Medium thickness plate X-shaped bevel welding technology without back chipping

A welding process and unclear technology, which is applied in submerged arc welding of stainless steel medium and thick plates, welding, and carbon steel fields, can solve the problems of difficult control of welding deformation, difficult operation of welding, and low production efficiency, so as to improve welding production efficiency, The effect of improving welding production efficiency and saving production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] This process mainly adopts submerged arc welding when the back side is unclear. The welding process steps of the X-shaped groove of the medium and thick plate include:

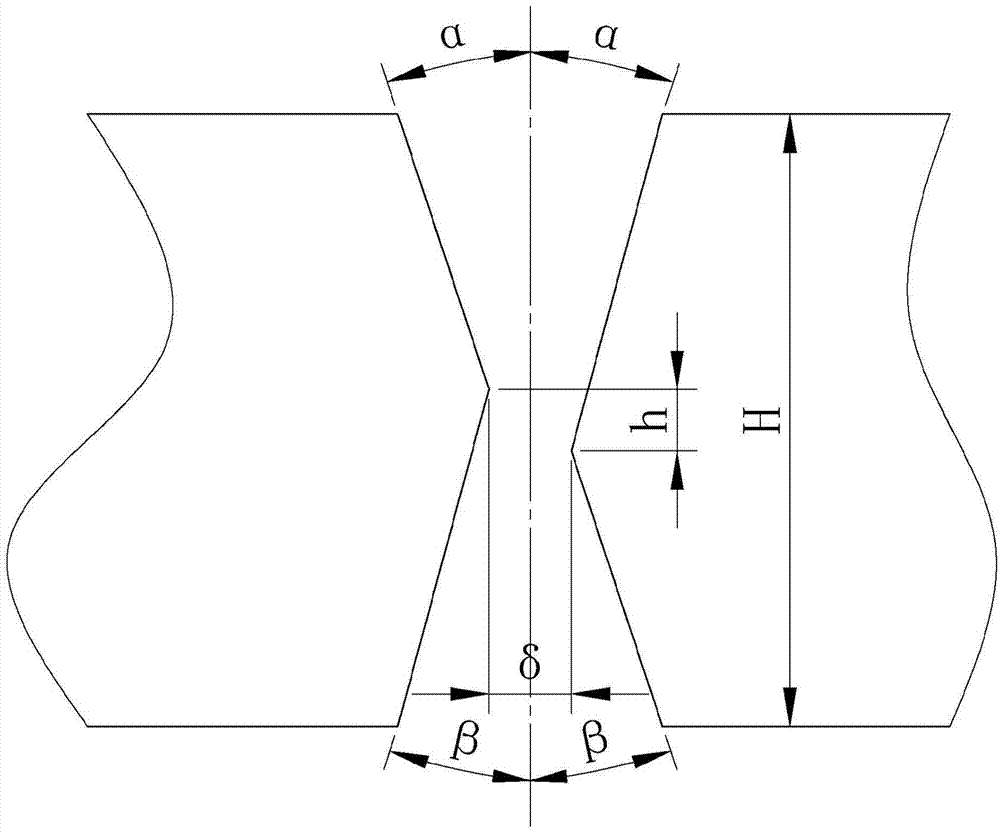

[0022] A Cutting and assembly before welding: First, flame cutting > type groove for 60mm Q345R plate, groove angle α is 300, and blunt edge size is 0mm; then, the two processed plates are butted and assembled, and the two slopes The butt joint gap δ is 3mm, the misalignment amount h is 2mm to form an X-shaped groove, and then perform spot welding positioning on the butt-joined X-shaped groove. cored wire.

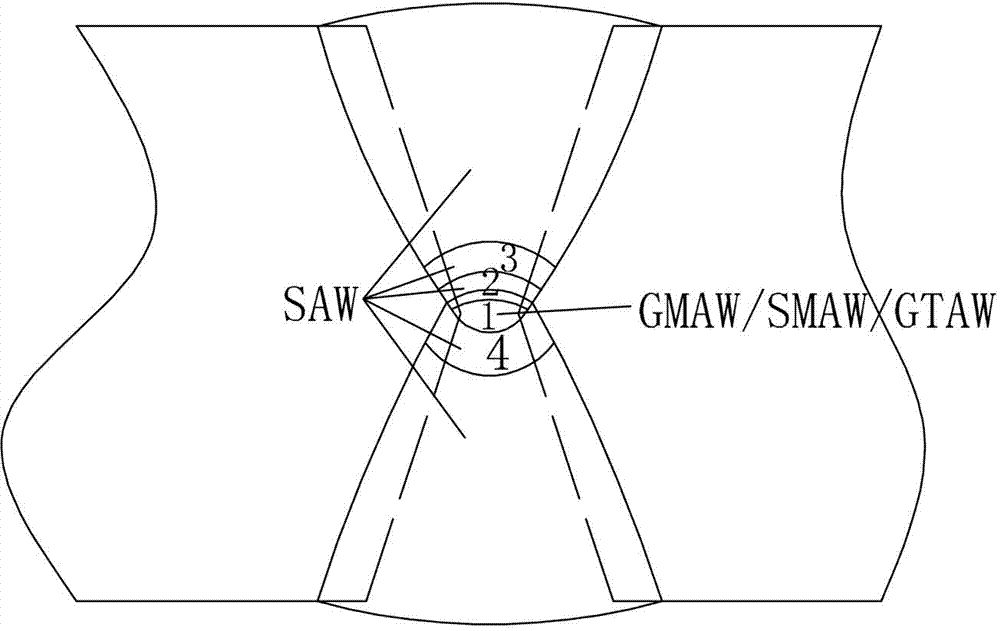

[0023] B front bottom welding: (such as figure 2 As shown in the 1st layer in ), use solid wire gas shielded welding for welding and ensure that the weld does not burn through. Use φ1.2mm solid wire, current is 150, voltage is 20V, and welding speed is 200mm / min.

[0024] C front small current submerged arc welding: ensure that the weld penetration depth is as large as possible without welding lea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com