Patents

Literature

368results about How to "Smooth swing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

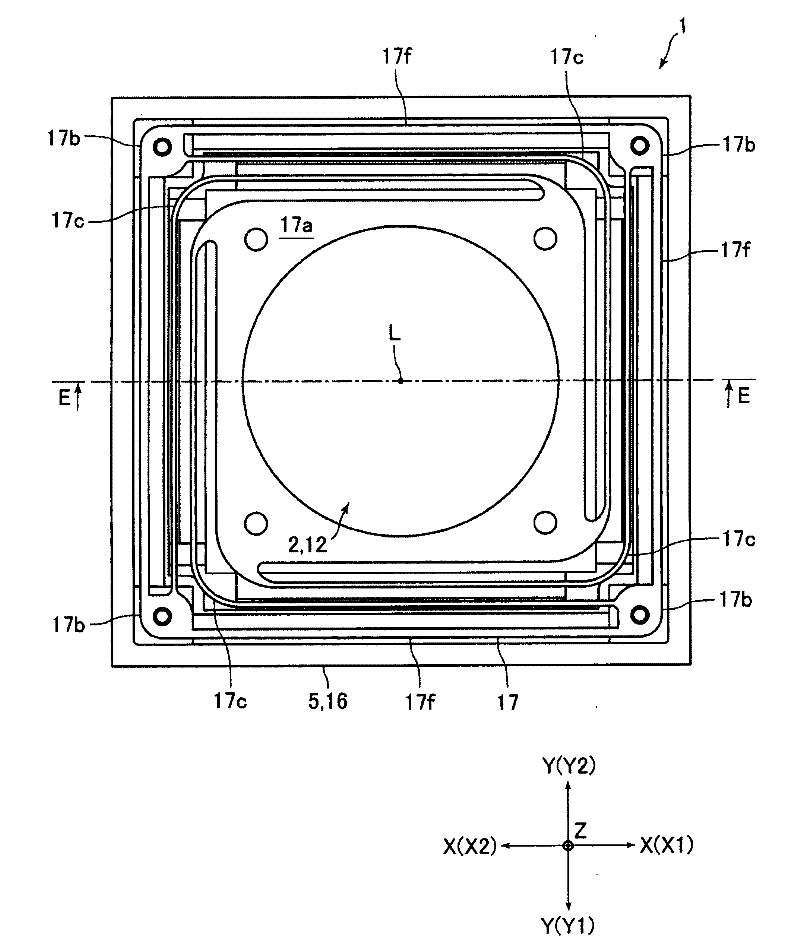

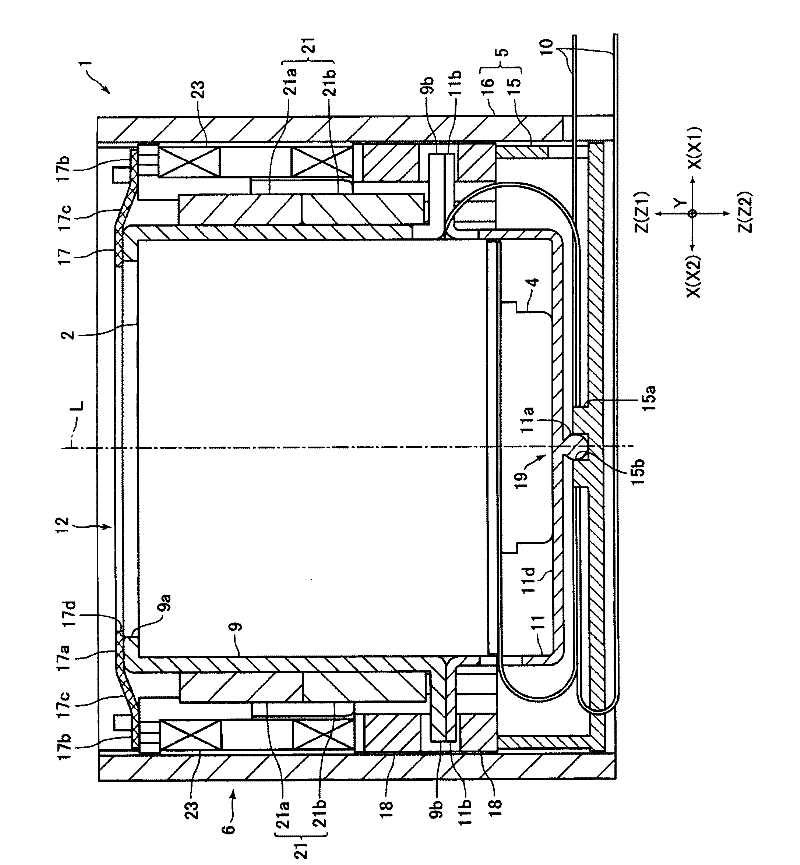

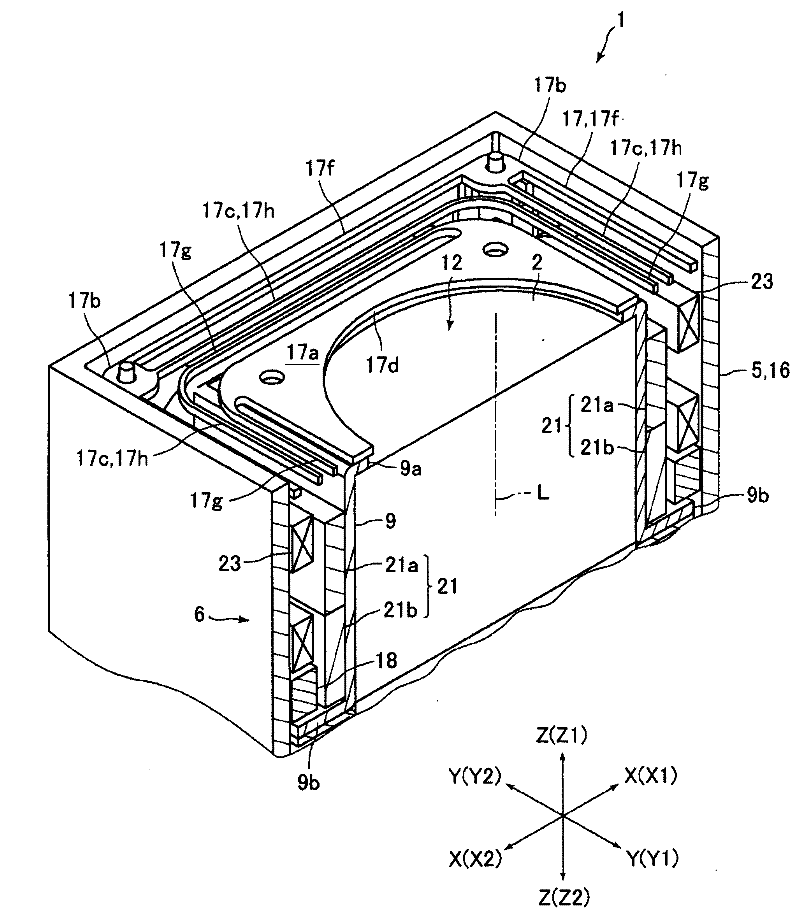

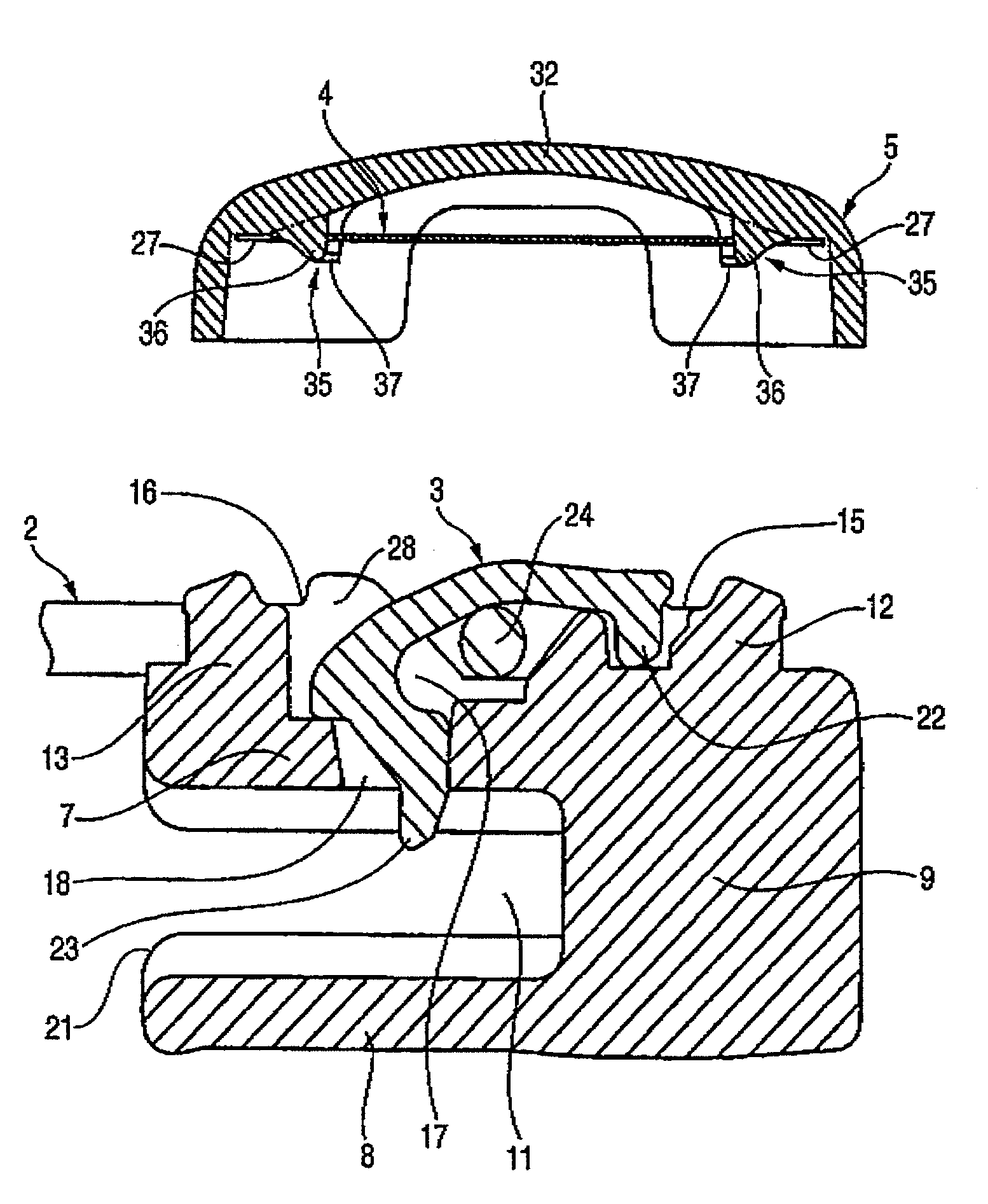

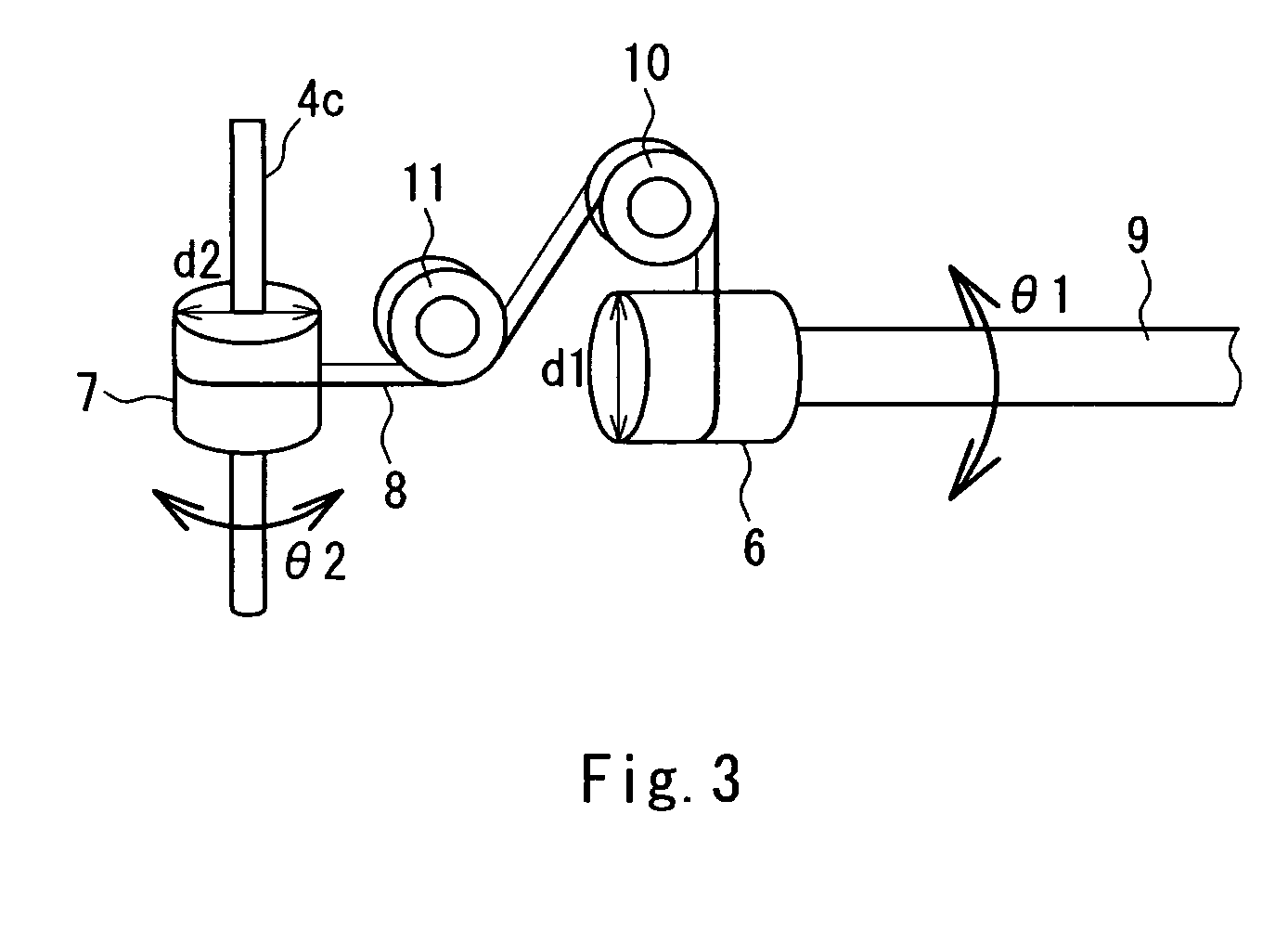

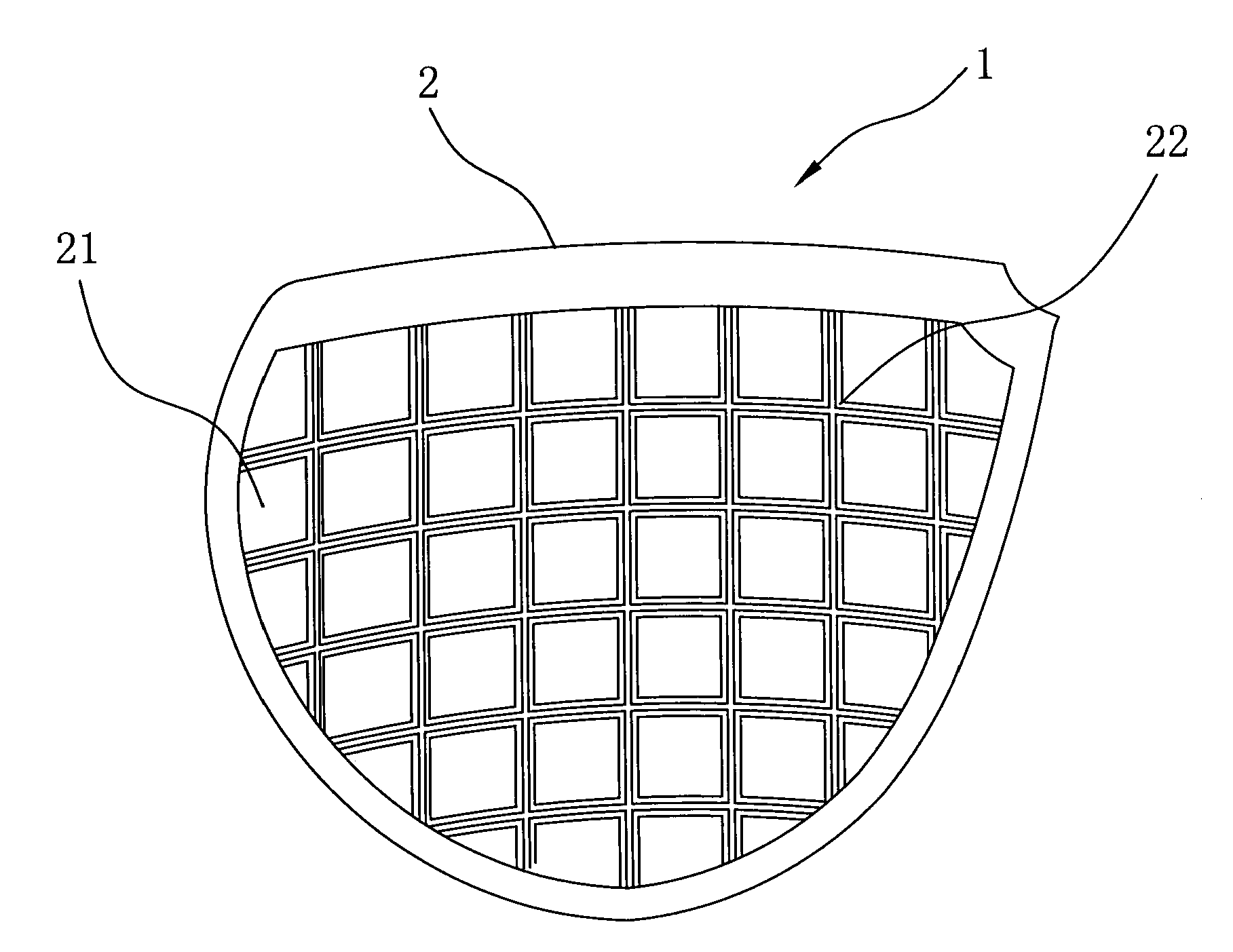

Imaging optical device

InactiveCN102177465ASmooth swingSmall spring constantTelevision system detailsPrintersOptical axisElectrical and Electronics engineering

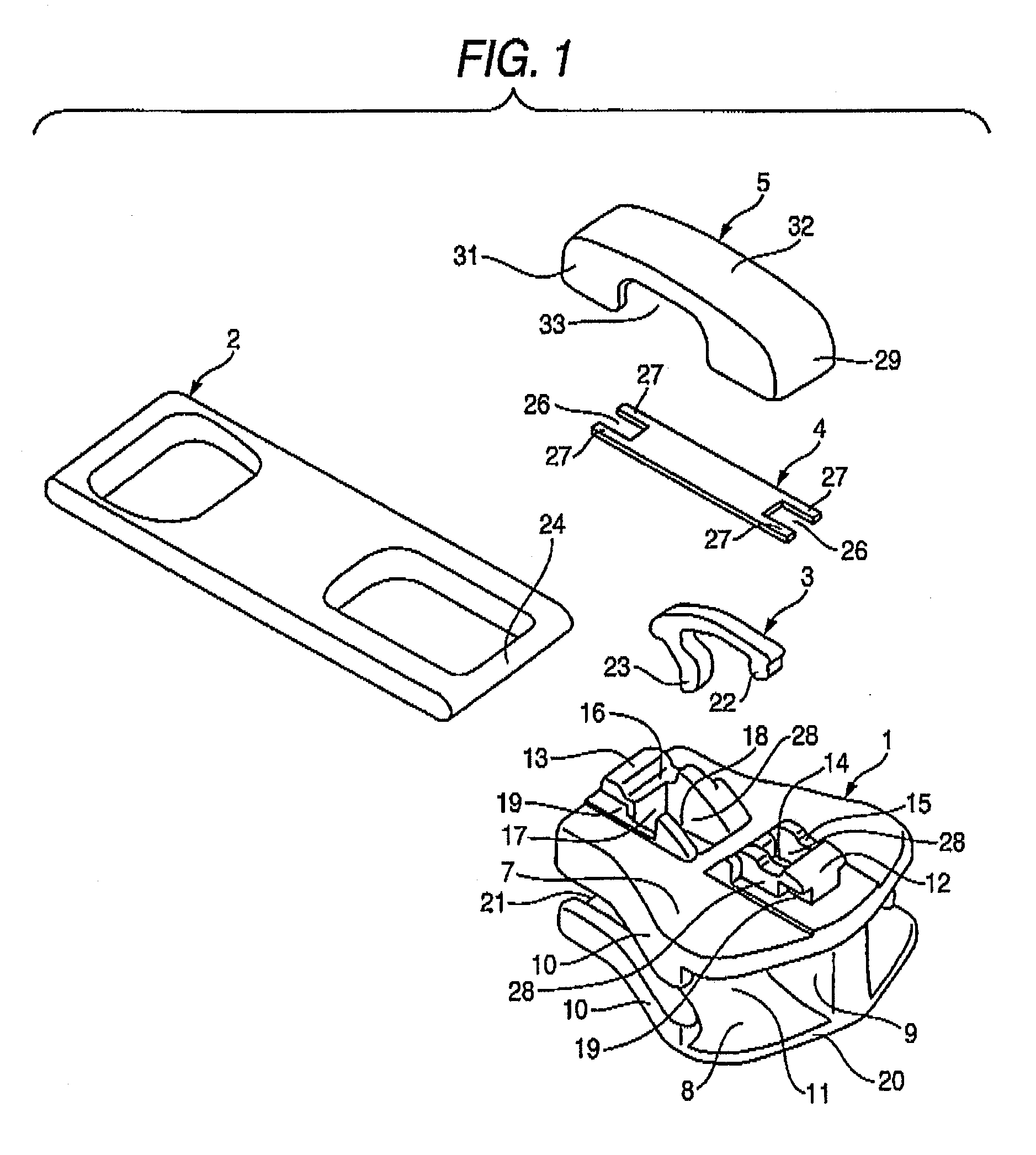

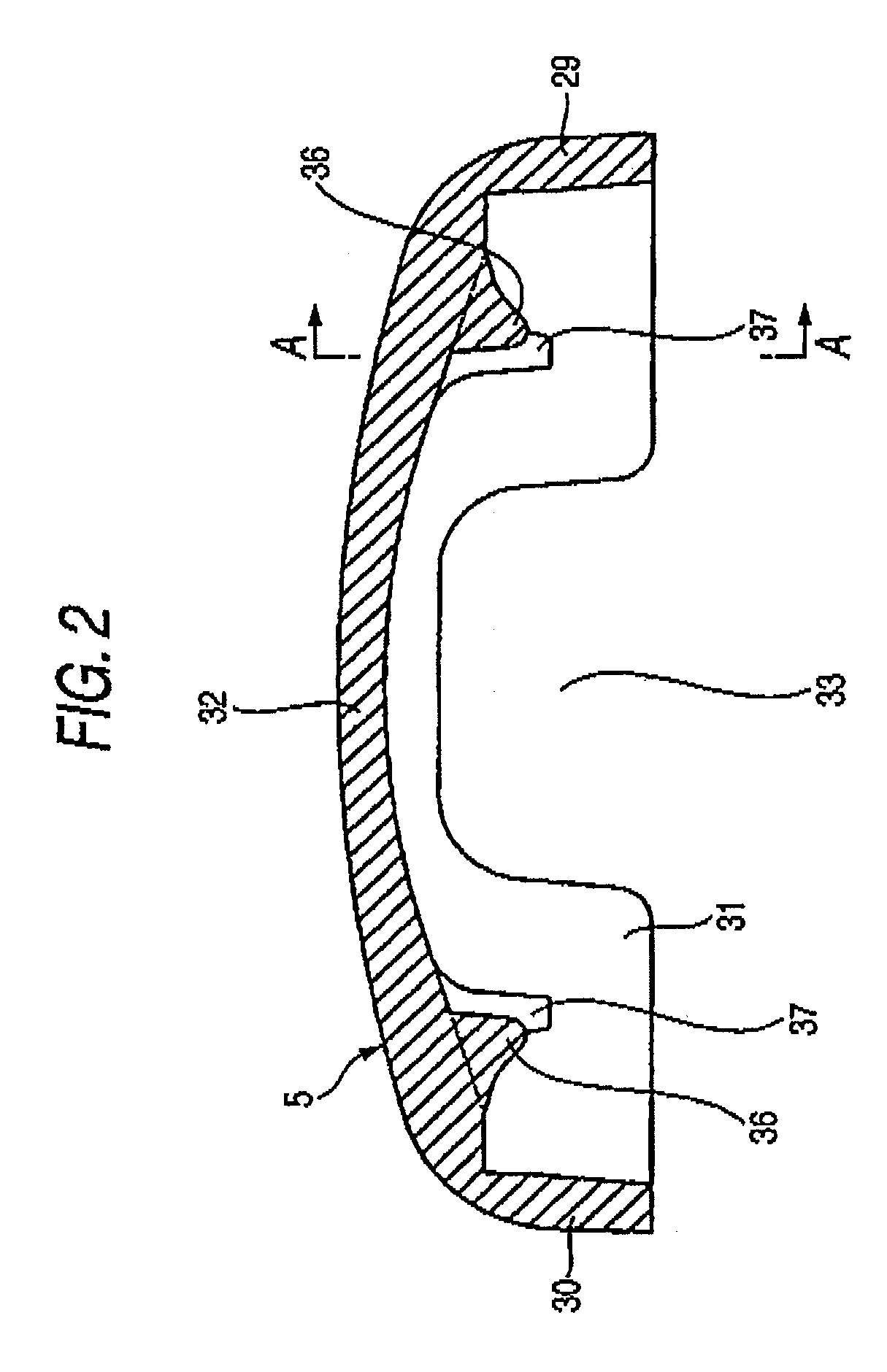

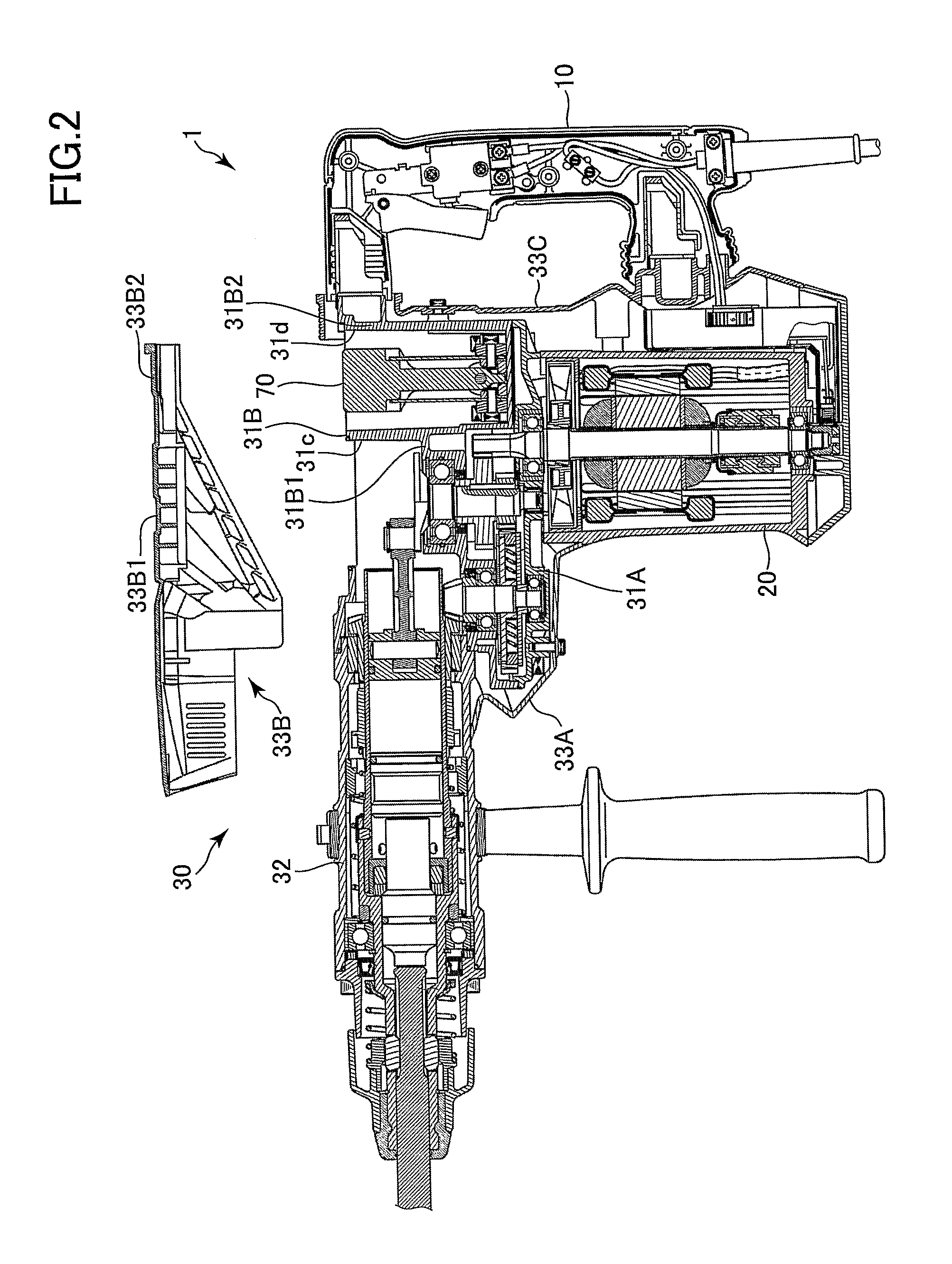

An imaging optical device configured such that shaking can be appropriately corrected by smoothly rocking a lens drive device on which a lens and an imaging element are mounted. An imaging optical device (1) comprises: a movable module (12) having a lens drive device (2) on which a lens and an imaging element are mounted; a support body (5) for supporting the movable module (12); a rocking drive mechanism for rocking the movable module (12); and a plate spring (17) for rockably supporting the movable module (12). The plate spring (17) is provided with a holding section (17a) for holding the movable module (12), a fixed section (17b) fixed to the support body (5), and a spring section (17c) for connecting the holding section (17a) and the fixed section (17b) to each other. The spring section (17c) can deform in the direction perpendicular to the optical axis (L) and in the direction of the optical axis.

Owner:SANKYO SEIKI MFG CO LTD

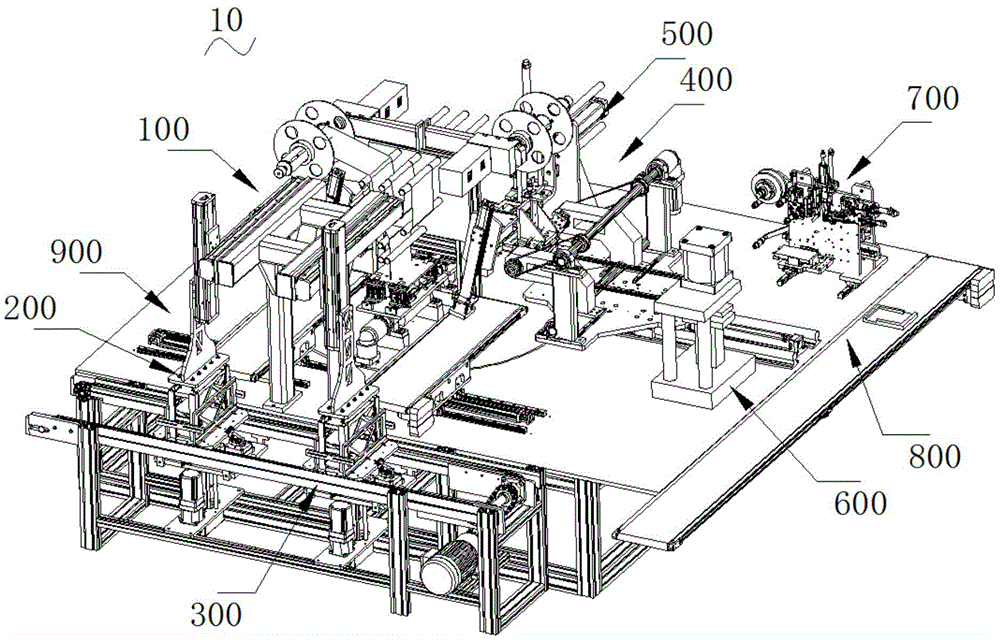

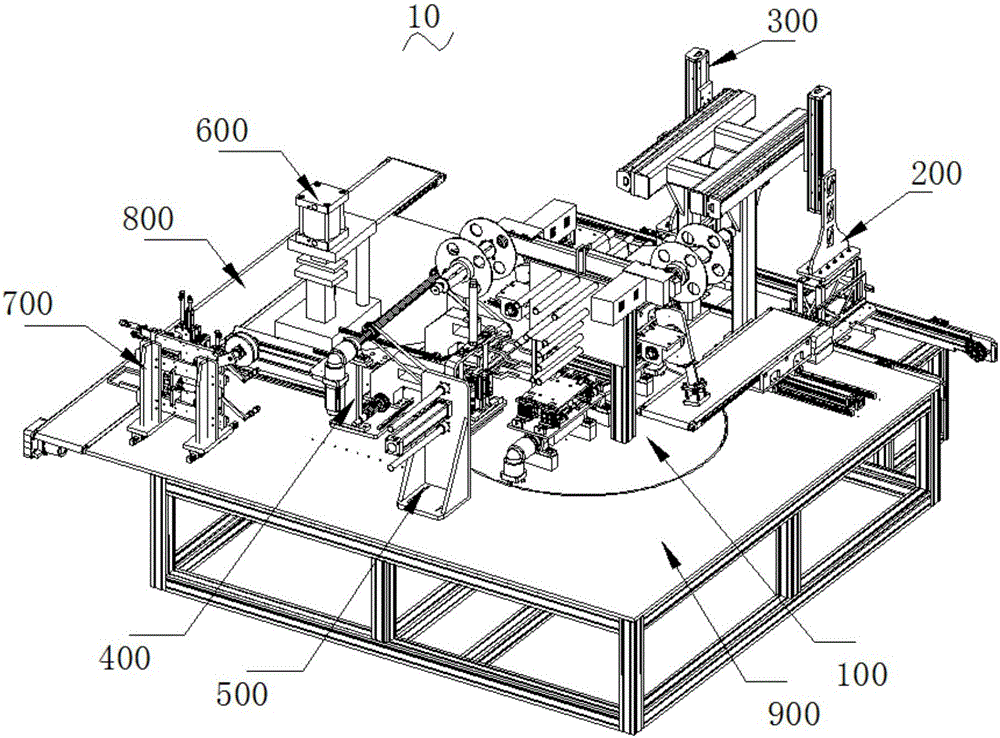

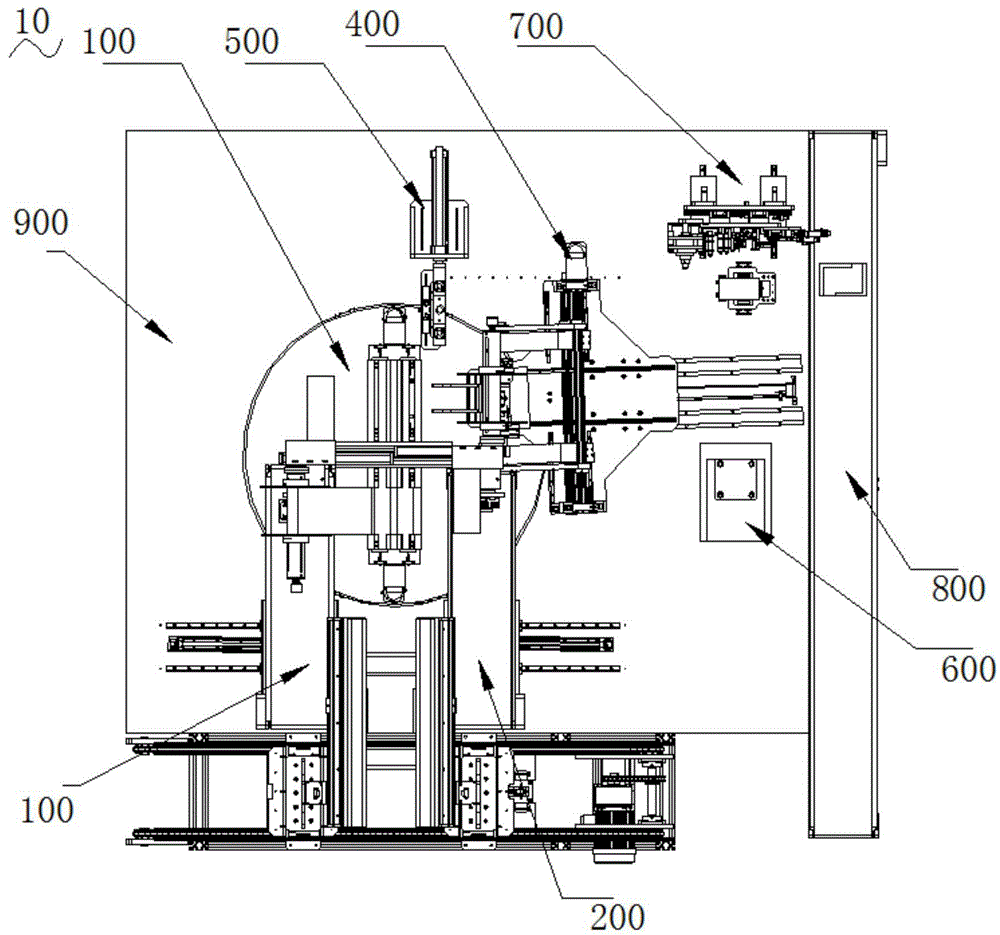

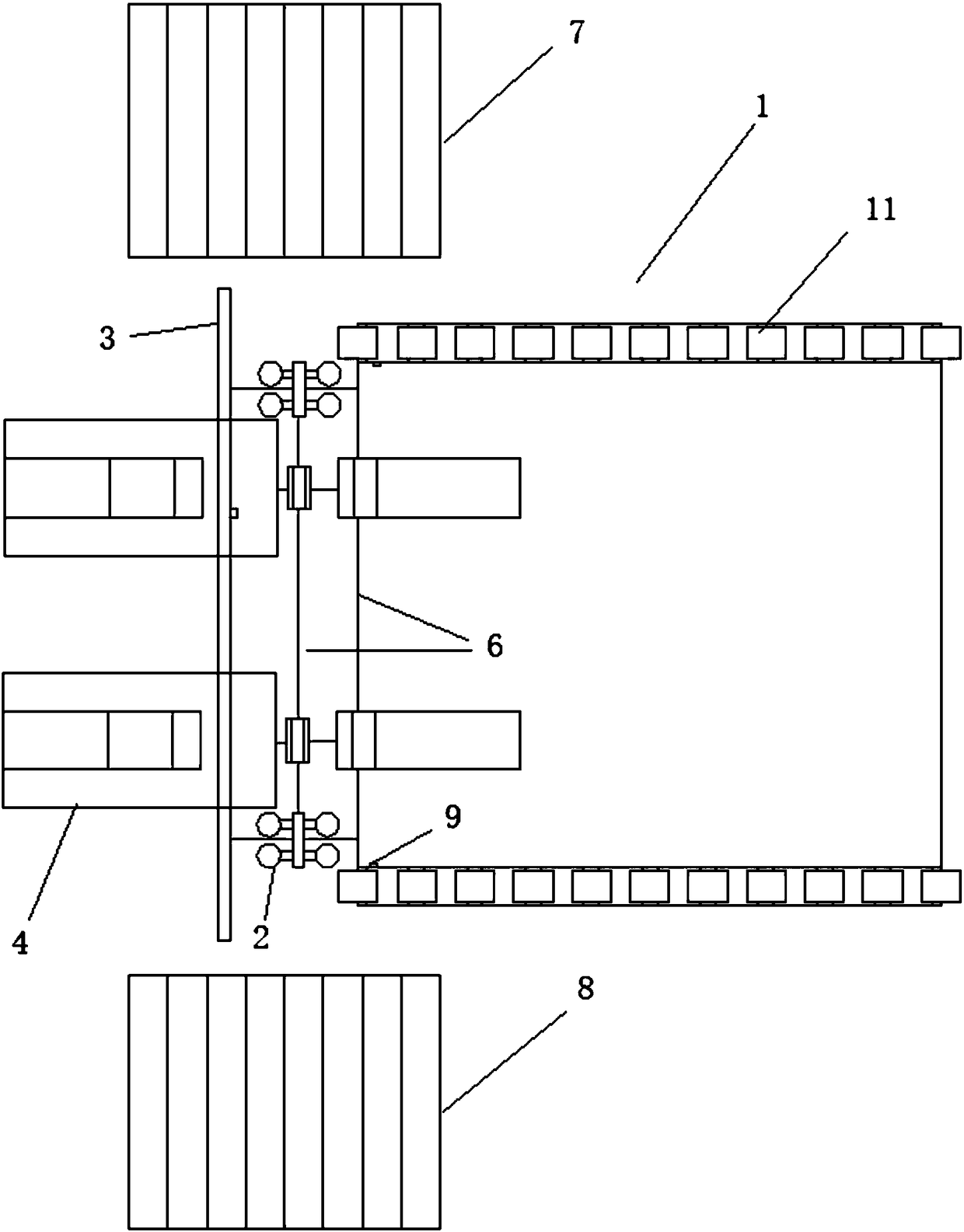

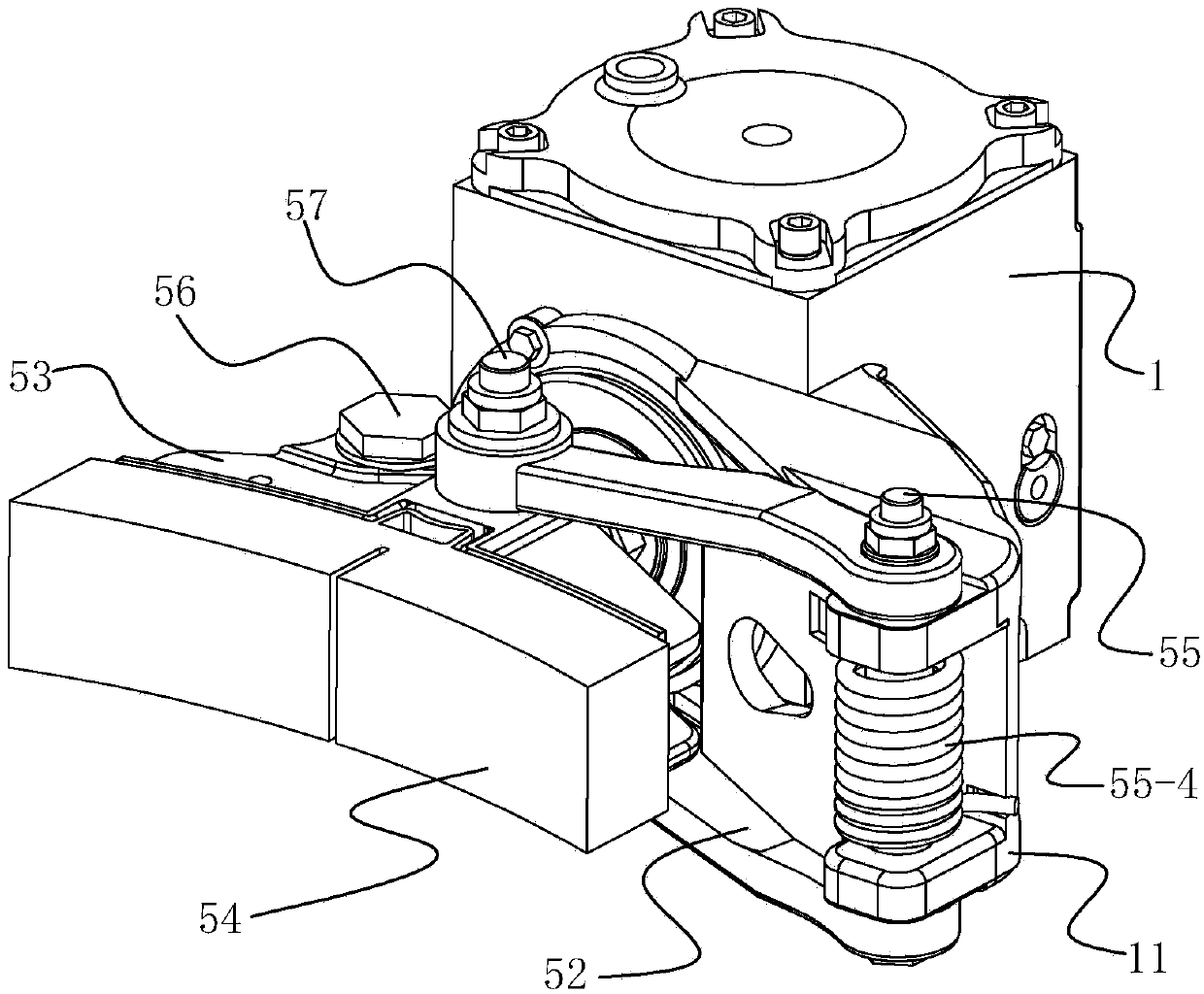

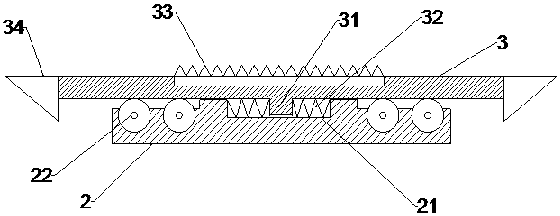

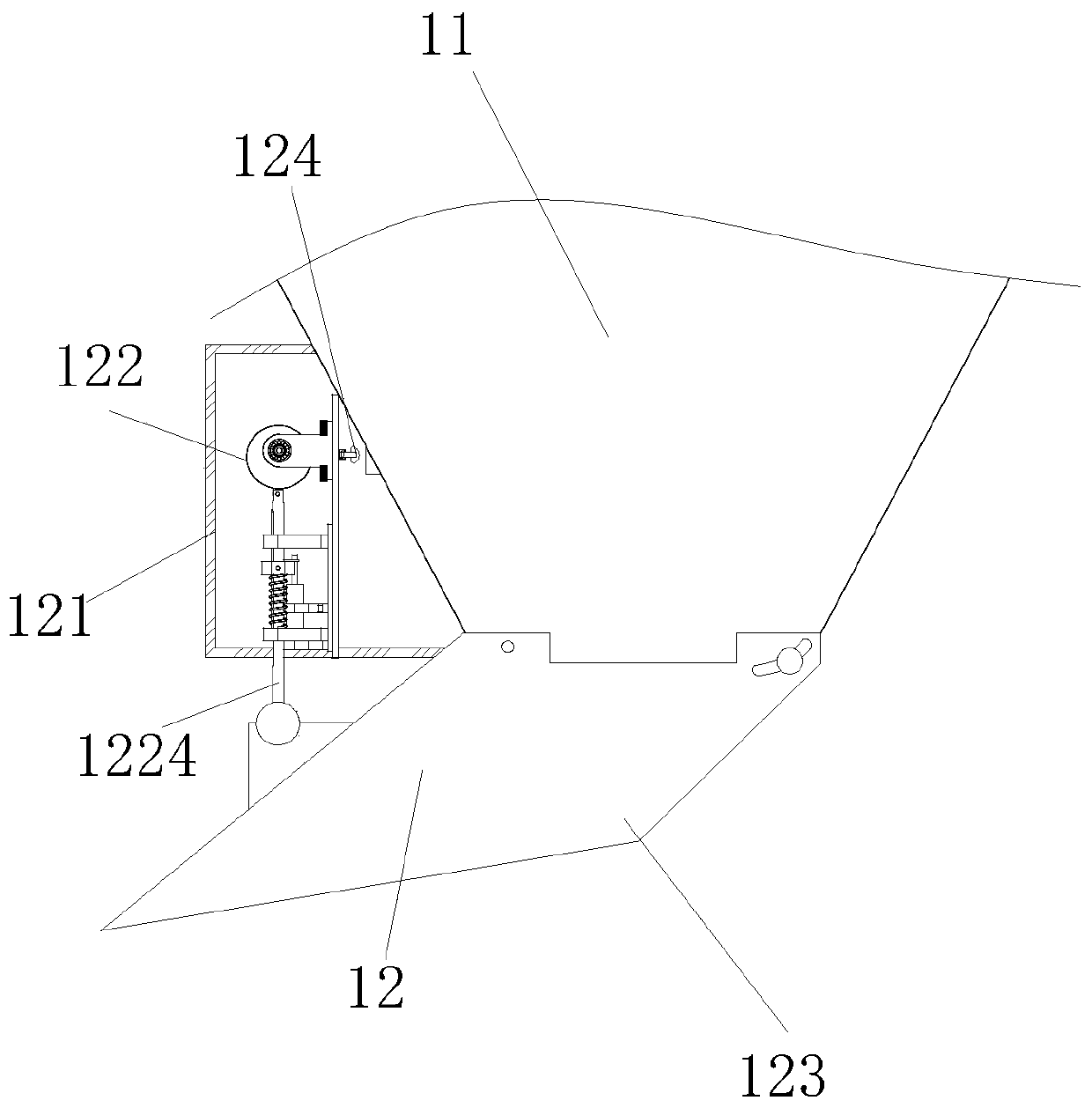

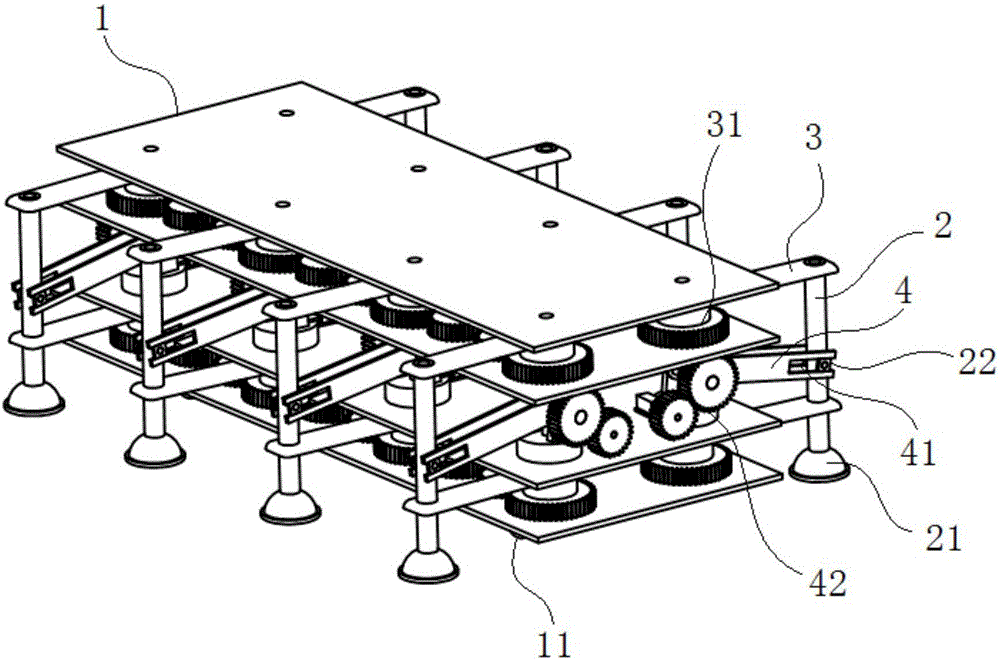

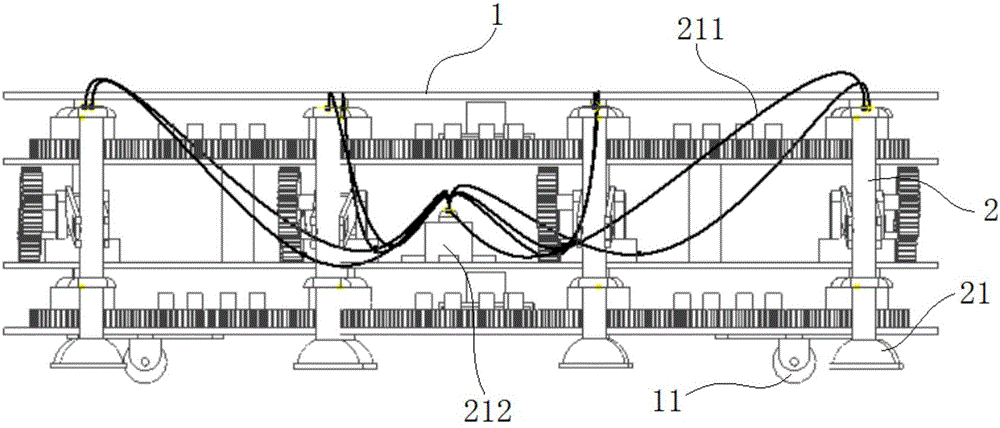

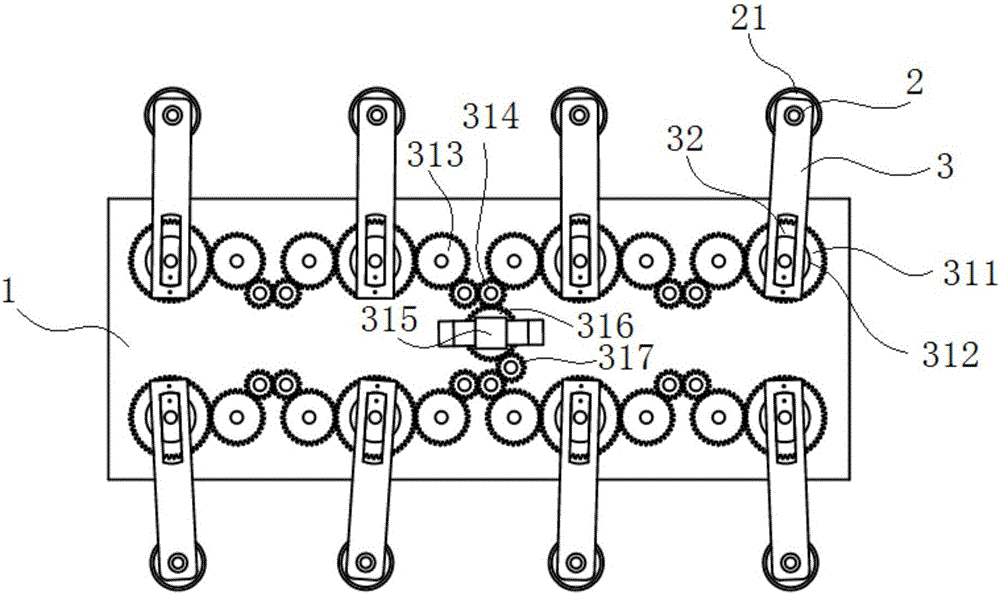

Integrated cell laminating machine and cell laminating method

ActiveCN106374144AHigh precisionImprove lamination qualityAssembling battery machinesFinal product manufactureVertical planeEngineering

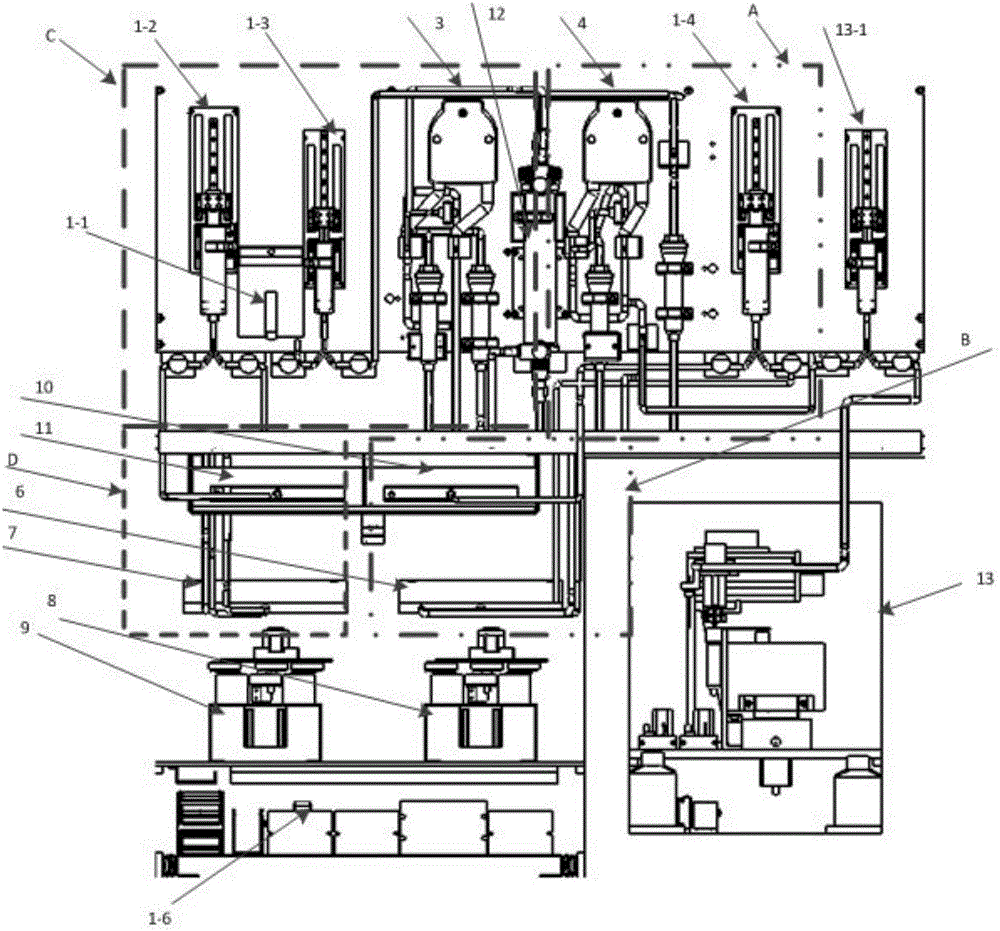

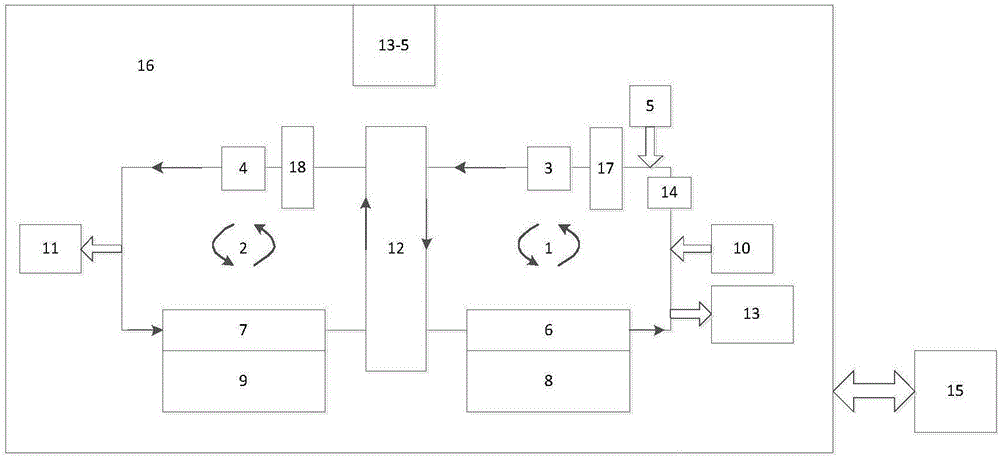

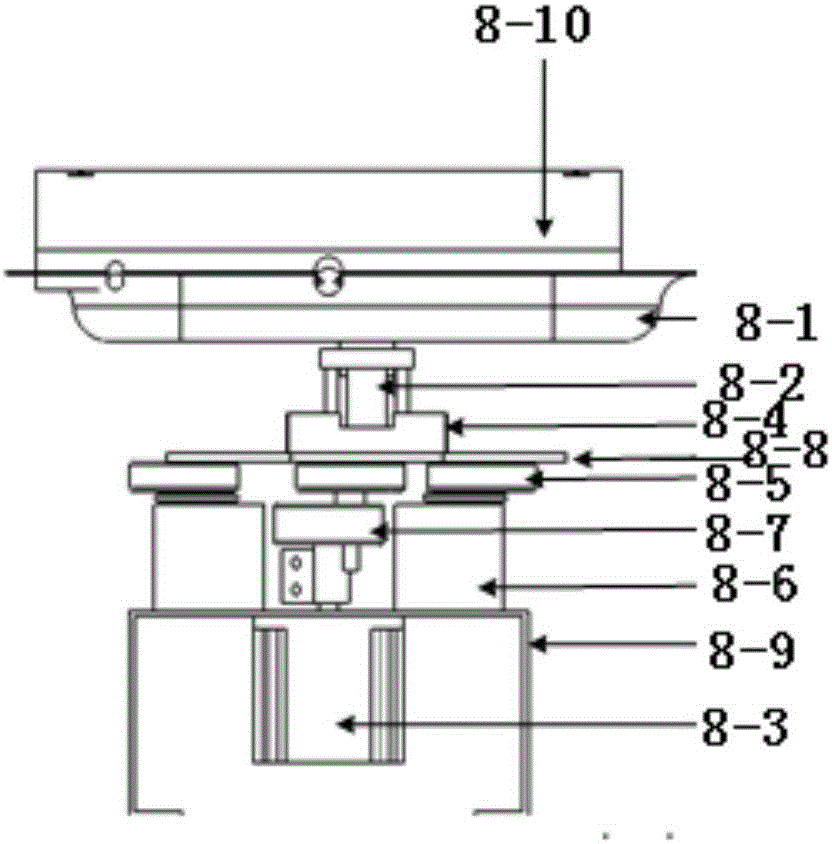

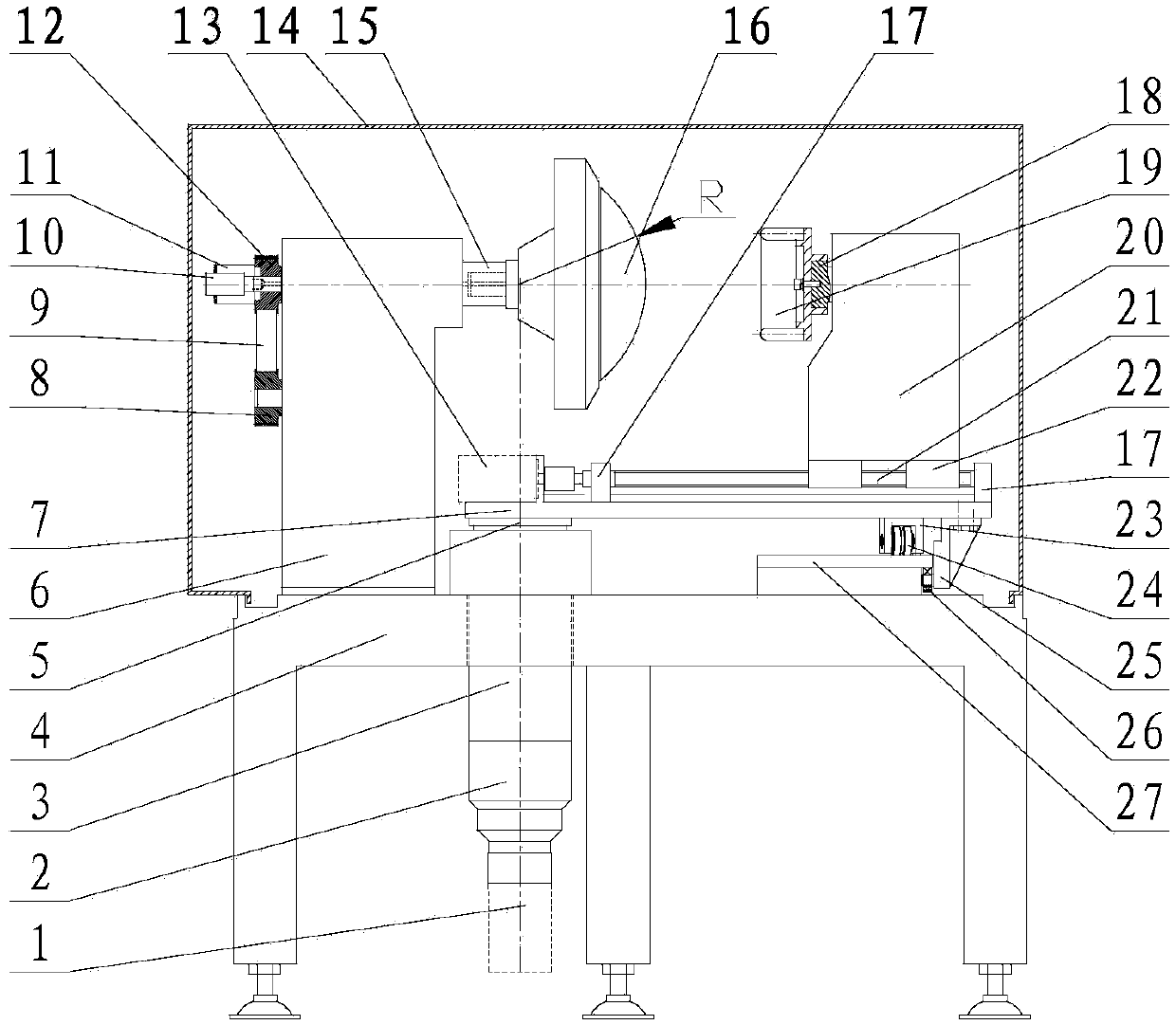

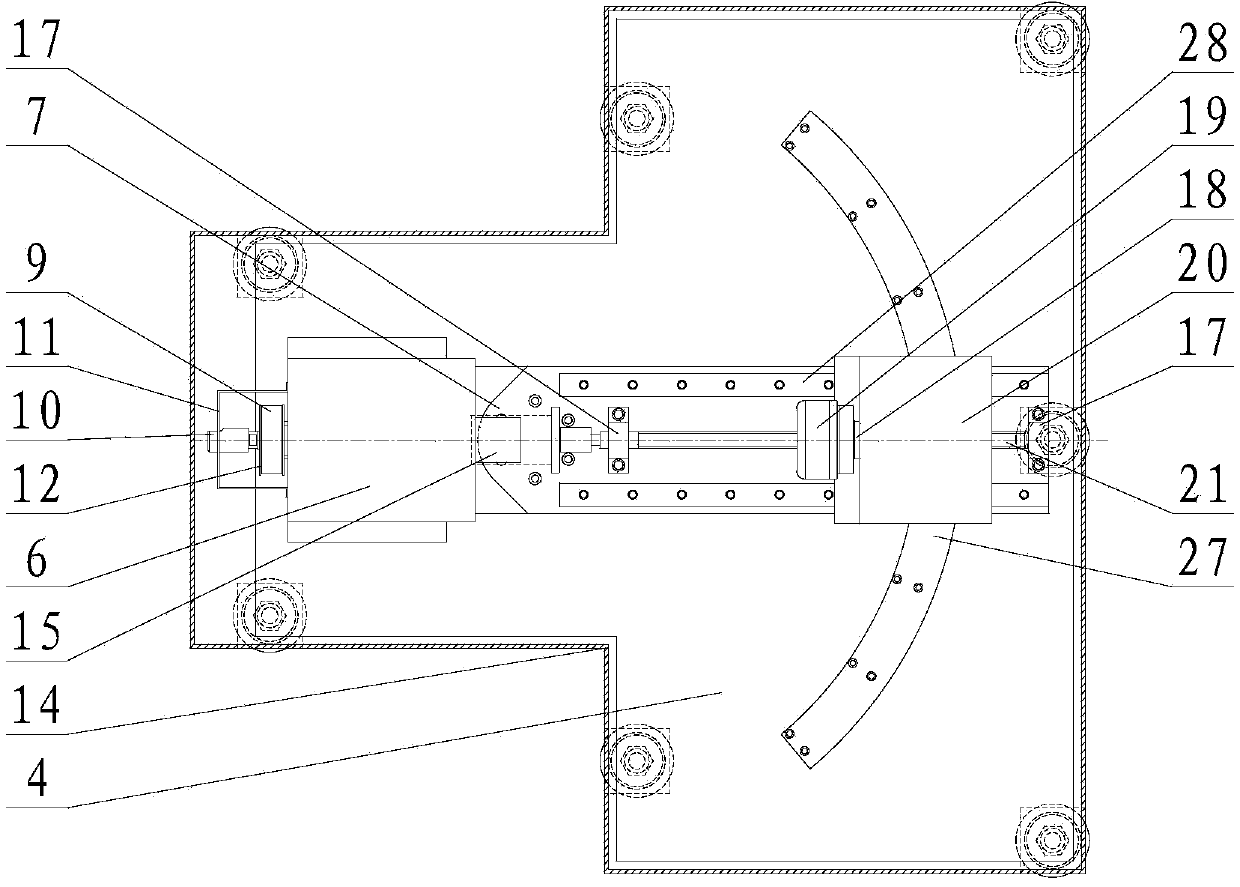

The invention relates to the technical field of battery lamination, particularly to an integrated cell laminating machine and a cell laminating method. The integrated cell laminating machine comprises a laminating station, wherein the laminating station comprises a rotary plate, a rotary plate rotating apparatus arranged below the rotary plate for driving the rotary plate to rotate, and multiple laminating apparatuses uniformly arranged on the rotary plate for performing lamination; each laminating apparatus comprises a laminating rotary platform, a laminating power mechanism for driving the laminating rotary platform to swing in a vertical plane, and a first attraction mechanism and a second attraction mechanism which are symmetrically arranged on the two sides of the laminating rotary platform for attracting and driving a positive plate and a negative plate to swing in a vertical plane, and a diaphragm material-releasing mechanism mounted above the laminating rotary platform for supplying diaphragms, wherein each laminating power mechanism is positioned at the bottom of the corresponding laminating rotary platform; and the swinging track of the laminating rotary platform is externally tangent with the swinging track of the corresponding first attraction mechanism and second attraction mechanism. The integrated cell laminating machine has high laminating efficiency, high laminating precision and good laminating quality.

Owner:GUANGDONG YI XINFENG INTELLIGENT EQUIP CO LTD

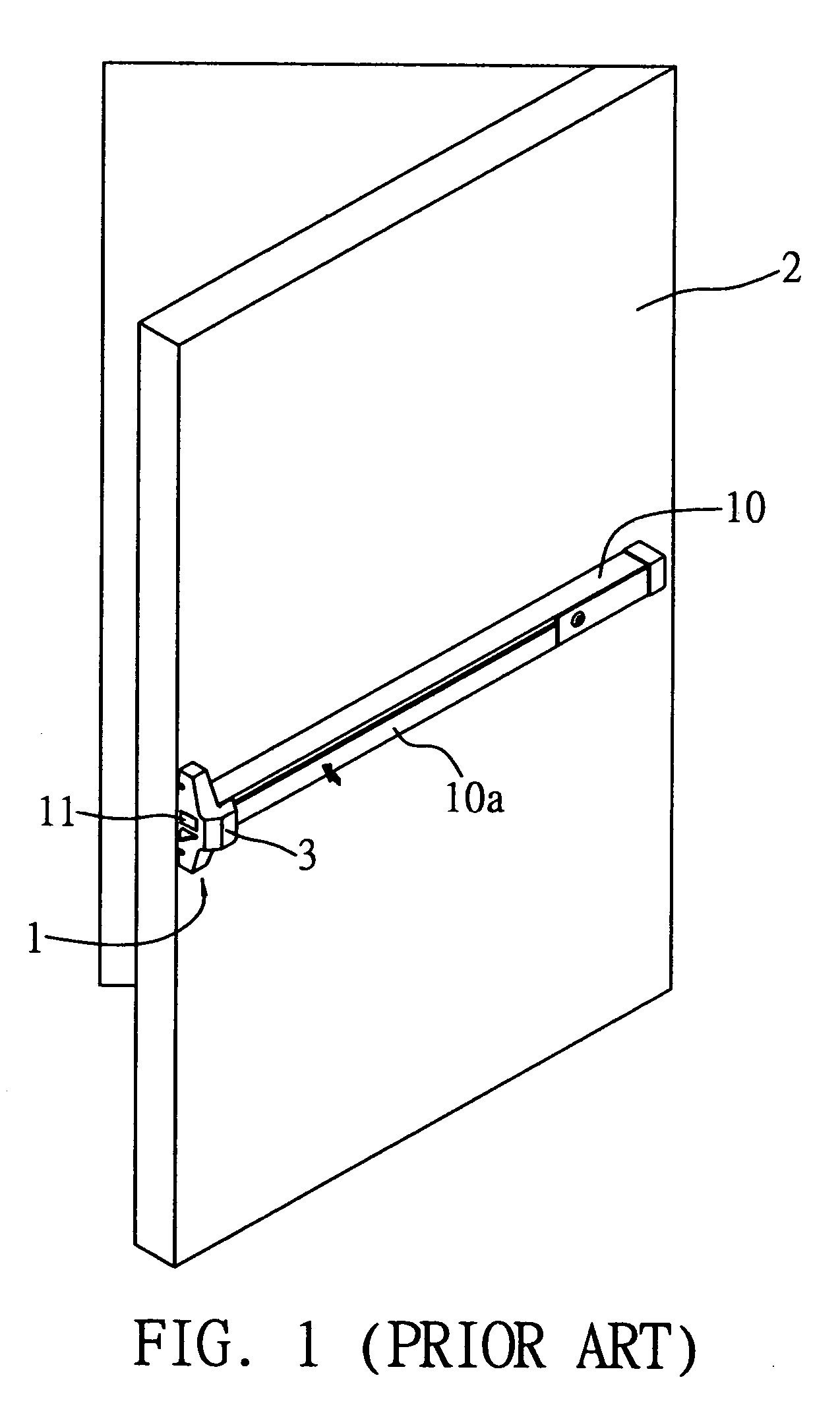

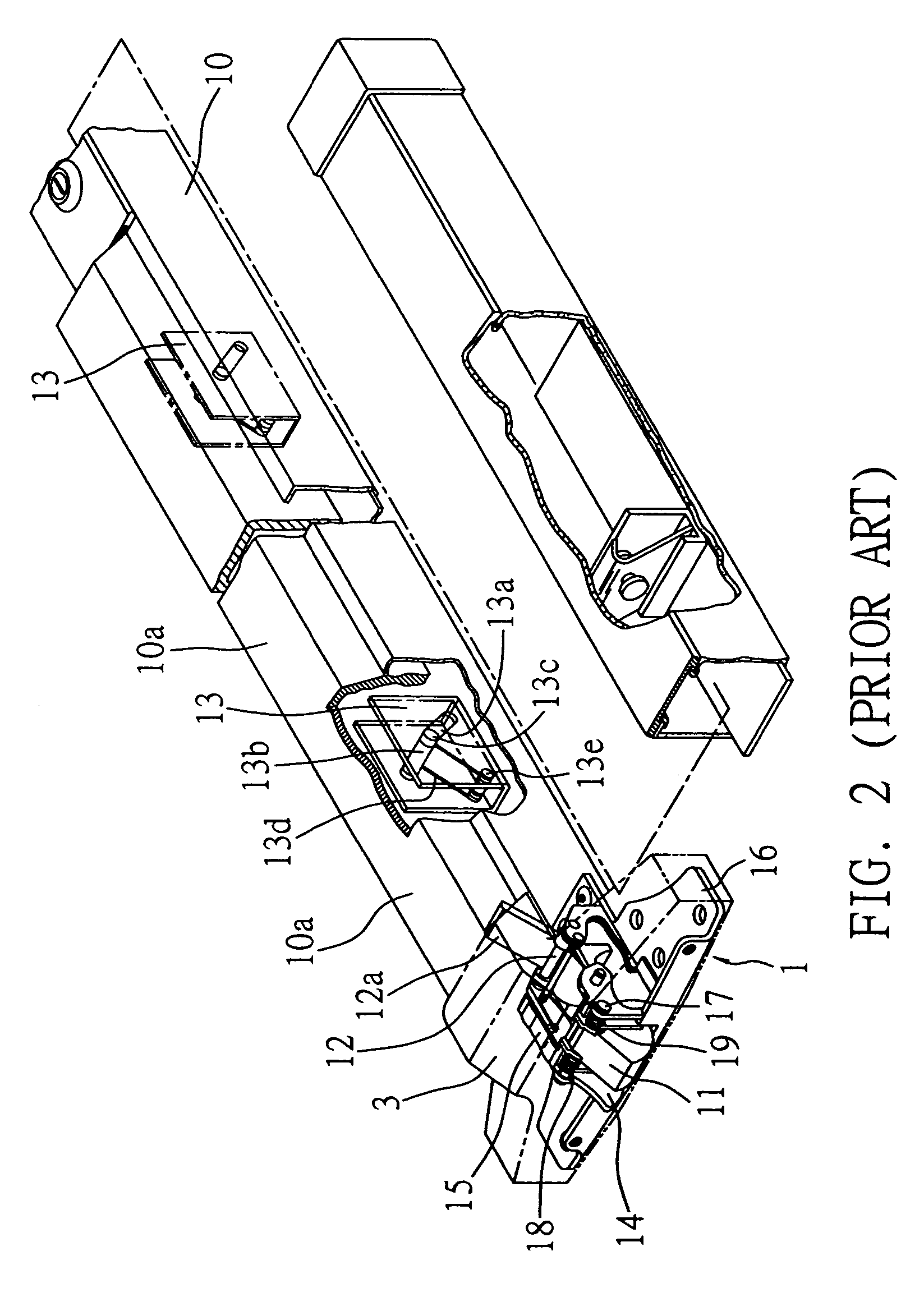

Fire-blocking door lock structure

ActiveUS7070210B2Rule out the possibilitySmooth swingBuilding locksFastening meansEngineeringMechanical engineering

Owner:LIN CHING TIEN

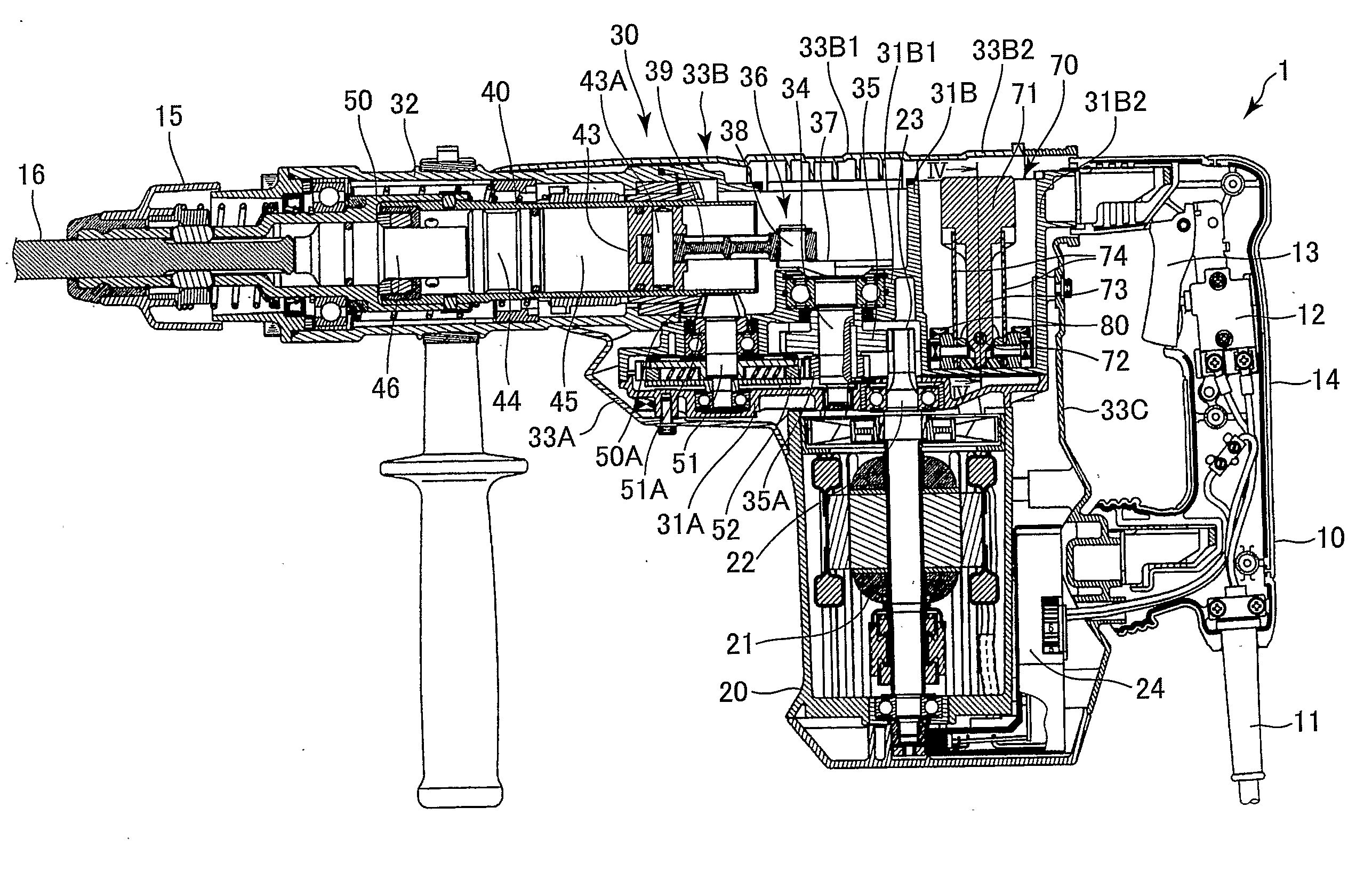

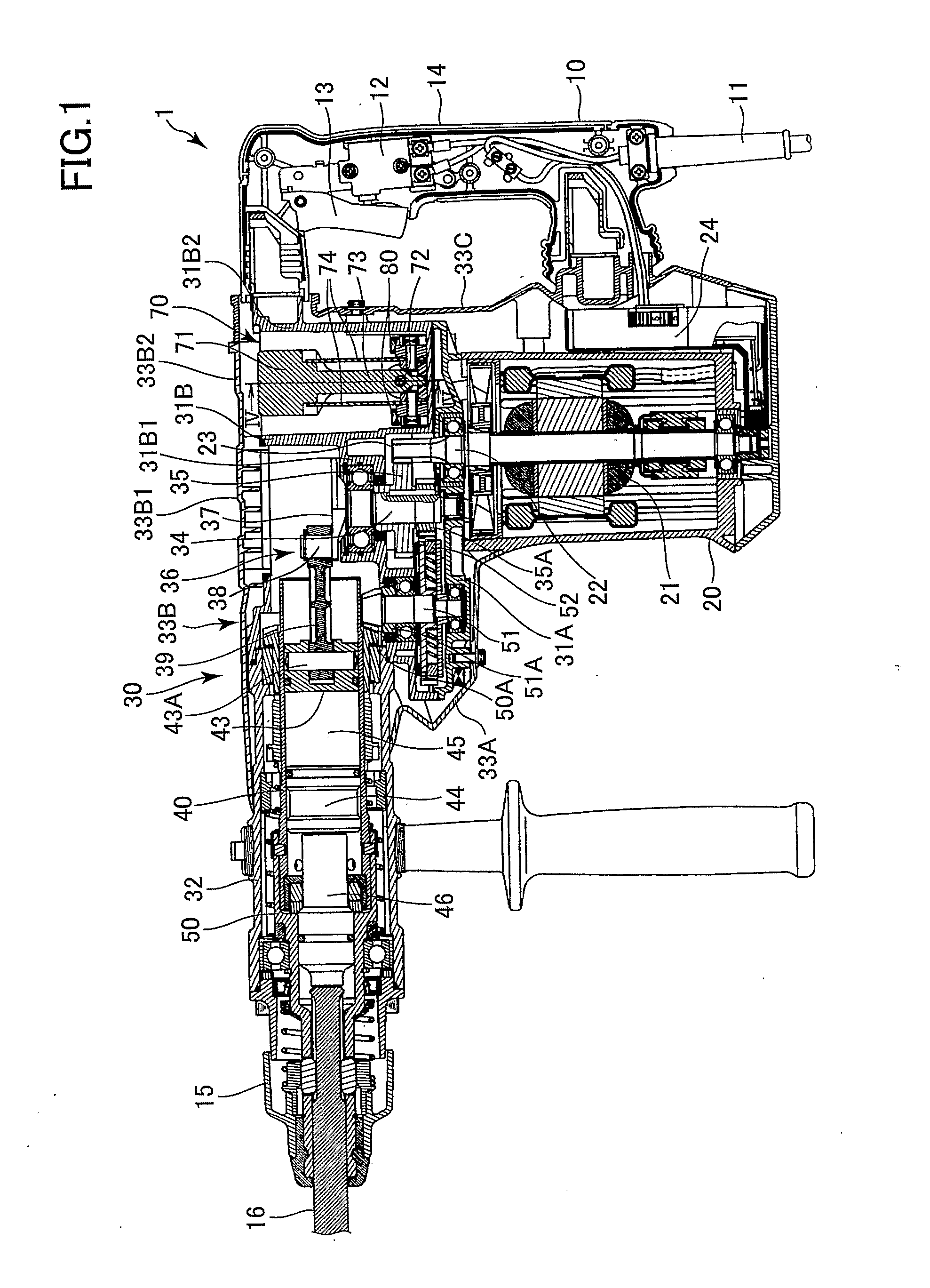

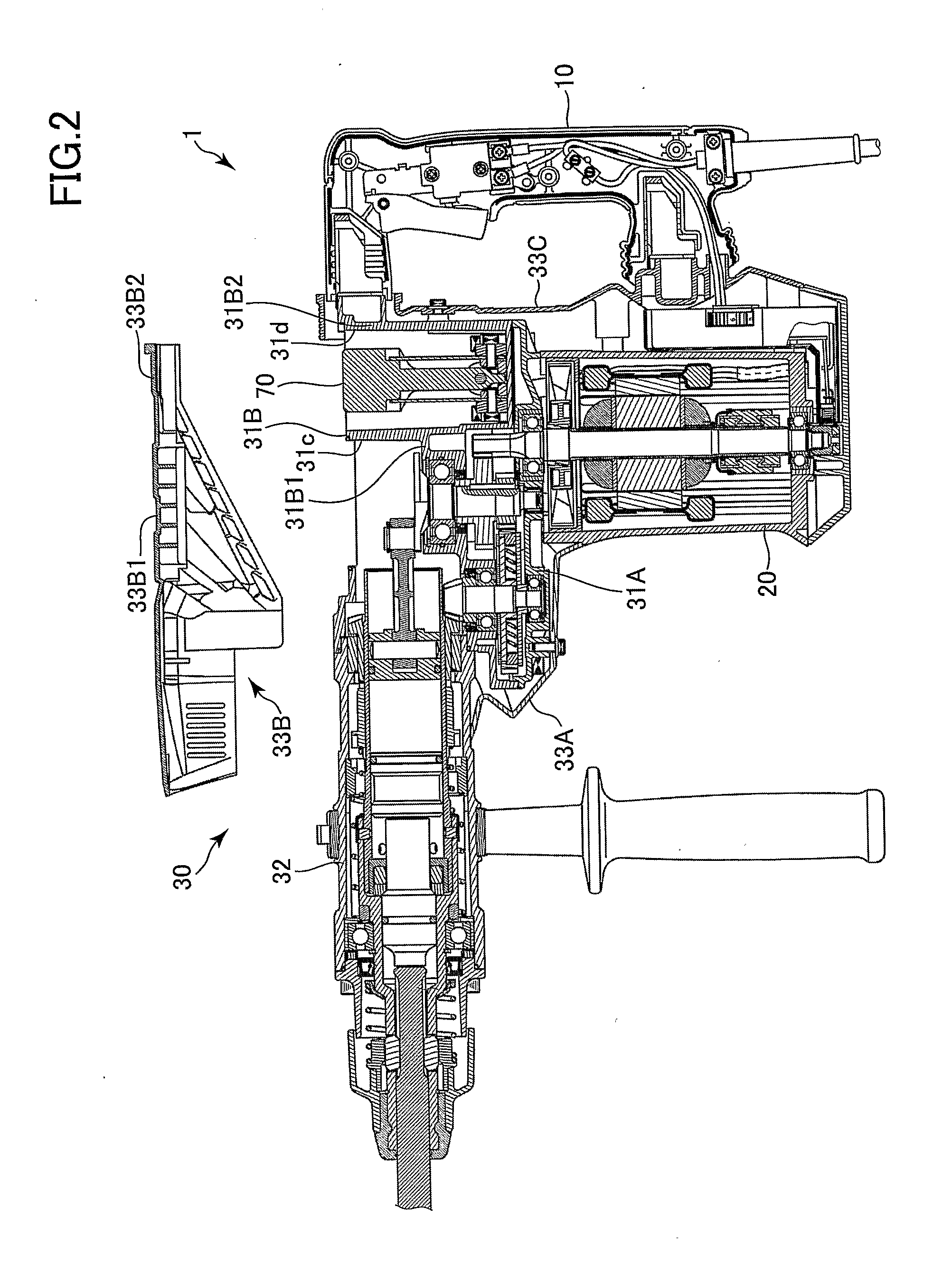

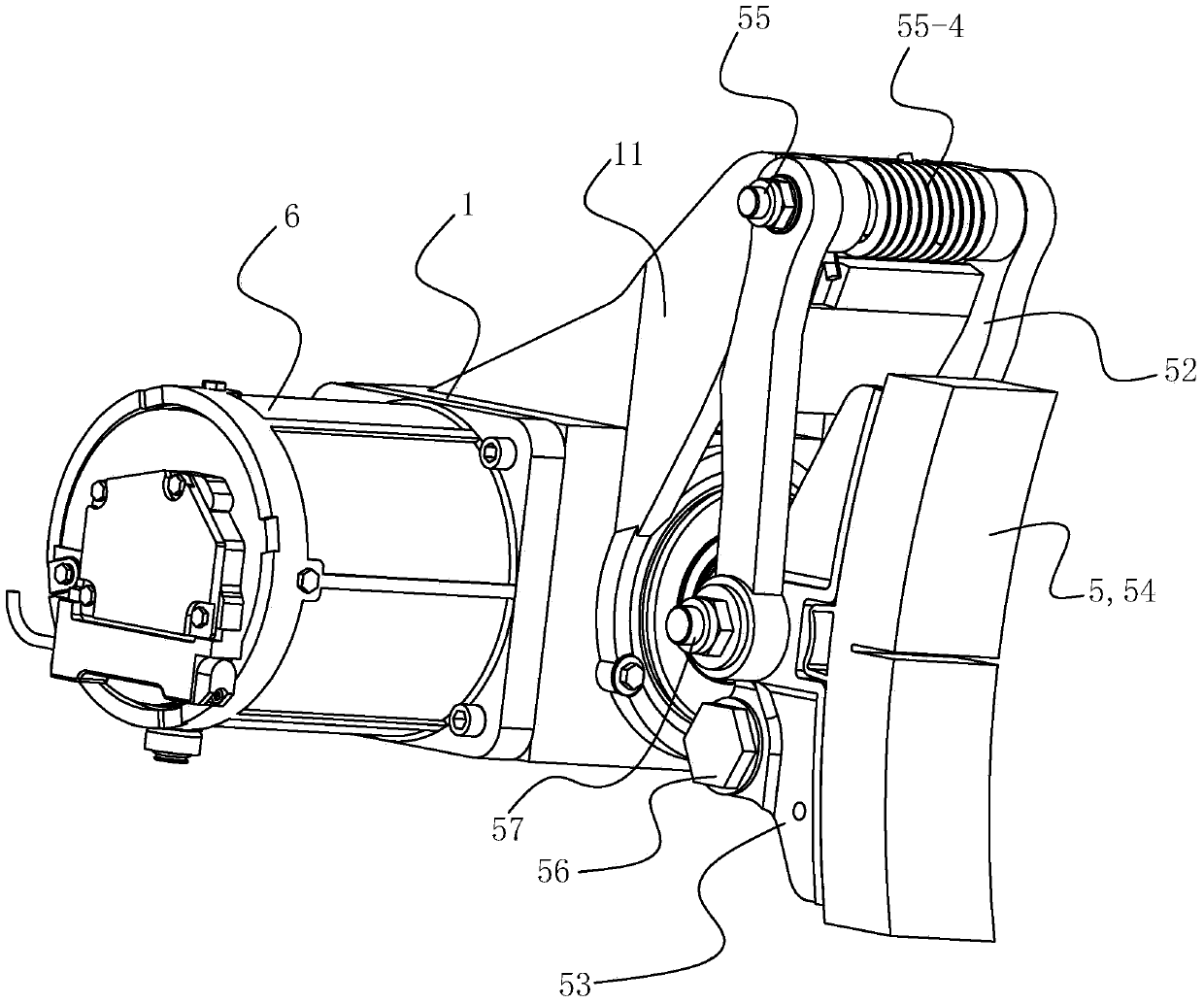

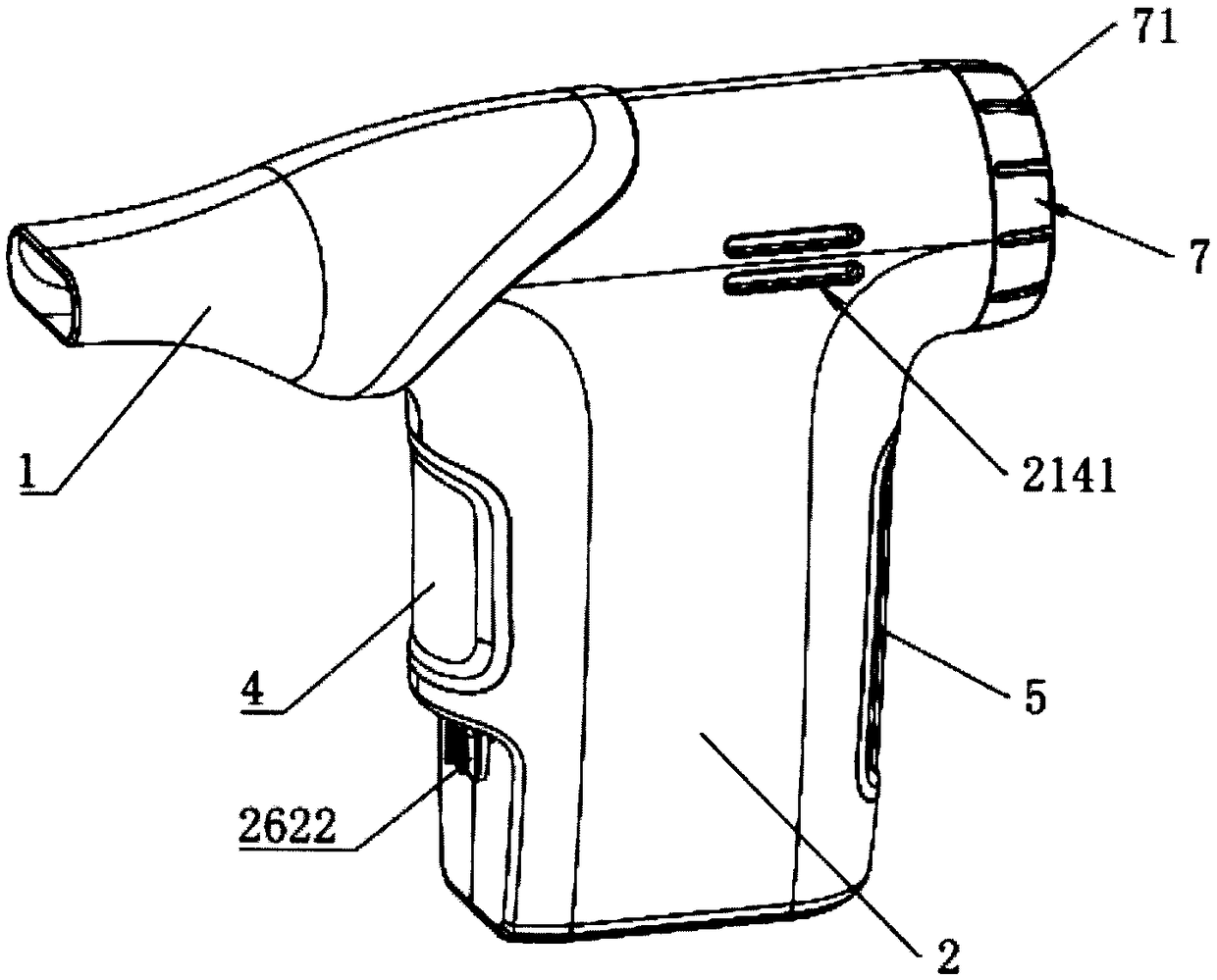

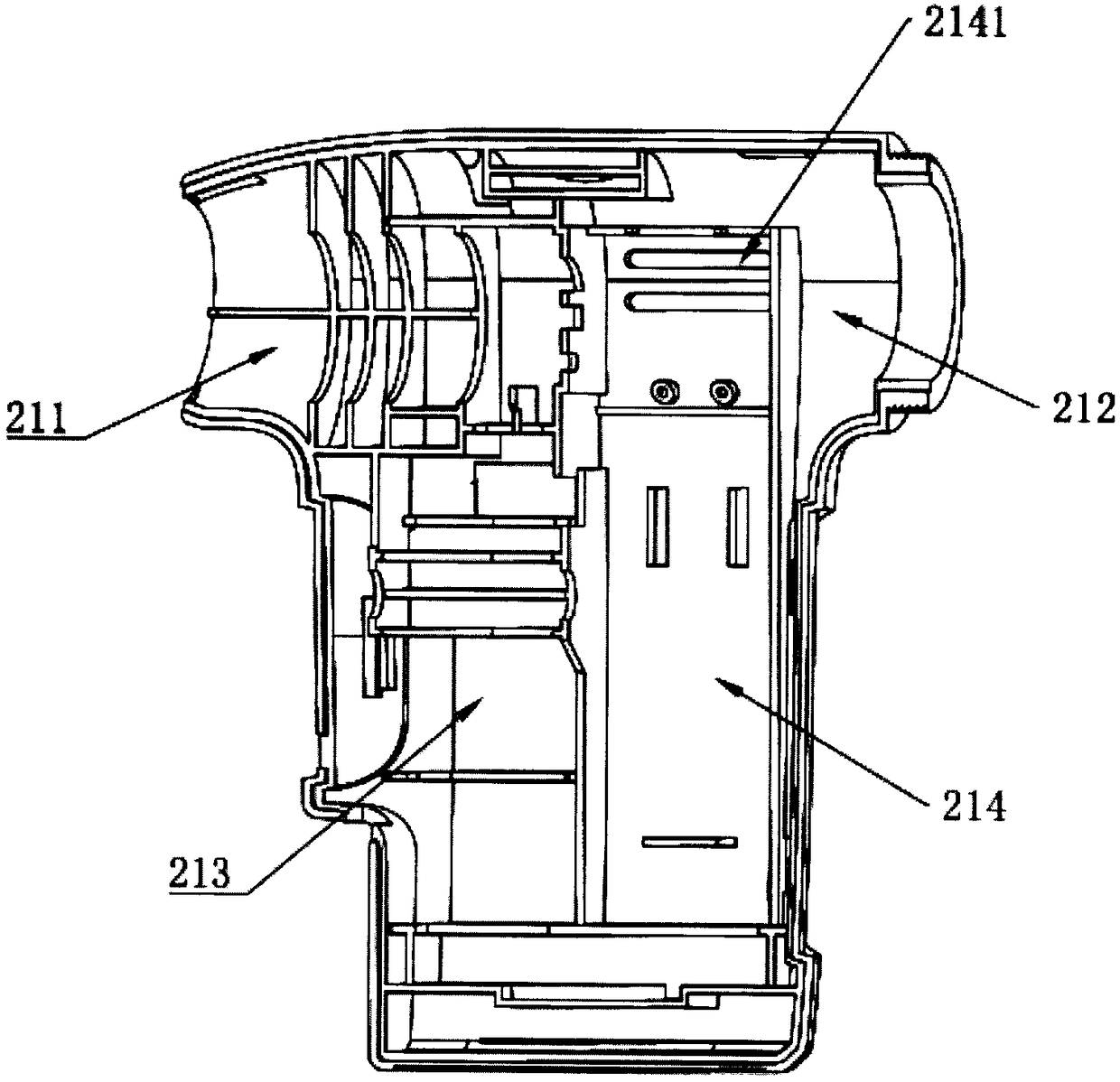

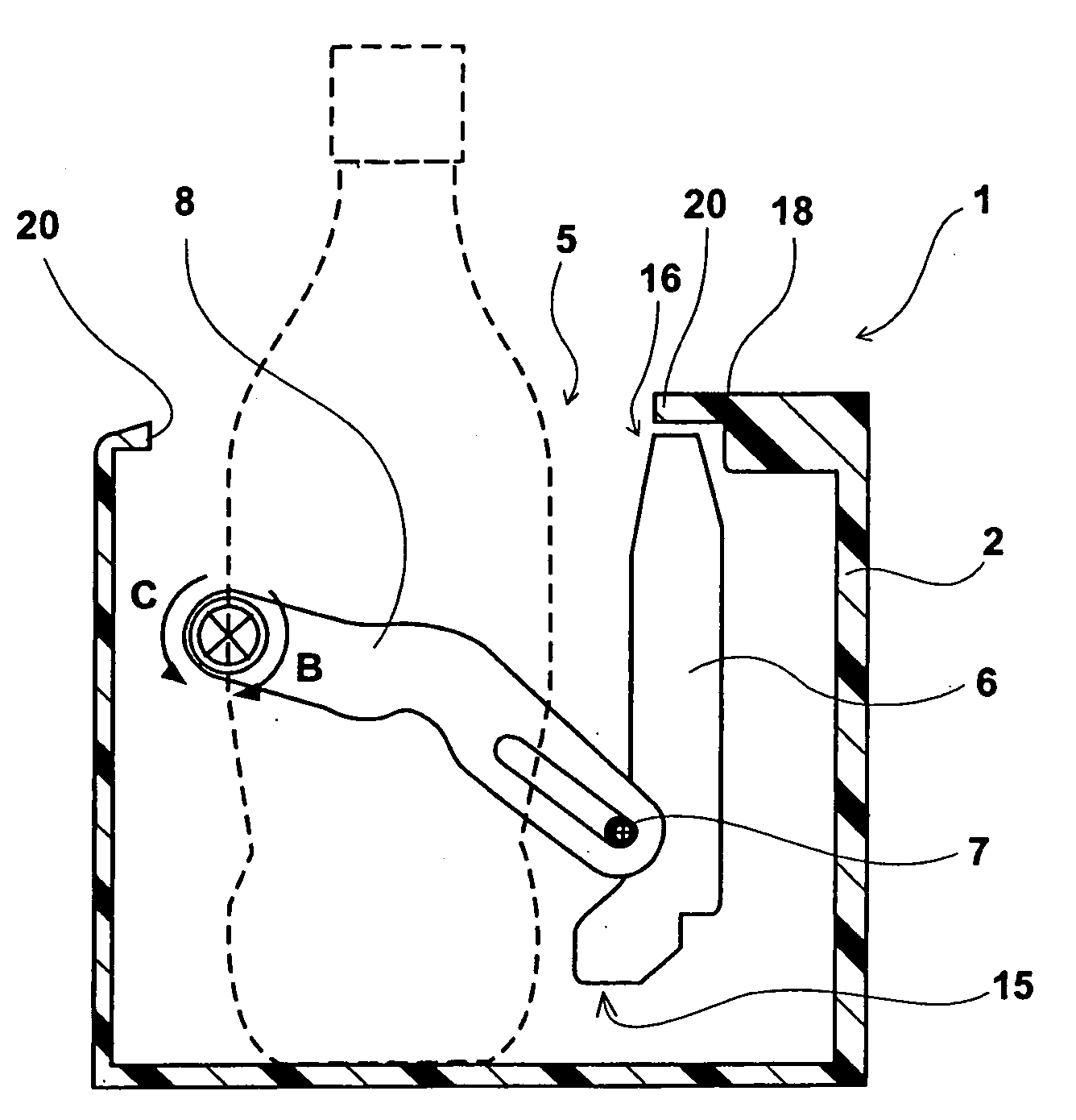

Reciprocating Tool

ActiveUS20100038105A1Reduce development of resistanceSufficient weightReciprocating drilling machinesConstructionsTool bitReciprocating motion

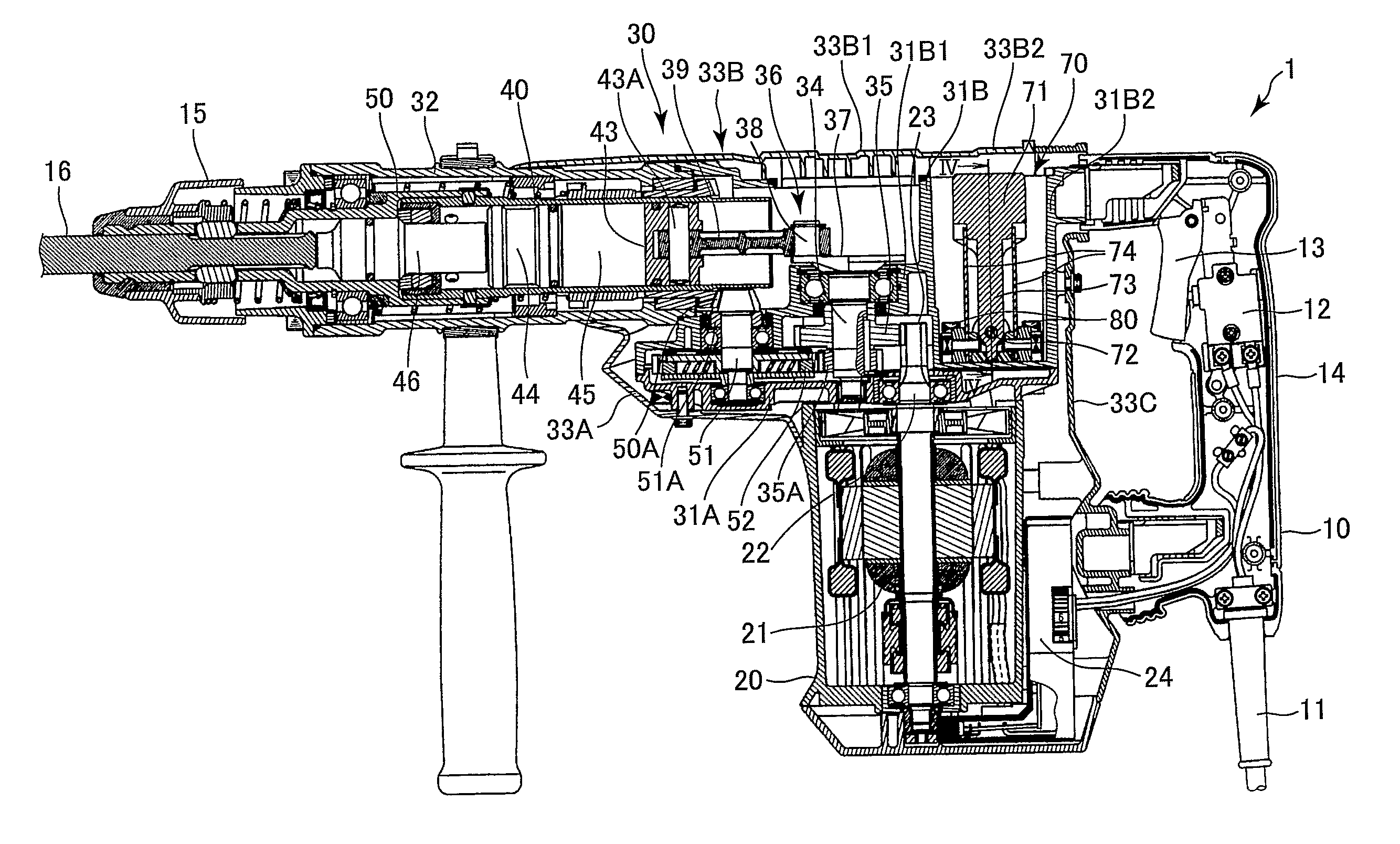

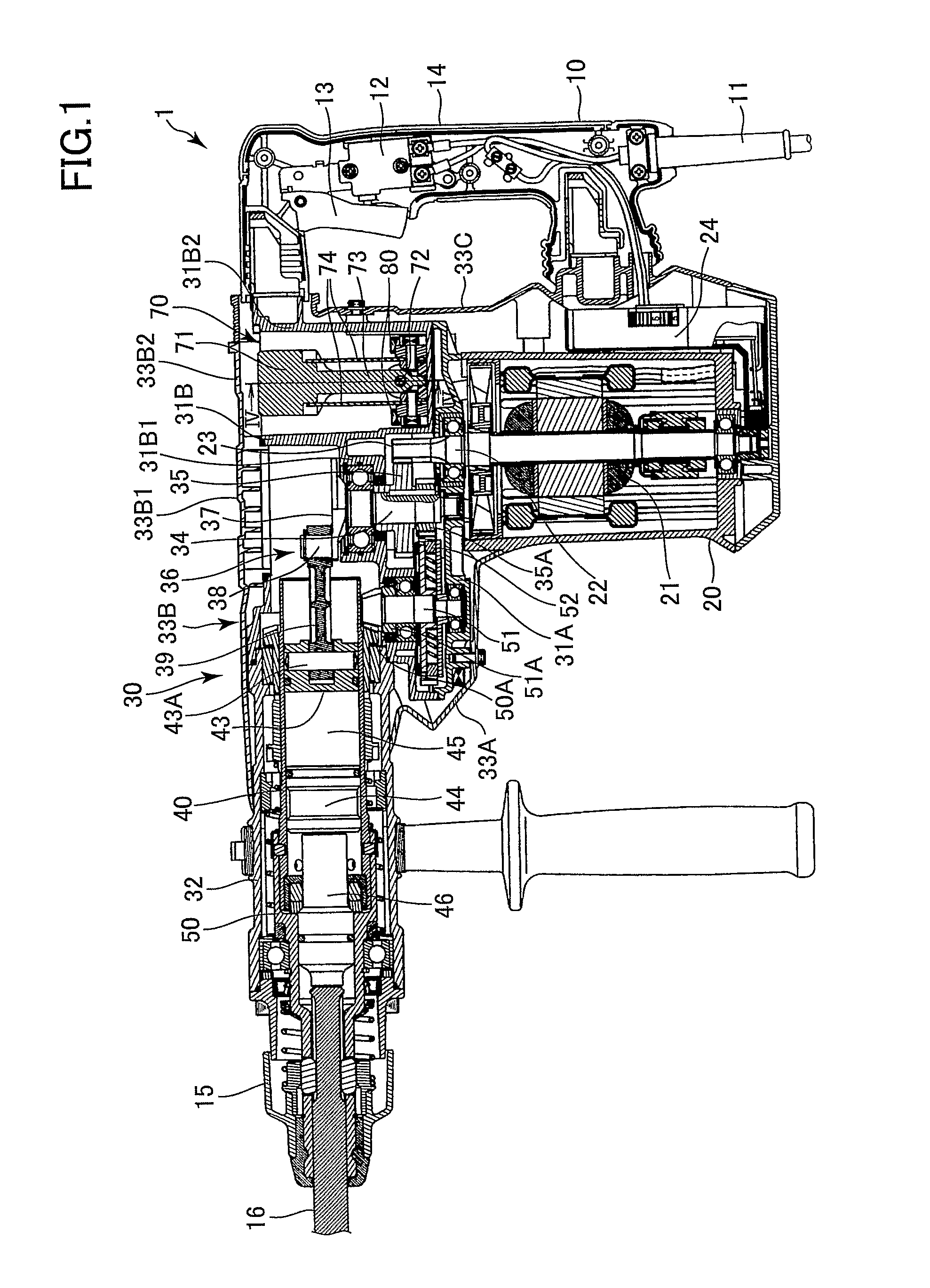

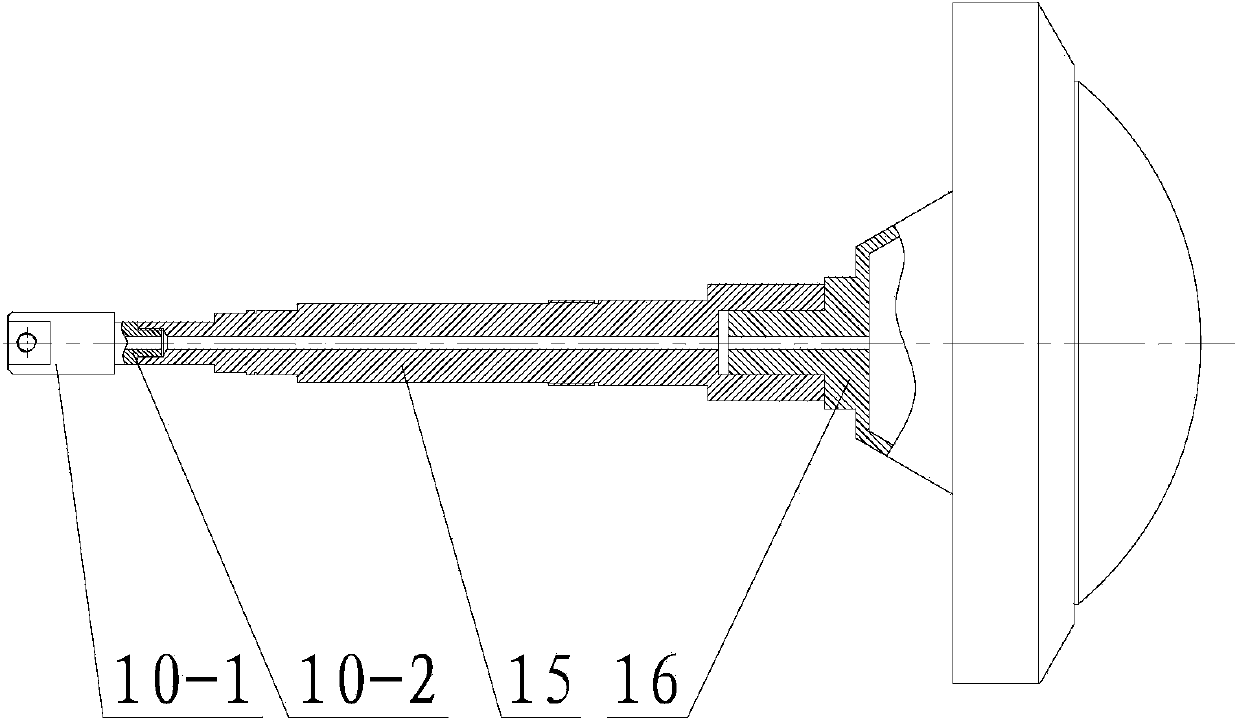

A reciprocating tool (1) includes a housing (20, 30), a driving source (21), a reciprocation conversion unit (34, 36), —and a vibration reduction mechanism (30). The driving source is accommodated in the” housing. The reciprocation conversion unit (34, 36) is supported by the housing and is configured to convert a driving force of the driving source into a reciprocating motion for providing a tool bit (16) movably supported to the housing with a reciprocating motion. The vibration reduction mechanism (70) includes a shaft (72), a weight (71), a support member (73), and a urging portion (74). The shaft i(72)s supported by the housing and extending in a direction perpendicular to directions of the reciprocating motion of the tool bit (41) t and has an axis. The weight (71) is located away from the shaft (72) and is swingable in a swinging direction. The support member (73) swingably supports the weight (71) about the axis of the shaft (72). The urging portion (74) urges the weight (71) toward a prescribed position of the weight in the swinging direction with respect to the housing.

Owner:HITACHI KOKI CO LTD

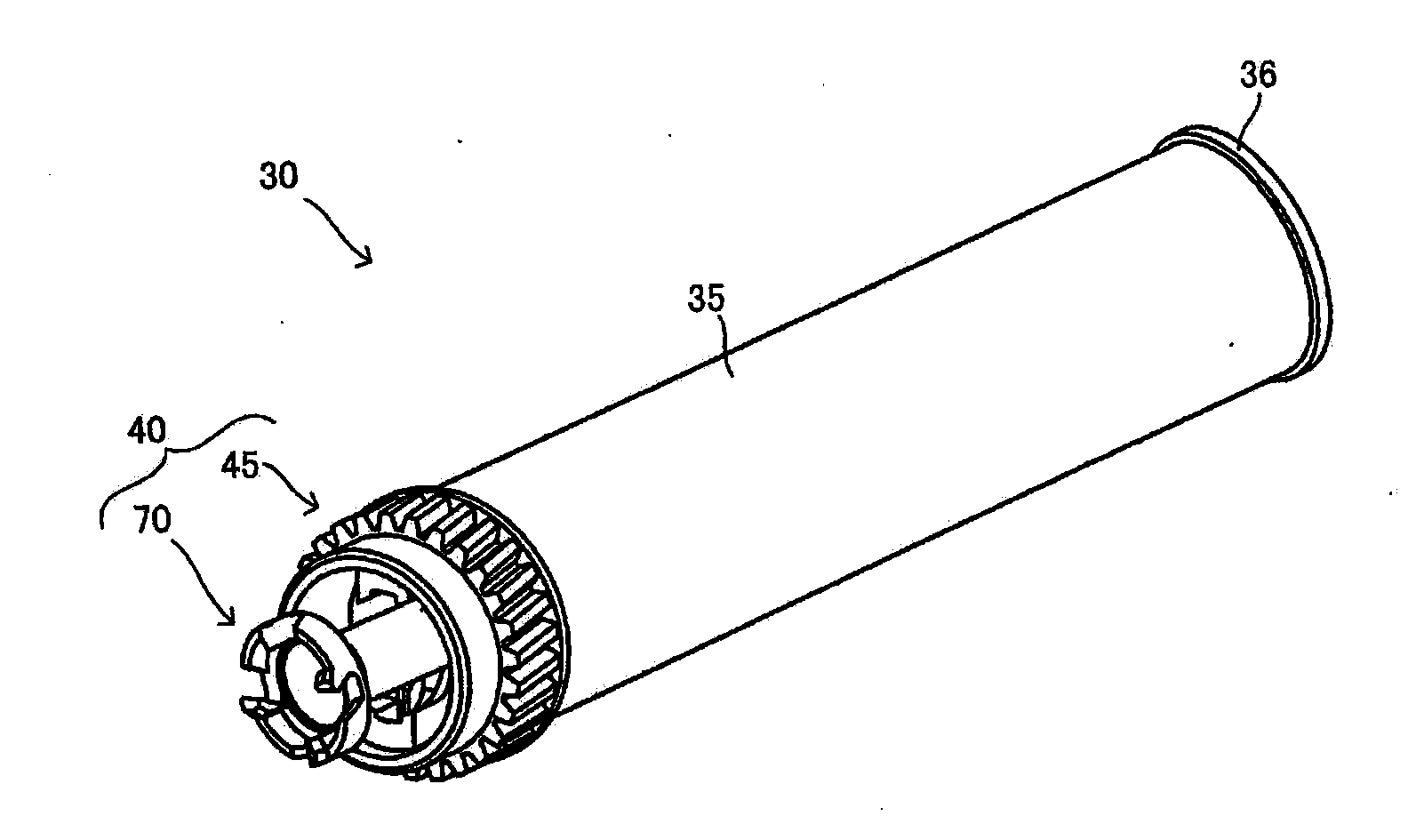

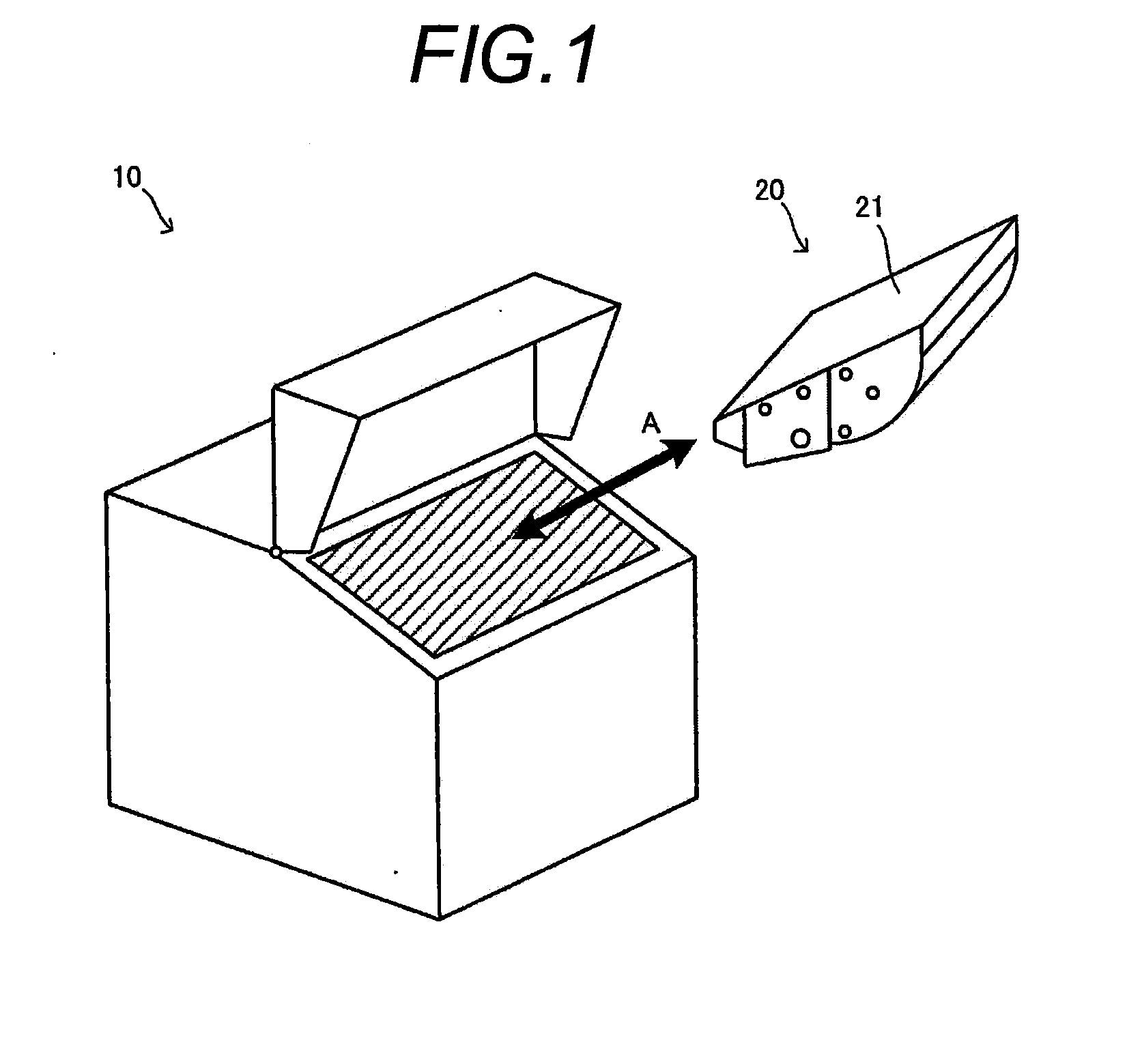

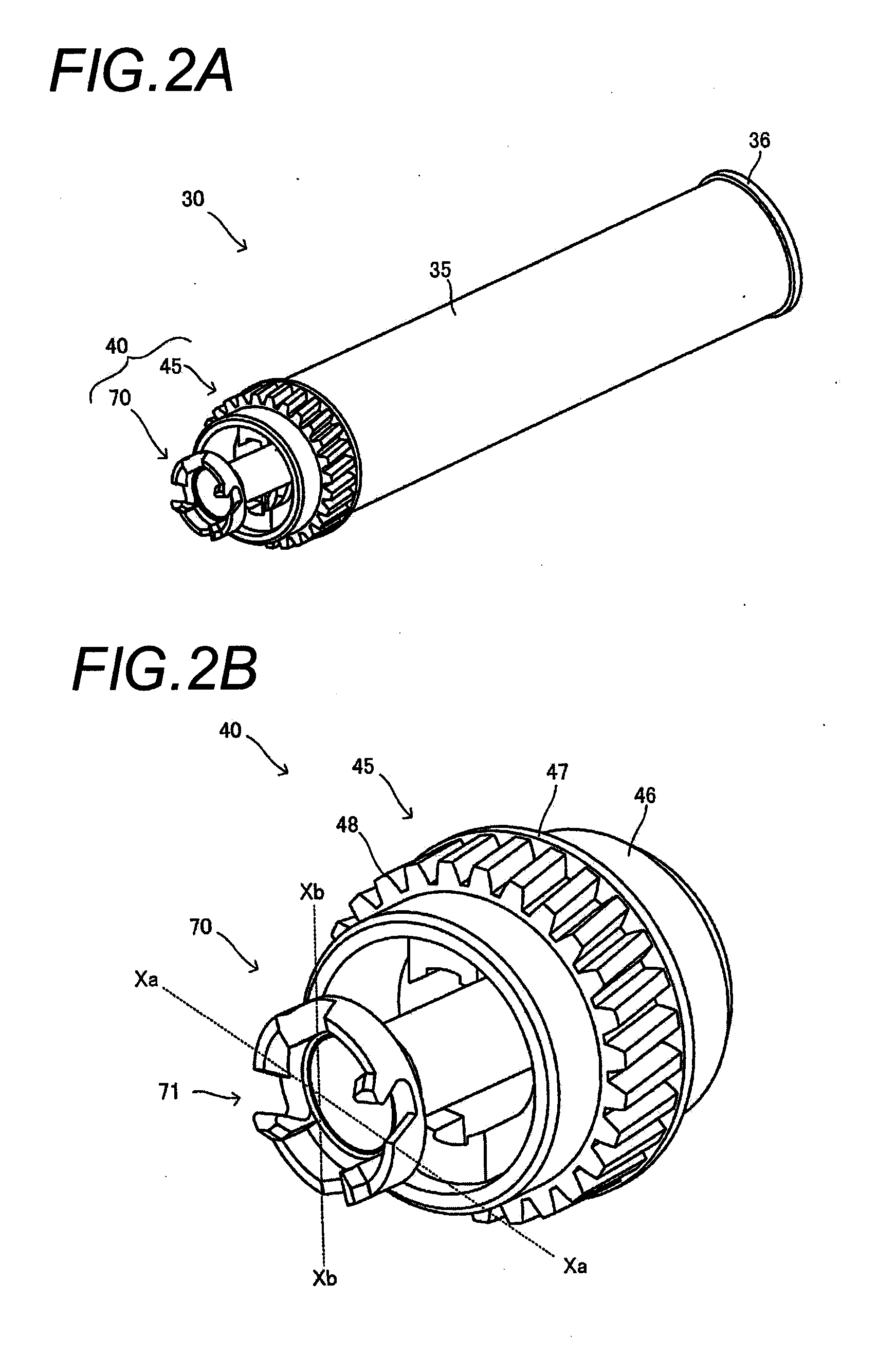

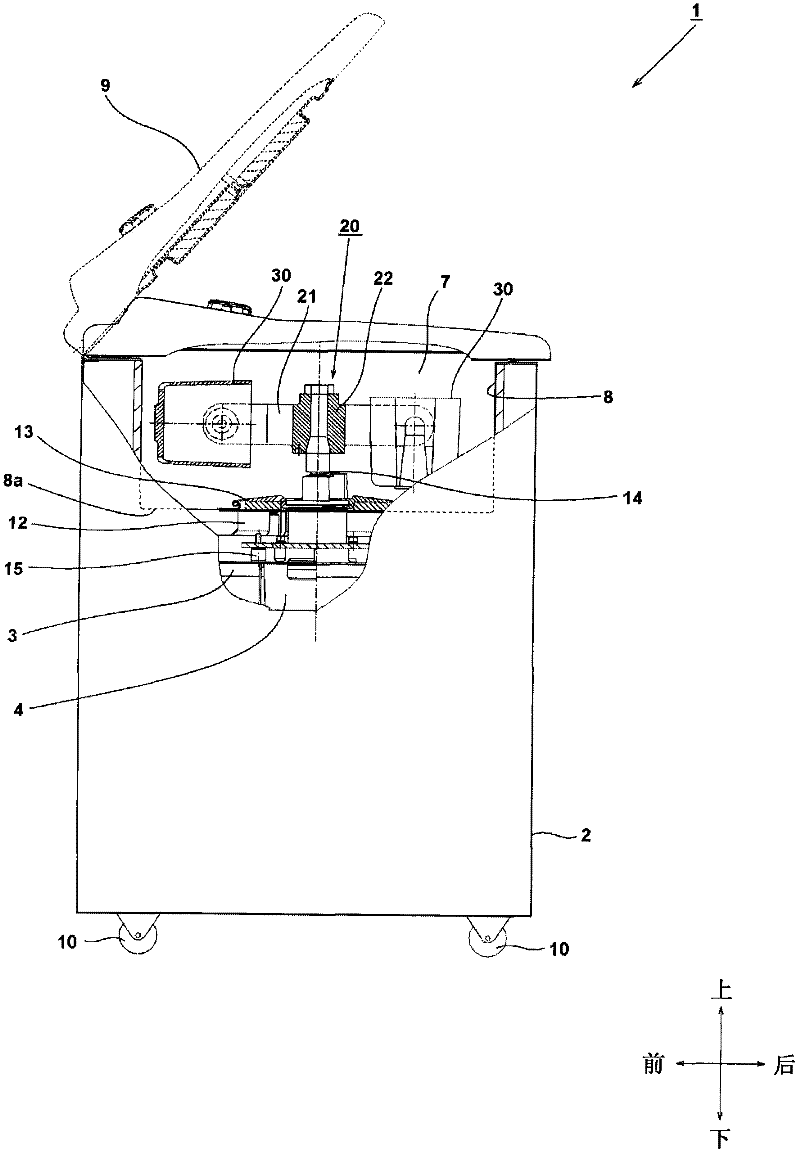

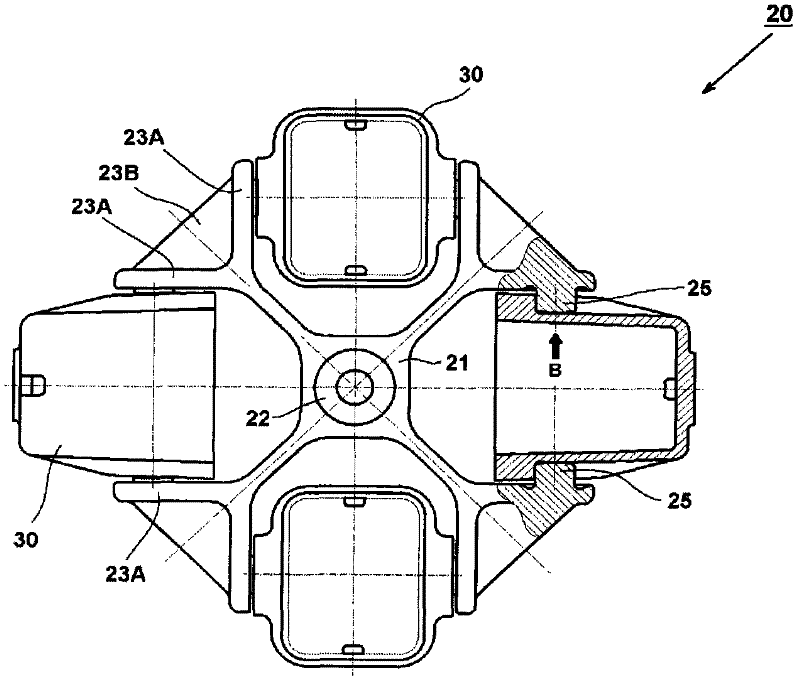

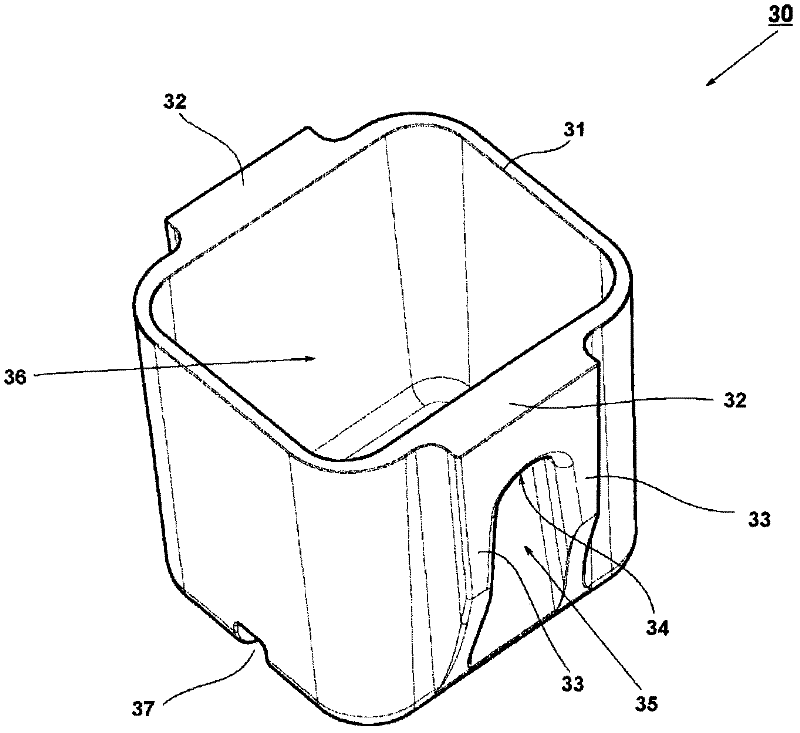

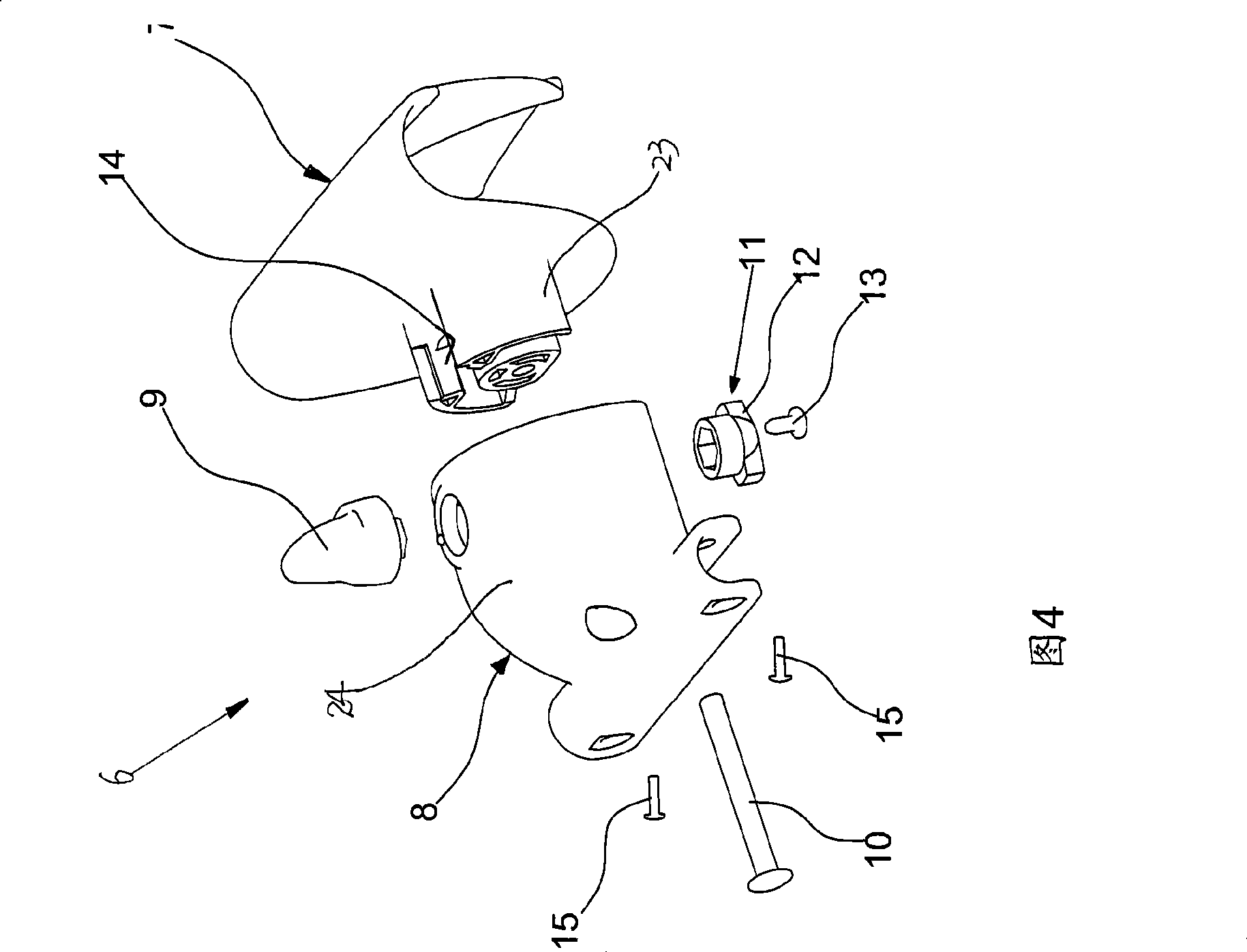

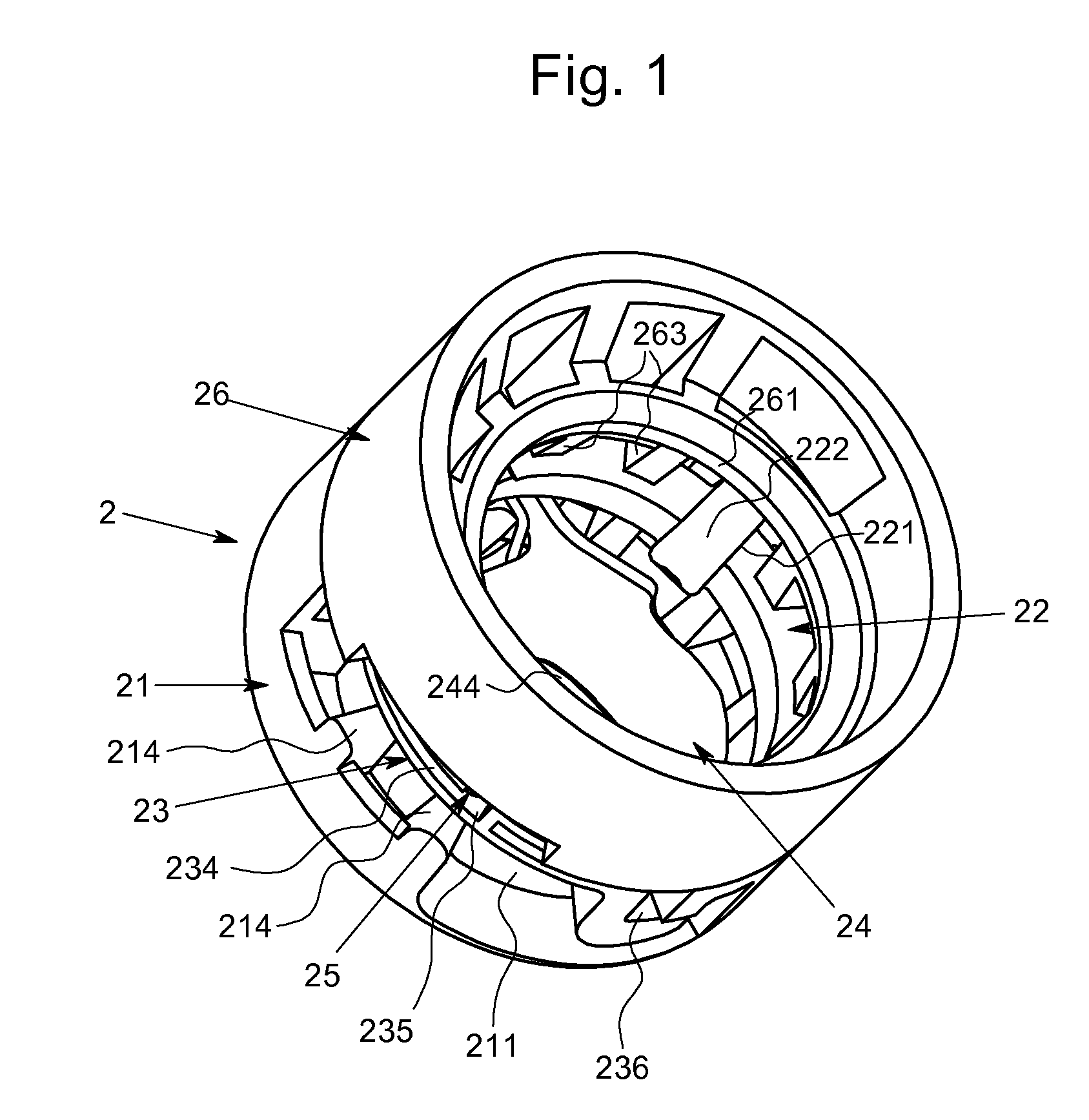

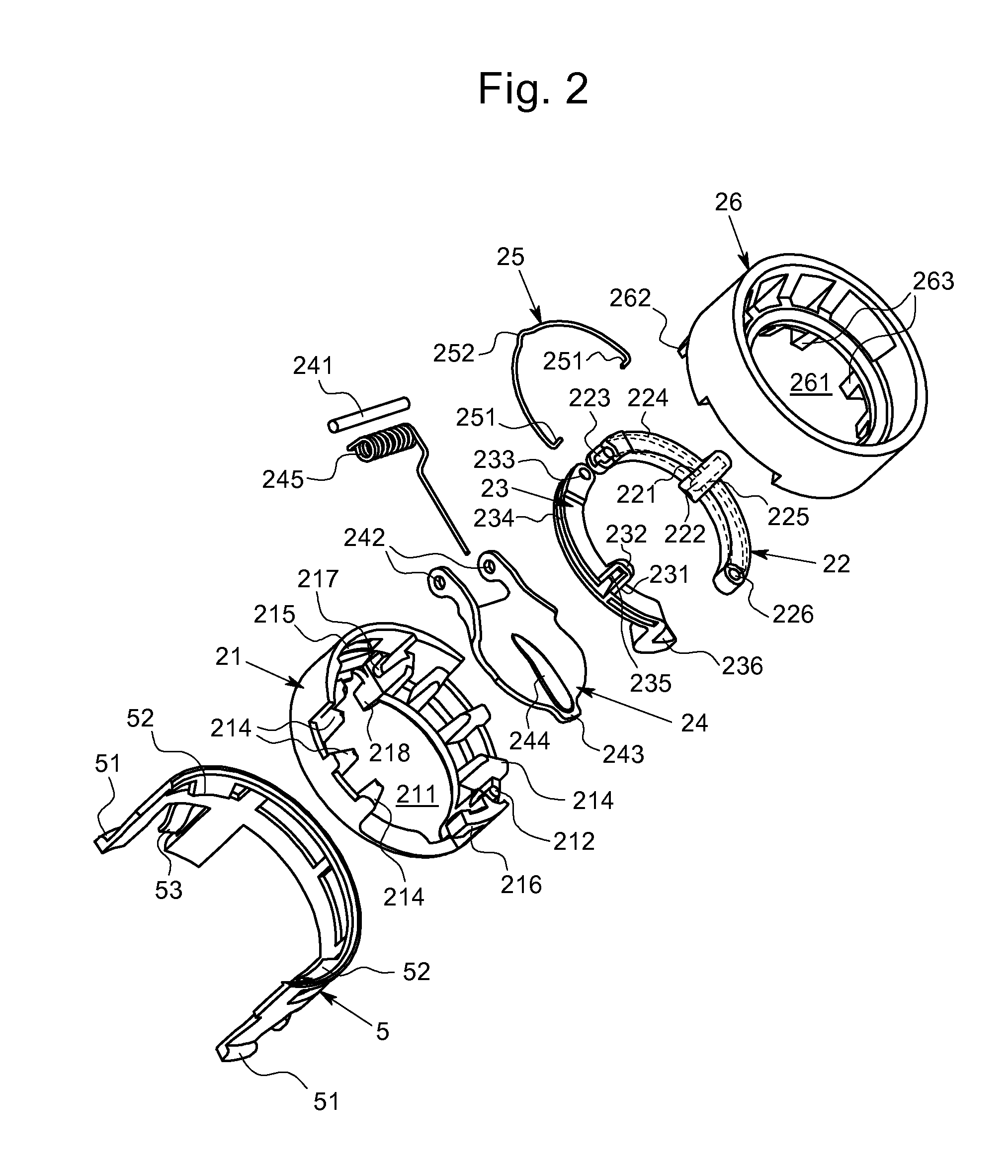

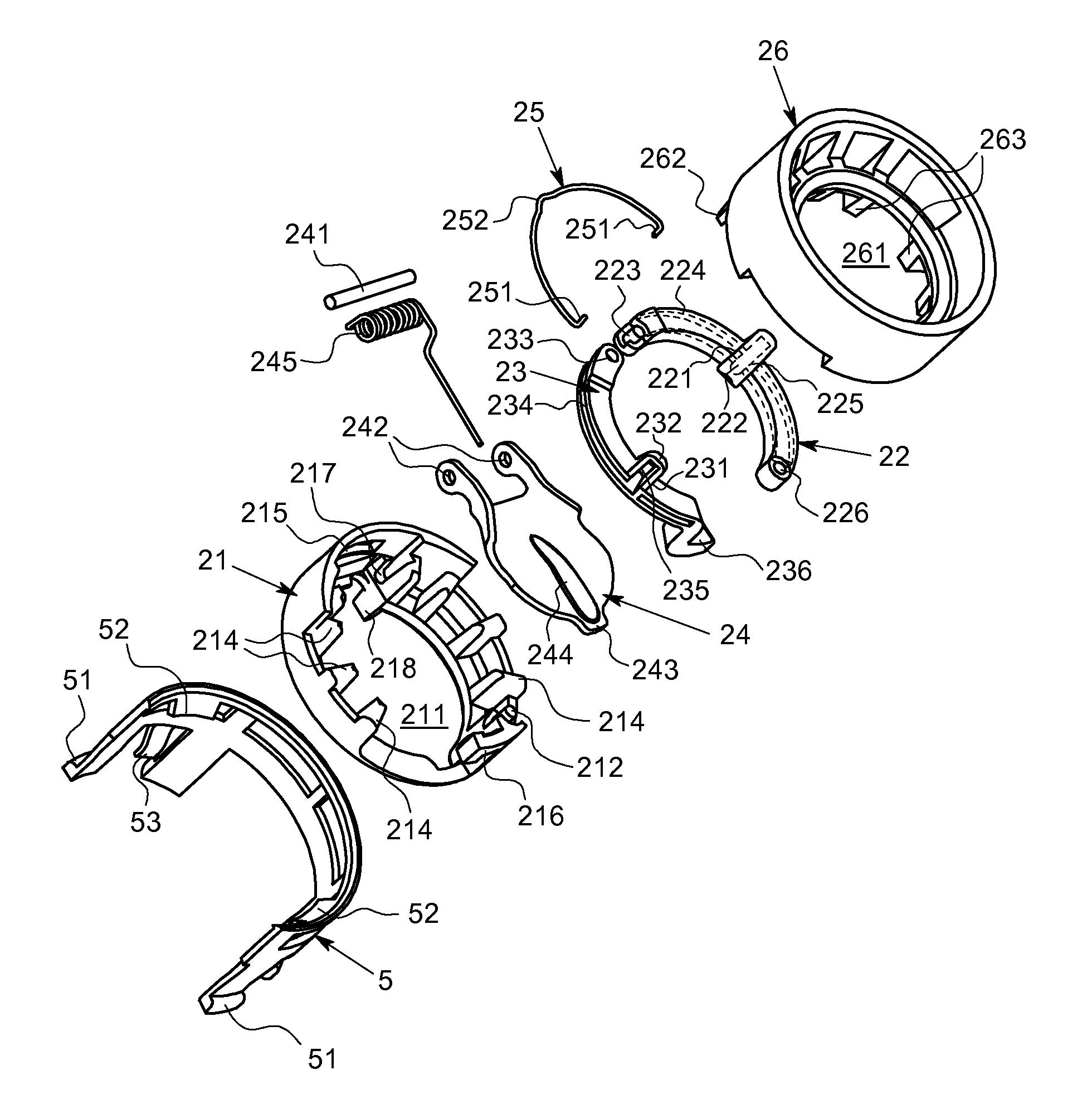

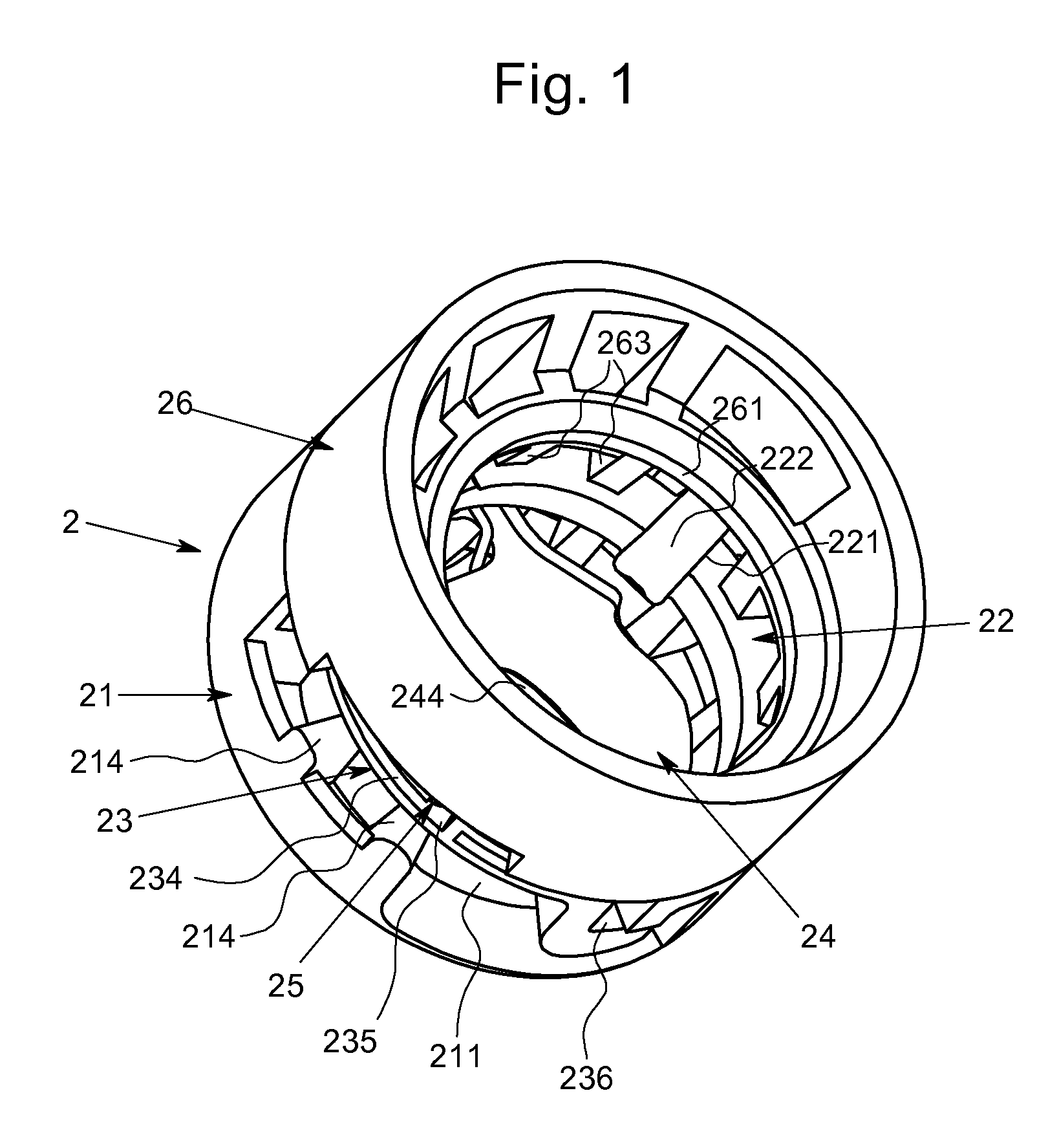

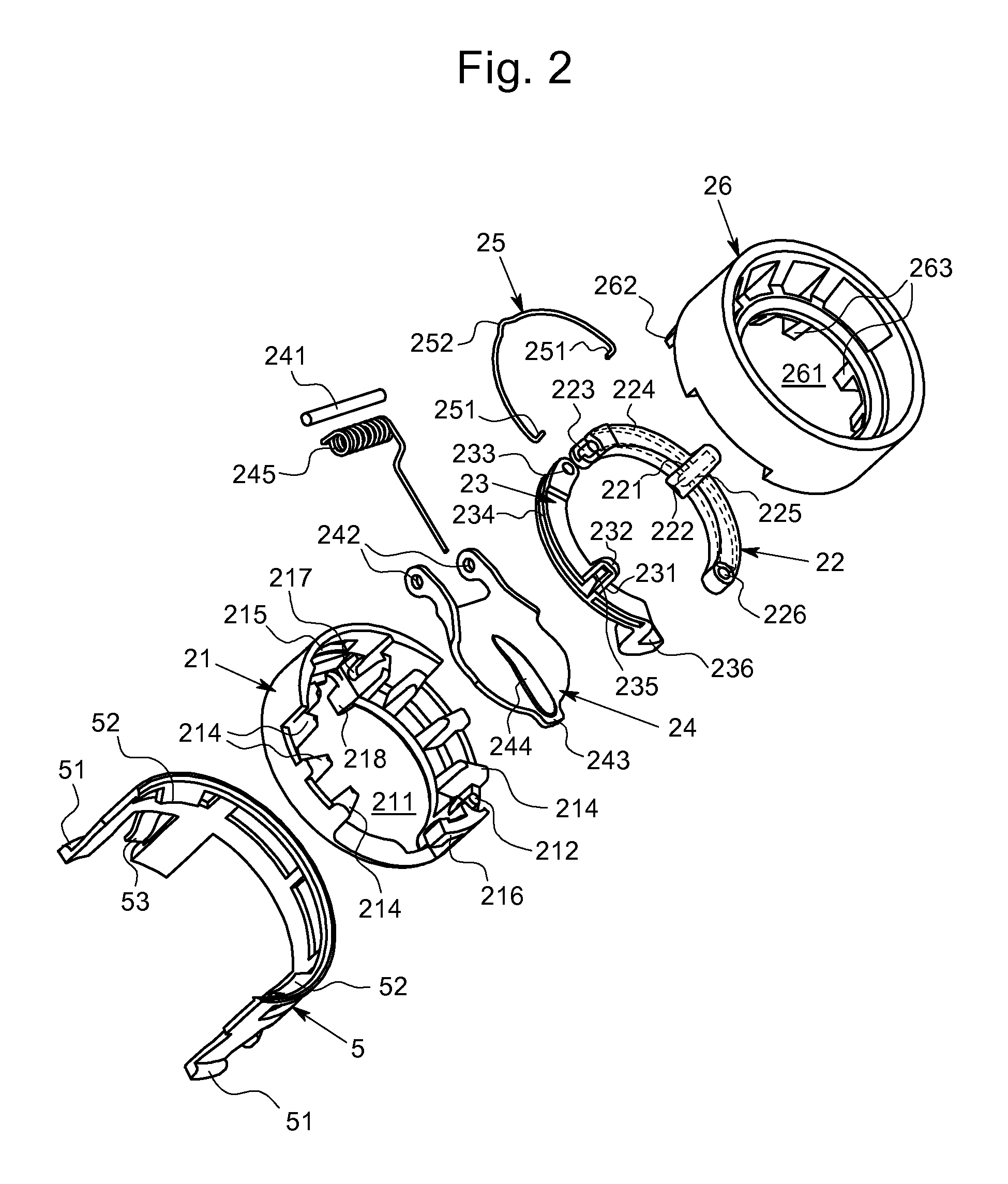

Bearing member, end member, photoreceptor-drum unit, and process cartridge

ActiveUS20160018777A1Easy to produceSmooth swingElectrographic process apparatusEngineeringMechanical engineering

Owner:MITSUBISHI CHEM CORP

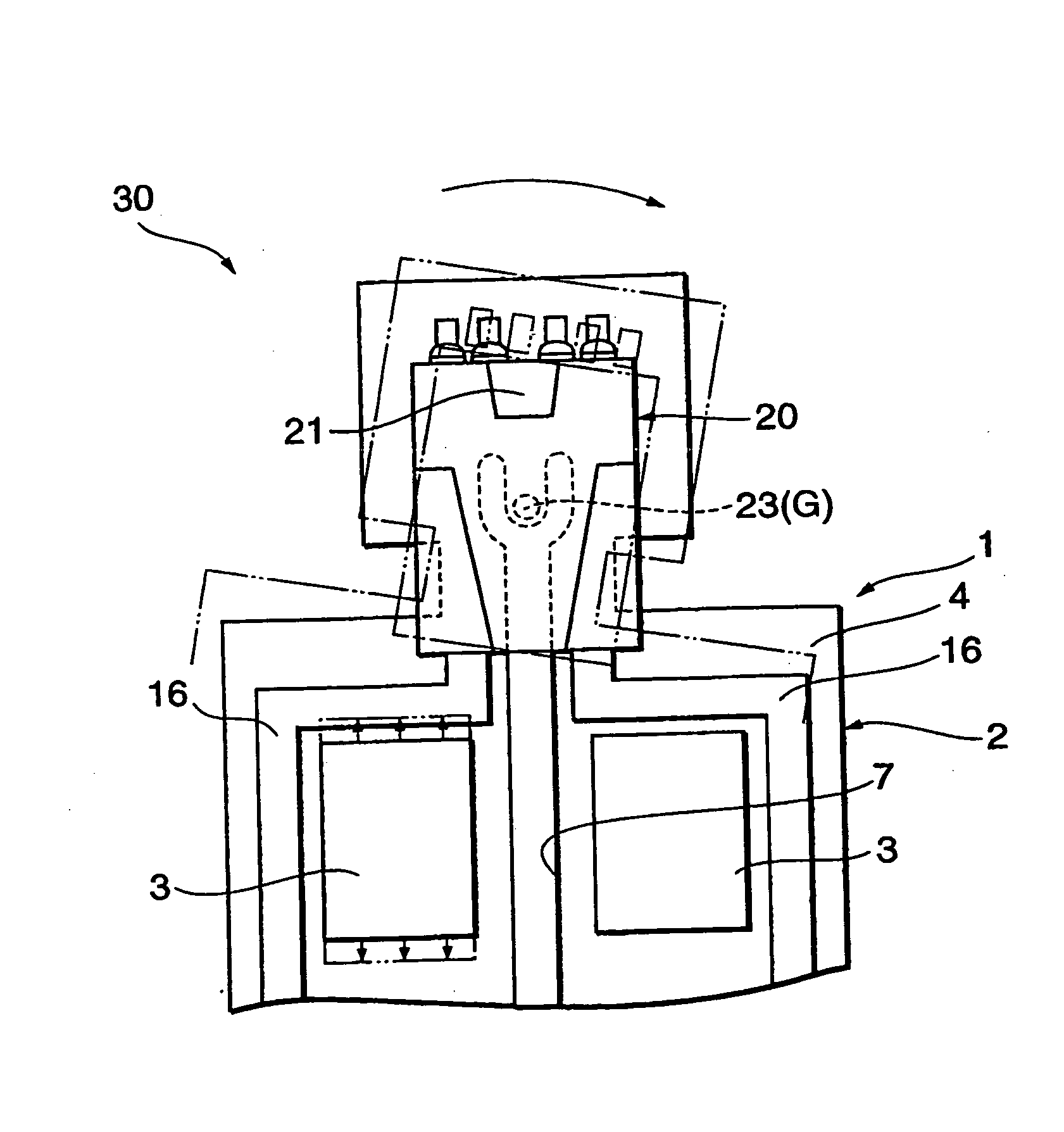

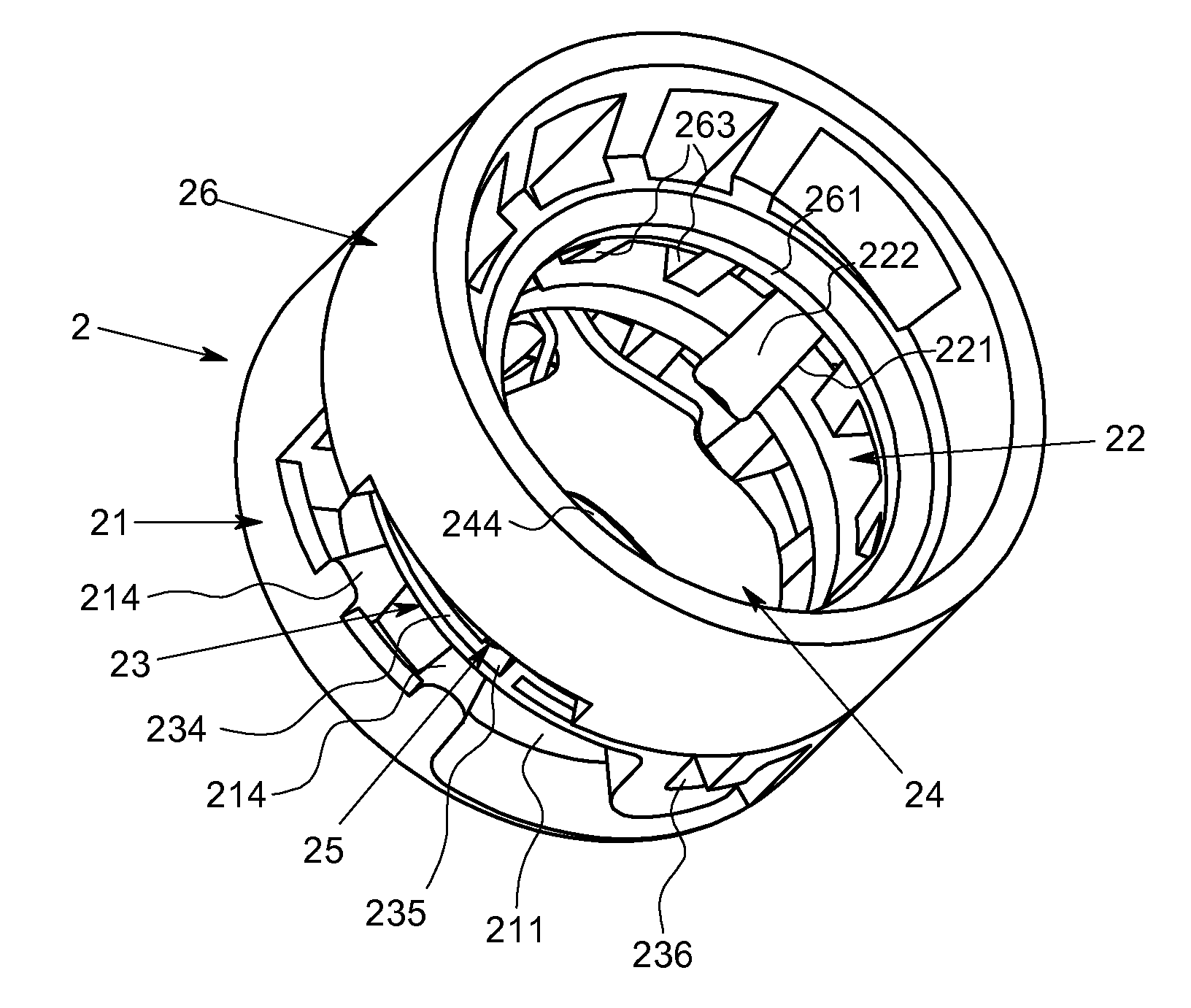

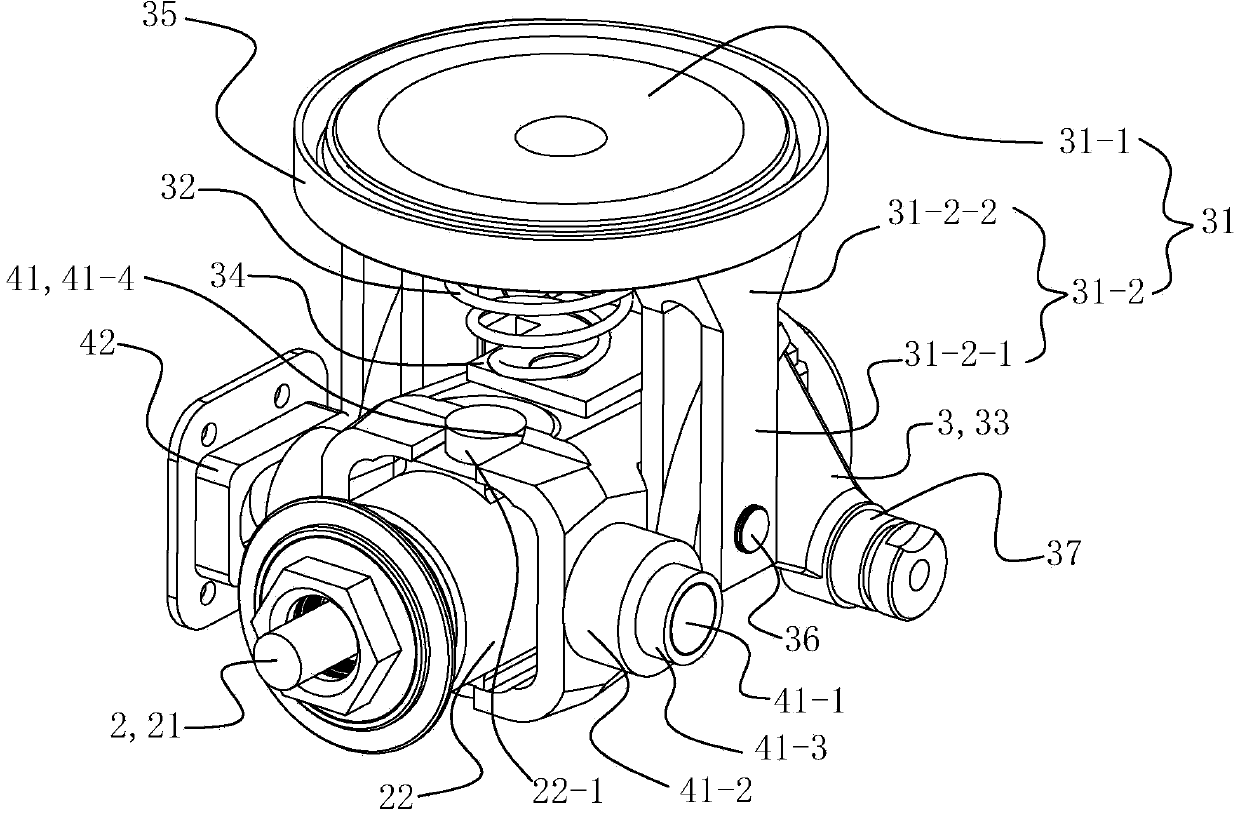

Siwing-bucket-rotor for centrifugal separator, and centrifugal separator

ActiveCN102463195ASmooth swingReduce frictional resistanceCentrifugesEngineeringMechanical engineering

The invention provides a siwing-bucket-rotor for a centrifugal separator. The sliding resistance of hanging buckets during swinging is inhibited so that poor rotation is eliminated. The siwing-bucket-rotor for a centrifugal separator comprises a rotor body. The rotor body is equipped with a plurality of arms, a plurality of hanging buckets and holding pins. The arms extend from the inner rim to the outer rim. The hanging buckets of the same shape are held on the corresponding arms in a swinging manner for holding samples. The holding pins are arranged on the arms in a way that the pins extend toward the tangential direction of the rotary direction of the rotor body and, are used for holding the hanging buckets in a swinging manner. Two clamping portions supported by the holding pins are arranged on the hanging buckets, and are supported by holding pin shafts. The sliding surfaces of holding pins are configured in a way that the axial width of a contact area when the hanging buckets stop swinging and the axial width of the contact area when the hanging buckets swing to a horizontal position through centrifugal separation operation are not fixed. For instance, the axial width of the contact area when the hanging buckets are static is smaller than the axial width of the contact area when the hanging buckets are rotating.

Owner:EPPENDORF HIMAC TECH CO LTD

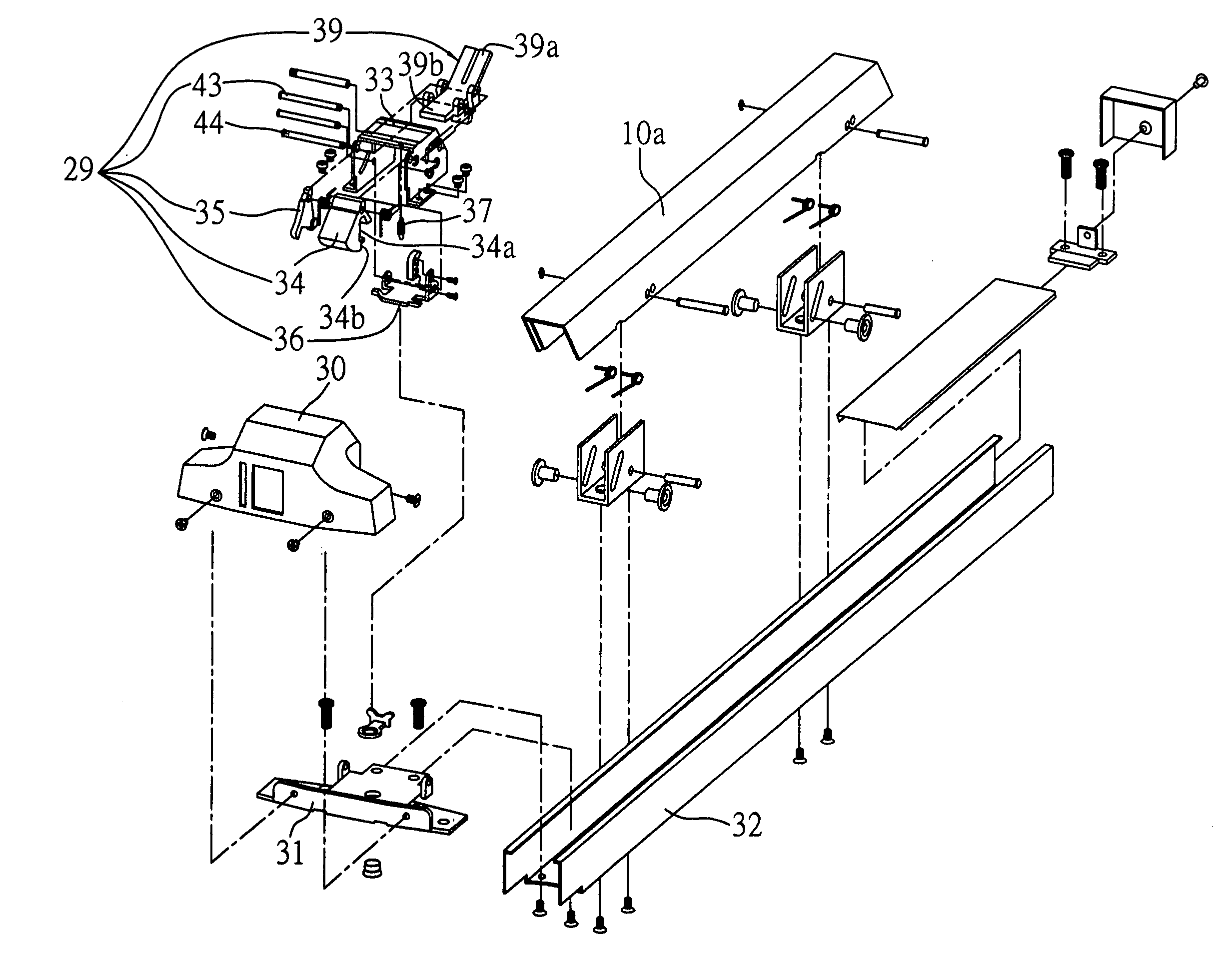

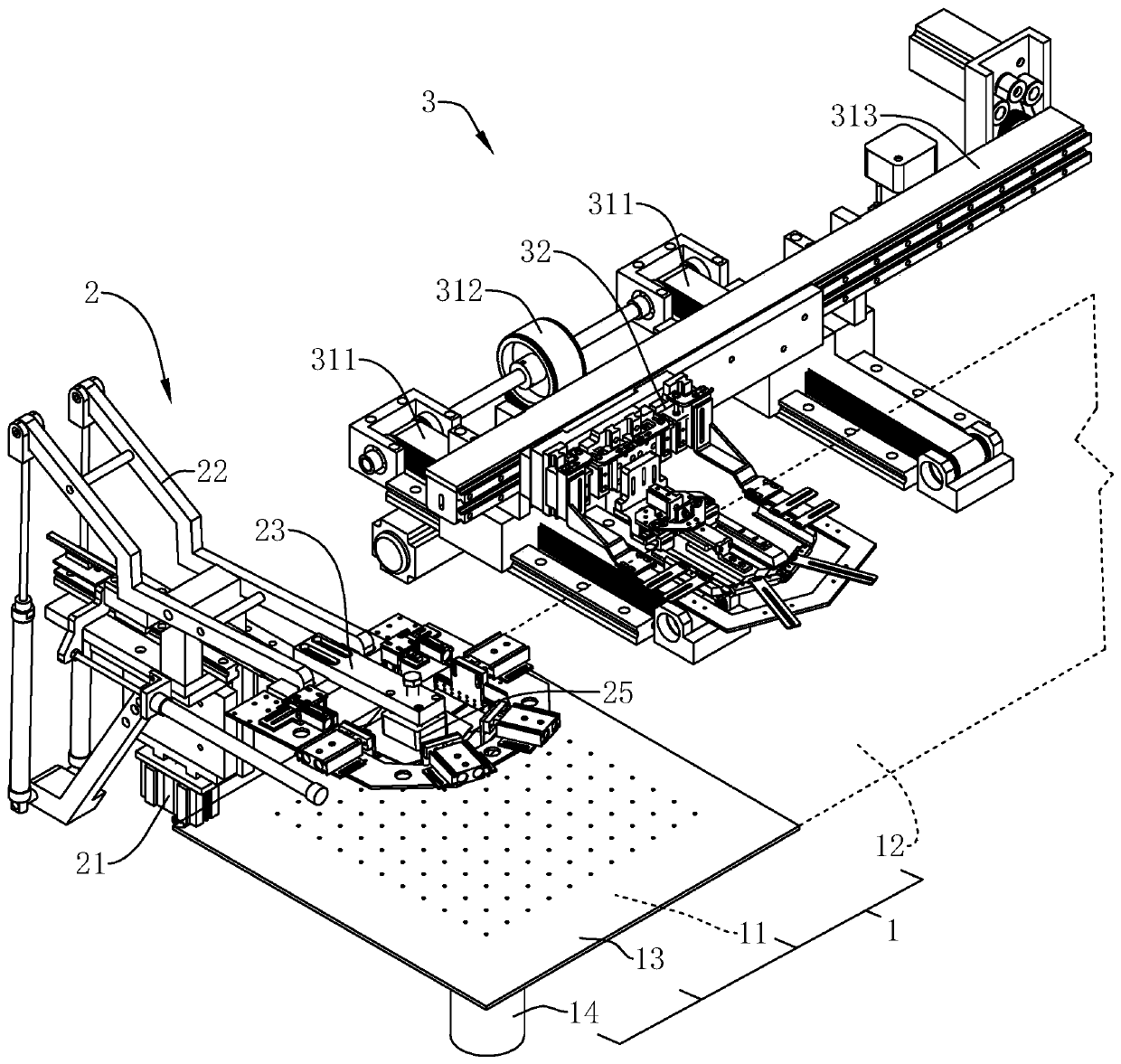

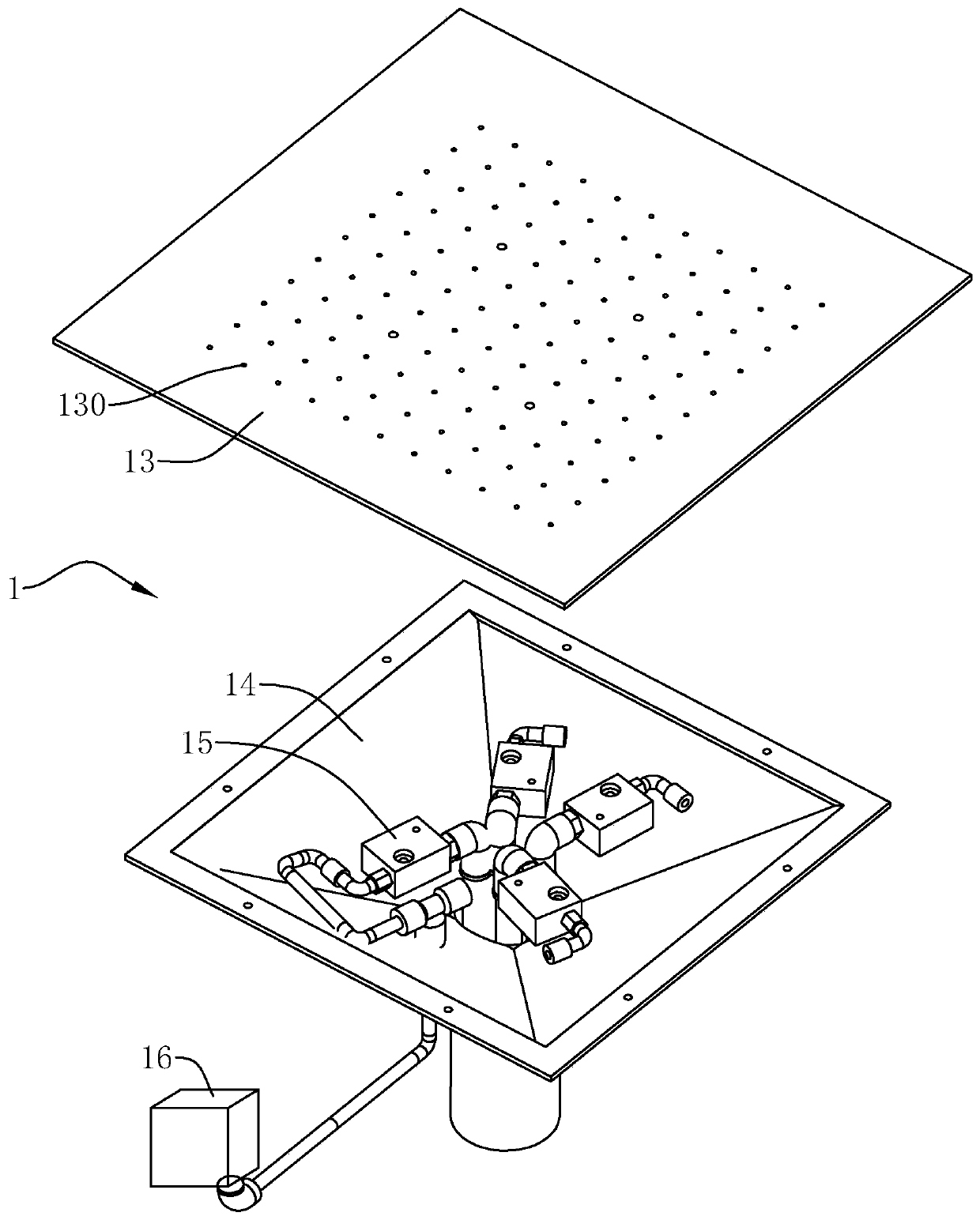

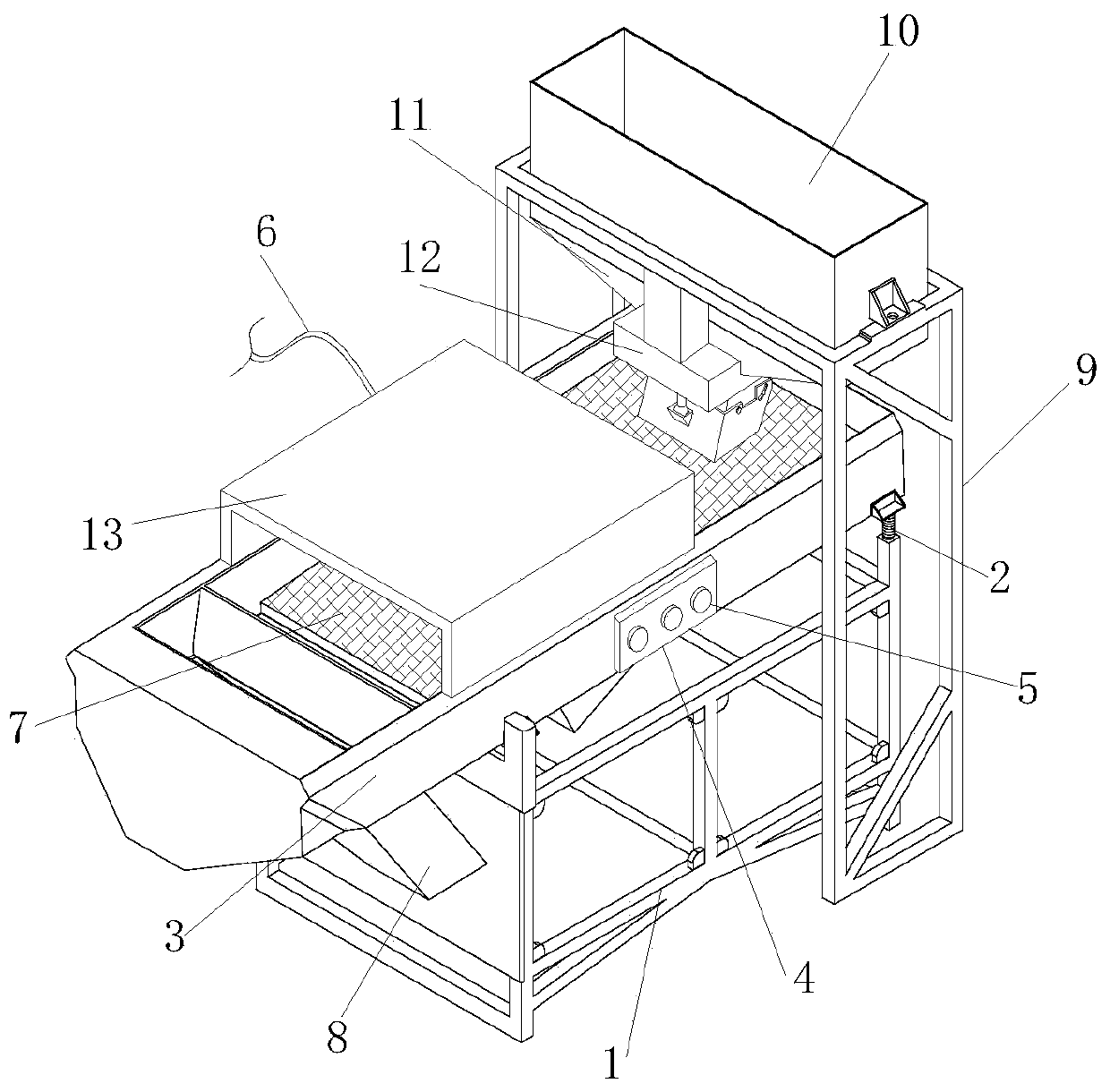

Automatic intelligent patch pocket machine and patch pocket manufacturing method

PendingCN110184754AQuick and efficientGuaranteed uptimeWork-feeding meansSewing-machine control devicesEnvironmentally friendlyReliability engineering

The invention discloses an automatic intelligent patch pocket machine and a patch pocket manufacturing method, and belongs to the technical field of patch pocket machines. In order to achieve the purposes of the efficiency, reliability and comprehensive performance of an intelligent patch pocket, according to the technical scheme, the machine is characterized by comprising a machine frame erectedon the ground, a working platform fixedly installed on the machine frame, used for adsorbing a bottom layer fabric and sewing the fabric, and provided with an adsorption setting region and a sewing region, a pocket fabric folding mechanism located above the adsorption setting region and fixedly installed on the machine frame for supporting, positioning, adsorbing, folding and placing the pocket fabric, a fabric pressing moving mechanism installed on the machine frame and used for switching, reciprocating and moving between the adsorption setting region and the sewing region, the fabric is subjected to outer frame edge pressing and an inner frame edge pressing, the fabric is pressed on the working platform to perform plane movement, the fabric is taken from the adsorption setting region tobe moved to the sewing region, dual-thread sewing is achieved through a sewing machine, and the machine achieves the effects of being efficient, rapid, stable and environmentally friendly.

Owner:傅东明

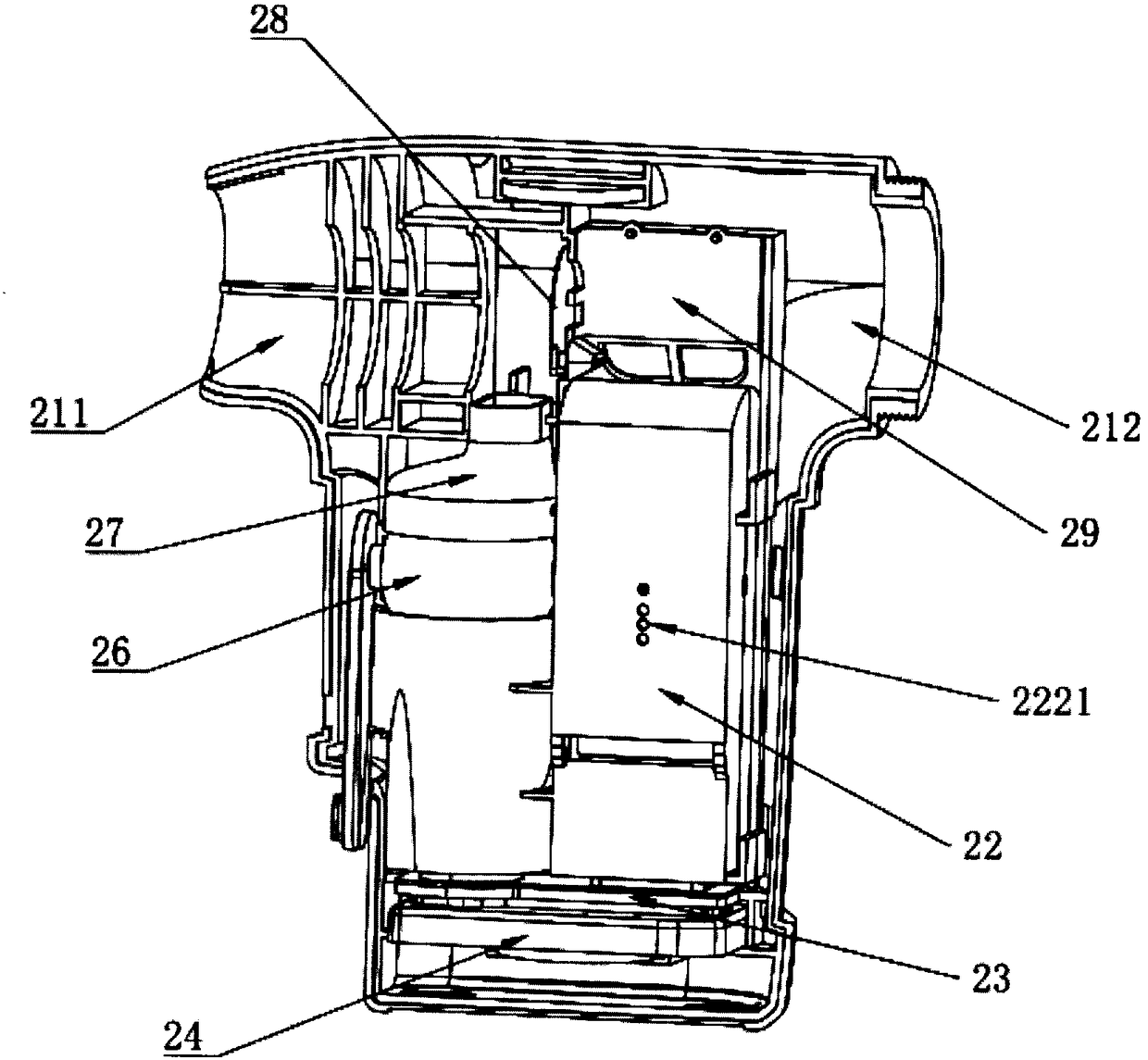

Biological culture device based on hemodialyzer

ActiveCN106190838AGet weight in real timeEasy to manufactureBioreactor/fermenter combinationsBiological substance pretreatmentsHemodialysisMicrobiology

The invention provides a biological culture device based on a hemodialyzer. The biological culture device comprises the hemodialyzer, a circulating pump, a swing weighing device, a sample collecting and storing device, a medicine-dosing device and a culture bag. The culture bag comprises a main culture bag and an auxiliary culture bag. The main culture bag is connected with the two ends inside a hemodialyzer main body to form a main circulation loop, and the auxiliary culture bag is connected with the two ends outside the hemodialyzer main body to form an auxiliary circulation loop. The sample collecting and storing device and the medicine-dosing device are connected with a pipe between the main culture bag and the hemodialyzer. The biological culture device is a cell or bacterium culture device which can monitor culture conditions, keep the monitor culture conditions stable, perform automatic liquid adding and sample, can simulate medicine concentration changes and is based on the hemodialyzer.

Owner:NANJING NORMAN BIOLOGICAL TECH

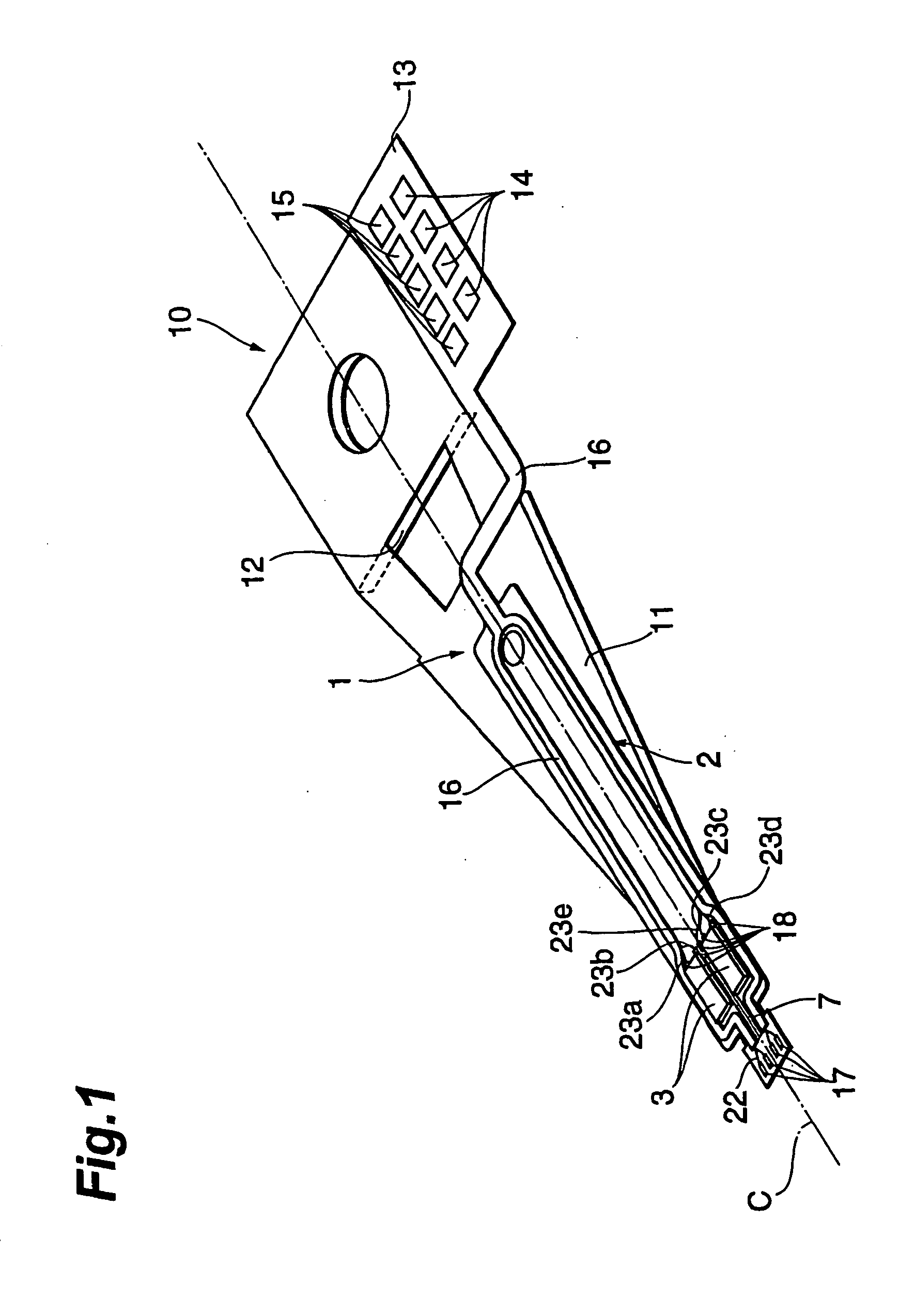

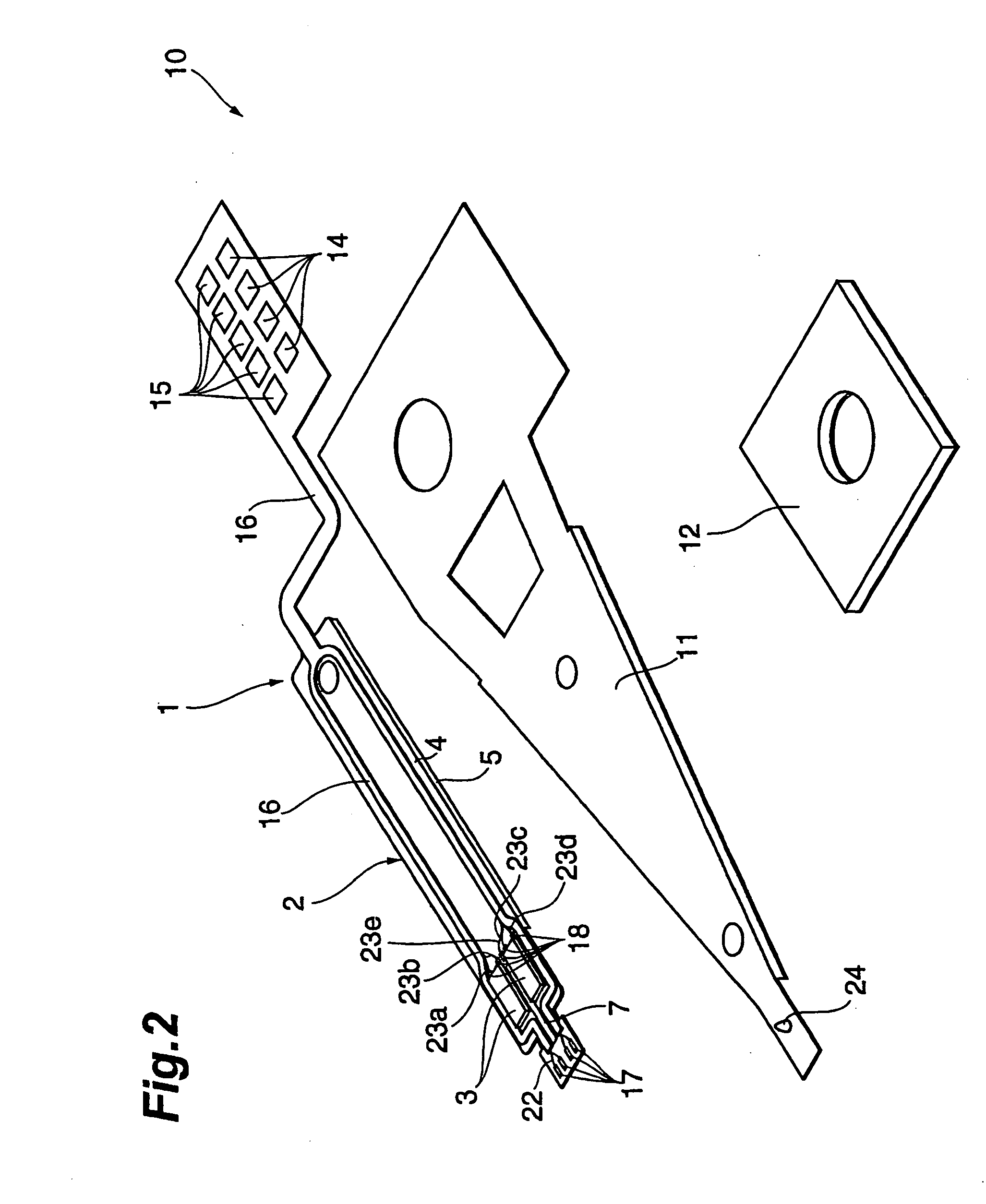

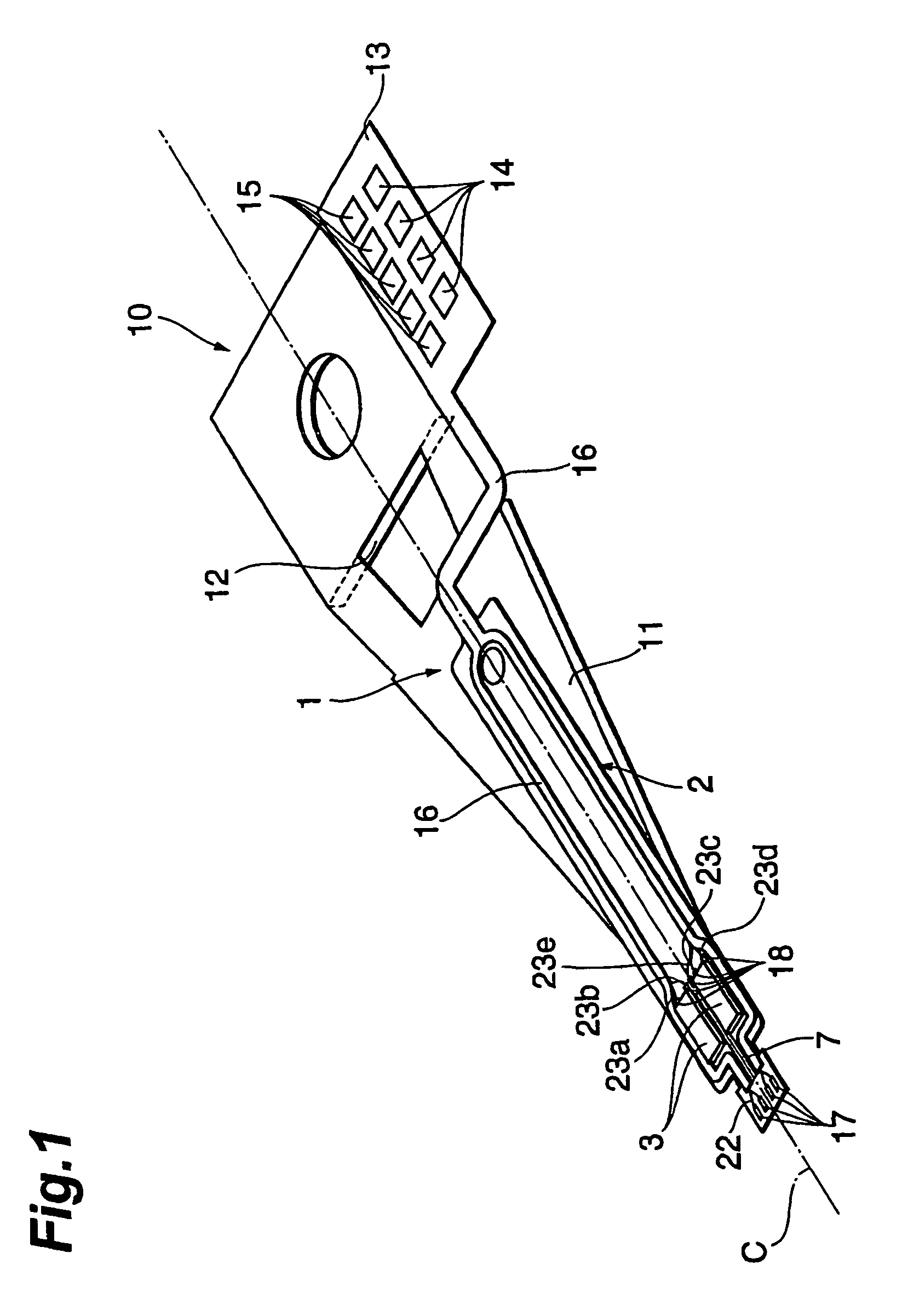

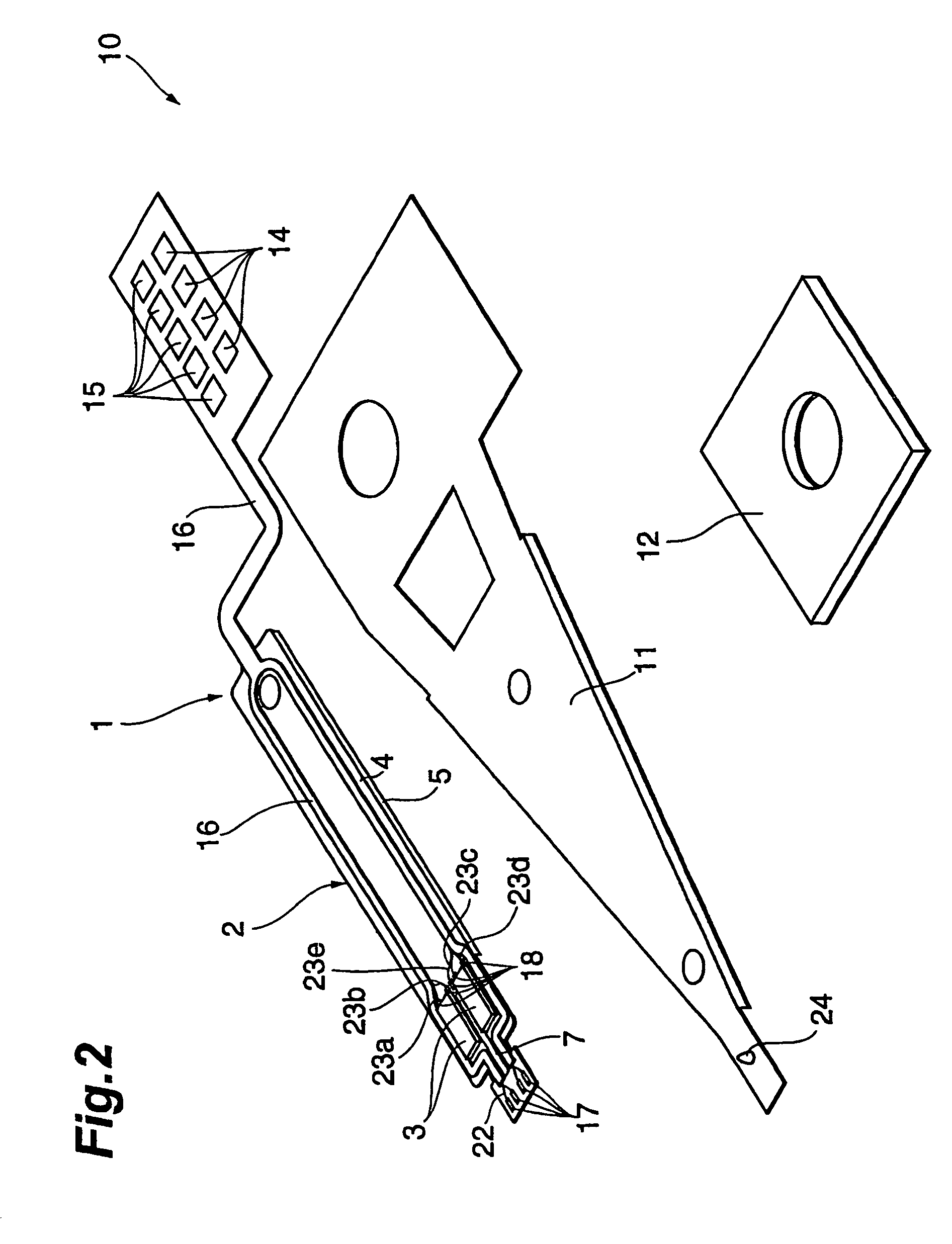

Flexure, suspsension, and head gimbal assembly

InactiveUS20050047024A1Improve accuracyIncrease speedElectrical connection between head and armArm with actuatorsEngineeringGimbal

A flexure is provided with a main body on which a wire for energizing a head slider is disposed. Head slider is mounted at the front end of the flexure. Two piezoelectric layer units, each including layered piezoelectric elements, are disposed so that two of the units sandwich a line that extends from head slider to a base portion of an arm member. A voltage can be applied individually to each of the piezoelectric elements. The shape of the piezoelectric layer units are changed by adjusting the voltage applied to each of the piezoelectric elements, thereby moving head slider freely.

Owner:TDK CORPARATION

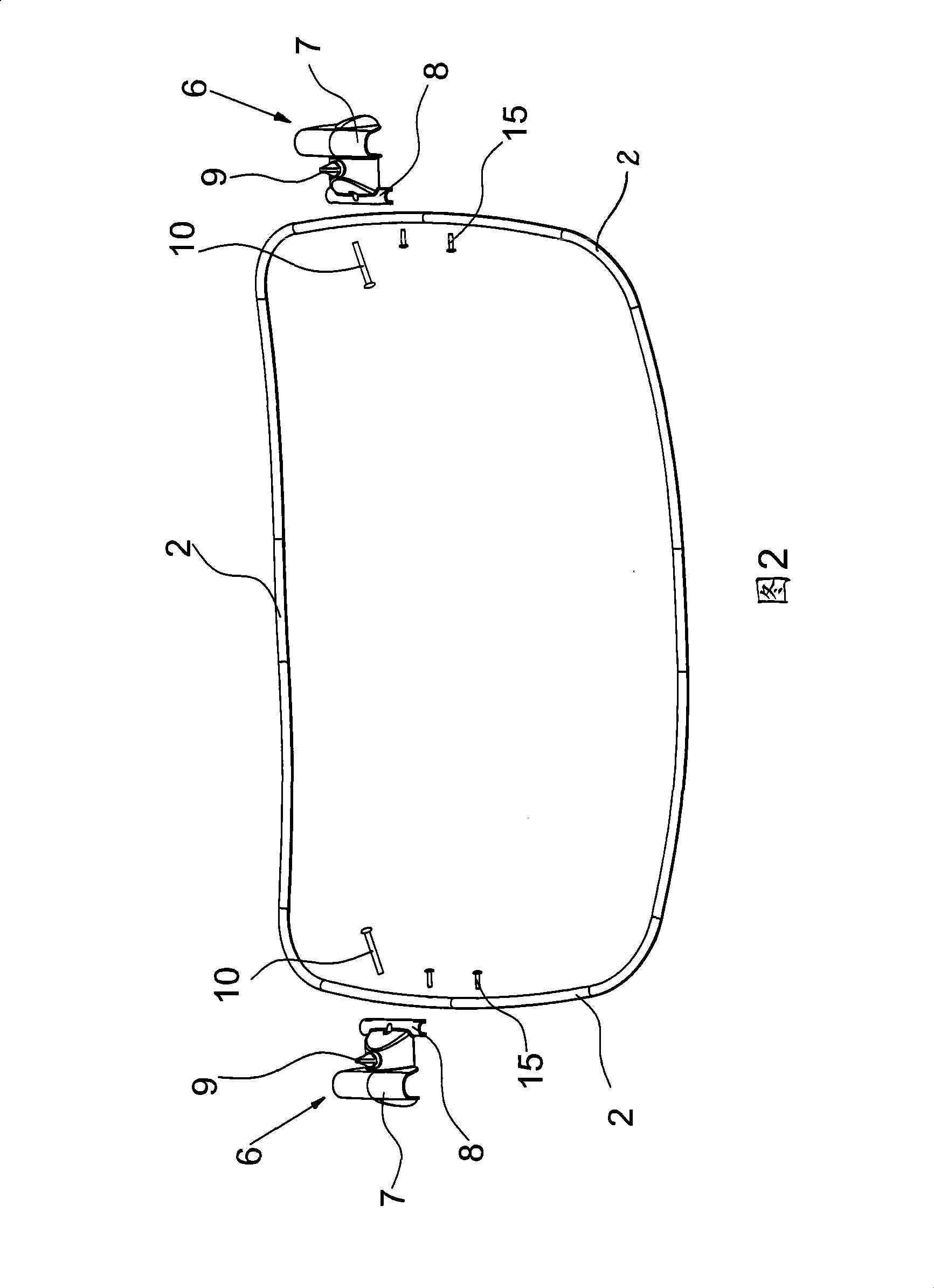

Slider for slide fastener with automatic stopper

A slider for a slide fastener with an automatic stopper, includes: a body; a pull; a pawl rod; a leaf spring; and a cover including front, back, side and upper walls. The side walls are provided at respective centers thereof with openings through which a pivotal shaft of the pull can be passed. A pair of mounting parts are provided in the front and in the back on an upper wing plate of the body. Holding mechanisms for holding the leaf spring are provided in the front and in the back on an inner face of the cover at respective positions inwardly separated from the front wall and the back wall. The leaf spring defines spaces between the holding mechanisms and the upper wall. The holding mechanisms hold the leaf spring at positions inwardly separated from opposite ends thereof. The cover is fixed to the front and back mounting parts.

Owner:YKK CORP

Reciprocating tool

ActiveUS8261854B2Extended service lifeReduce MechanismsReciprocating drilling machinesConstructionsReciprocating motionEngineering

A reciprocating tool (1) includes a housing (20, 30), a driving source (21), a reciprocation conversion unit (34, 36), —and a vibration reduction mechanism (30). The driving source is accommodated in the” housing. The reciprocation conversion unit (34, 36) is supported by the housing and is configured to convert a driving force of the driving source into a reciprocating motion for providing a tool bit (16) movably supported to the housing with a reciprocating motion. The vibration reduction mechanism (70) includes a shaft (72), a weight (71), a support member (73), and a urging portion (74). The shaft i(72)s supported by the housing and extending in a direction perpendicular to directions of the reciprocating motion of the tool bit (41) t and has an axis. The weight (71) is located away from the shaft (72) and is swingable in a swinging direction. The support member (73) swingably supports the weight (71) about the axis of the shaft (72). The urging portion (74) urges the weight (71) toward a prescribed position of the weight in the swinging direction with respect to the housing.

Owner:KOKI HLDG CO LTD

Off-line-type gas bag polishing tool finisher

ActiveCN103586775AWill not affect normal workImprove work efficiencyAbrasive surface conditioning devicesDrive wheelReducer

The invention discloses an off-line-type gas bag polishing tool finisher, and relates to a gas bag polishing device. The off-line-type gas bag polishing tool finisher is high in efficiency, low in cost, easy to operate and high in reliability. The off-line-type gas bag polishing tool finisher is provided with a swing motor, a planetary reducer, a swing main shaft box, a base, a swing shaft, a gas bag main shaft box, a swing arm, a driving wheel, a belt, a rotary connector, a rotary connector support, a driven wheel, a feeding motor, a protective cover, a gas bag main shaft, a gas bag tool, a lead screw support, a grinding wheel main shaft, a finishing grinding wheel, a grinding wheel main shaft box, a lead screw, a sliding block, a swing arm supporting base, a supporting bearing, a barb frame, a barb bearing, an arc guide rail, a guide rail, a gas bag driving motor and a grinding wheel driving motor. The off-line-type gas bag polishing tool finisher can effectively improve the working efficiency of a gas bag polishing machine and meanwhile has obvious effects in the aspects of improving the finishing efficiency of the gas bag tool, improving the reliability of the finishing process, reducing the cost and the size of finishing equipment and the like.

Owner:XIAMEN UNIV

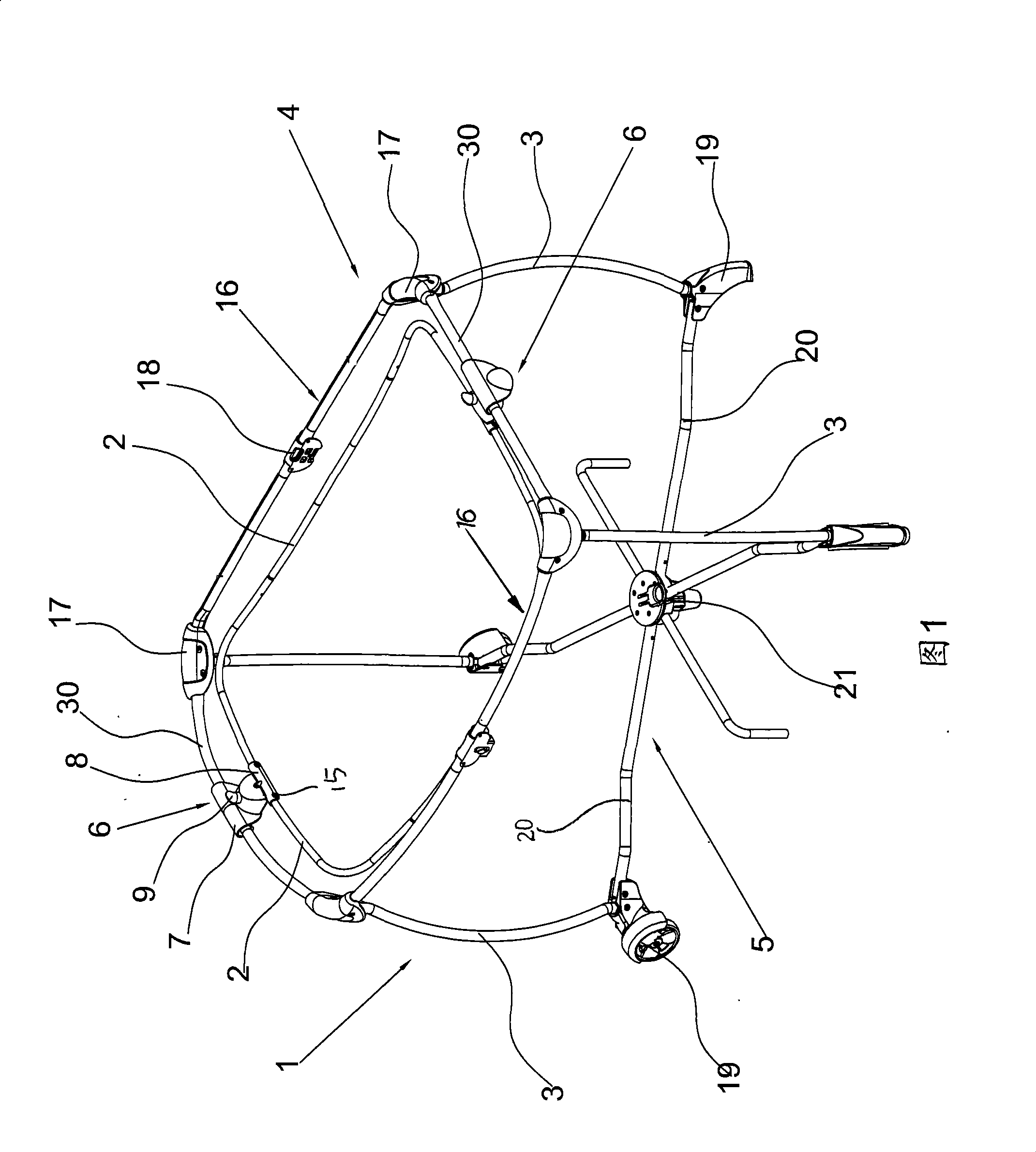

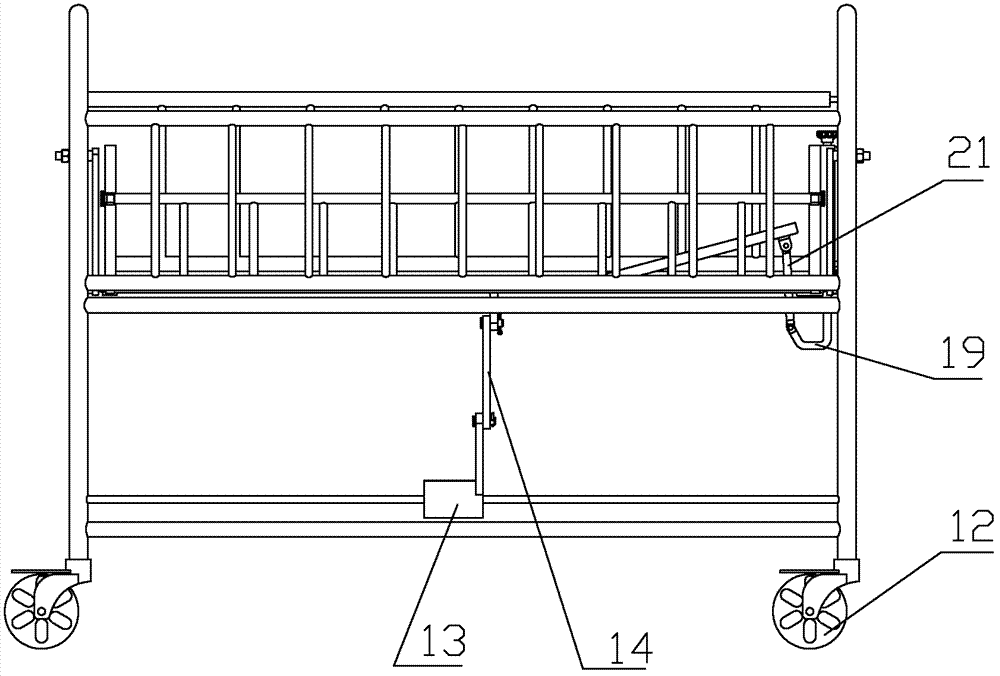

Game enclosure frame with sleeping basket

Owner:GOODBABY CHILD PROD CO LTD

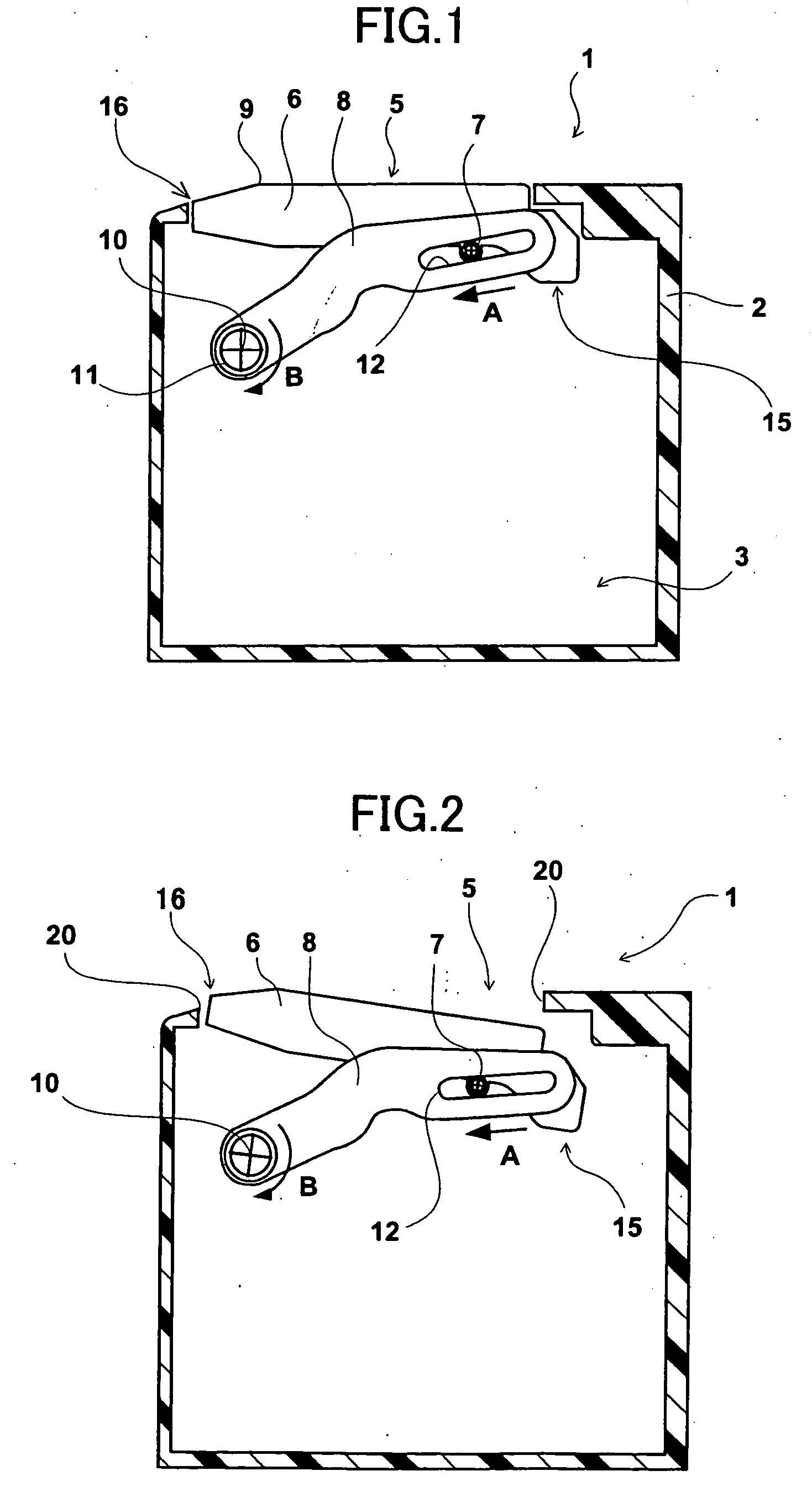

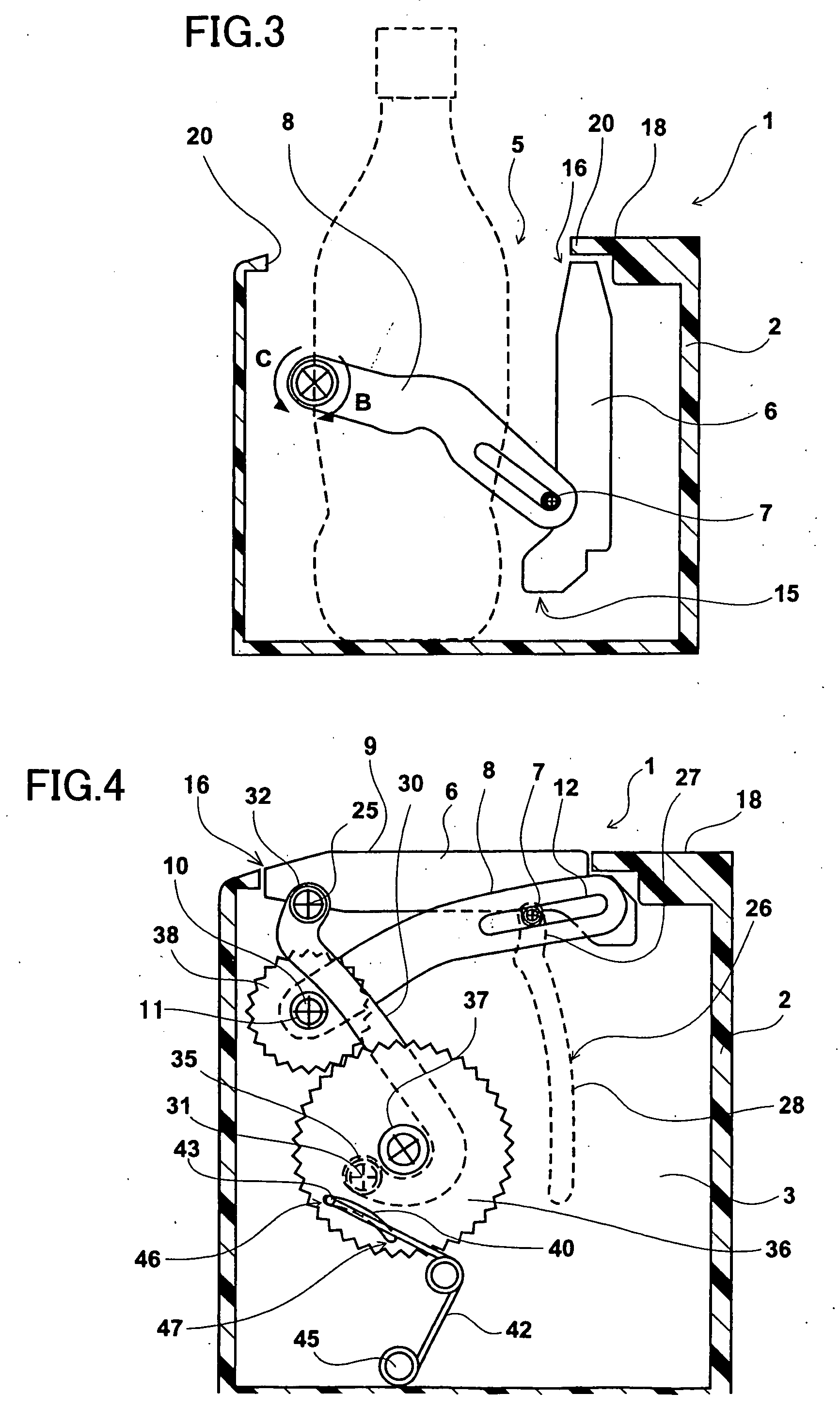

Misfueling Preventing Apparatus

ActiveUS20150102031A1Avoid damageEasy to handleClosures to prevent refillingLiquid materialNozzleEngineering

Present disclosure is a misfueling preventing apparatus discriminating a fuel filler nozzle based on an outer diameter of the fuel filler nozzle. The misfueling preventing apparatus includes a base, a first link arm, a second link arm, a flapper and the stopper. The first link arm has a first trigger projection. The second link arm has a second trigger projection. If the fuel filler nozzle of light diesel oil pushes the first trigger projection and the second trigger projection, the first link arm and second link arm swing to a direction to which the first link arm and second link arm open to allow the flapper rotates to open.

Owner:ASTEER

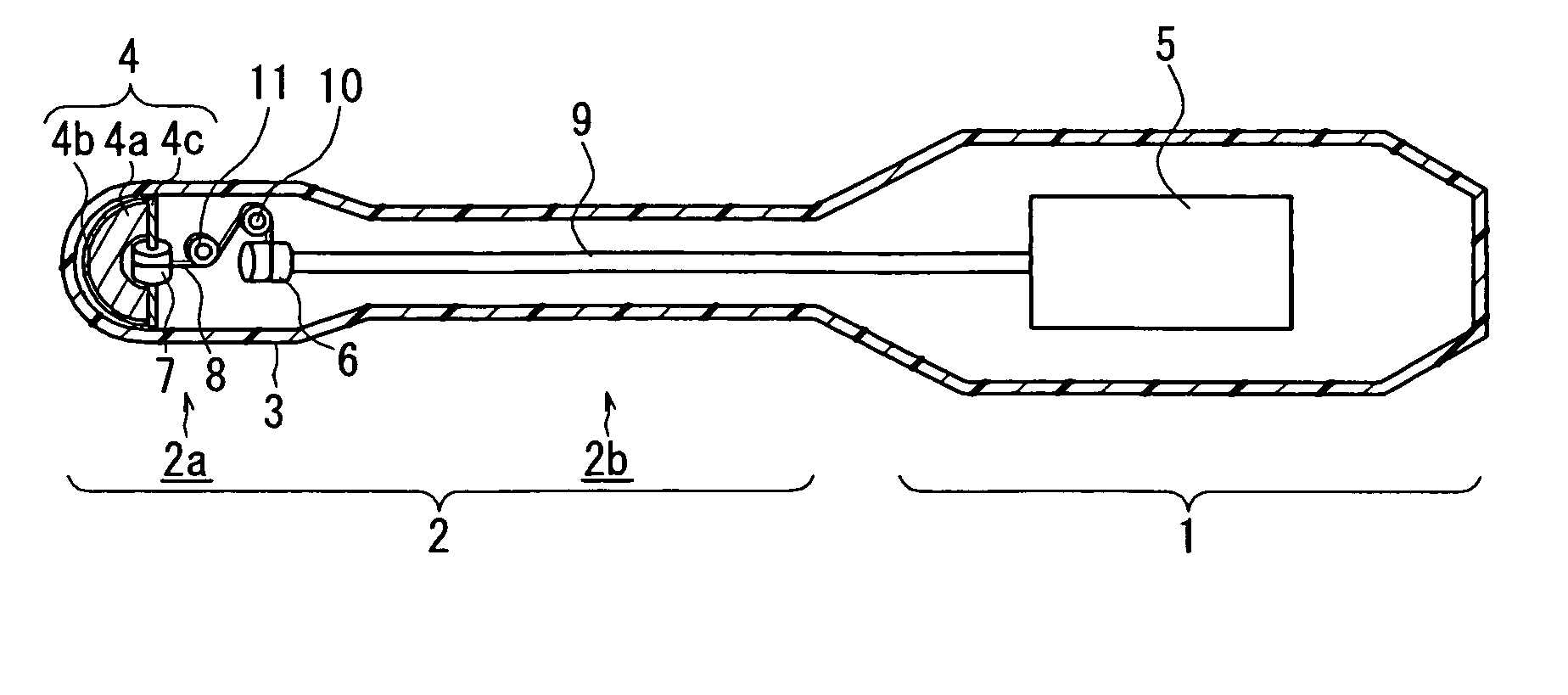

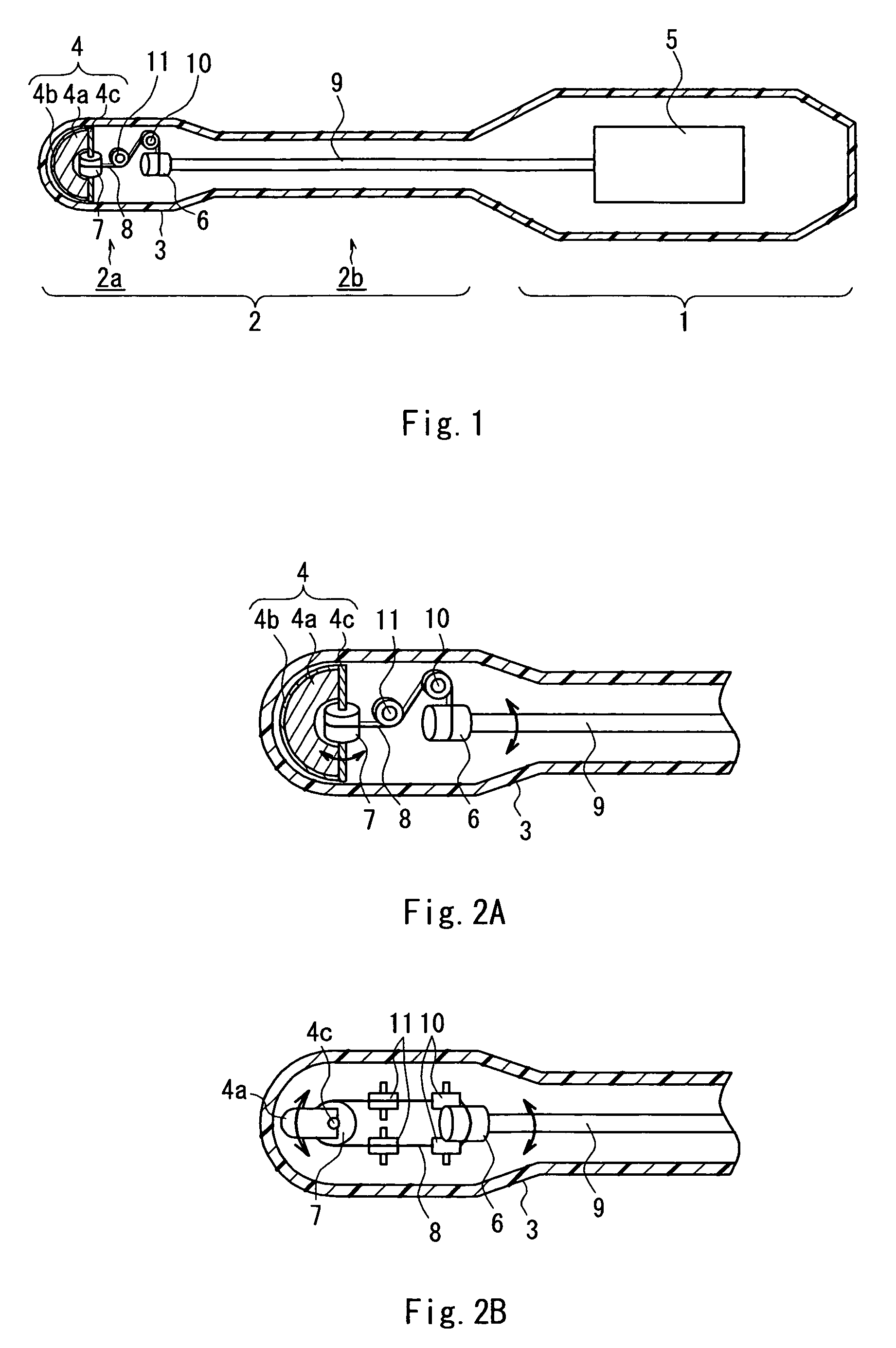

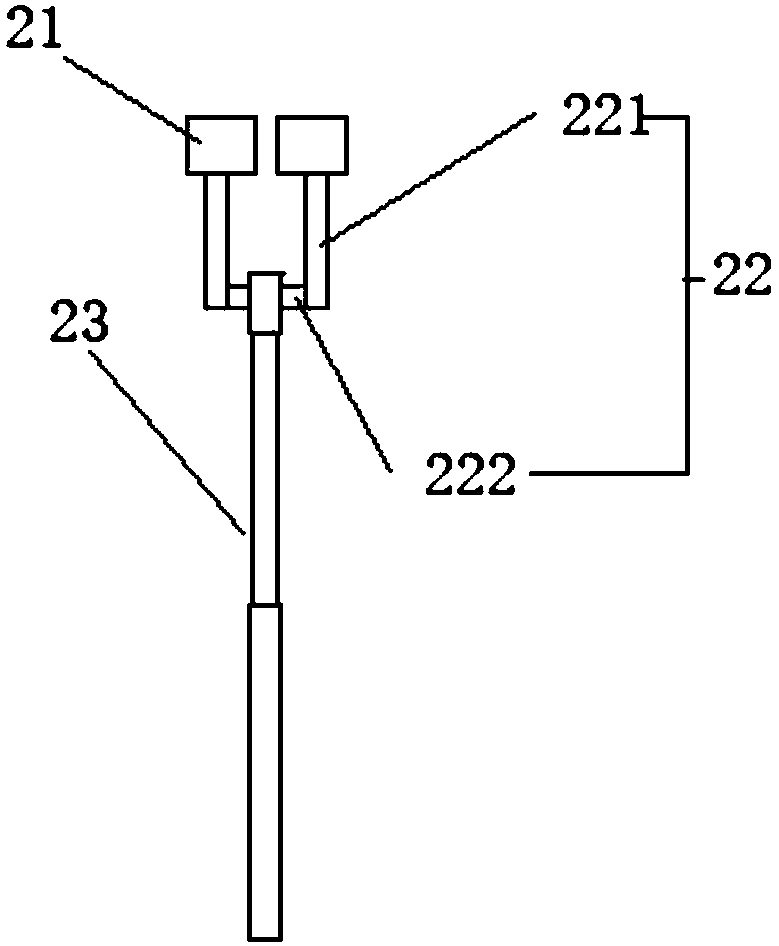

Ultrasonic probe

ActiveUS8083681B2Reduce displacementAccurate imagingUltrasonic/sonic/infrasonic diagnosticsSurgeryTransducerEngineering

An ultrasonic probe according to the present invention includes an inserting portion to be inserted into a body cavity and a grip portion 1 held by an operator outside of the body cavity. The inserting portion 2 includes a transducer unit 4, a rotation axis provided in the transducer unit 4, and a swing mechanism for swinging the transducer unit 4 around the rotation axis as a center, and the grip portion 1 includes a motor 5 for generating a driving force for driving the swing mechanism. The swing mechanism includes a shaft 9 connected to the motor 5, a first pulley 6 attached coaxially to the shaft 9, a second pulley 7 attached coaxially to the rotation axis of the transducer unit 4, and a wire 8 connecting the first pulley 6 and the second pulley 7.

Owner:KONICA MINOLTA INC

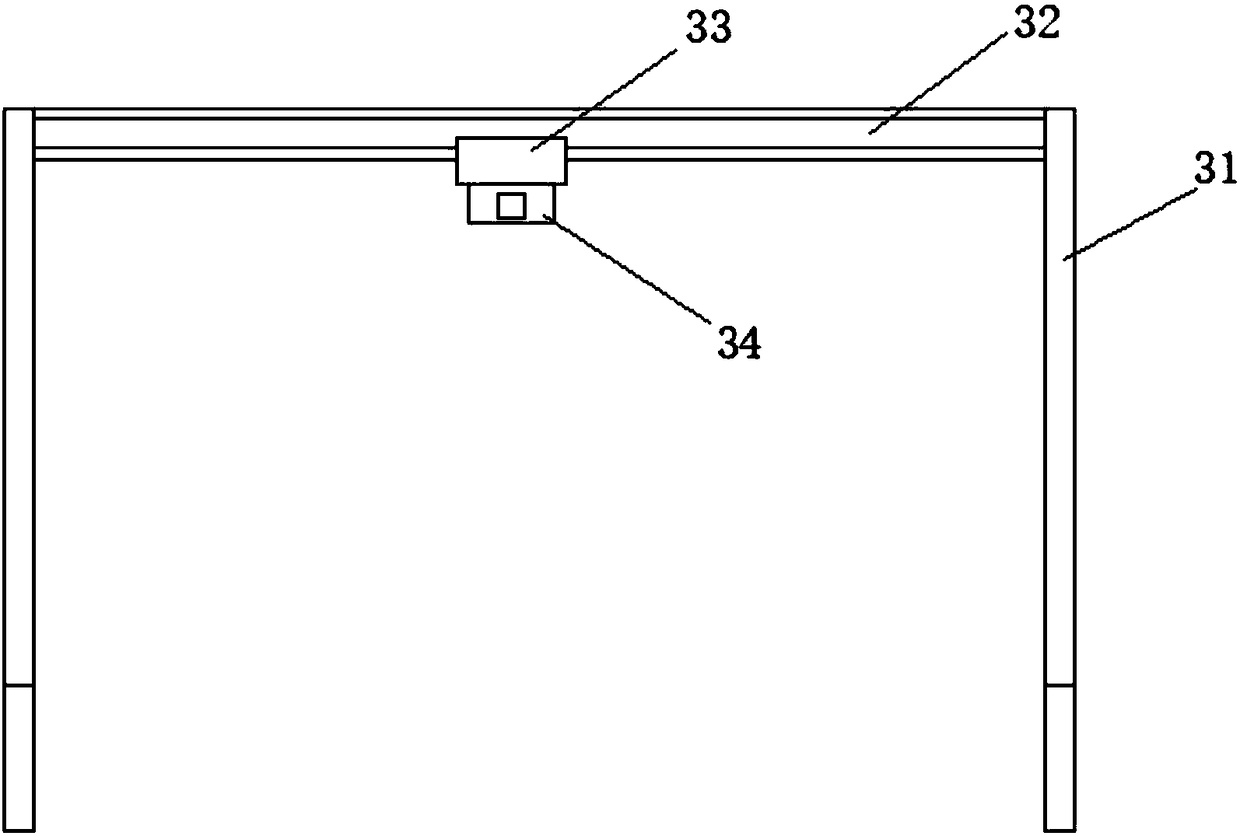

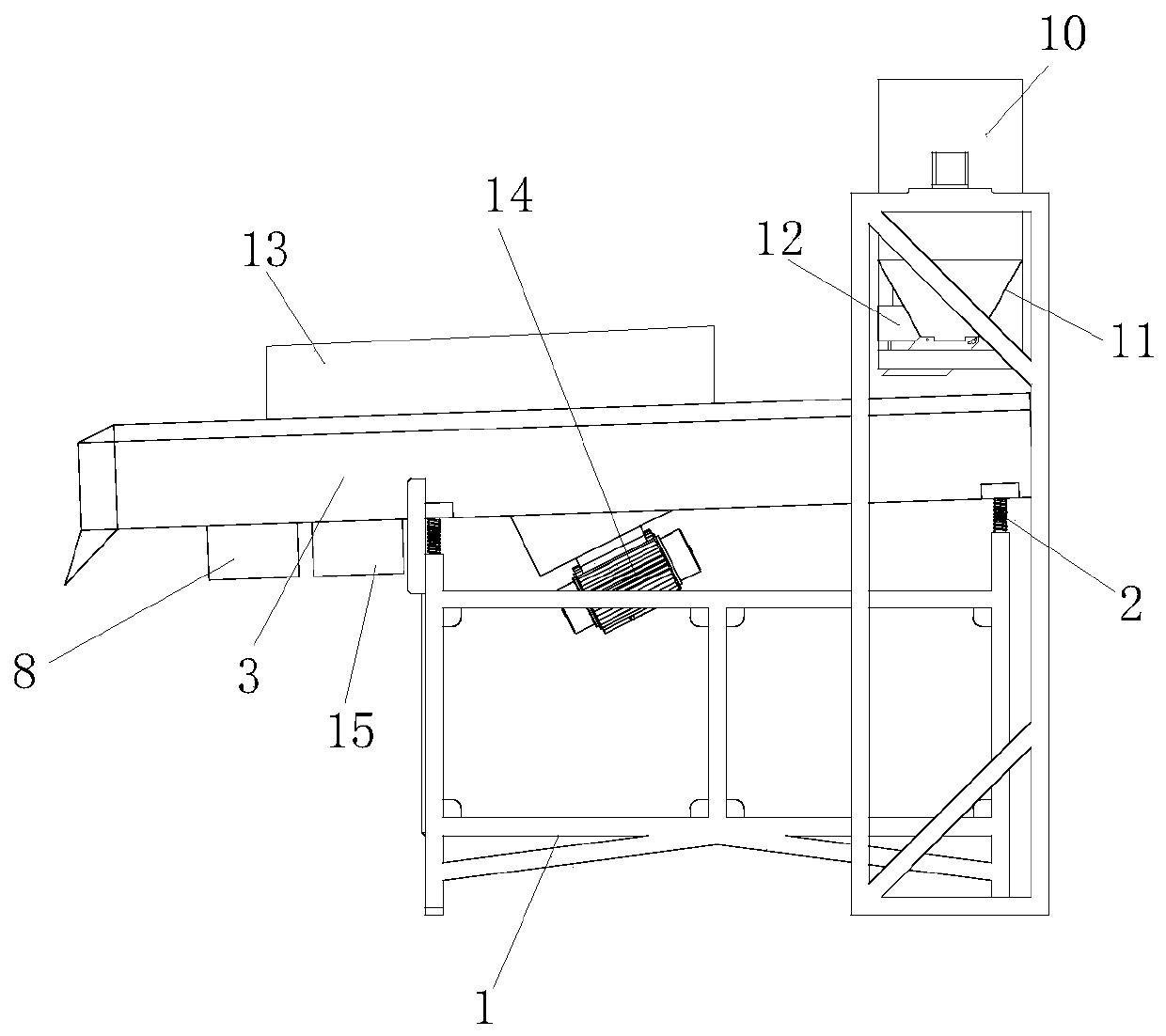

T-shaped elevator guide rail linearity detection system

InactiveCN108278982AGentle and gentle flipReduce shockUsing optical meansMotor driveEconomic benefits

The invention relates to a T-shaped elevator guide rail linearity detection system which comprises a bracket, transverse conveying devices, longitudinal conveying devices, a guide rail linearity detection device and guide rail overturning devices; the transverse conveying devices, the longitudinal conveying devices, the guide rail linearity detection device and the guide rail overturning devices are arranged on the bracket; and the guide rail linearity detection device is arranged on a linear rail which spans the transverse conveying devices. The T-shaped elevator guide rail linearity detection system provided by the invention realizes detection of the guide rail linearity by adopting a CCD laser displacement sensor and is accurate in detection result and simple and convenient to operate without complex machines and equipment. By adopting the T-shaped elevator guide rail linearity detection system, automatic overturning of the guide rail is realized, the production efficiency is improved, the labor cost is reduced, and increase of economic benefit of an enterprise is facilitated; as the overturning devices are provided with buffer mechanisms respectively, impact when the elevator guide rail is contacted to buffer blocks is reduced, and the elevator guide rail is protected; and by adopting a motor drive swing arm to perform overturning on the elevator guide rail, overturning ismore gentle, and harm on the elevator guide rail is also smaller.

Owner:吴江市通宇电梯轨道有限公司

Tread brake device

The invention relates to a tread brake device. The tread brake device comprises a cylinder body, a spindle subassembly, a force amplifying mechanism, a thrust ring and a brake shoe swinging mechanism, wherein the brake shoe swinging mechanism comprises an adjusting head, a suspender, a brake shoe support, a brake shoe and a damping subassembly; the suspender is rotatably connected to the cylinder body; the adjusting head and the brake shoe support are rotatably connected to the suspender; the brake shoe and the damping subassembly are arranged on the brake shoe support; the brake shoe support comprises a left side plate and a right side plate; the adjusting head is sleeved on a lead screw and is connected with a clearance adjusting mechanism; a baffle is arranged on the adjusting head and is positioned between the left side plate and the right side plate; threaded holes are formed in positions, which correspond to the baffle, of the left side plate and the right side plate; the damping subassembly comprises screw covers, compression disc springs and friction blocks; the screw covers are screwed in the threaded holes; the compression disc springs are arranged in inner cavities of the screw covers; and each friction block is clamped between the corresponding compression disc spring and the baffle. The brake shoe of the tread brake device can well cling to a tread of a wheel, and abnormal abrasion of parts due to vibration impact can be avoided.

Owner:CRRC CHANGZHOU TECH MARK IND CO LTD +1

High-efficiency production method of safety braid

ActiveCN104674567AEasy to operateHigh yarn stabilization efficiencySafety beltsAuxillary apparatusYarnAfter treatment

The invention discloses a high-efficiency production method of a safety braid. The high-efficiency production method comprises the following steps: (1) receiving and inspecting raw materials; (2) pre-treating the raw materials; (3) stabilizing yarns; (4) threading the yarns; (5) changing the yarns, and braiding; (6) preparing a dyeing solution; (7) carrying out dyeing pretreatment; (8) carrying out dyeing and color fixation; (9) carrying out dyeing after-treatment; (10) detecting a finished product braid; (11) cutting the braid; and (12) packaging the braid, and warehousing the packaged braid. The high-efficiency production method has beneficial effects that the operability is high, the yarn stabilizing efficiency is high, the yarn stabilizing effect is good, the accuracy and the intelligence in positioning are realized, the orderliness in processing and production is realized, the fault rate of machines is reduced, the dyeing effect is improved, the relatively high dyeing degree and the relatively attractive appearance are guaranteed, and the service life of the safety braid is prolonged.

Owner:LANGXI FEIMA IND FABRICS

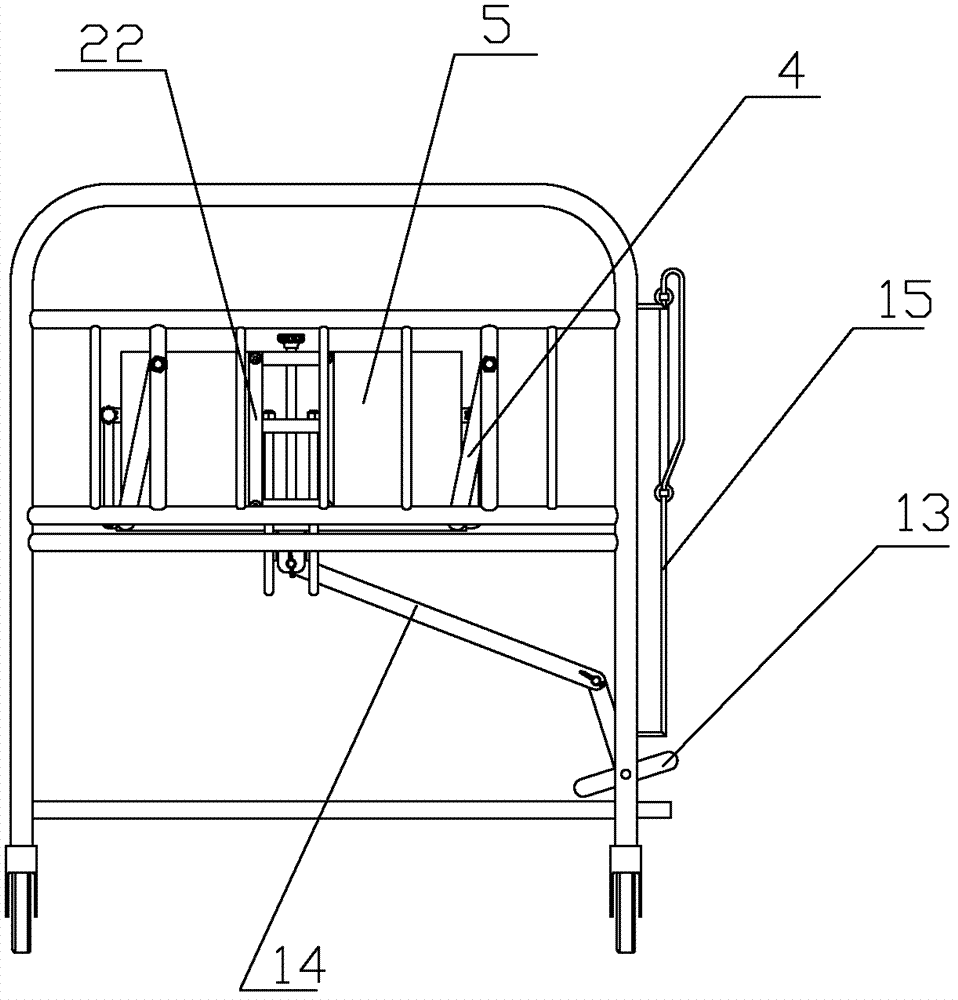

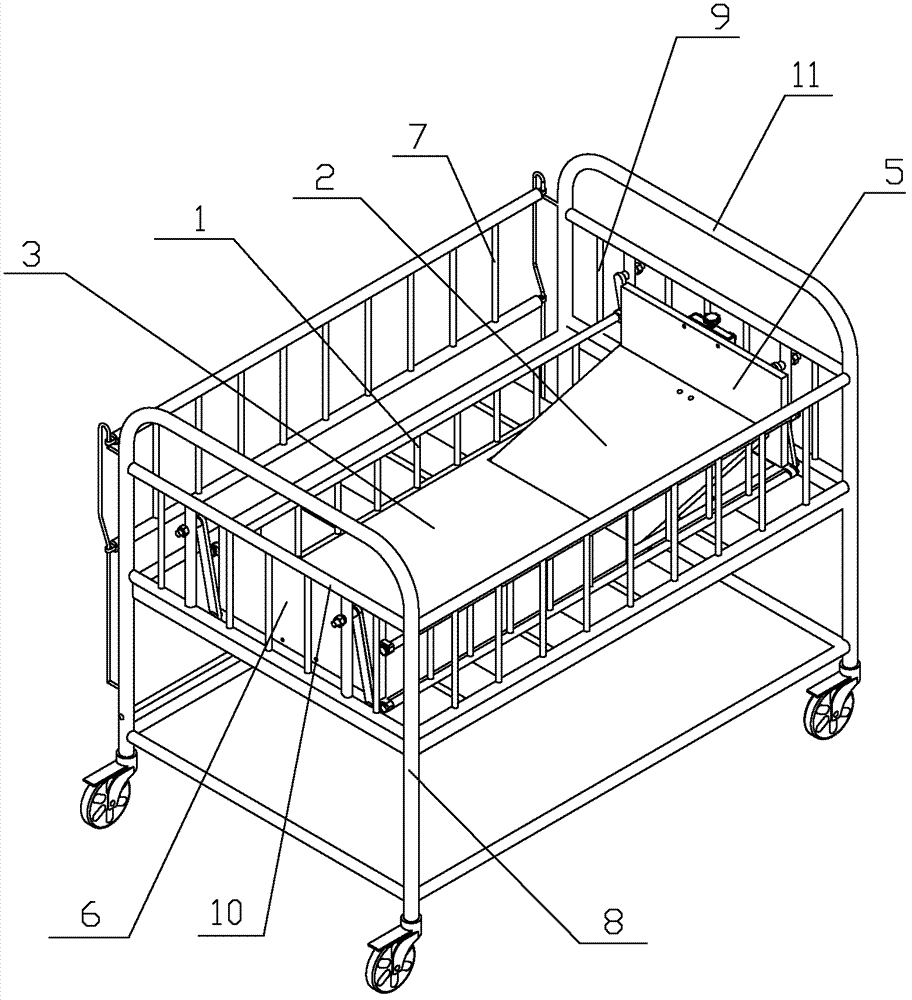

Pedal type baby bed

The invention discloses a pedal type baby bed. The pedal type baby bed comprises a swinging bed and an outer bed, wherein the swinging bed is placed in the outer bed; two ends of the swinging bed are respectively and movably connected with a bedside (9) or a bed tail (10) of the outer bed through a swinging rod (4); a pedal plate (13) arranged at the lower part of a bedstead (8) of the outer bed is movably connected with the center of the bottom of the swinging bed through a connecting rod (14); a bed plate of the swinging bed is formed by a movable bed plate (2) and a fixed bed plate (3); and one end of the movable bed plate (2) is hinged with the fixed bed plate (3) and the other end of the movable bed plate is connected with an angle adjusting device. The pedal type baby bed has the advantages of being simple in structure, stable for swinging, convenient for being used for breast feeding and the like.

Owner:CHENGDU UNIV

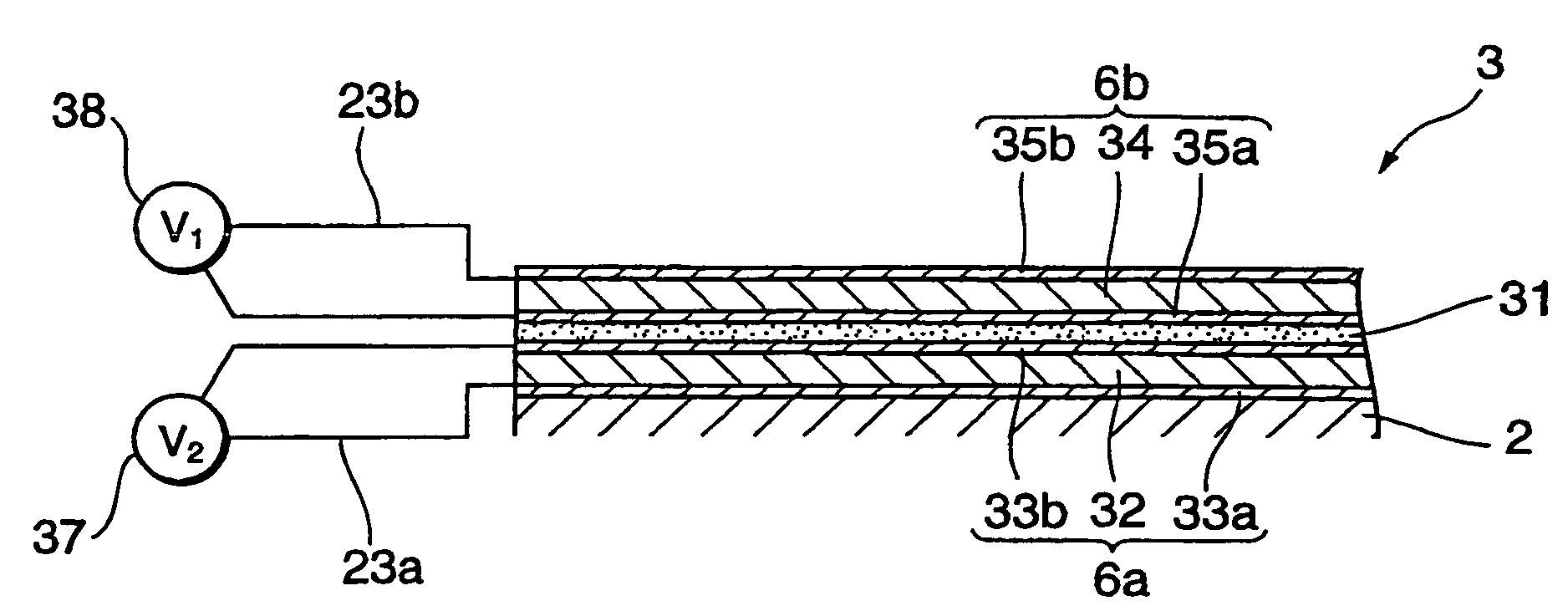

Flexible, suspension, and head gimbal assembly with piezoelectric layer units addressable by a voltage

InactiveUS7630175B2Improve accuracyIncrease speedElectrical connection between head and armArm with actuatorsEngineeringElectric wire

A flexure is provided with a main body on which a wire for energizing a head slider is disposed. Head slider is mounted at the front end of the flexure. Two piezoelectric layer units, each including layered piezoelectric elements, are disposed so that two of the units sandwich a line that extends from head slider to a base portion of an arm member. A voltage can be applied individually to each of the piezoelectric elements. The shape of the piezoelectric layer units are changed by adjusting the voltage applied to each of the piezoelectric elements, thereby moving head slider freely.

Owner:TDK CORPARATION

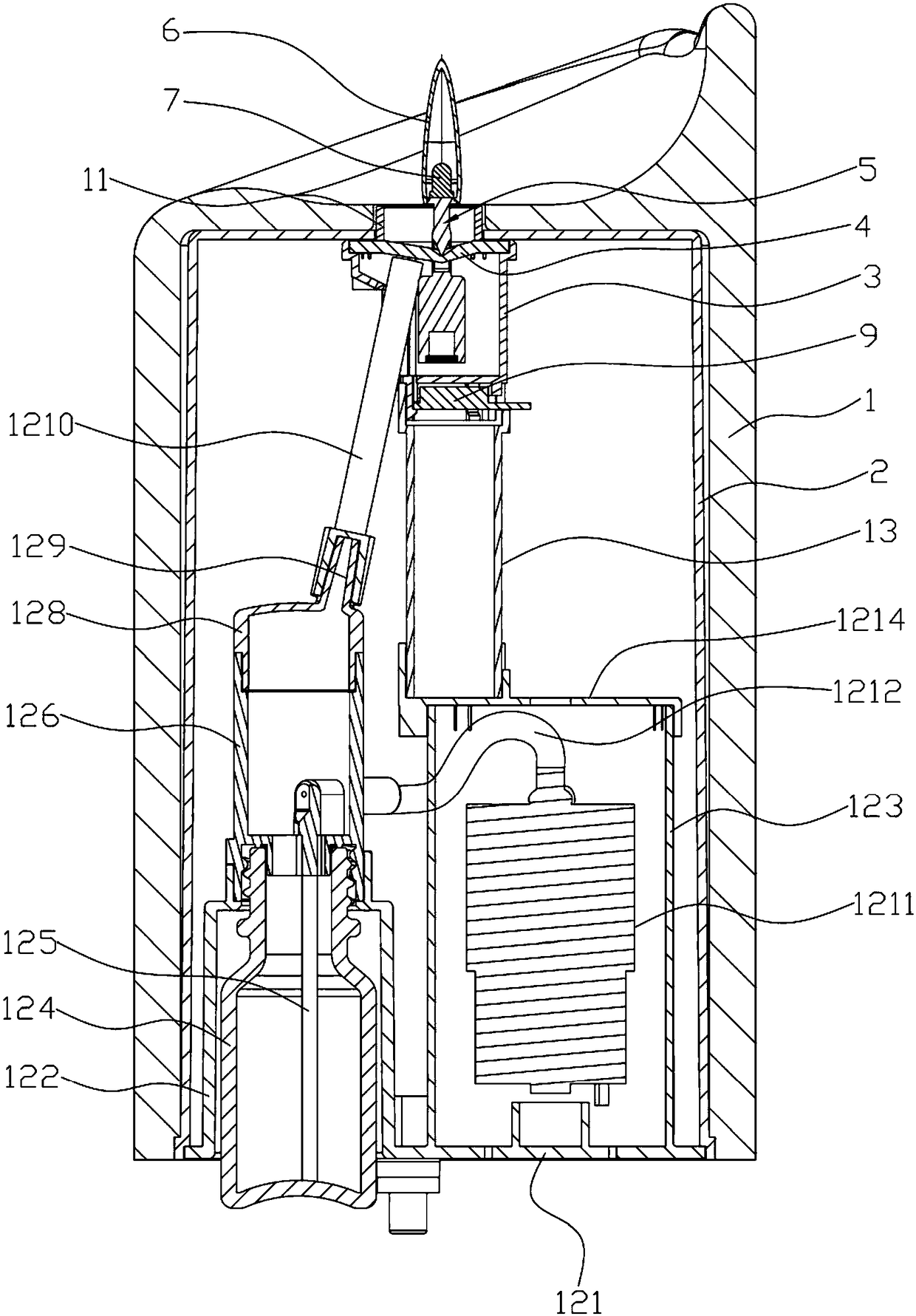

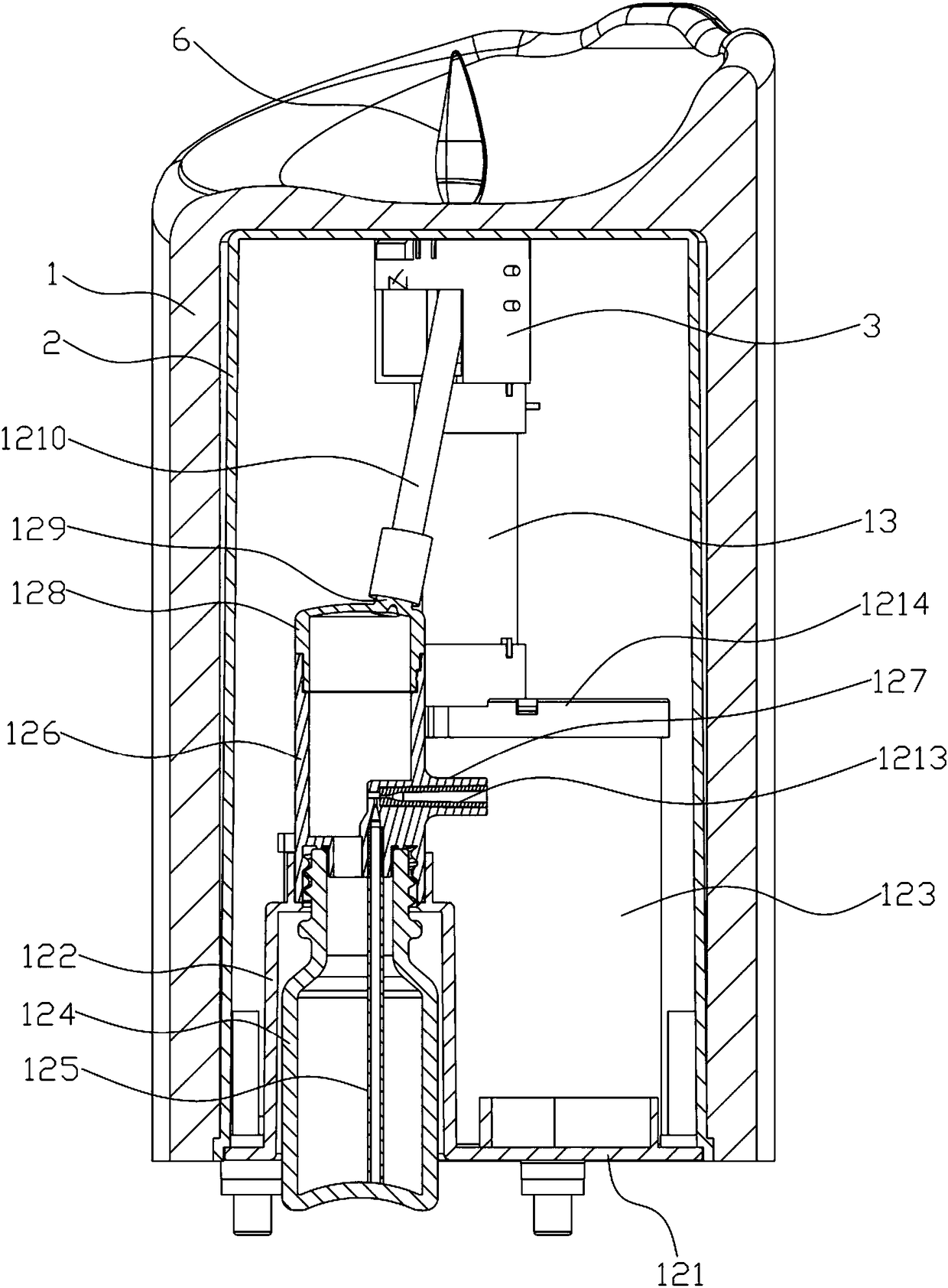

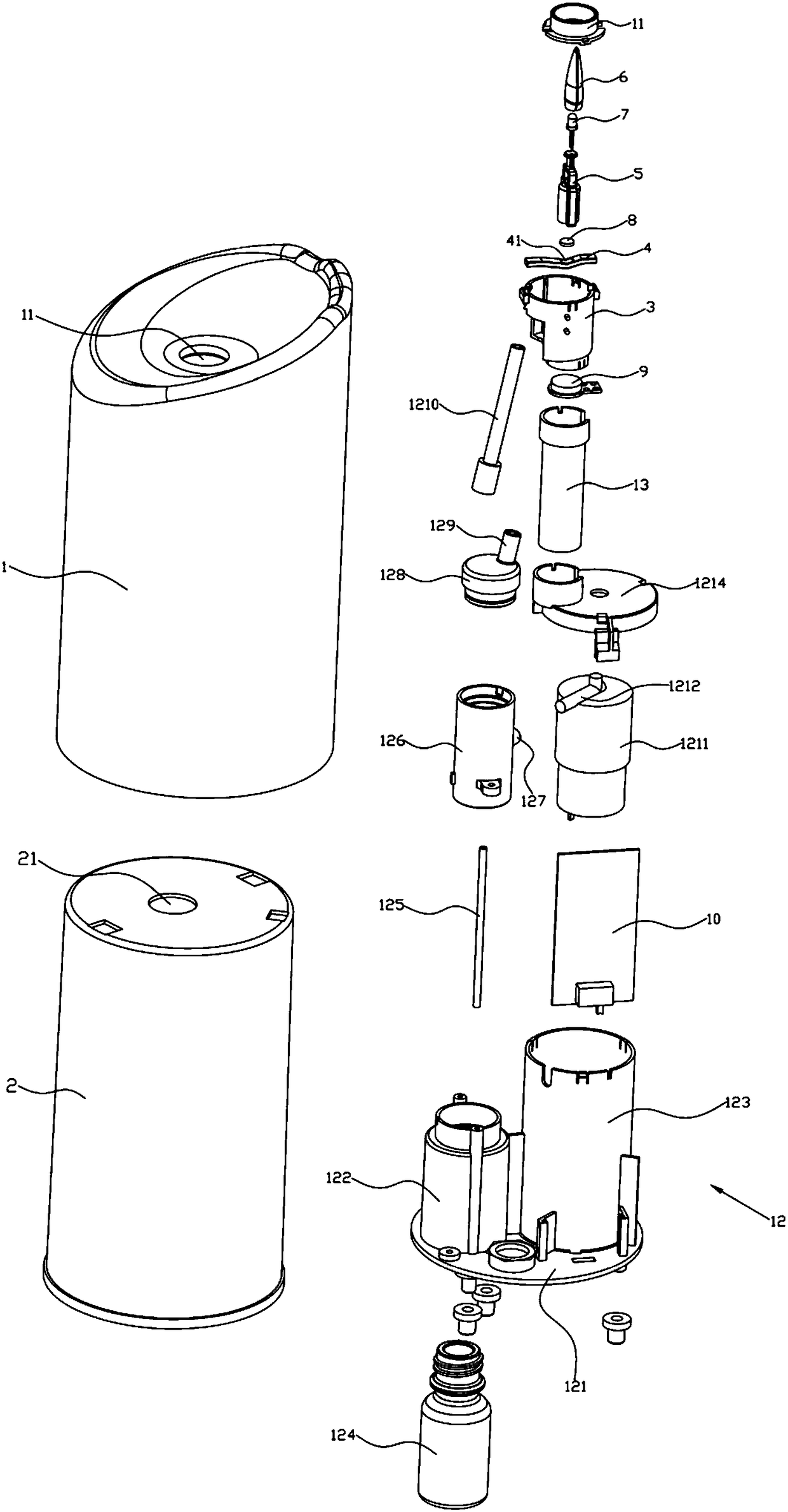

Electronic simulation candle

ActiveCN108105711AWon't fall offFirmly connectedElectric lightingGaseous substancesElectricityCandle

The invention discloses an electronic simulation candle which comprises a barrel body; a first through hole is formed in the top of the barrel body; a mounting barrel is fixedly arranged at the innersurface of the top of the barrel body; the top of the mounting barrel is connected with a strip-shaped first bracket in a buckling manner; the first bracket is arranged in the radial direction of themounting barrel; a second bracket capable of swinging freely is hung on the first bracket; the upper part of the second bracket penetrates through a second through hole and the first through hole; thelower part of the second bracket is arranged in the barrel body; a hollow and transparent flame cover is fixedly arranged at the top of the second bracket; at least one LED is fixedly arranged in theflame cover; at least one magnet block is fixedly arranged at the lower end of the second bracket; an electromagnetic coil is fixedly arranged at the bottom of the mounting barrel; and the LED and the electromagnetic coil are electrically connected with a power supply control board separately. The first bracket is connected with the mounting barrel conveniently and stably, so that the situation that the second bracket swings on the first bracket stably in a long term is ensured; and the first bracket and the mounting barrel are subjected to mass production independently, so that the production cost and the reject ratio are lowered and the production efficiency is improved.

Owner:GUANGDONG YAYI SEMICON APPLIED SCI & TECH CO LTD

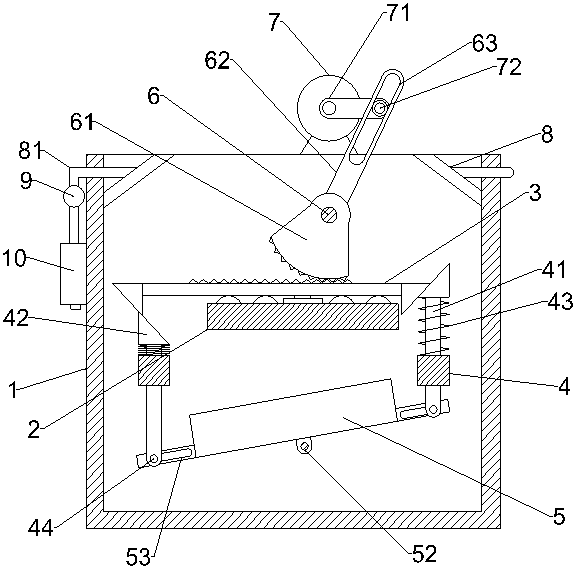

Dustproof sieving device for powder material for chemical experiment

The invention discloses a dustproof sieving device for a powder material for a chemical experiment. The dustproof sieving device comprises an outer shell, a horizontal arrangement plate, a horizontalsliding plate, a sliding sleeve, a swing sleeve, a fixed rotary shaft and a motor. The horizontal arrangement plate, the horizontal sliding plate, the sliding sleeve, the swing sleeve, the fixed rotary shaft, a dust hood, an air pipe, an air pump and a dedusting box are arranged on the outer shell. The horizontal arrangement plate is provided with a sliding clamping groove and a supporting roller.The horizontal sliding plate is provided with a limiting protrusion, a limiting spring, a rack and an upper oblique block. The sliding sleeve is provided with a sliding rod, a lower oblique block, areset spring and a sliding rotary shaft. The swing shaft is provided with a sieve box, a rotary horizontal arrangement plate and a movable supporting part. A sector gear, a swing rod and a sliding groove are arranged on the periphery of the fixed rotary shaft. The motor, a rotary rod and a sliding protrusion are arranged at the upper end of the outer shell. The horizontal sliding plate swings leftand right on the horizontal arrangement plate, thus, the sliding rod drives the swing sleeve to swing left and right, the sieving efficiency is improved, and dust flying is avoided by additionally arranging an air pump and the dedusting box.

Owner:吴子敬

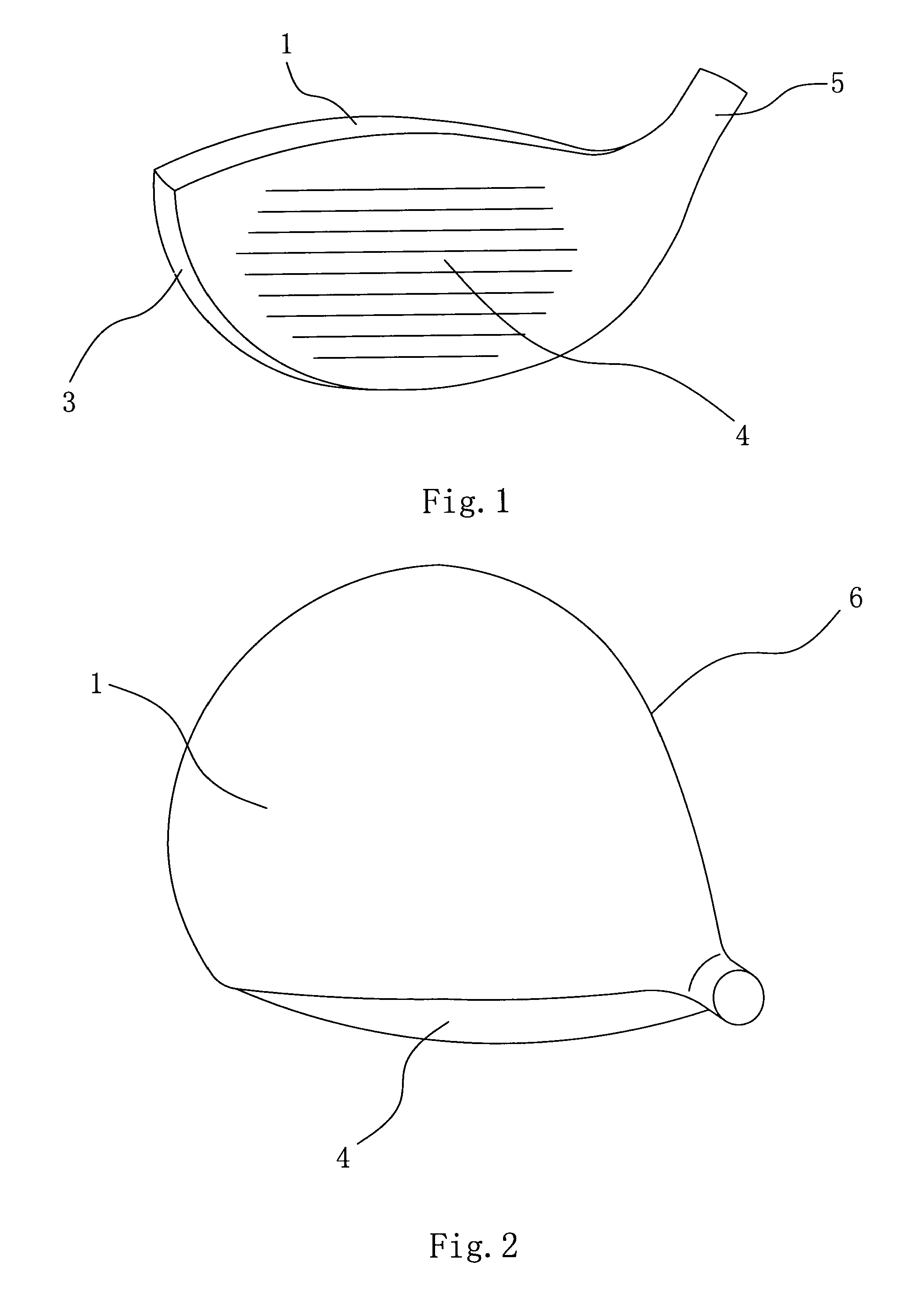

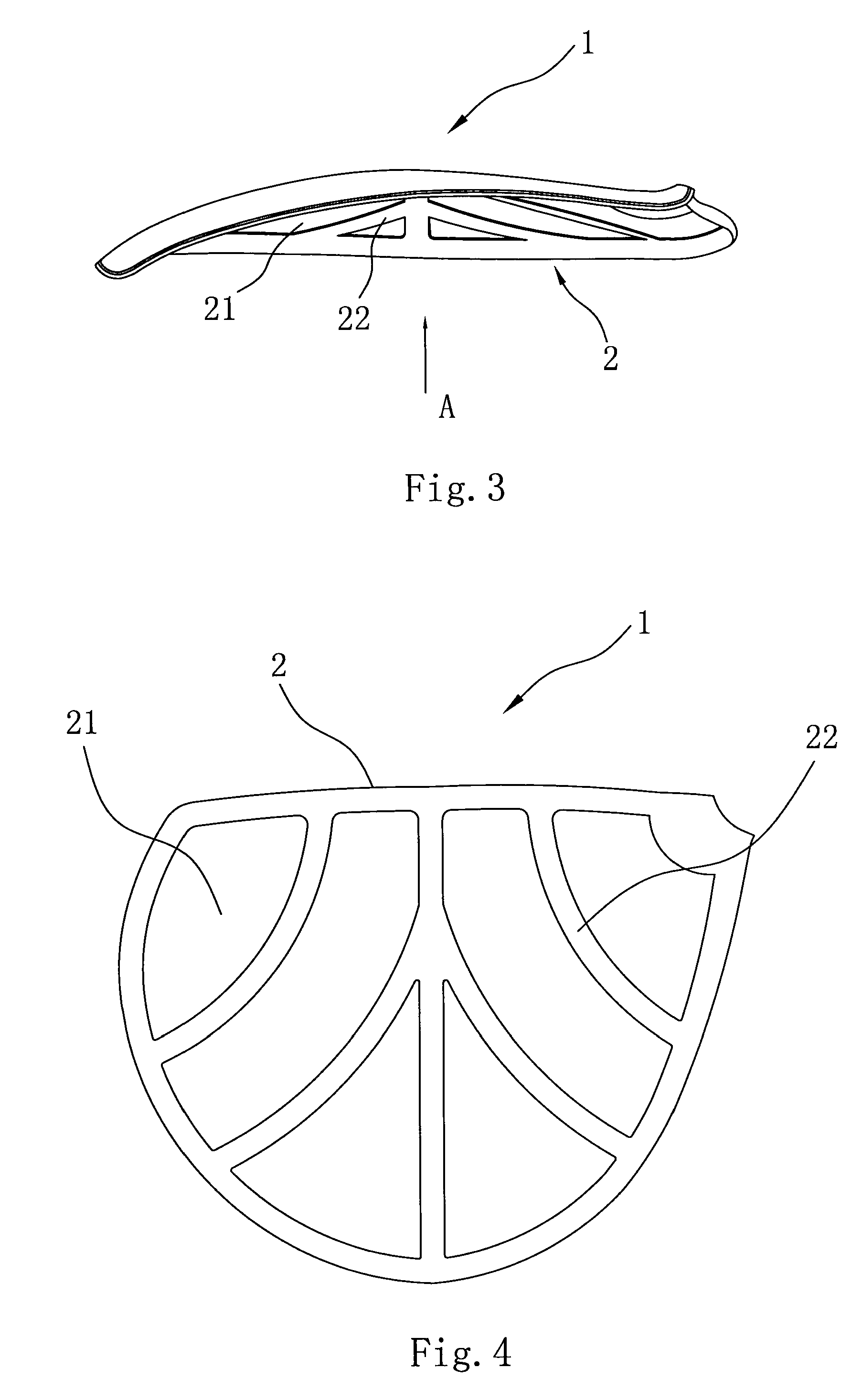

Titanium alloy golf club head

A titanium alloy golf club head and a method for manufacturing the same are provided. The golf club head comprises a head base, a hitting face at a front edge of the head base and a top lid on the top of the head base. The head base, the hitting face and the top lid are connected to each other to form an entirety. The top lid has an inside surface comprising a plurality of recesses. With the recesses, the weight of the head is reduced while the volume of the head is increased. Meanwhile, the thickness of walls of the head base and of the hitting face does not need to be reduced. Since the weight of the top lid is reduced, the center of gravity of the head is lowered. A rib is formed between two adjacent recesses in the inside surface of the top lid so that an impact force on the head can be efficiently dispersed and the strength of the head is improved.

Owner:NI JINTU

Magnetic cycle vibration breathing rehabilitation training device

ActiveCN109011414ATo loosen phlegm and expel phlegmAchieve the purpose of drug treatmentGymnastic exercisingPhysical medicine and rehabilitationGas chamber

The embodiment of the invention discloses a magnetic cycle vibration breathing rehabilitation training device, and belongs to the medical device field; the magnetic cycle vibration breathing rehabilitation training device mainly comprises a blowing nozzle and a device main body; the device main body comprises a housing, a breathing rehabilitation training gas chamber, an exhale non return valve and a gas guide non return valve; an exhale path and an inhale path of the exhale non return valve and the gas guide non return valve are singly separated; the inhale / exhale end of the device main bodyis provided with a replaceable function box, thus assisting a user to excrete sputum and train a respiration muscle, and carrying out medicament treatment in the same time.

Owner:朗态健康科技(北京)有限公司

Sandy soil screening device for road and bridge construction

The invention discloses a sandy soil screening device for road and bridge construction. The sandy soil screening device for road and bridge construction comprises a reciprocating pushing device and acleaning mechanism; a pushing mechanism is arranged in a protective frame, and a first motor drives a cam to do eccentric motion, so that a push rod is enabled to move in a reciprocating manner to push a swinging frame to swing, and the advantage of quickly driving a swinging mechanism to link is achieved; the swinging mechanism is arranged at the bottom of a discharge nozzle, and when the push rod moves in a reciprocating manner, the swinging frame can be driven to swing around a positioning shaft, so that the swinging frame is enabled to slide at the upper end of a sliding shaft through a sliding chute, the swinging frame can swing stably, and the advantages of preventing sand from being conveyed and concentrated on one point and increasing the screening efficiency are achieved; and thecleaning mechanism is arranged at the top of the screening frame, and a second motor drives a pinion to rotate, so that a bull wheel drives a driving handle to swing around a fixed disc through a movable handle, the driving handle drives a brush plate to brush the upper end of a screen, and the advantage of preventing the sand on the screen from remaining is achieved.

Owner:林法平

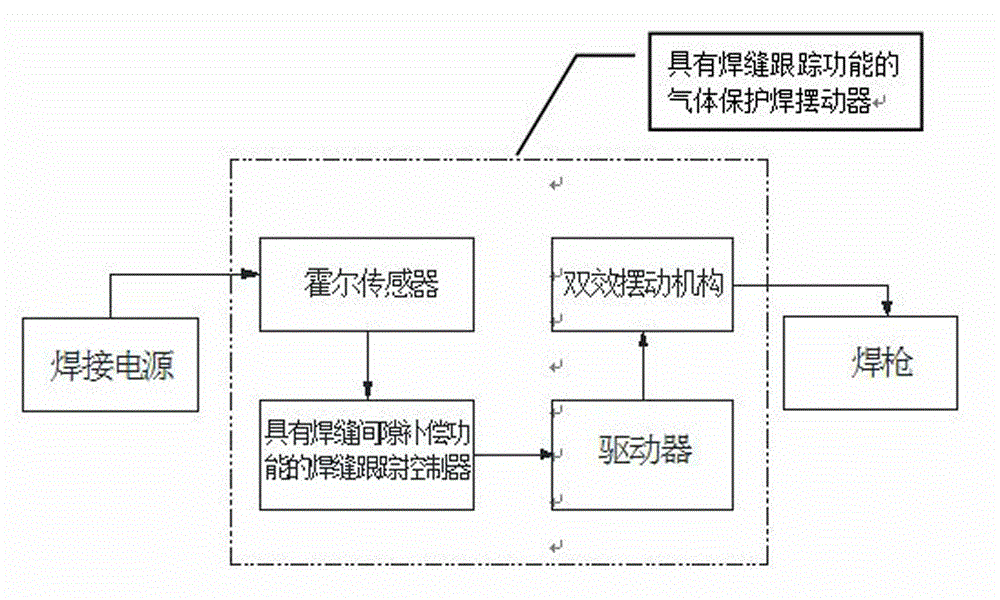

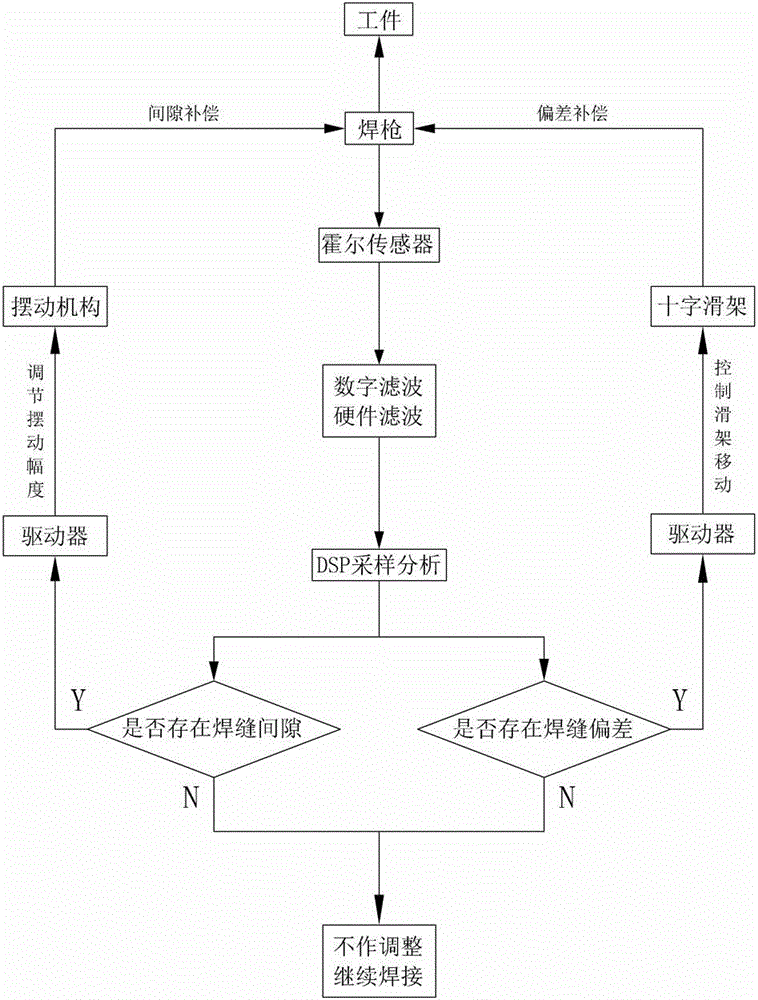

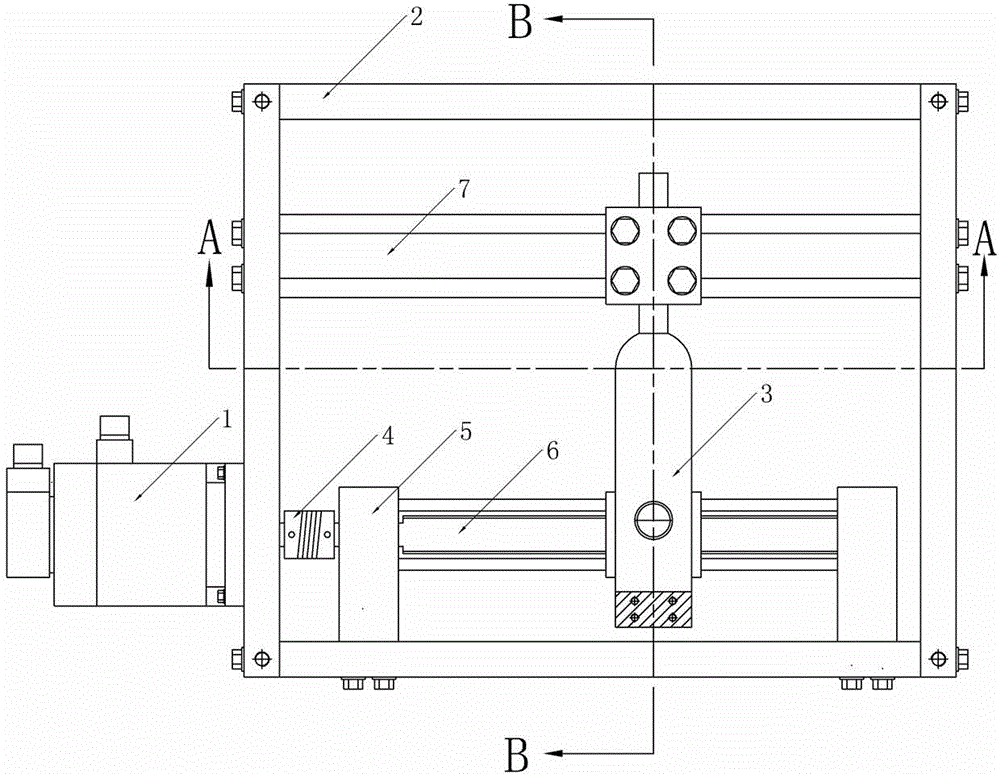

Gas shielded welding oscillator with welding joint tracing function

ActiveCN104475926ALarge coverageRealize real-time compensationElectrode supporting devicesElectrical controlEngineering

The invention discloses a gas shielded welding oscillator with a welding joint tracing function and belongs to a welding automation control device. The gas shielded welding oscillator with the welding joint tracing function mainly solves the technical problems of large welding joint gap and the like due to the fact that an existing oscillator is incapable of detecting and compensating a workpiece processing error, an assembly error, welding heat deformation and the like errors in real time. According to the technical scheme, the gas shielded welding oscillator with the welding joint tracing function comprises a Hall sensor, a welding joint tracing controller with a welding joint gap compensation function, a driver and a double-effect swinging mechanism, the welding joint tracing controller detects and compensates the welding joint gap caused by workpiece processing errors, assembly errors and welding heat deformation in real time according to signals gathered by the Hall sensor, and under the electric control and the driver control, the double-effect swinging mechanism freely changes between horizontal swinging and pendular swinging and automatically regulates the swinging amplitude and swinging frequency. The gas shielded welding oscillator with the welding joint tracing function is mainly used for welding.

Owner:湖南艾克机器人有限公司

Feet-type robot

The invention discloses a feet-type robot. The feet-type robot comprises a robot body, feet, translation swinging rods, a first power mechanism, a foot lifting swinging rods and a second power mechanism, wherein wheels are arranged at the bottom of the robot body; the feet are shaped like hollow rods; vacuum suckers are arranged at the lower ends of the feet; the upper ends of the feet are connected with an air pump through hoses; the four pairs of feet are arranged on the robot body in sequence from front to back; each foot movably sleeves the outer end of each translation swinging rod; each translation swinging rod is arranged on the robot body through a front-and-back swinging mechanism; the first power mechanism is used for providing power to the front-and-back swinging mechanism; a first sliding slot is formed in the outer end of each foot lifting swinging rod; a sliding block is arranged on each foot; The feet are movably embedded in the first sliding slots of the foot lifting swinging rods through the sliding blocks; each foot lifting swinging rod is arranged on the robot body through a up-and-down swinging mechanism; and the second power mechanism is used for providing power to the up-and-down swinging mechanisms. According to the feet-type robot disclosed by the invention, it is easy to drive the feet to do translation and foot lifting actions so that the robot is conveniently controlled to move.

Owner:GUANGXI UNIV

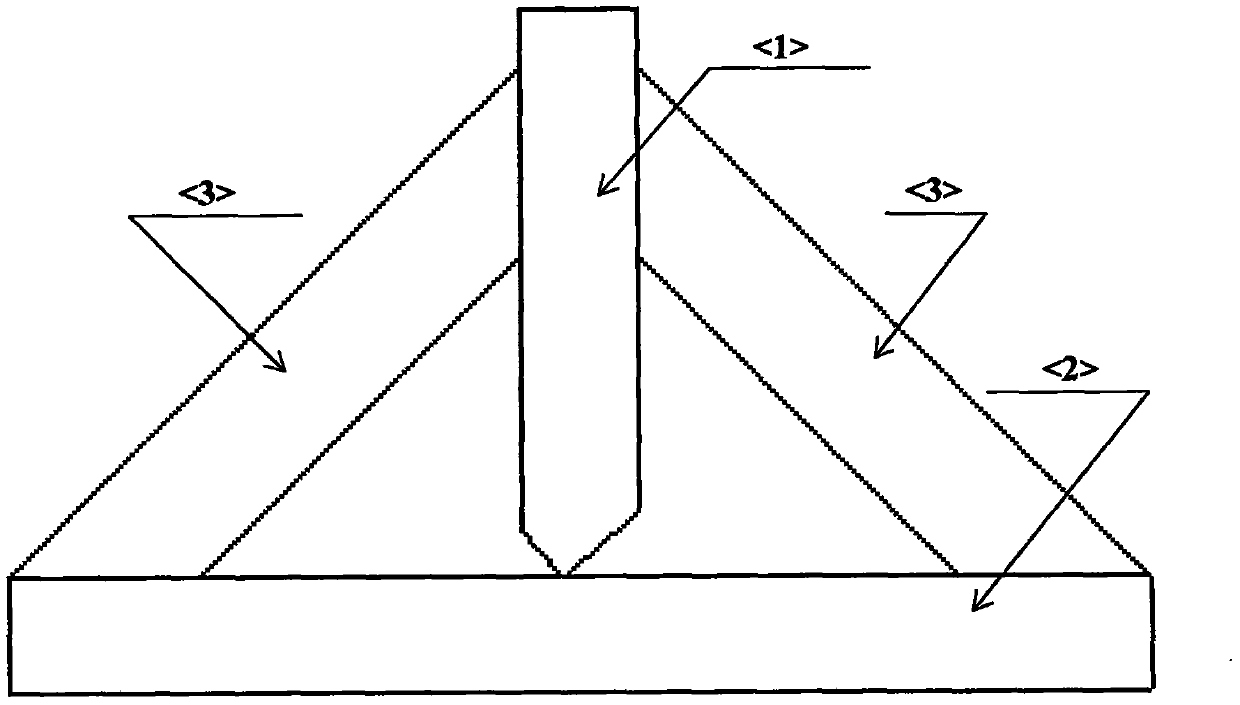

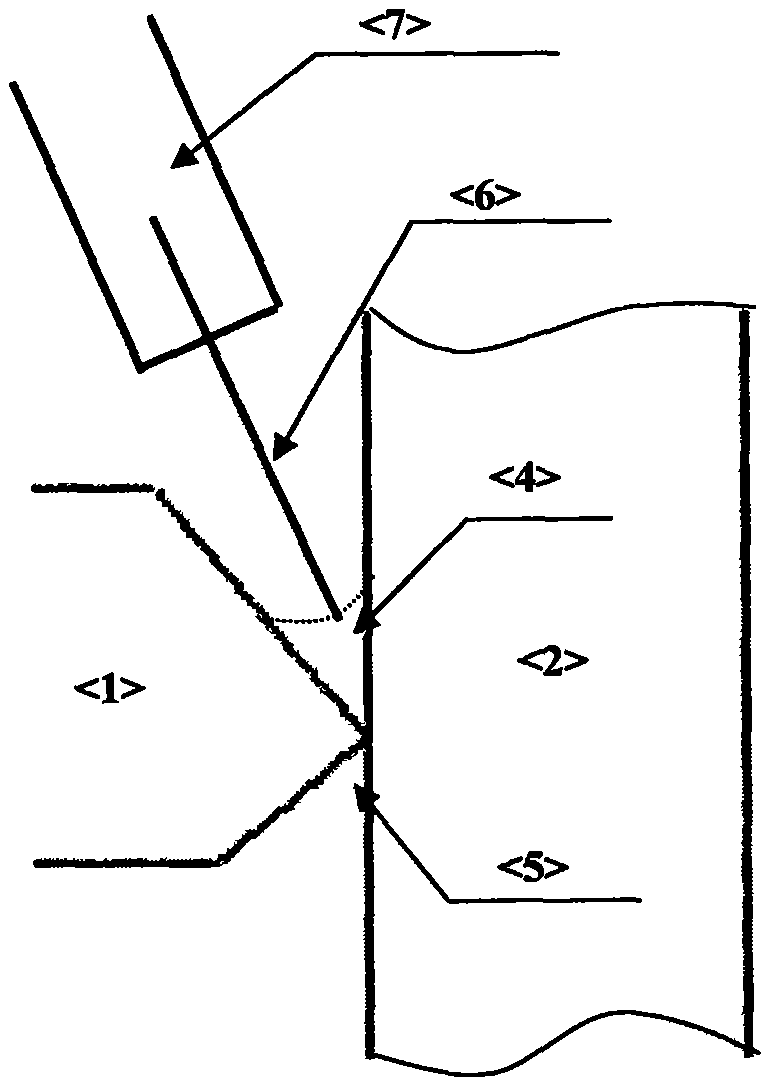

back chipping-free and full penetration (I level component) robot welding technology of medium plate K-shaped groove

InactiveCN107866624ASmooth swingSave welding consumablesArc welding apparatusUltrasound testWeld seam

The invention belongs to the technical field of steel structure welding, and discloses a back chipping-free and full penetration robot welding technology of a medium plate (t>=30 mm) K-shaped groove.The robot welding technology comprises the steps that plates are prepared, the plates are cut so as to form a technology groove, splicing welding is conducted on the plates, a lead-in arc plate and alead-out arc plate are additionally installed, and full-length welding is conducted on an additionally installed rib plate. Welding is conducted on the two medium plates by applying the robot weldingtechnology, then the lead-in arc plate and the lead-out arc plate are dismounted, and ultrasonic checking is conducted on a welding seam of a spliced plate. In the welding process of the medium plates, it is ensured that the quality level of the welding seam can reach the requirement of a full penetration welding I level, welding deformation is small, back chipping treatment does not need to be conducted on a welding pass, welding materials are saved, the production cost is reduced, a large number of human resources can be saved by adopting robot automation welding, the manual labor intensityis relieved, meanwhile, the production efficiency is high, and the construction requirements for being advanced in technology, and capable of saving energy and reducing consumption are met.

Owner:TANGSHAN KAIYUAN AUTOWELDING SYST

Misfueling preventing apparatus

A misfueling preventing apparatus discriminates a fuel filler nozzle based on an outer diameter of the fuel filler nozzle. The misfueling preventing apparatus includes a base, a first link arm, a second link arm, a flapper and a stopper. The first link arm has a first trigger projection. The second link arm has a second trigger projection. If the fuel filler nozzle of light diesel oil pushes the first trigger projection and the second trigger projection, the first link arm and second link arm swing to a direction to which the first link arm and second link arm open to, placing the flapper in an openable state.

Owner:ASTEER

Container holder

InactiveUS20060006185A1Improve the decorative effectNot easy to interfereVehicle arrangementsWash-standsSemi openEngineering

Owner:TOYODA GOSEI CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com