Mini round four-core electric connector and assembly method thereof

A kind of electrical connector, circular technology, applied in the direction of two-part connection device, parts of connection device, connection, etc., can solve the problems of easy failure, inconvenient use, high processing cost, etc., and achieve high reliability and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] A micro-circular four-core electrical connector. The micro-circular four-core electrical connector in this embodiment can specifically meet the following use requirements:

[0050] 1. Resistant to large temperature differences in the environment, the temperature range is: -60 ° C ~ 155 ° C;

[0051] 2. Vibration and shock environment is harsh, random vibration (power spectral density 0.6512 / Hz, total acceleration root mean square value 29.2G), contact fault duration is not more than 1μs, stable and reliable; impact resistance 980m / s 2 ;

[0052] 3. Four cores, compact arrangement of contact pairs;

[0053] 4. Small contact resistance, on-resistance ≤ 700mΩ;

[0054] 5. Insulation resistance: ≥500MΩ;

[0055] 6. Dielectric withstand voltage: 600V.

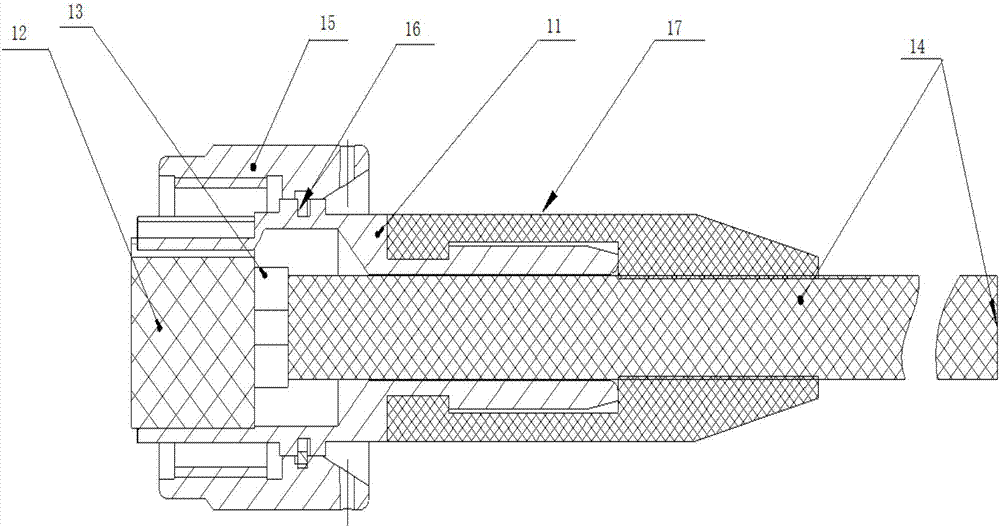

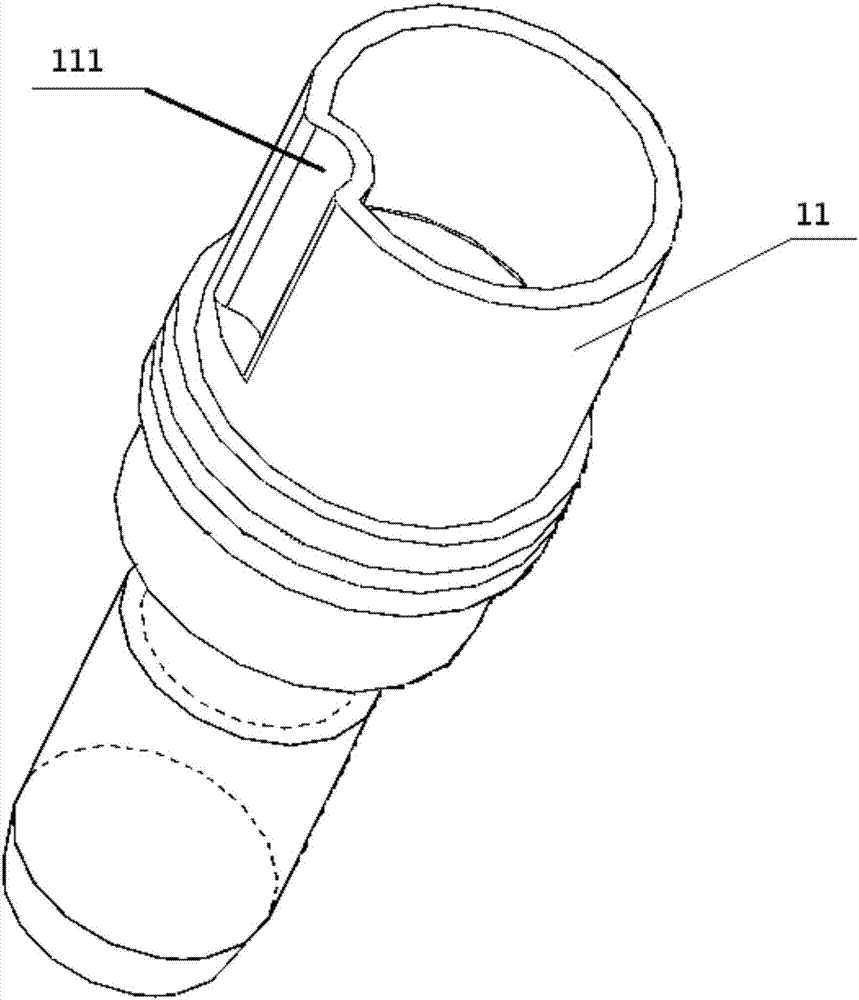

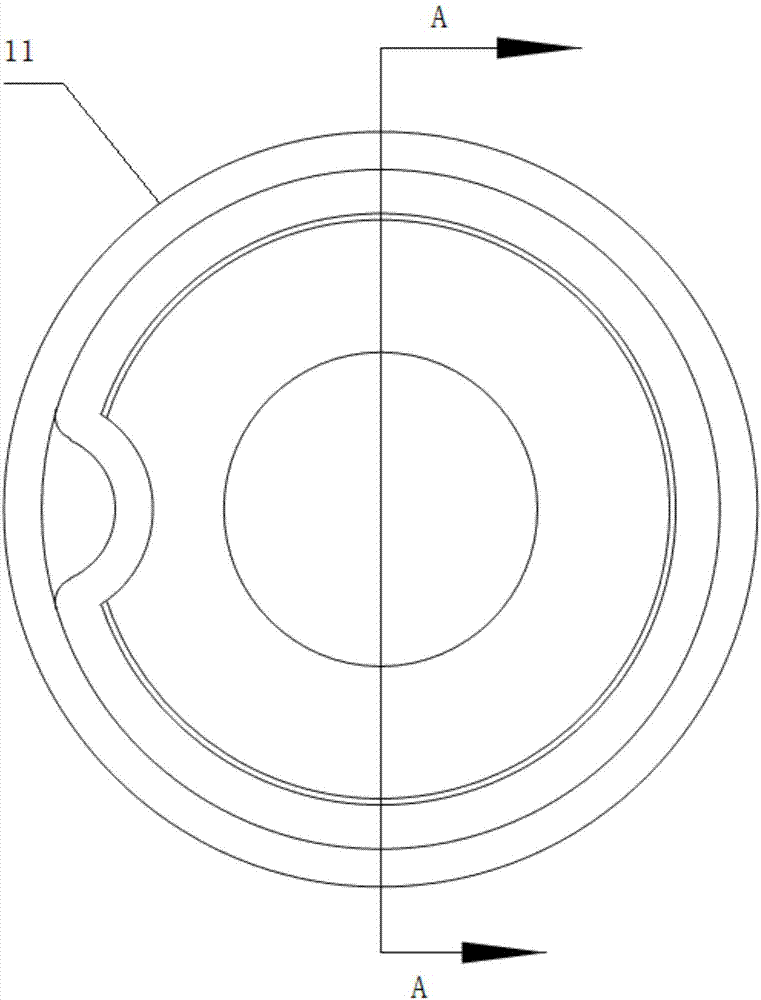

[0056] Such as Figure 1 to Figure 11 As shown, the micro-circular four-pin electrical connector includes a plug assembly and a socket assembly. The plug assembly includes a plug housing 11, and the two ends of the plug ...

Embodiment 2

[0079] Such as Figures 12 to 15 Shown, a kind of assembly method of microcircular four-core electric connector, comprises the following steps:

[0080] A. Crimp the first cable 14 at the tail of the jack 13, and crimp the second cable 24 at the tail of the pin 23; specifically, crimp the wires of the corresponding cable to the tail of the jack 13 or the pin 23;

[0081] B. Adhesively fix the socket 13 connected with the first cable 14 on the socket base 12, insert the pin 23 connected with the second cable 24 on the pin base 22, and then insert the pin 23 Bonding and fixing on the pin base 22, the adhesive can be DG-4 adhesive when bonding, and the glue must not exceed the tail boundary of the jack base 12 and the pin base 22;

[0082] C. Install the jack base 12 connected with the jack 13 in the plug housing 11, and form the cavity between the outer circumference of the end where the first cable 14 is connected to the jack 13 and the inner wall of the jack 13 housing Inject ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com