPUMATE INC

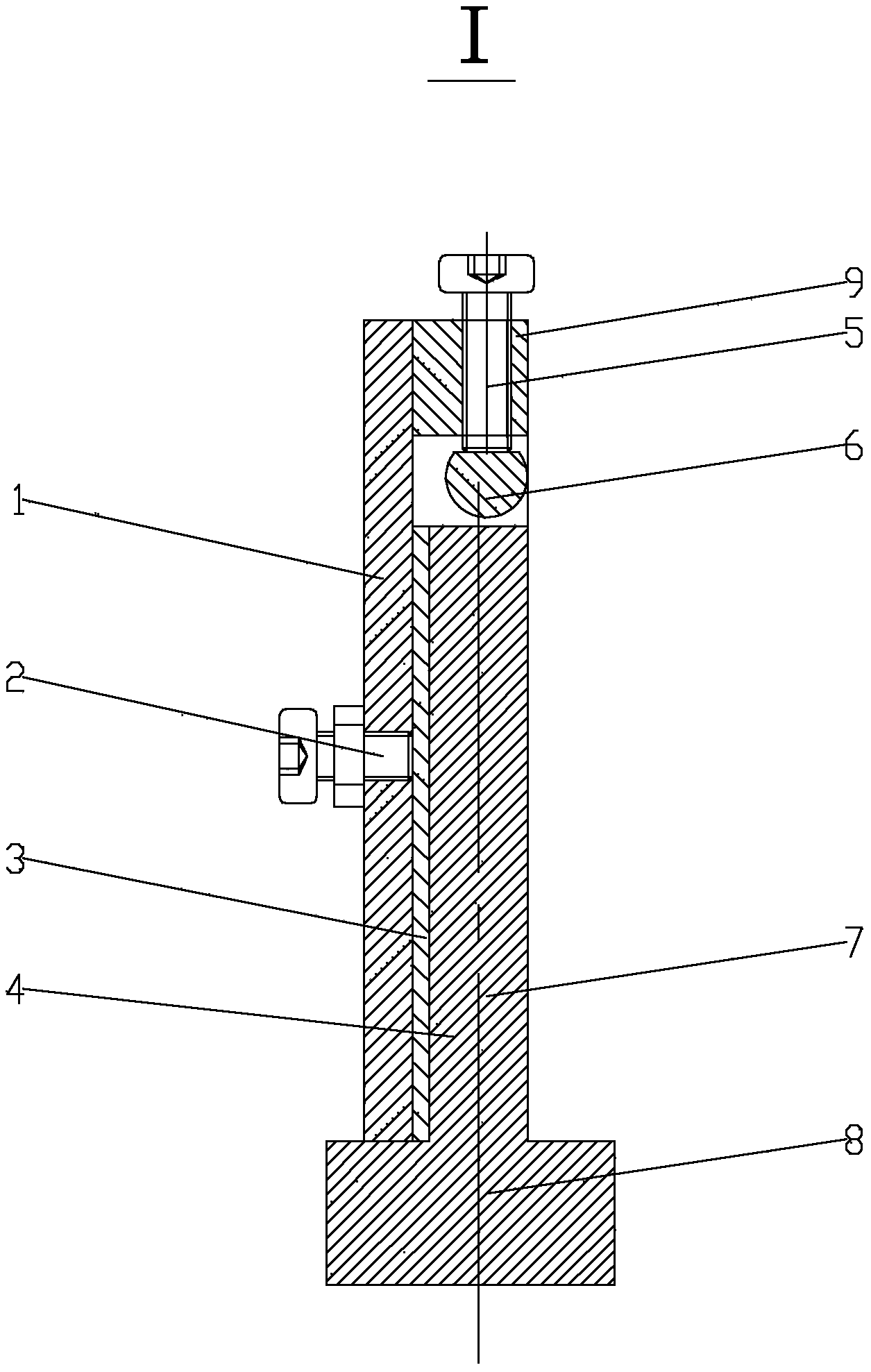

Rotary type oily particle filling material box sealing mechanism

InactiveCN103950562AIncrease contact densitySimple structureLiquid materialEngineeringMechanical engineering

The invention relates to a rotary type oily particle filling material box sealing mechanism, particularly relates to a sealing mechanism for an oily granular fluid food filling equipment material box, and belongs to the technical field of filling. The rotary type oily particle filling material box sealing mechanism comprises an outer side pressing plate, side adjustment bolts, an inner side pressing plate, a sealing ring, upper adjustment screws, an upper pressing plate and a top side pressing plate, wherein the sealing ring and the top side pressing plate are arranged on an inner ring of the outer side pressing plate; a plurality of upper adjustment screws are arranged on the top side pressing plate; the upper pressing plate is arranged between the top side pressing plate and the sealing ring; a plurality of side adjustment bolts are arranged on the outer side pressing plate; the inner side pressing plate is arranged between the outer side pressing plate and the sealing ring. According to the rotary type oily particle filling material box sealing mechanism, contact density of the sealing ring and a quantification valve fixing disk is enhanced, so that the sealing property of the sealing ring and the quantification valve fixing disk is improved; the pressing force on the side surface and the upper part of the sealing ring can be adjusted, and various requirements can be met.

Owner:无锡隆俊机械制造有限公司

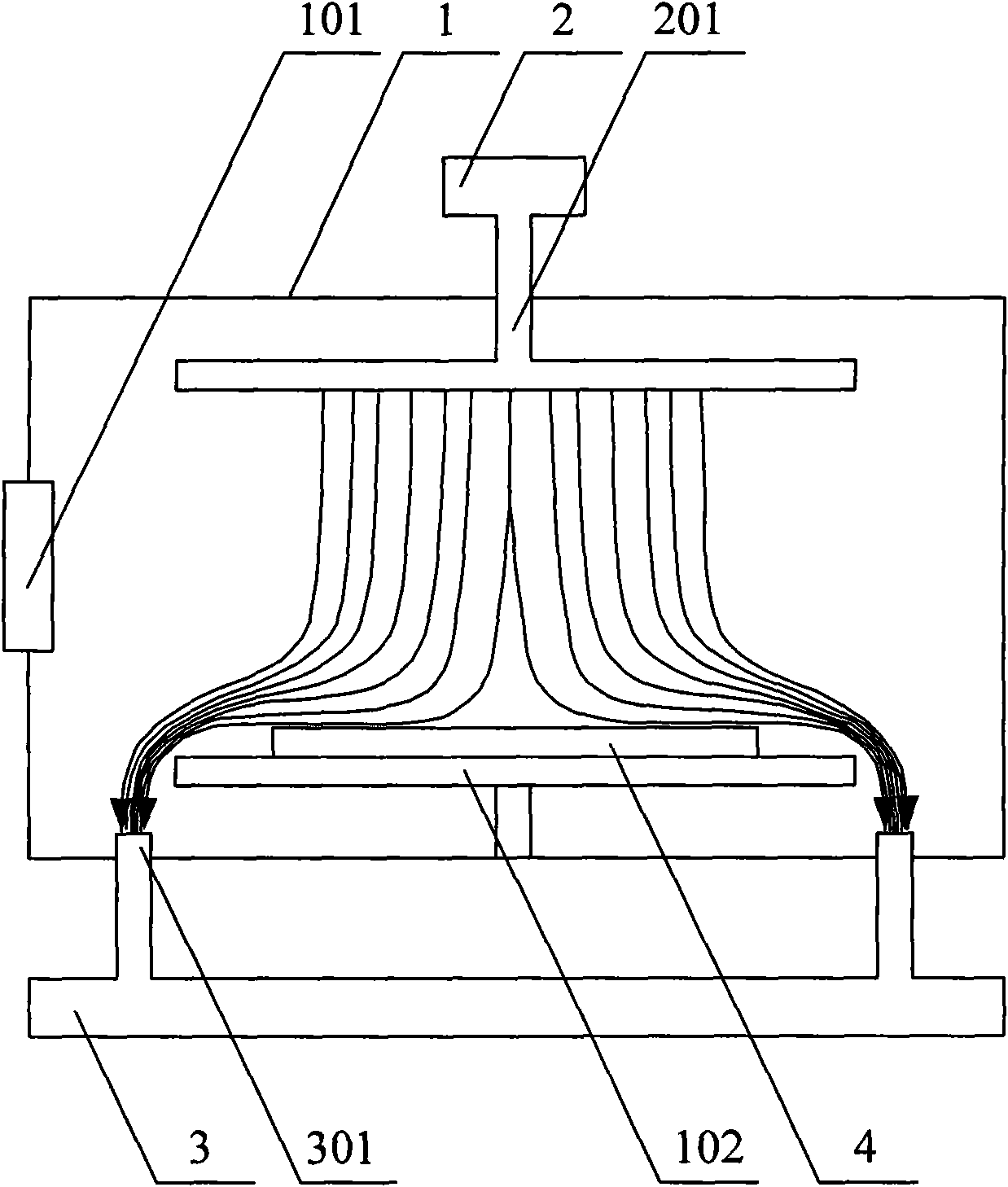

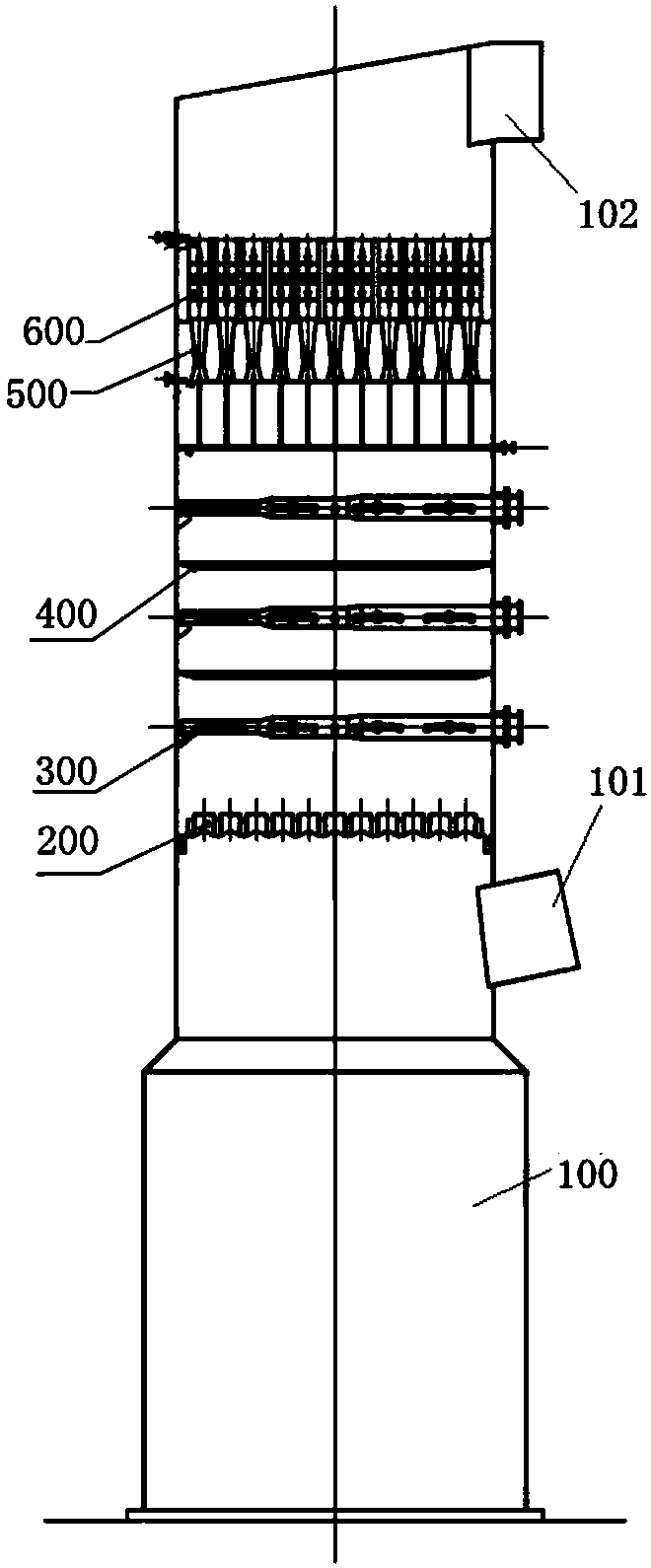

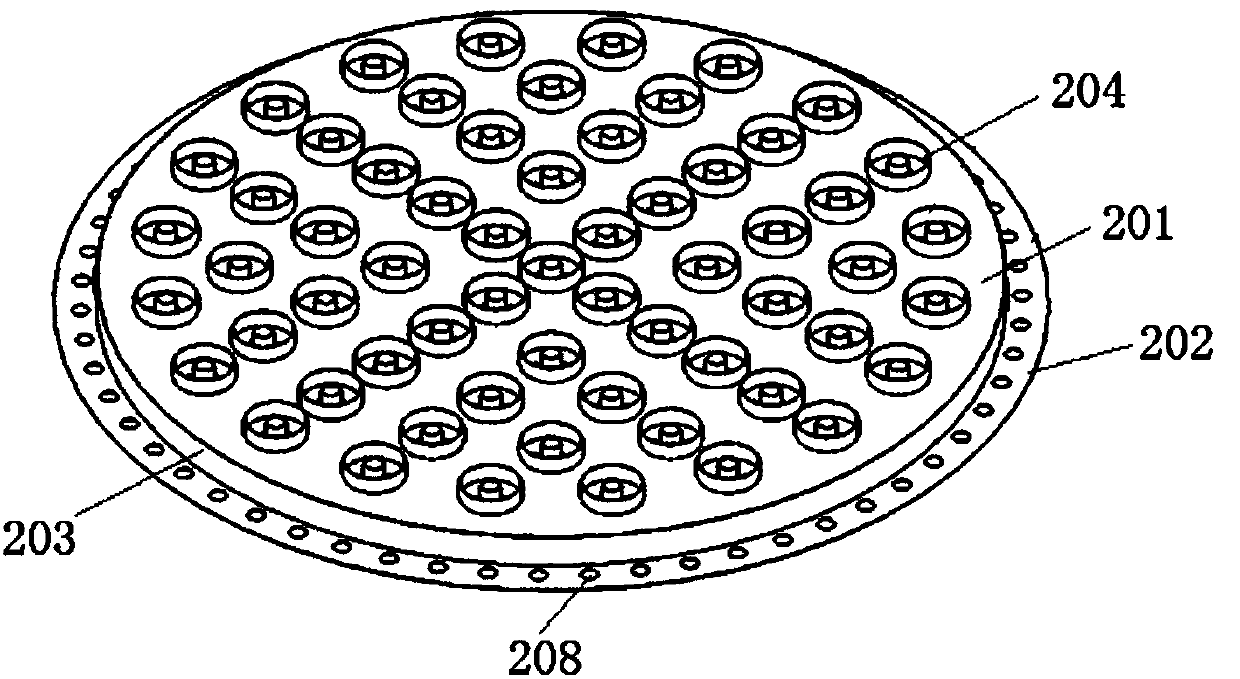

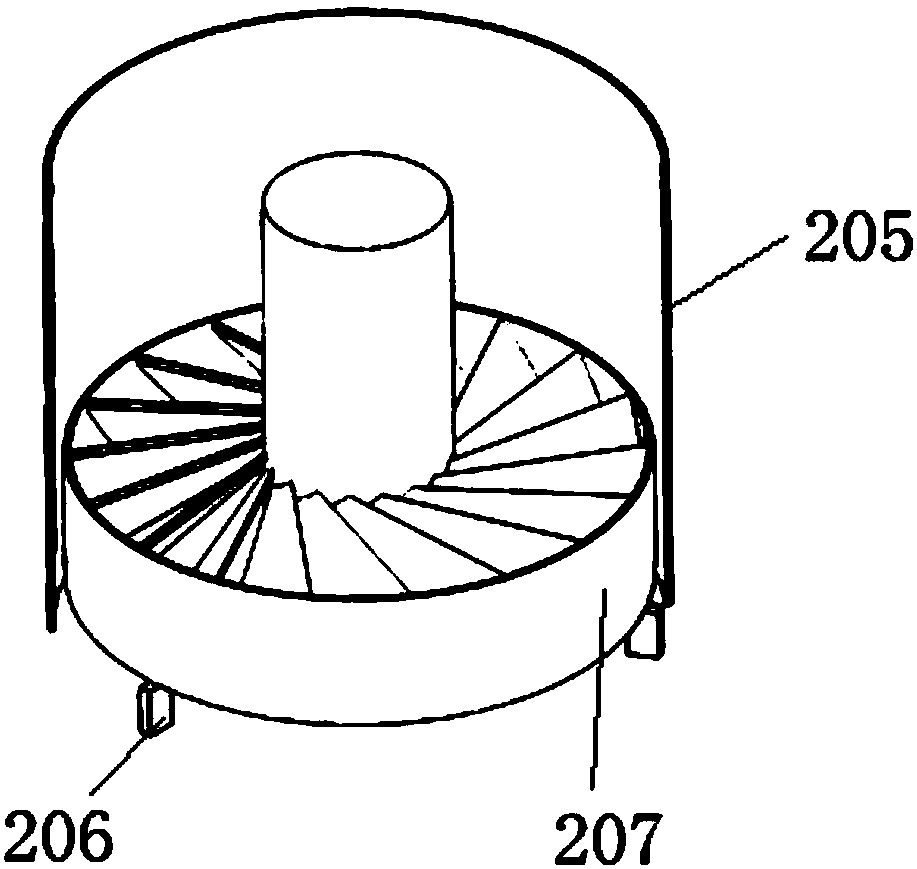

An integrated ultra-clean desulfurization and dust removal device

ActiveCN105727700BAchieve deep removalIncrease contact timeCombination devicesGas treatmentSlurryEngineering

The invention discloses an integrated ultra-clean desulfurization and dust removal device, which comprises: a tank body, the shell of which forms a closed space; an air inlet; a chimney connected to the top of the shell of the tank body; The tank body is sequentially provided with a mechanical centrifugal turbulent unit, a high-efficiency spray unit, a high-efficiency energy-gathering ring unit, a multi-tube Venturi unit, a mechanical centrifugal defogging unit, and a flushing spray layer from bottom to top. The beneficial effects of the present invention are: the flue gas enters the absorption tower, passes through the mechanical centrifugal turbulent unit to form an upward turbulent swirling airflow and the spray system from top to bottom to generate a controllable turbulent space, so that the gas-liquid-solid three-phase extended contact time, increase the contact density, fully integrate, improve the mass transfer efficiency, and realize the deep removal of sulfur dioxide. The flue gas then enters the mechanical centrifugal demisting device, and the mist and dust are thrown to the inner wall of the tube bundle under the action of centrifugal force, and are captured by the liquid film on the pipe wall at the same time, so as to realize the deep removal of mist and dust.

Owner:TONGZHENG ENVIRONMENT PROTECTION GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com