Concentric-square-shaped groove frame machining method and series connection insert joint bending die

An insert and bending technology, which is applied in the field of mechanical stamping, can solve the problems of increasing the cost of mold manufacturing, etc., and achieve the effects of quick mold change, improved effect, and shortened processing hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] The present invention will be described in further detail below in conjunction with the accompanying drawings.

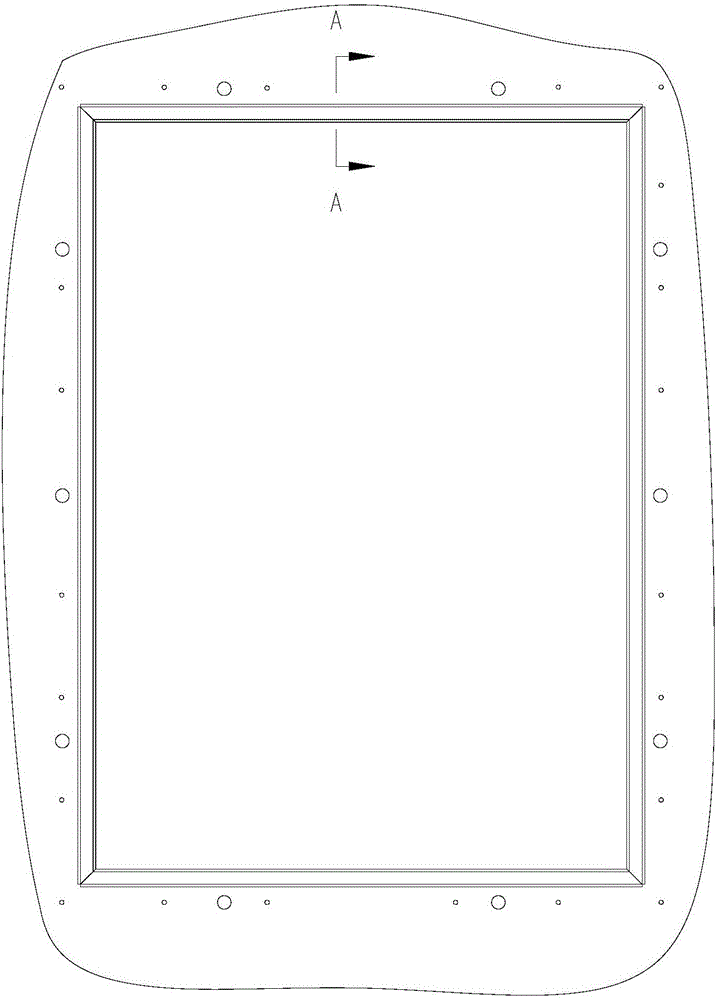

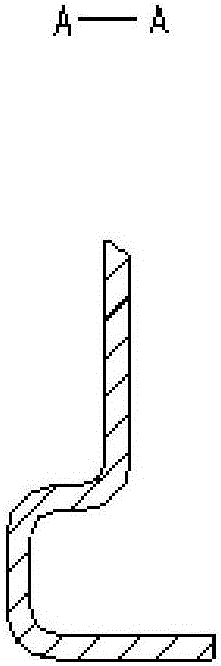

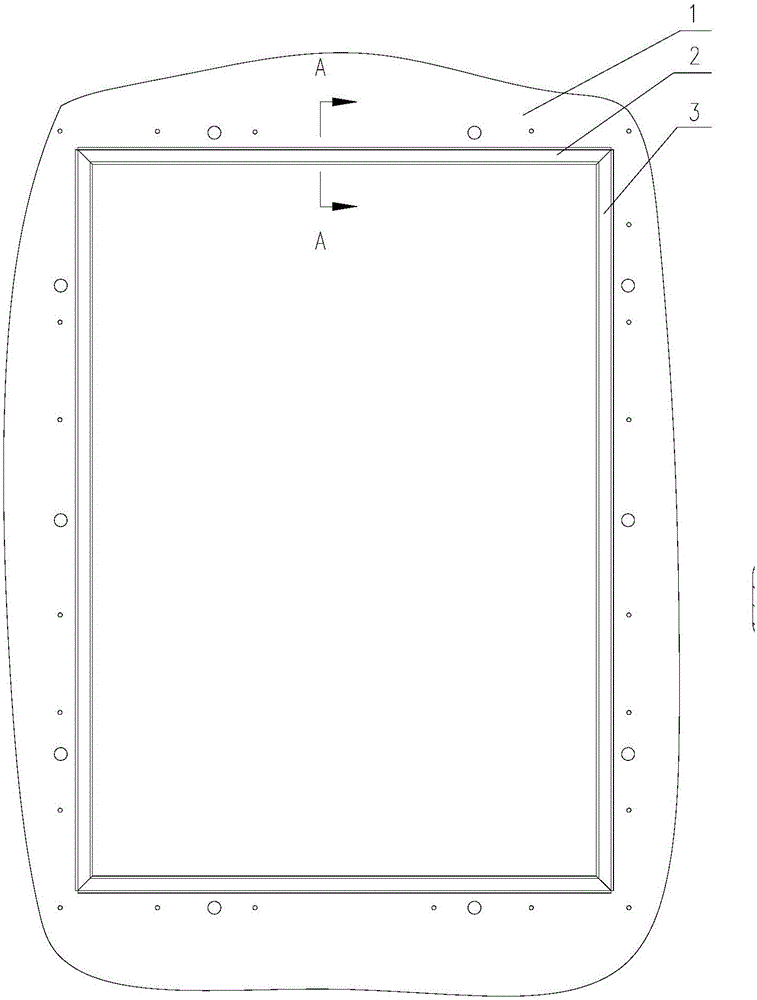

[0062] A kind of simple series insert bending mold of the present invention is made of punch assembly (such as Figure 9 ), die components (such as Figure 10 ) and positioning devices (such as Figure 11 ) consists of three parts. Both the convex mold assembly and the concave mold assembly use inserts in series to combine the convex and concave mold inserts, according to the characteristics of the diversification of the length and size of the return-shaped groove frame.

[0063] The convex and concave mold inserts are made into seven lengths of 50, 80, 100, 150, 200, 300, and 500mm respectively. The seven sizes can be freely combined with various lengths. The inserts are connected in series without traces, so as to adapt to the diversification of product sizes. At the same time, the utilization rate of the punch and the die can be improved, so that one mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com