Patents

Literature

47results about How to "High contact density" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Connector

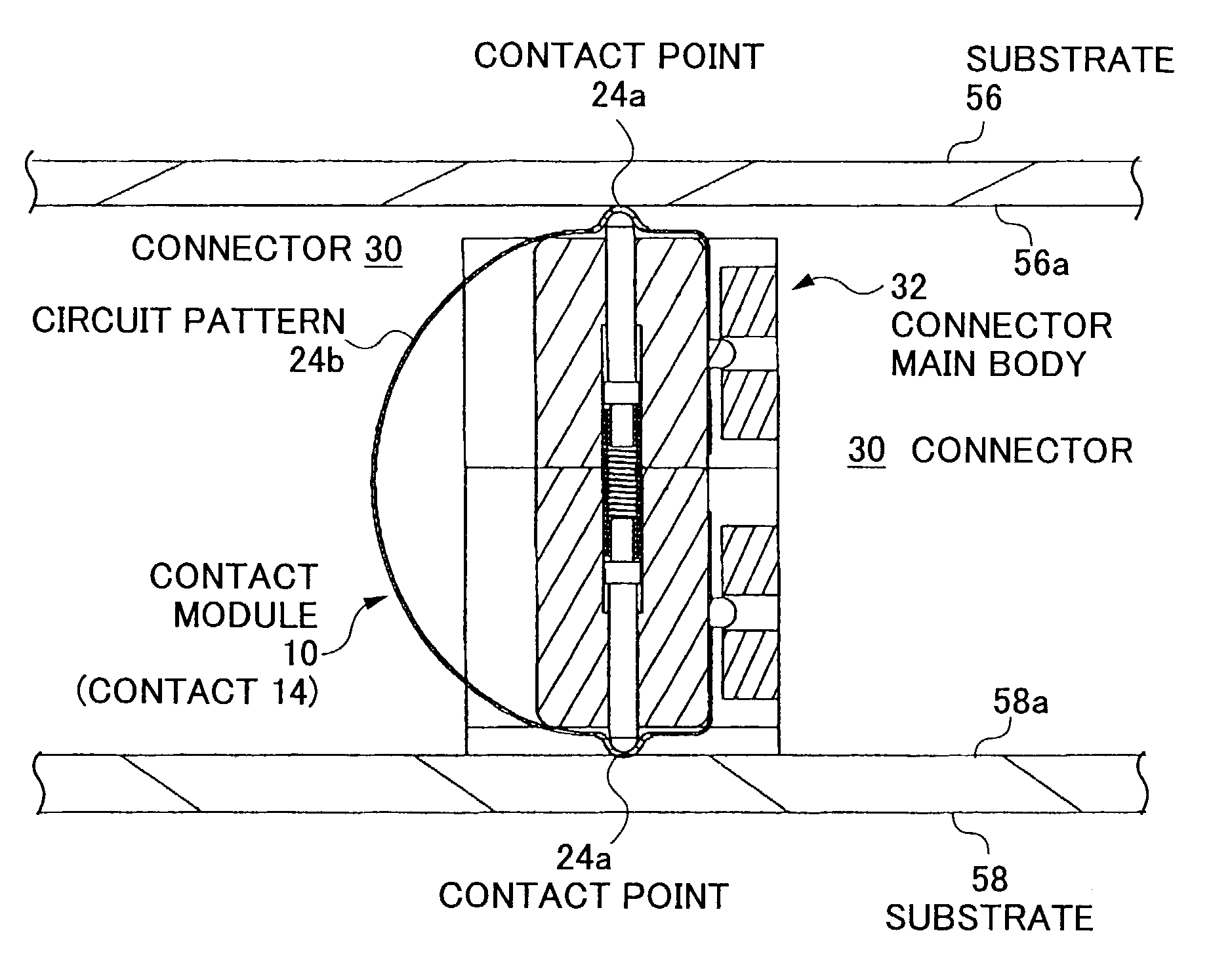

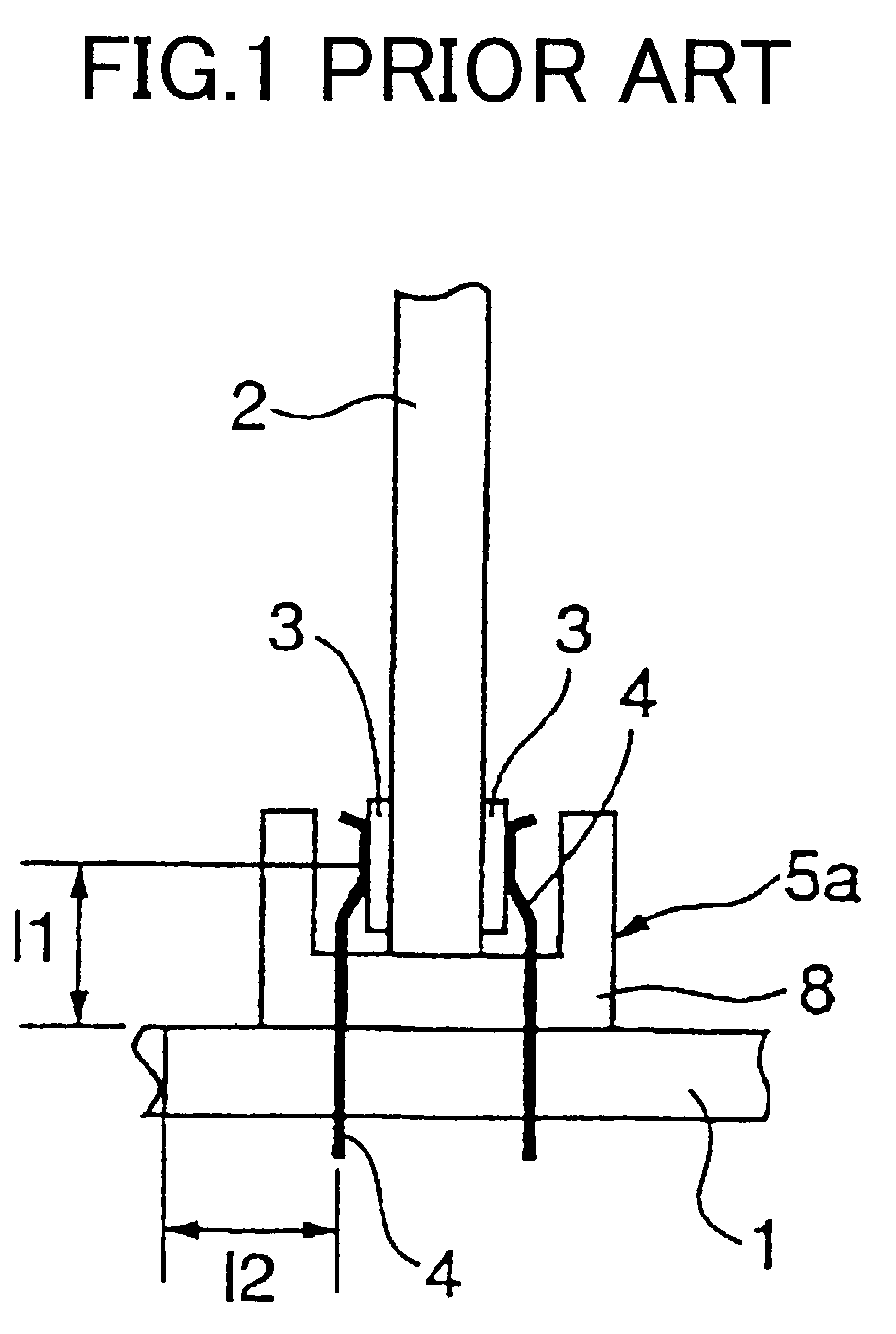

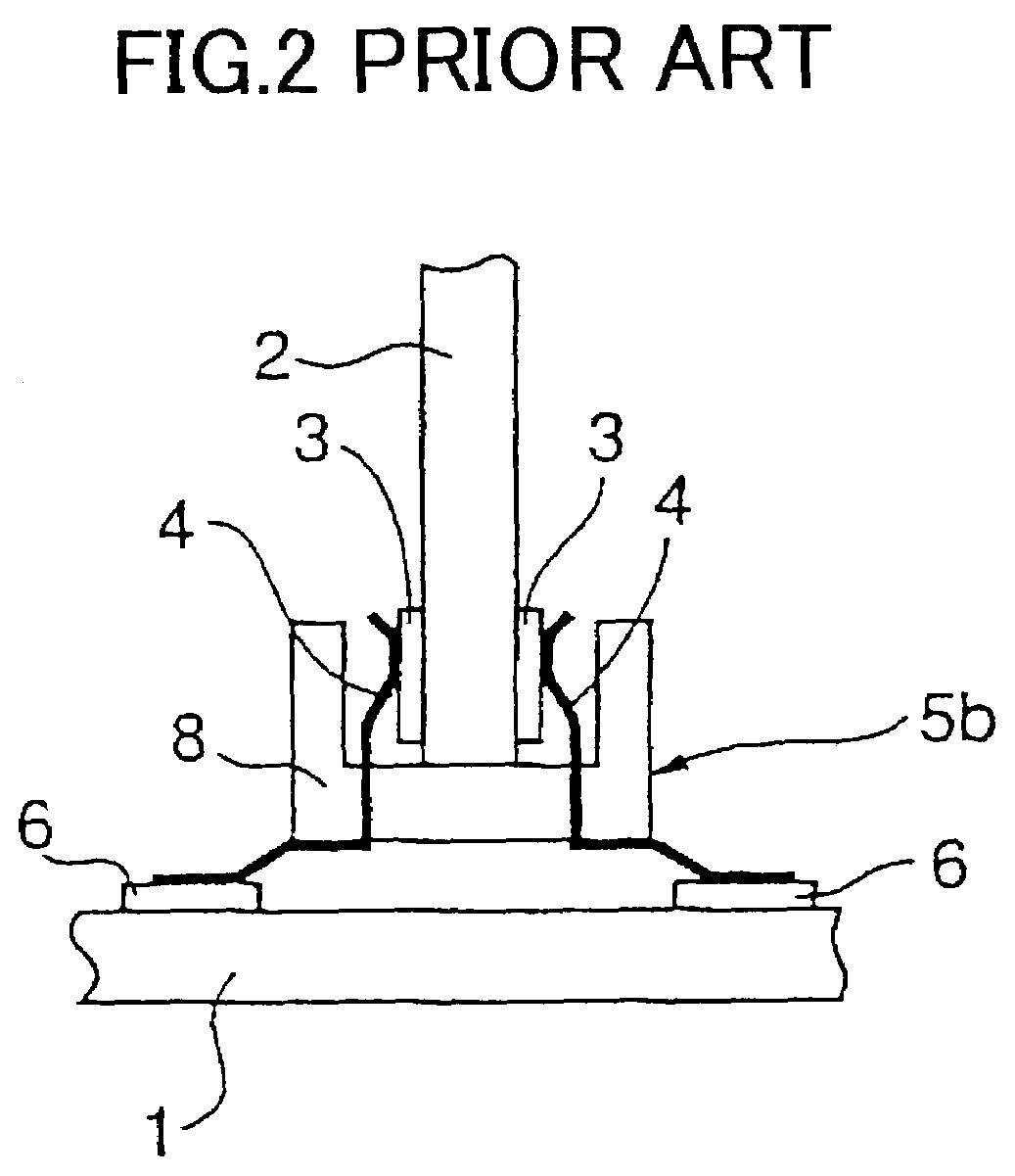

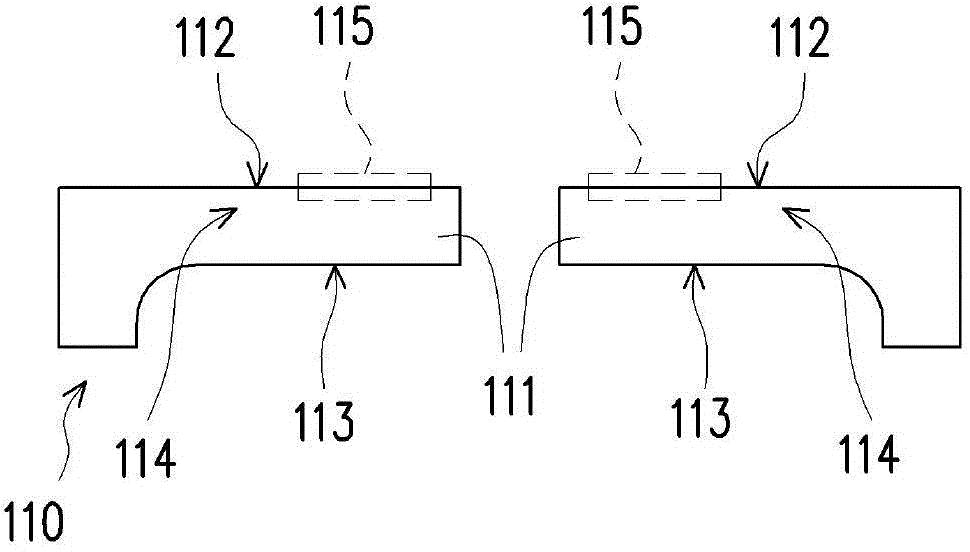

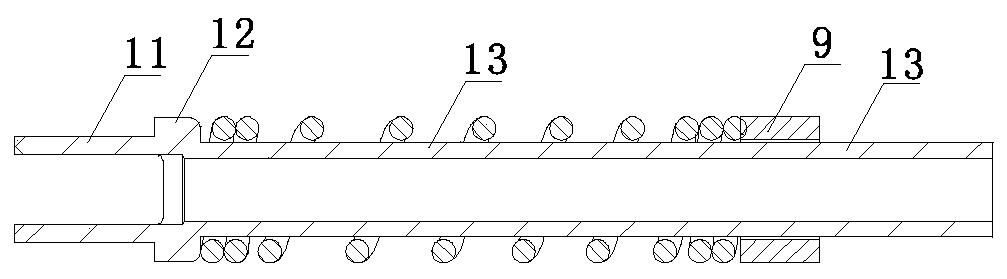

InactiveUS7121837B2Small sizeHigh contact densityLine/current collector detailsElectrical measurement instrument detailsHigh densityCoil spring

A new connector that is reduced in size and has a higher density of contacts implemented therein is provided. This connector has a contact module arranged on a connector main body. The contact module is formed into a sheet structure, and a plurality of contacts are arranged therein. Further, the contact module is bent into a C-shaped structure along the extending direction of the contacts, and is implemented to the connector main body in this state. Contact points of the connector are energized by sets of a coil spring and two push pins arranged on both sides of the coil spring so that these contact points protrude from holes formed at the connector main body.

Owner:FUJITSU COMPONENENT LTD

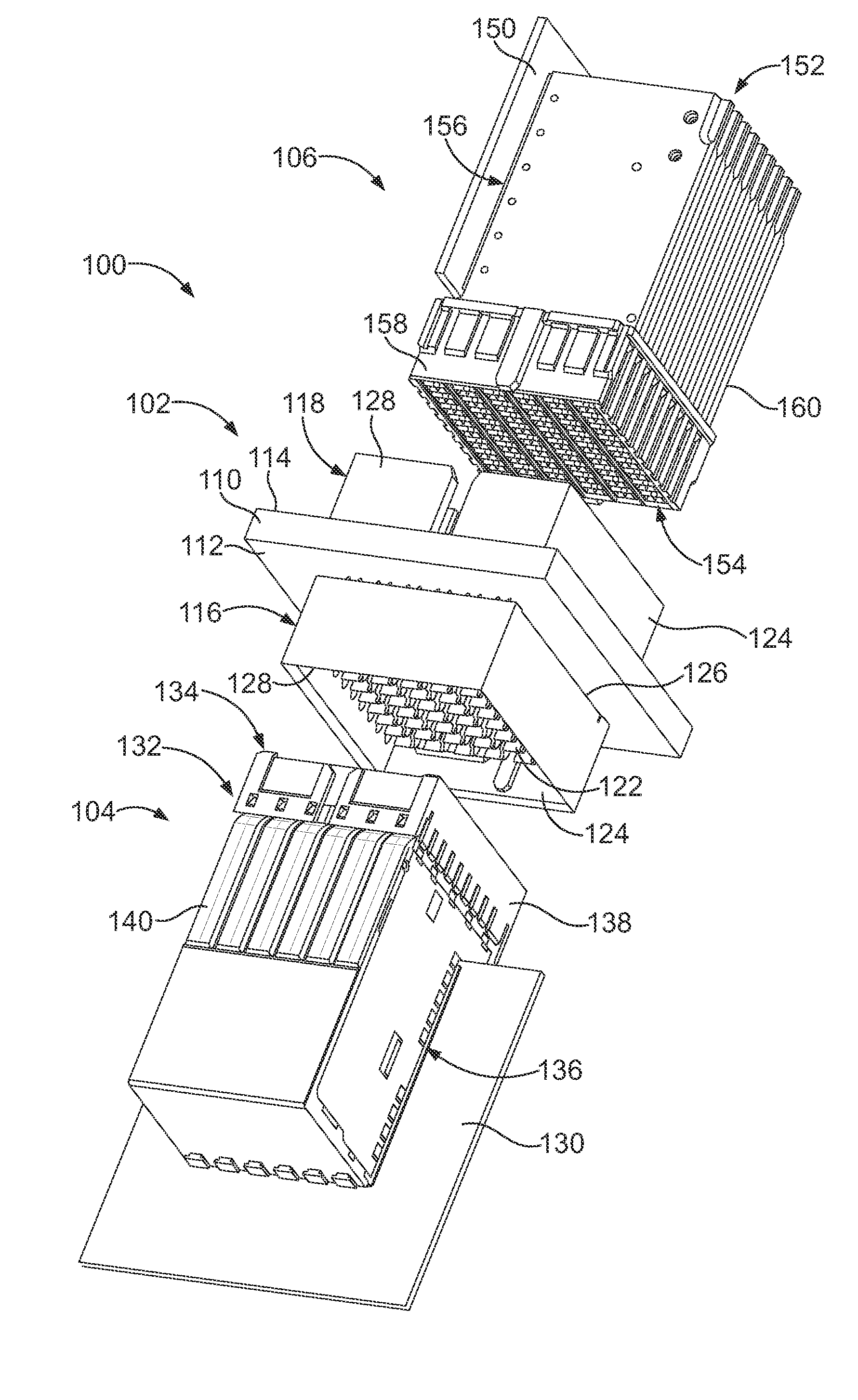

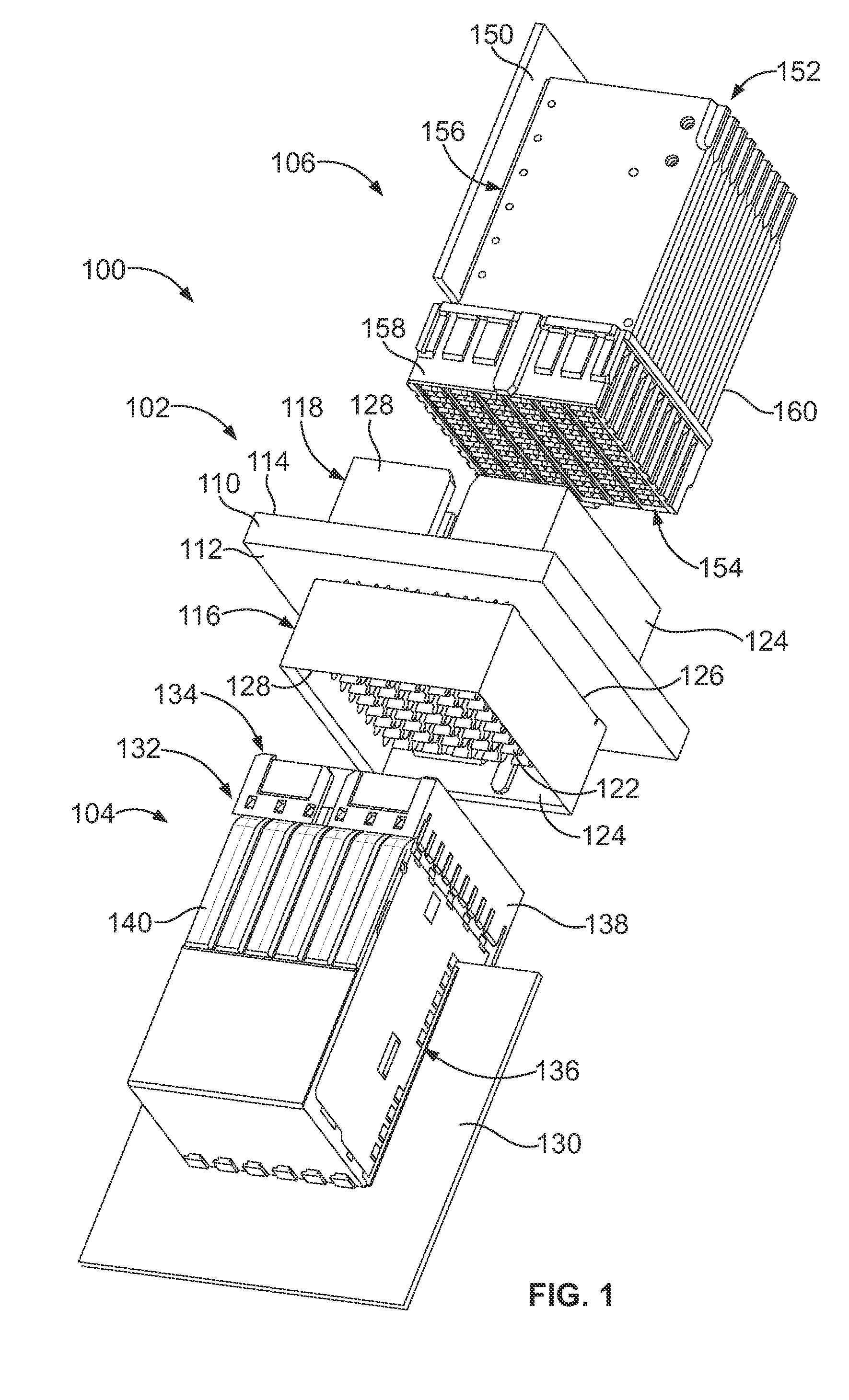

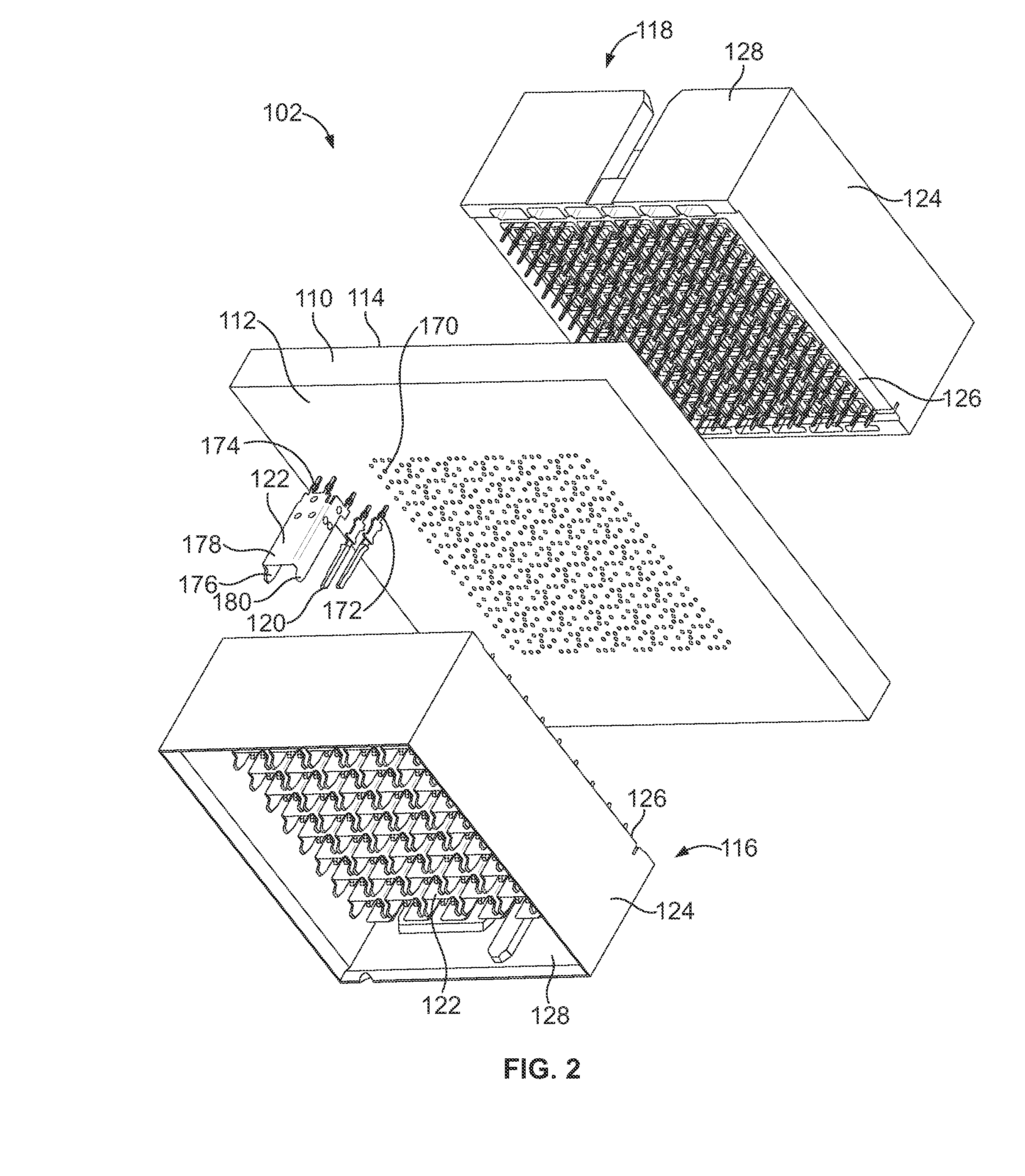

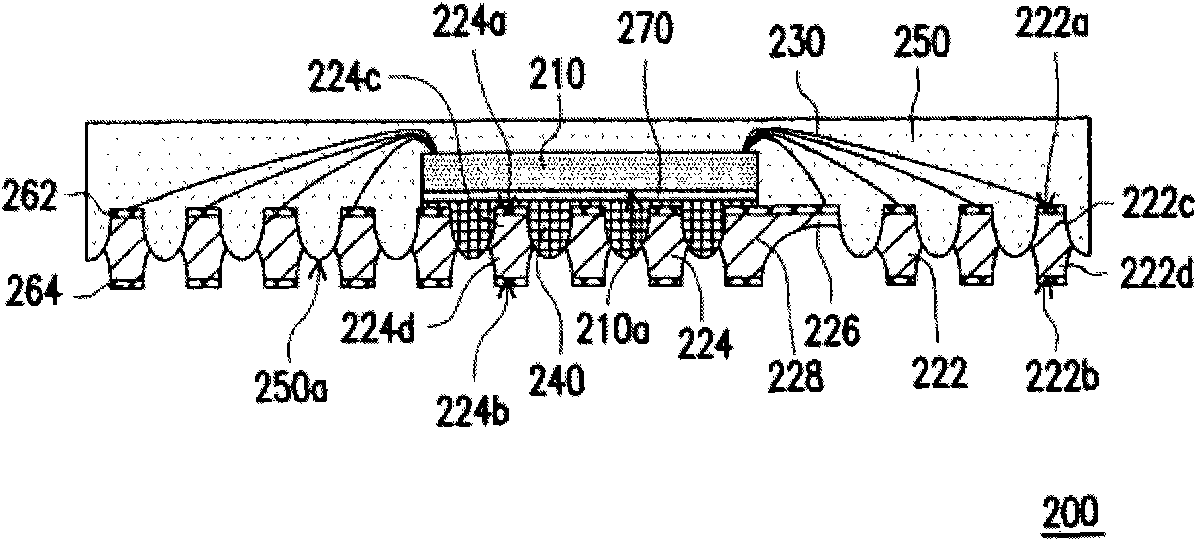

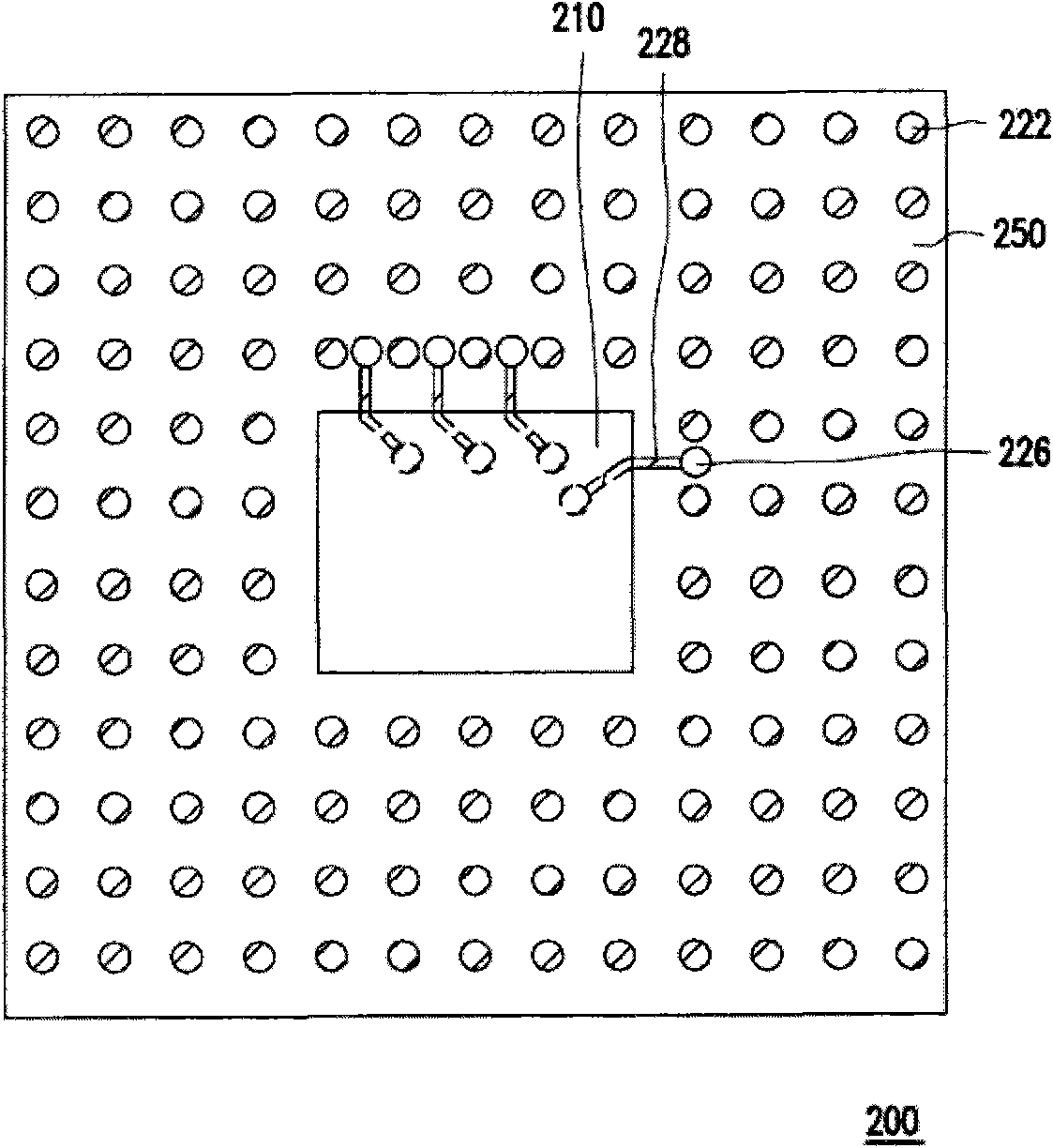

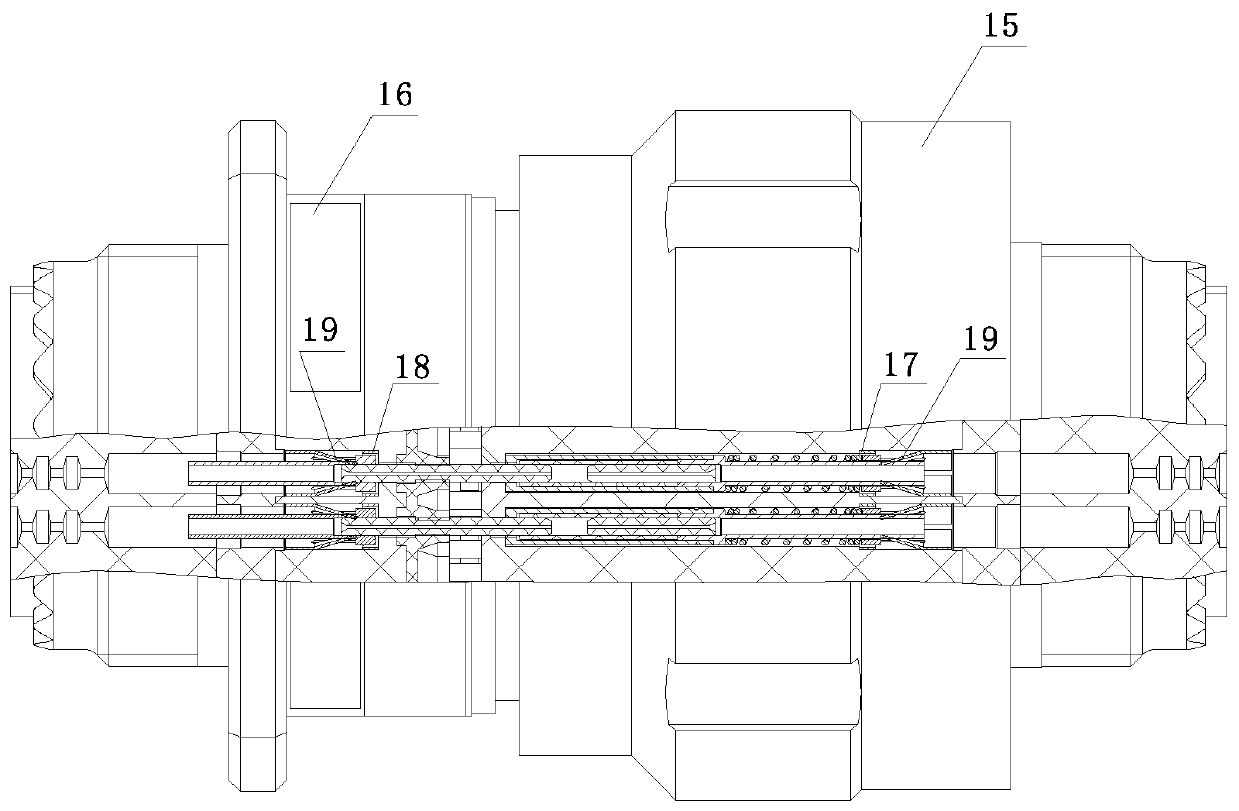

Receptacle assembly for a midplane connector system

ActiveUS20130288539A1High contact densityImprove signal integrityElectrically conductive connectionsCoupling device detailsEngineeringMechanical engineering

A receptacle assembly includes a contact module having a conductive holder and a frame assembly received in the conductive holder. The frame assembly includes a first frame and a second frame, each frame having at least two frame members each supporting a differential pair of receptacle signal contacts and being separated by a gap. The first and second frames are interested such that at least one frame member of the first frame is received in a corresponding gap of the second frame between frame members of the second frame and such that at least one frame member of the second frame is received in a corresponding gap of the first frame between frame members of the first frame.

Owner:TYCO ELECTRONICS LOGISTICS AG (CH)

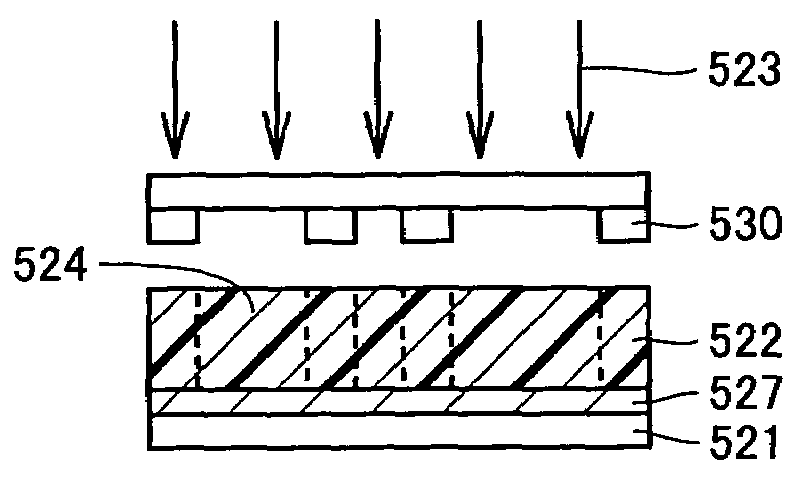

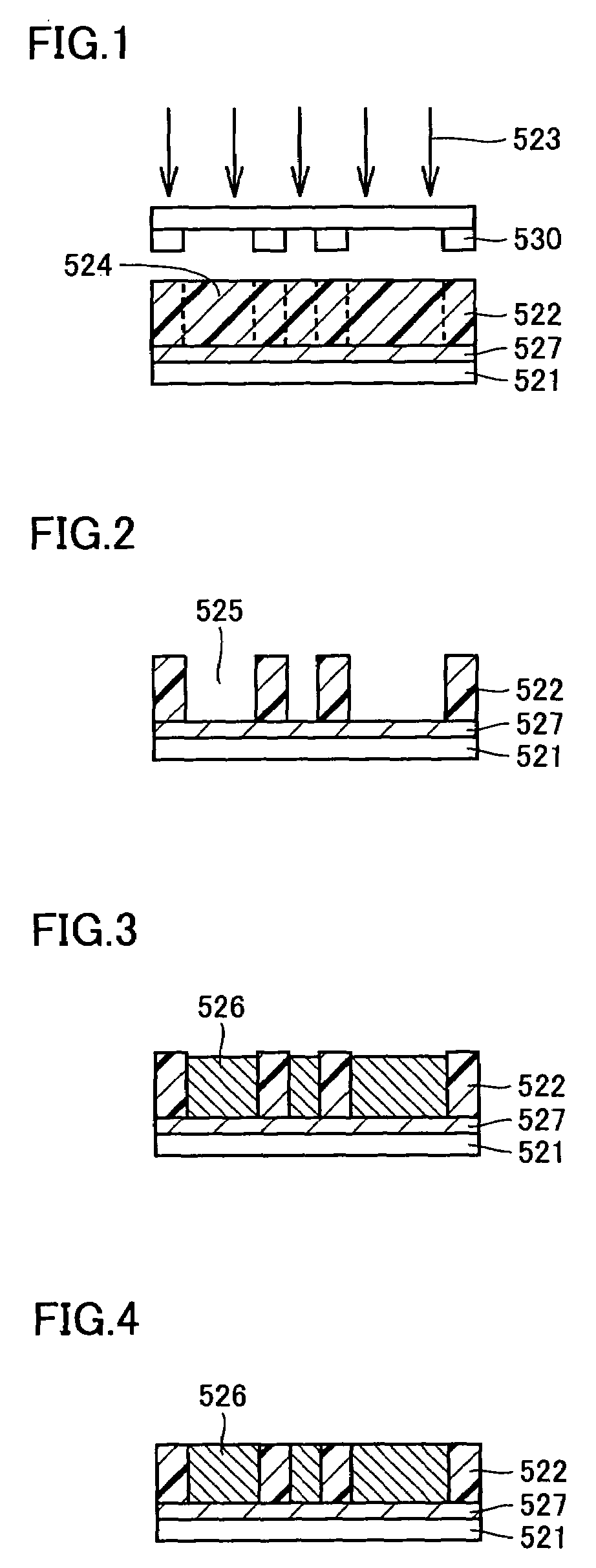

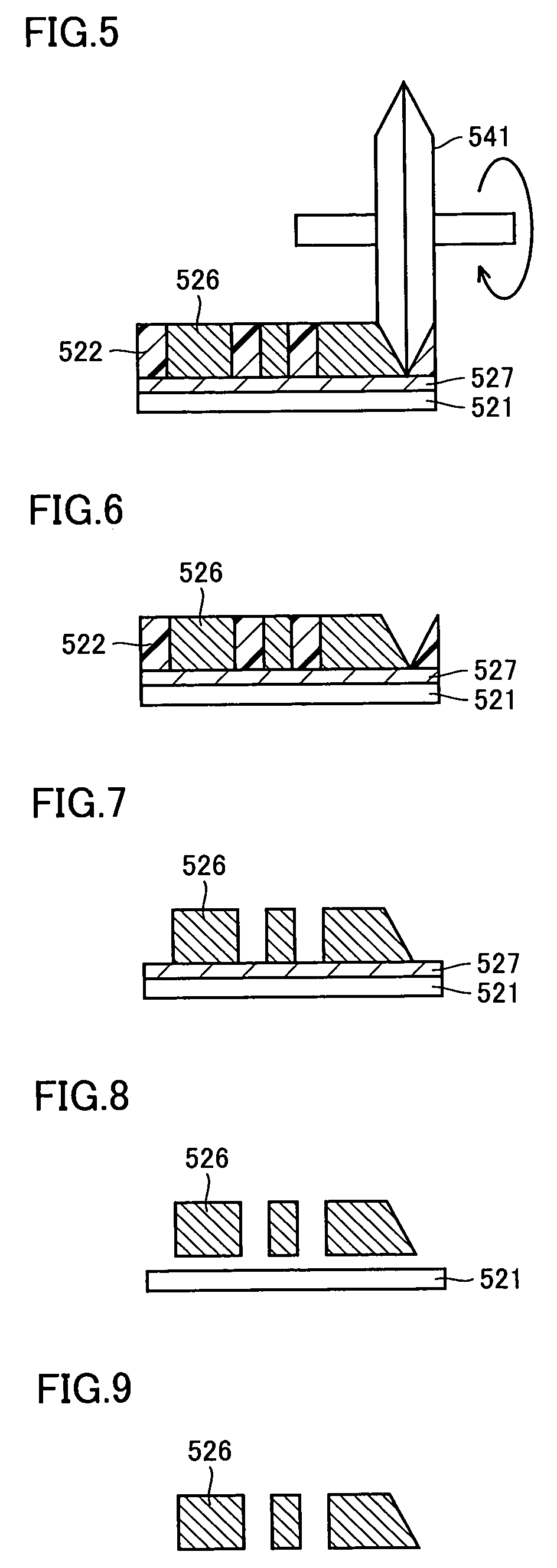

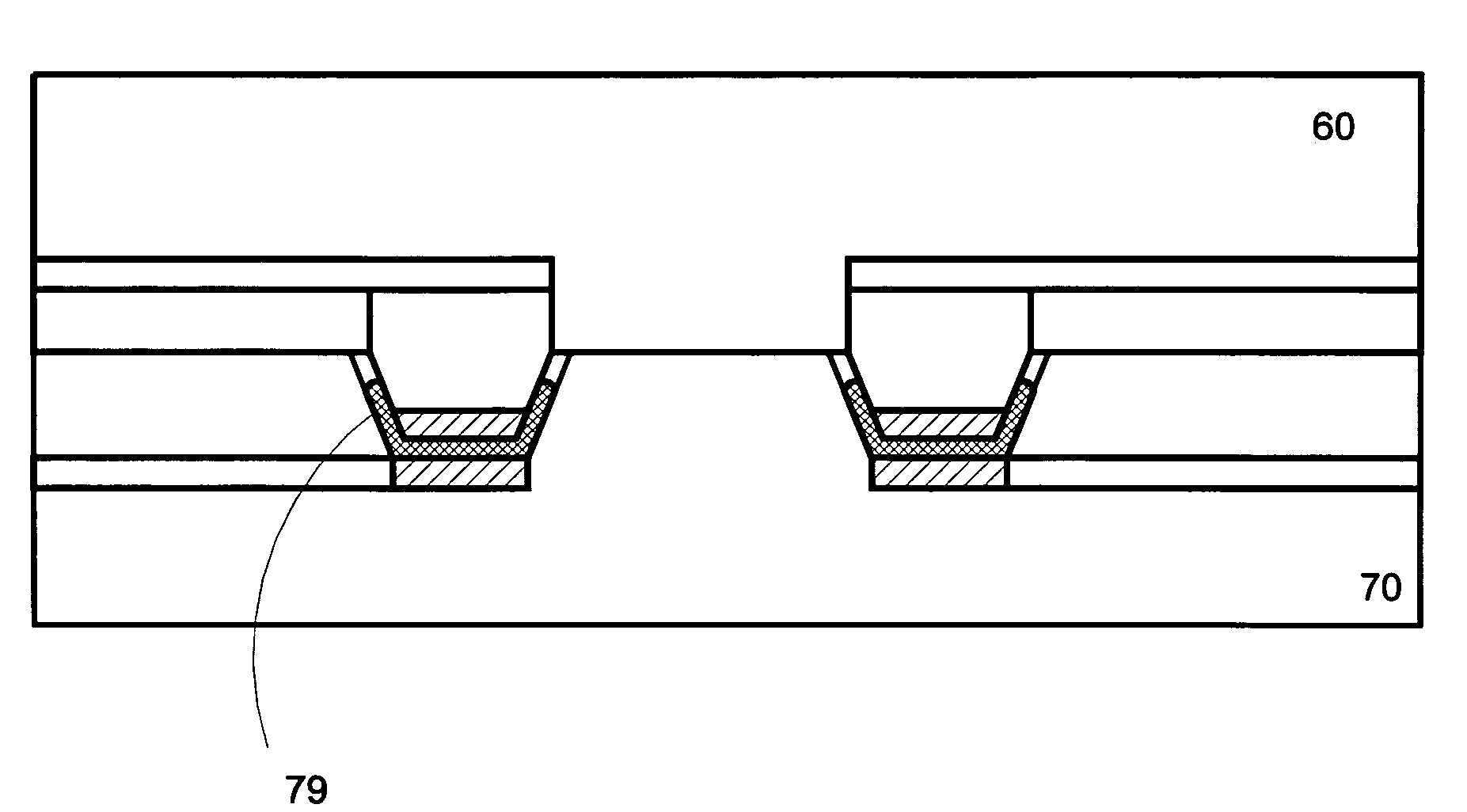

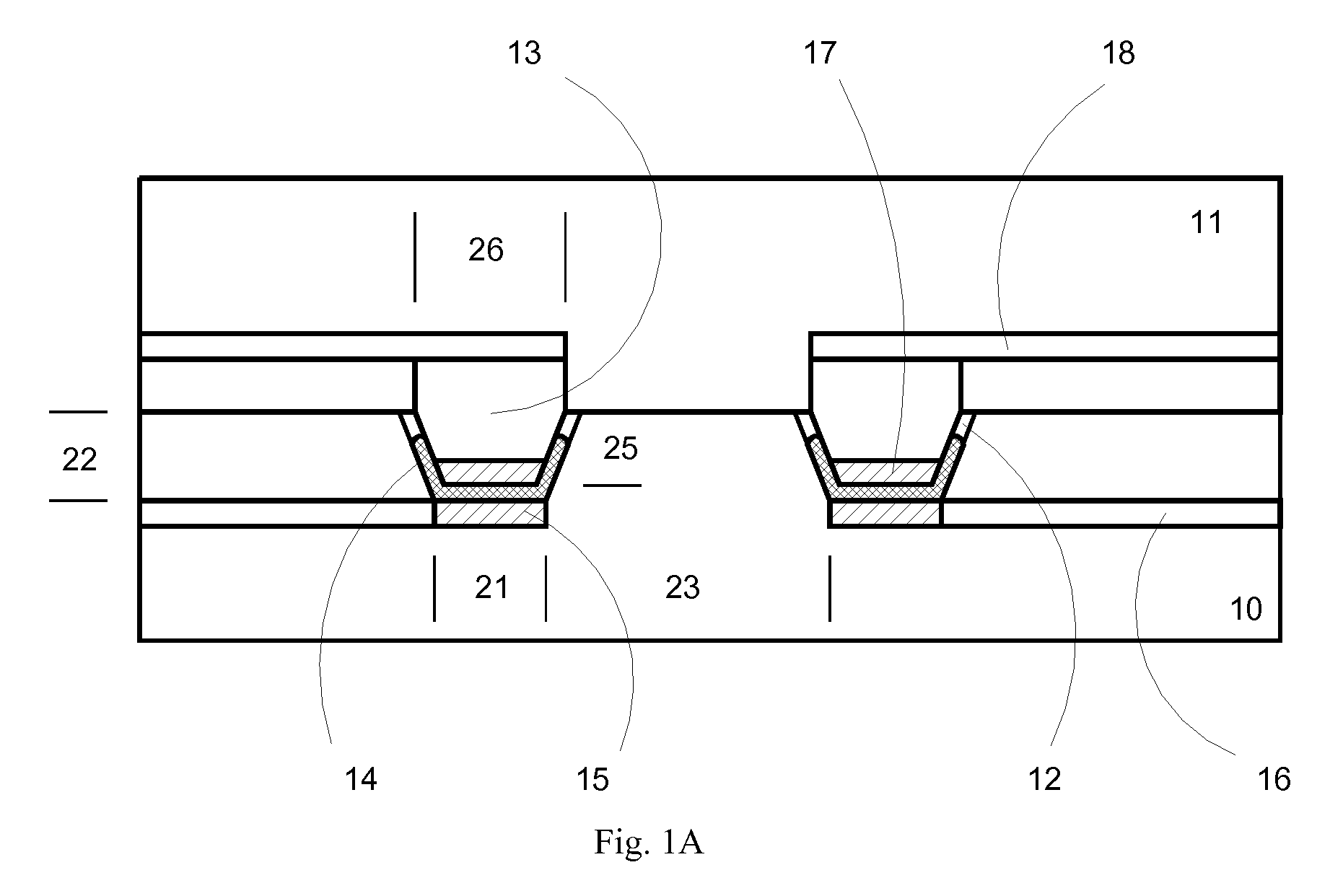

Contact probe, method of manufacturing the contact probe, and device and method for inspection

InactiveUS7151385B2Increase contact pressureReliable conductionContact member manufacturingSemiconductor/solid-state device testing/measurementResistEngineering

A method of manufacturing a contact probe includes an electroforming step of, using a resist film (522) arranged on a substrate (521) as a pattern frame having a shape corresponding to a contact probe, performing electroforming to fill a gap in the resist film (522) to form a metal layer (526), a tip end shaping step of obliquely removing and sharpening that part of the metal layer (526) which serves as a tip end portion of the contact probe, and a take-out step of taking out only the metal layer (526) from the pattern frame.

Owner:SUMITOMO ELECTRIC IND LTD

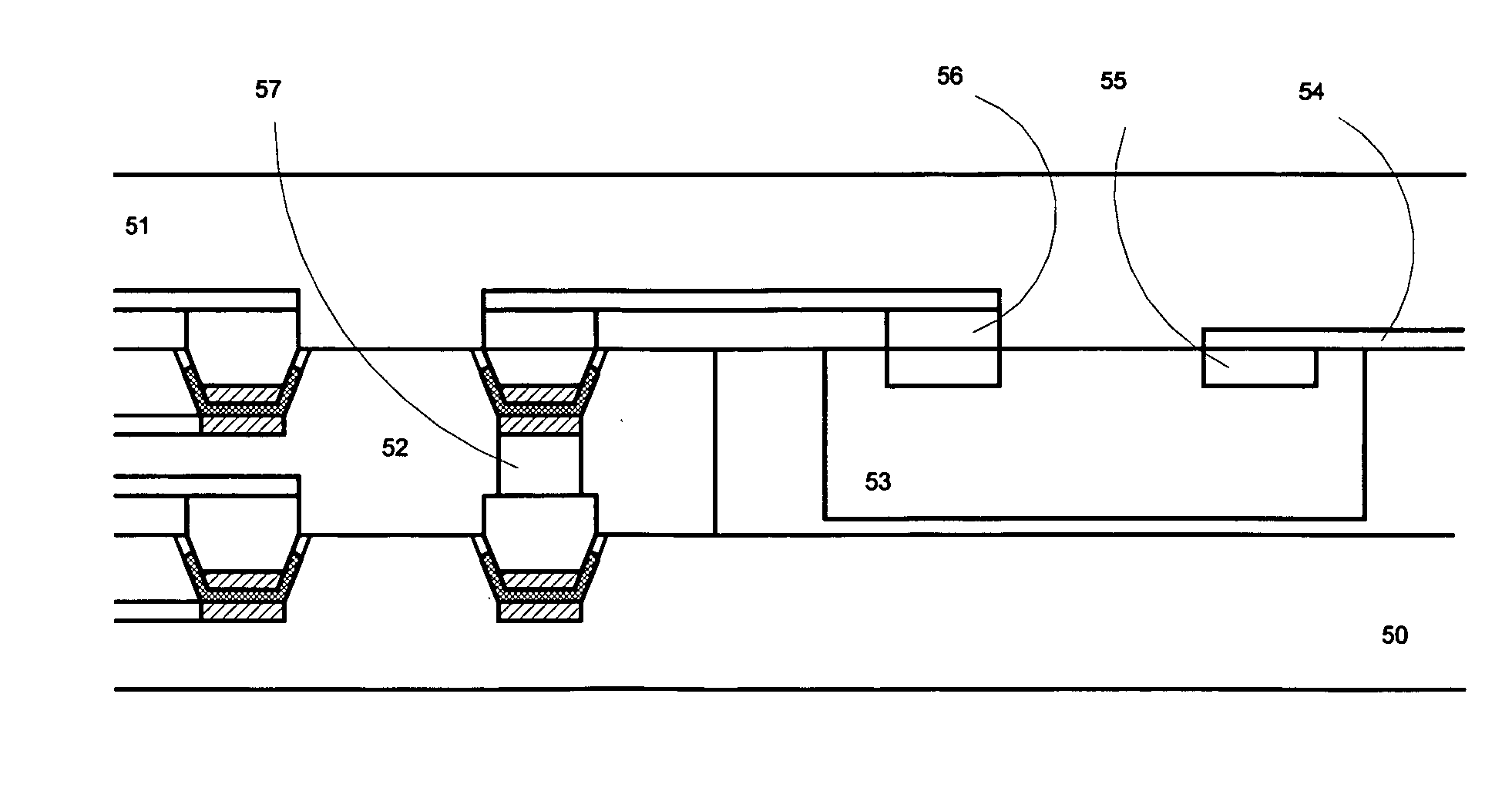

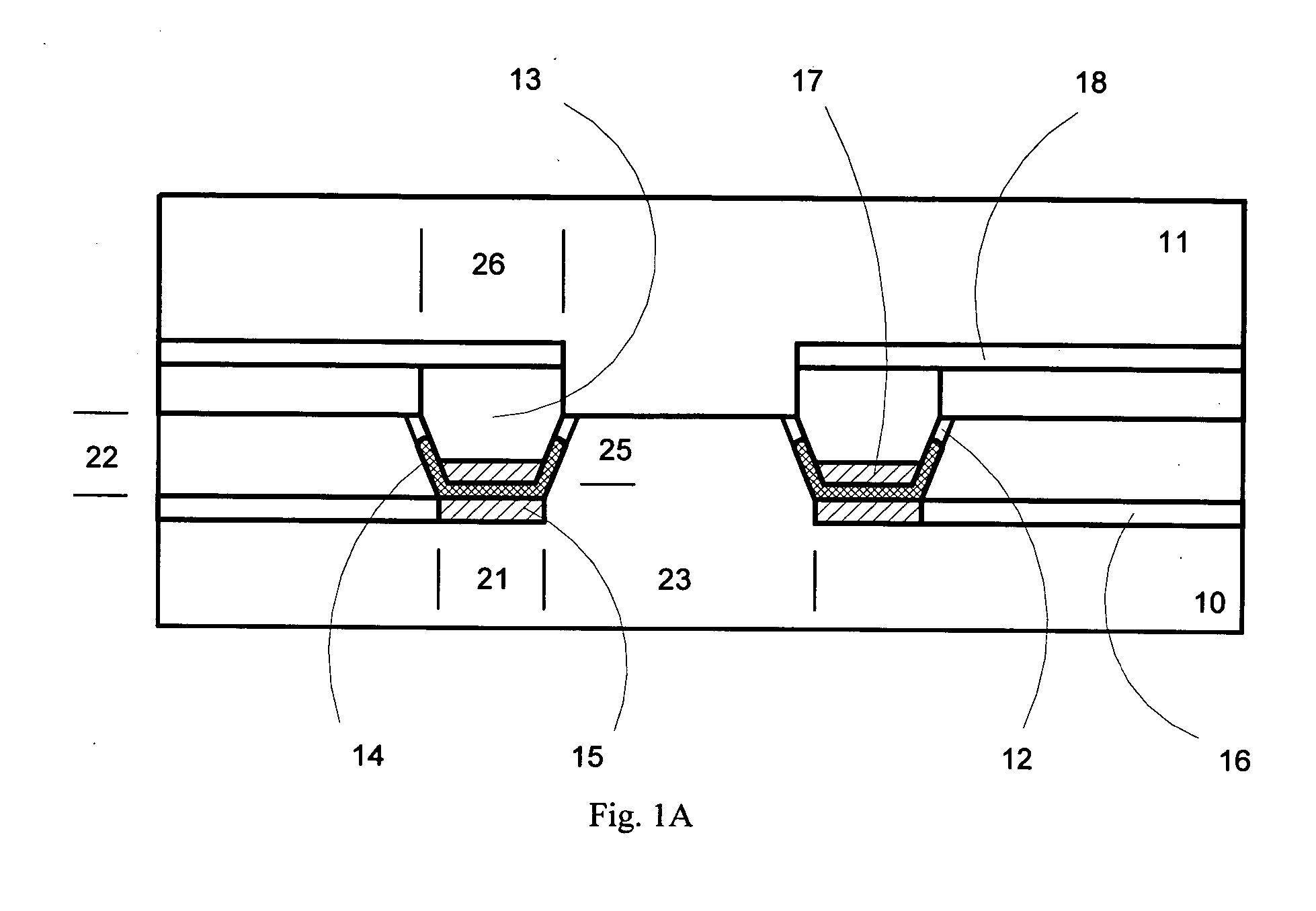

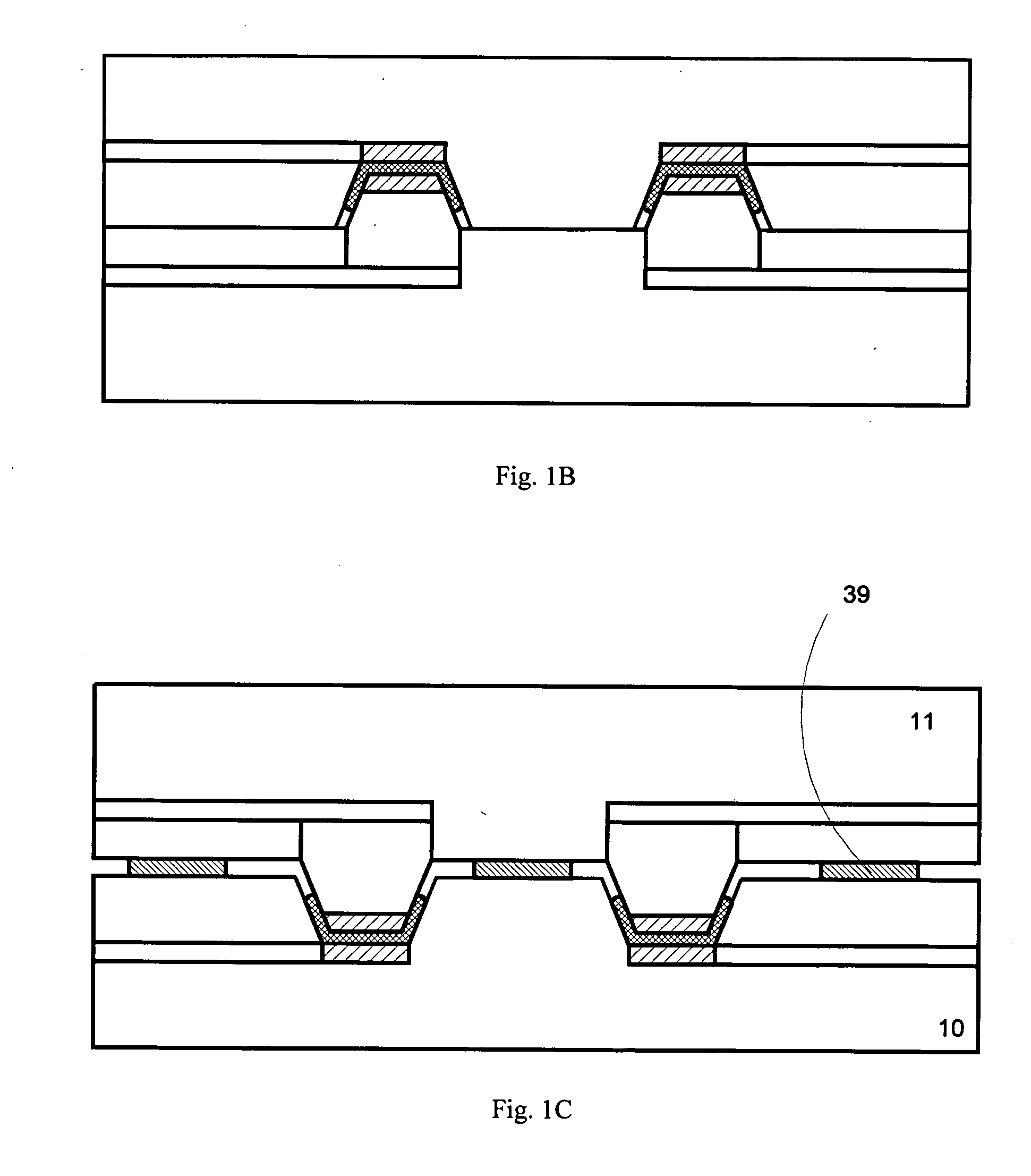

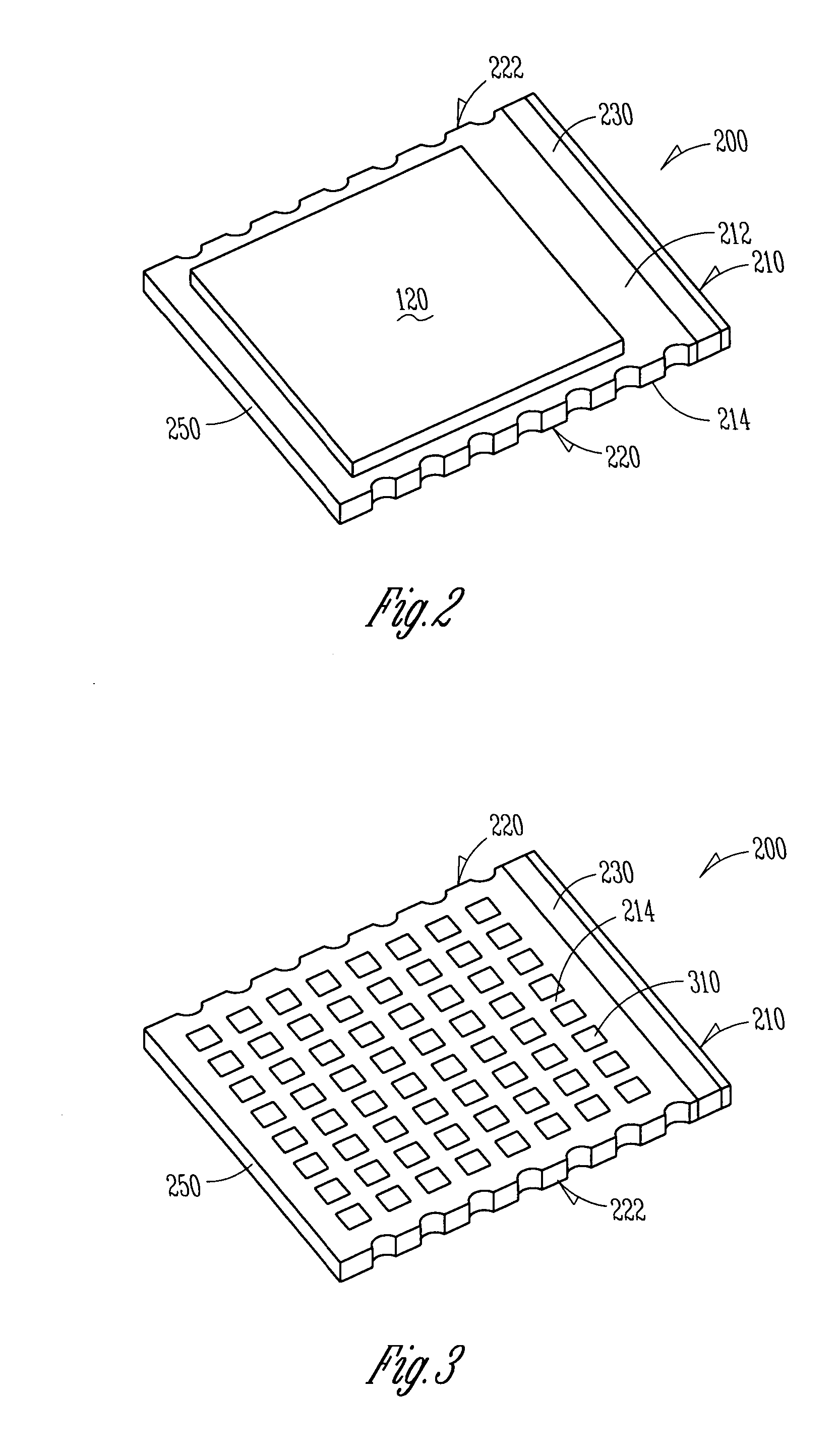

Method of packaging and interconnection of integrated circuits

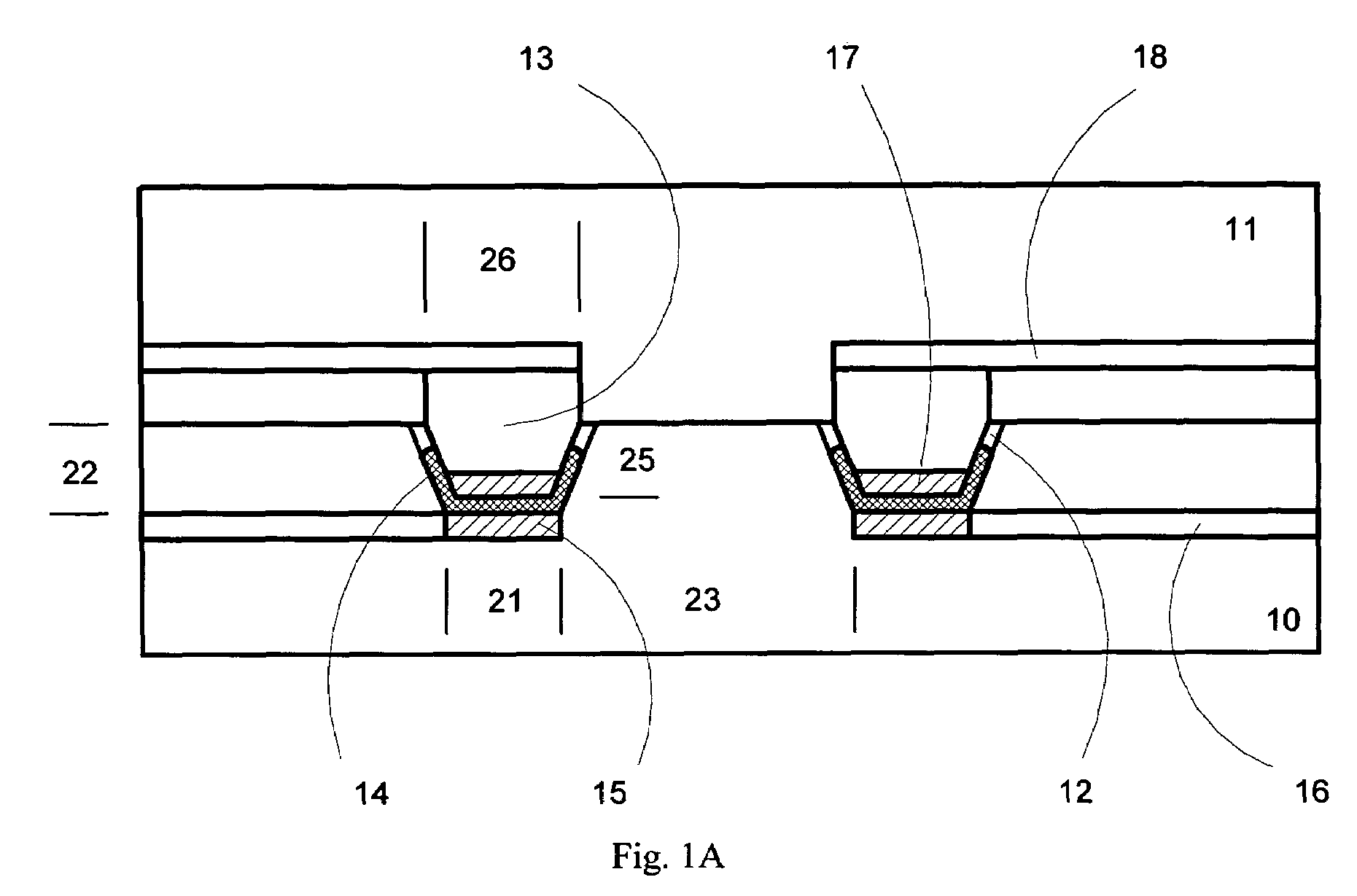

InactiveUS20070040272A1High densityAdhesionSemiconductor/solid-state device detailsSolid-state devicesMicron scaleContact pad

A semiconductor chip packaging on a flexible substrate is disclosed. The chip and the flexible substrate are provided with corresponding raised and indented micron-scale contact pads with the indented contact pads partially filled with a liquid amalgam. After low temperature amalgam curing, the chip and the substrate form a flexible substrate IC packaging with high conductivity, controllable interface layer thickness, micron-scale contact density and low process temperature. Adhesion between the chip and the substrate can be further enhanced by coating other areas with non-conducting adhesive.

Owner:INTELLEFLEX CORP +1

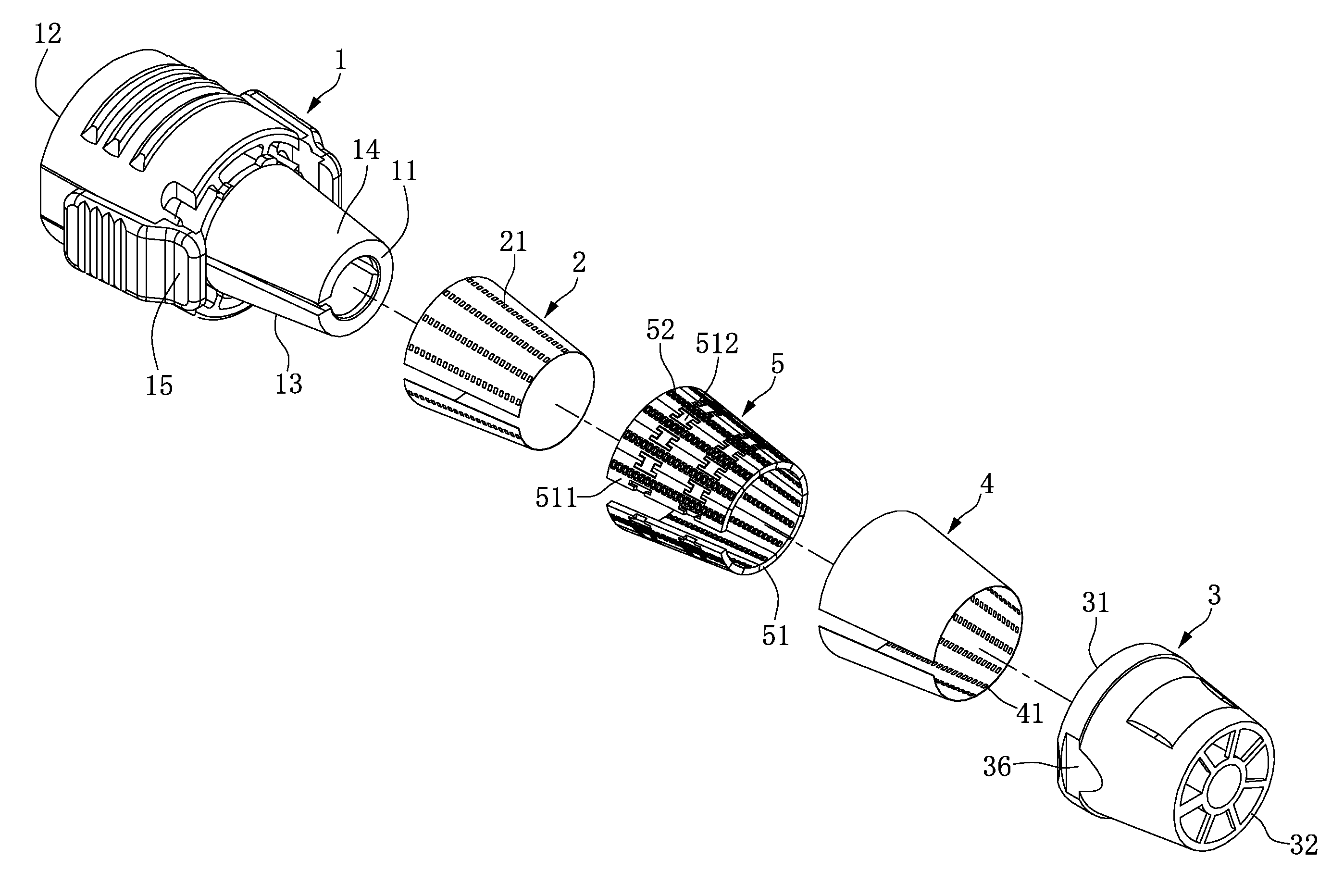

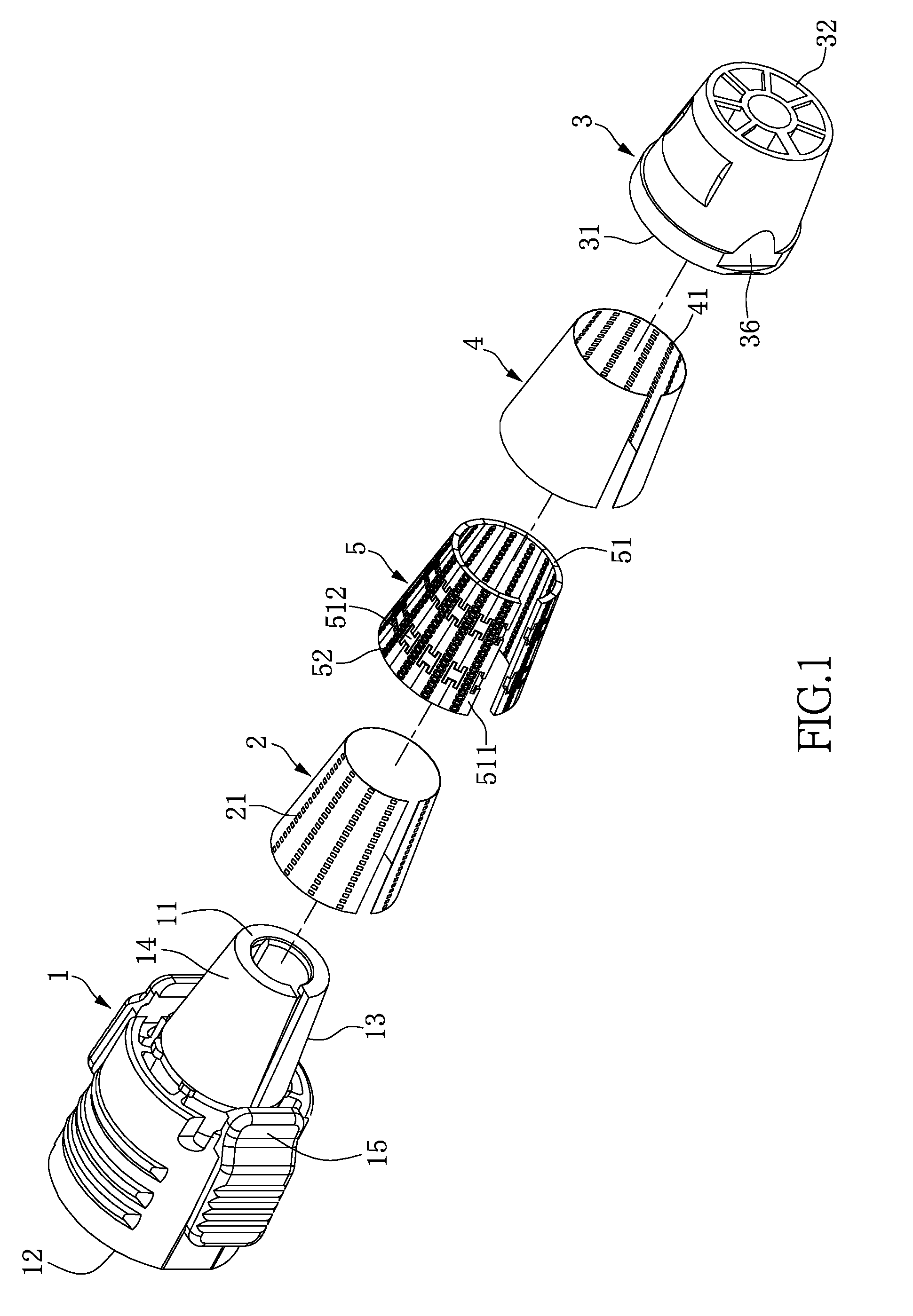

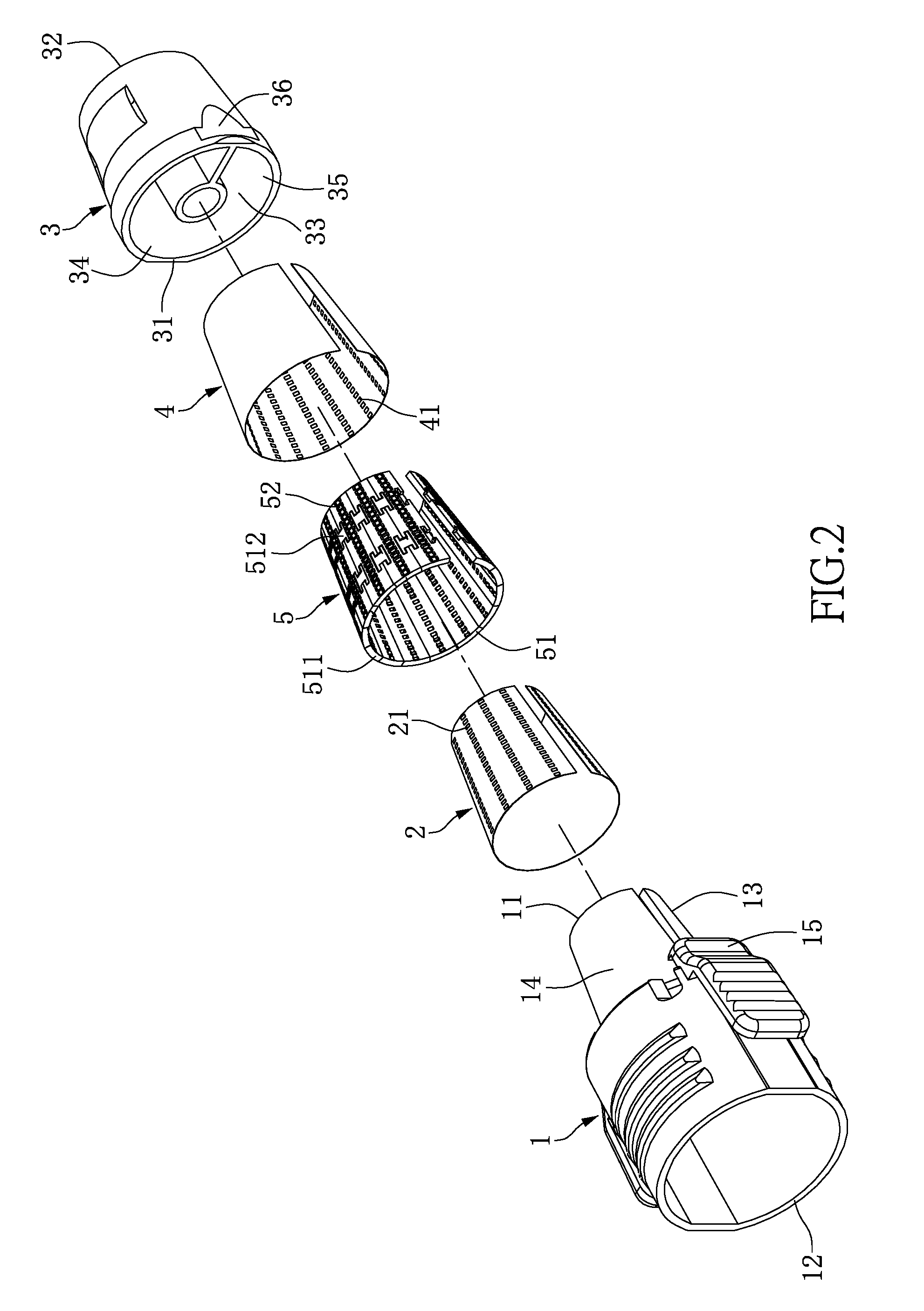

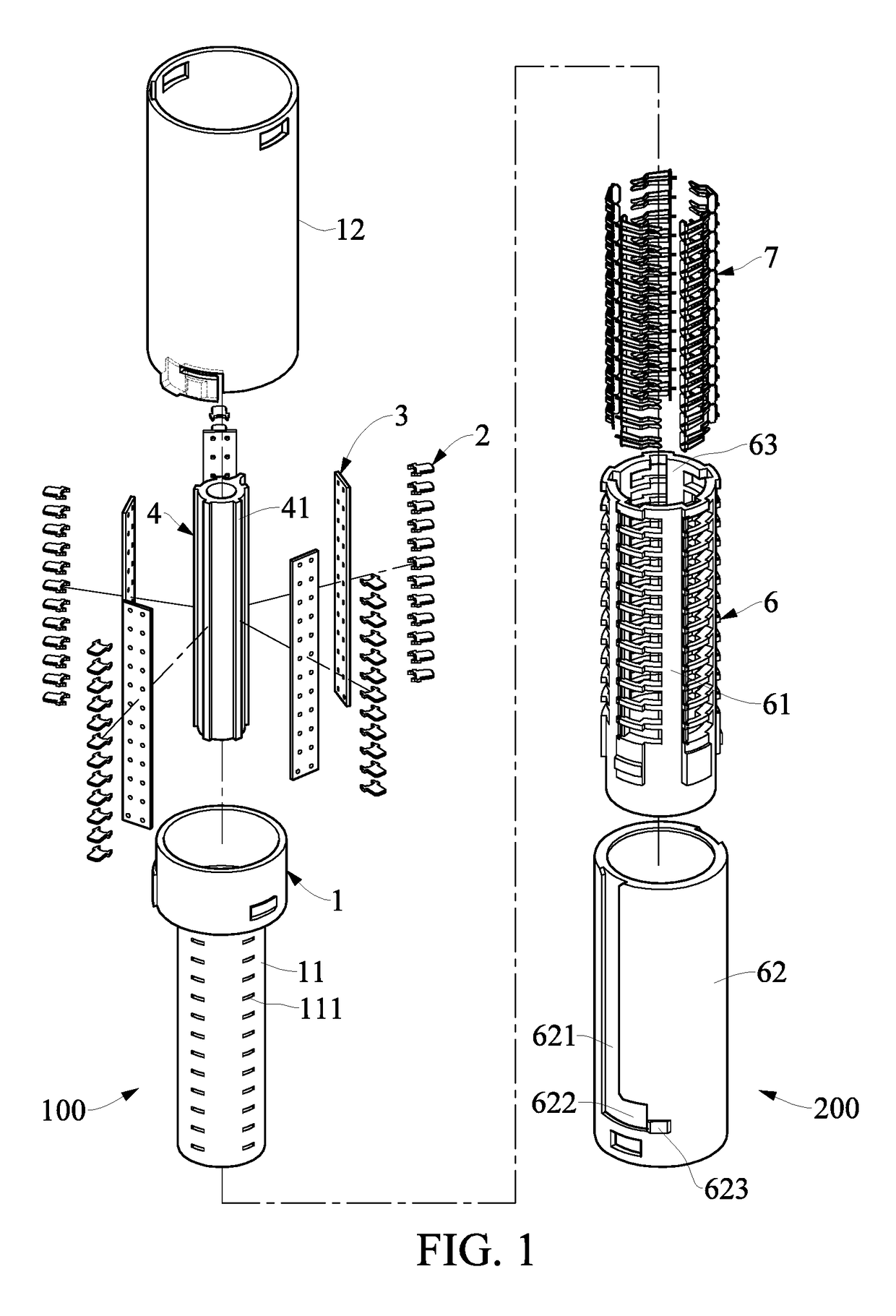

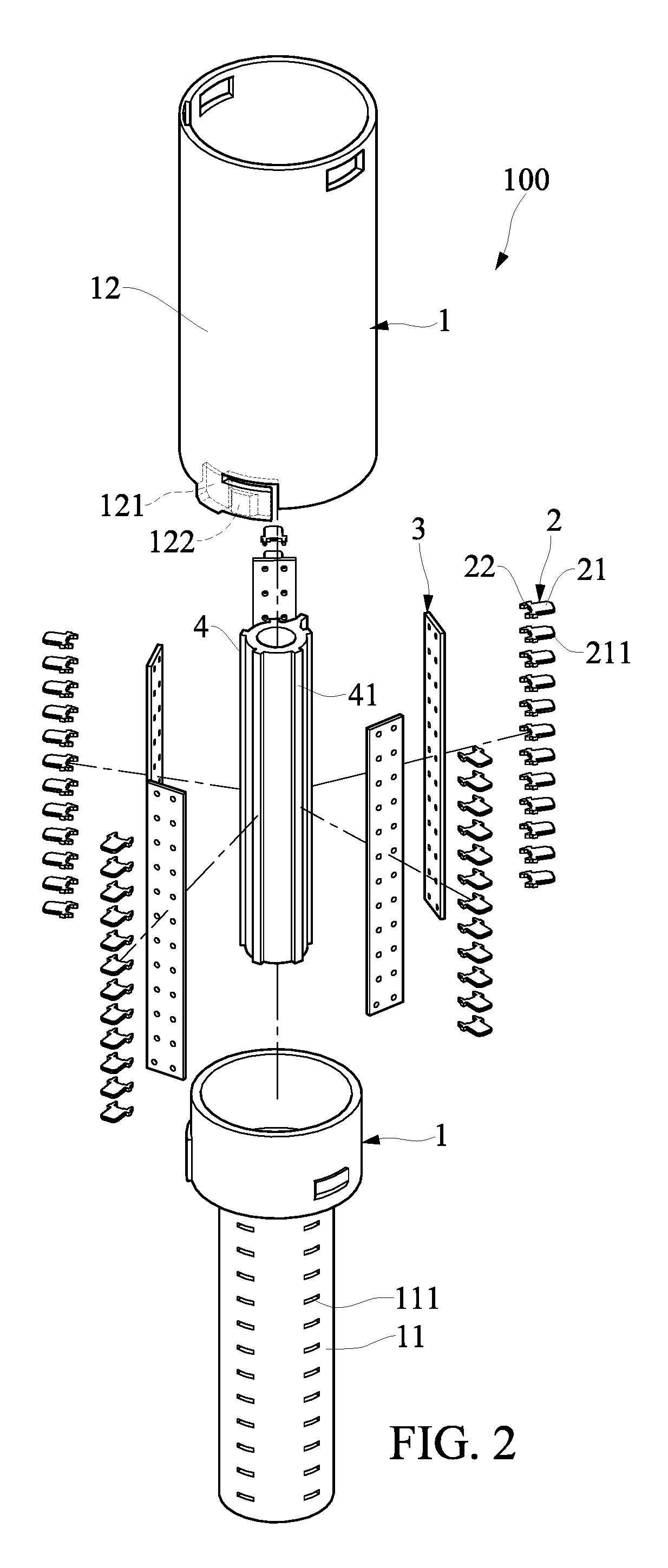

Connector with high contact density

ActiveUS9496638B1High contact densityHigh densityElectrically conductive connectionsIncorrect coupling preventionEngineeringContact density

A connector with high contact density includes interior casing, first contact set, exterior casing, second contact set, and conducting element. The interior casing has a plug portion and a first slope. The first contact set is disposed in the first slope of the interior casing, and the first contact set has a plurality of first contact points. A containing space is formed inside the exterior casing, and the containing space is formed with a second slope, a second contact set is disposed in the second slope and has a plurality of second contact points. A conducting element includes an insulating main body and connecting terminals. The connecting terminals are disposed in the insulating main body and exposed to the exterior and interior of the insulating main body. The plug portion inserts into the containing space, so the first contact points contact the second contact points by the connecting terminals.

Owner:NEXTRONICS ENG CORP

Method of packaging and interconnection of integrated circuits

InactiveUS7618844B2High densityAdhesionSemiconductor/solid-state device detailsSolid-state devicesMicron scaleContact pad

Owner:INTELLEFLEX CORP +1

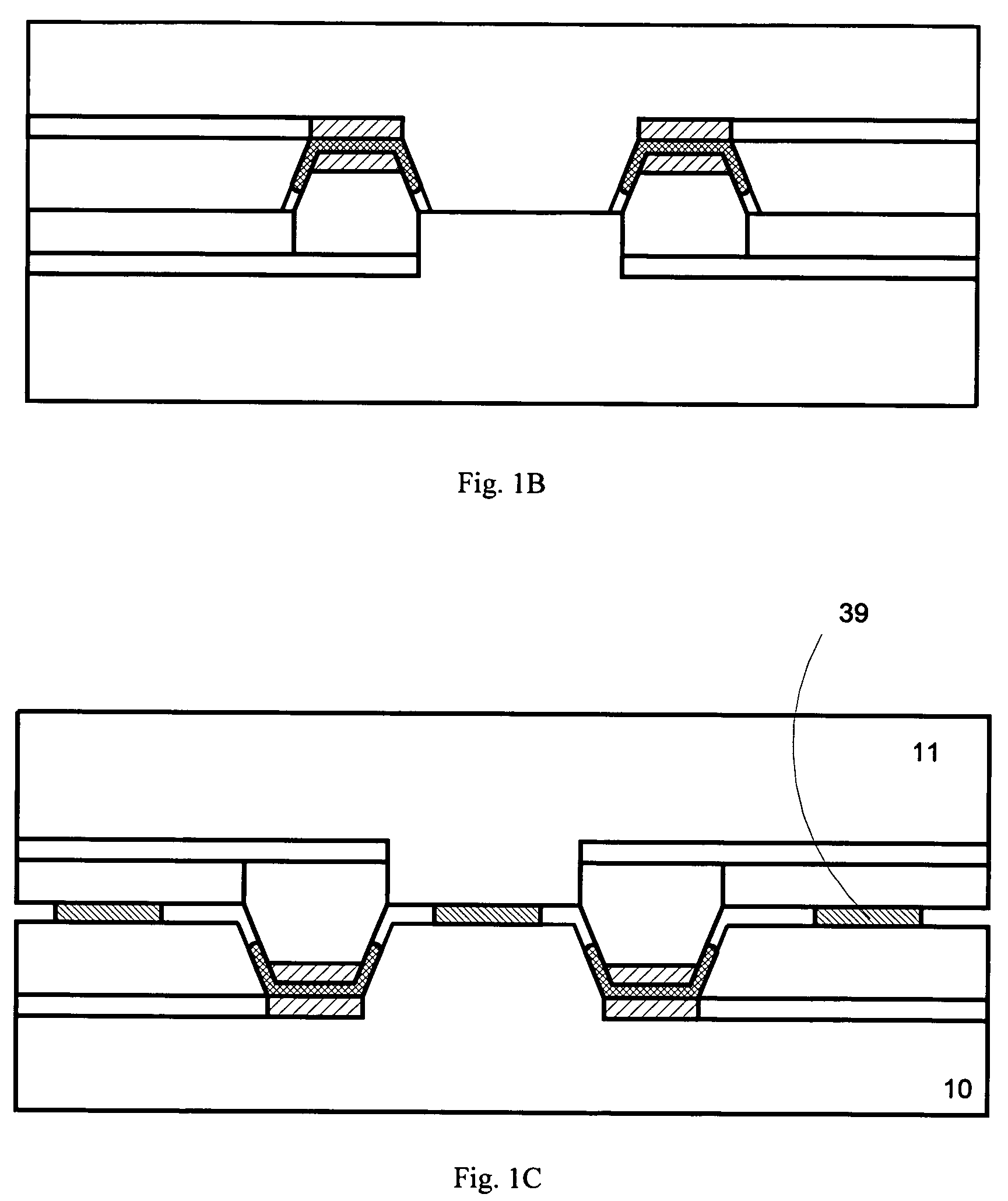

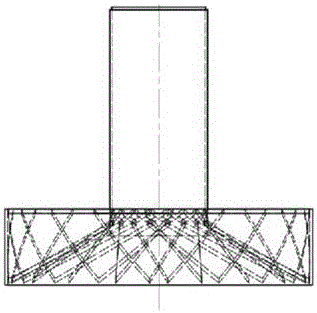

Integrated ultra-clean desulfurization and dust collection device

ActiveCN105727700AIncrease contact timeHigh contact densityCombination devicesGas treatmentSolid phasesContact time

The invention discloses an integrated ultra-clean desulfurization and dust collection device. The integrated ultra-clean desulfurization and dust collection device comprises a tank body, a gas inlet and a chimney, wherein a sealed space is formed by a tank body shell; the chimney is connected with the top part of the tank body shell; and the tank body is provided with a mechanical centrifugal fitting unit, a high-efficiency spraying unit, a high-efficiency energy concentrating ring unit, a multi-tube venturi unit, a mechanical eccentric demisting unit and a washing and spraying layer in sequence from bottom to top. The integrated ultra-clean desulfurization and dust collection device disclosed by the invention has the beneficial effects that flue gas enters an absorbing tower, upward torrential and rotary gas flow formed by the mechanical centrifugal fitting unit, and slurry sprayed by the spraying system from top to bottom generate a controllable torrential space, so that the contact time of a gas phase, a liquid phase and a solid phase is prolonged, the contact density is increased, the fusion is sufficient, the mass transferring efficiency is improved and deep removal of sulfur dioxide is realized; then the flue gas enters a mechanical centrifugal demisting device, and mist droplets and dust are thrown onto the inner wall of a pipe bundle under the action of eccentric force and are captured by a liquid film on the pipe wall simultaneously, so that the deep removal of the mist droplets and the dust is realized.

Owner:TONGZHENG ENVIRONMENT PROTECTION GRP CO LTD

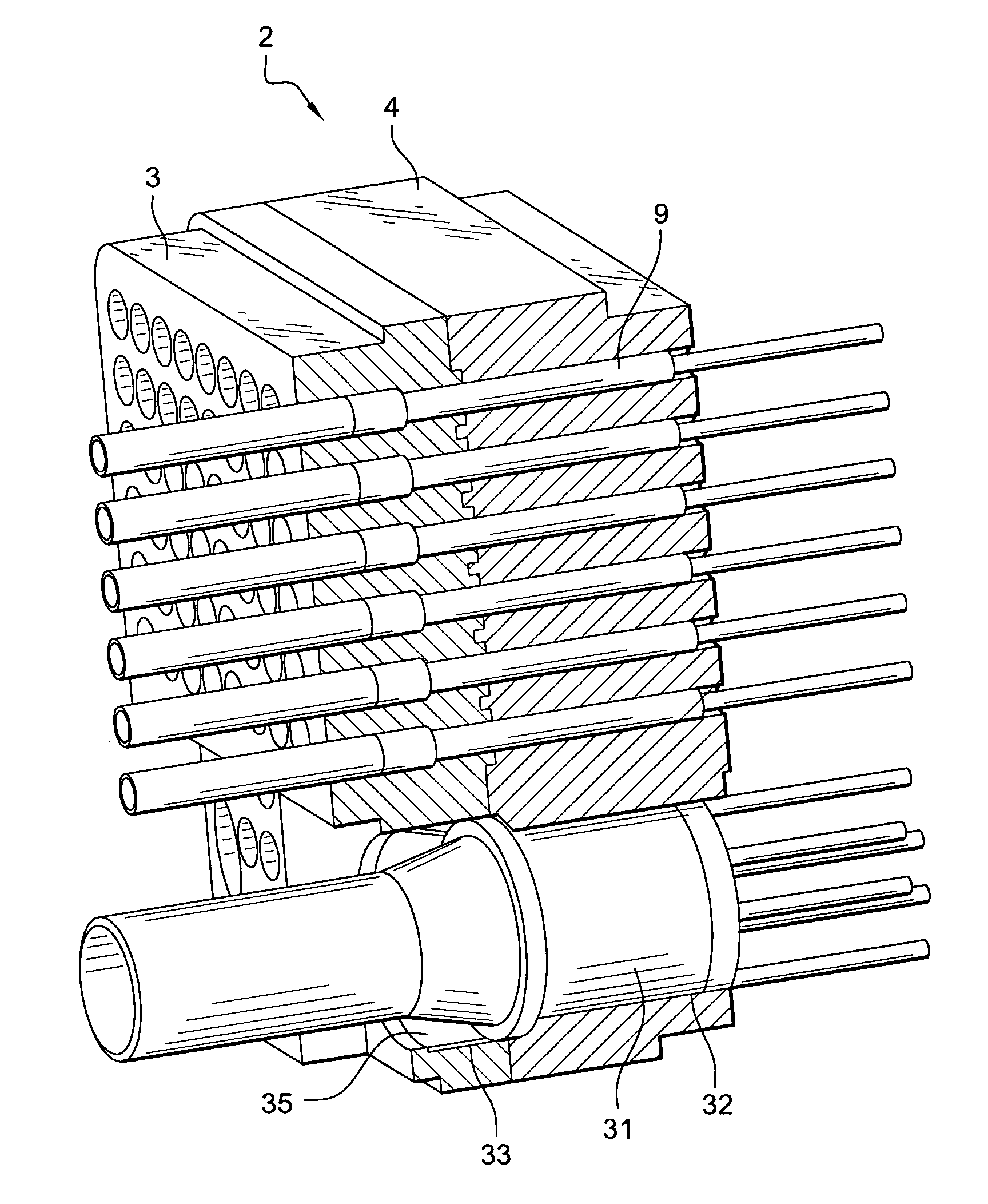

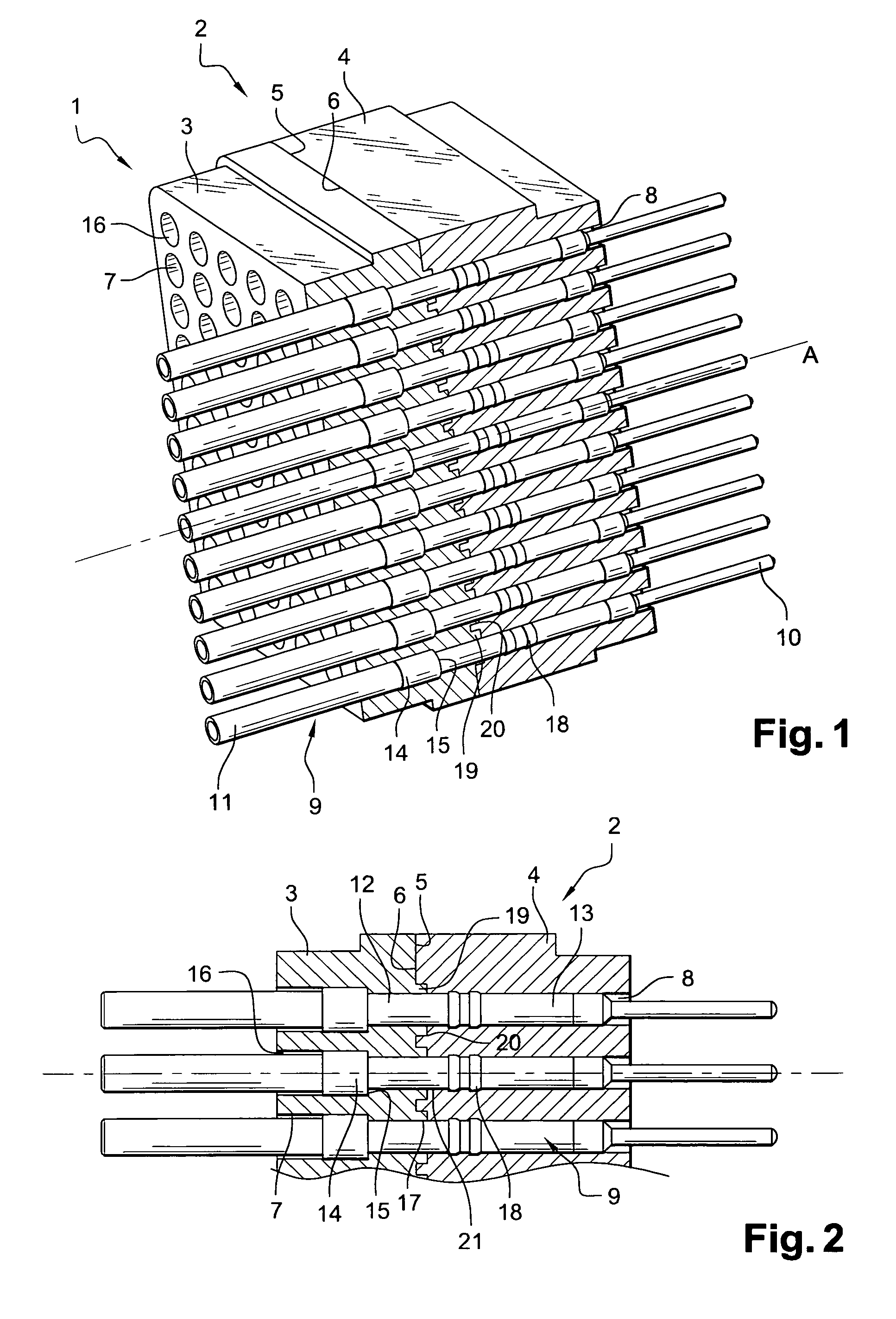

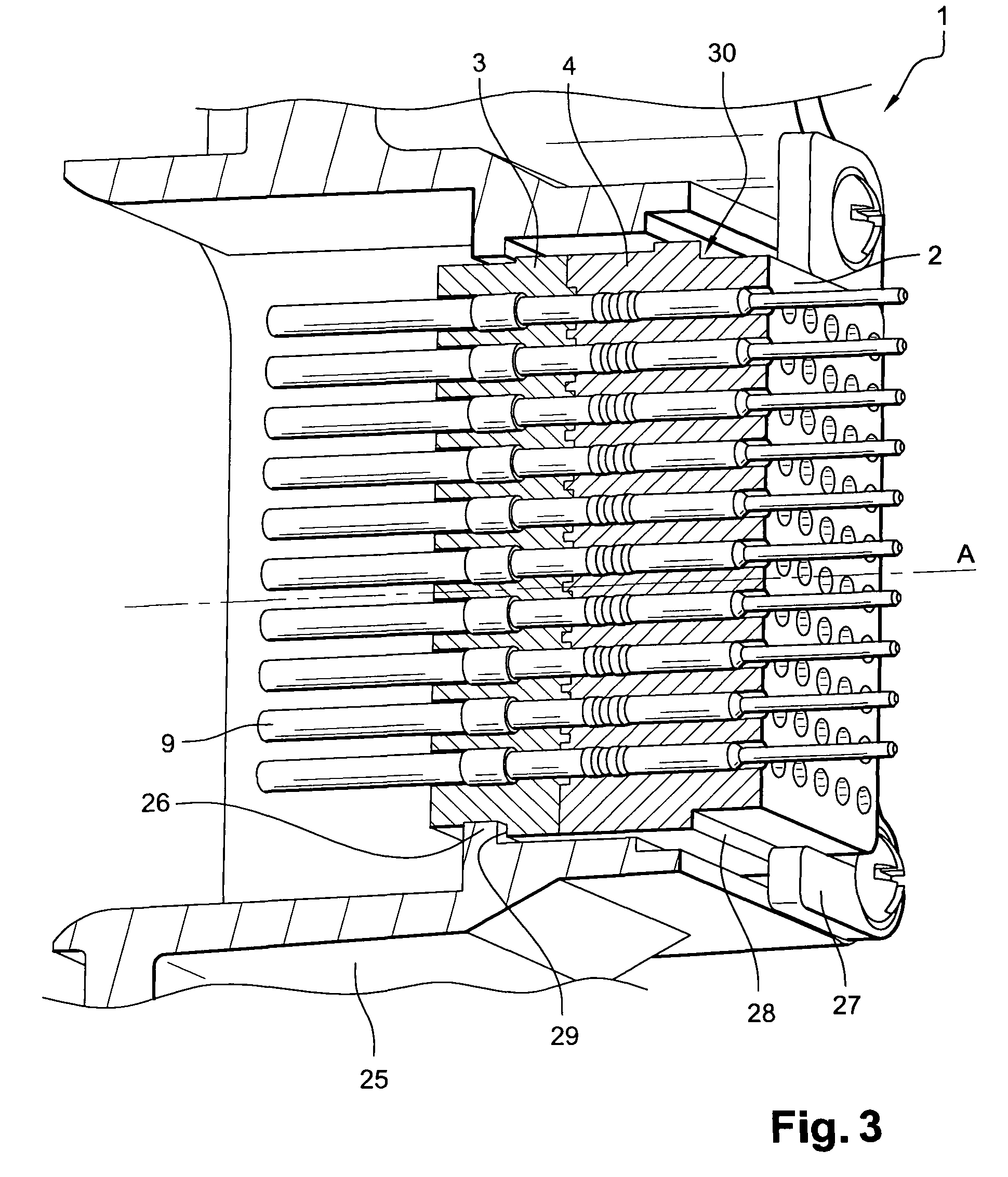

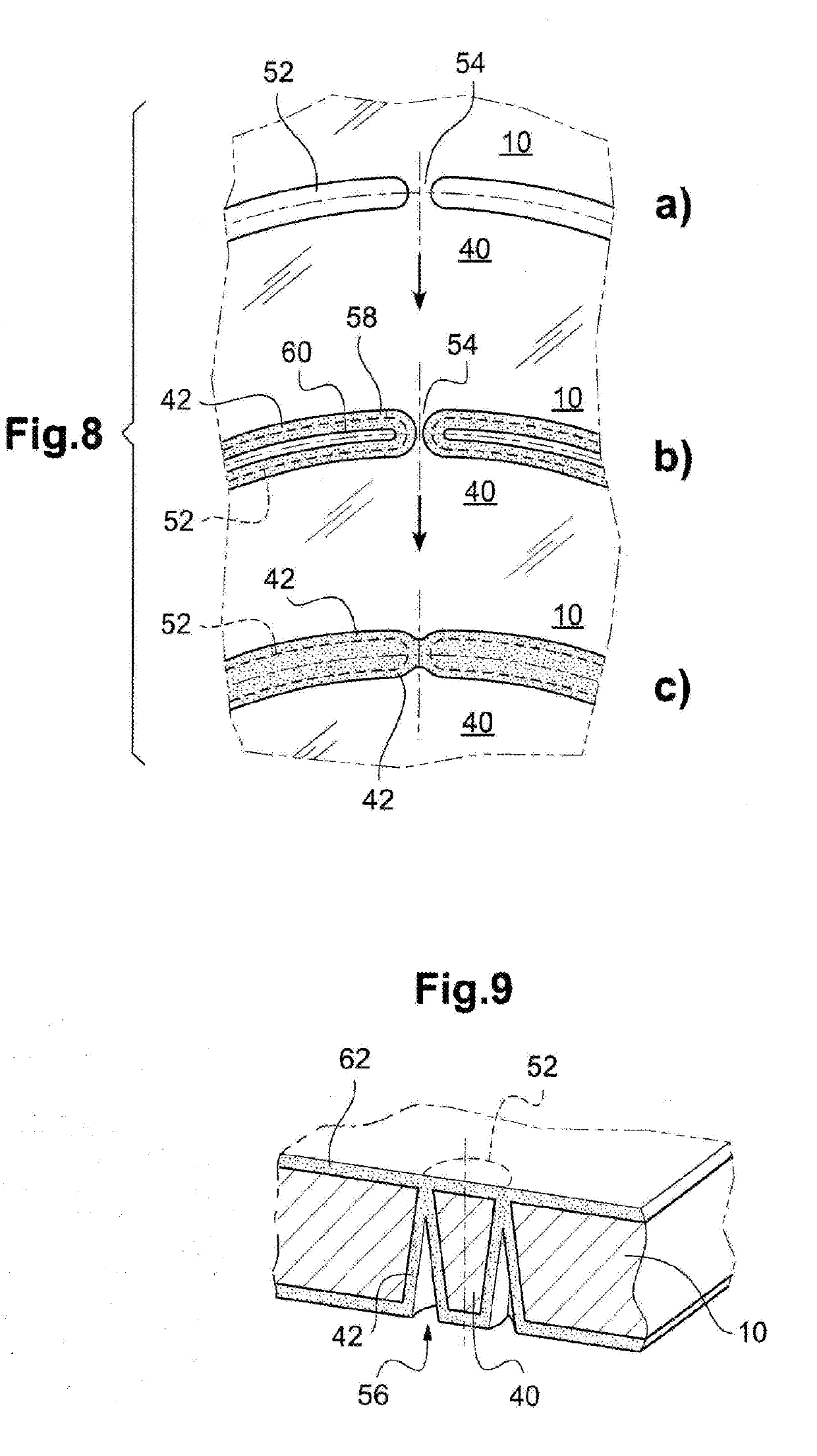

Connection unit and mounting process for such a connection unit

InactiveUS8029325B2Improve automationHigh contact densityContact member assembly/disassemblyElectric discharge tubesEngineeringMechanical engineering

Owner:SOURIAU

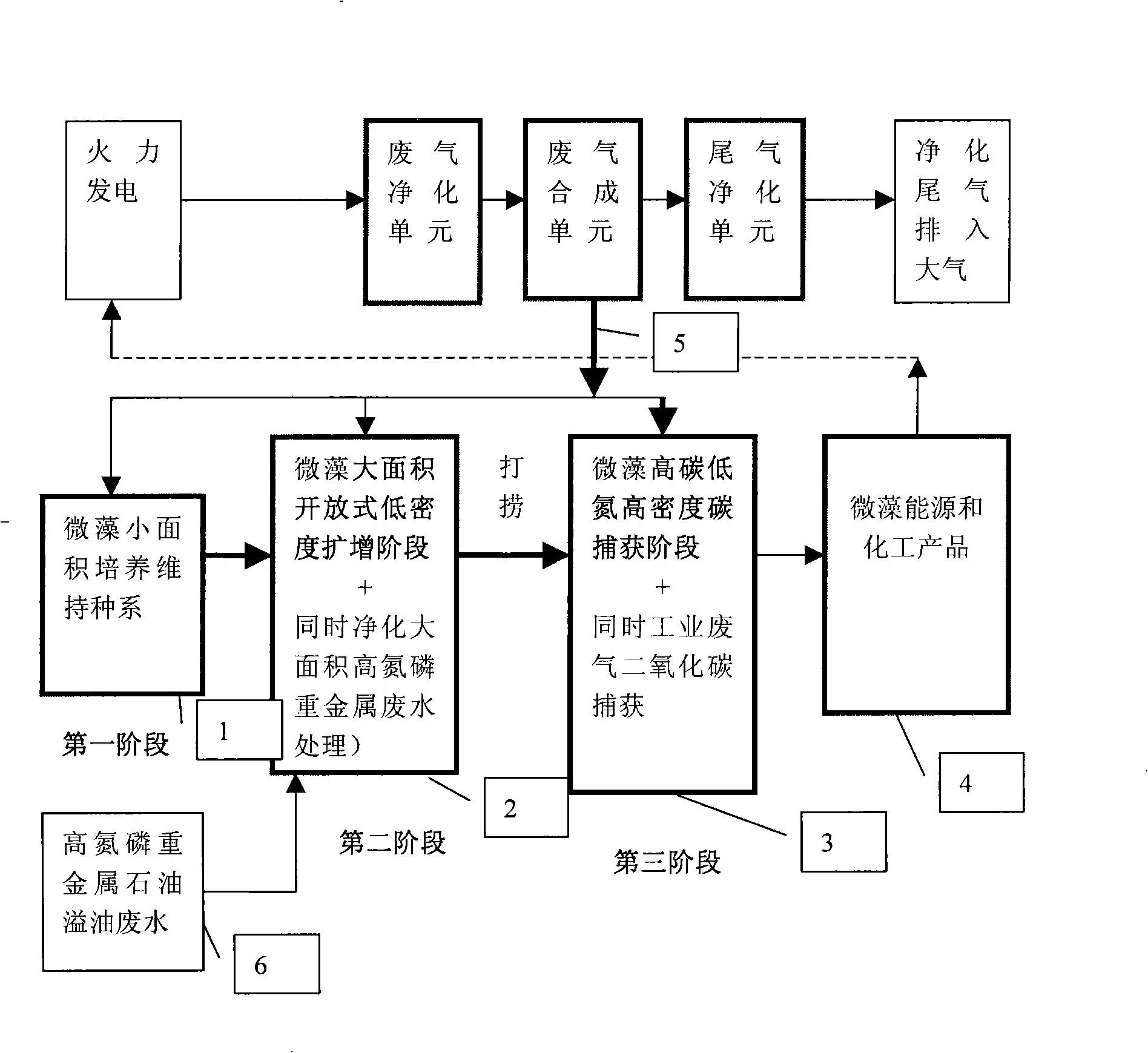

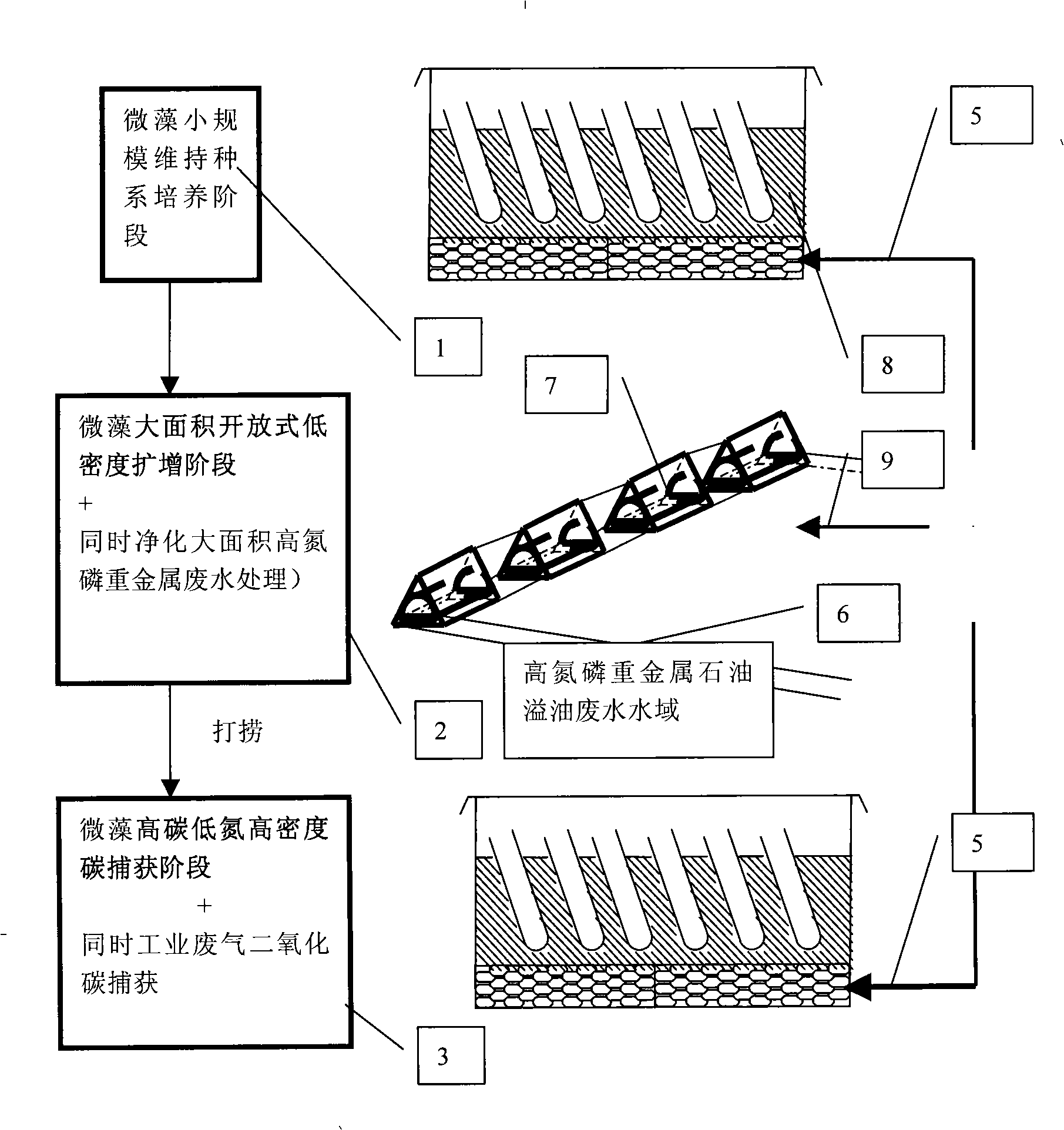

Industrialized culture method and device for photosynthetic autotroph

InactiveCN101280273AHigh contact densityIncrease channel lengthBioreactor/fermenter combinationsBiological substance pretreatmentsIndustrial wasteCarbon dioxide

The invention relates to an industrialized culturing method and a device of photoautotrophic microorganism, in particular to micro-algae culturing. The conventional high nitrogen and high density micro-algae culturing method is changed in the method, the culturing is executed by dividing into three stages, namely the germ line maintenance stage, the large area open type low density augmentation stage and the high carbon low nitrogen high density carbon capture stage. The three stages respectively achieve objects of large area micro-algae industrialization culturing with low cost, enhancing carbohydrate content and lipid content of the micro-algae, integrating the micro-algae culturing and the industrial waste gas carbon dioxide capture integrated with the waste water purification. The realization of the micro-algae culturing ensures that the pollution elements discharged into the environment can be reclaimed in a large scale with low cost, the potential usage lies in micro-algae bio-energy manufacture, the industrial waste gas carbon dioxide capture, the large area high nitrogen and phosphorus heavy metal petroleum overflow wastewater treatment, the chemical synthesis and the paper making.

Owner:朱洪

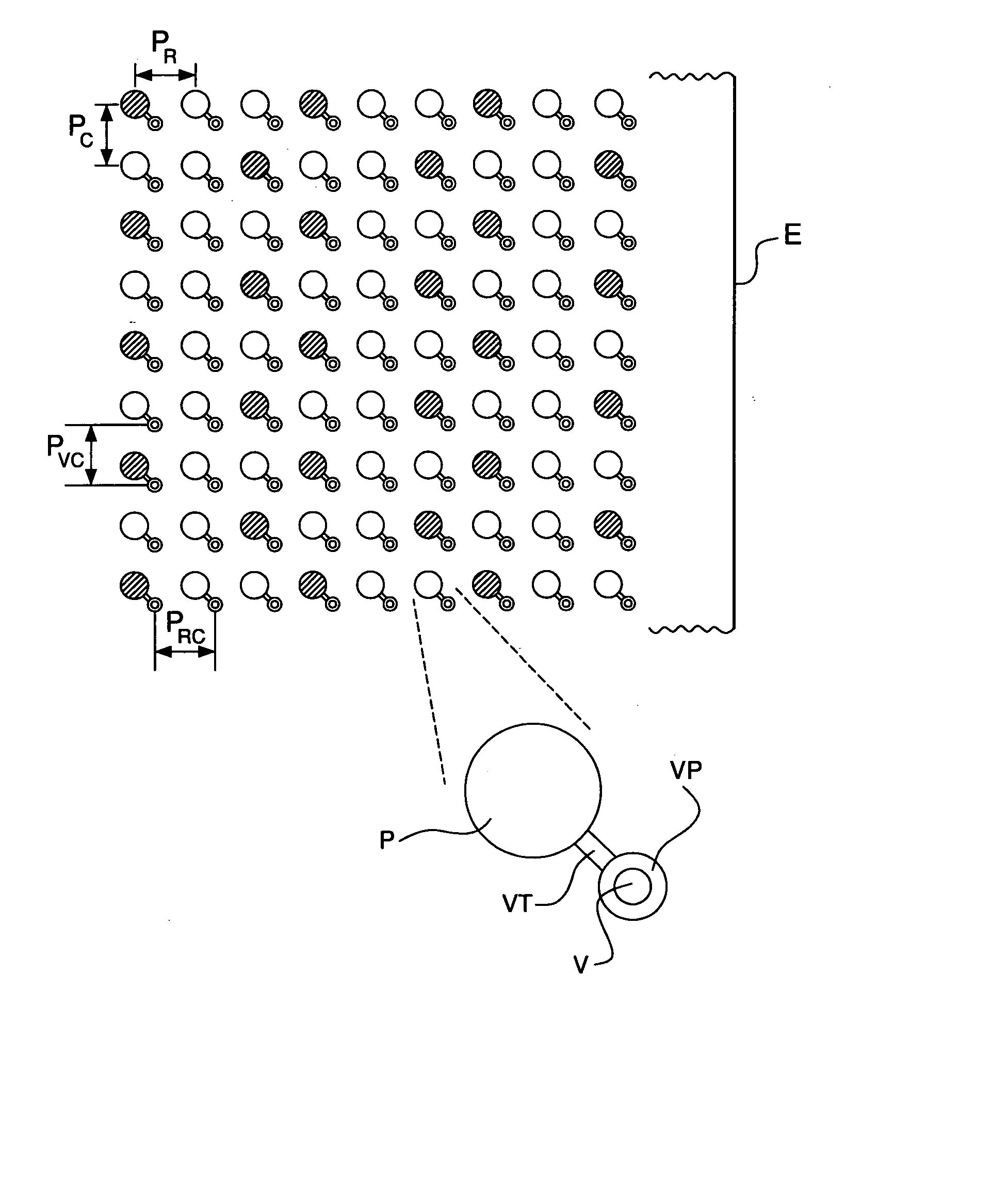

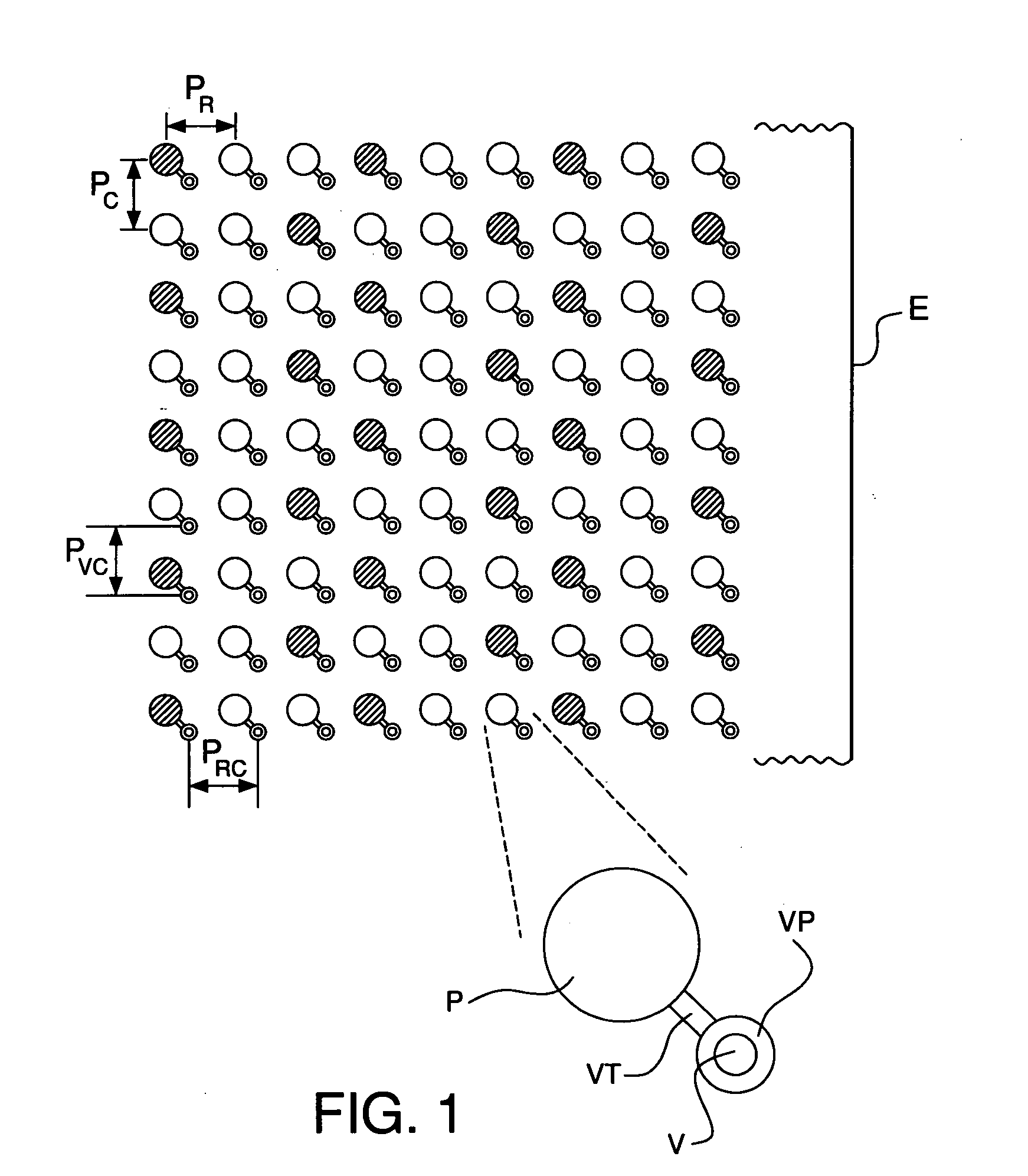

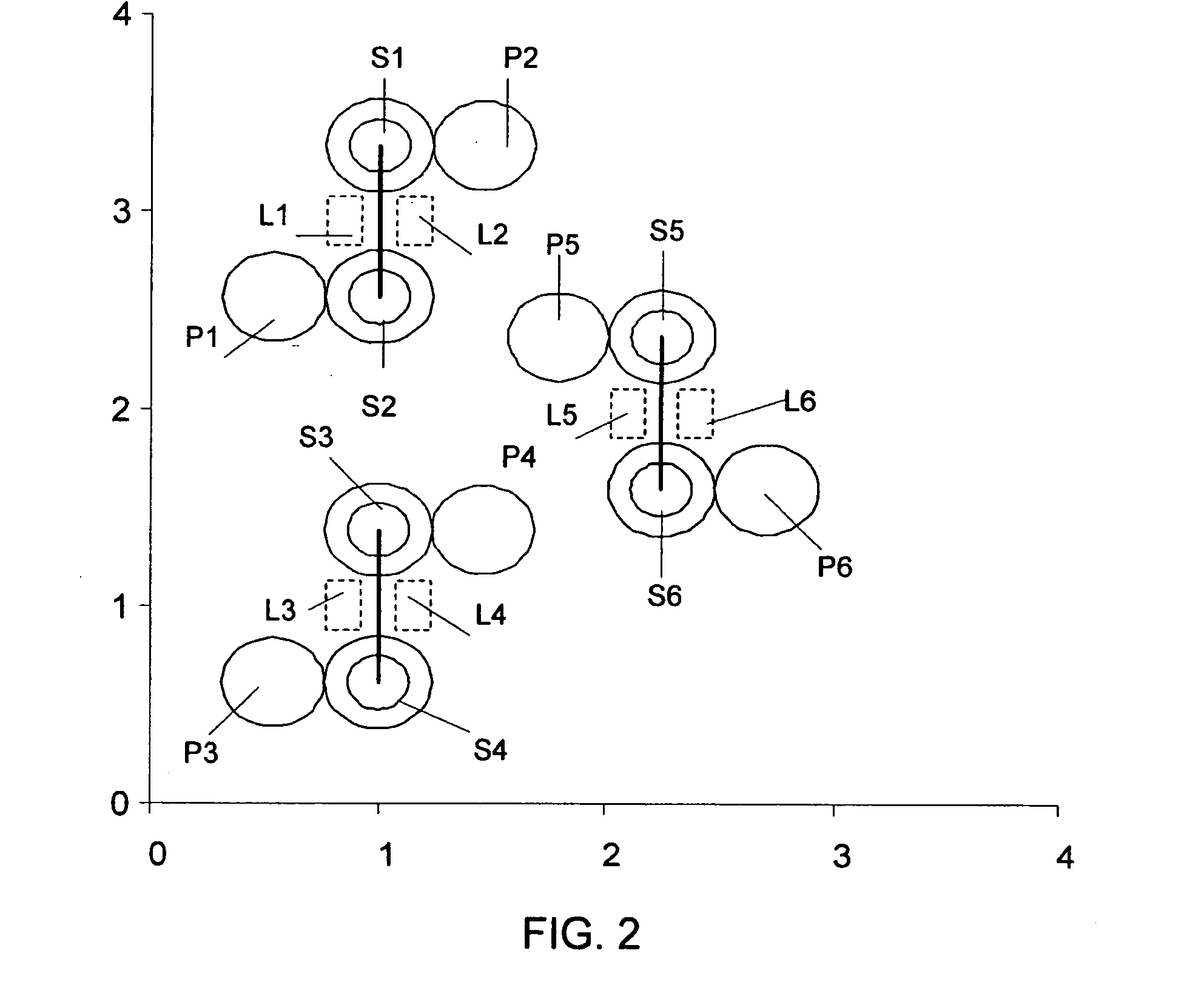

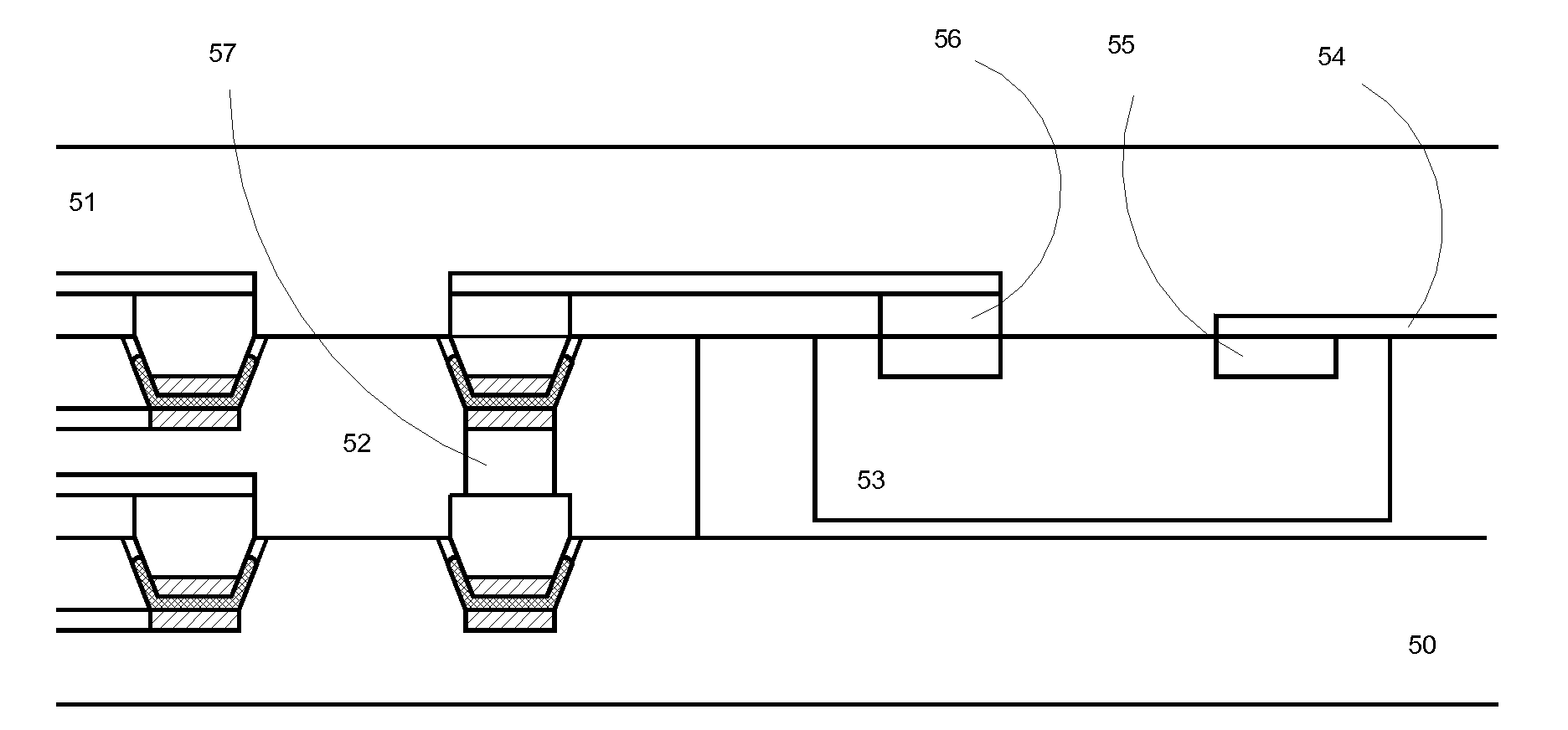

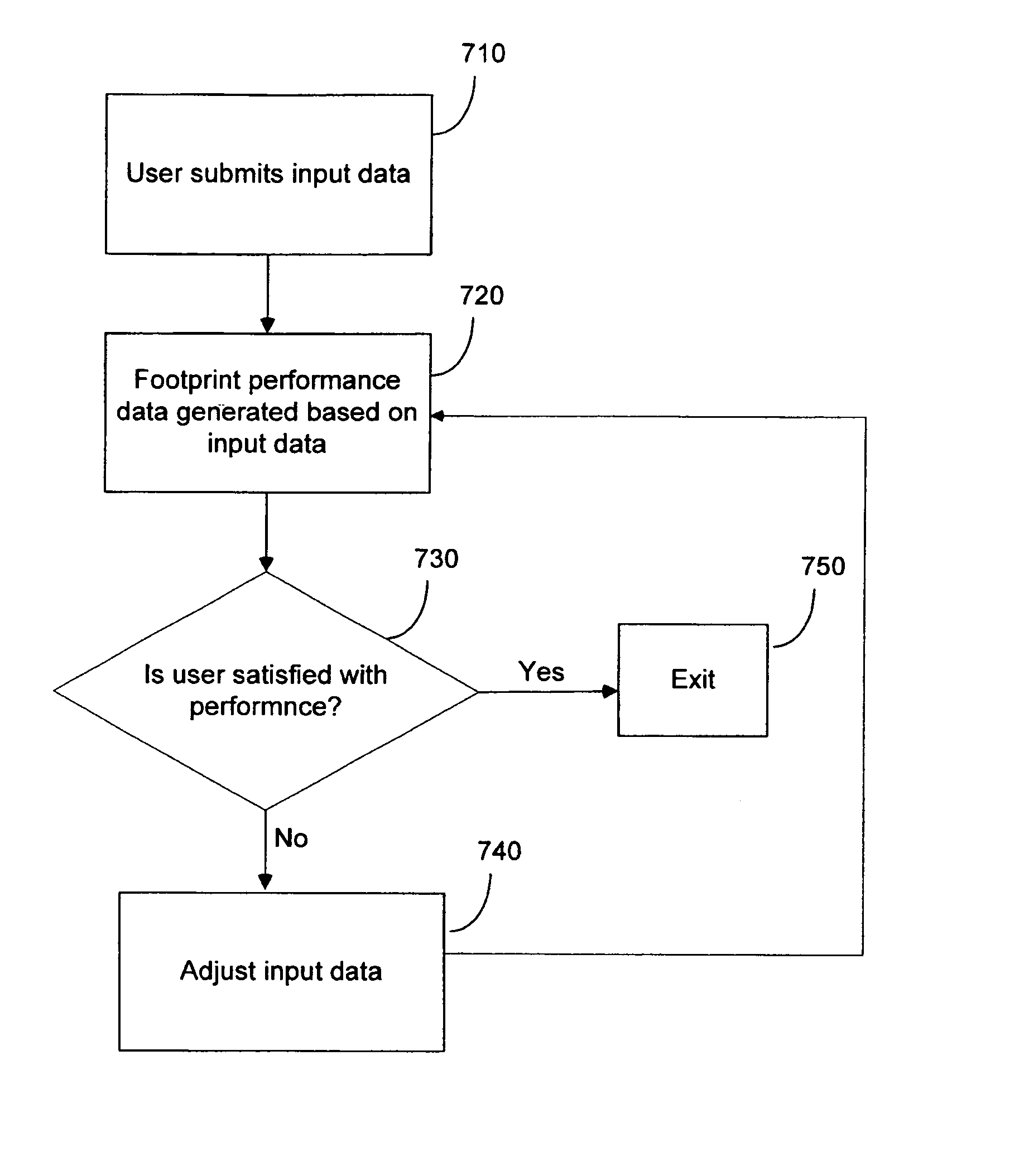

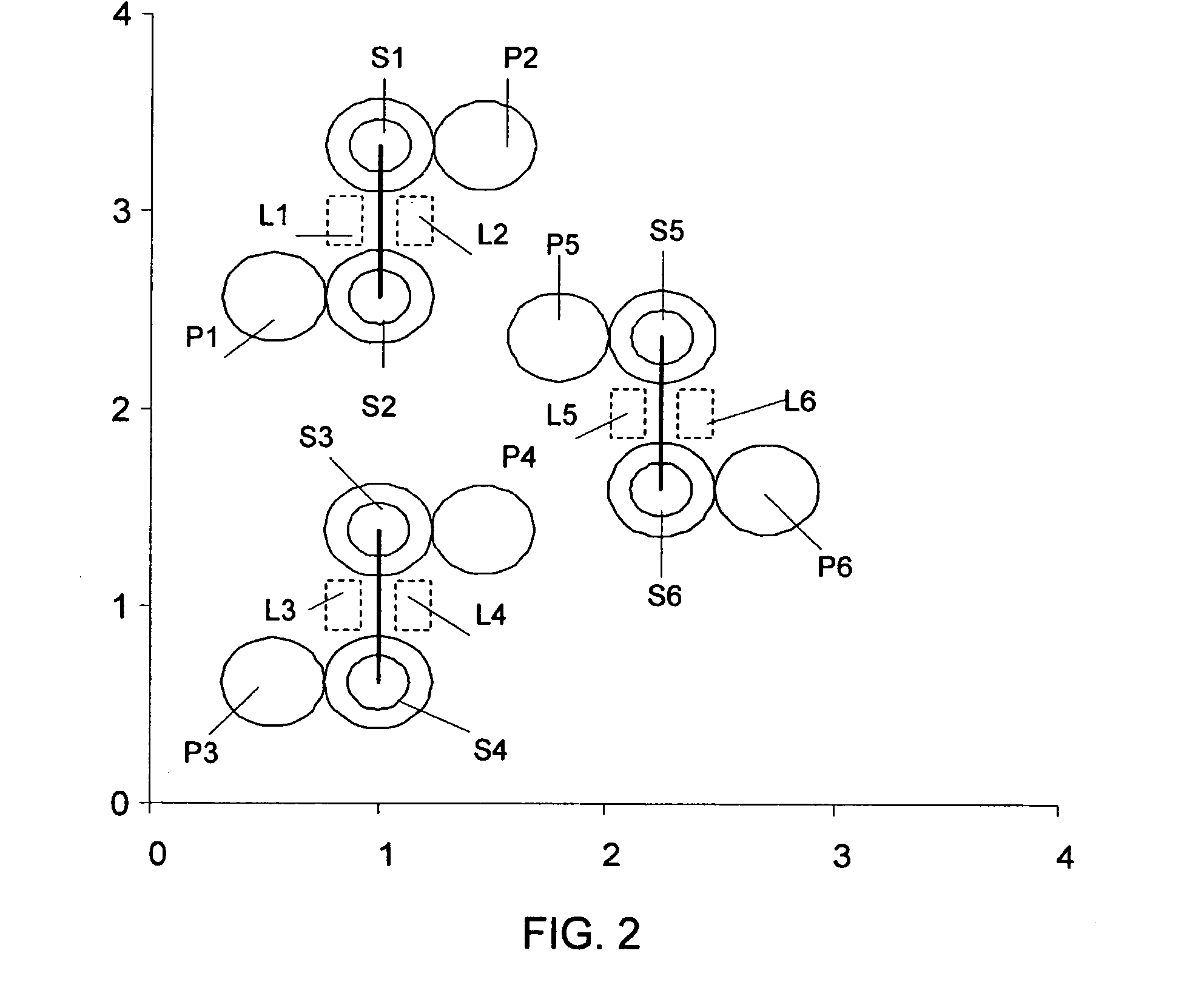

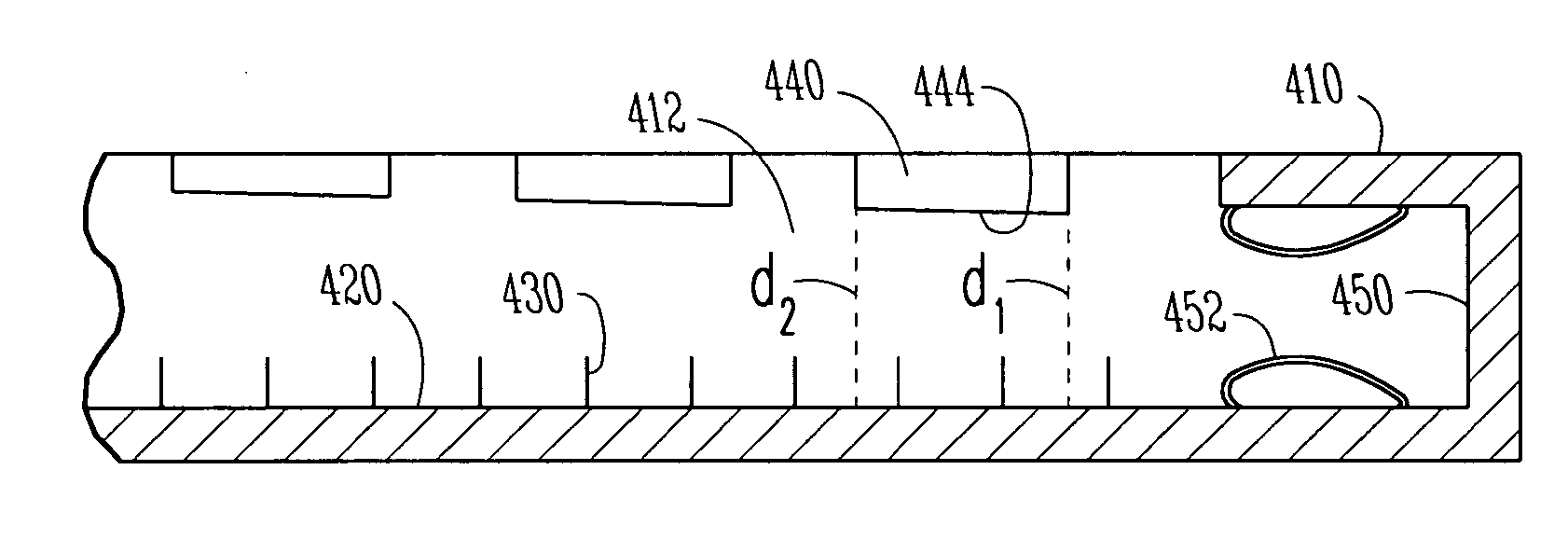

High-Frequency, High-Signal-Density, Surface-Mount Technology Footprint Definitions

ActiveUS20060231833A1Increased signal contact densitySuppress crosstalkSemiconductor/solid-state device detailsPrinted circuit aspectsSurface mountingElectrical connection

Methods for designing SMT connector footprints are disclosed. A circuit board may have disposed thereon an arrangement of SMT pads and corresponding vias. The arrangement of vias may differ from the arrangement of SMT pads. The arrangement of SMT pads may differ from the arrangement of contacts in a connector the footprint is designed to receive. The terminal ends of the contacts may be jogged or bent for electrical connection with the SMT pads. The SMT pads and vias may be arranged in a number of ways that increase signal contact density of the board, while limiting cross-talk and providing adequate impedance and routing space on the board. An interactive tool for designing such a footprint is disclosed.

Owner:FCI AMERICAS TECH LLC

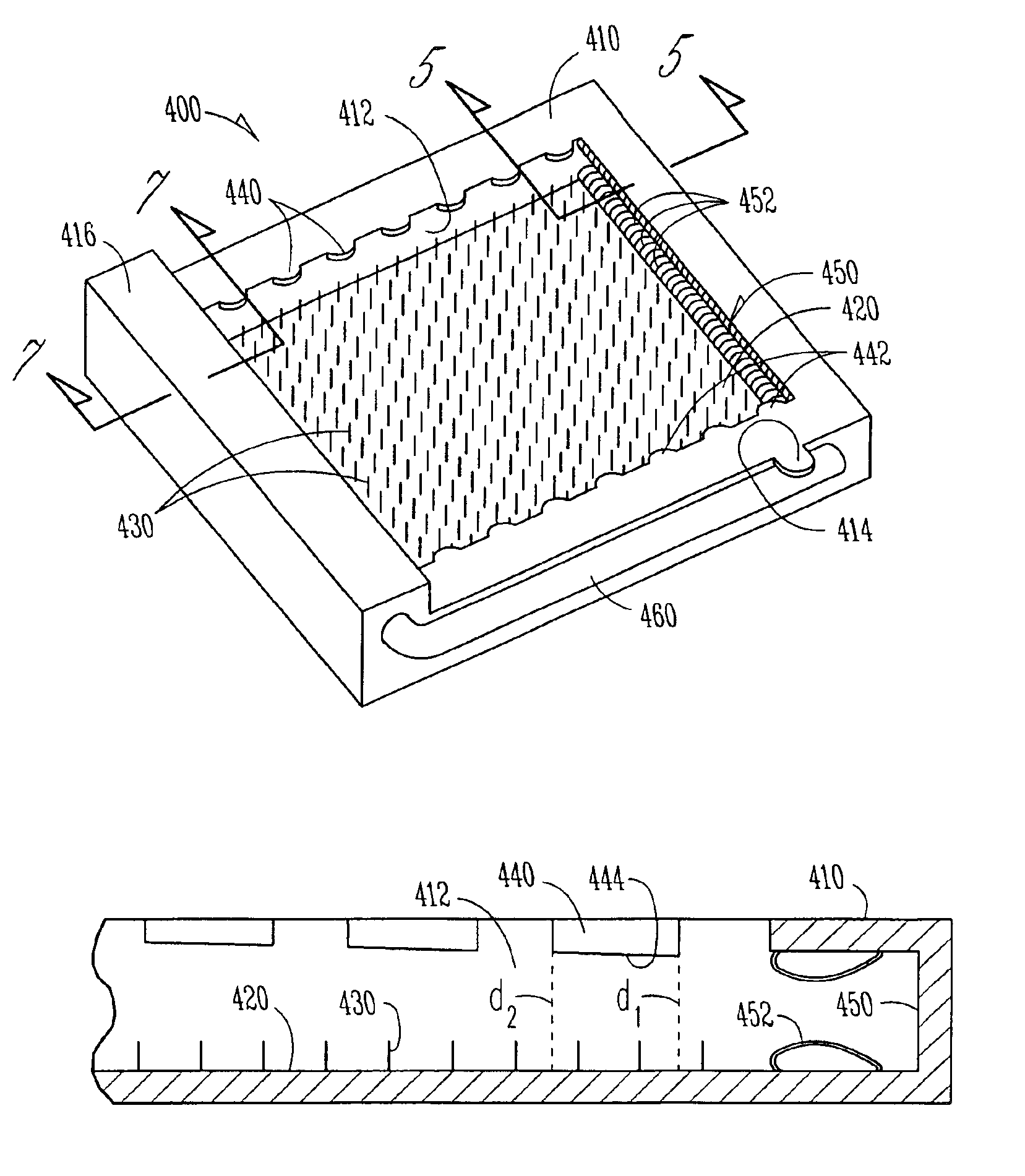

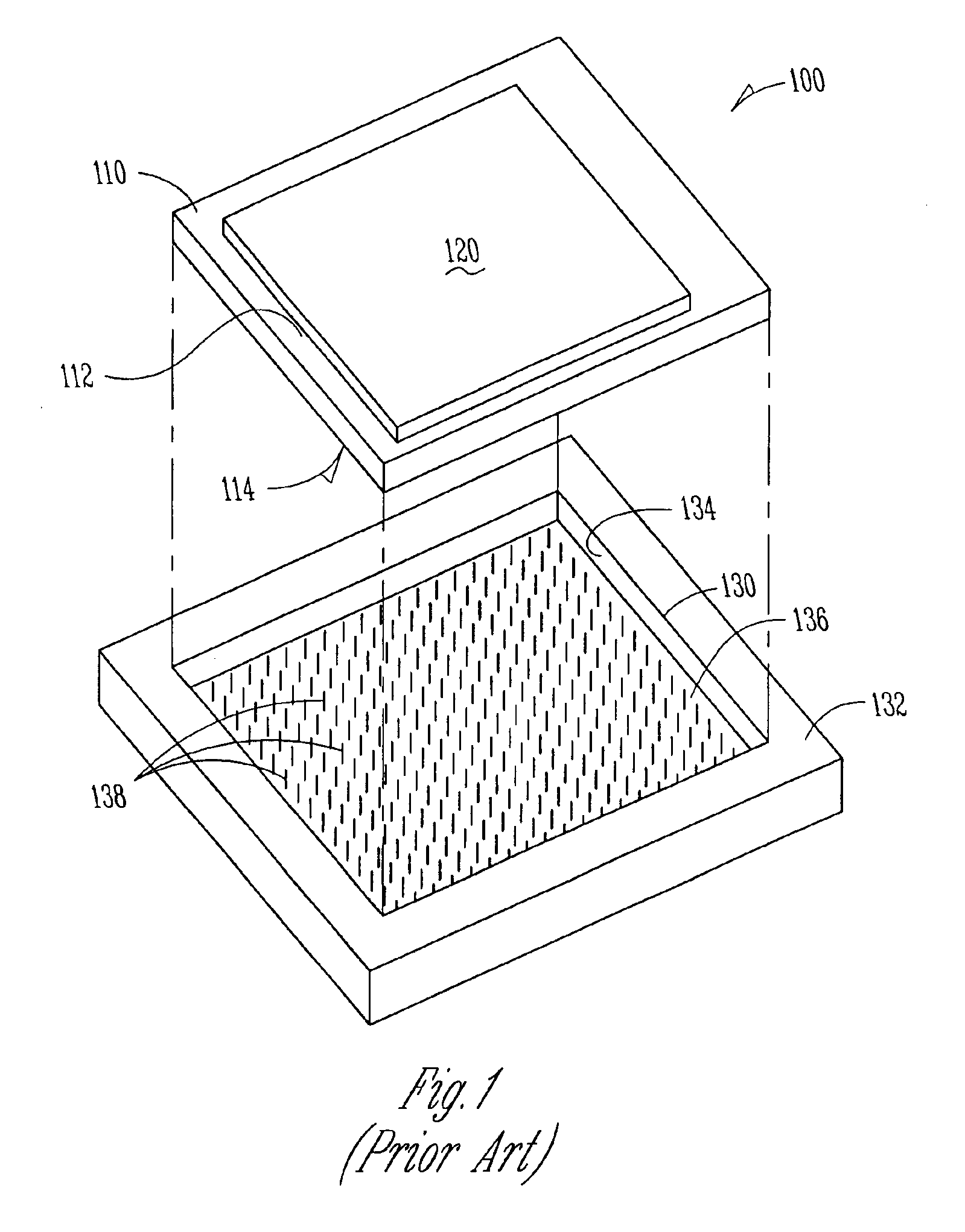

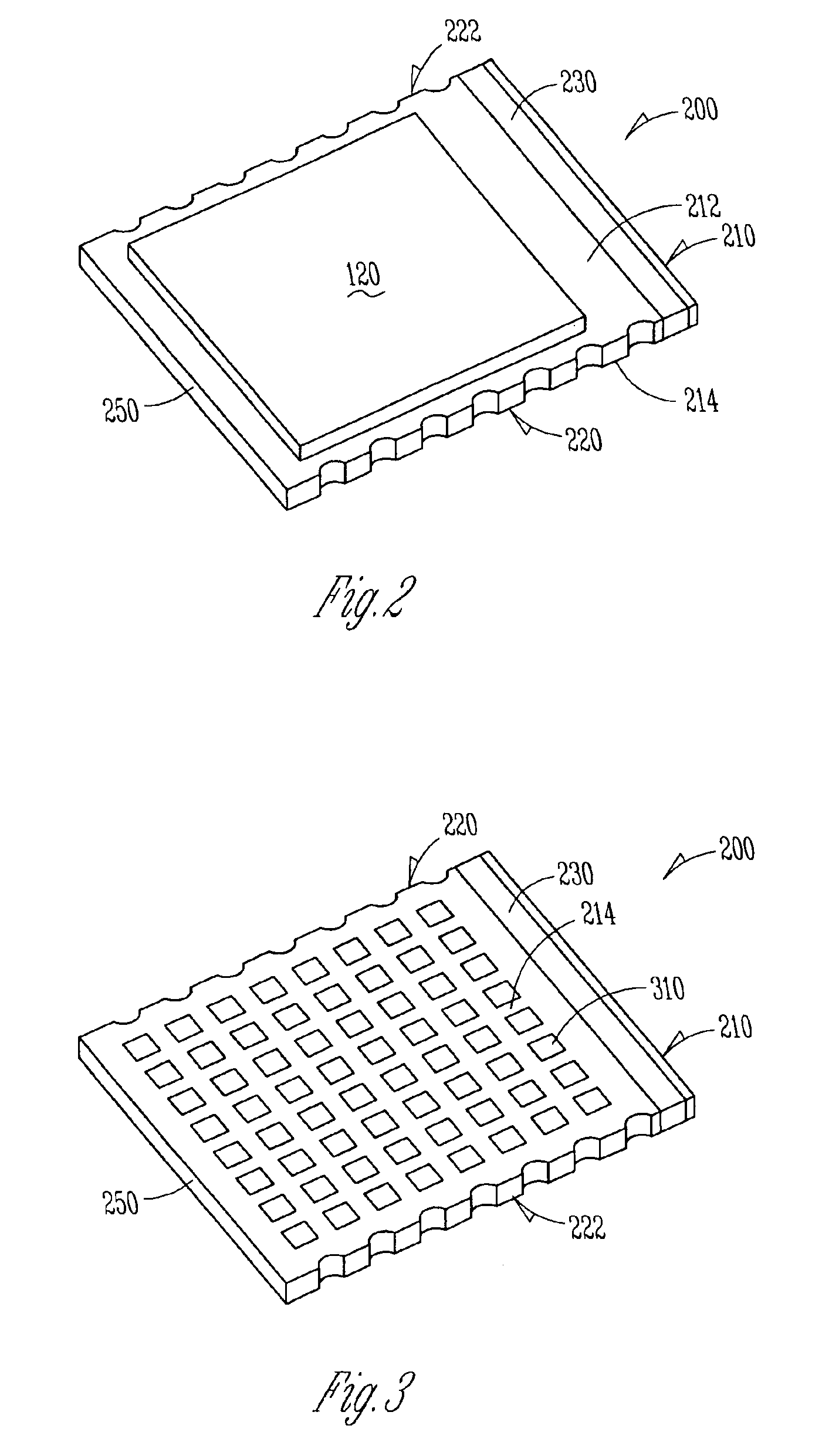

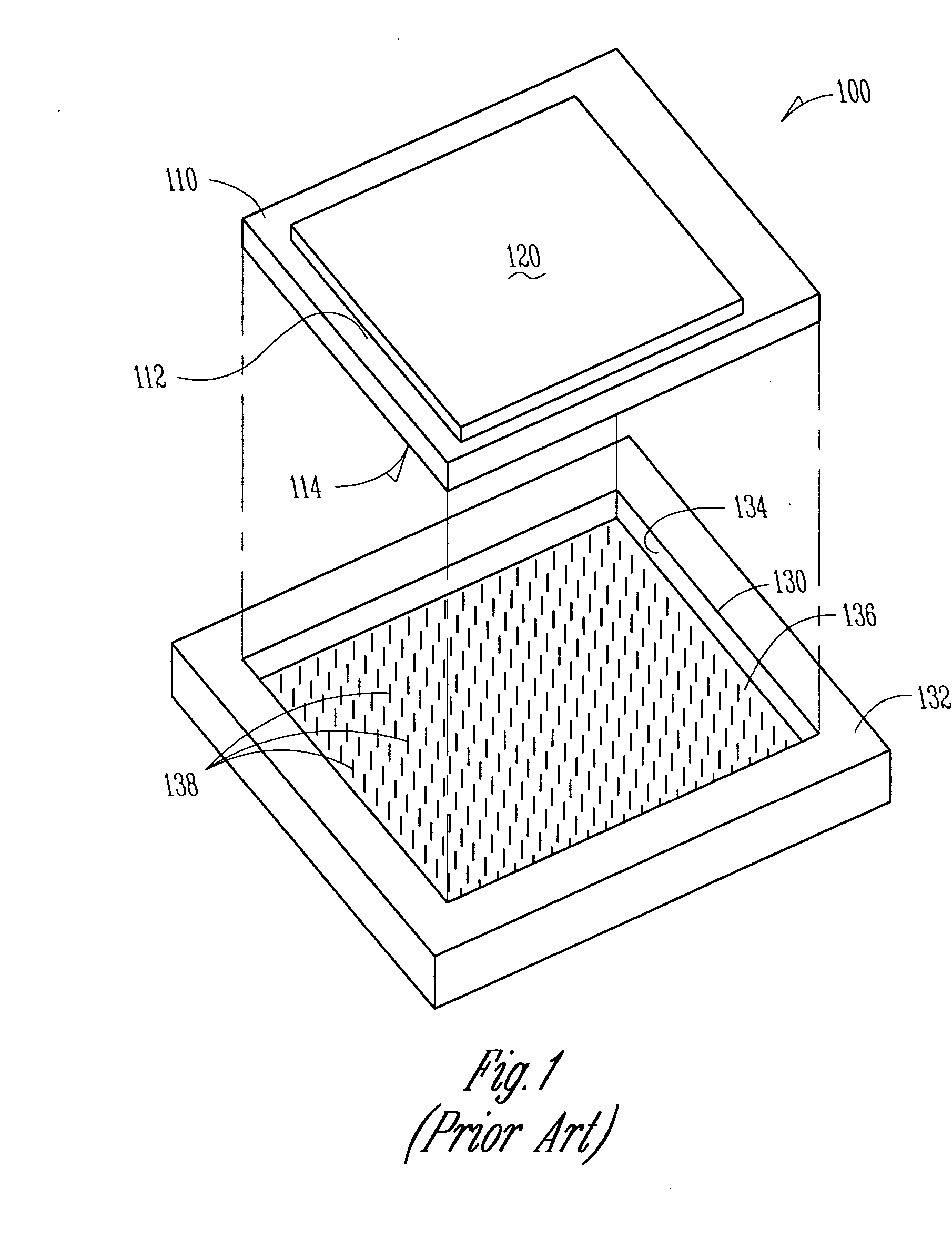

High-power LGA socket

InactiveUS6870251B2Reliable good electricalIncrease loadEngagement/disengagement of coupling partsSemiconductor/solid-state device detailsElectrical conductorEngineering

A system for providing electrical contacts between a die and an electrical device includes a die and a package. The package includes a first major surface, a second major surface, a first scalloped edge, a second scalloped edge and a solid end adapted for insertion into a slot. The solid end and the scalloped edges carry current greater than the current needed for an input / output signal. The socket includes a base having an opening therein adapted to receive the package. A slot is located at one end of the opening in the base. The slot is provided with a plurality of conductors for carrying currents greater than the current needed for an input / output signal. A first edge and second edge of the opening include a plurality of spaced overhangs positioned over the opening. The overhangs are sloped with respect to the major planar surface.

Owner:INTEL CORP

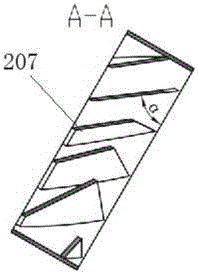

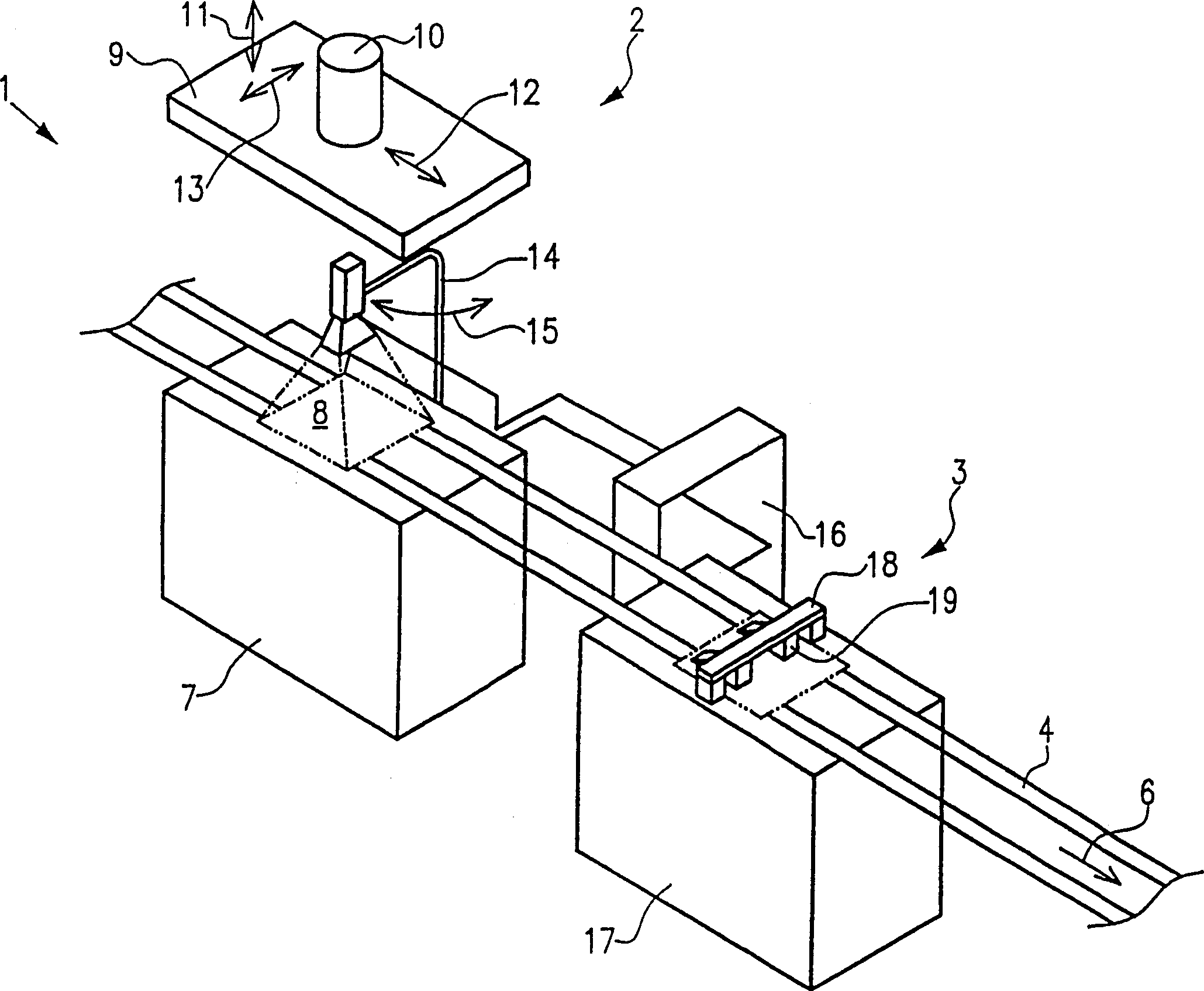

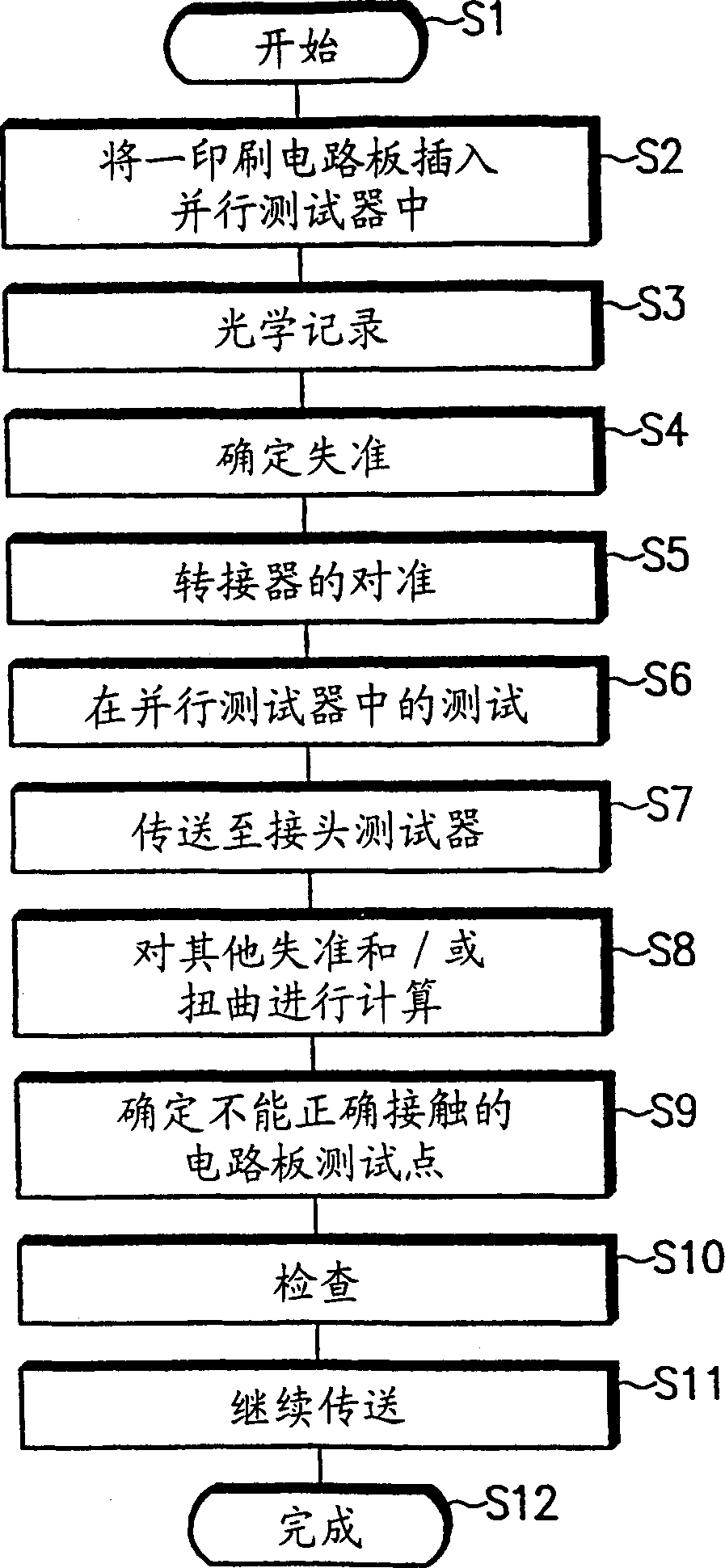

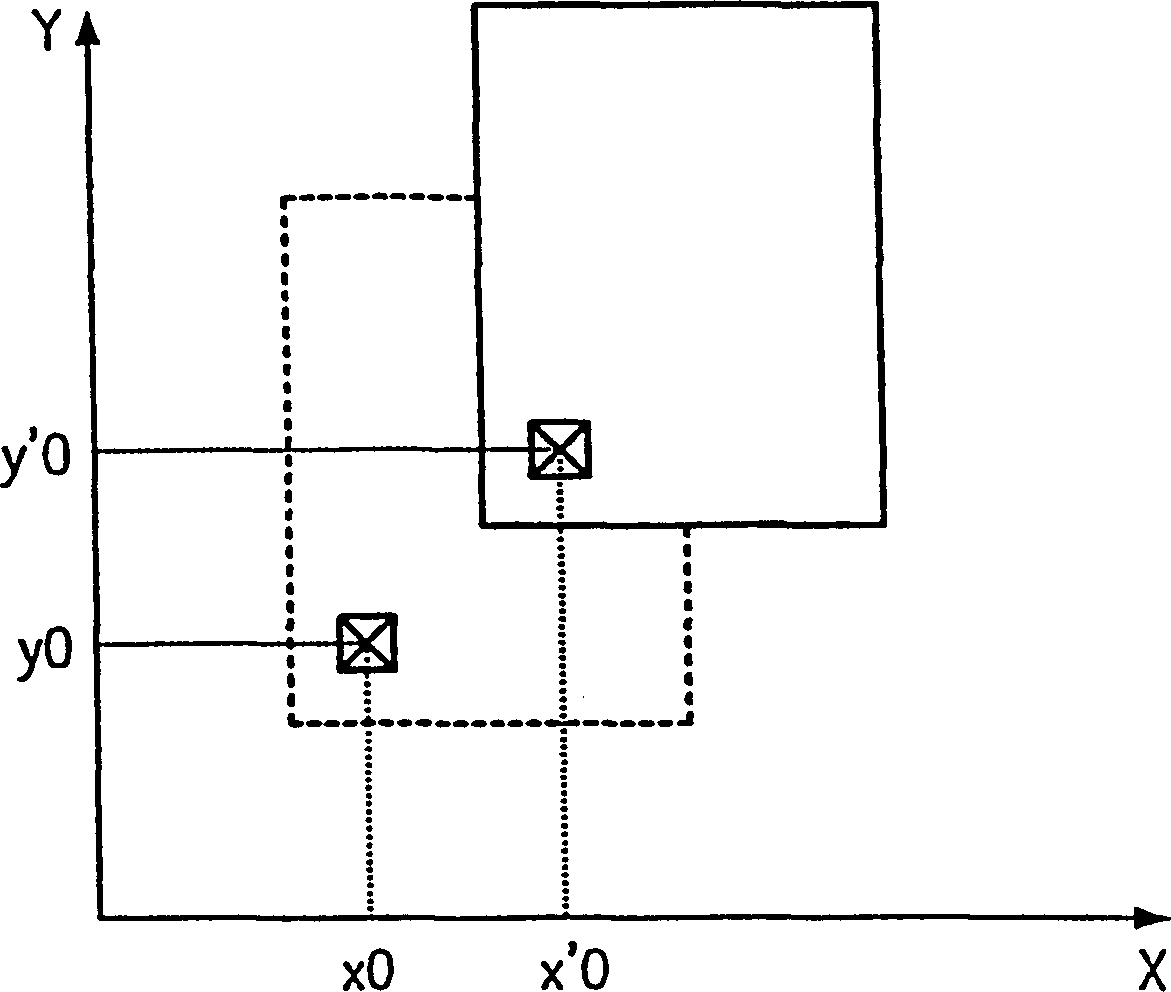

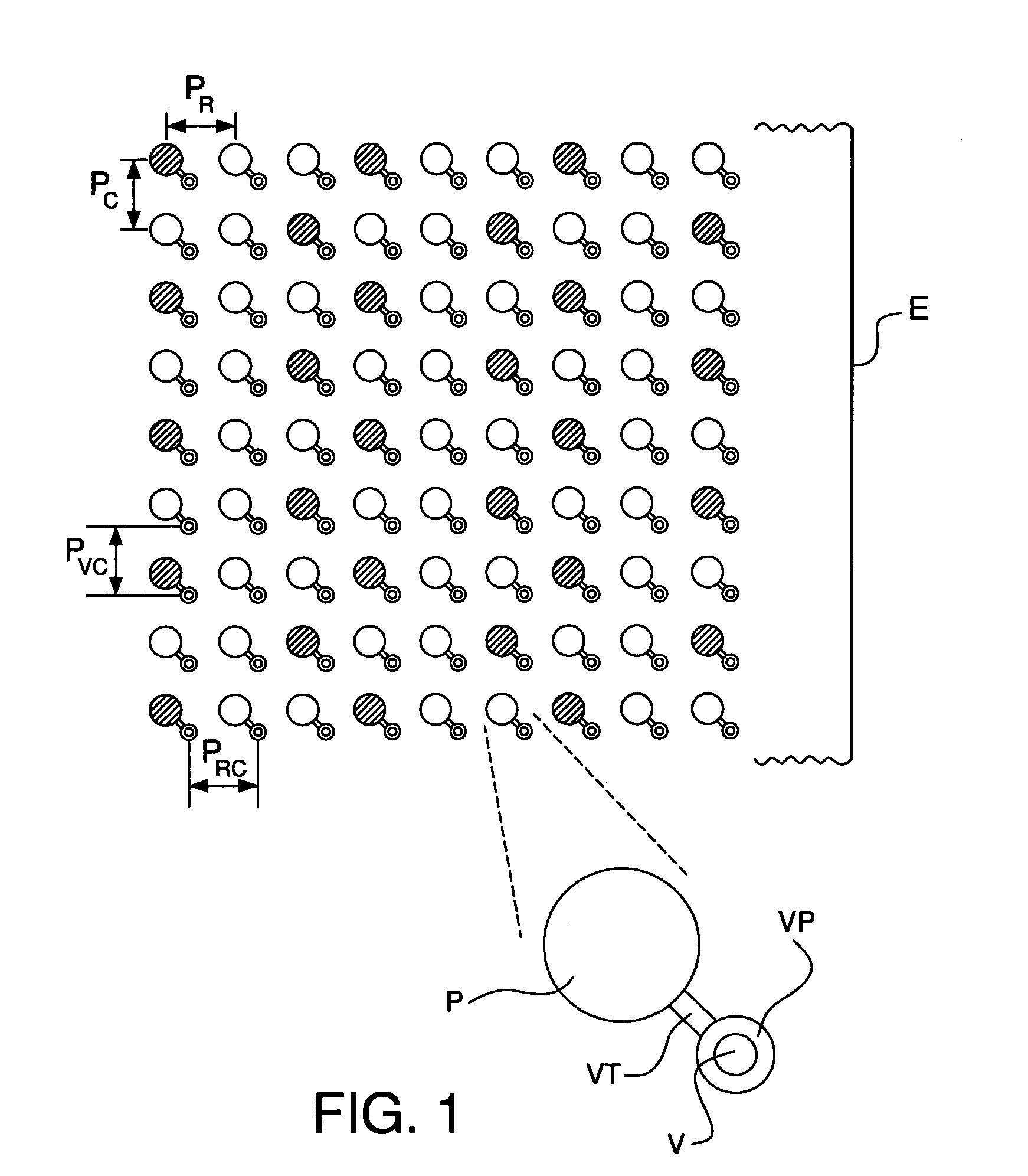

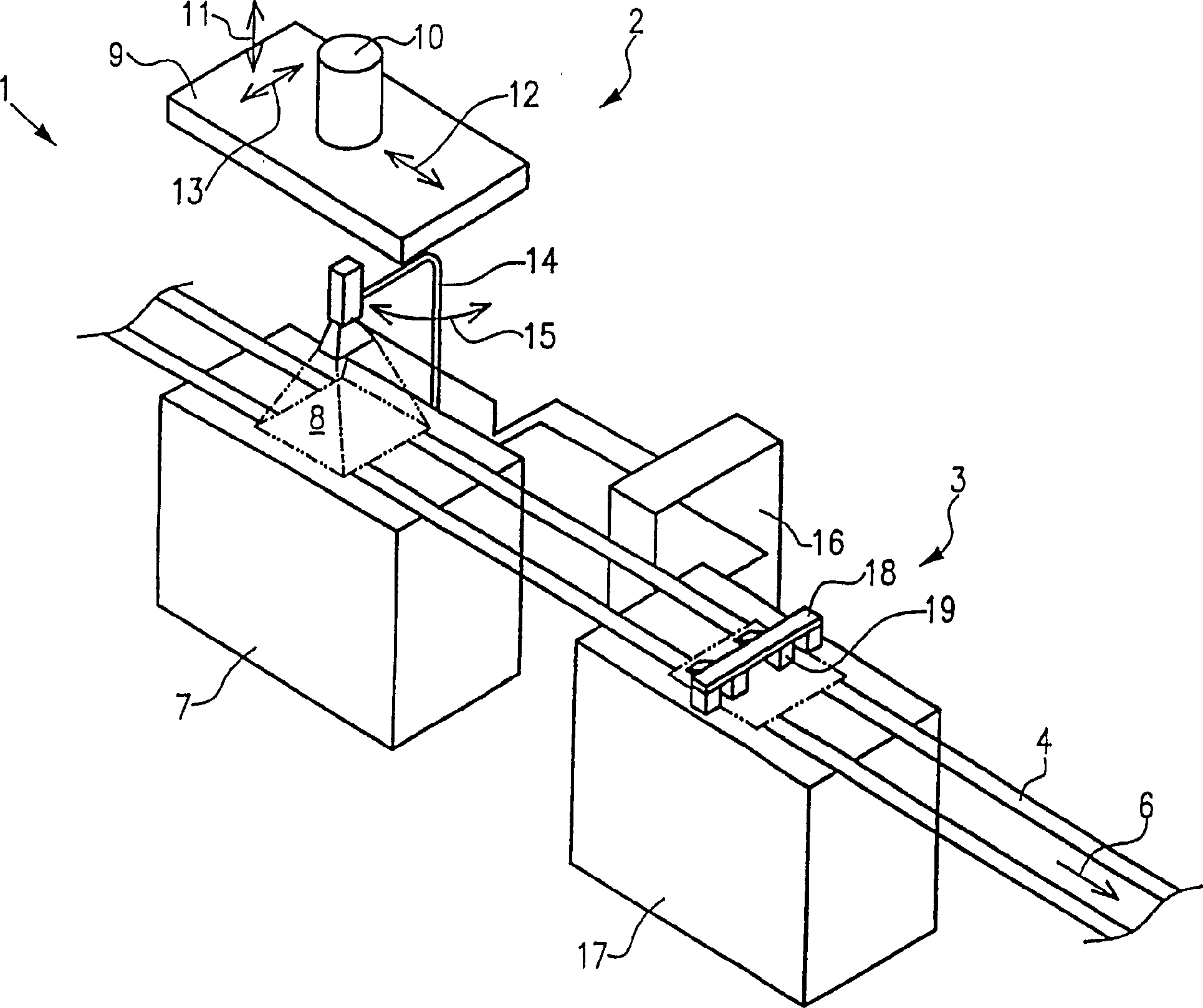

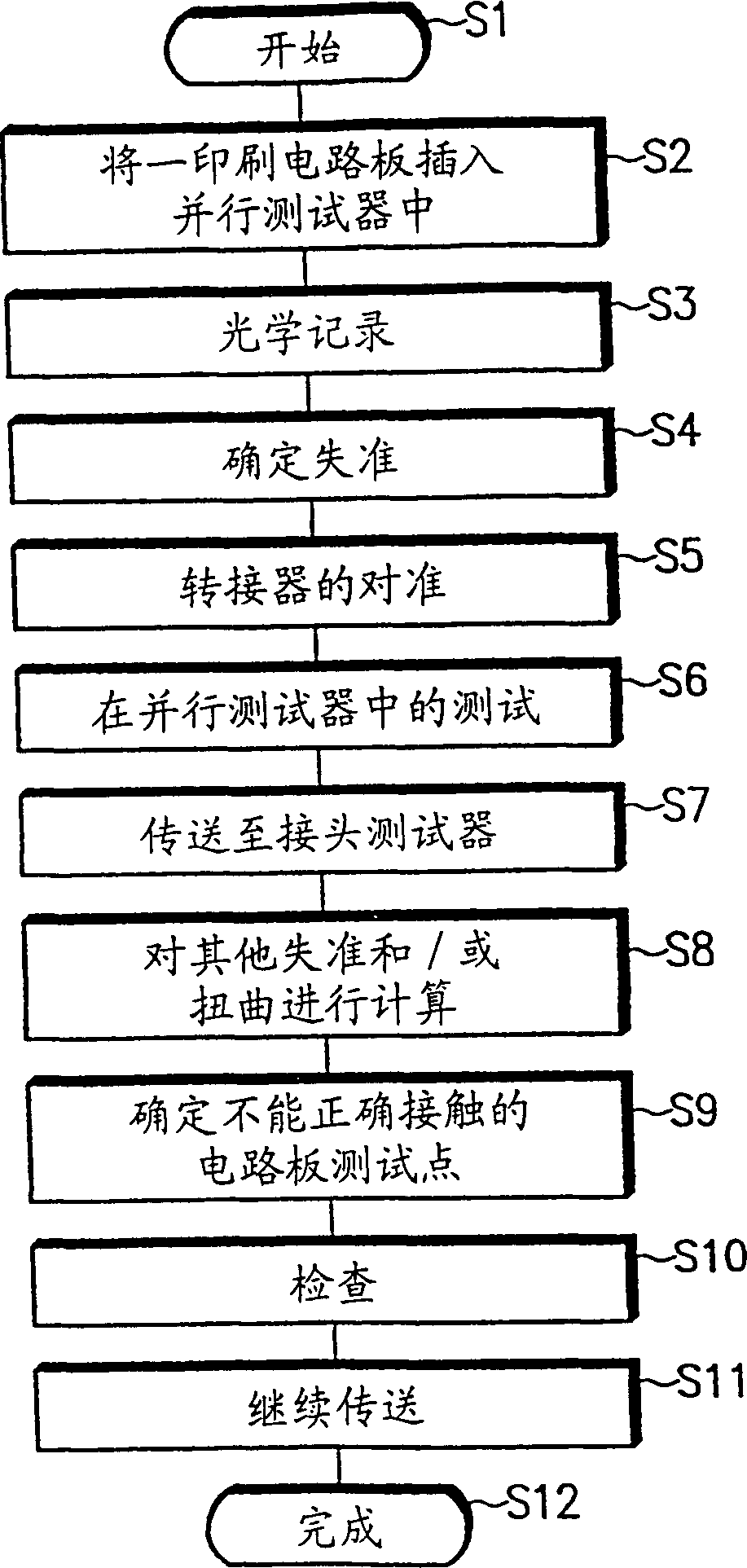

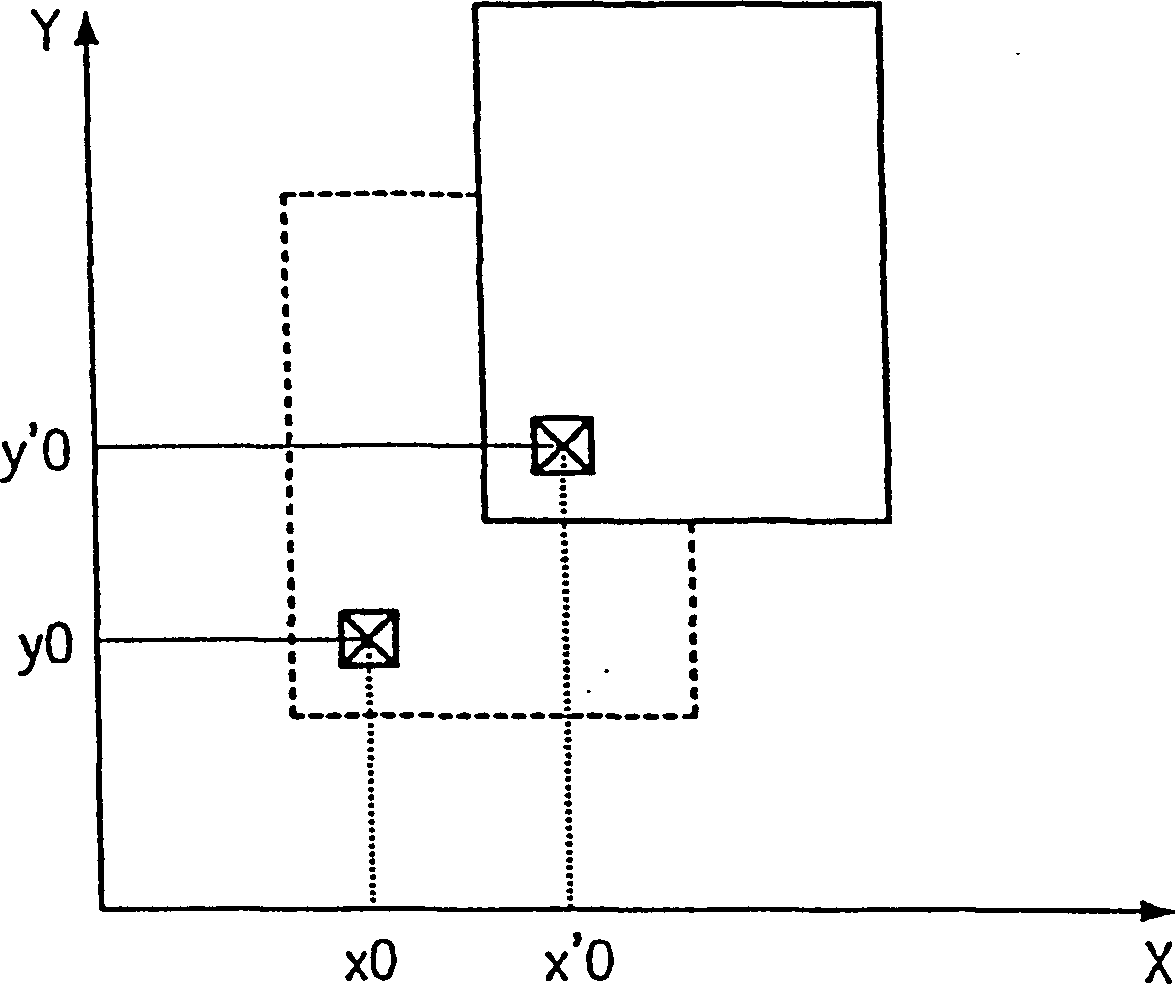

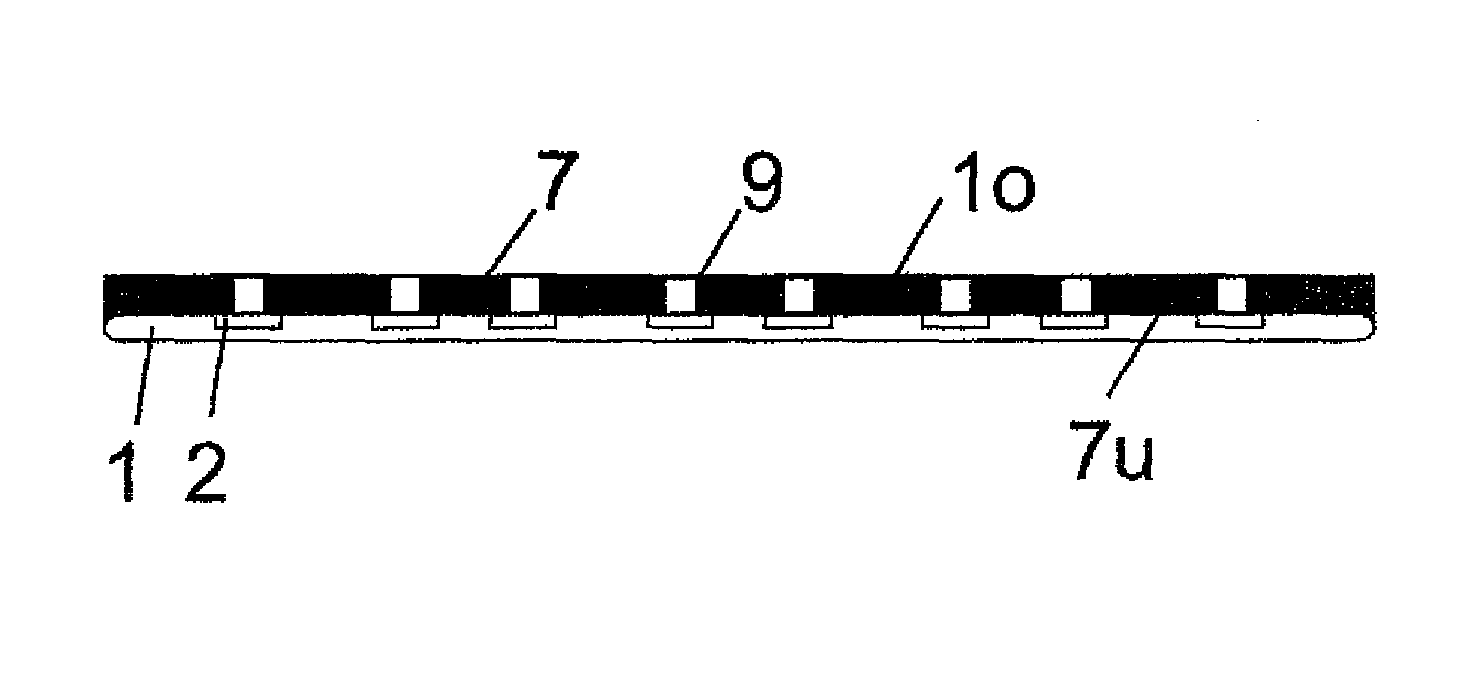

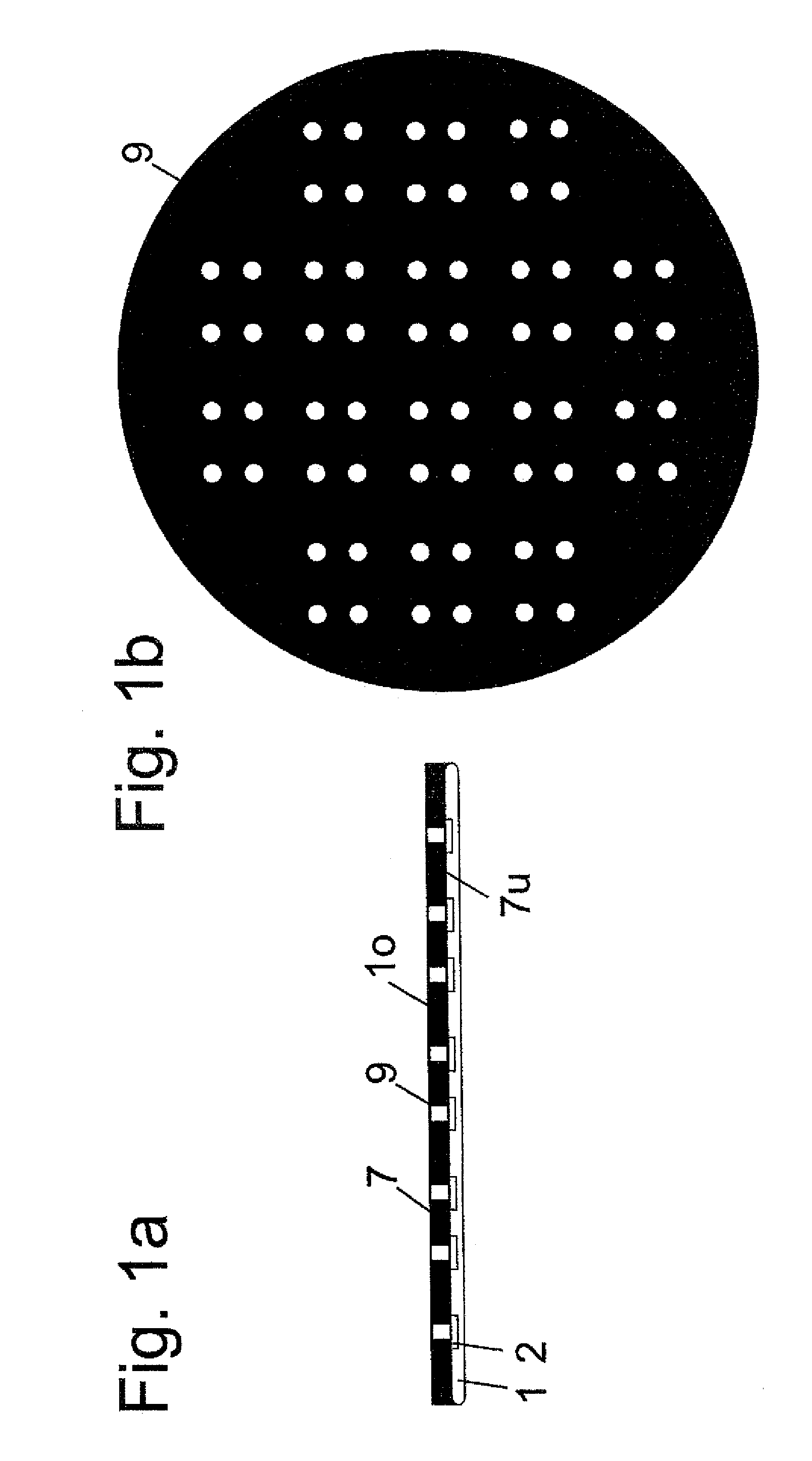

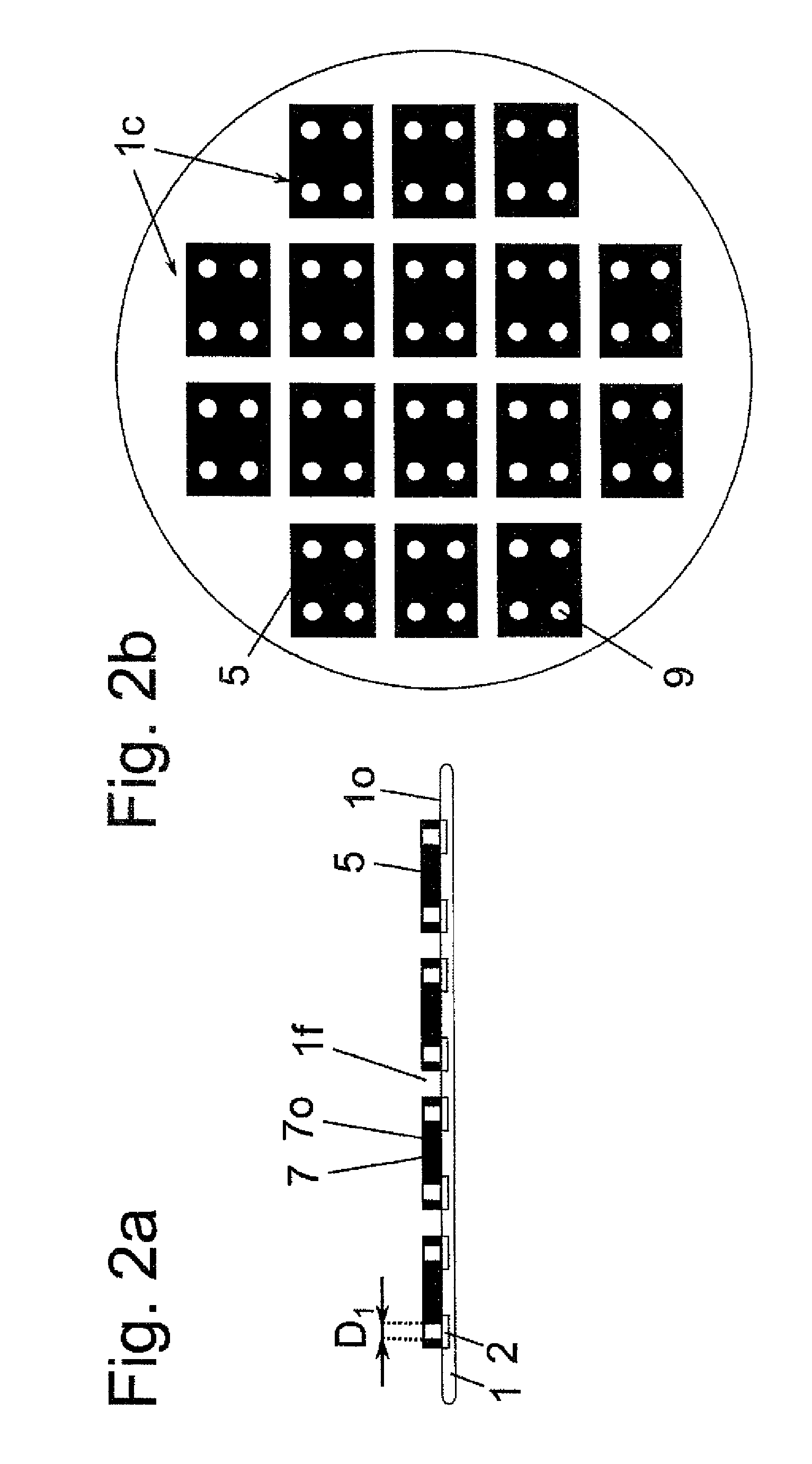

Method and device for testing printed circuit boards with a parallel tester

InactiveCN1449499AShort timeEasy and Reliable ScanningElectrical measurement instrument detailsPrinted circuit manufactureElectrical conductorContact element

The invention relates to a method and device for testing printed circuit boards with a parallel tester. The printed circuit boards comprise strip conductors whose end points are embodied as printed circuit board testing points which can be contacted during testing. The method comprises the following steps; testing a printed circuit board with a parallel tester, whereby the printed circuit board testing points of the printed circuit board are brought into contact with the contact elements of the parallel tester; determining the printed circuit board testing points which are either judged to be unable to be put correctly into contact with the parallel tester or deemed to be basically unable to be put into contact with the parallel tester; and re-measuring the printed circuit board test points judged to be unable to be put correctly into contact or the non contactable printed circuit board test points and also the strip conductors connected to said points by means of a device which is independent from the contact elements in the parallel tester.

Owner:ATG TEST SYST

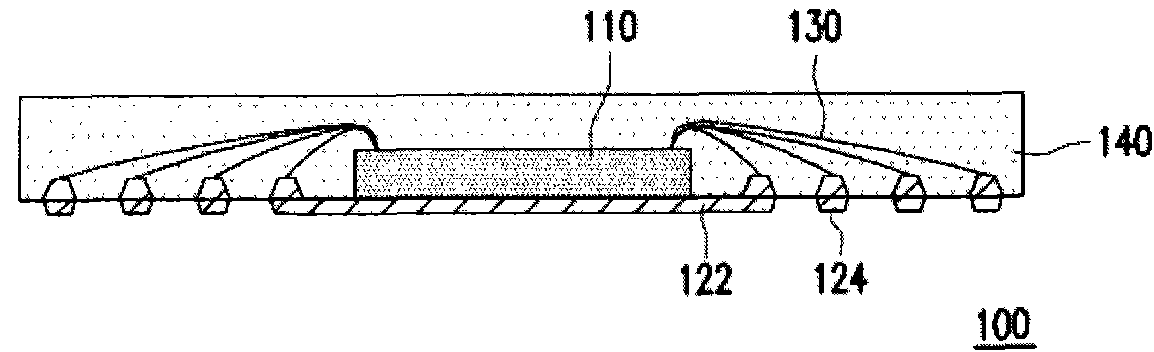

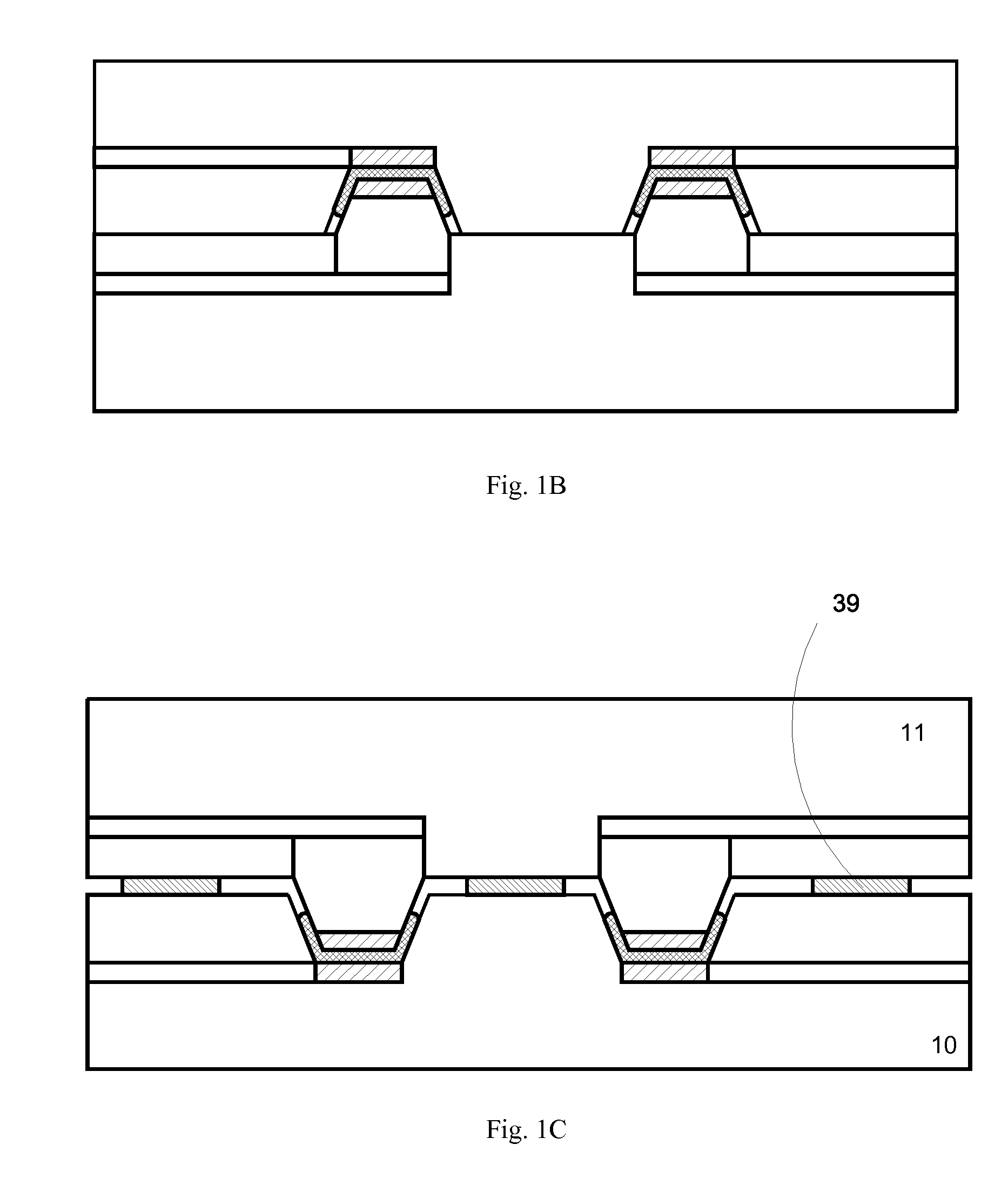

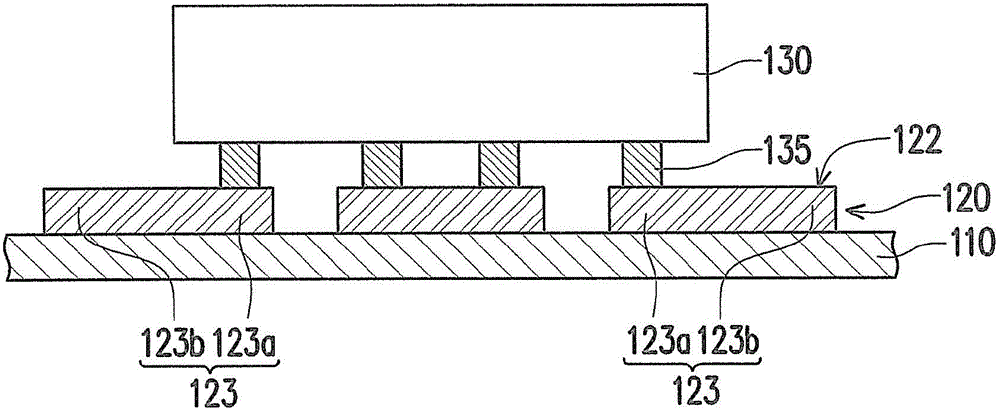

Semiconductor packaging structure and semiconductor packaging process

ActiveCN101944520AEfficient use ofHigh contact densitySemiconductor/solid-state device detailsSolid-state devicesSemiconductor packageEngineering

The invention relates to a semiconductor packaging structure and a semiconductor packaging process. The semiconductor packaging structure has a full-array design, a first pin is arranged on the periphery of a chip and a second pin used as a contact is further arranged below the chip so that the space below the chip can be effectively utilized to improve the density of the contact of the semiconductor packaging structure. The invention also relates to a process of the semiconductor packaging structure.

Owner:ADVANCED SEMICON ENG INC

Method of packaging and interconnection of integrated circuits

InactiveUS20100038770A1High densityAdhesionSemiconductor/solid-state device detailsSolid-state devicesMicron scaleContact pad

A semiconductor chip packaging on a flexible substrate is disclosed. The chip and the flexible substrate are provided with corresponding raised and indented micron-scale contact pads with the indented contact pads partially filled with a liquid amalgam. After low temperature amalgam curing, the chip and the substrate form a flexible substrate IC packaging with high conductivity, controllable interface layer thickness, micron-scale contact density and low process temperature. Adhesion between the chip and the substrate can be further enhanced by coating other areas with non-conducting adhesive.

Owner:INTELLEFLEX CORP +1

High-frequency, high-signal-density, surface-mount technology footprint definitions

ActiveUS7284221B2Suppress crosstalkHigh contact densitySemiconductor/solid-state device detailsPrinted circuit aspectsElectrical connectionSurface-mount technology

Methods for designing SMT connector footprints are disclosed. A circuit board may have disposed thereon an arrangement of SMT pads and corresponding vias. The arrangement of vias may differ from the arrangement of SMT pads. The arrangement of SMT pads may differ from the arrangement of contacts in a connector the footprint is designed to receive. The terminal ends of the contacts may be jogged or bent for electrical connection with the SMT pads. The SMT pads and vias may be arranged in a number of ways that increase signal contact density of the board, while limiting cross-talk and providing adequate impedance and routing space on the board. An interactive tool for designing such a footprint is disclosed.

Owner:FCI AMERICAS TECH LLC

Method and device for testing printed circuit boards with a parallel tester

InactiveCN1187619CShort timeEasy and Reliable ScanningElectrical measurement instrument detailsPrinted circuit manufactureElectrical conductorEngineering

Owner:ATG TEST SYST

Chip package structure and manufacturing method thereof

ActiveCN106206480AReduce widthReduce spacingSemiconductor/solid-state device detailsSolid-state devicesResistSolder mask

A chip package structure including a lead frame, a chip, a plurality of solder bumps, a solder resist layer and an encapsulant is provided. The lead frame has a plurality of inner leads. Each of the inner leads has an upper surface, a lower surface, two side surfaces opposite to each other and a bonding area on the upper surface. The chip is disposed on the lead frame and has an active surface. Each of the solder bumps connects the active surface and the bonding area of each of the inner leads. The solder resist layer is disposed on at least one of the lower surface or the two side surfaces of each of the inner leads. The encapsulant covers the lead frame, the chip, the solder bumps and the solder resist layer. A manufacturing method of the chip package structure is also provided.

Owner:CHIPMOS TECH INC

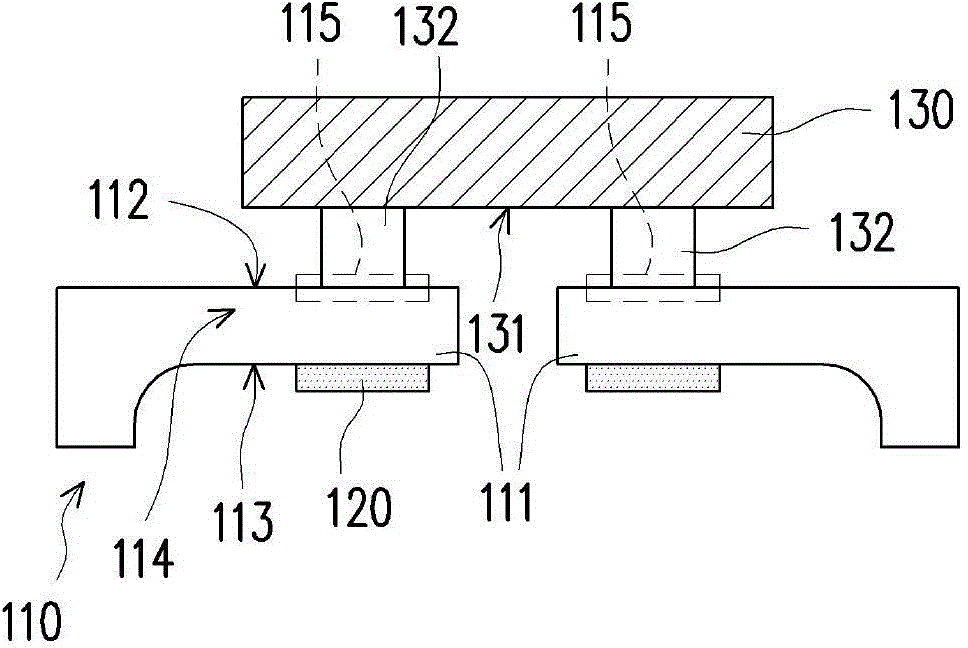

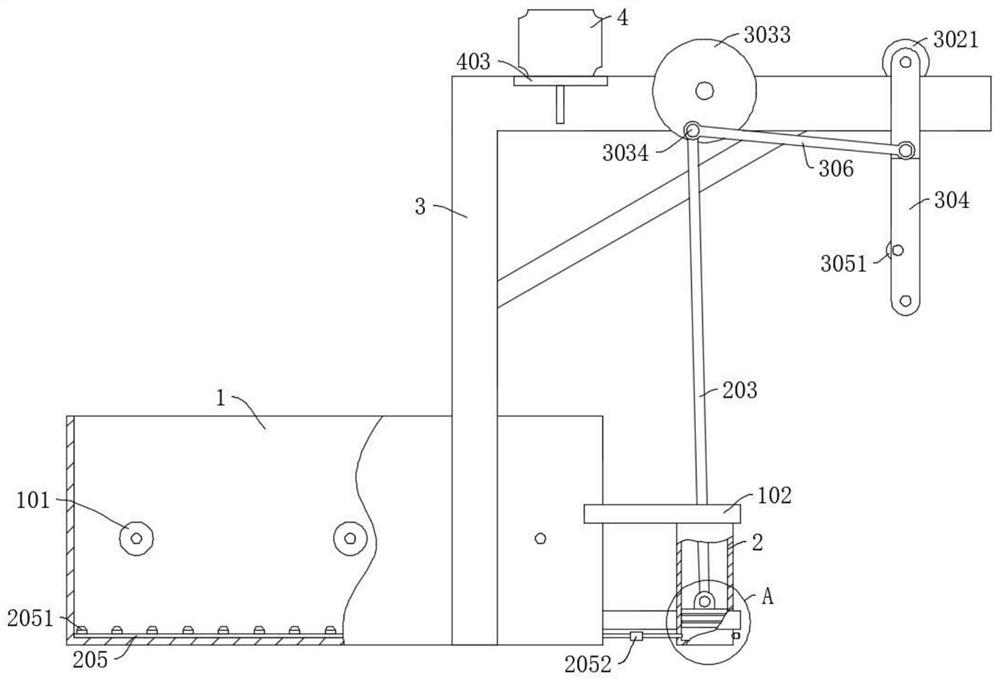

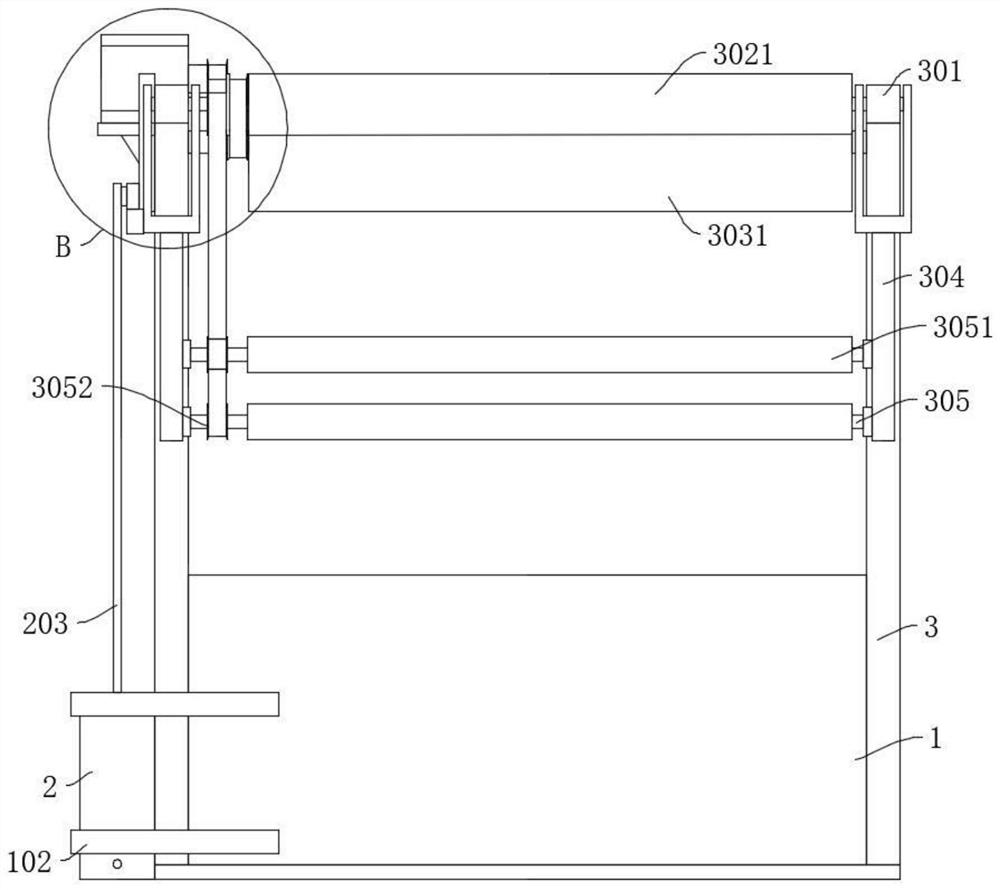

Printing and dyeing equipment for textiles

InactiveCN111621945AReduce conveying speedReduce moisture contentLiquid/gas/vapor treatment machines driving mechanismsTextile treatment carriersLiquid storage tankPulley

The invention discloses printing and dyeing equipment for textiles, and belongs to the technical field of printing and dyeing equipment. Printing and dyeing equipment for textiles comprises a liquid storage tank and a support, a blowing mechanism is arranged at the bottom of the liquid storage tank, a first rotating shaft is connected with a first belt pulley and a first roller, a second rotatingshaft is connected with a second belt pulley and a second roller, the first belt pulley is rotationally connected with the second belt pulley, and the top of the support is connected with a driving part; a third rotating shaft is rotationally connected to a rocker, a third belt pulley and a third roller are connected to the third rotating shaft, the third belt pulley is rotationally connected withthe first belt pulley, and a first positioning column is connected to the rocker; the second rotating shaft is connected with a turntable, the turntable is connected with a second positioning column,and the first positioning column is rotationally connected with the second positioning column; and a pressurizing cylinder is connected to the liquid storage tank, a piston is slidably connected intothe pressurizing cylinder, a first hinge seat is connected to the piston, and the first hinge seat is rotationally connected with the second positioning column. The rocker swings for air drying and blowing disturbance, the water content of cloth is reduced, and the coloring efficiency is improved.

Owner:钱炜

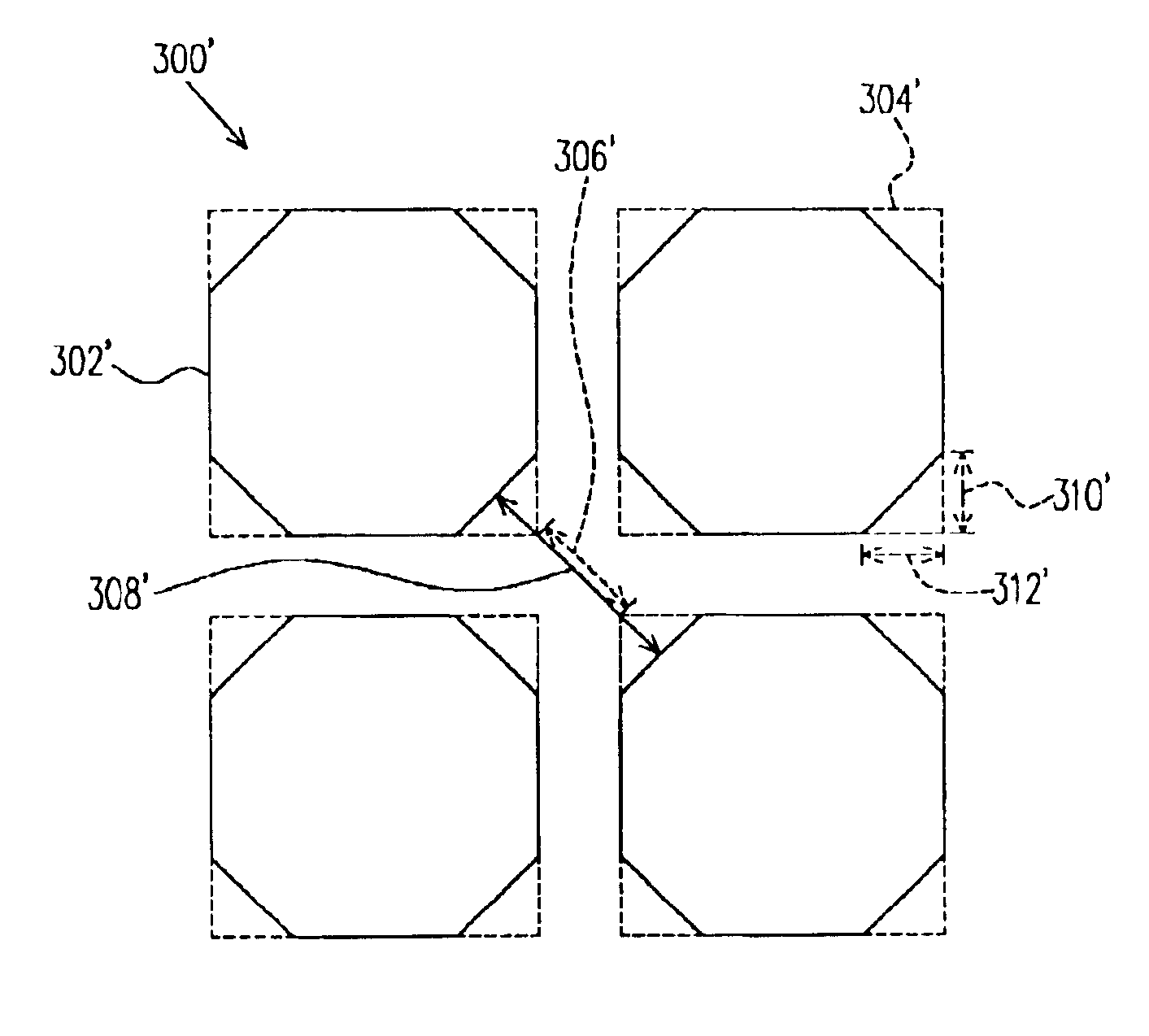

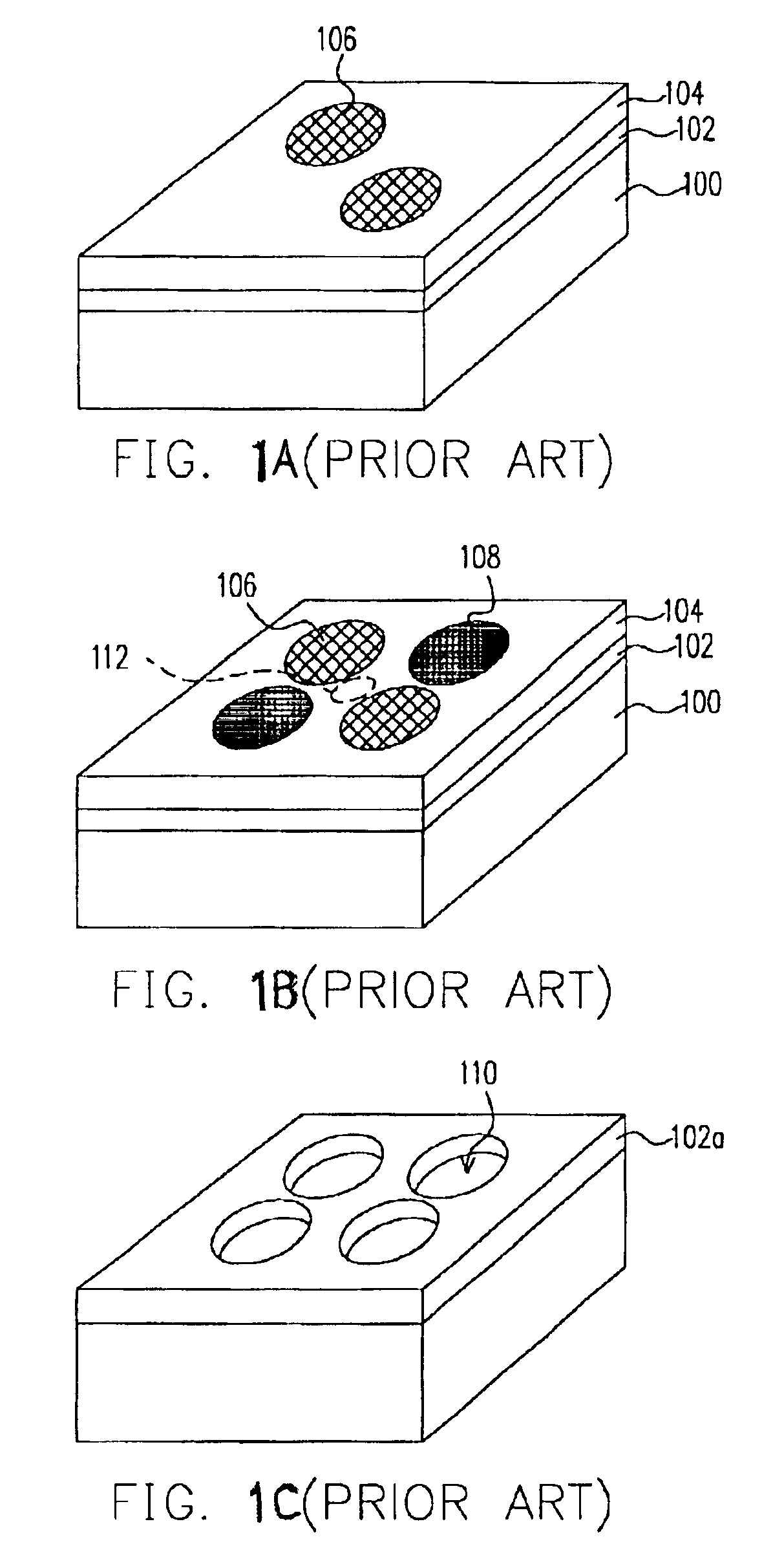

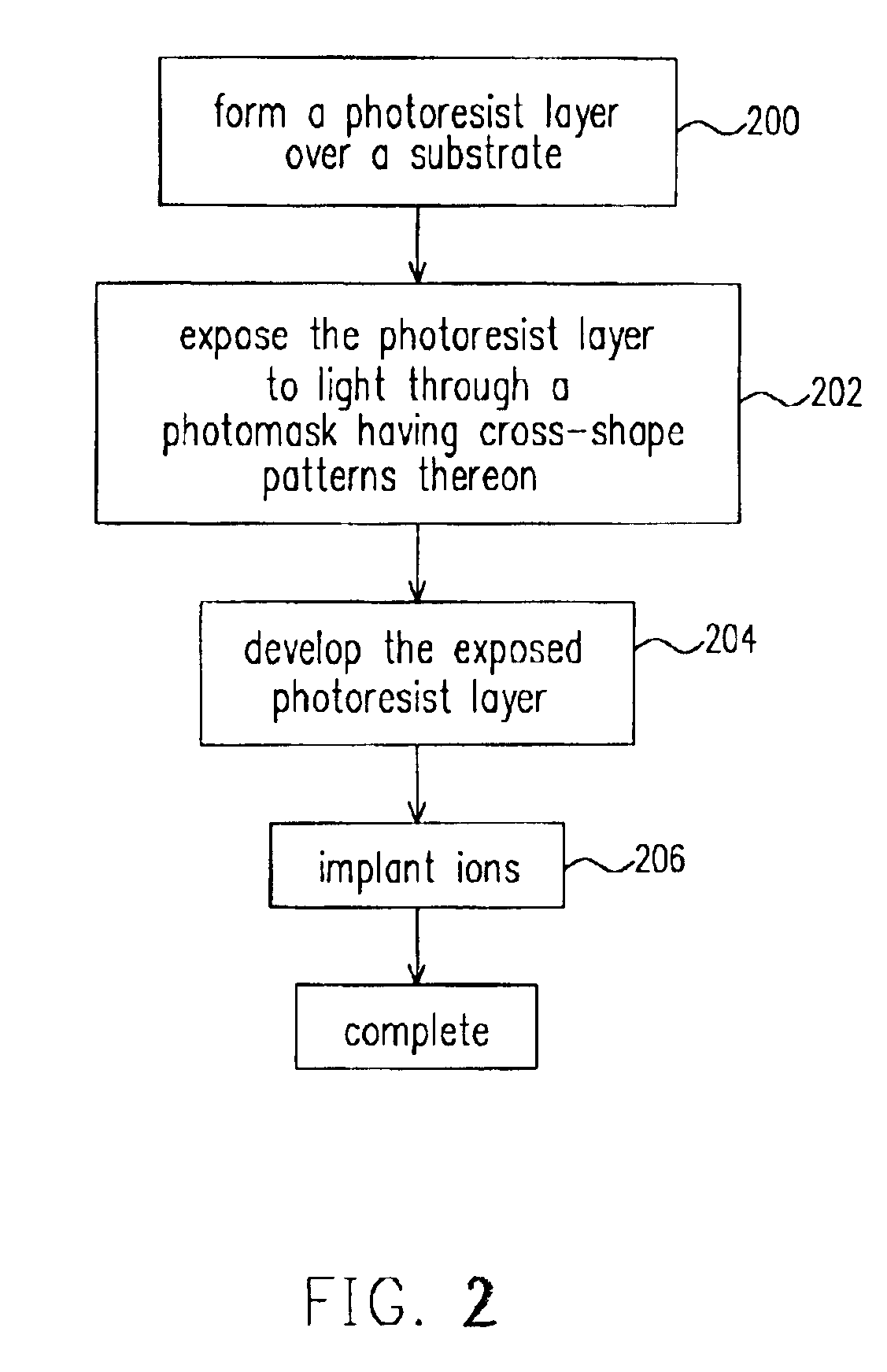

Hole forming by cross-shape image exposure

InactiveUS6861176B2Improve image contrastOptical image contrast between contacts is improvedPhotomechanical apparatusSemiconductor/solid-state device manufacturingPhotomaskContrast ratio

A method of forming holes in a layer through a cross-shape image exposure. The method includes removing a section from each corner of the rectangular patterns on a photomask to form cross-shape patterns so that circular or elliptical contact holes are formed on a photoresist layer after photo-exposure and development. Optical image contrast between contacts is increased by the cross-shape patterns on the photomask.

Owner:MACORNIX INT

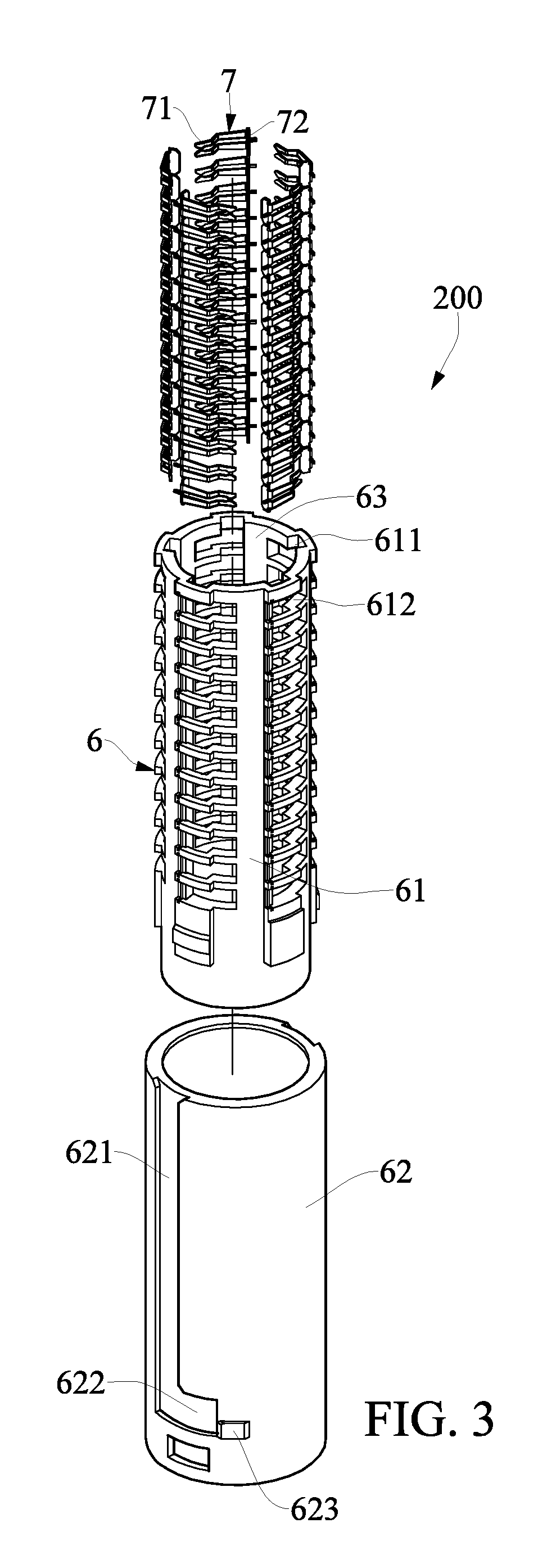

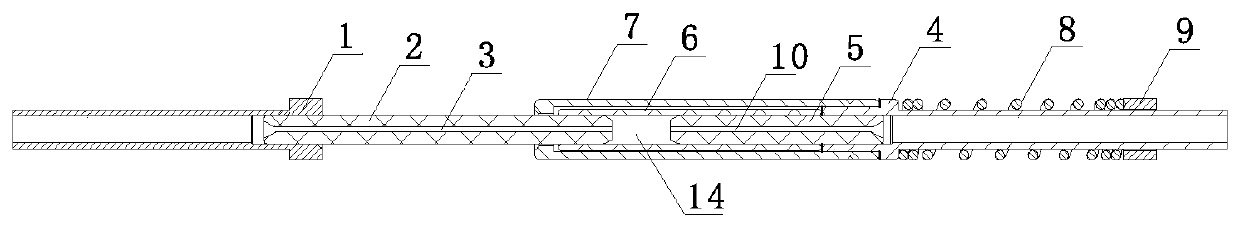

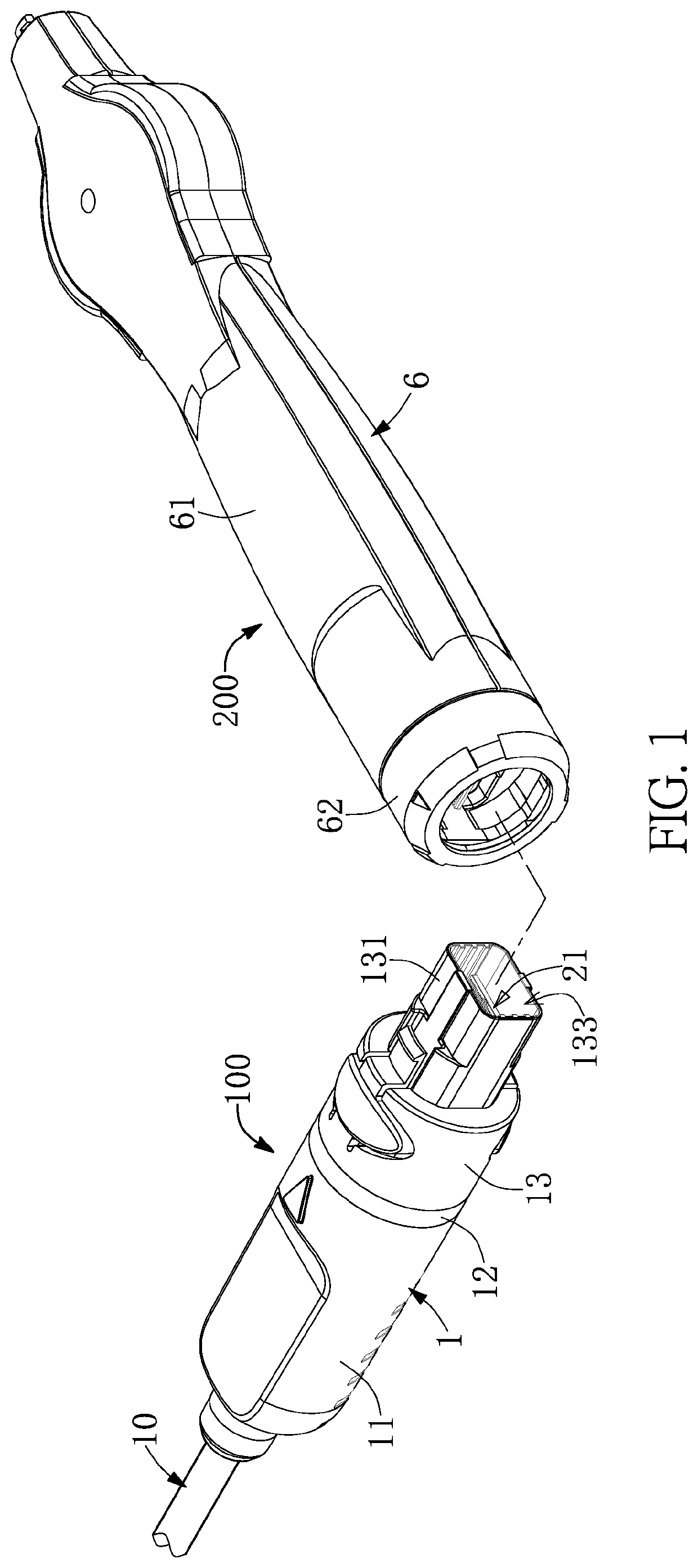

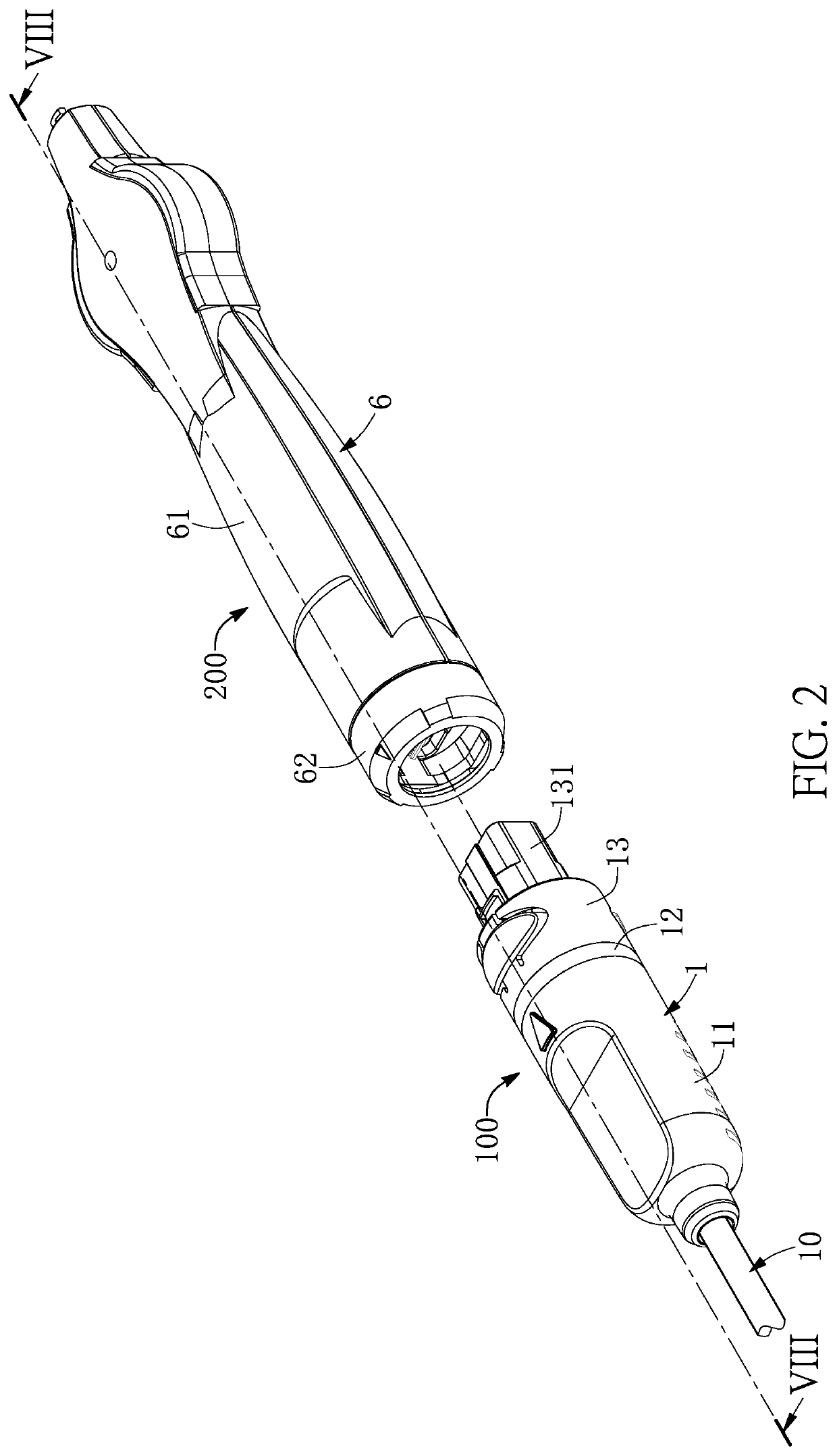

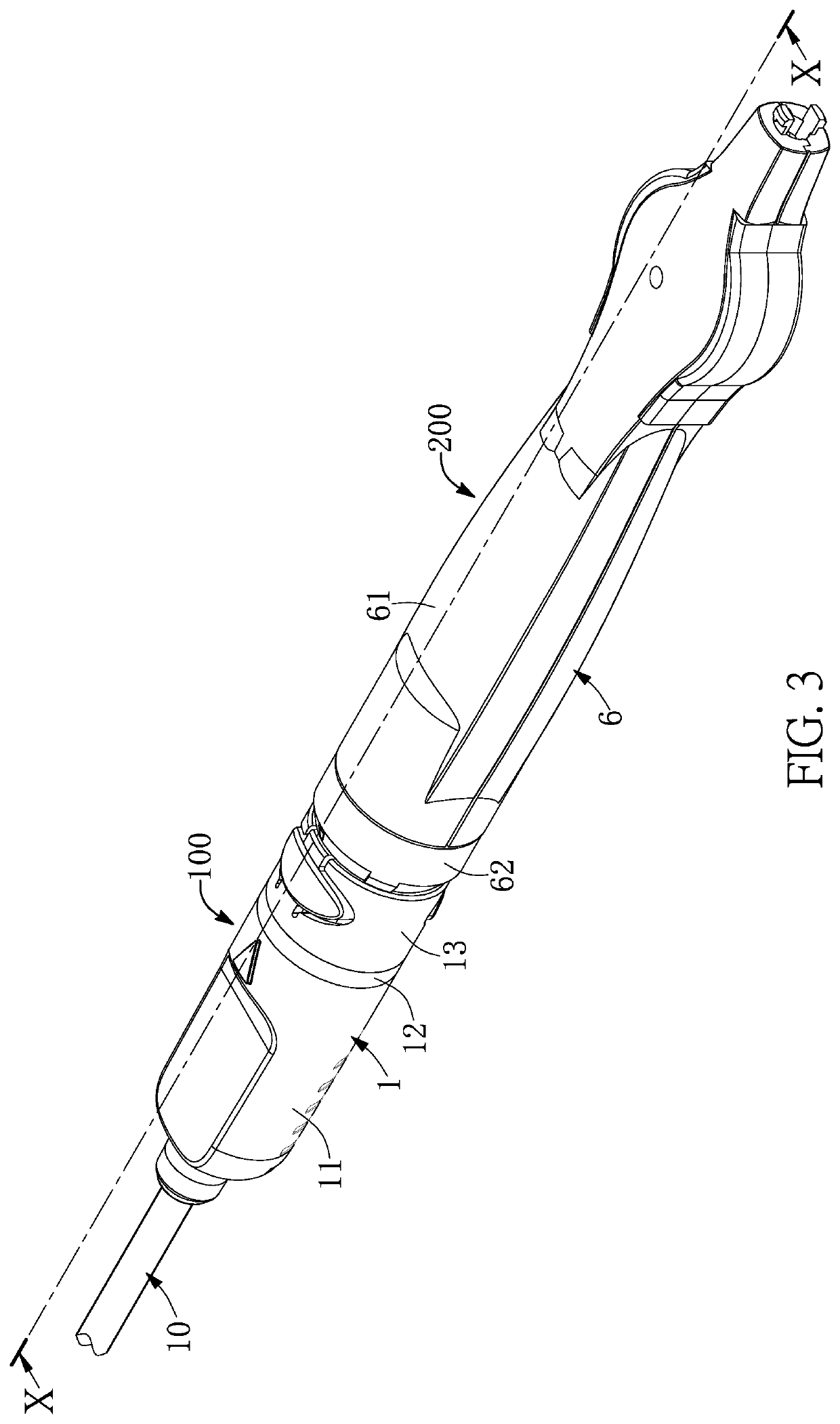

Connecting device with high-density contacts

ActiveUS10186802B1Increase density of contactHigh contact densityCoupling contact membersTwo-part coupling devicesEngineeringElectrical and Electronics engineering

A connecting device with high-density contacts includes a plug connector and a socket connector. The plug connector has a first insulated housing and a plurality of first terminals. The first insulated housing has a post portion. The first terminals are disposed on the post portion. The socket connector has a second insulated housing and a plurality of second terminals. The second insulated housing has a barrel portion formed with an accommodating space. The second terminals are disposed on the barrel portion. The post portion of the plug connector is inserted into the accommodating space. The plug connector and the socket connector are rotatable relative to each other. First contacting portions of the first terminals are clipped between two contacting portions of the second terminal, so that the first terminals are conductively contacted with the second terminals. Thus, the present disclosure provides signal contacts with high-density and high-reliability.

Owner:NEXTRONICS ENG CORP

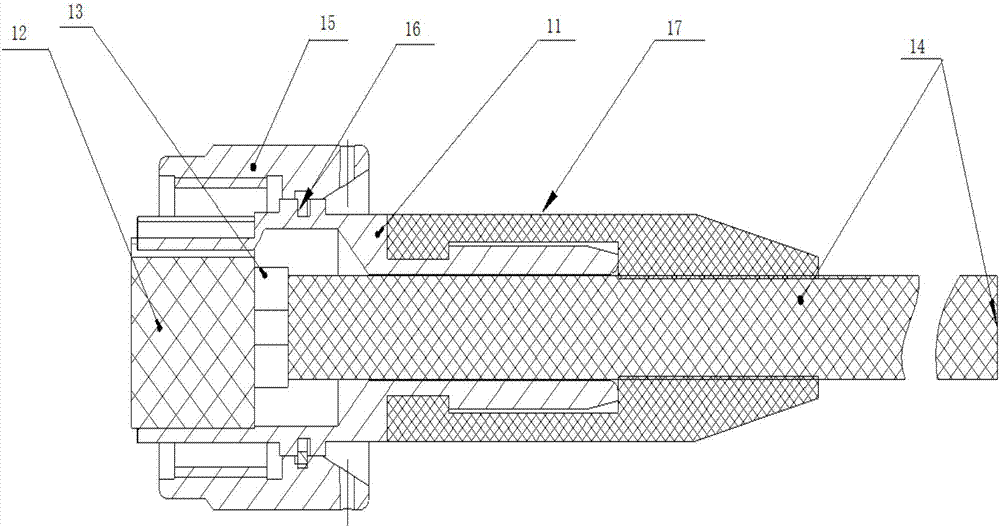

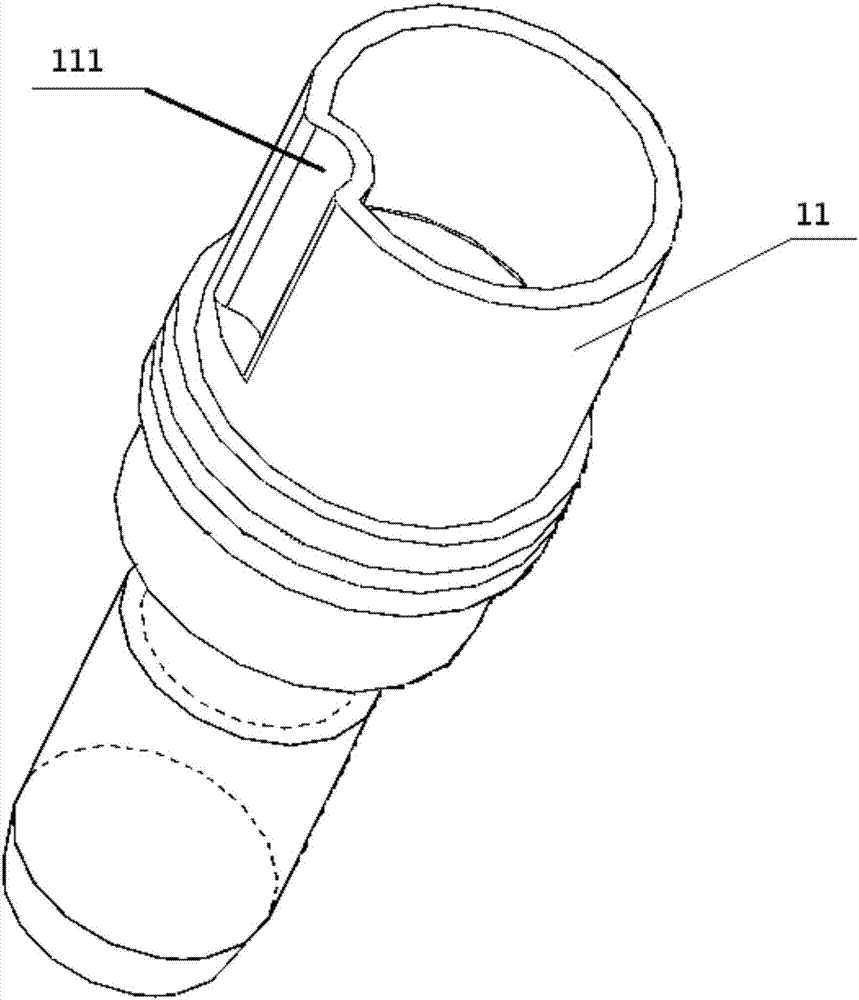

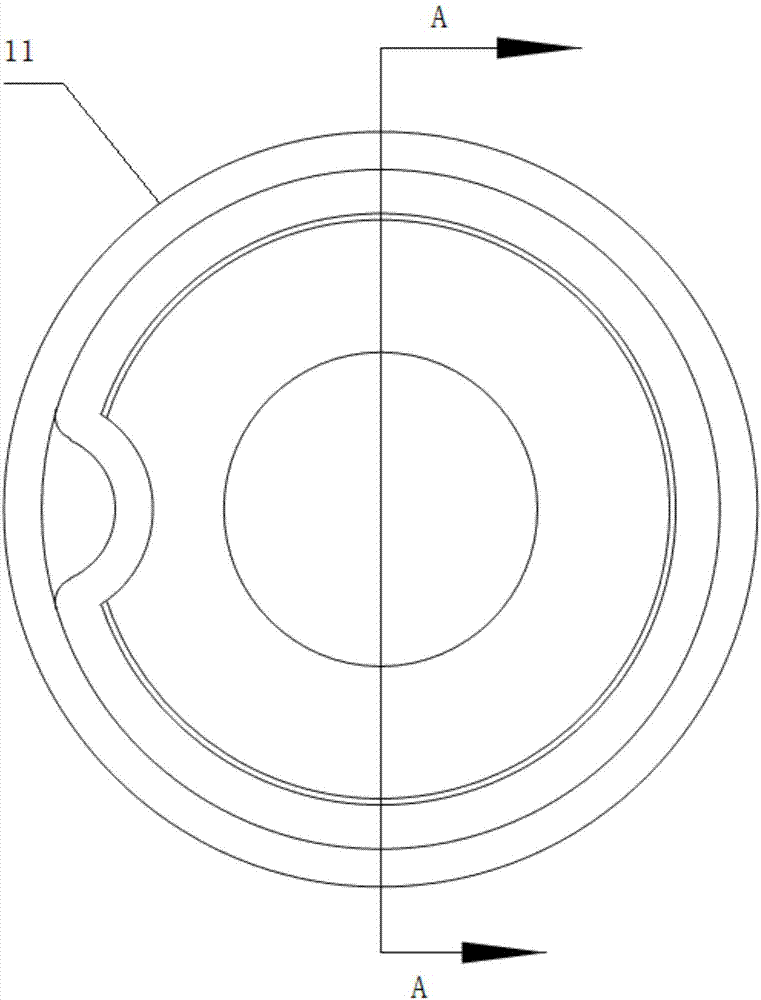

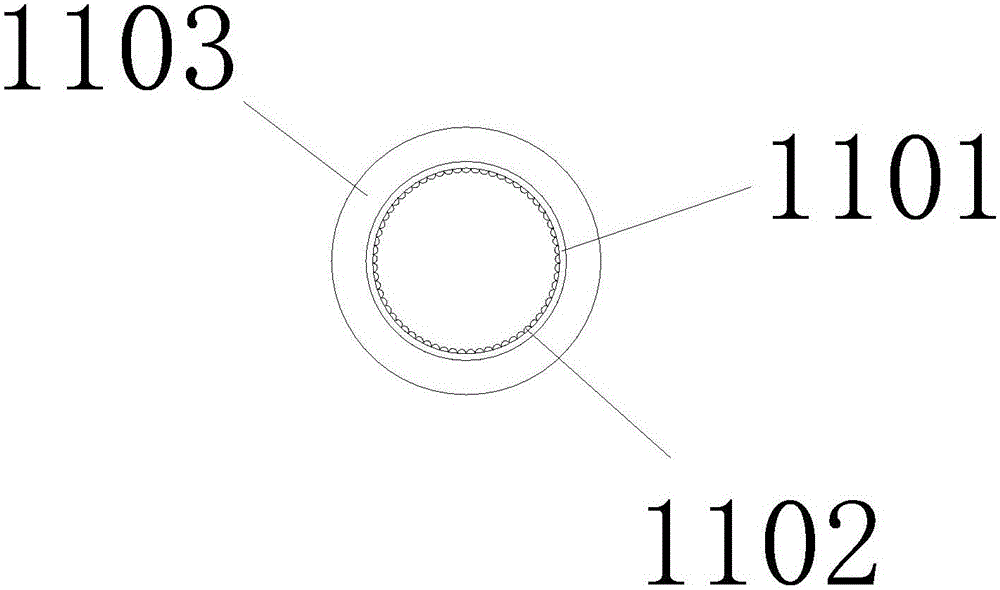

Optical fiber contact member and optical fiber connector using same

InactiveCN109975931AReduce overall sizeImprove contact densityCoupling light guidesOptical fiber connectorData transmission

The invention relates to an optical fiber contact member and an optical fiber connector using the same. The optical fiber contact member comprises a pin contact member and a jack contact member, wherein a ceramic pin I is arranged in the pin contact member, a ceramic pin II is arranged in the jack contact member, a rear sleeve pipe on the jack contact member is limited by means of a limiting mechanism in a plug connector, a rear diameter section of a jack flange plate can slide in the rear sleeve pipe, and two ends of a spring in the jack contact member are fixed to the rear end surface of a boss of the jack flange plate and the front end surface of the rear sleeve pipe respectively; and the ceramic pin I applies an insertion force to the ceramic pin II so that the spring is stressed to compress when the pin contact member and the jack contact member are inserted, and the ceramic pin I and the ceramic pin II are in tight contact to form reliable optical fiber connection under the action of spring forces. The optical fiber contact member is simple in structure and small in size, 22 pairs of the optical fiber contact members can be arranged on a No. 13(C) shell body, thus the node density and data transmission amount of the connector are improved, and the pin contact member and the jack contact member are of detachable structures, thereby facilitating the maintenance in the laterstage.

Owner:CHINA AVIATION OPTICAL-ELECTRICAL TECH CO LTD

High-power LGA socket

InactiveUS20050164529A1Reliable good electricalIncrease loadSemiconductor/solid-state device detailsSolid-state devicesElectrical conductorMechanical engineering

A system for providing electrical contacts between a die and an electrical device includes a die and a package. The package includes a first major surface, a second major surface, a first scalloped edge, a second scalloped edge and a solid end adapted for insertion into a slot. The solid end and the scalloped edges carry current greater than the current needed for an input / output signal. The socket includes a base having an opening therein adapted to receive the package. A slot is located at one end of the opening in the base. The slot is provided with a plurality of conductors for carrying currents greater than the current needed for an input / output signal. A first edge and second edge of the opening include a plurality of spaced overhangs positioned over the opening. The overhangs are sloped with respect to the major planar surface.

Owner:INTEL CORP

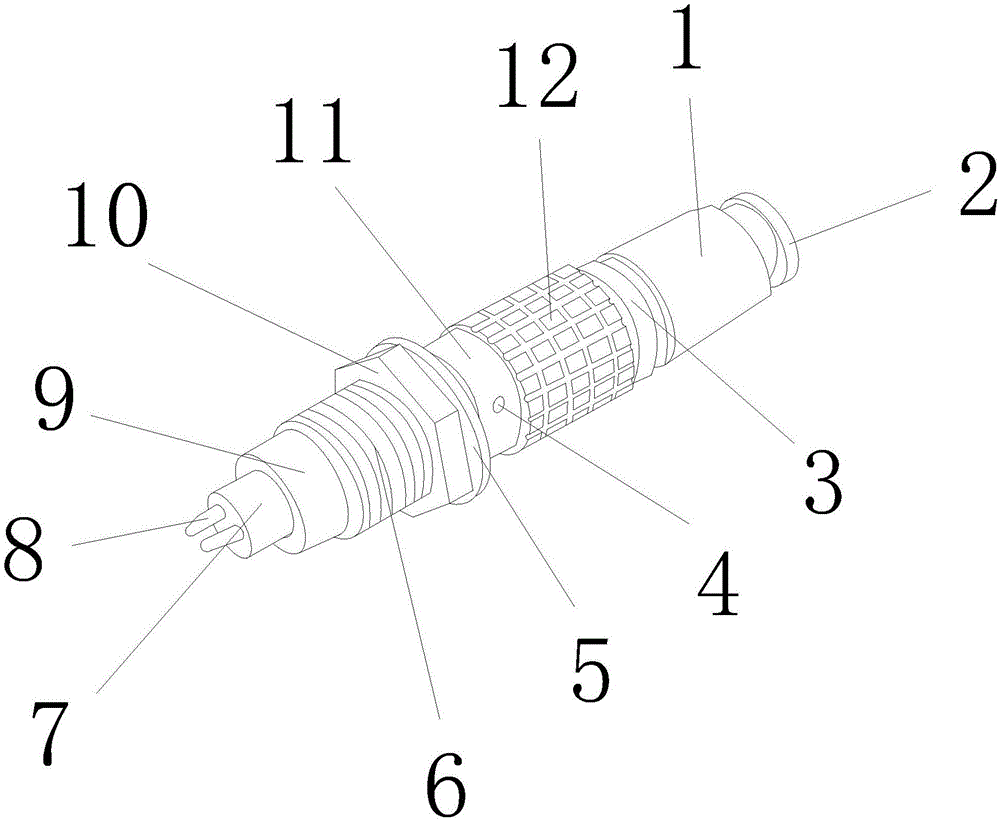

Mini round four-core electric connector and assembly method thereof

PendingCN107994372ASimple structureCompact structureContact member assembly/disassemblyCoupling contact membersElectricityAviation

The invention discloses a mini round four-core electric connector. The mini round four-core electric connector comprises a plug component and a socket component. The plug component comprises a plug shell. A jack base, a jack and a first cable are mounted in the plug shell. A connection ring and a plug bushing sleeve the plug shell. A clamp ring is arranged at the joint between the connection ringand the plug shell. The socket component comprises a socket shell. A pin base is mounted in the socket shell. A pin is fixed to the pin base. A second cable is connected with the pin. An O-ring is arranged on a waist pad of the socket shell. Locking nuts are mounted on two sides of the socket shell. The mini round four-core electric connector shares the features of high contact density and small size with round connectors, has the advantages of high density, lightweight and microminiaturization, can be applied to severe environments with high vibration and impact, is applicable to occasions with special requirements on space and equipment lightweight, and can be widely applied to aviation and spaceflight fields and environments with large environment temperature change.

Owner:MIANYANG CITY JINHUA WESTERN ELECTRIC MFG

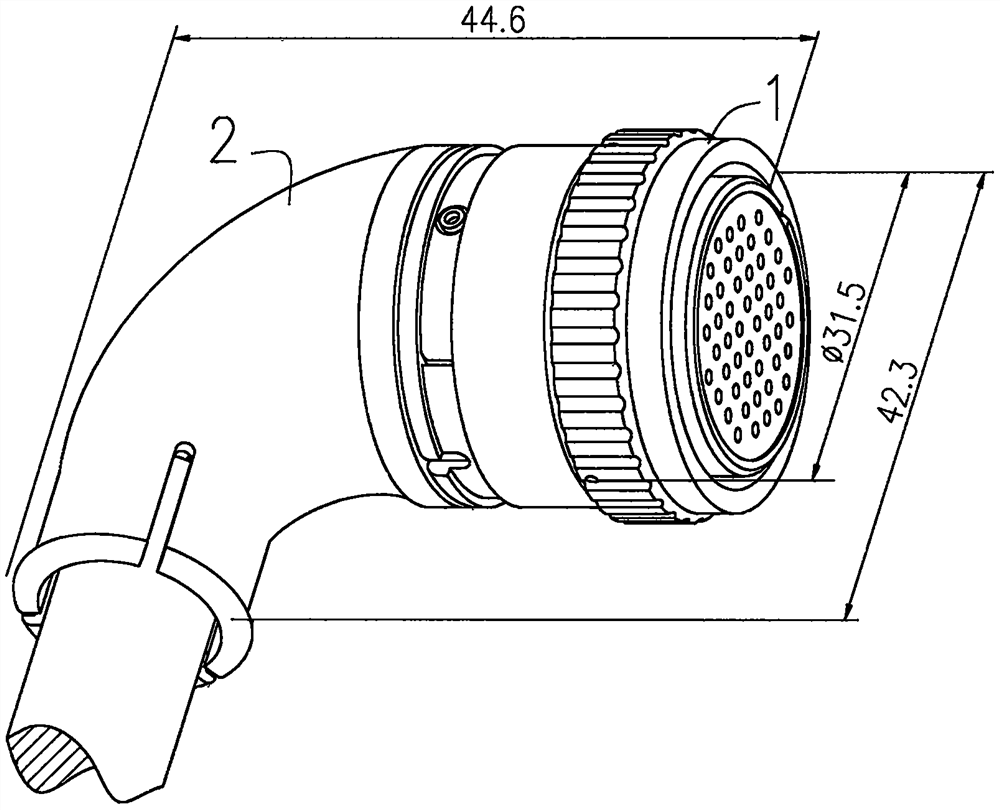

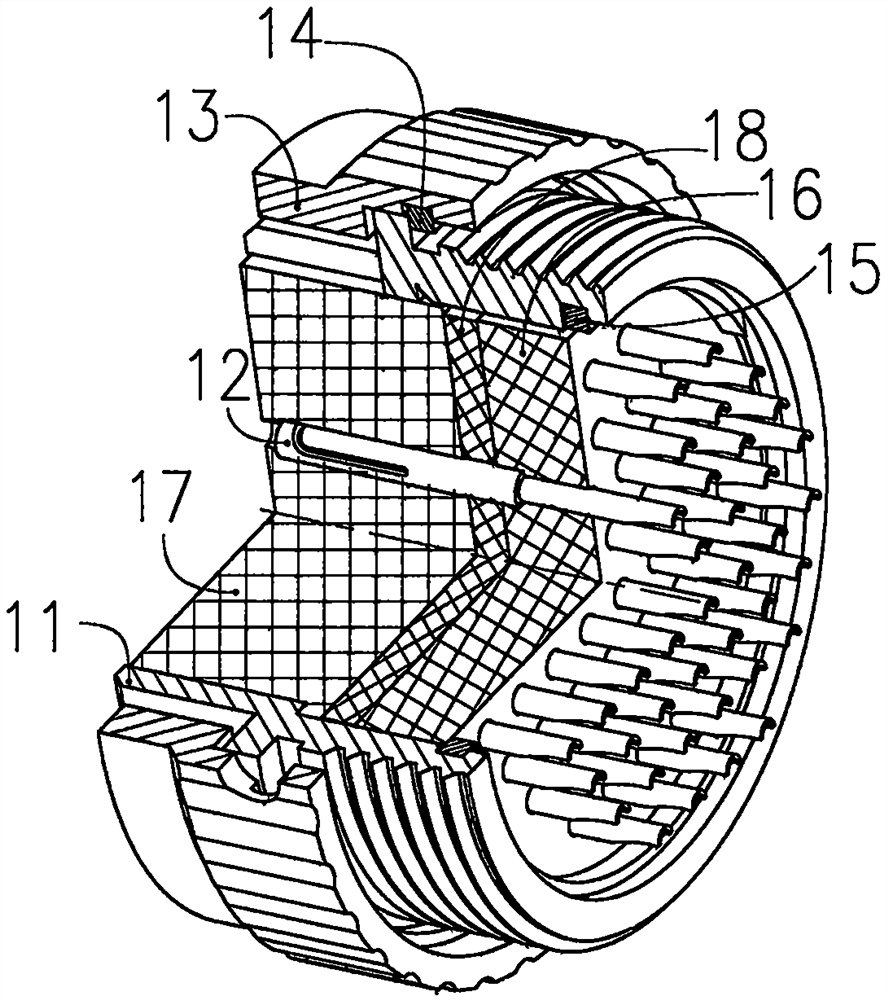

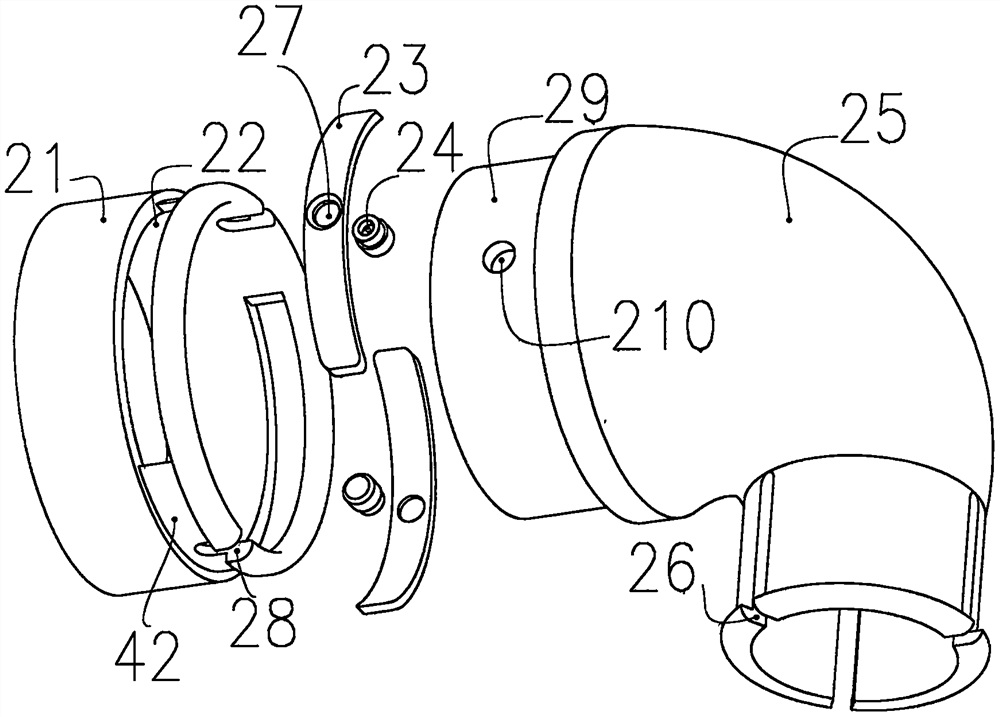

High-density plug connector with bent tail accessory

PendingCN111668635AHigh contact densitySimple structureEngagement/disengagement of coupling partsSecuring/insulating coupling contact membersHigh densityEngineering

The invention relates to a high-density plug connector with a bent tail accessory. The high-density plug connector with the bent tail accessory comprises a plug and a bent tail accessory matched withthe plug, wherein the plug and the tail accessory achieve fixation and adjustment of a cable outgoing angle through a positioning ring and a pin. The connector is simple in structure, compact in size,high in contact density and small in occupied space, and can meet the use of any required cable outgoing angle.

Owner:ZHENGZHOU ASTRONAUTIC ELECTRONICS TECH

High-density connecting device

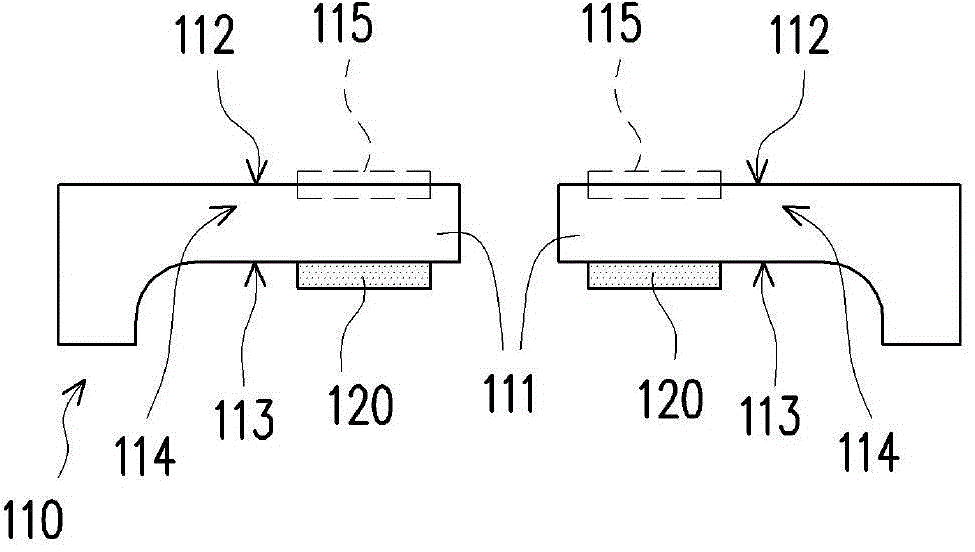

ActiveUS20220231440A1High contact densityGenerate high-density signal contactsCoupling contact membersTwo-part coupling devicesHigh densityEngineering

A high-density connecting device is provided. The high-density connecting device includes a first connecting module and a second connecting module. The first connecting module includes a first casing assembly, a first circuit board, and a first socket connector. The second connecting module includes a second casing assembly, a second circuit board, and a second socket connector. When the first connecting module is mated with the second connecting module, a junction end of the first circuit board and a junction end of the second circuit board are inserted into the first socket connector and the second socket connector, respectively, so that the junction end of the first circuit board and the junction end of the second circuit board are electrically connected to the first socket connector and the second socket connector, respectively.

Owner:NEXTRONICS ENG CORP

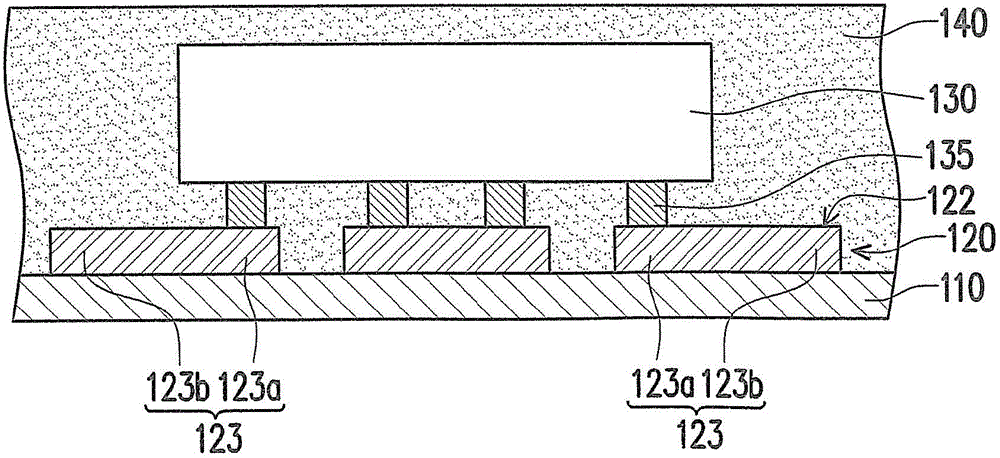

Method for fastening chips with a contact element onto a substrate provided with a functional layer having openings for the chip contact elements

ActiveUS9245869B2Good electrical contactImprove throughputSemiconductor/solid-state device detailsSolid-state devicesEngineeringContact element

A method for tacking of chips onto a substrate at chip positions which are distributed on a surface of the substrate. The method includes the following steps: formation or application of a function layer onto the substrate, removing the function layer from the substrate at the chip positions at least in the region of contacts to uncover the contacts, tacking chips onto one chip contact side of the function layer at the chip positions and contacting the chips with the contacts via contact elements.

Owner:EV GRP E THALLNER GMBH

Rapid connector for medical equipment

InactiveCN106602373AHigh contact densitySimple and fast plugging and unpluggingCoupling device detailsMedicine/surgery connectorsMedical equipmentPoint density

The invention discloses a rapid connector for medical equipment. The rapid connector for medical equipment comprises a rotation shaft, a fixing ring, a connection end, a dismounting button, a backing plate, a thread head, an elastic head, a circuit joint male end, a ring sleeve, a hexagonal nut, an antiskid fixing device and an induction locking system, wherein the rotation shaft is fixedly connected with the fixing ring, the antiskid fixing device is fixedly provided with the dismounting button, the antiskid fixing device is movably connected with the induction locking system, the thread head is movably connected with the antiskid fixing device through the backing plate, the backing plate is movably connected with the ring sleeve through thread head, and the hexagonal nut is movably connected with the antiskid fixing device. The rapid connector is advantaged in that the antiskid fixing device is set, connection point density of the connector is made to be high, a self-locking system is simple and rapid to plug, vibration prevention and impact prevention can be effectively realized, disconnection caused by pulling the cable can be prevented, and the rapid connector is completely safe an reliable to use.

Owner:天津市嘉盛河滨科技有限公司

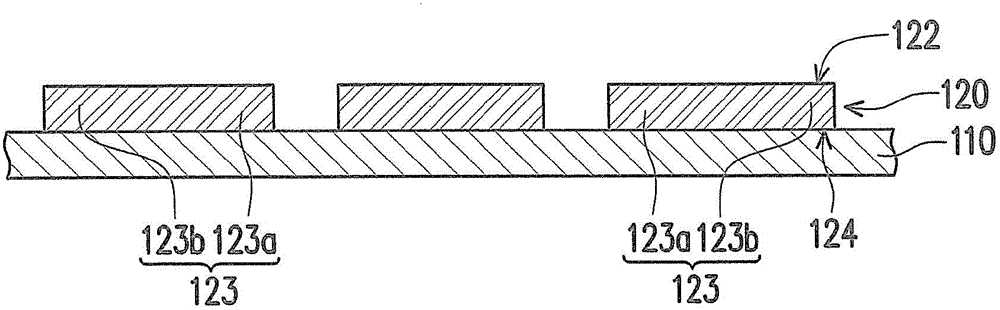

Semiconductor package structure and manufacturing method thereof

ActiveCN103367180BReduce thicknessReduce the distance of electrical linesSemiconductor/solid-state device detailsSolid-state devicesSemiconductor packageColloid

Provided are a semiconductor package structure and a manufacture method thereof. The manufacture method of the semiconductor package structure comprises: forming a patterned circuit layer on a metallic bearing board, wherein the material of the metallic bearing board is different from that of the patterned circuit layer; bonding at least one chip on the metallic bearing board in a flip manner, wherein the chip is electrically connected with the patterned circuit layer; forming packaging colloid on the metallic bearing board so as to cover the chip, the patterned circuit layer, and a part of the metallic bearing board; executing an etching step so as to remove the metallic bearing board until a bottom surface of the patterned circuit layer and a bottom surface of the packaging colloid are exposed; forming an insulating layer on the bottom surface of the patterned circuit layer and the bottom surface of the packaging colloid, wherein the insulating layer comprises multiple openings which expose at least parts of the patterned circuit layer; forming multiple external connection terminals so as to be electrically connected with the exposed patterned circuit layer of the insulating layer.

Owner:CHIPMOS TECH INC

Methods of manufacturing a hermetic and isolating feedthrough for an electronic device casing, in particular made of titanium

ActiveUS20190099604A1Robust mechanical holdingReduce the center distanceAnti-noise capacitorsElectrotherapyElectrical isolationTitanium

A device casing includes a wall having a metallic substrate and electrical connection of a feedthrough that includes a metal through-element made at least in a zone of isolation of the area of the feedthrough from the substrate material, in the form of an islet of closed contour, physically and electrically isolated from the substrate. An interface for coupling the through-element to the substrate provides the mechanical securing of the through-element to the substrate and the electrical isolation thereof and includes a peripheral lateral layer made of an electrically isolating material that surrounds the through-element over the whole periphery thereof and extends transversally through the thickness of the thinned area of the substrate. The substrate, the through-element and the lateral layer form a monolithically integrated unit, and the lateral layer provides essentially and directly both the mechanical securing and the electrical isolation between through-element and substrate.

Owner:MISTIC

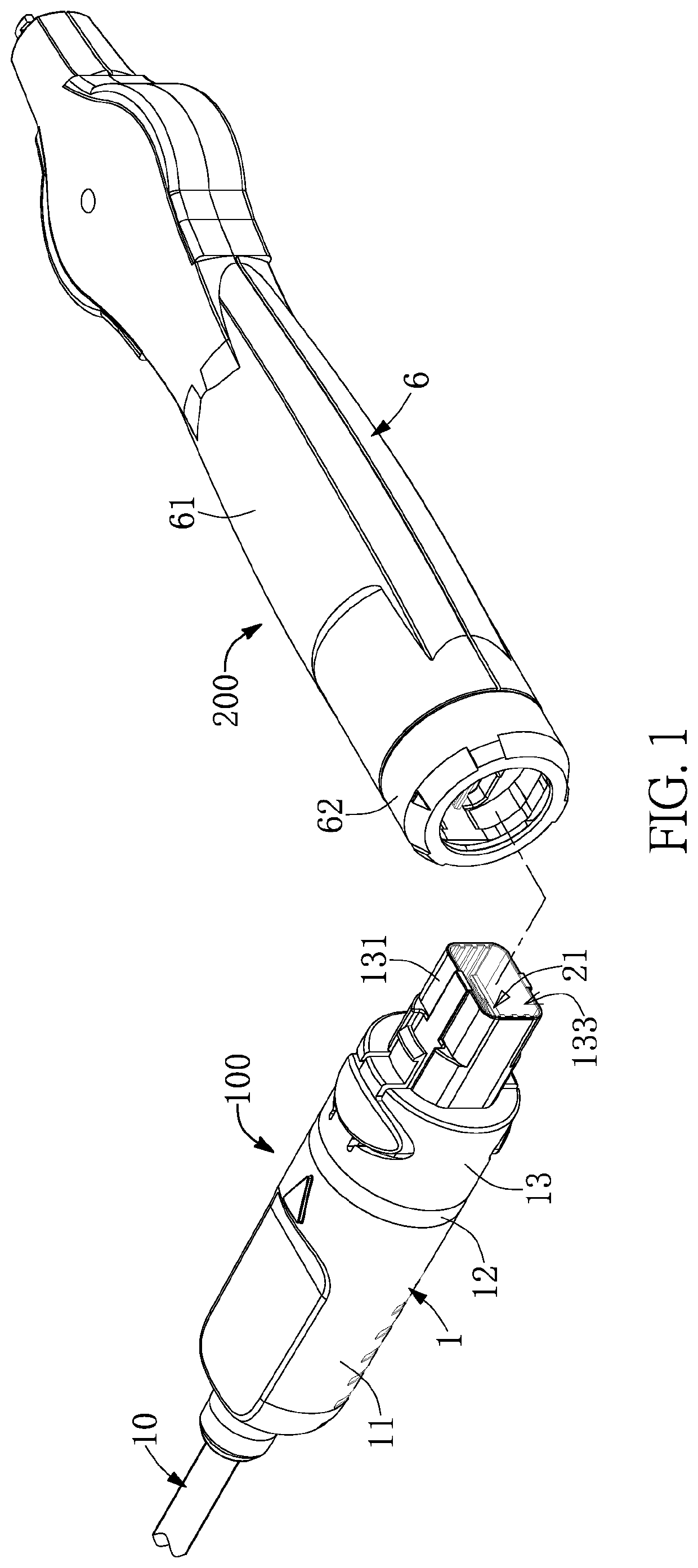

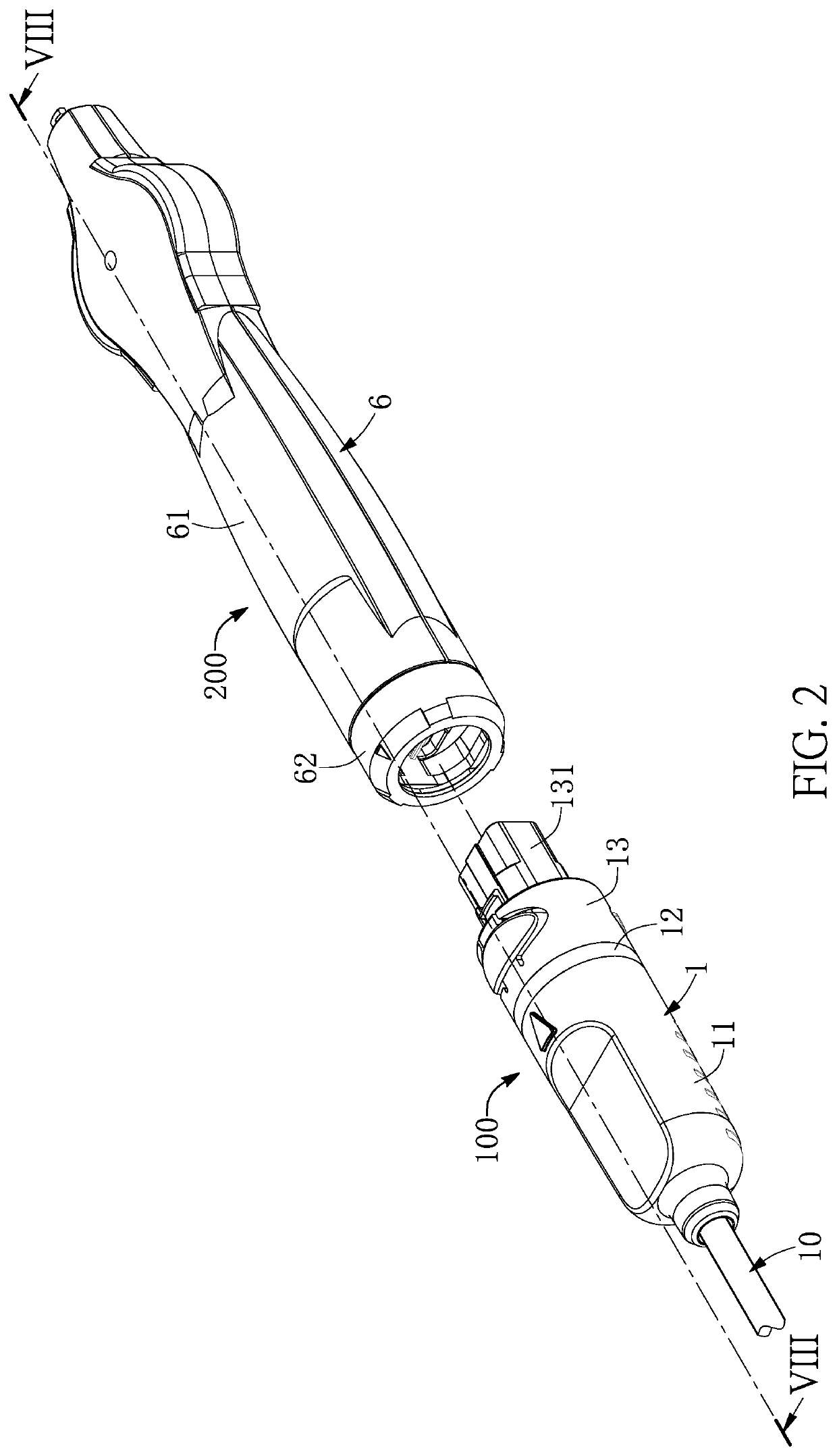

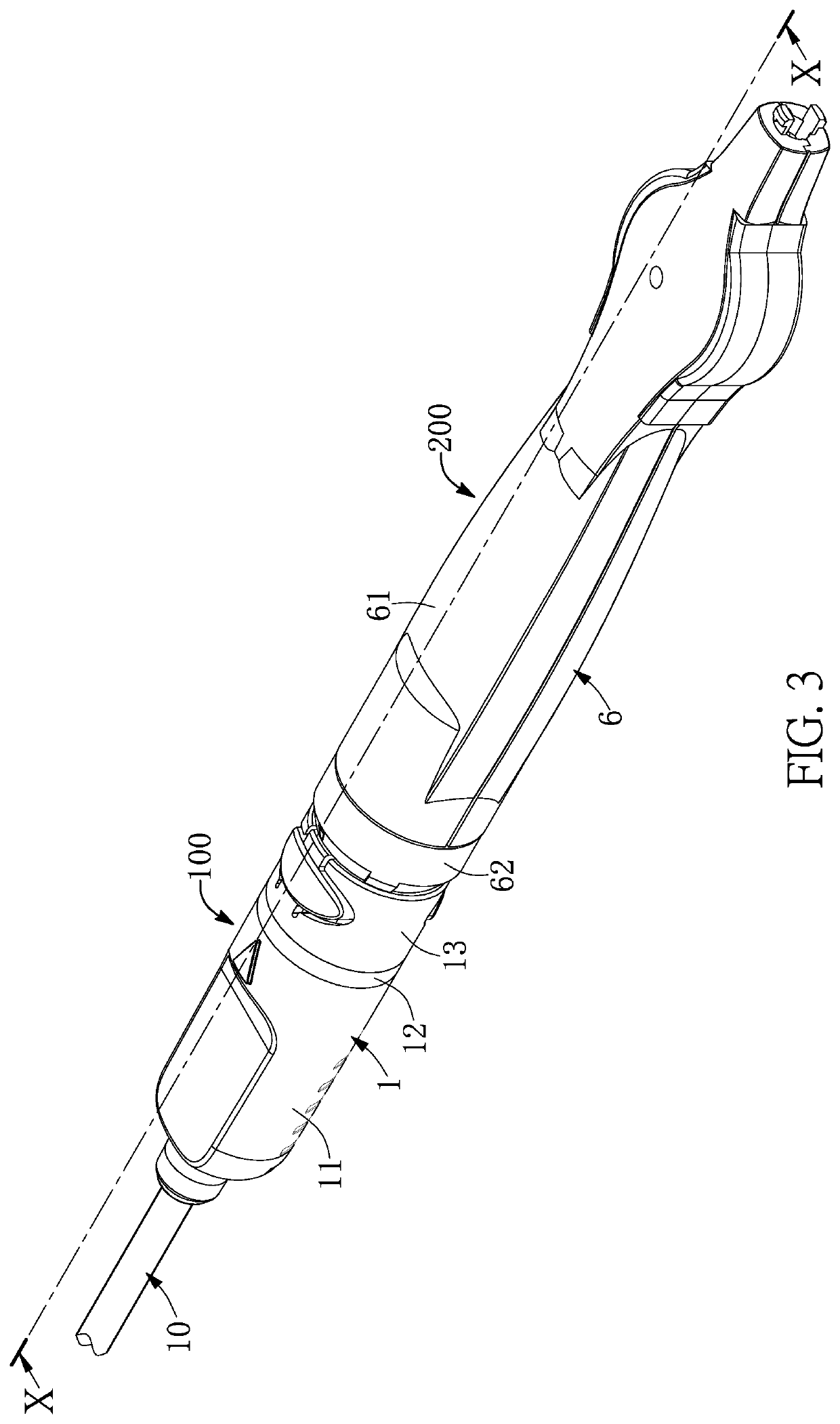

High-density connecting device

ActiveUS11424566B2High contact densityGenerate high-density signal contactsCoupling contact membersTwo-part coupling devicesHigh densityMechanical engineering

A high-density connecting device is provided. The high-density connecting device includes a first connecting module and a second connecting module. The first connecting module includes a first casing assembly, a first circuit board, and a first socket connector. The second connecting module includes a second casing assembly, a second circuit board, and a second socket connector. When the first connecting module is mated with the second connecting module, a junction end of the first circuit board and a junction end of the second circuit board are inserted into the first socket connector and the second socket connector, respectively, so that the junction end of the first circuit board and the junction end of the second circuit board are electrically connected to the first socket connector and the second socket connector, respectively.

Owner:NEXTRONICS ENG CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com