Improved welding process for longitudinal joint grooves of thick-walled container barrels

A technology for container cylinders and thick-walled containers, which is applied in the field of improved welding technology, can solve the problems of large amount of deposited metal in the weld seam, high risk of welding defects, and long welding cycle, so as to improve production efficiency and save welding consumables , the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

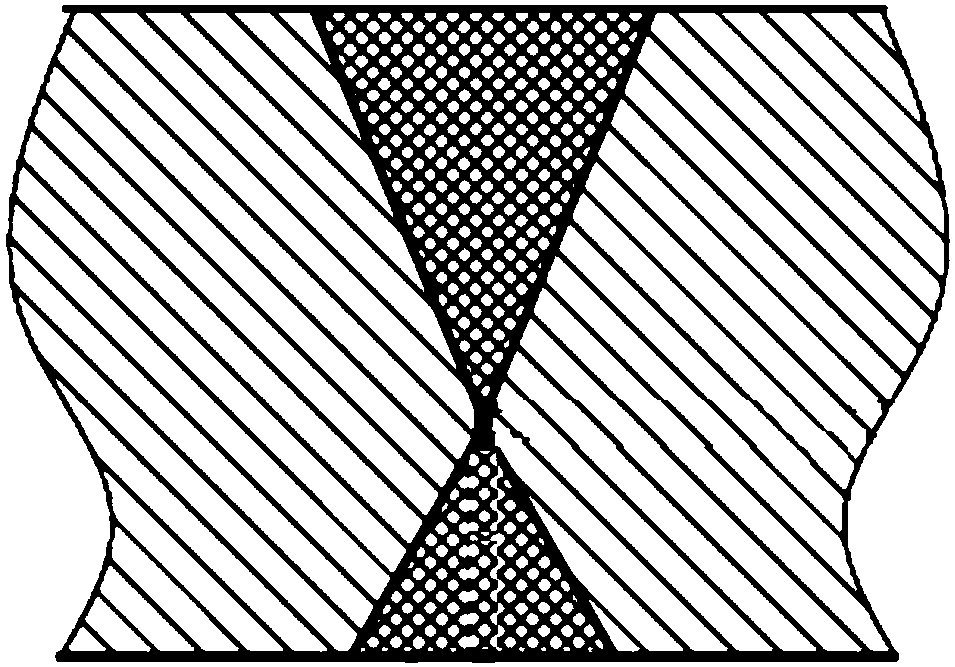

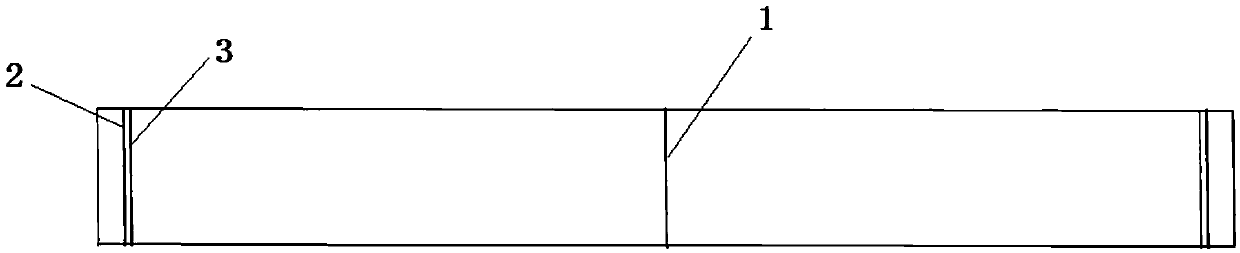

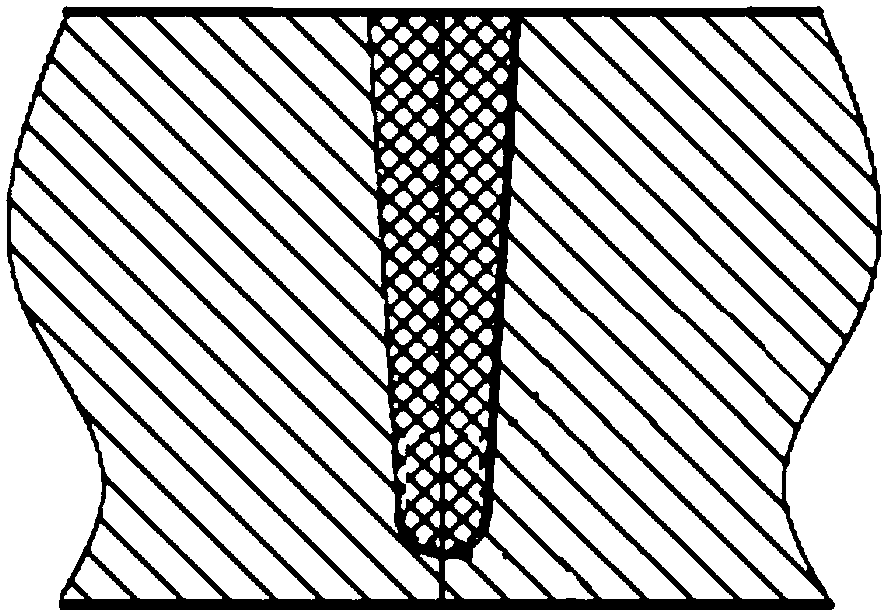

[0030] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

[0031] The improved welding process for the longitudinal seam groove of the thick-walled container cylinder of the present invention is suitable for the process of making a thick-walled container cylinder from a steel plate with a plate thickness of more than 100 mm, and includes the following steps,

[0032] Step (A), measuring the thickness of the steel plate used to make the container cylinder, the thickness of the steel plate is 2-4mm larger than the wall thickness of the container cylinder to be produced;

[0033] Step (B), calculating the milling length of the steel plate, the specific process, as shown in the formula (1),

[0034] ΔL=πDm- L=π(Di+S)- L (1)

[0035] Among them, L is the e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com