TIG welding device for butt joint of LNG pipeline and welding method thereof

A technology of welding device and welding method, which is applied in welding equipment, electrode support device, welding rod characteristics and other directions to achieve the effects of improving deposition efficiency, reducing groove size and improving welding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following examples can enable those skilled in the art to understand the present invention more comprehensively, but the present invention is not limited to the scope of the described examples.

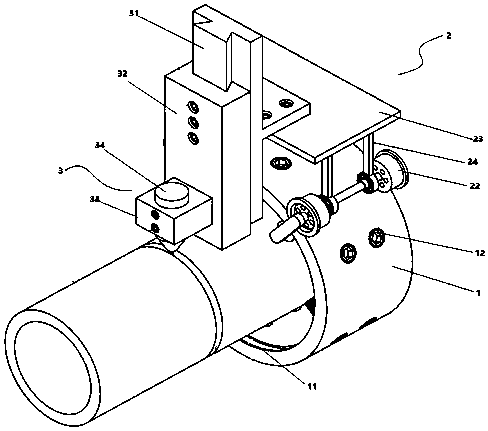

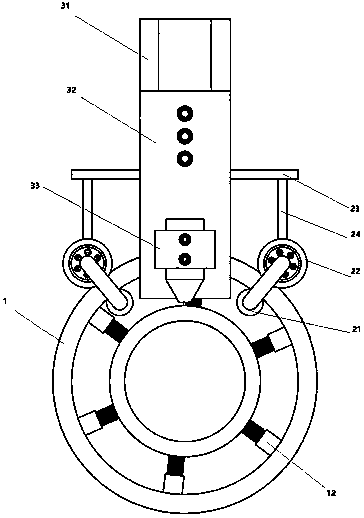

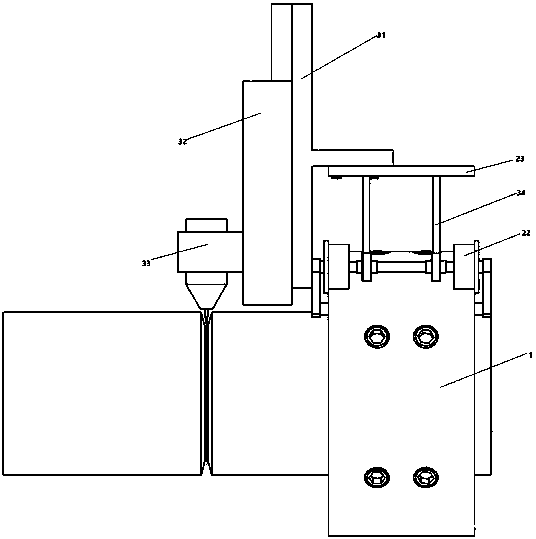

[0029] Such as Figure 1 to Figure 4 A TIG welding device for butt jointing of LNG pipelines shown includes a circular track 1, a mobile trolley module 2 and a welding module 3; the mobile trolley module 2 is set on the circular track 1, and the welding module 3 is set on the mobile On the trolley module 2 and extends out of the circular track.

[0030] The circular track 1 has a cylindrical structure, and the inner wall at both ends of the circular track 1 is provided with a track groove 11 along the circumferential direction; a number of bolt holes are evenly distributed along the circumferential direction on the circular track 1 and the bolt holes The axis passes through the axis of the ring track 1; a pipe locking bolt 12 is arranged in the bolt hole.

[0031] The mob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com