Method for enhancing back cover bond stress based on offshore steel inclined pile foundation

A technology of holding force and steel inclined piles, which is applied in the field of enhancing the holding force of the back cover, which can solve the problems affecting the construction progress and quality, water seepage, cracking of joints, etc., and achieve the effect of ensuring bearing capacity, reducing damage and improving bonding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

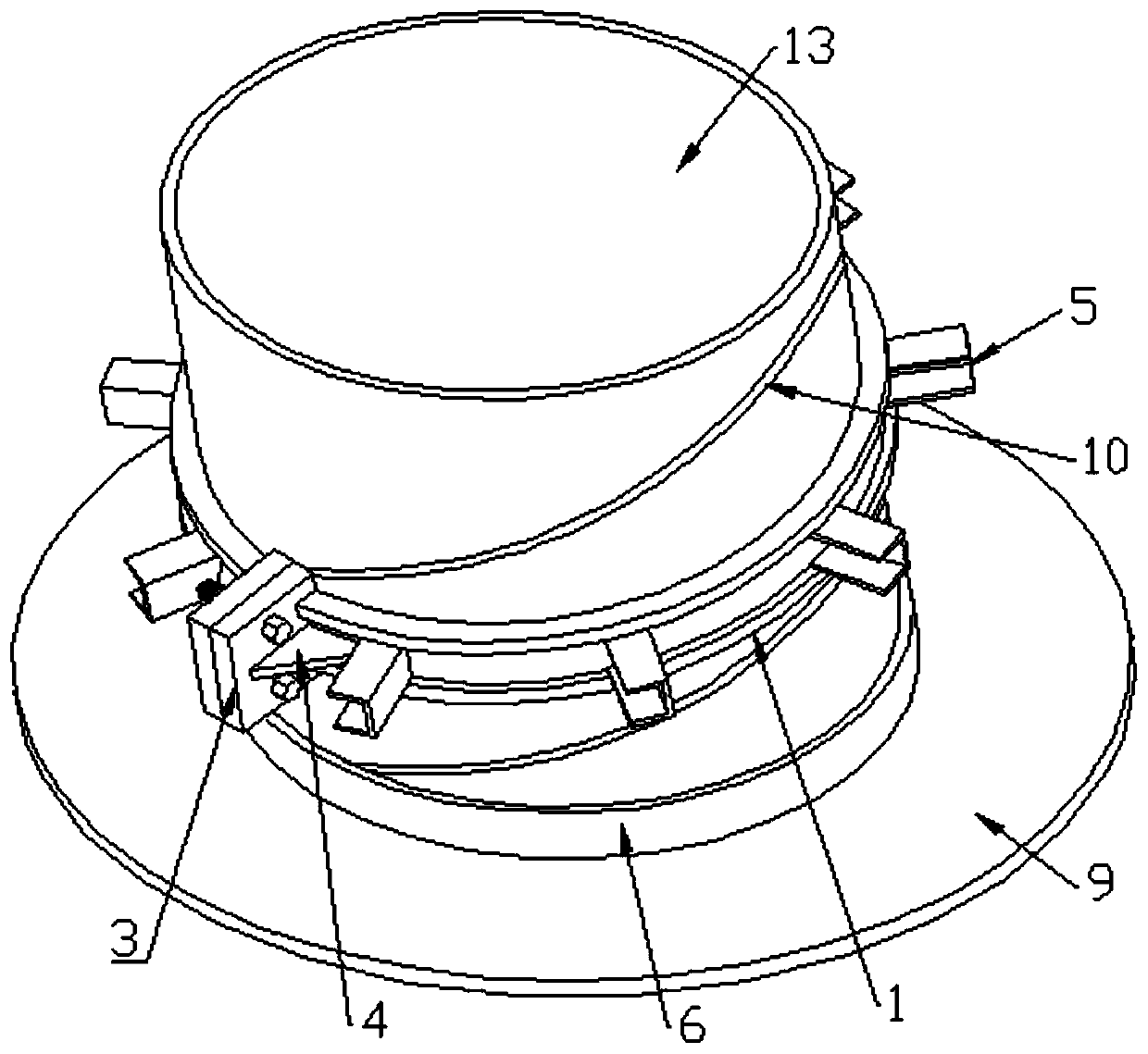

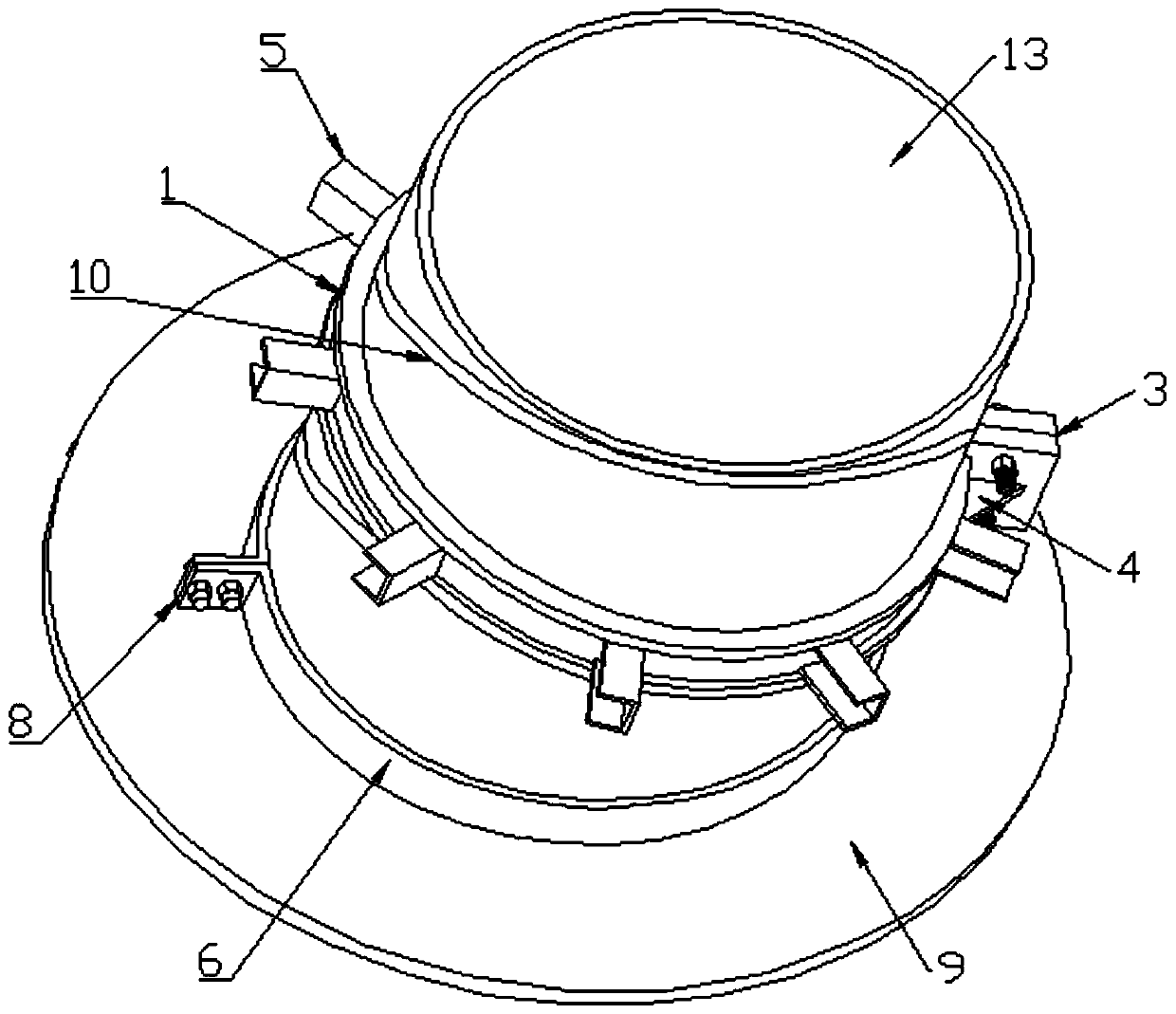

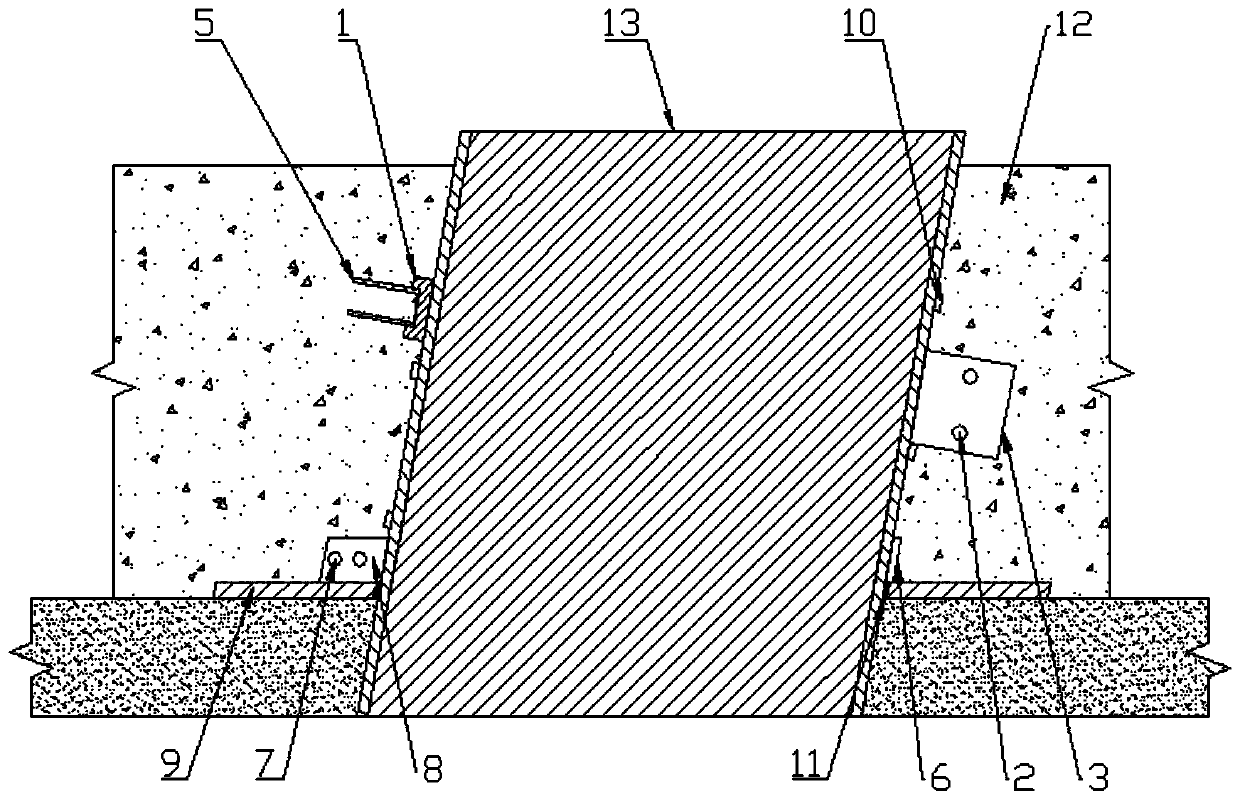

[0027] Such as Figure 1 to Figure 3 As shown, a method for enhancing the grip strength of the back cover based on the offshore steel inclined pile foundation includes the following steps:

[0028] (1) Prefabricated shear strength: take a certain length of channel steel and bend it into an annular channel steel 1, weld a connecting plate 3 with a connecting hole 1 2 vertically at both ends of the channel steel, and weld reinforcement between the two Rib 4 is taken as an extension 5 with a length of 20-30cm and welded to the outer side of the annular channel steel 1 along the diameter direction;

[0029] (2) Prefabricated hole sealing assembly: take a strip steel of a certain length and bend it into an annular strip steel 6, and the two ends of the annular strip steel 6 are vertically welded with a connecting plate 2 8 with a connecting hole 2 7, on the annular strip steel 6 And the bottom end of connecting plate 2 8 is vertically welded with ring-shaped bottom cover plate 9; ...

Embodiment 2

[0034] Such as Figure 1 to Figure 3 As shown, a method for enhancing the grip strength of the back cover based on the offshore steel inclined pile foundation includes the following steps:

[0035] (1) Prefabricated shear strength: take a certain length of channel steel and bend it into an annular channel steel 1, weld a connecting plate 3 with a connecting hole 1 2 vertically at both ends of the channel steel, and weld reinforcement between the two Rib 4 is taken as an extension 5 with a length of 20-30cm and welded to the outer side of the annular channel steel 1 along the diameter direction;

[0036] (2) Prefabricated hole sealing assembly: take a strip steel of a certain length and bend it into an annular strip steel 6, and the two ends of the annular strip steel 6 are vertically welded with a connecting plate 2 8 with a connecting hole 2 7, on the annular strip steel 6 And the bottom end of connecting plate 2 8 is vertically welded with ring-shaped bottom cover plate 9; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com