Patents

Literature

60results about How to "Save welding consumables" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Narrow-gap all position pusle automatic argon arc welding technique for dissimillar nicklel-based alloys

ActiveCN1947913AReduce thicknessImprove welding efficiencyArc welding apparatusFurnace typesSteel tubeNarrow gap

An automatic pulse argon arc welding technology for the butt connection between different two tubes by using Ni-base alloy as isolating layer includes such steps as build-up welding at least three layers of stainless steel in low-alloy steel tube, build-up welding an isolating Ni-base alloy layer, machining the bevels of isolating Ni-base alloy layer and stainless steel tube, butt locating, and TIG welding.

Owner:SHANGHAI BOILER WORKS

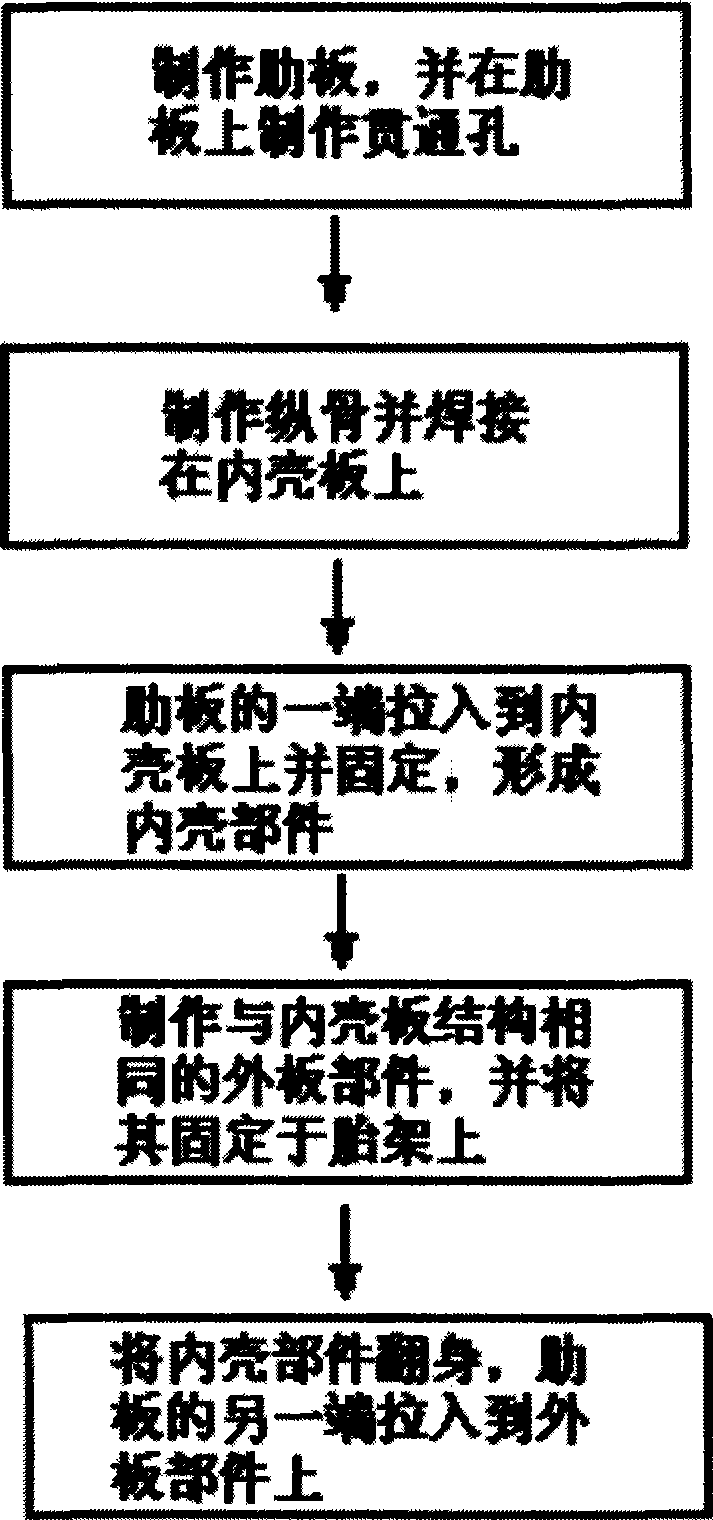

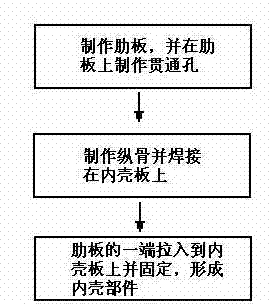

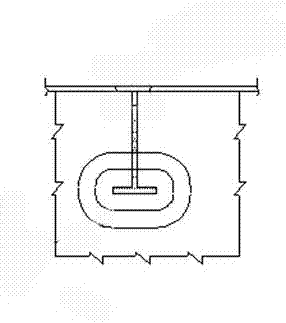

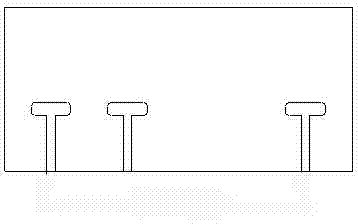

Method for drawing costal scute in shipbuilding

ActiveCN101372258AAdvantages of the pull methodBuild Quality ApprovalVessel partsMarine engineeringScute

The invention relates to a floor pull-in method in shipbuilding, which includes the following steps: the shape of a floor and a through hole of the floor are cut according to the accuracy requirements of ships; a longitudinal frame is manufactured according to the accuracy requirements; inner hulls are pieced together by welding and the longitudinal frame is installed by welding; a first floor is pulled in the inner hull and is welded to form an inner hull component; the inner hull component is measured and the first floor is rigidly reinforced; a hoisting ring is arranged on the inner hull component; an outside plate component is made and fixed on a moulding bed, a hoisting apparatus is used for hauling the hoisting ring to overturn the inner hull component and to cause the upper through hole of the floor to be aligned with a longitudinal frame terminal of the outside plate component, and then a second floor of the inner hull component is pulled in; a welding technique is determined, and the inner hull component and the outside plate component are welded to form whole ship sections. On the basis of a single floor pull-in method, the method can further improve the pull-in accuracy of floors, thus greatly reducing the quantity of patches required in shipbuilding in sections and improving the production efficiency of building in sections.

Owner:SHANGHAI JIANGNAN CHANGXING SHIPBUILDING +1

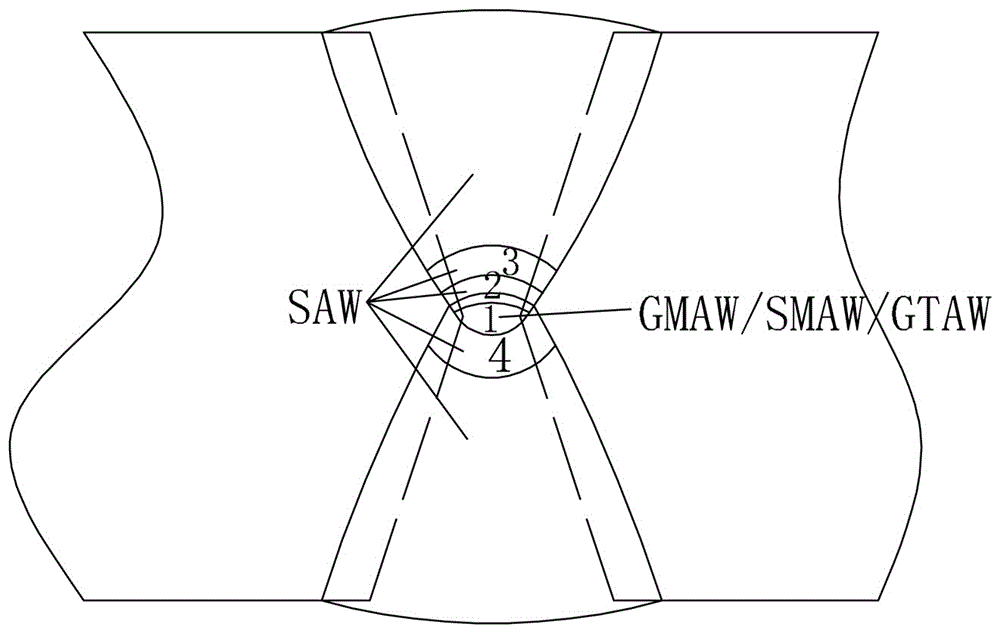

Welding technology for barrel

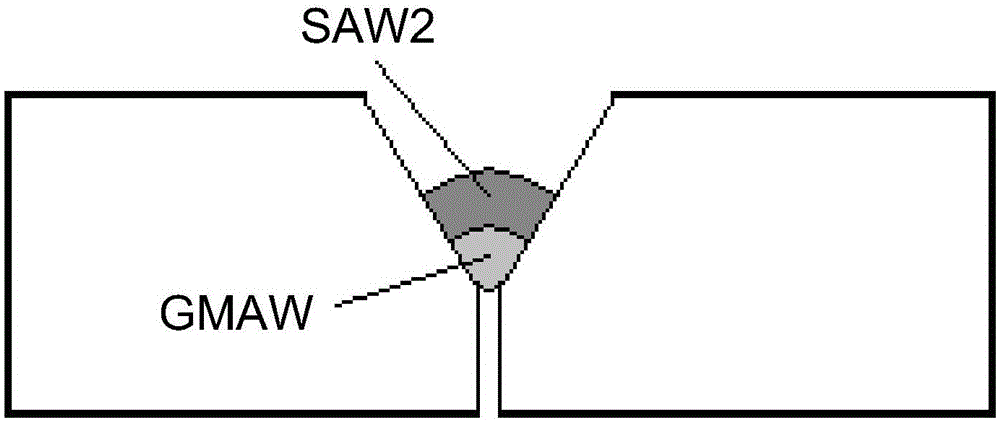

ActiveCN105234535AIncreased welding efficiency and productivityIncrease productivityArc welding apparatusWelding/soldering/cutting articlesThick plateEngineering

The invention discloses a welding technology for a barrel. The welding technology comprises the following steps: an inner groove machining step, wherein an inner groove is formed through machining and assembling, and the inner groove is an inverted-V-shaped groove; an inner groove welding step, wherein the inner groove is welded, and double-power three-wire submerged arc welding is adopted for welding of the inner groove; an outer groove machining and inner groove back chipping step, wherein the outer groove machining and the inner groove back chipping are performed through one step, and the outer groove is a U-shaped groove; and an outer groove welding step, wherein the outer groove is welded, and double-power three-wire submerged arc welding is adopted for welding of the outer groove. According to the welding technology for the barrel disclosed by the invention, the problems in the prior art that the welding efficiency of the low-alloy high-strength steel thick plate of the barrel is low; manual carbon arc air gouging backing chipping needs to be performed at root parts; the metal filling amount is large at the weld joint; and the like are solved. The welding efficiency and the production efficiency of the welding technology is improved by 2-3 times compared with a traditional technology; the welding material is saved by 10%-20%; carbon arc air gouging backing chipping is not needed; and manual work is reduced by 50%.

Owner:SHANGHAI ZHENHUA HEAVY IND

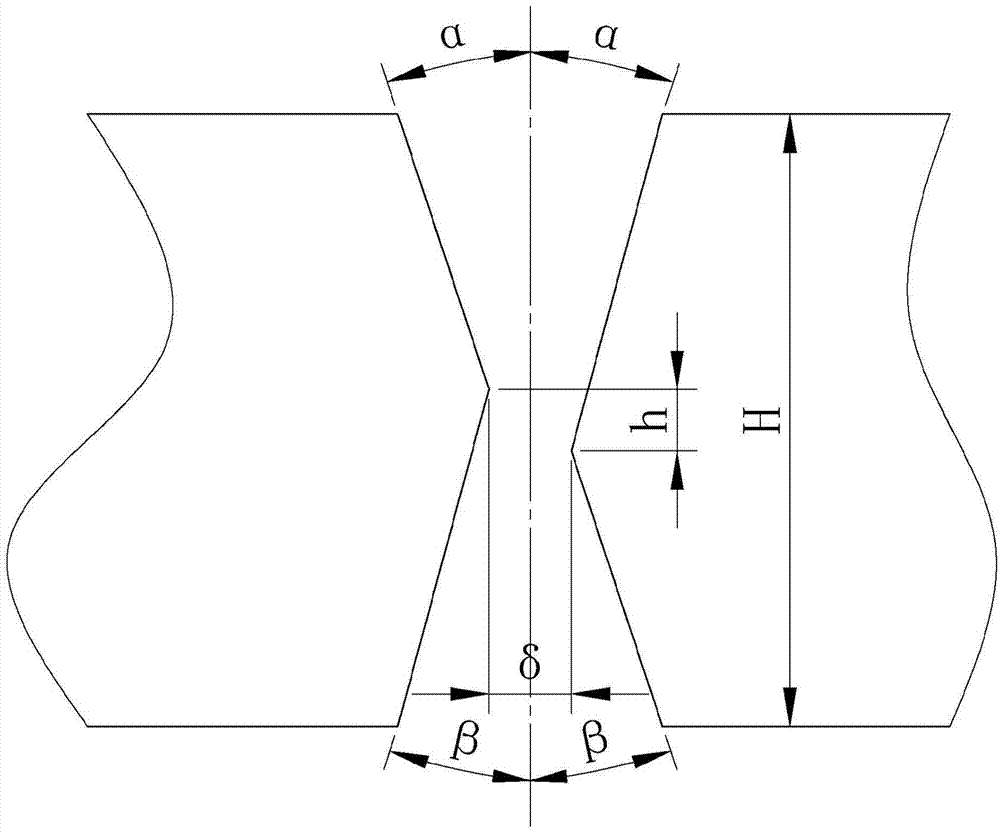

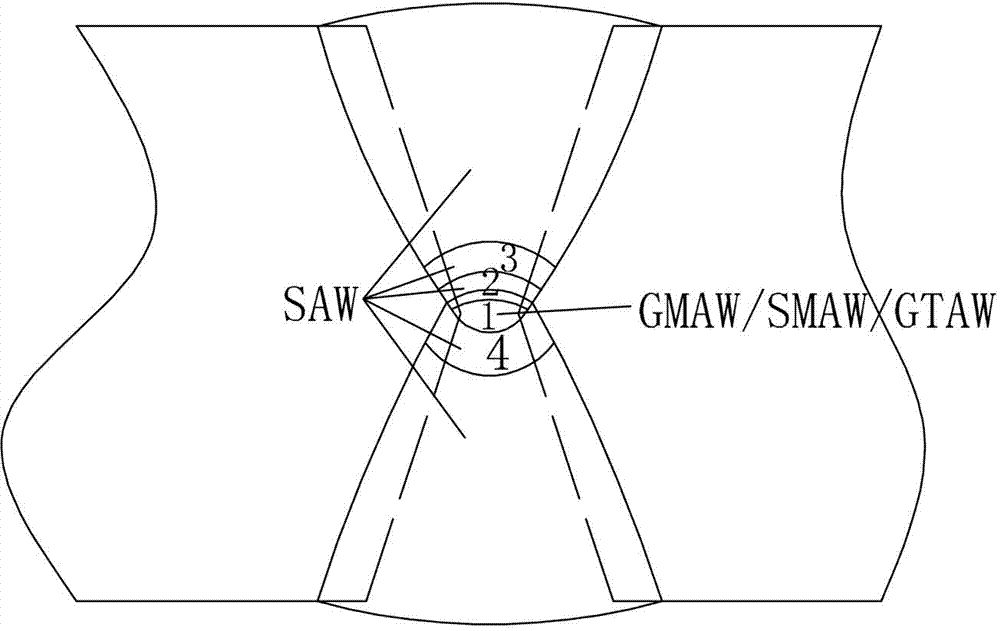

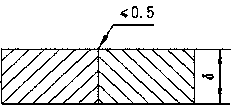

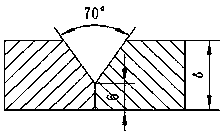

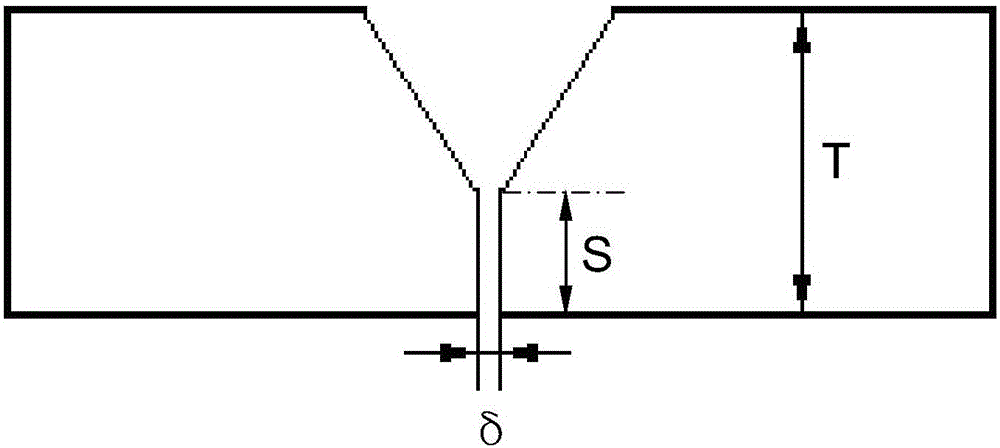

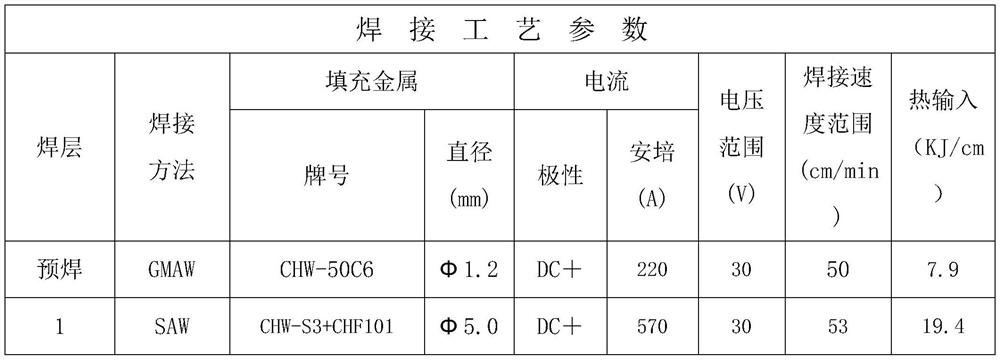

Medium thickness plate X-shaped bevel welding technology without back chipping

ActiveCN104493342AButt welding problem solvingReduce manufacturing costArc welding apparatusWelding/soldering/cutting articlesElectricityThick plate

A medium thickness plate X-shaped bevel welding technology without back chipping belongs to the technical field of welding, especially to the technical field of carbon steel, stainless steel medium thickness plate submerged arc welding. The submerged arc welding is used to weld without back chipping. The technology comprises the following steps: A pre-welding cutting and assembling; B front backing welding; C front low-current submerged arc welding; D back welding; E residue filling and cover welding. The technology method is suitable for welding weld seams of more than 10 mm, and is not sensitive to the differentiation change in the quality of bevels, the assembly clearance, the misalignment value and the surface roughness and suitable for the actual production. A lot of welding materials and electricity are saved, the back chipping and the welding time is shortened, the production cost is obviously saved, and the welding production efficiency is increased.

Owner:RUIDONG GRP

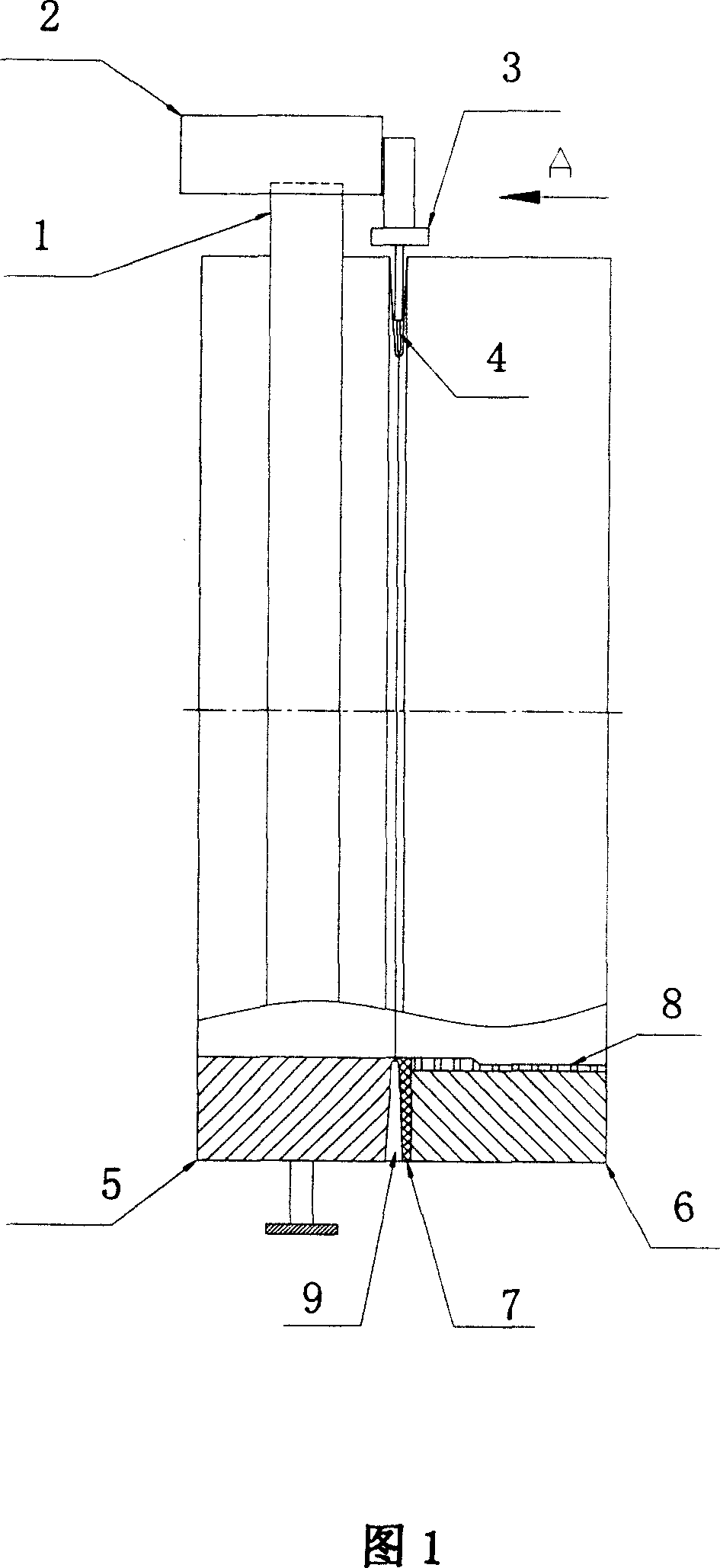

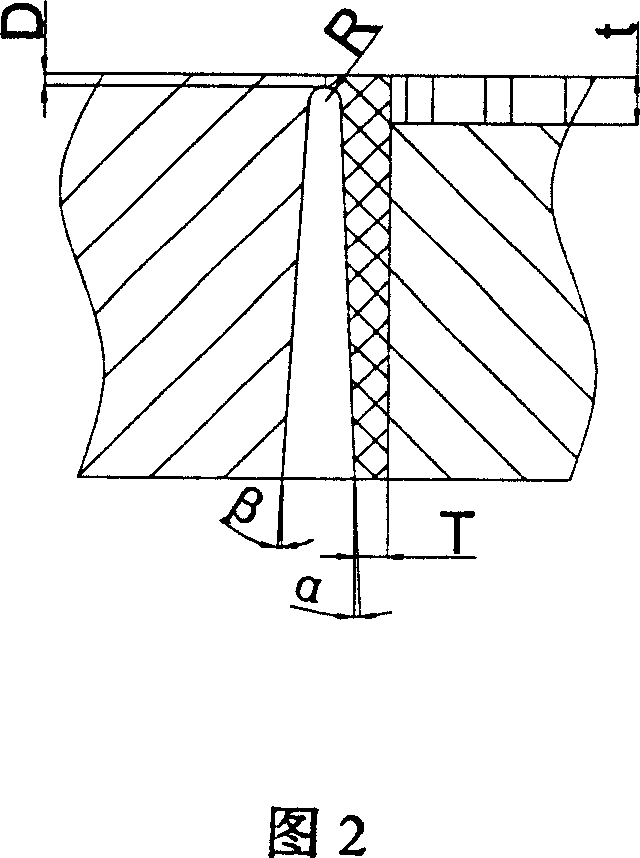

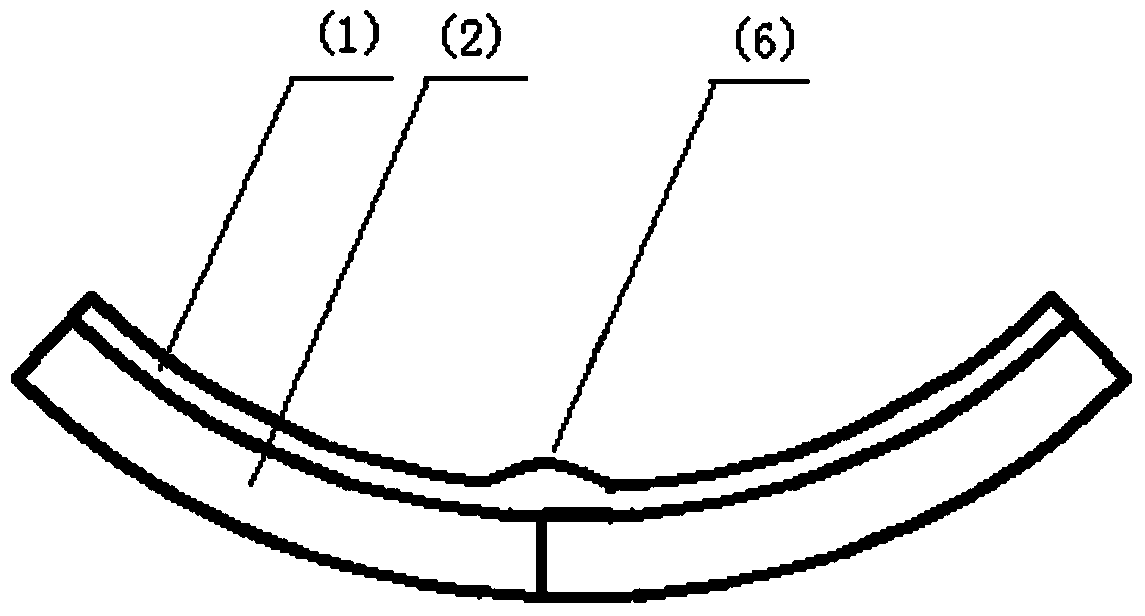

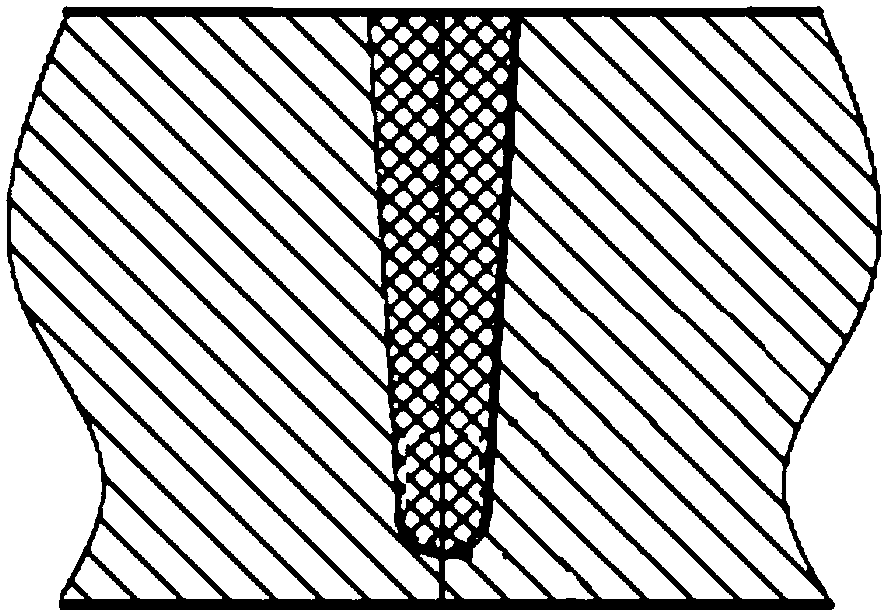

Pipe-shell type heat converter pipe plate and hemispherical closing head single-side welding narrow gap welding technology

InactiveCN101164729AReduce widthReduce the angleArc welding apparatusHeat exchange apparatusShell and tube heat exchangerSpray coating

The present invention relates to a shell-and-tube heat exchanger and hemispherical head one-side weld narrow gap welding process. It is characterized by that its backing weld adopts pen-type manual argon shielded are welding process, its welding material adopts mushroom-type consumable backing ring; the transion weld adopts electrode electric arc welding process, adopts spray coating spatter-proof material; and its main weld adopts narrow gap submerged-arc automatic welding process.

Owner:SHANGHAI ELECTRIC POWER GENERATION EQUIPMENT CO LTD

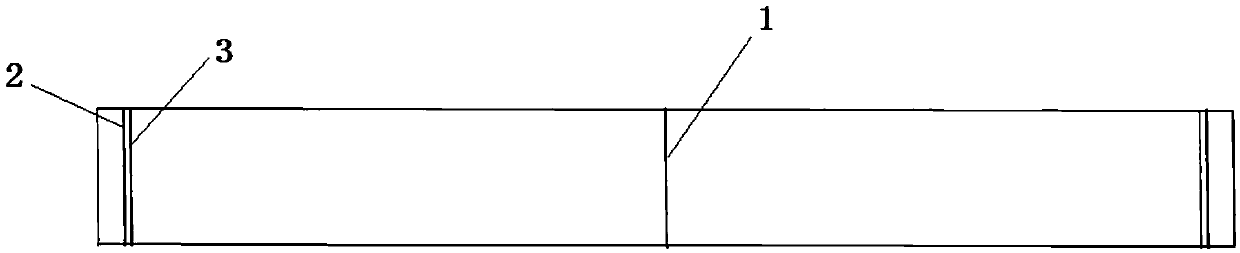

Welded pipe and manufacturing method thereof

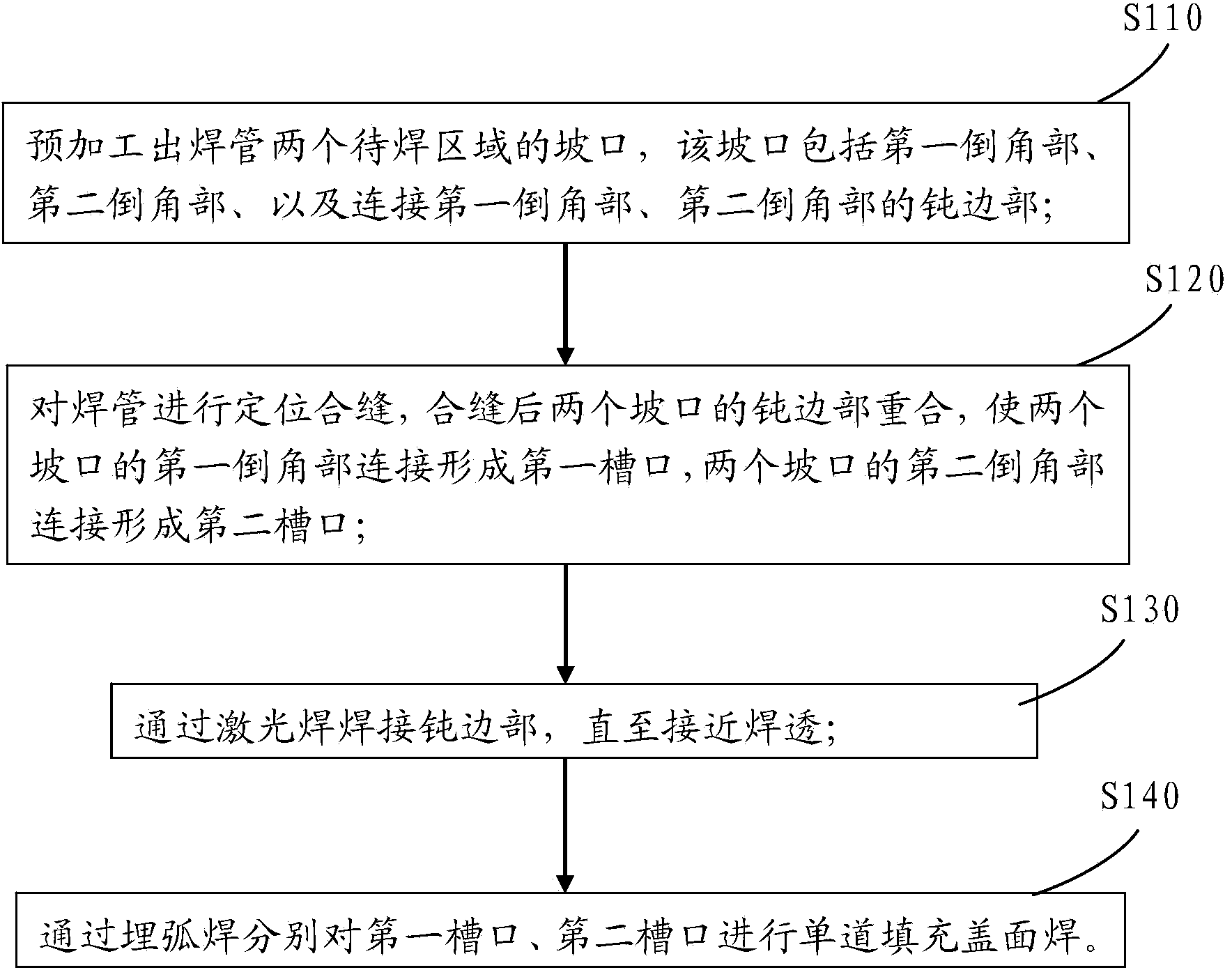

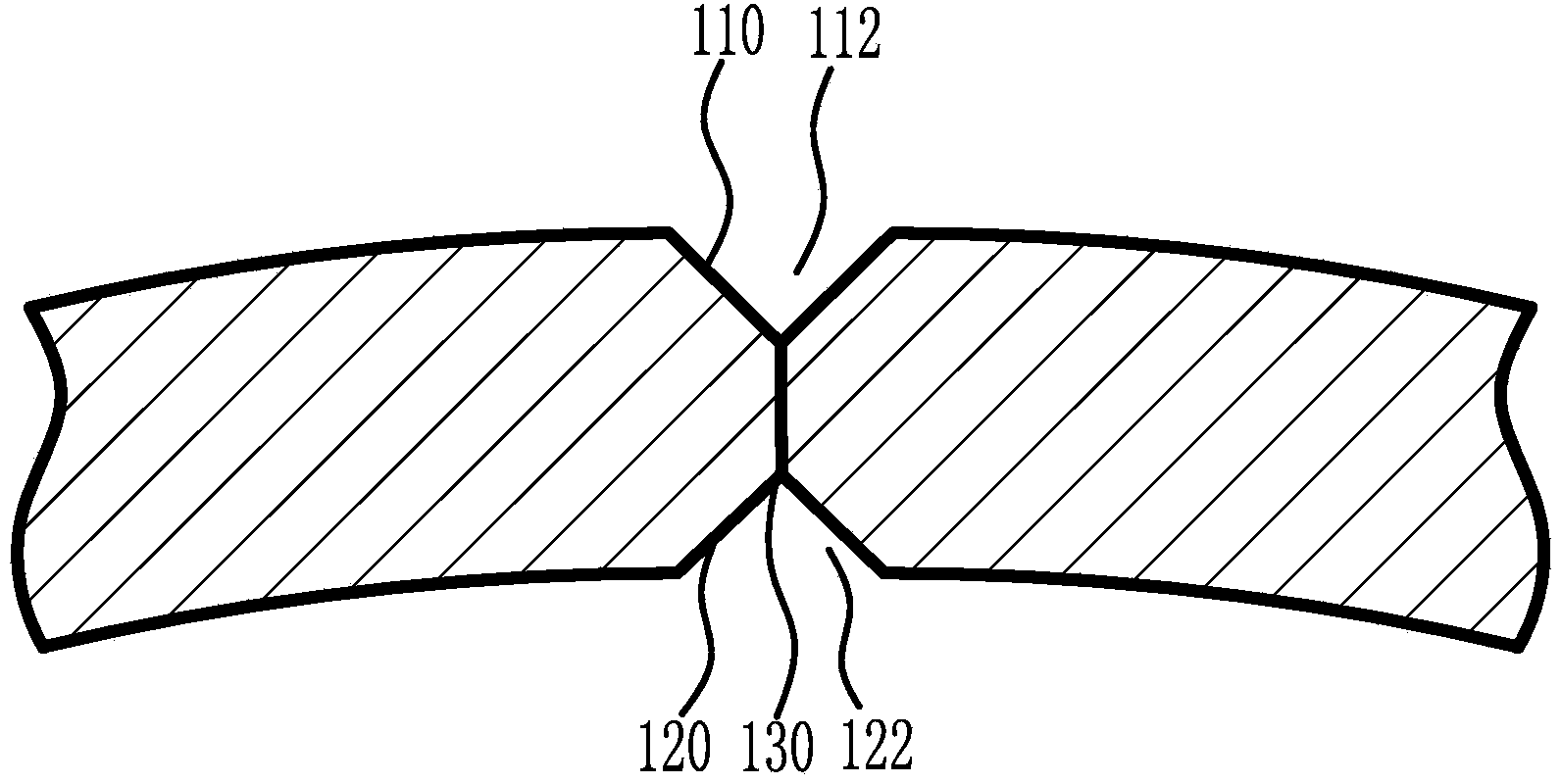

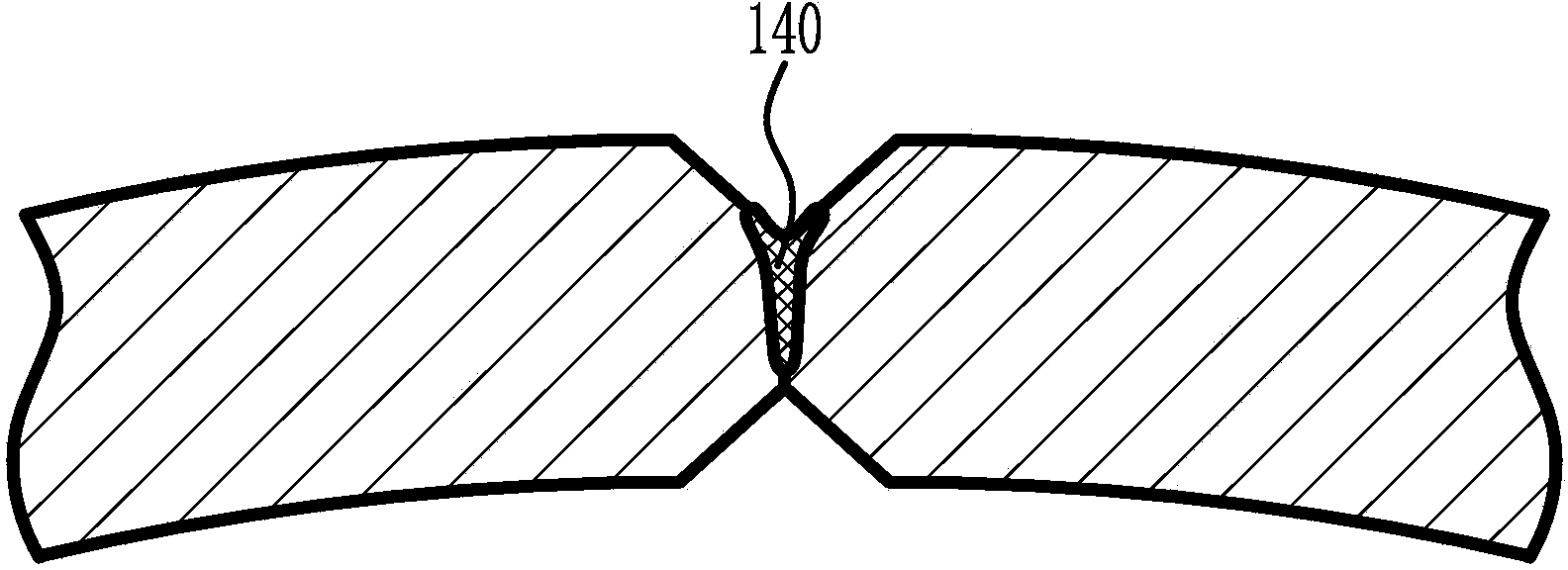

ActiveCN103551750AImprove welding efficiencyImprove welding qualityWelding/soldering/cutting articlesMetal working apparatusEngineeringWeld seam

The invention discloses a welded pipe manufacturing method which includes preprocessing two grooves of an area to be welded of a welded pipe with each groove comprising a first chamfer portion, a second chamfer portion and a truncated edge portion connected with the first chamfering portion and the second chamfering portion; conducting location seam closure on the welding pipe, enabling the truncated edge portions of the two grooves to coincide after the seam closure, and enabling the first chamfer portions of the two grooves to be connected to form a first groove opening and the second chamfer portions of the two grooves to be connected to form a second groove opening; welding the truncated edge portions through laser welding till the truncated edge portions are almost subjected to weld penetration; conducting single-run filling cosmetic welding on the first groove opening and the second groove opening through submerged-arc welding. According to the welded pipe manufacturing method, butt connection of the truncated edge portions of the grooves in the middle of a welding seam is achieved through laser welding, then the submerged-arc welding is utilized to achieve single-run welding, welding times are reduced, preheating and heat insulation are not required, welding production efficiency can be greatly improved, post-welding surplus seam height and lossless yield of the welding seam are higher than those in the prior art, and the performances of the welding seam such as strength, toughness and bending performance are better than those in the prior art.

Owner:番禺珠江钢管(珠海)有限公司

Method for controlling welding deformation between seal head and skirt transition section

ActiveCN103128459AReduce surfacing areaSave man hoursWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMechanical engineering

The invention provides a method for controlling welding deformation between a seal head and a skirt transition section. The method includes welding a processing pad above a position, used for assembling the skirt transition section according to design, of the outer wall of the seal head; welding the skirt transition section at the bottom of the processing pad, and performing bead weld between the inner side surface of the skirt transition section and the seal head; removing the processing pad; and performing girth welding on the seal head and a barrel, and performing bead weld between the upper surface of the skirt transition section and the seal head. The method overcomes defects of the prior art; the welding deformation between the seal head and the skirt transition section can be effectively controlled; welding quality is guaranteed while welding materials are saved; and meanwhile, miss-match of welding joints can be guaranteed during assembling of the seal head and the barrel, and product quality is greatly improved.

Owner:SHANGHAI BOILER WORKS

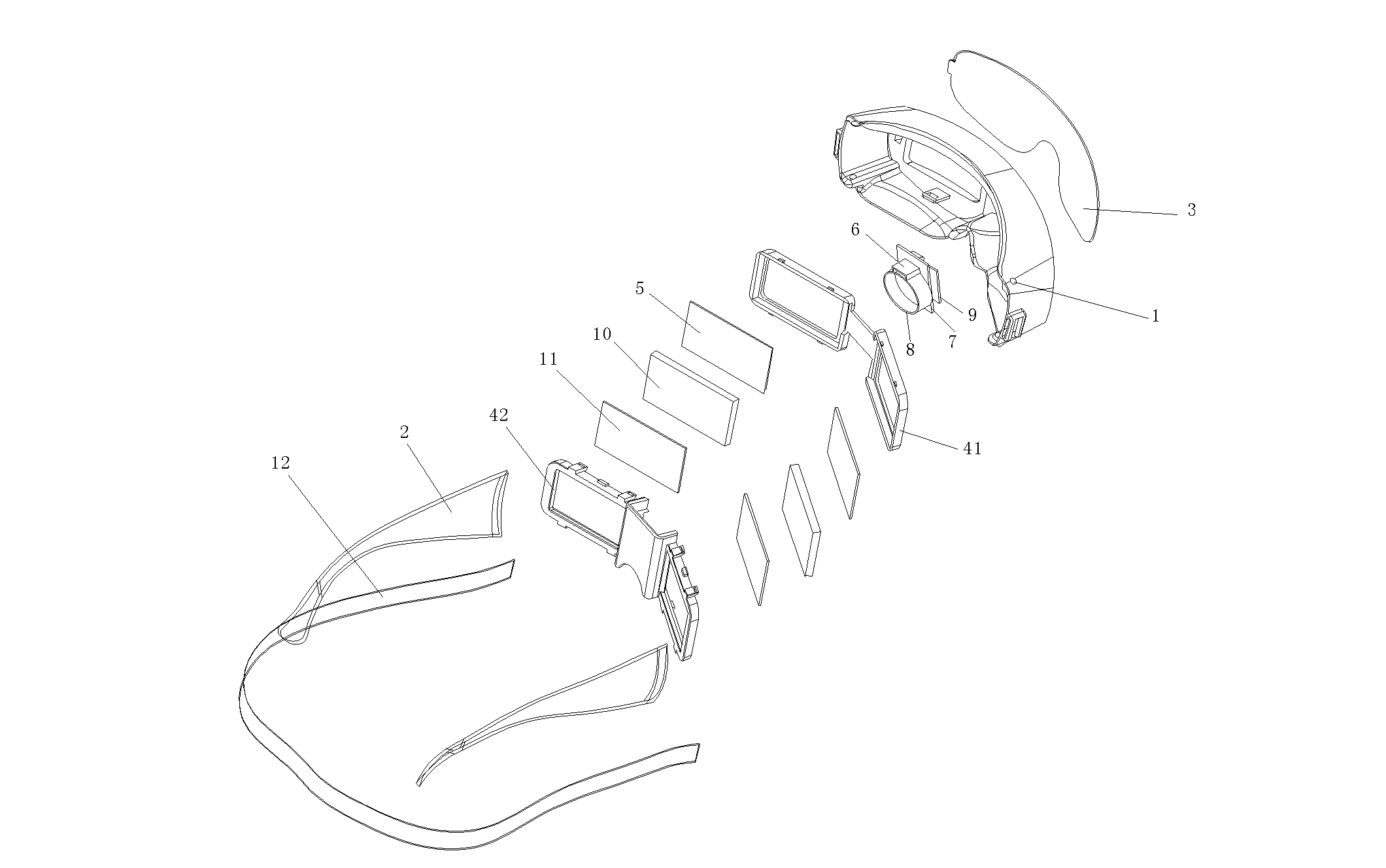

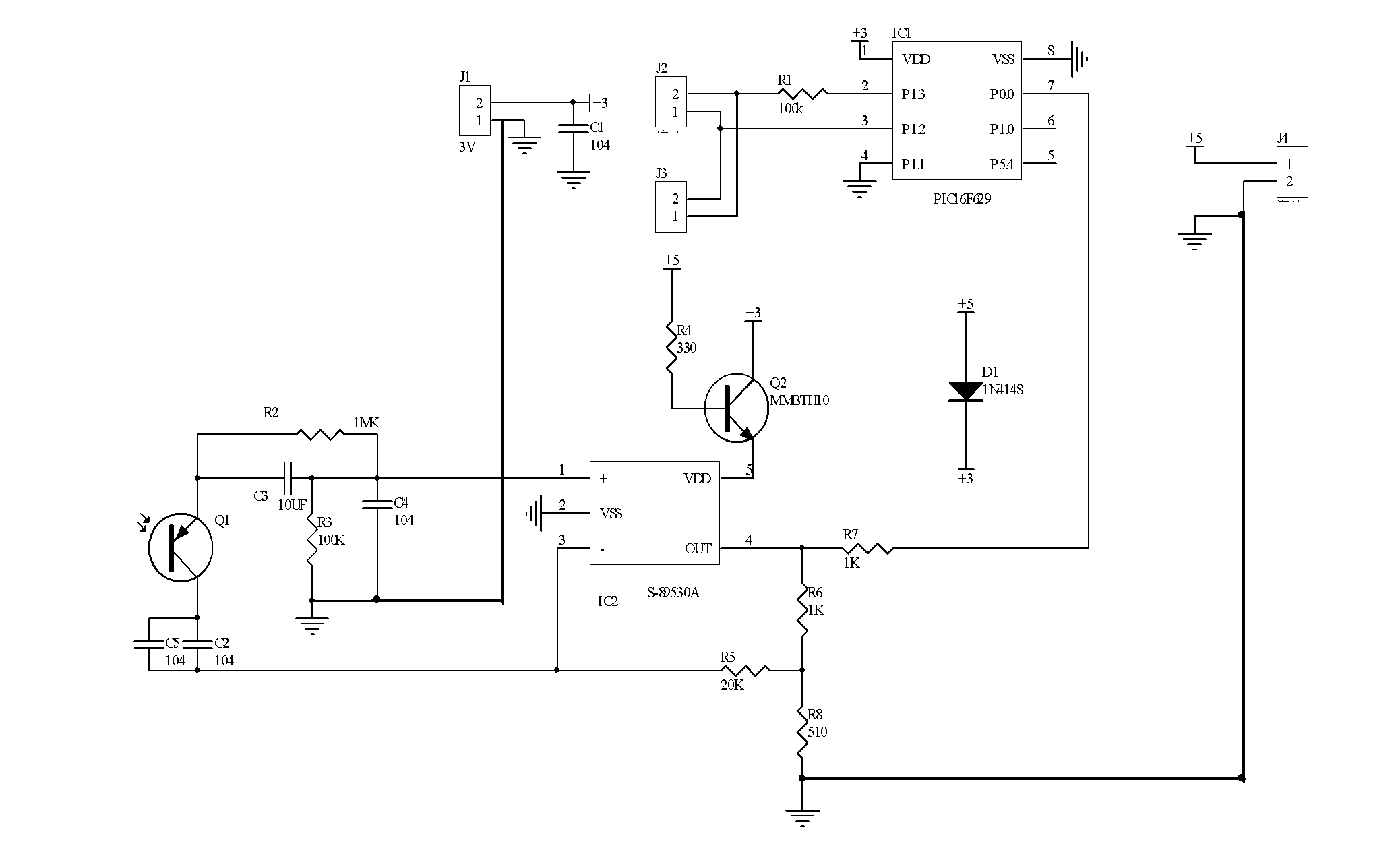

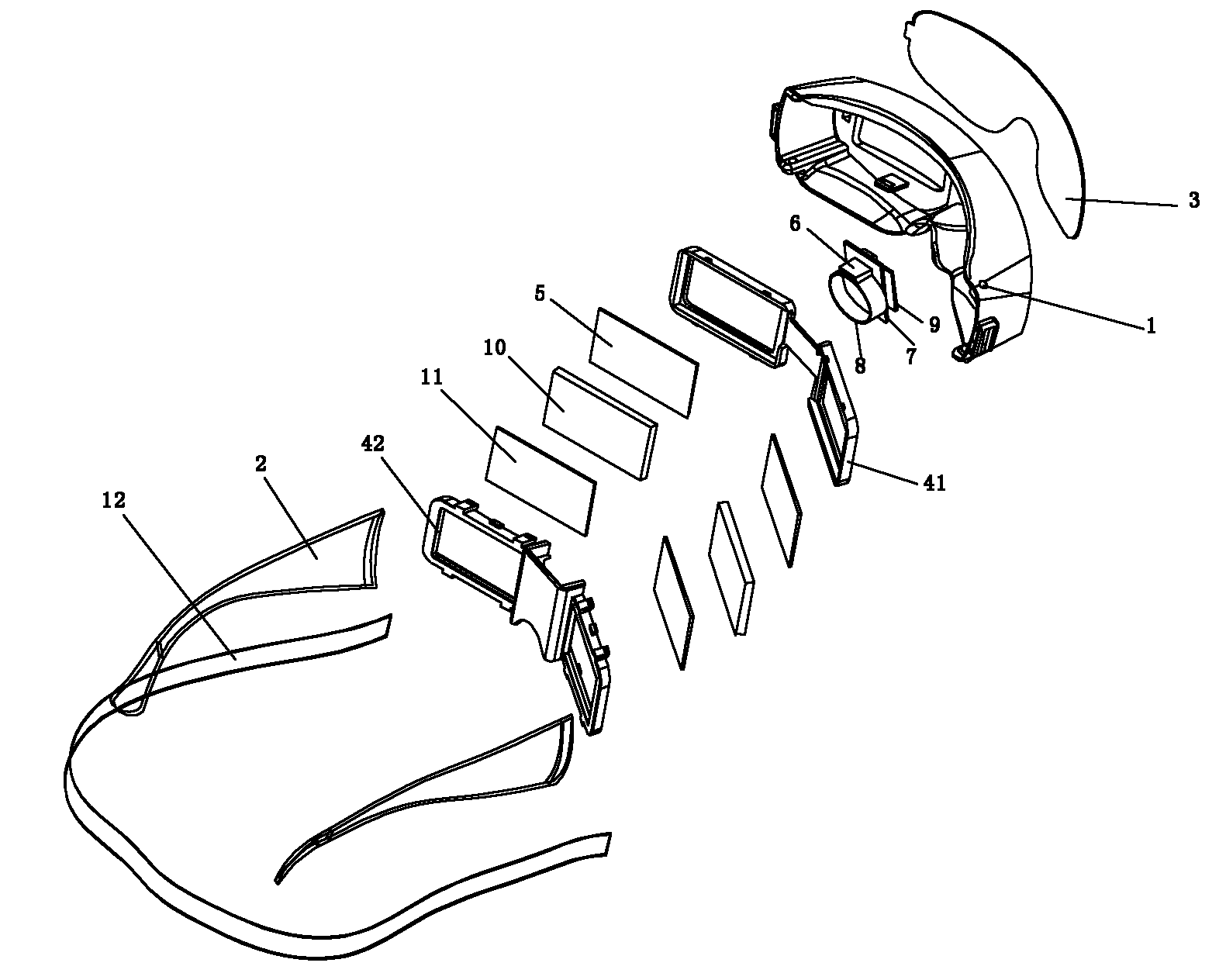

Automatic light-transforming blinkers for welding operation

ActiveCN102551953AAvoid harmAchieve eye protection functionGogglesEye-masksProtecting eyeLiquid crystal light valve

The invention relates to automatic light-transforming blinkers for welding operation, and relates to blinkers. The automatic light-transforming blinkers for the welding operation can automatically transform light according to light intensity on operation sites during welding operation to protect eyes effectively. The automatic light-transforming blinkers are provided with a glass frame, glass tips, an eyeglass and an automatic light-transforming device, wherein the automatic light-transforming device is provided with a frame cover, light filters, liquid crystal light valve plates and a photoelectric control circuit; the frame cover is connected with the glass frame; the light filters and the liquid crystal light valve plates are arranged on the frame cover; the light filters are positioned behind the eyeglass and face the internal surface of the eyeglass; the liquid crystal light valve plates are positioned behind the light filters and face the internal surfaces of the light filters; the photoelectric control circuit is provided with a photoelectric sensor, a control circuit and a direct-current power supply; the photoelectric sensor is arranged on the glass frame; a probe of the photoelectric sensor is exposed and faces the internal surface of the eyeglass; the signal output end of the photoelectric sensor is connected with the signal input end of the control circuit; and the signal output end of the control circuit is connected with the signal input ends of the liquid crystal light valve plates.

Owner:厦门高科防静电装备有限公司

Process for production of double-metal metallurgical composite tube through high frequency resistance welding method and composite tube

InactiveCN103978299AAvoid the effects of corrosion resistanceHigh bonding strengthMetal rolling arrangementsMetal layered productsCorrosion resistant alloyElectric resistance welding

The invention provides a process for production of a double-metal metallurgical composite tube through a high frequency resistance welding method and the composite tube. The process comprises the steps that firstly, a metallurgical composite steel tube with an inner corrosion-resistant alloy lining and an outer base tube is formed; secondly, weld joint grooves in the lining are formed; thirdly, the metallurgical composite tube is formed; fourthly, weld joints for repair welding are formed, so that continuity of the corrosion-resistant alloy lining is achieved. The production process has the advantages of both hot rolling metallurgical composition and electric resistance welding; a hot-rolled metallurgical composite base layer and the lining are combined in a metallurgical mode through a hot rolling method, so that high combination strength is achieved, and the situation that the corrosion resistance of the lining is affected by alloying element dilution due to dissimilar metal welding is avoided. Due to the fact that the base tube and a lining tube are combined in a metallurgical mode, the composite tube can be subjected to circumferential weld welding on a construction side with no need for circumferential build-up welding or sealing welding of tube ends. The production process is simple, convenient, easy to implement, and reliable in quality; transition welding materials are not needed between the base tube and the lining, so the welding materials and welding time can be saved, and production efficiency is high.

Owner:BEIJING LONGSHINE OIL TUBULAR TECH +1

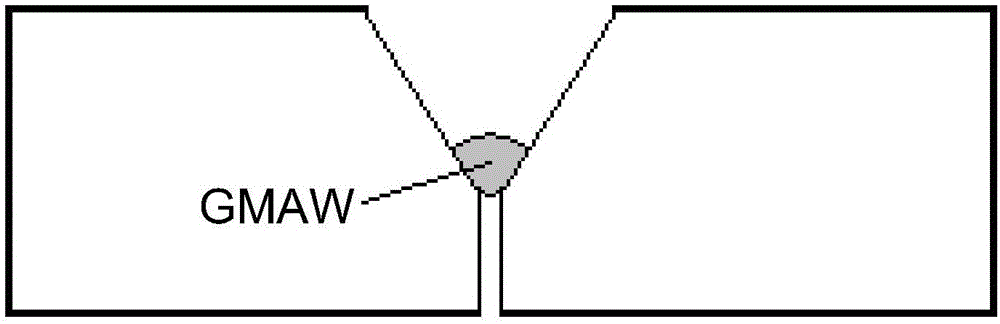

Narrow-gap metal active gas (MAG) welding method for large-thickness shroud type diaphragms of turbines

InactiveCN102935545AReduce groove sizeImprove deposition efficiencyArc welding apparatusEngineeringSpot welding

The invention relates to a narrow-gap MAG welding method for large-thickness shroud type diaphragms of turbines to solve problems of conventional groove forms of prior turbine diaphragms, low production efficiency of CO2 shielded welding, instable welding quality, and high repair rate and production cost. The method comprises that narrow-gap V-shaped grooves (usually 6 degrees to 8 degrees) are opened on a diaphragm outer ring and a diaphragm body respectively, a main weld joint of a gas outlet side is spot welded, and cross spot welding is performed; a spot welding Z-shaped connection block is assembled on a middle split surface of the diaphragm, and a spot welding lead and an arc blowout plate are assembled on the other side; a main welding joint of a gas inlet side of the diaphragm is spot welded firmly; gas passages of the gas inlet side and the gas outlet side are covered with a layer of asbestos cloth, and a rigid ring is welded; preheating and welding are preformed, and the diaphragm is completed through the MAG welding method; and de-stressing heat treatment is performed after welding. The narrow-gap MAG welding method for large-thickness shroud type diaphragms of turbines is applied in the mechanical welding field.

Owner:HARBIN TURBINE

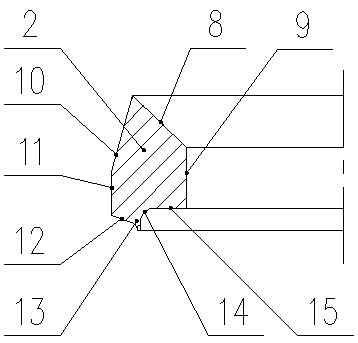

back chipping-free and full penetration (I level component) robot welding technology of medium plate K-shaped groove

InactiveCN107866624ASmooth swingSave welding consumablesArc welding apparatusUltrasound testWeld seam

The invention belongs to the technical field of steel structure welding, and discloses a back chipping-free and full penetration robot welding technology of a medium plate (t>=30 mm) K-shaped groove.The robot welding technology comprises the steps that plates are prepared, the plates are cut so as to form a technology groove, splicing welding is conducted on the plates, a lead-in arc plate and alead-out arc plate are additionally installed, and full-length welding is conducted on an additionally installed rib plate. Welding is conducted on the two medium plates by applying the robot weldingtechnology, then the lead-in arc plate and the lead-out arc plate are dismounted, and ultrasonic checking is conducted on a welding seam of a spliced plate. In the welding process of the medium plates, it is ensured that the quality level of the welding seam can reach the requirement of a full penetration welding I level, welding deformation is small, back chipping treatment does not need to be conducted on a welding pass, welding materials are saved, the production cost is reduced, a large number of human resources can be saved by adopting robot automation welding, the manual labor intensityis relieved, meanwhile, the production efficiency is high, and the construction requirements for being advanced in technology, and capable of saving energy and reducing consumption are met.

Owner:TANGSHAN KAIYUAN AUTOWELDING SYST

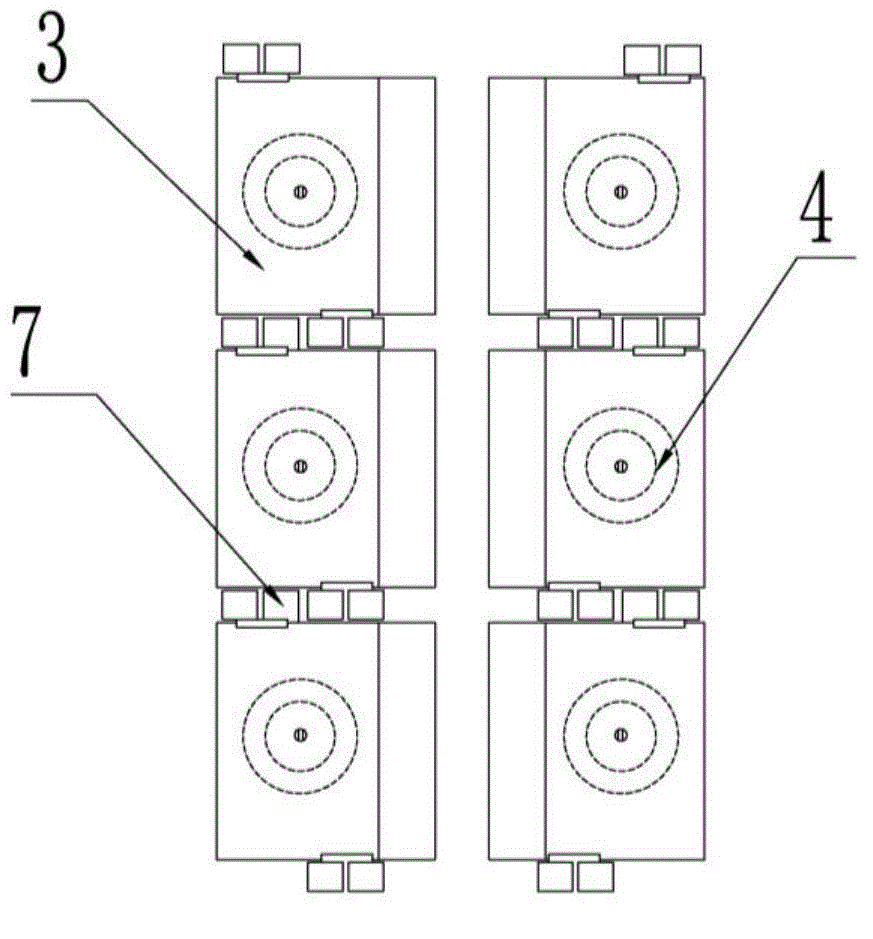

Device and method for controlling suspension welding seam root gap and welding deformation in self-supporting mode

ActiveCN104625318AWell formedEasy to useWelding/cutting auxillary devicesArc welding apparatusEngineeringWeld seam

The invention discloses a device and method for controlling a suspension welding seam root gap and welding deformation in a self-supporting mode. The device comprises a positioning block, upper rigid press blocks, a lower rigid press block and a forming groove. The positioning block comprises a positioning block body and a positioning part, wherein the positioning part penetrates through the seam root gap and is embedded in the forming groove. The upper rigid press blocks are symmetrically installed on the two sides of the positioning block body, the lower rigid press block is provided with provided with an inward-concave part matched with the forming groove, and the forming groove is formed in the inward-concave part. Magnets are installed in the upper rigid press blocks and the lower rigid press block. The invention further discloses the method with the device for controlling the suspension welding seam root gap and the welding deformation in the self-supporting mode used. The device for controlling the suspension welding seam root gap and the welding deformation in the self-supporting mode is convenient to use, low in cost and high in adaptation, the transverse retraction and staggered edges of a welding seam can be controlled, the welding deformation can be reduced, and it can be ensured that the back face of the welding seam is good in formation.

Owner:CSSC HUANGPU WENCHONG SHIPBUILDING COMPANY

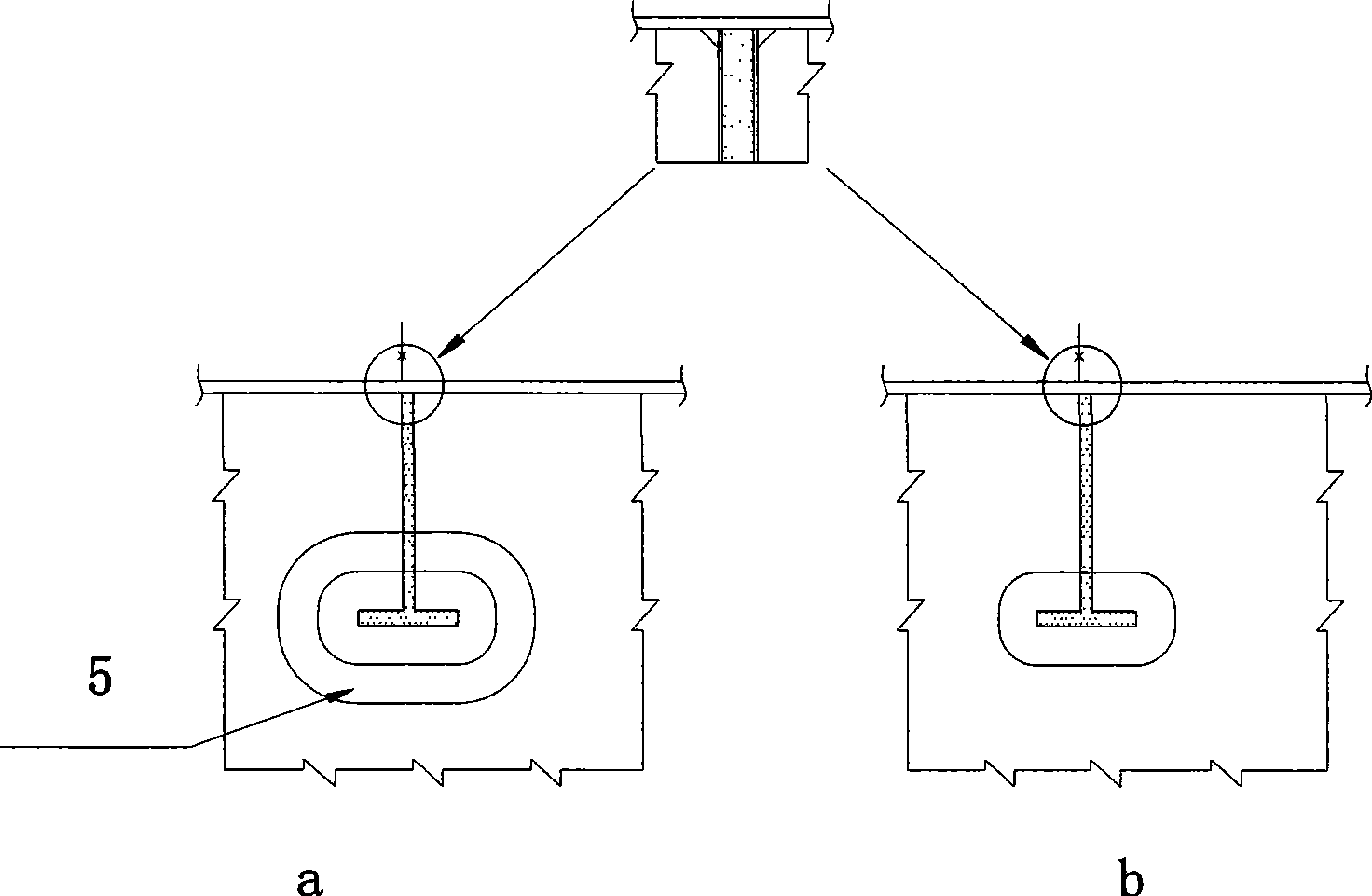

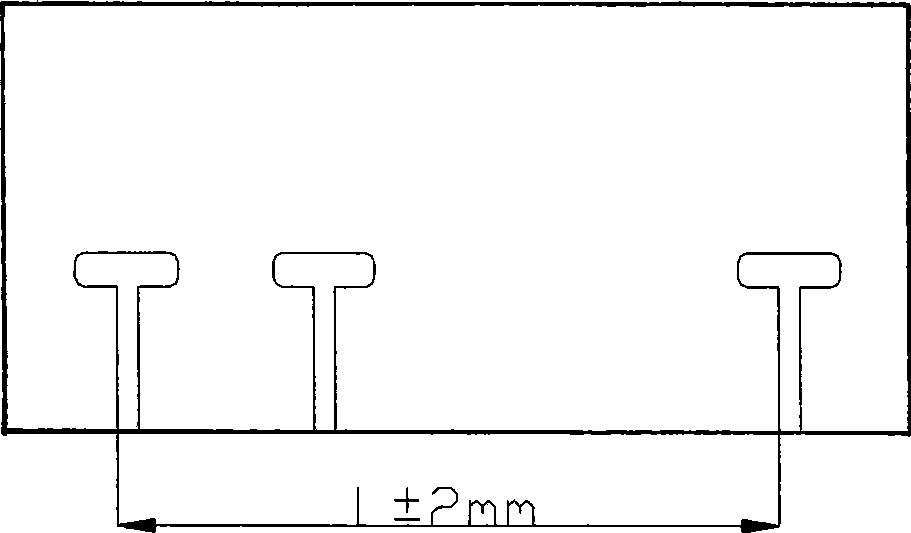

Pull-in manufacturing method of rib plates of ship shell plate

InactiveCN104260825ASave steelReduce labor and labor intensityWatercraft hull designVessel partsEngineeringSurface plate

Owner:JIANGSU YANGZI XINFU SHIPBUILDING CO LTD

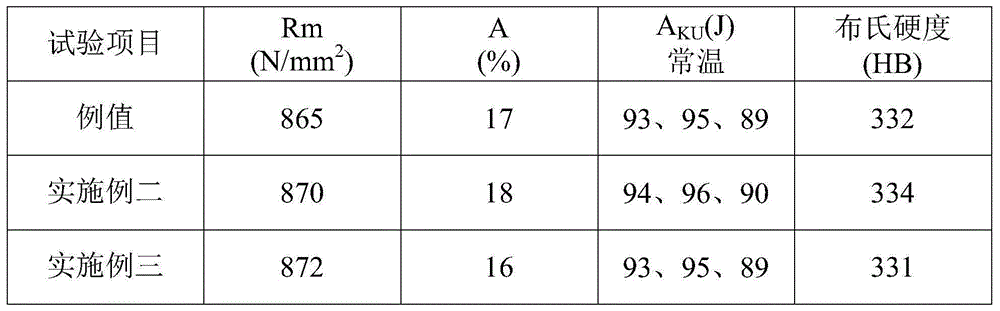

Self-protection flux-cored wire for steel rail repair welding

ActiveCN105149814AStrong wind resistanceSuitable for online repair workRailsWelding/cutting media/materialsSlagFerrosilicon

The invention provides a self-protection flux-cored wire for steel rail repair welding. A flux core of the self-protection flux-cored wire comprises alloy components and slag system components. The alloy components include, by weight, 0.05-0.20 part of C, 0.60-1.20 parts of Cr, 1.00-3.50 parts of Ni, 0.30-0.70 part of Mo and 0.005-0.05 part of Zr. The slag system components include, by weight, 8-12 parts of Fe2O3, 0.5-3.5 parts of BaCO3, 12-17 parts of aluminum magnesium alloy, 24-32 parts of BaF2, 7-13 parts of CaF2, 13-18 parts of LiF2, 9-15 parts of rare earth ferrosilicon and 4-9 parts of Al2O3. According to the self-protection flux-cored wire for steel rail repair welding, no protective gas is needed in the welding process, the wire can make gas by itself to form the protective atmosphere, the wind resistant capacity is strong, welding can be applied under the four-level wind power, and the self-protection flux-cored wire is suitable for repair working on field steel rails.

Owner:TIANJIN GOLDEN BRIDGE WELDING MATERIALS GRP

Intelligent and efficient welding method of thin-wall stainless steel

InactiveCN108247228AStrong coverageImprove welding efficiencyArc welding apparatusPlasma welding apparatusAutomatic controlEngineering

The invention discloses an intelligent and efficient welding method of thin-wall stainless steel, and belongs to the field of welding of the machine building industry. The defect in the prior art areovercome. According to the method, P+T complex process welding equipment is adopted, and a welding method of combining plasma arc welding and argon tungsten-arc welding through an automatic control system is adopted. In the welding process, a workpiece is fixed, and a welding gun moves. Plasma arc welding and argon tungsten-arc welding can be synchronously completed in the welding process, and canalso be completed step by step. According to a step method, after through welding is carried out at a time through plasma arc welding, automatic wire filling is carried out through argon tungsten-arcwelding, and face covering is completed. When the thickness of a plate ranges from 3 mm to 8 mm, chamfering is not needed, and the synchronous method can be used. When the thickness of the plate is larger than 8 mm, chamfering is needed, and the step method can be used. The method is high in welding quality, single-face welding and double-face forming can be achieved, and welding efficiency is greatly improved; and welding materials are saved, the labor environment is improved, and the method is widely suitable for welding of circular longitudinal seams and plate seams of a thin-plate stainless steel container.

Owner:LANZHOU LS HEAVY EQUIP

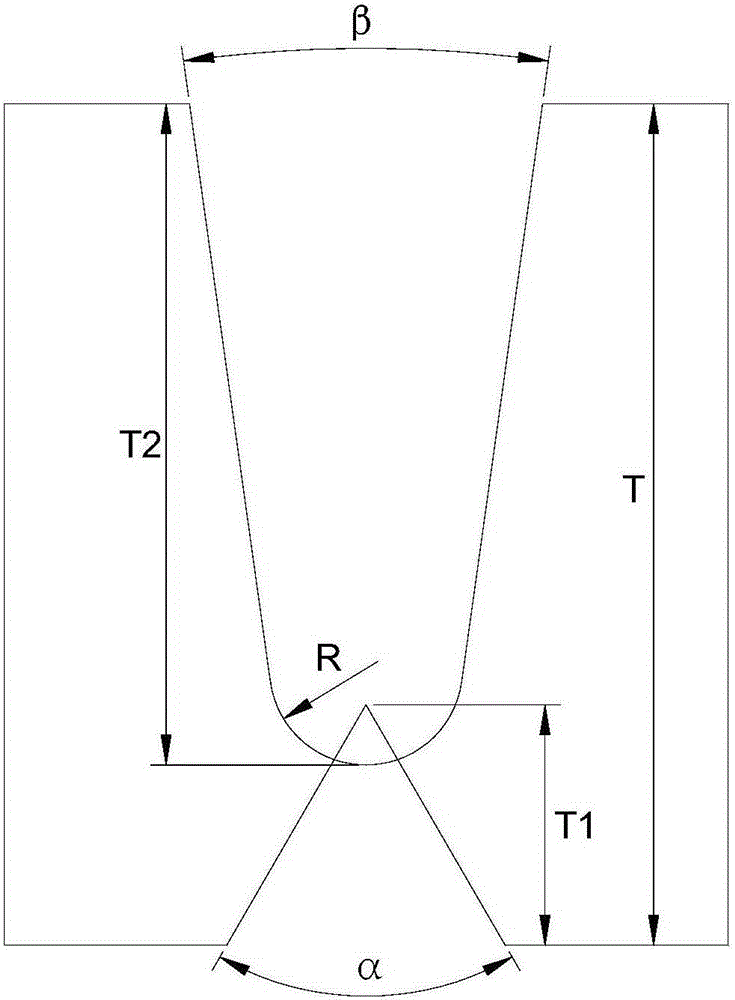

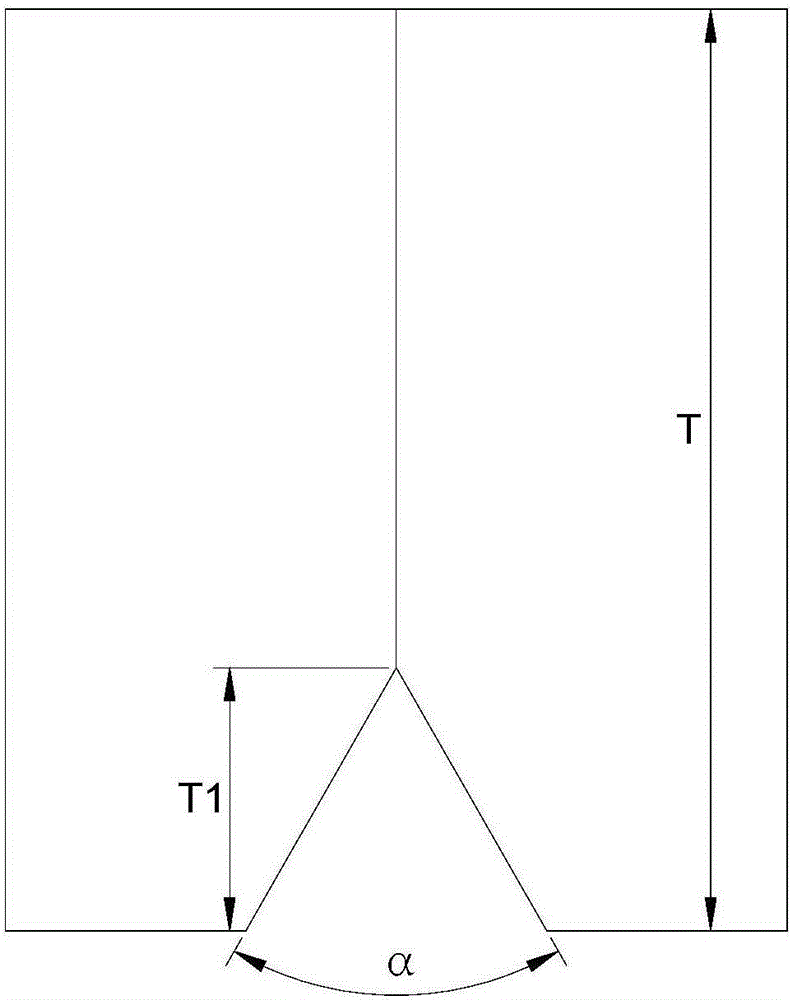

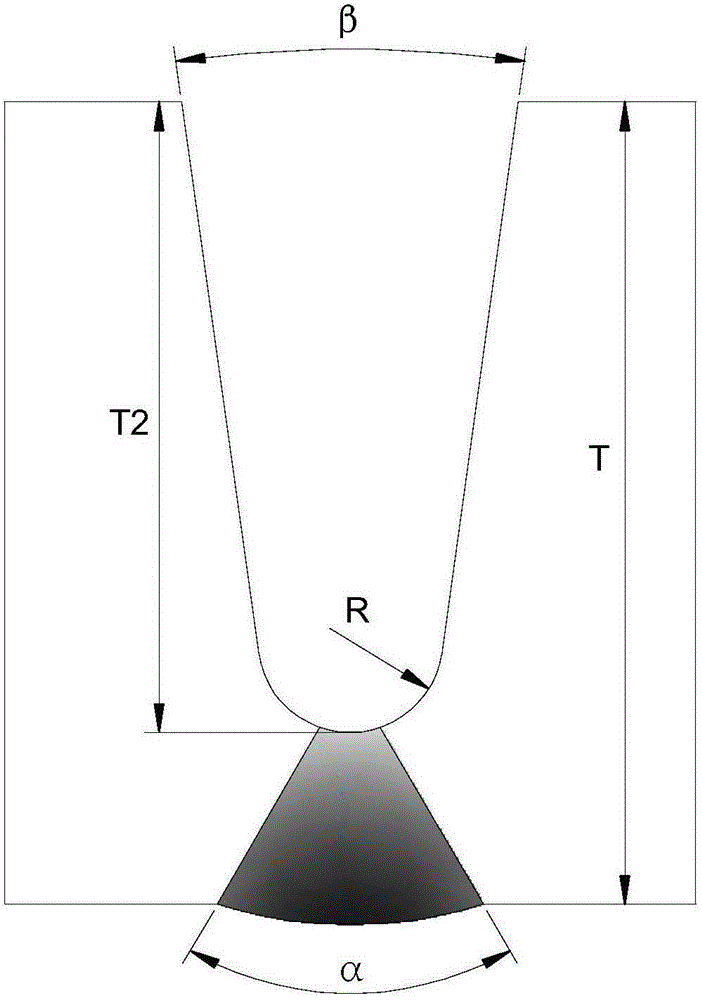

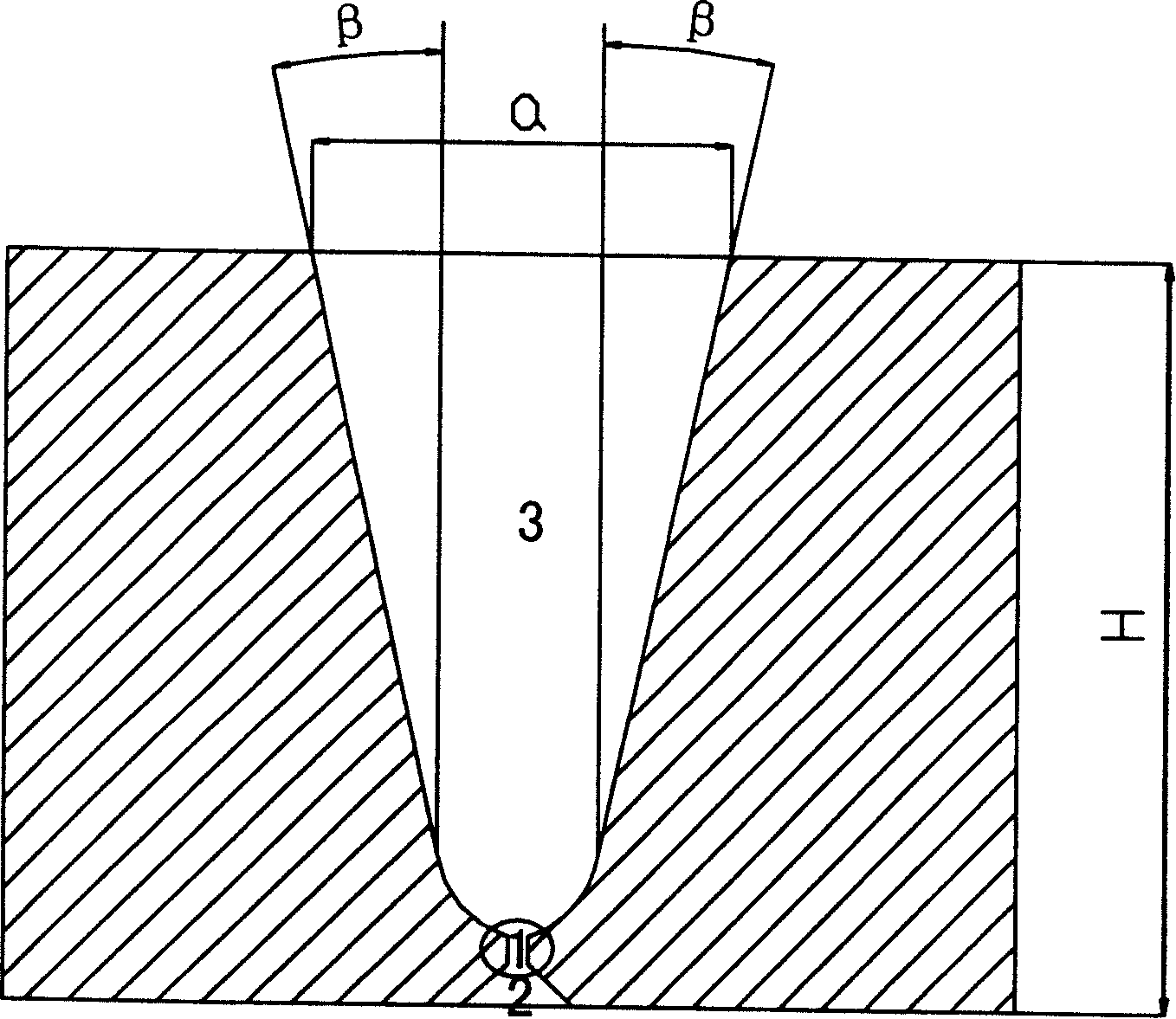

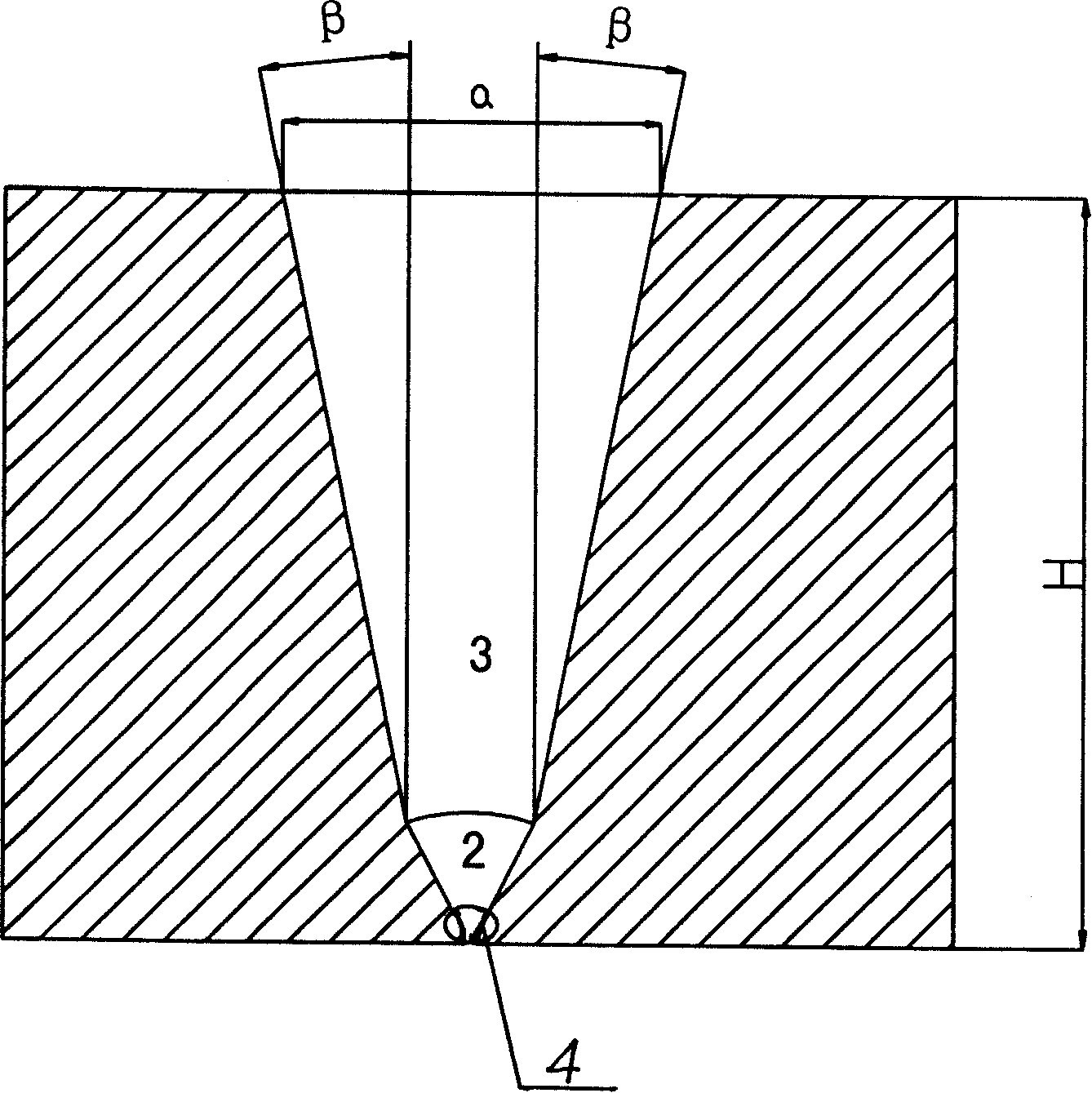

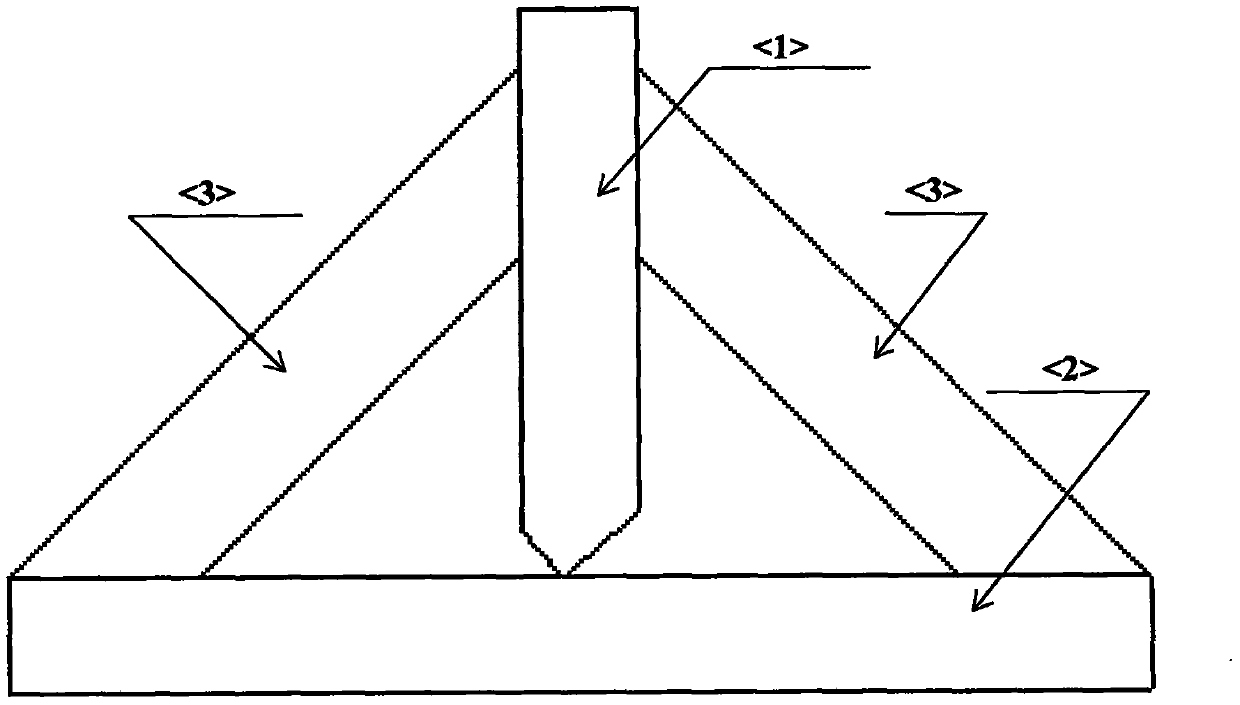

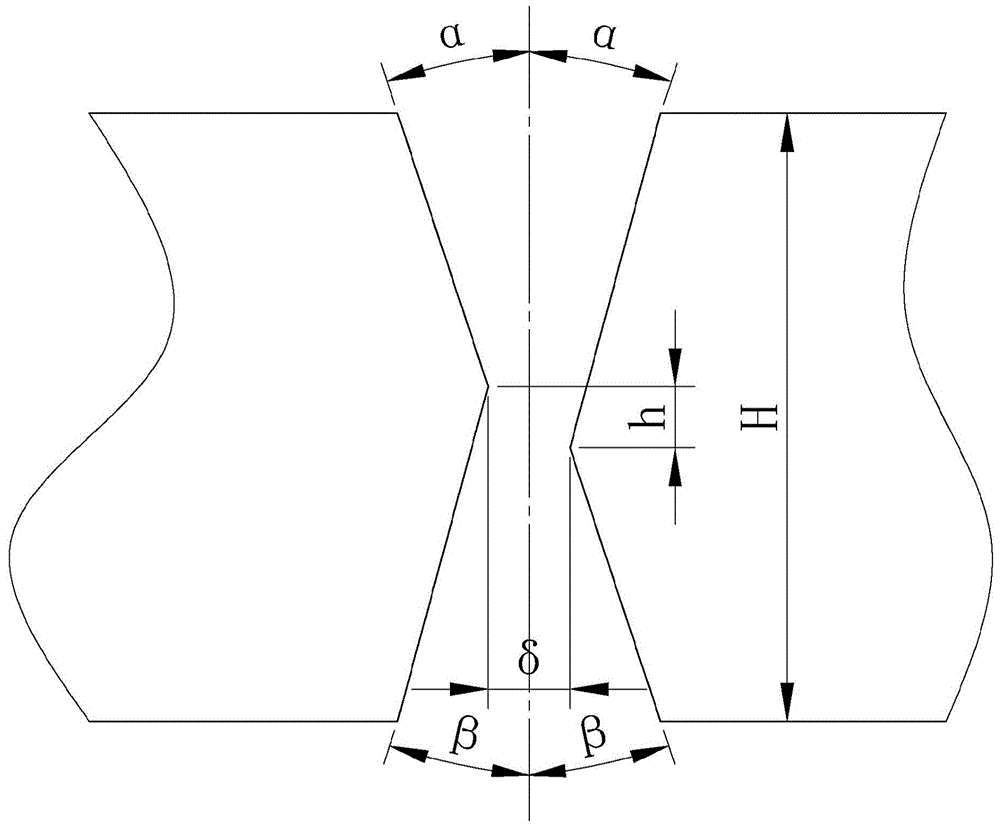

Improved welding process for longitudinal joint grooves of thick-walled container barrels

InactiveCN107639359AImprove pass rateSave welding consumablesWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMiddle line

The invention discloses an improved welding process for longitudinal joint grooves of thick-walled container barrels. The improved welding process is applicable to steel plates thicker than 100mm. Theprocess includes: calculating straight length of a steel plate; marking a net material line and a center line on the steel plate; performing pre-bending and coiling forming; performing gas cutting toremove a pressure head of a three-roller plate bending machine from a container barrel section; performing processing of a narrow gap U-shaped groove according to the net material line; returning tothe three-roller plate bending machine to perform closing, rolling and aligning; finally starting a welding process; after welding is completed, subjecting the container barrel section to roundness correction. The improved welding process has advantages that a great quantity of welding materials are saved, labor intensity is relieved, production efficiency is improved, the once qualification rateof weld joints is greatly increased, and a promising application prospect is achieved.

Owner:ERZHONG GROUP ZHANJIANG HEAVY EQUIP FACTORYCO

Turn over bracket for flat plate

InactiveCN1701906AImprove work efficiencyReduce labor intensityWelding/cutting auxillary devicesVessel partsInvestment materialBilateral symmetry

This invention relates to flat pallet turn bracket and belongs to shipbuilding field, which comprises beam channel, two pieces of stiffeners, two pieces of non-skid square bars and two strength circular rings; set circular holes taken two points of bilateral symmetry along the center line of beam channel as the centers of circle; set stiffeners in back surface break angle of beam channel and non-skid square bars near the circular holes on beam channel right surface. This invention overcomes the shortcomings, the difficult problem that can not turn over in existing technique, and workpiece shortage and auxiliary material waste problem. Structure is simple and convenient to circuit use; operation staff will have high work efficiency and low labor intensity. This invention can save cost and has so many aforementioned advantages.

Owner:SHANGHAI WAIGAOQIAO SHIP BUILDING CO LTD

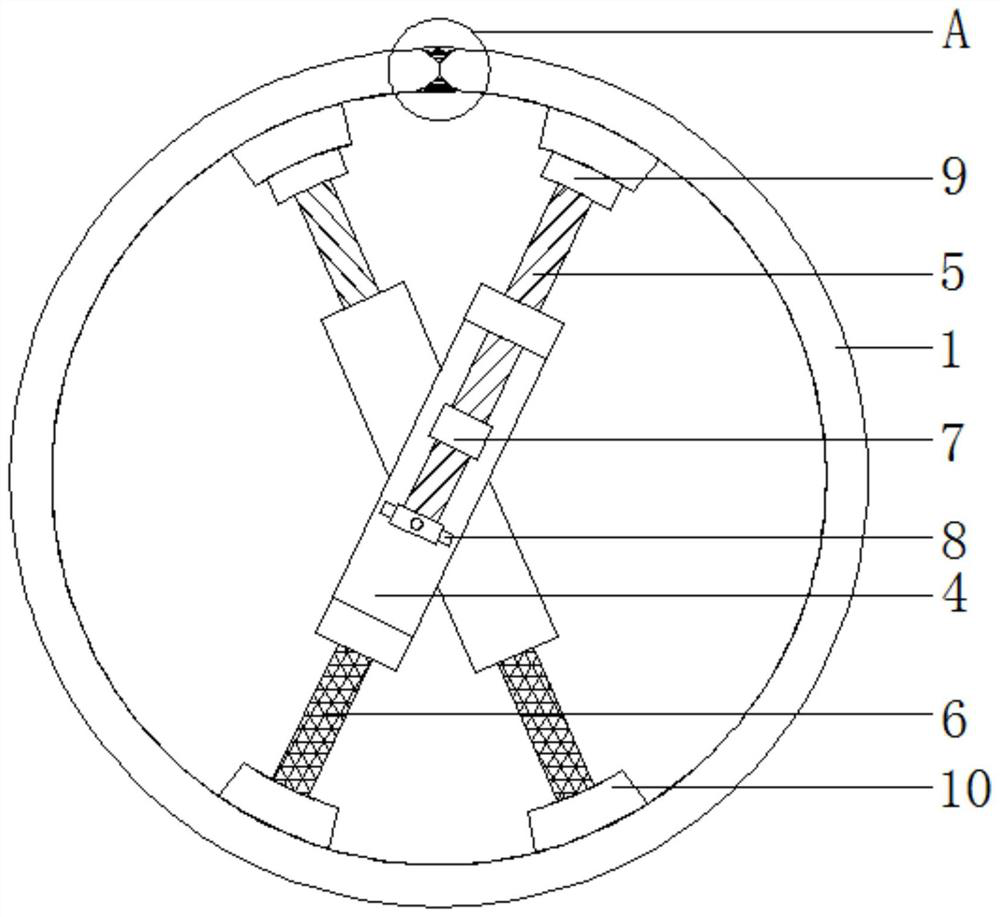

Method for enhancing back cover bond stress based on offshore steel inclined pile foundation

InactiveCN109778891AImprove stress resistanceGuaranteed firmnessFoundation engineeringReinforced concreteRebar

The invention discloses a method for enhancing back cover bond stress based on an offshore steel inclined pile foundation and relates to the technical field of civil engineering. The method comprisesthe steps of prefabricating shear connectors, prefabricating a hole sealing assembly, welding spiral ribs, assembling a prefabricated part, pouring concrete and sealing, and the like. The shear connectors are arranged on the periphery of the steel pipe pile, part of stress transmitted by the reinforced concrete layer can be transmitted in the direction perpendicular to the axis of the steel pipe pile, and therefore the compression resistance of the reinforced concrete layer is improved, and meanwhile the firmness of connection between concrete and the shear connectors can be guaranteed throughthe arranged extending pieces.

Owner:CCCC SHEC FOURTH ENG

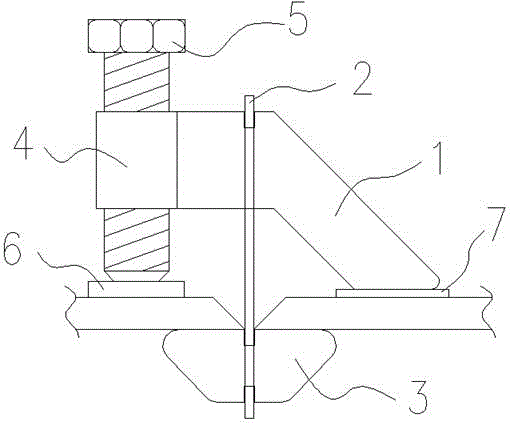

Movable horse board

InactiveCN104476069ASave materialSave welding consumablesWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMotherboard

The invention relates to a movable horse board. The movable horse board comprises a main board, a plug board, a base plate, a nut and a bolt, wherein the main board is composed of a horizontal component and an oblique component; the upper end of the plug board is arranged on the main board, and plug board is vertical to the horizontal component on the main board; the lower end of the plug board is arranged on the base plate; one end of the horizontal component of the main board is connected with the nut while the other end is connected with the oblique component; the bolt is arranged in the nut. The movable horse board has advantages that the movable horse board can be used repeatedly, a lot of horse board material, welding material, manpower and the like are saved; the subsequent horse board cutting, grinding and paint repairing workload is reduced; the movable horse board is beautiful and does not have horse legs.

Owner:WISON NANTONG HEAVY IND

Concentric-square-shaped groove frame machining method and series connection insert joint bending die

ActiveCN106734443ASolve the production narrow mouth problemReduce the length of split weldingShaping toolsUltimate tensile strengthWelding defect

The invention provides a concentric-square-shaped groove frame machining method and a series connection insert joint bending die, and belongs to the technical field of mechanical stamping. Welding defects are reduced, leveling labor hours caused by heat deformation are shortened, and the labor intensity is reduced; and the problem about production narrow openings of Z-shaped bending is solved. The die is composed of three parts including a male die assembly, a female die assembly and a positioning device; insert series connection combining and jointing male and female die inserts are adopted in the male die assembly and the female die assembly correspondingly; the male die assembly comprises seven male die inserts of the same structure and with different lengths; and the concentric-square-shaped groove frame machining method comprises three times of bending. An insert joint tool bending process technology is used for reducing the split welding length, and a common angle supplementing process method is used for manufacturing. Bending of multiple products is completed through the insert joint bending die, the die manufacturing cost is reduced, die replacement can be rapidly carried out, and the product batch consistency is improved.

Owner:BEIJING NORTH VEHICLE GROUP CORP

2205 dual-phase steel automatic welding method

InactiveCN109909584ARealize automatic weldingNo splashArc welding apparatusPlasma welding apparatusSlagEngineering

The invention relates to a 2205 dual-phase automatic welding method. The method includes the steps that longitudinal seams and circular seams of a tube body are welded by adopting a PAW / TIG dual-gun switching longitudinal seam automatic welding system and a PAW / TIG dual-gun switching circular seam automatic welding system. When the slag thickness of the 2205 dual-phase stainless steel tube body is4-10 mm, an I-shaped groove type is adopted, a groove is planned to be a straight edge in a straight-edge butt-jointing mode, and automatic PAW is used for self fusion welding without filler wires once and then is switched to automatic argon arc welding for covering with the filler wires once; and when the slab thickness of the 2205 dual-phase stainless steel tube body is 10-15 mm, a Y-shaped joint groove type is adopted, the groove angle is 75 degrees, the unilateral is 37.5 degrees, the truncated edge is 6 mm, and the automatic PAW is used for self fusion welding without the filler wires once, and then is switched to automatic GTAW for covering with the filler wires 2-4 times until full welding. According to the 2205 dual-phase automatic welding method, back gouging is not needed, automatic welding is achieved, the welding production efficiency is high, no spatter, powder, arc light, and noise exist in the welding process, shapes of welding lines are neat and beautiful, and the quality of whole equipment is improved.

Owner:TIANHUA INST OF CHEM MACHINERY & AUTOMATION

A Welding Process for Unclear Root of X-shaped Groove of Medium and Heavy Plate

ActiveCN104493342BButt welding problem solvingReduce manufacturing costArc welding apparatusWelding/soldering/cutting articlesElectricityThick plate

Owner:RUIDONG GRP

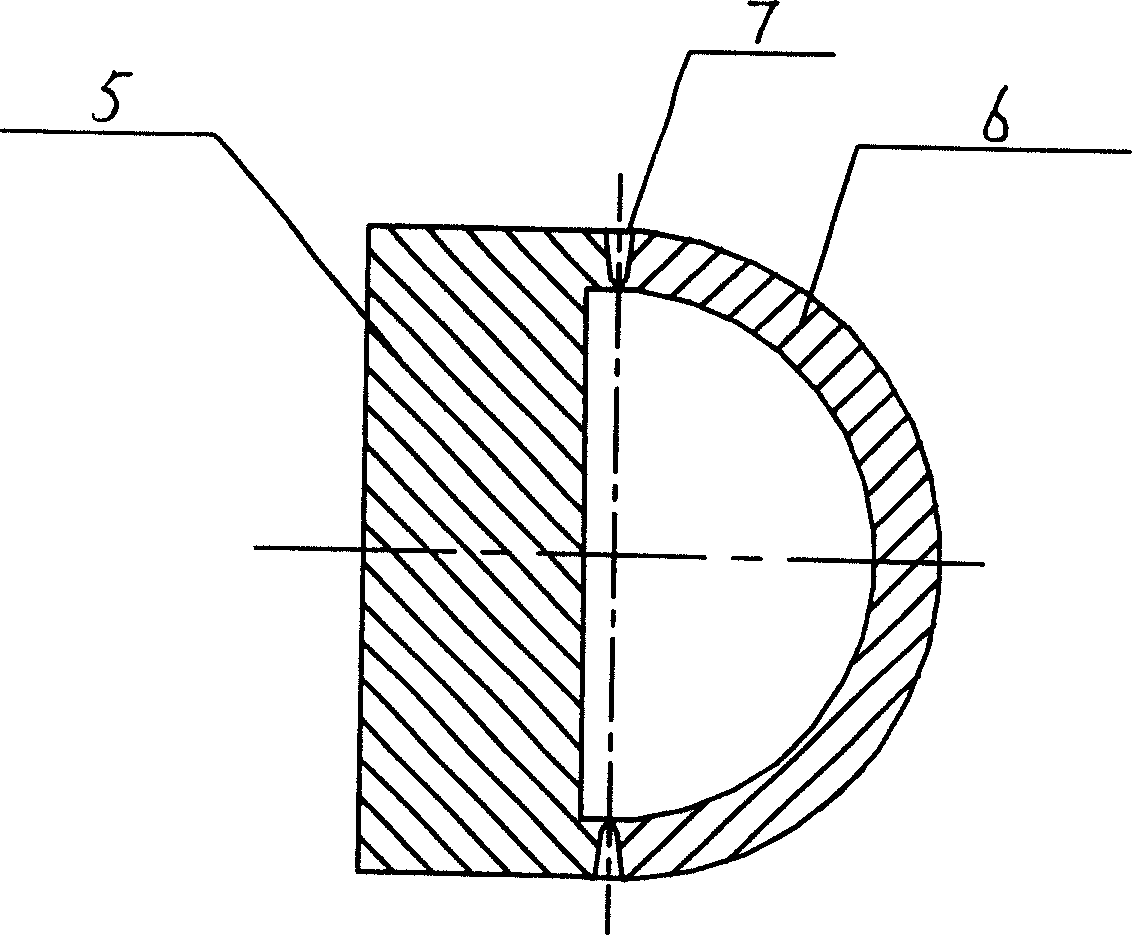

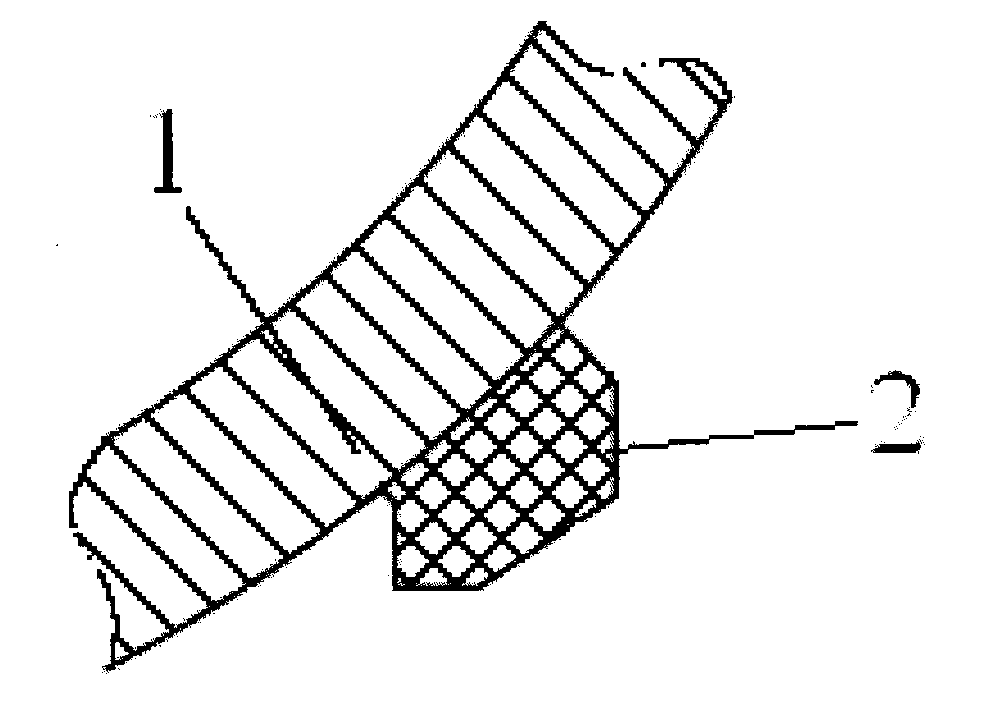

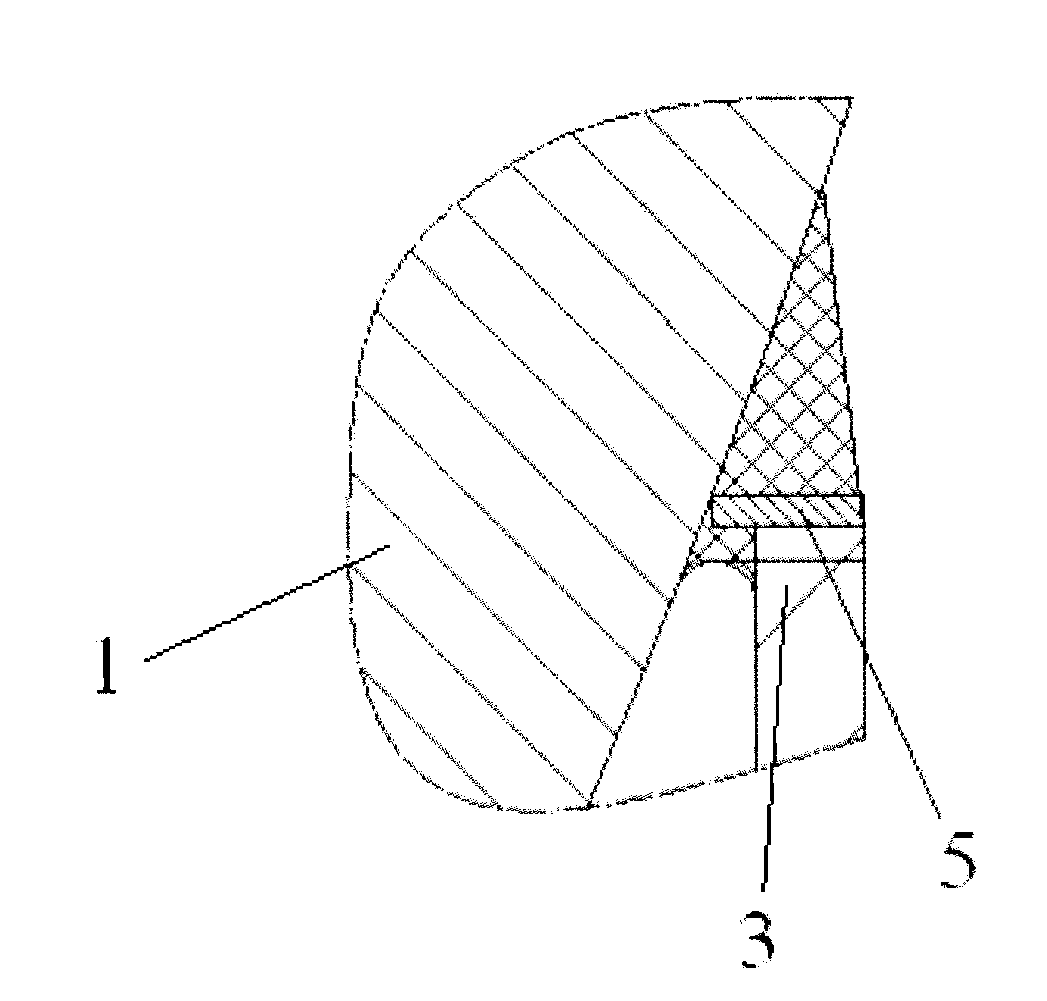

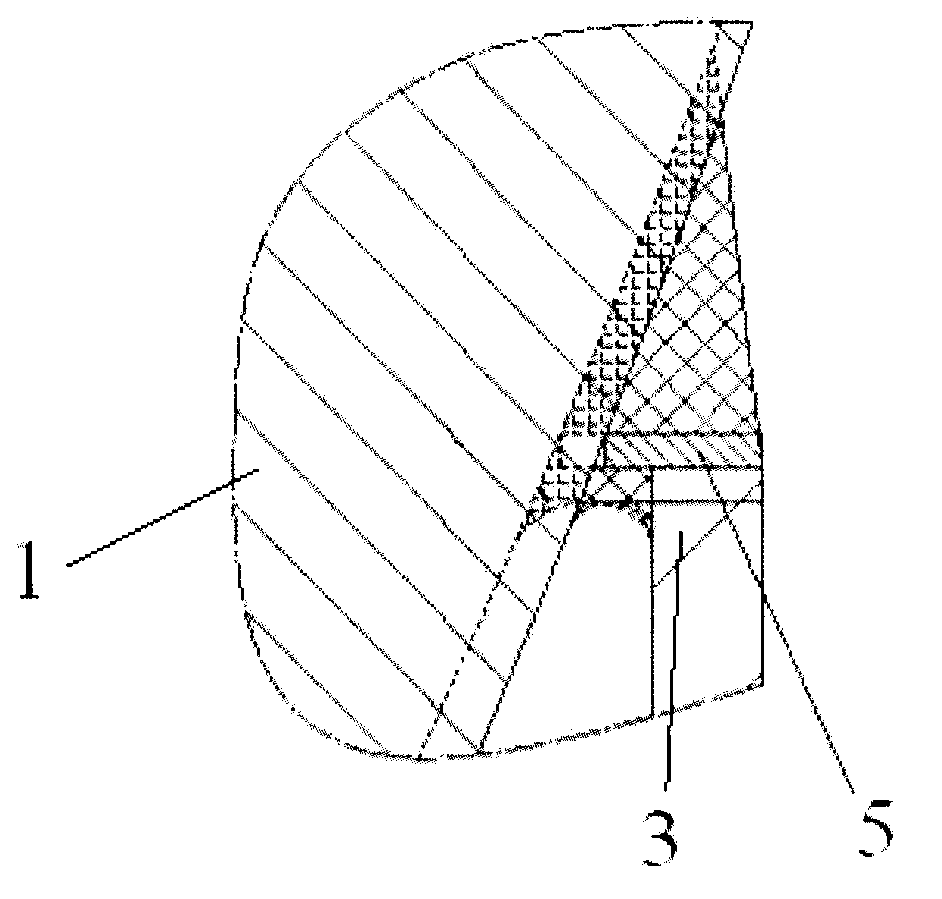

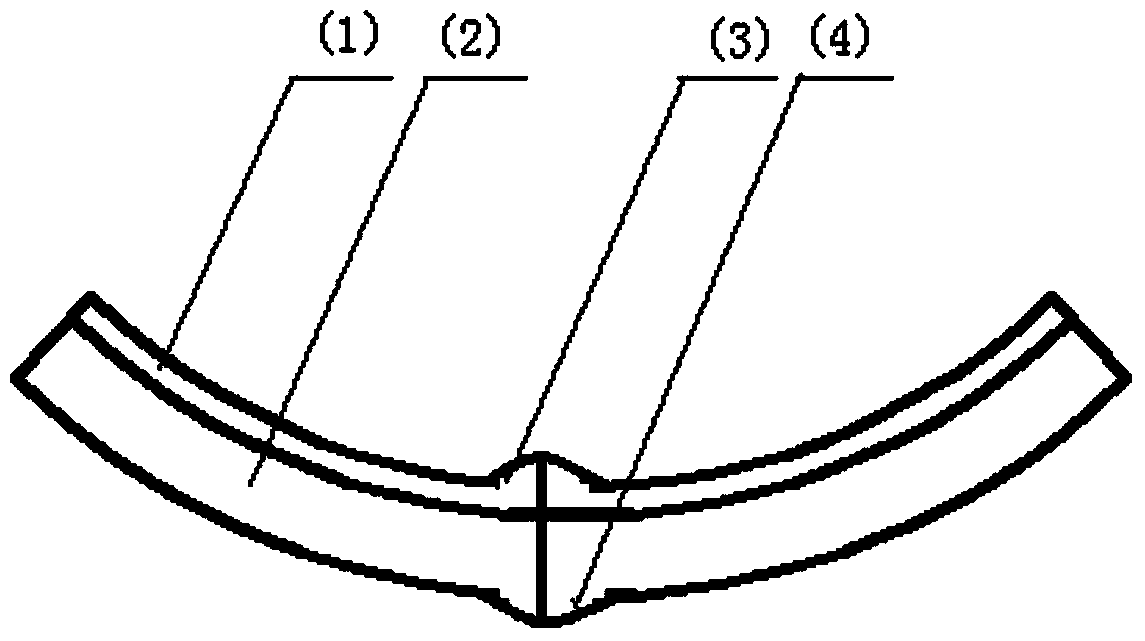

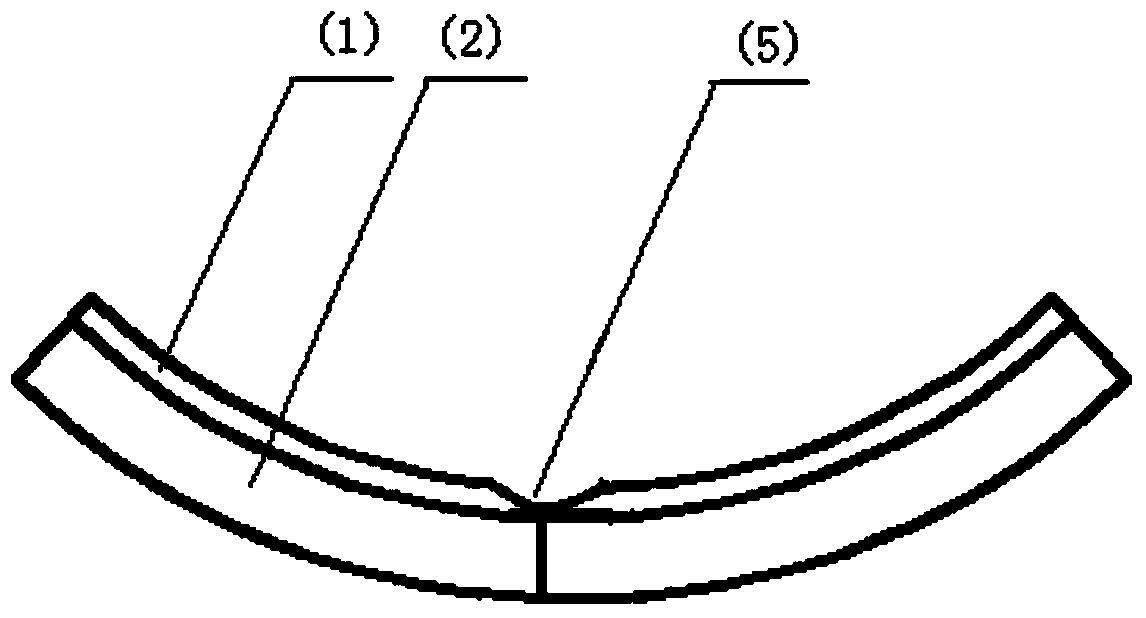

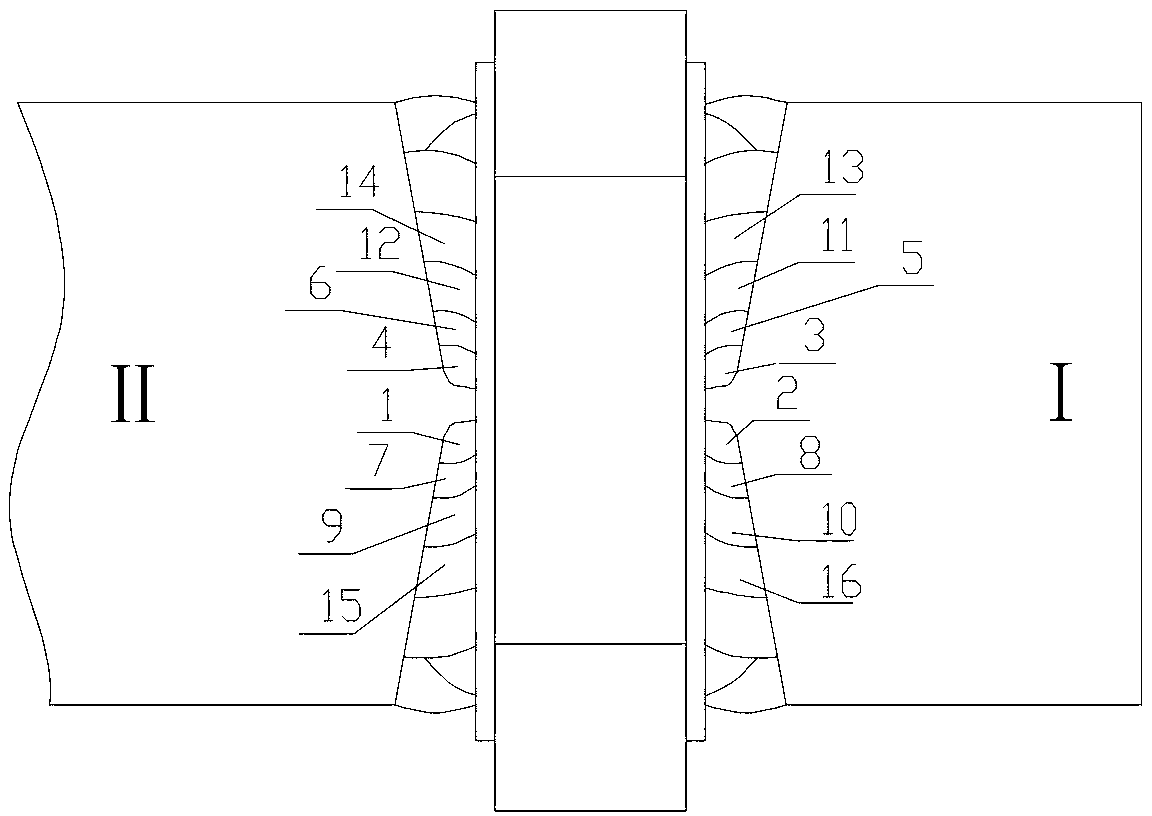

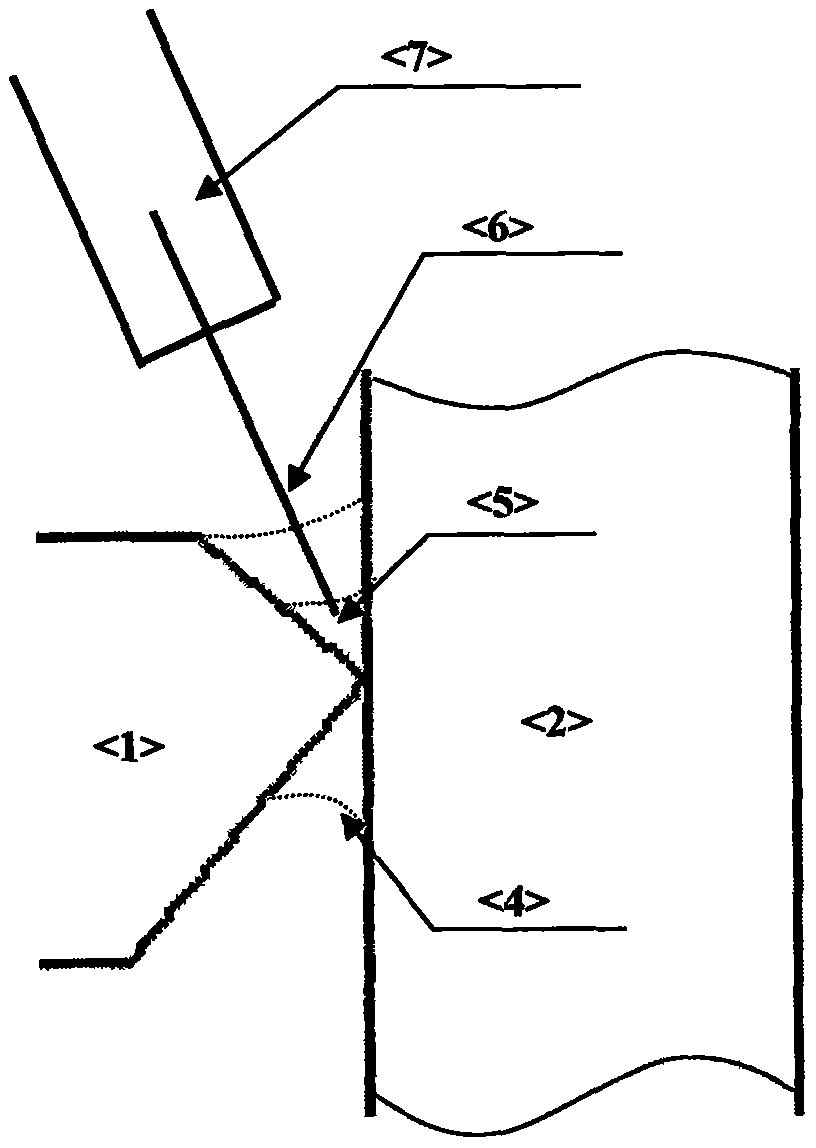

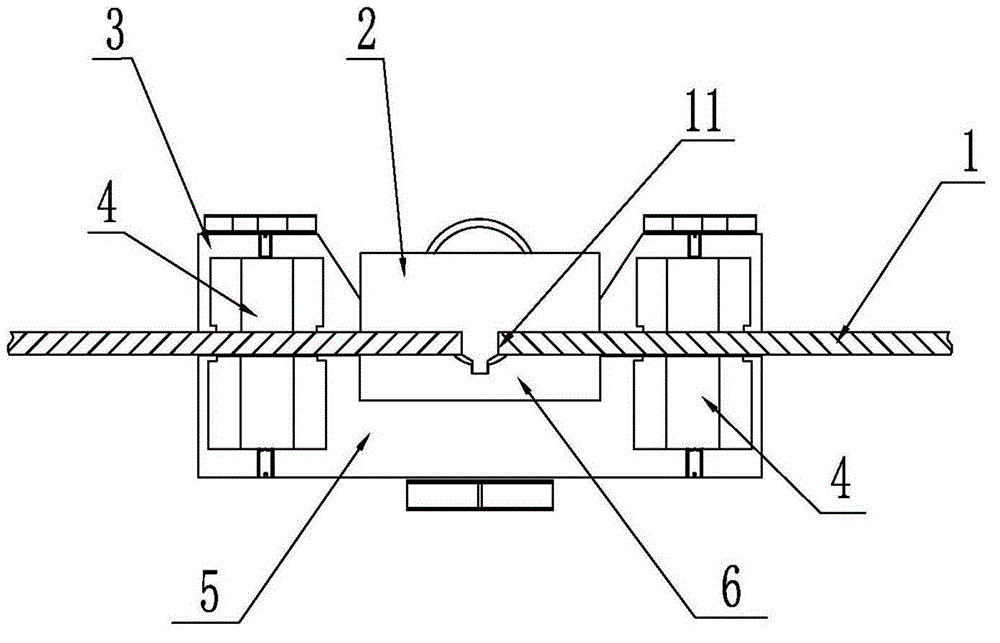

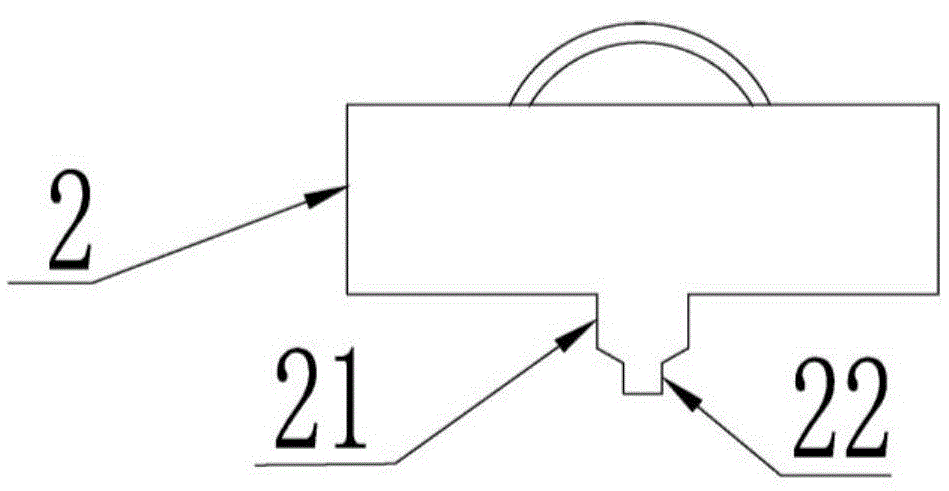

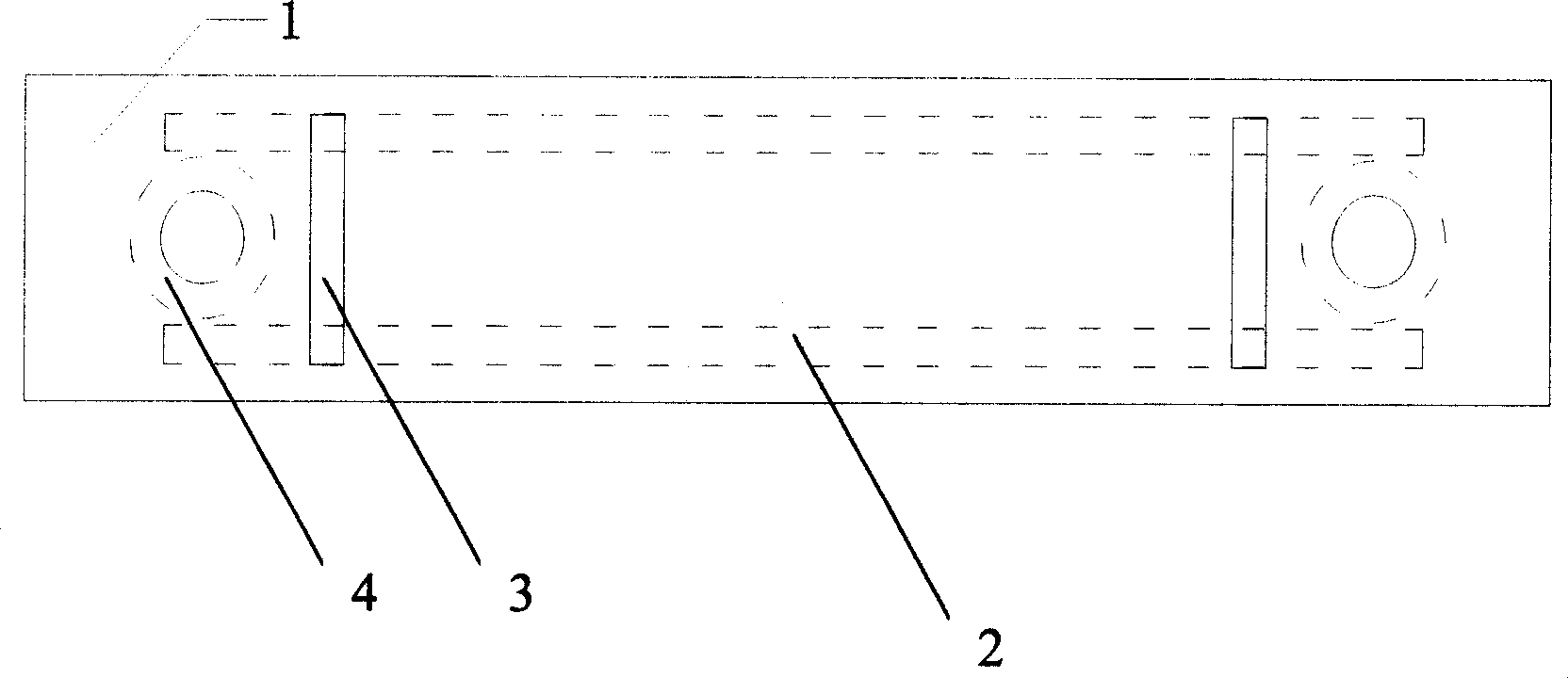

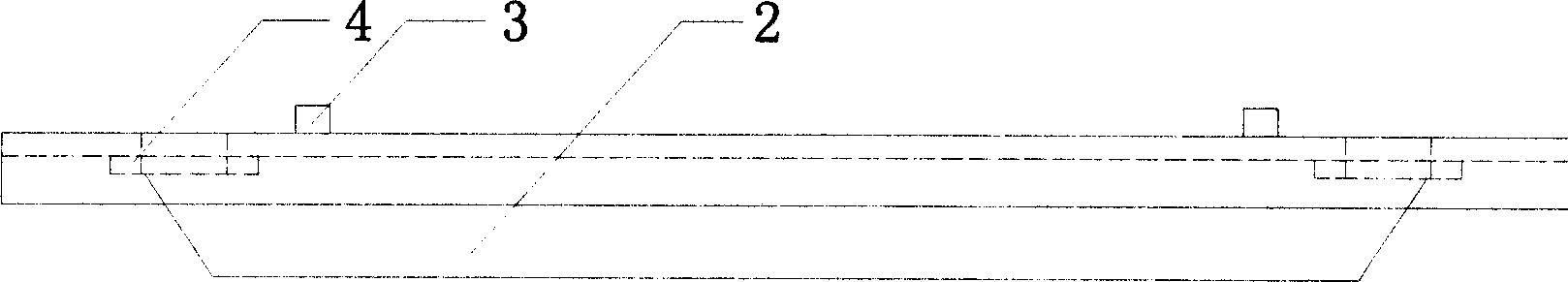

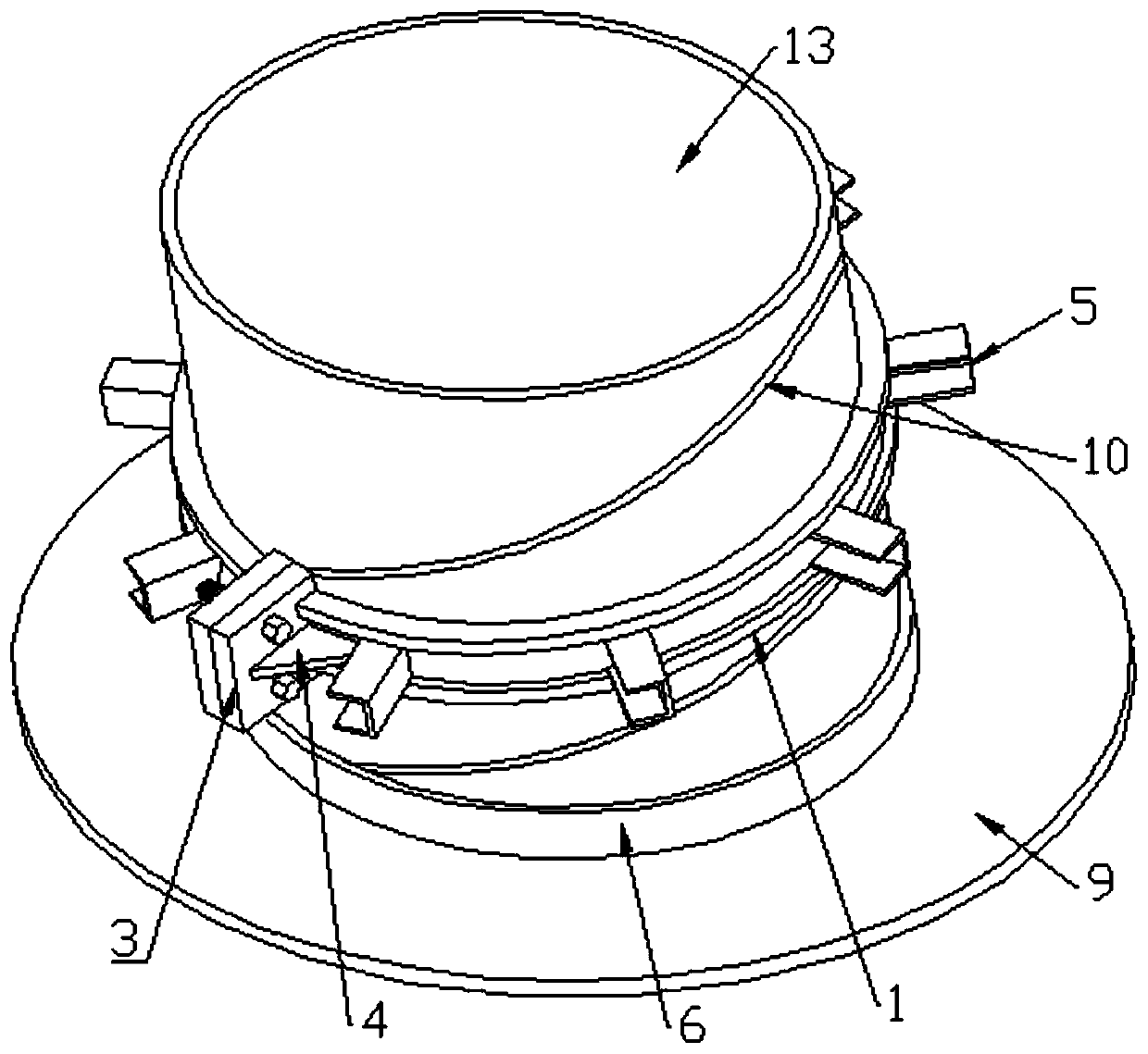

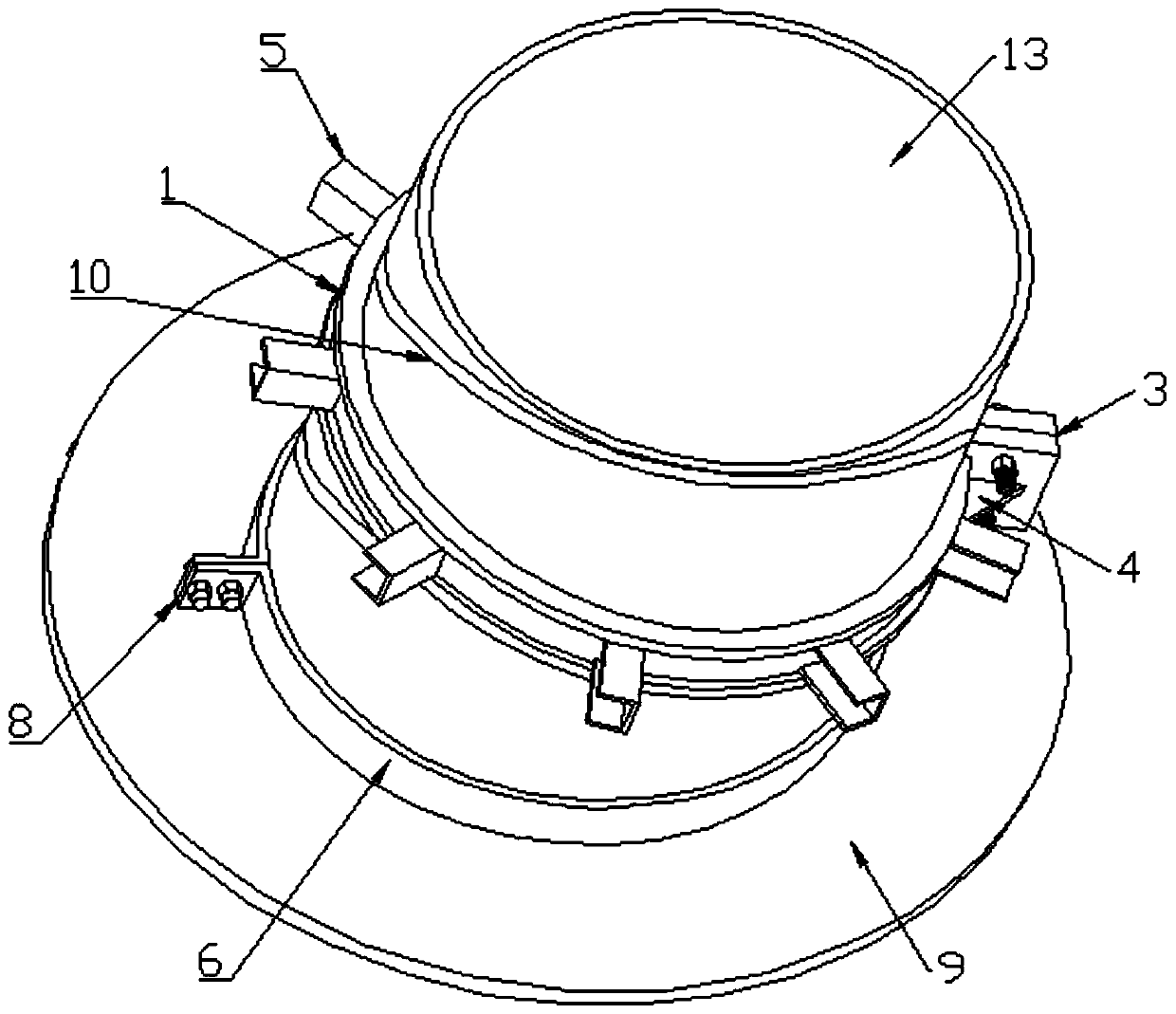

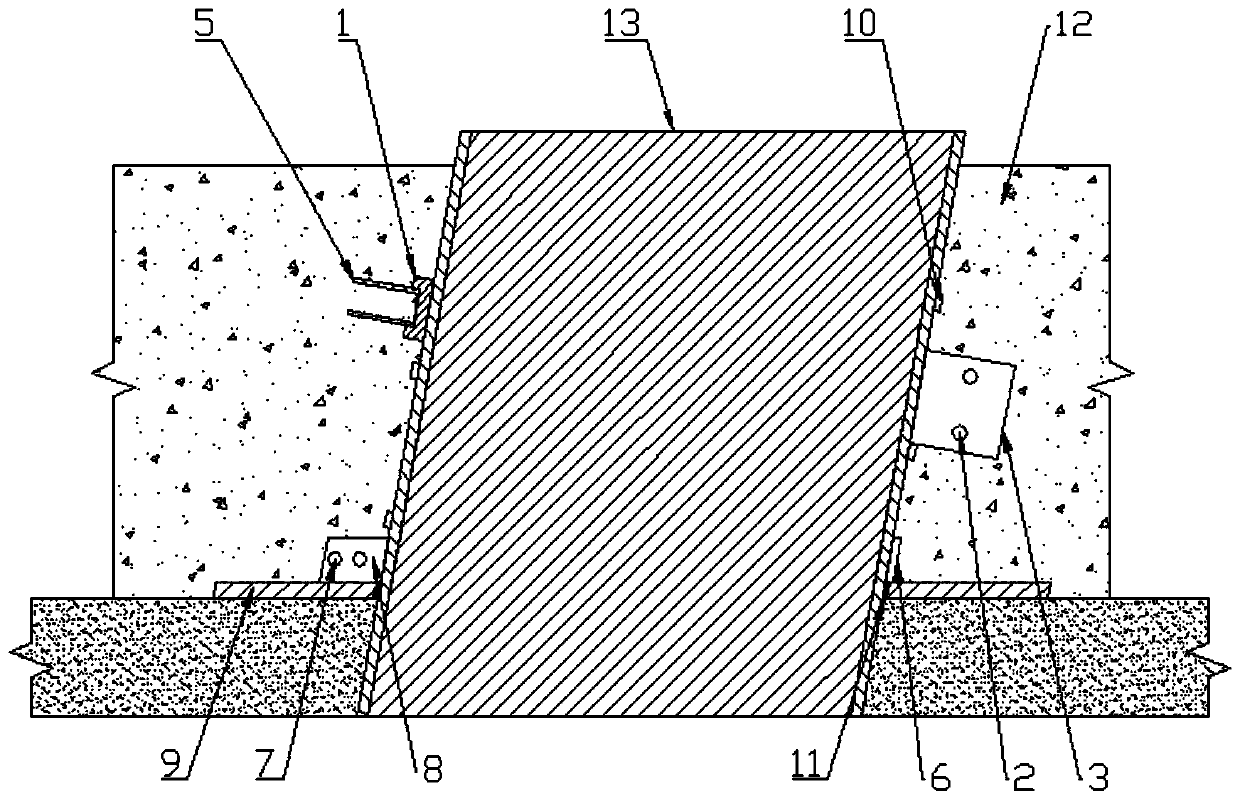

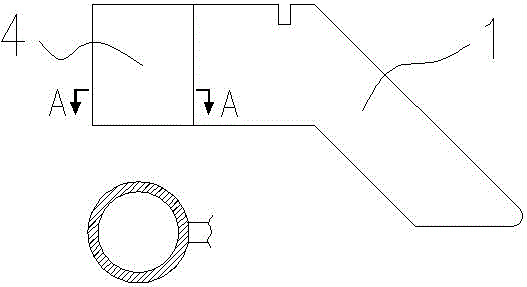

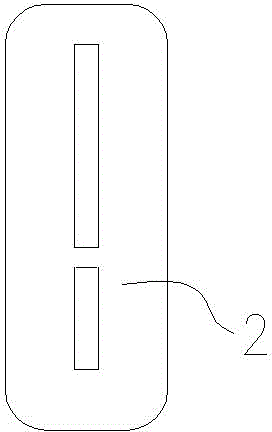

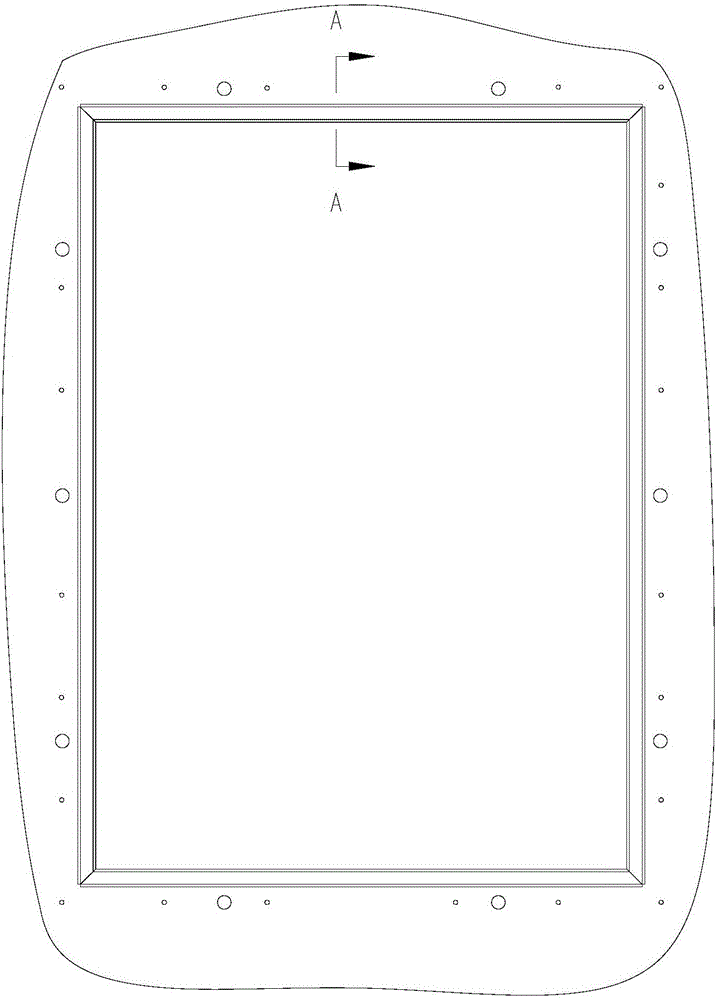

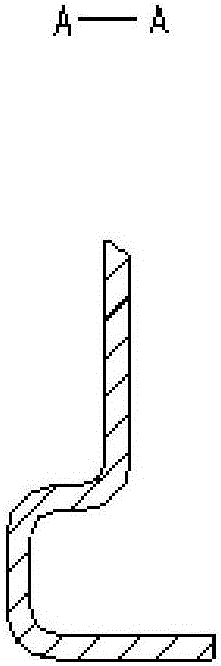

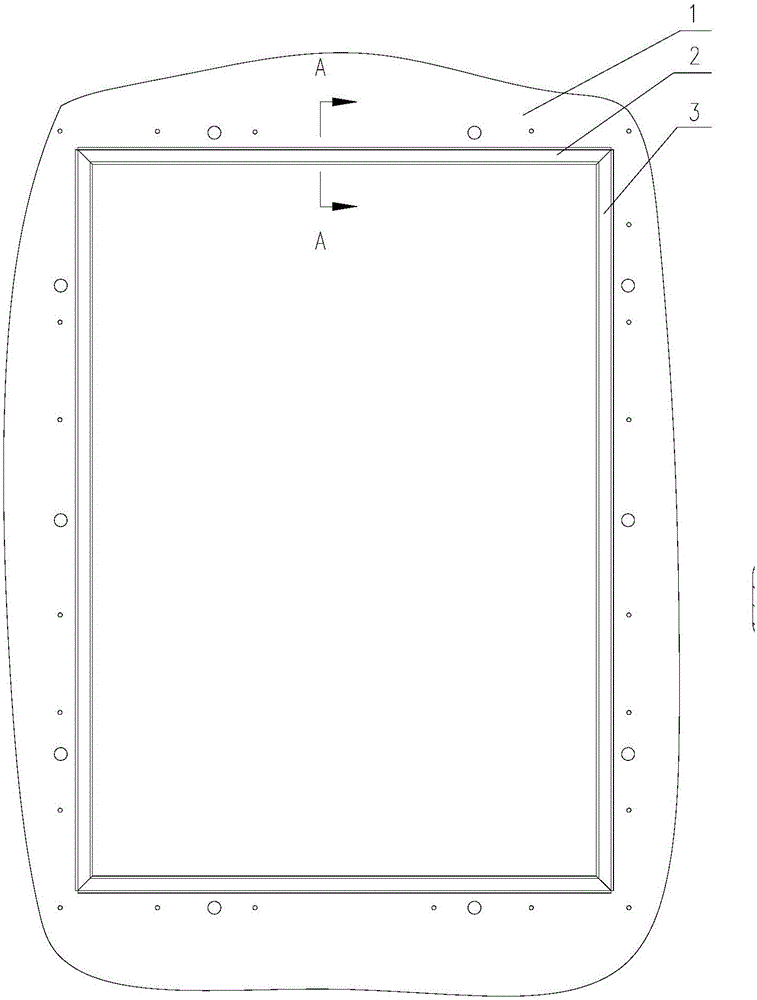

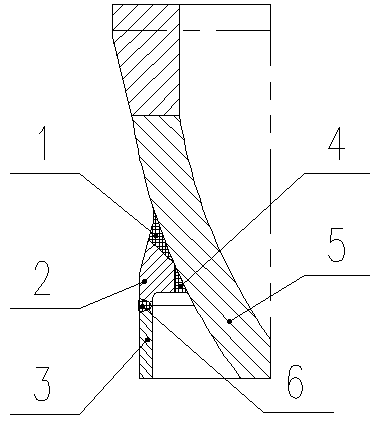

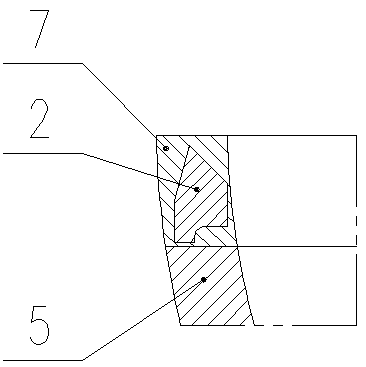

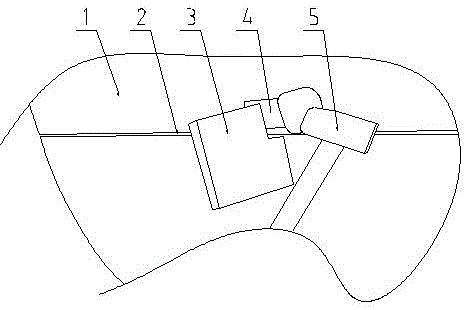

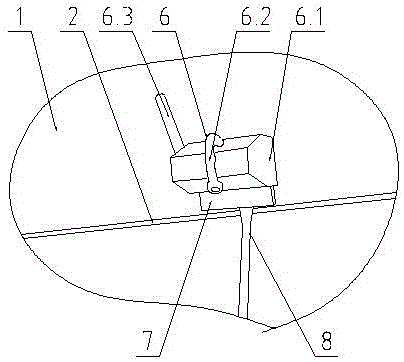

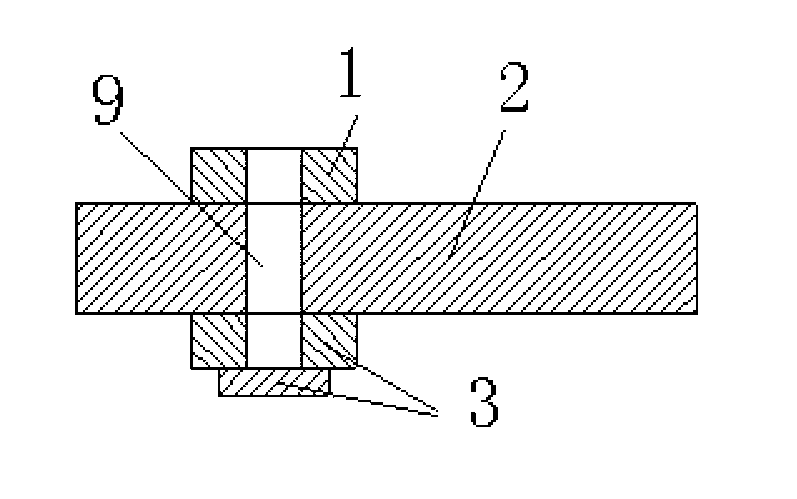

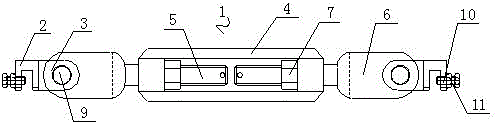

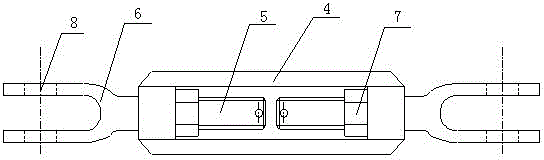

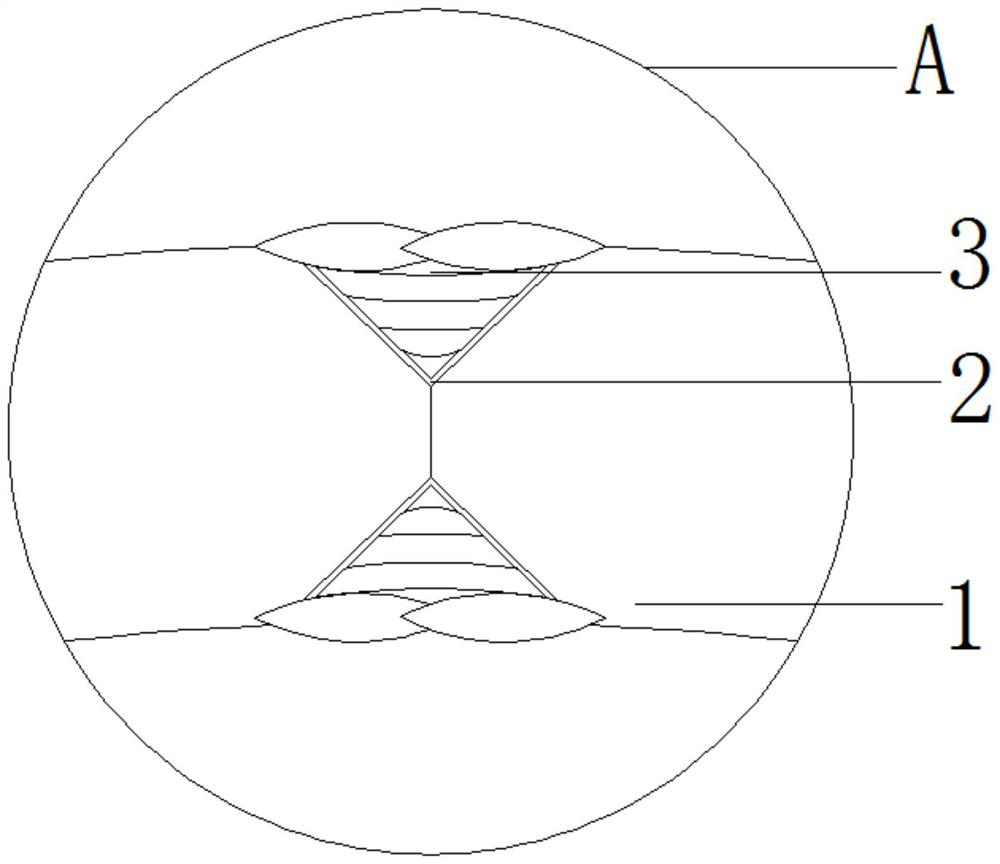

Connecting structure of skirt seat and bottom sealing head

InactiveCN109958877ASave welding consumablesSave manufacturing cyclePressure vesselsMaterial consumptionWeld seam

The invention relates to a connecting structure of a skirt seat and a bottom sealing head. The connecting structure of the skirt seat and the bottom sealing head comprises an upper welding seam (1), aconnecting member (2), a skirt seat cylinder / transition section (3), a lower welding seam (4), the sealing head (5), a circumferential welding seam (6) and sealing head end excess materials (7). Theconnecting structure is compact in structure and small in welding seam cross-section size, required weld metal is only about 30% of a traditional bead welding type, the manufacturing method is simpler, the manufacturing period is short, processing excess materials can be utilized, the cost is low, the quality is reliable, and compared with the prior art, the defects of complex manufacturing process, more welding materials consumption, large welding workload, long period, high cost and the like are overcome to a great extent.

Owner:HARBIN BOILER

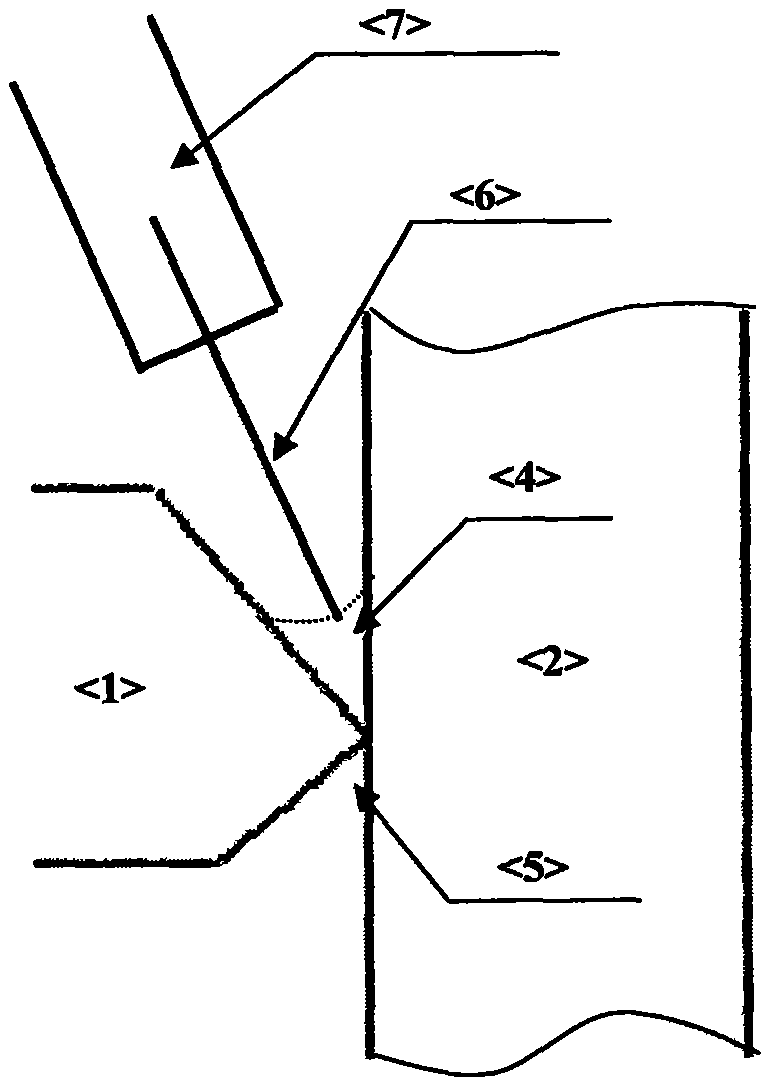

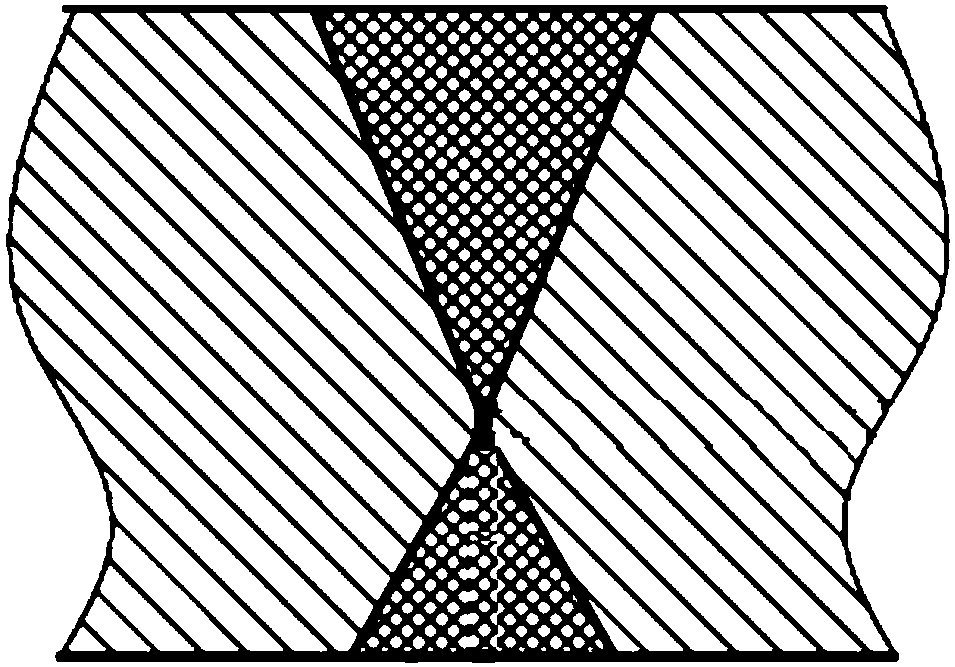

Unclear root welding method for thick plate Y-groove with unequal gap

ActiveCN103495797BAvoid wastingAvoid pollutionArc welding apparatusMetal working apparatusPower flowThick plate

The invention discloses an unequal-gap non-back-gouging welding method of Y-type beveled edges of thick plates. The method includes the steps of (1) cutting and assembling before welding, (2) front face bottoming welding, (3) front face small-current submerged-arc welding, (4) front face filling and cosmetic welding and (5) back face large-current submerged-arc welding, wherein in the first step, steel plates are cut to form beveled edges, and the Y-type beveled edges are formed through unequal-gap assembly; in the second step, gas shielded welding is utilized, and swing welding is performed through solid welding wires; in the third step, a small current makes the submerged-arc welding not burn through the bottoming welding; in the fourth step, a plurality of streaks of welding is performed on the front faces with the conventional current submerged-arc welding to perform front face filling and facing; in the fifth step, under the condition that carbon back gouging is not performed, a large current is directly utilized to perform submerged-arc welding on the back faces, and the large current makes the fusion depth of the back face submerged-arc welding larger than the size of truncated edges of the Y-type beveled edges.

Owner:SHANGHAI ZHENHUA HEAVY IND

Column plate longitudinal seam abutting method

InactiveCN105904141AReduce labor intensityGuaranteed surface qualityWelding/cutting auxillary devicesAuxillary welding devicesWeld seamEngineering

The invention relates to a column plate longitudinal seam abutting method. The method comprises the following steps: taking a positioning tool, wherein the tool comprises a permanent magnetic lifting jack, a strip-shaped plate is arranged at the front side of the permanent magnetic lifting jack and is higher than the bottom surface of the permanent magnetic lifting jack; fixedly adsorbing the permanent magnetic lifting jack on one side of a column plate longitudinal seam so as to align the strip-shaped plate to the column plate longitudinal seam; inserting a crowbar into a clearance between the strip-shaped plate and a column plate, assembling and positioning the dislocated longitudinal seam by utilizing the lever force of the crowbar and welding the assembled and positioned part; moving the permanent magnetic lifting jack along one side of the longitudinal seam, assembling and positioning the un-welded part again and welding until the overall column plate longitudinal seam is abutted. The column plate longitudinal seam abutting method disclosed by the invention is convenient to operate, time-saving and labor-saving; the overall plate seam needs not to be grinded because an original horse plate is cancelled, the quality of the plates at the two sides of a welding seam is guaranteed, and the appearance quality is considerably improved after painting is finished.

Owner:CHENGXI SHIPYARD

Method for repairing internal defects of large-sized forge pieces through electroslag welding with tube electrode

The invention discloses a method for repairing internal defects of large-sized forge pieces through electroslag welding with a tube electrode. The method comprises the following steps of: 1, drilling through and removing defects in a workpiece to obtain a defect through hole, and arranging an ending plate and an arc striking plate above and below the defect through hole; 2, making a tube electrode and a welding wire serving as an electrode extend inwards, fixing on the arc striking plate below the inside of the defect through hole, and grounding the workpiece; 3, arcing the welding wire and the arc striking plate in a short-circuiting way, continuously adding a powdery welding flux into the defect through hole, increasing the welding wire feeding speed and lowering the welding voltage to insert the welding wire into a slag basin; 4, increasing a molten welding seam metal, raising the liquid level, cooling and condensing till the slag basin rises to the upper edge of an axle center through hole of the ending plate; and 5, cutting the arc striking plate and the ending plate which are bonded together off, and grinding the upper and lower condensing surfaces of the defect through hole. The method for repairing through electroslag welding with the tube electrode disclosed by the invention is easy, convenient and reliable, and has high welding efficiency.

Owner:MCC SFRE HEAVY IND EQUIP

Clamping tool for web assembly

ActiveCN106002774AAssembly saves time and effortEasy to installWork holdersEngineeringElectrical and Electronics engineering

The invention discloses a clamping tool for web assembly. The clamping tool comprises a lock spiral buckle, clamping grooves and connecting plates; the lock spiral buckle includes a stay cable connecting piece, cable rods and U-shaped cable heads; two cable rods are provided, and are symmetrically connected to two ends of the stay cable connecting piece; one ends of the cable rods are connected with the U-shaped cable heads; external threads are arranged at the other ends of the cable rods; a pair of clamping grooves and a pair of connecting plates are respectively provided, and are symmetrically connected to two ends of the lock spiral buckle; the connecting plates are vertically connected into U-shaped grooves of the U-shaped cable heads of the lock spiral buckle through bolts A; and openings of the clamping grooves are downwards, and are welded to the connecting plats through inner side plates of the clamping grooves. The clamping tool for web assembly has the following advantages: the web clamping tool is more convenient for installation and disassembly; the web installation safety is greatly improved; a lot of welding materials are saved; the generality is high; and the tool is suitable for assembling various rail crane main beam webs.

Owner:NANTONG ZHENHUA HEAVY EQUIP MFG

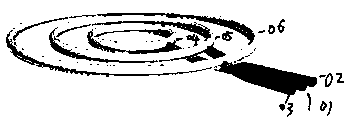

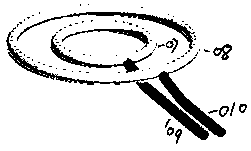

Ring-shaped gas stove head and manufacturing method thereof

The invention discloses a ring-shaped gas stove head and a manufacturing method thereof. The ring-shaped gas stove head is mainly composed of a ring-shaped metal ring and a gas inlet tube, wherein thering-shaped metal ring is bent by a tube bending machine; the gas inlet tube is provided with an arc shape bent by the tube bending machine; the ring-shaped metal ring and the gas inlet tube can be combined into a multi-ring-shaped gas stove head, for example a single-ring-shaped gas stove head, a double-ring-shaped gas stove head and a three-ring-shaped gas stove head; small fire holes formed byan air plasma cutter are formed in the upper surface of the metal ring; and the small fire holes close to the gas inlet tube are designed to be scarce or are relatively small in diameter, so that combustion heating is more uniform. The ring-shaped gas stove head is simple in processing and manufacturing, is high in production speed, is low in cost, saves fuels, and has a relatively good use and popularization value.

Owner:许建立

Suction cylinder steel pipe machining and manufacturing technology for suction type jacket

InactiveCN112475558AIncrease profitEasy to operateWelding/cutting auxillary devicesAuxillary welding devicesManufacturing technologySuction force

The invention discloses a suction cylinder steel pipe machining and manufacturing technology for a suction type jacket, and relates to the field of submerged-arc welding steel pipe machining and manufacturing. The suction cylinder steel pipe machining and manufacturing technology involves a suction cylinder steel pipe and comprises the following steps that in the machining process of the suction cylinder steel pipe, steel plates are spliced firstly, and then the steel plates are rolled, in the rolling process, cylinder deformation caused by self-weight collapse of the steel pipe is prevented through side support and top support auxiliary tools, longitudinal seam submerged-arc welding is conducted after rolling is completed, well supports and inner reinforcing rings are additionally arranged at the two ends of a single-section steel pipe, multiple sections of cylinders are assembled on a special rotating roller with side holding arm supports and transferred to a welding station througha combined axis vehicle, during circular seam welding, multiple stations are synchronously carried out. According to the suction cylinder steel pipe machining and manufacturing technology for the suction type jacket, firstly, the steel plates are spliced, after the steel plates are spliced, circular seam grooves are machined, butt joint line deviation is controlled, and it is guaranteed that the misalignment amount of the rolled steel plates meets the technological requirement.

Owner:HEFEI ZIKING PIPE INC

Aero-engine turbine rear case support plate long crack A-TIG welding restoration method

ActiveCN110328492ANarrow grooveWeld seam cross-sectional area is smallArc welding apparatusAviationHeat-affected zone

The invention relates to an aero-engine turbine rear case support plate long crack A-TIG welding restoration method. The method includes the following steps: S1, grinding and cleaning; S2, coating a crack with soldering flux; S3, argon arc welding; S4, benchwork grinding; S5, stress relief heat treatment; and S6, inspection. The idea of performing active TIG welding (A-TIG) to restore the long crack of a rear case support plate of an aero-engine turbine is put forwards in the method, the heat input of a welded joint is low, welding heat affected zones are reduced, and the mechanical property of the welded joint is improved. The deformation amount of an intermediate case is greatly reduced compared with that in a TIG welding method. The engine maintenance cost is greatly reduced and the engine maintenance period is shortened.

Owner:PLA NO 5719 FACTORY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com