Method for repairing internal defects of large-sized forge pieces through electroslag welding with tube electrode

An internal defect, casting and forging technology is applied in the field of tube electrode electroslag welding repair of internal defects of large castings and forgings. , The effect of good welding quality and high welding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

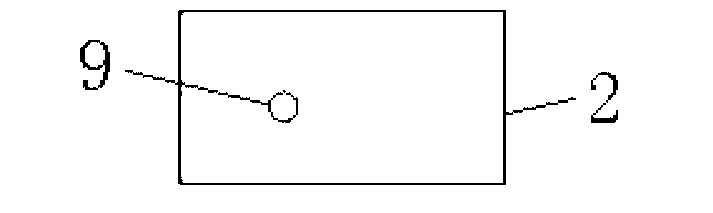

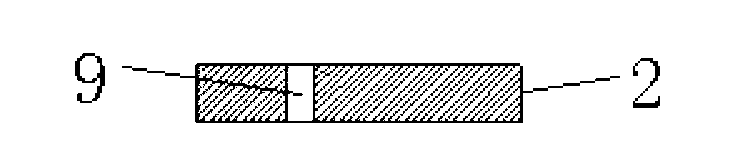

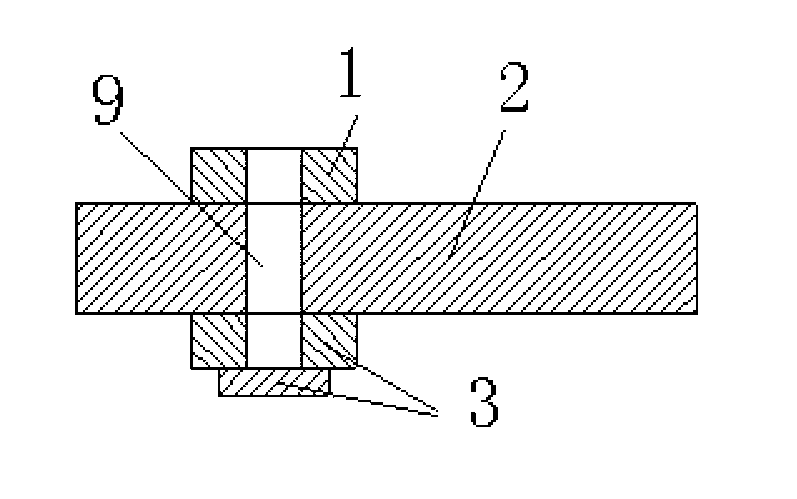

Image

Examples

Embodiment

[0032] Tube electrode electroslag welding is carried out on the archway with a thickness of 500mm.

[0033] The specific operating process parameters are:

[0034] Welding consumables: H10Mn2, HJ431;

[0035] Wire diameter: ¢3;

[0036] Wire feeding speed: 200m / h, the welding wire does not swing;

[0037] Tube specification: φ10X3 steel pipe, 20#;

[0038] Depth of slag pool: 50mm;

[0039] Welding voltage: 38-40V;

[0040] Welding current: 400A.

[0041] The tube electrode electroslag welding repair method for internal defects of large castings and forgings of the present invention breaks through the technical prejudice that electroslag welding can only weld type II grooves for the internal defects of large castings and forgings, and only requires drilling rules Larger welding space, fewer welding defects, flaw detection is basically a one-time pass. The processing does not occupy a large machine tool, the welding method is simple and reliable, the welding efficiency i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com