Printing and dyeing equipment for textiles

A technology for printing and dyeing equipment and textiles, applied in the field of printing and dyeing equipment for textiles, can solve the problems of long coloring process time and unsatisfactory effect, and achieve the effect of improving conveying uniformity, reducing water content and ensuring sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

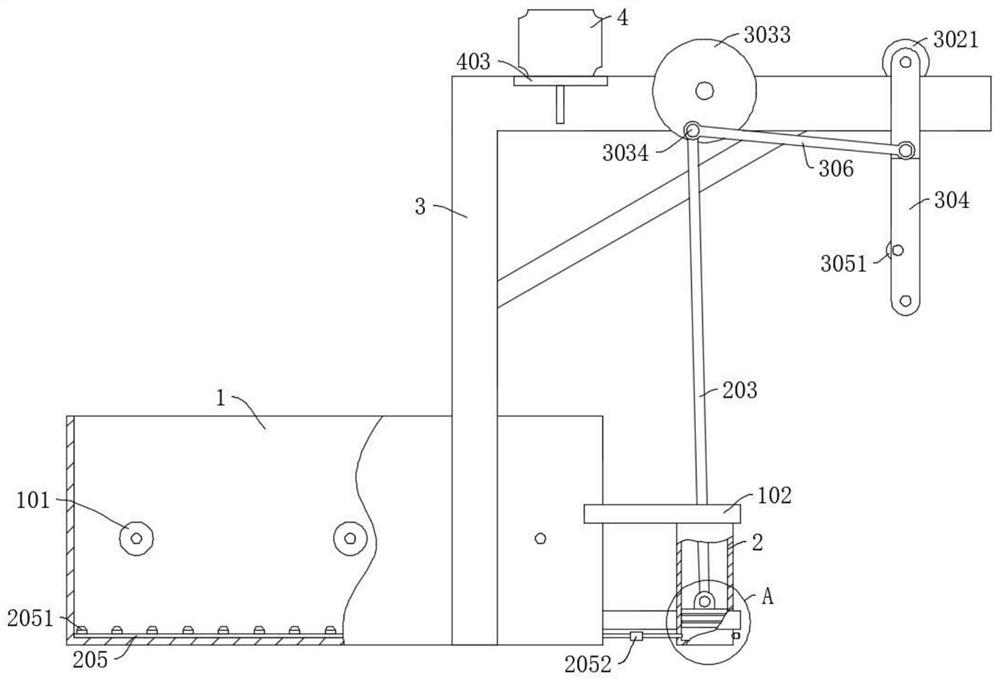

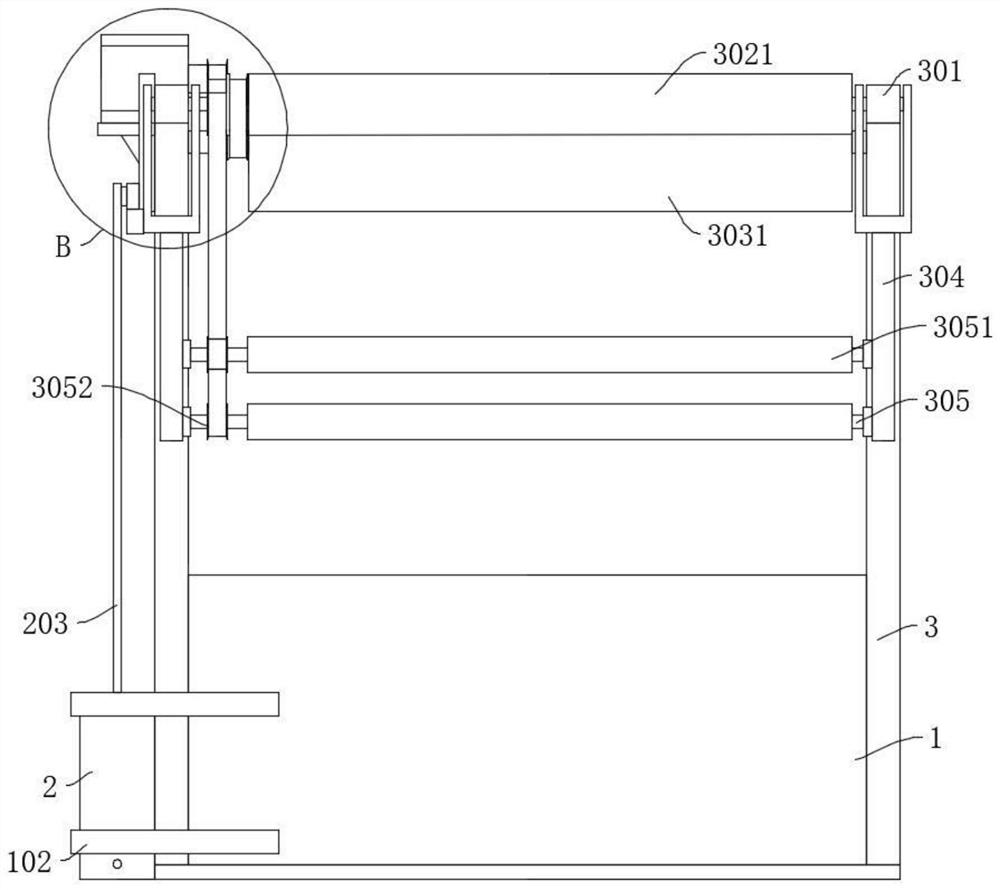

[0032] refer to Figure 1-5 , a printing and dyeing equipment for textiles, comprising a liquid storage tank 1 and a bracket 3 fixedly connected to the side wall of the liquid storage tank 1, an auxiliary roller 101 is rotatably connected in the liquid storage tank 1, and a blowing mechanism is arranged at the bottom of the liquid storage tank 1, The top of the support 3 is sequentially connected with a first rotating shaft 302 and a second rotating shaft 303 from top to bottom, and the first rotating shaft 302 is fixedly connected with a first pulley 3022 and a first roller 3021 in sequence from left to right, and the second rotating shaft 303 is fixedly connected with the second pulley 3032 and the second roller 3031 sequentially from left to right, the first pulley 3022 is connected with the second pulley 3032 through the rotation of the belt, and the top of the bracket 3 is fixedly connected with a pulley for driving the second pulley. The driving part of the wheel 3032 ro...

Embodiment 2

[0034] refer to figure 1 with Figure 4, is basically the same as that of Embodiment 1, furthermore, the drive unit includes a drive motor 4, a mount 403 is fixedly connected to the bracket 3, the drive motor 4 is fixedly connected to the mount 403, and the output end of the drive motor 4 is fixedly connected to a The drive shaft 401 is fixedly connected with the fourth pulley 402 on the drive shaft 401, and the fourth pulley 402 is rotationally connected with the second pulley 3032 by a belt, and the driving motor 4 utilizes the fourth pulley 402 to drive the second pulley 3032 to rotate. Realize sequential feeding, and when the humidity of the textile is too high to meet the coloring requirements, the conveying speed can be reduced by means of a low transmission ratio of the belt, so that the textile can swing several times and reduce the moisture content.

Embodiment 3

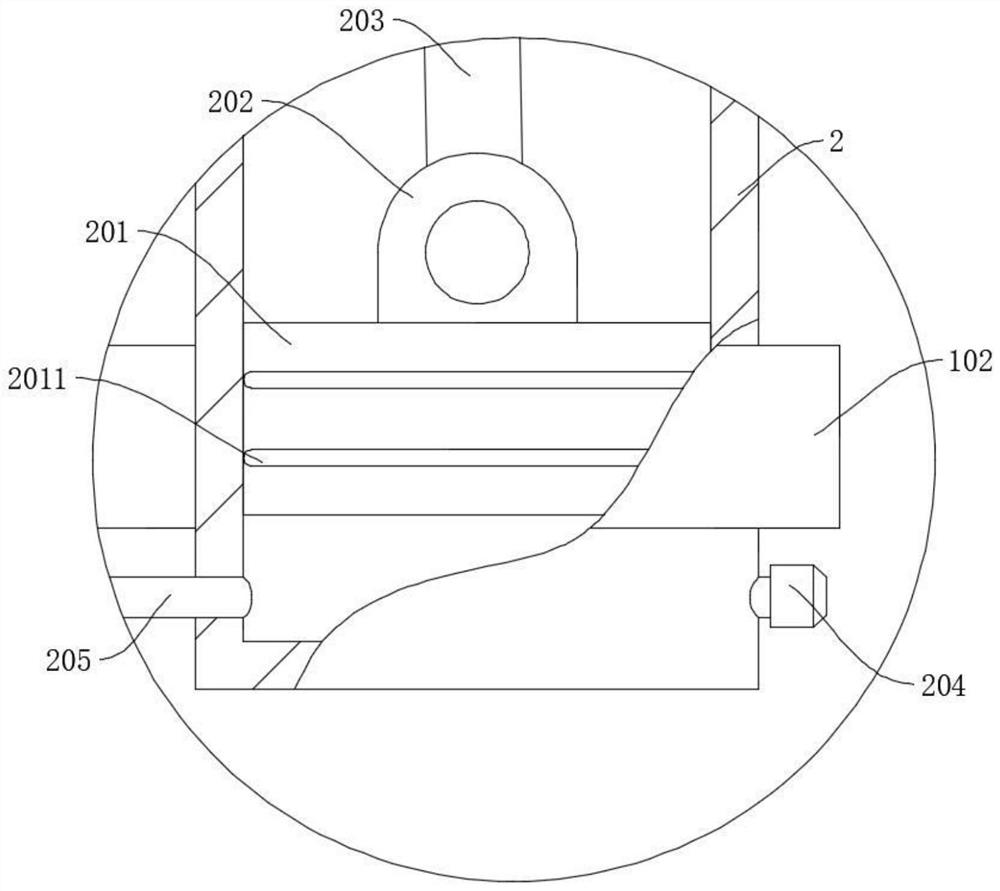

[0036] refer to Figure 1-2 , is basically the same as in Embodiment 1, furthermore, the blowing mechanism includes an air supply pipe 205 and a blowing nozzle 2051 connected to the air supply pipe 205, the air supply pipe 205 is fixedly connected to the bottom wall of the liquid storage tank 1, and the air supply pipe 205 It runs through the inner wall of the liquid storage tank 1 and extends to the outside and is fixedly connected to the booster cylinder 2. The first check valve 2052 is fixedly connected to the air supply pipe 205. There are multiple sets of spray nozzles 2051, and multiple sets of spray nozzles 2051 Evenly distributed on the air supply pipe 205, the outer wall of the liquid storage tank 1 is fixedly connected with a support plate 102, the booster cylinder 2 is fixedly connected with the support plate 102, and the bottom of the booster cylinder 2 is fixedly connected with a second one-way valve 204, a piston 201 A sealing ring 2011 is connected to the top, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com