Narrow-gap metal active gas (MAG) welding method for large-thickness shroud type diaphragms of turbines

A welding method and narrow gap technology, applied in the field of mechanical processing, can solve the problems of low gas shielded welding production efficiency, unstable welding quality, high production cost, etc., to improve metal deposition efficiency, save welding materials, reduce shrinkage and deformation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

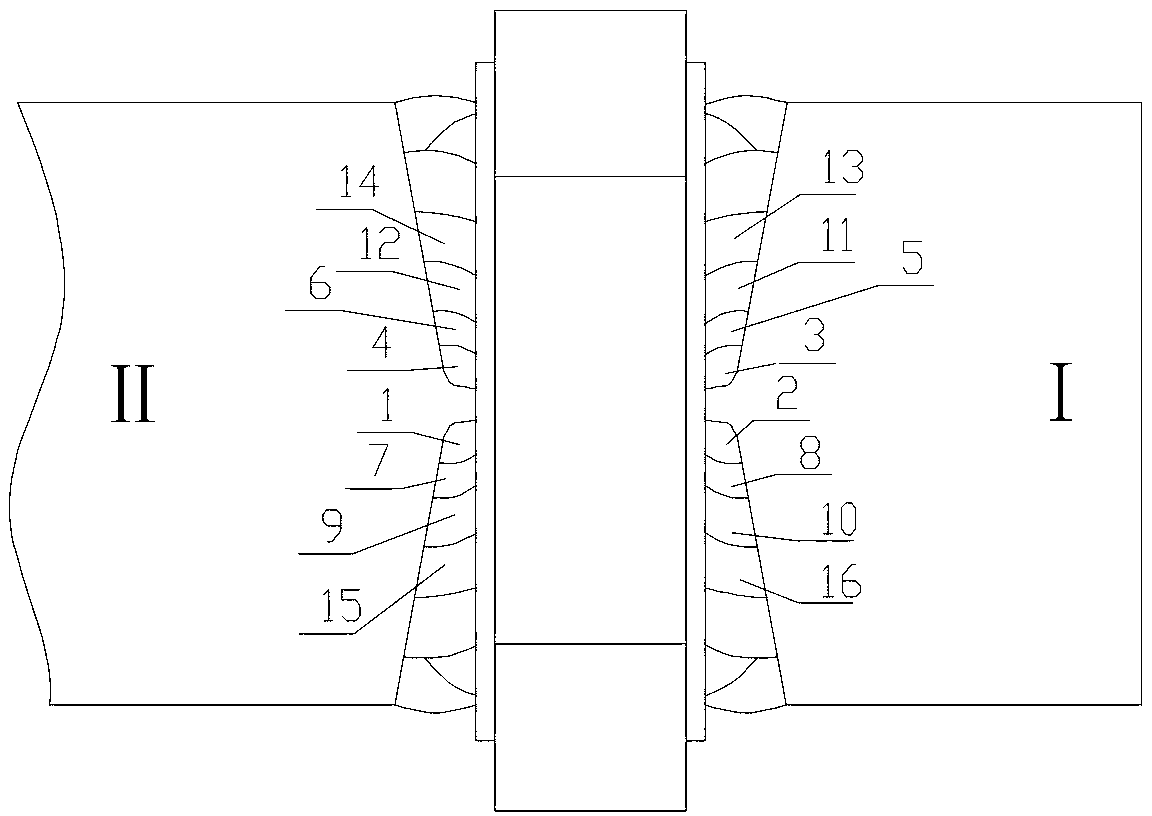

[0014] Specific embodiment 1: The narrow gap MAG welding method of the large thickness shroud diaphragm of the steam turbine of this embodiment is carried out in the following steps:

[0015] 1. Diaphragm outer ring and diaphragm body are respectively provided with deep and narrow gap V-shaped grooves, and the diaphragm outer ring, cascade and diaphragm body are assembled on the assembly platform, and then the main weld on the steam outlet side is spot-welded, and then crossed Spot welding and slag removal; wherein, the V-shaped groove angle of the narrow gap between the outer ring of the partition and the partition body is 6-8°, the length of each spot is 30-40mm, and only spot welding is used for spot welding layer;

[0016] 2. Assemble spot welding Z-connecting block on one side of the partition in the partition, and install spot welding lead and arc extinguishing plate on the other side;

[0017] 3. Turn the partition over and spot weld the main weld on the inlet side of the par...

specific Embodiment approach 2

[0023] Specific embodiment two: this embodiment is different from specific embodiment one in that after spot welding in step one, it is ensured that the error range of the pitch circle diameter is within Φ±0.75mm, and the error range of the throat width is within ±0.25mm. Other steps and parameters are the same as in the first embodiment.

[0024] The beneficial effects of the present invention are verified through the following tests:

[0025] 1. Assemble the diaphragm outer ring, cascade and diaphragm body on the assembly platform. The narrow gap V-groove angle between the diaphragm outer ring and the diaphragm body is 6-8°, and then spot welding the main weld on the steam outlet side. Cross-spot welding is performed again, and the slag is removed; wherein each point of the spot welding is 30-40mm long, and only one layer is spot-welded during spot welding;

[0026] 2. Assemble spot welding Z-connecting block on one side of the partition in the partition, and install spot welding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com