Welded pipe and manufacturing method thereof

A manufacturing method and technology for welded pipes, which are applied to manufacturing tools, welding equipment, tubular objects, etc., can solve the problems of difficulty in greatly improving welding efficiency, poor welding quality, and large amount of metal filling, so as to improve welding production efficiency and reduce welding times. , the effect of saving welding consumables

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Embodiments of the present invention are described in detail below in conjunction with accompanying drawings:

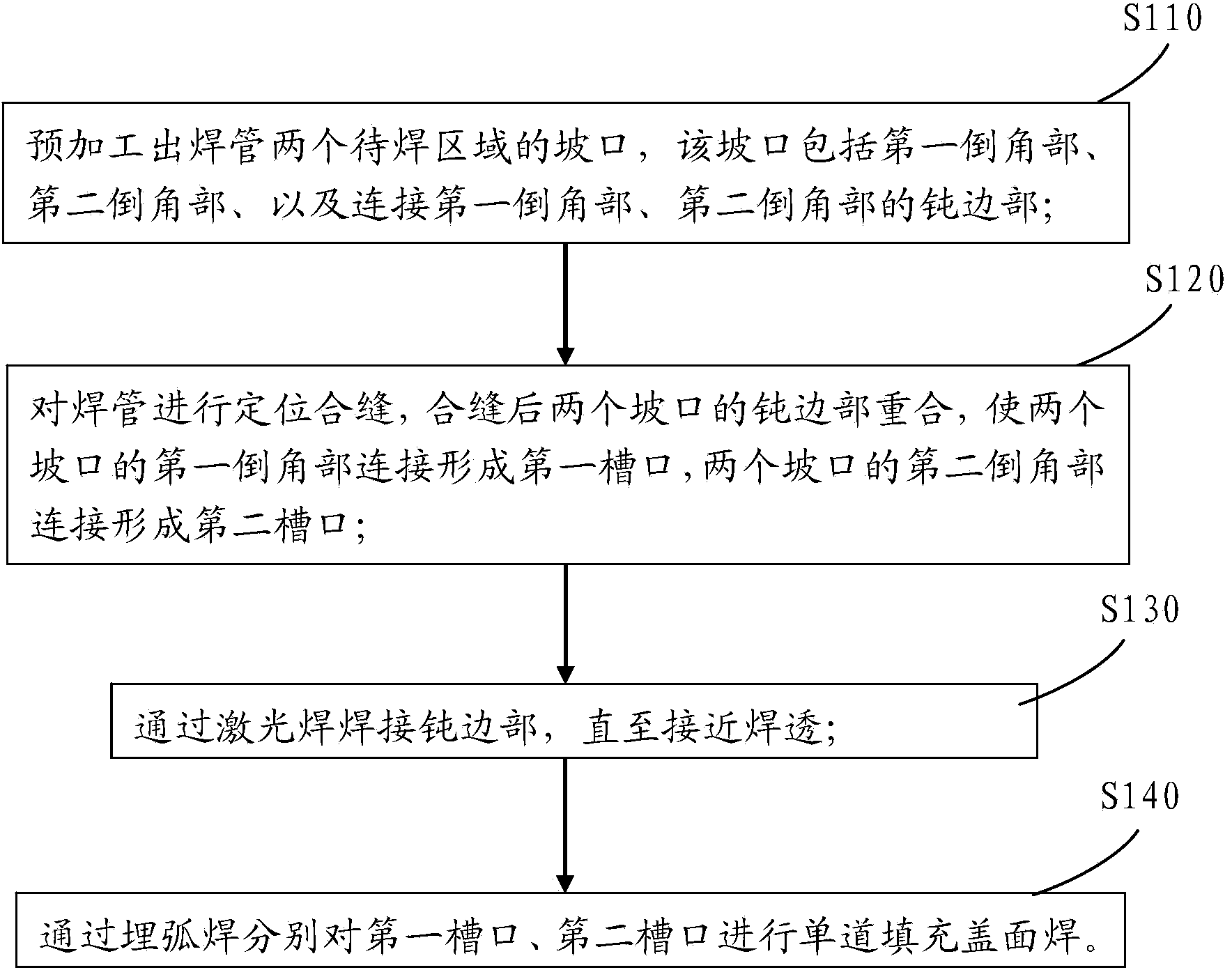

[0027] Such as figure 1 Shown, a kind of welded pipe manufacturing method comprises the steps:

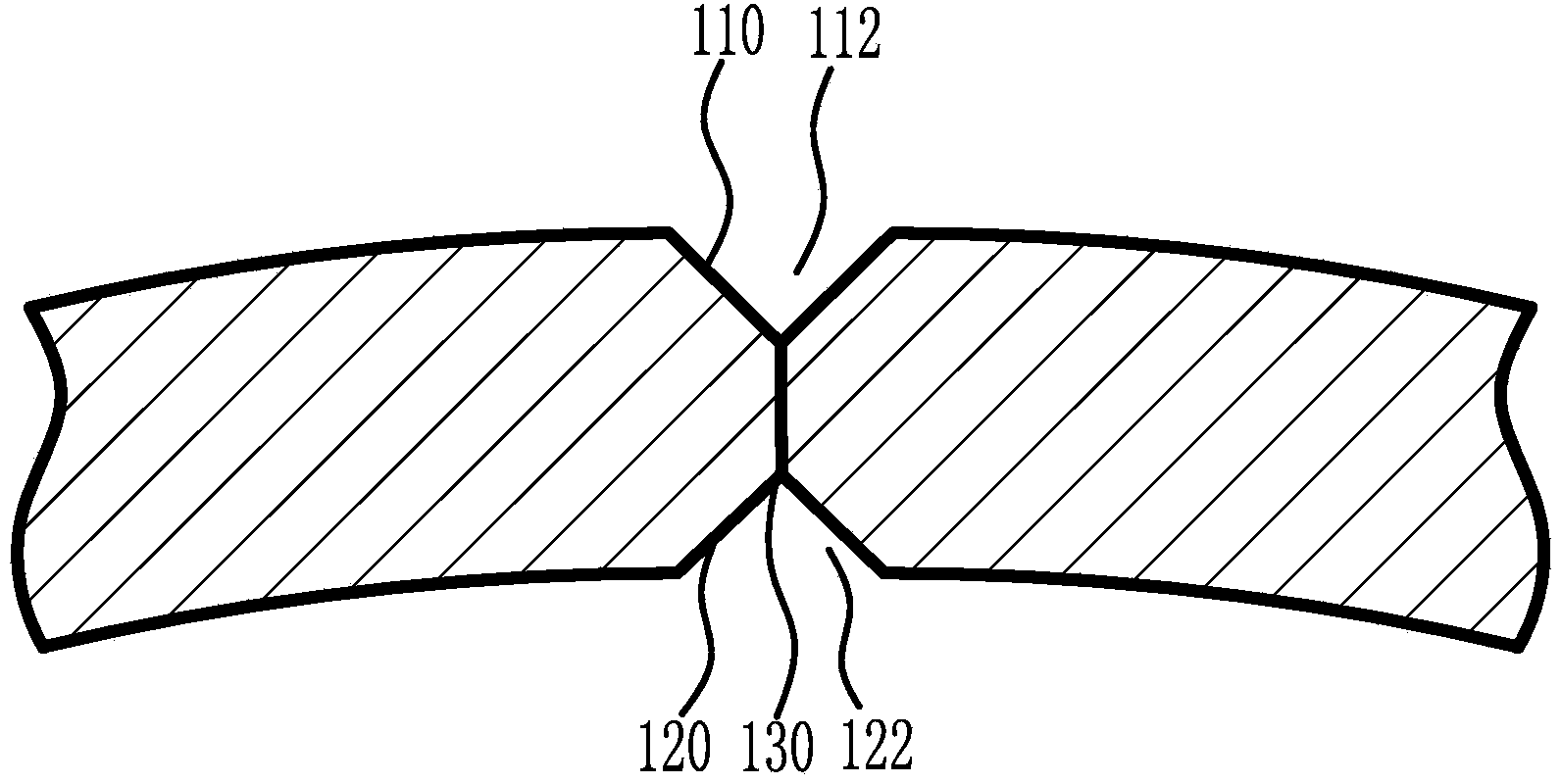

[0028] S110: pre-processing the grooves of the two areas to be welded of the welded pipe, the grooves include a first chamfer, a second chamfer, and a blunt edge connecting the first chamfer and the second chamfer;

[0029] S120: Position and join the welded pipe. After joining, the blunt edges of the two grooves coincide, so that the first chamfers of the two grooves are connected to form the first notch, and the second chamfers of the two grooves are connected. connecting to form a second notch;

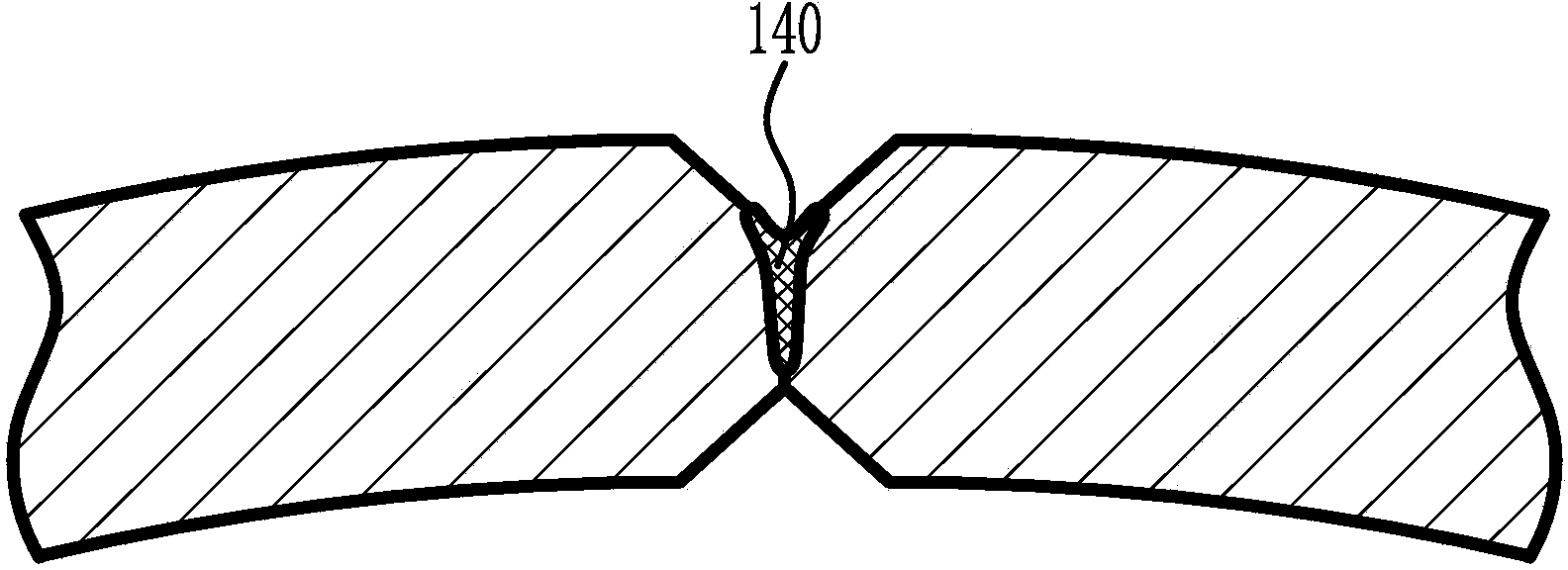

[0030] S130: Welding the blunt edge by laser welding until close to penetration;

[0031] S140: Perform single-pass filling and cover welding on the first notch and the second notch respectively by submerged arc welding.

[0032] The manufacturing method of the weld...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com