Narrow-gap all position pusle automatic argon arc welding technique for dissimillar nicklel-based alloys

A technology of nickel-based alloys and dissimilar metals, applied in metal processing equipment, arc welding equipment, welding media, etc., can solve the problems of unstable welding quality, difficult control of dilution rate, and large consumption of welding materials, and achieve stable welding quality, Improved welding efficiency and low consumption of welding consumables

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

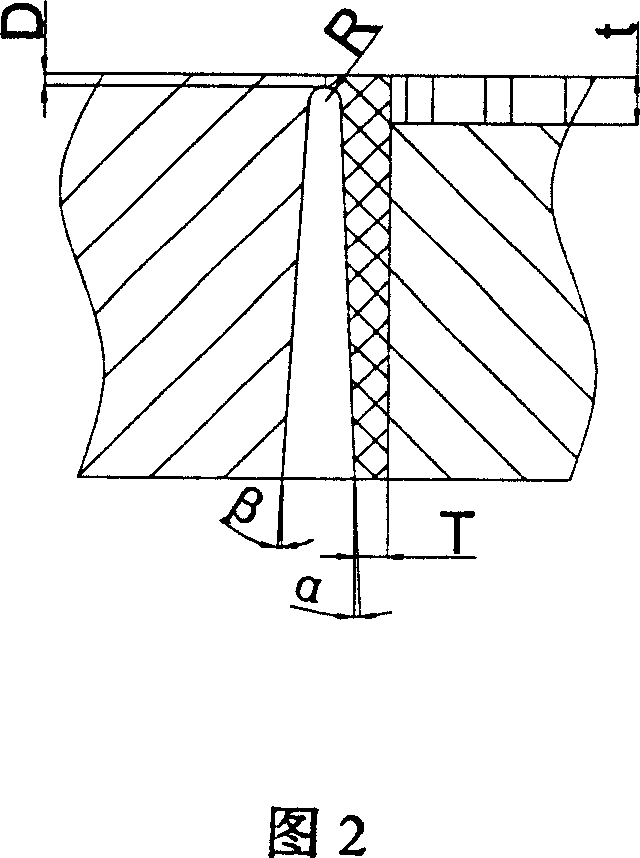

[0030] Stainless steel pipe 5 size: outer diameter 900mm, inner diameter 676mm; low-alloy steel pipe 6: inner wall including 6mm / end inner wall local 12mm thick stainless steel surfacing layer, size: outer diameter 900mm, inner diameter ≤ 676mm;

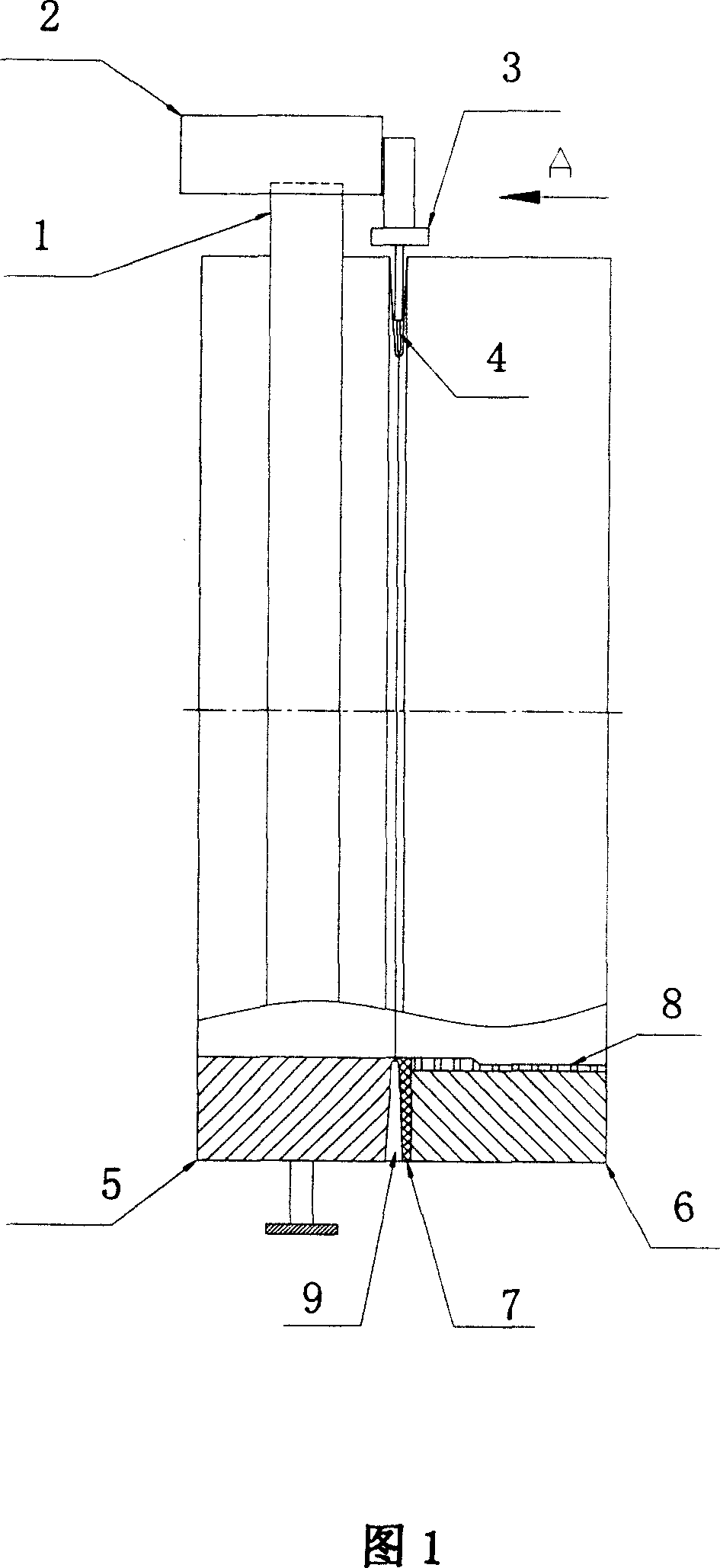

[0031] As shown in Figure 1, it is a schematic diagram of all-position welding of dissimilar nickel-based alloys with narrow gaps. The GT-VI narrow gap welding equipment manufactured by LIBURDI Company is used, including F-type heads and special gas hoods with double protection effects.

[0032] Its method is:

[0033] Step 1: surfacing 309L / 308L stainless steel surfacing layer 8 in the low alloy steel pipe 6 by means of hot wire pulse tungsten argon arc welding, with a thickness of 6 mm, in the end near the nickel-based alloy isolation layer 7 surfacing welding Surfacing three layers of 308L stainless steel within the range of 30mm, so that the thickness of the whole stainless steel surfacing layer that is locally piled up is 6mm, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com